Crack Development in Compacted Loess Subjected to Wet–Dry Cycles: Experimental Observations and Numerical Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Sample Preparation

2.3. Test Method

2.4. Crack Treatment Methods

3. Results

3.1. Evaluation of the Impact of Initial Moisture Content on the Cracking of Compacted Loess

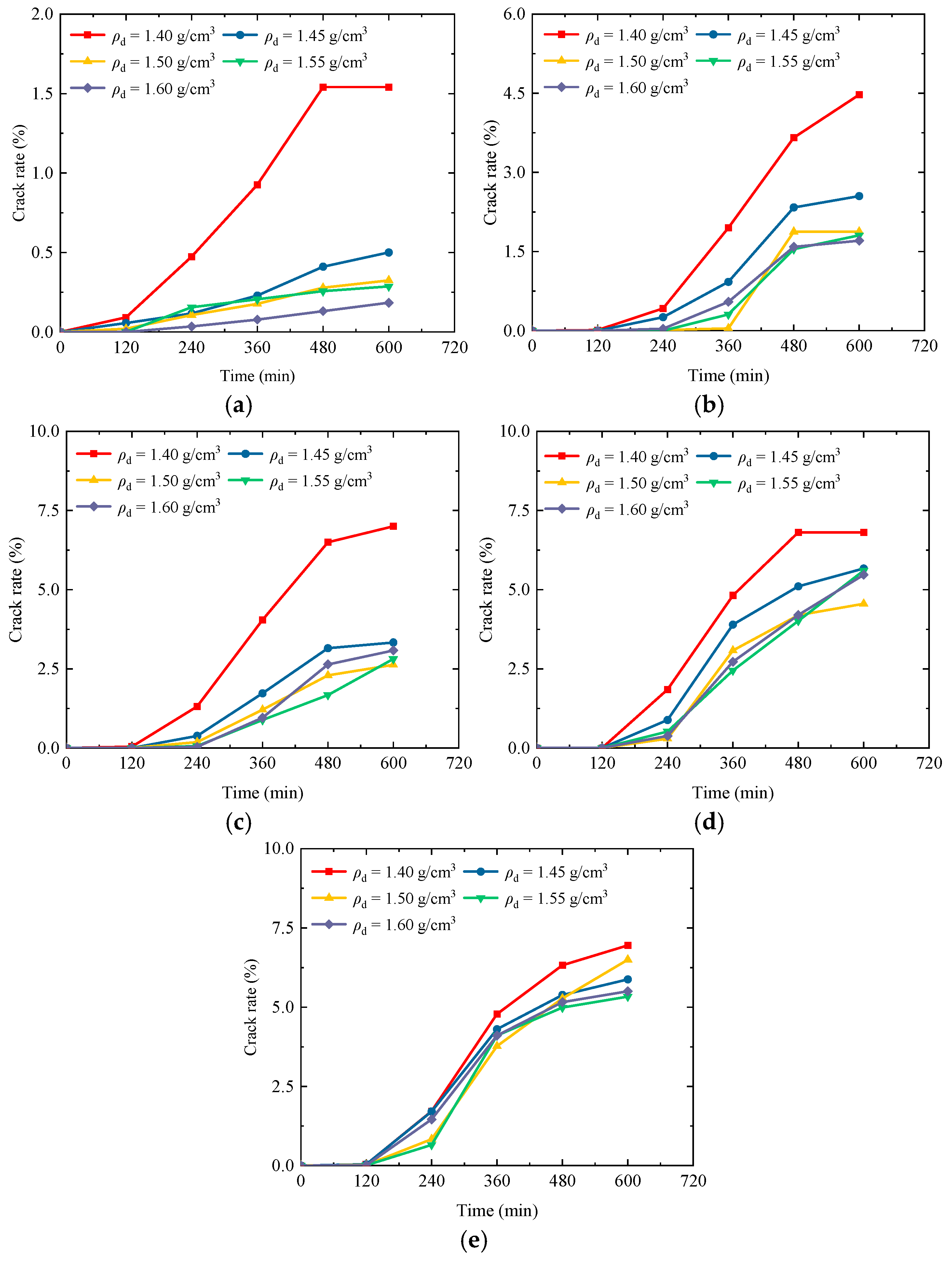

3.2. Analysis of the Influence of Dry Density on the Cracking of Compacted Loess

3.3. Evaluation of the Impact of Thickness on Cracking of Compacted Loess

4. Analysis of Numerical Simulation Results

4.1. Model Establishment

4.2. Result Analysis

4.3. Model Verification

5. Conclusions

- (1)

- With increasing wet–dry cycle count, the number of cracks gradually increases. Under the first wet–dry cycle, the lower the initial water content, the fewer cracks are generated. Conversely, the higher the initial moisture content, the more cracks there are. This suggests that the initial moisture content has a significant impact on the development of fractures.

- (2)

- The lower the dry density of compacted loess, the easier it is to crack, and the earlier the cracking time, the faster the stability. With progressive wet–dry cycling, the crack rate of all samples exhibits an upward trend, and the growth duration of the crack rate and the crack development cycle of high dry density samples are longer.

- (3)

- Under the first wet–dry cycle, the soil sample with a thickness of 0.5 cm showed the fastest cracking response. In comparison, the crack rate of the 1.0 cm and 1.5 cm samples showed a gradient decrease with increasing thickness, indicating that thickness has a resistance to crack formation during the initial phases. After the second wet–dry cycle, the crack development of all samples showed an accelerated trend, indicating that the wet–dry cycling substantially influences the formation of soil cracks.

- (4)

- Using simulation-based analysis, it was found that the thin soil cracked earlier than the thick soil, and the fracture network presented a typical pattern of “priority cracking at the four corners and central expansion”. Once soil cracks form, they will continue to expand along the original crack shape during the subsequent drying process.

- (5)

- In future research, the influence of multiple factor coupling mechanisms on the cracking of compacted loess can be studied, such as the coupling effect of dry-wet freeze–thaw cycles or the impact of different temperature wet coupling effects on crack initiation and propagation, to enrich the research on soil cracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chertkov, V.Y. Modelling cracking stages of saturated soils as they dry and shrink. Eur. J. Soil Sci. 2002, 53, 105–118. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Gao, X.; Ding, Q.; Shan, W.; Guo, H.; Zhuo, J. Cracks evolution and micro mechanism of compacted clay under wet-dry cycles and wet-dry-freeze-thaw cycles. Cold Reg. Sci. Technol. 2023, 214, 103944. [Google Scholar] [CrossRef]

- Amagu, A.C.; Eze, S.N.; Jun-Ichi, K.; Nweke, M.O. Geological and geotechnical evaluation of gully erosion at Nguzu Edda, Afikpo Sub-basin, southeastern Nigeria. J. Environ. Earth Sci. 2018, 8, 148–158. [Google Scholar]

- Gao, Q.F.; Yu, H.C.; Zeng, L.; Huang, Y.X. Characterization of water retention behavior of cracked compacted lateritic soil exposed to wet-dry cycles. Bull. Eng. Geol. Environ. 2023, 82, 61. [Google Scholar] [CrossRef]

- Amagu, C.A.; Enya, B.O.; Kodama, J.I.; Sharifzadeh, M. Impacts of Addition of Palm Kernel Shells Content on Mechanical Properties of Compacted Shale Used as an Alternative Landfill Liners. Adv. Civ. Eng. 2022, 2022, 9772816. [Google Scholar] [CrossRef]

- Tang, C.S.; Zhu, C.; Cheng, Q.; Zeng, H.; Xu, J.J.; Tian, B.G.; Shi, B. Desiccation cracking of soils: A review of investigation approaches, underlying mechanisms, and influencing factors. Earth Sci. Rev. 2021, 216, 103586. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, R.; Zi, J.; Han, J.; Liu, K. Evaluation of the treatment variables on the shear strength of loess treated by microbial induced carbonate precipitation. J. Mountain Sci. 2025, 22, 1075–1086. [Google Scholar] [CrossRef]

- Chompoorat, T.; Thepumong, T.; Khamplod, A.; Likitlersuang, S. Improving mechanical properties and shrinkage cracking characteristics of soft clay in deep soil mixing. Constr. Build. Mater. 2022, 316, 125858. [Google Scholar] [CrossRef]

- El Hajjar, A.; Ouahbi, T.; Eid, J.; Hattab, M.; Taibi, S. Shrinkage cracking of unsaturated fine soils: New experimental device and measurement techniques. Strain 2020, 56, e12352. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, M.; Cheng, C.; Han, J.; Zhao, Y.; Jia, P. Experimental and analytical study on the bearing capacity of caisson foundation subjected to V-H combined load. Mar. Georesour. Geotechnol. 2025, 1–14. [Google Scholar] [CrossRef]

- Guo, H.; Li, W.; Dang, F.; Wang, Y.; Fu, J.; Tao, M. The shrinkage crack characteristics of jute fiber-modified clay under wet-dry cycle conditions. Constr. Build. Mater. 2025, 472, 140840. [Google Scholar] [CrossRef]

- Yue, J.; Huang, X.; Zhao, L.; Wang, Z. Study on the factors affecting cracking of earthen soil under dry shrinkage and freeze–thaw conditions. Sci. Rep. 2022, 12, 1816. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.S.; Shi, B.; Liu, C.; Gao, L.; Inyang, H.I. Experimental investigation of the desiccation cracking behavior of soil layers during drying. J. Mater. Civ. Eng. 2011, 23, 873–878. [Google Scholar] [CrossRef]

- Zhou, R.; Wang, B.T.; Han, S.Y.; Wang, D.Y.; Zhang, F.H. Mechanisms of crack development and strength deterioration in compacted expansive soils under controlled wetting-drying conditions. Eng. Fail. Anal. 2024, 159, 108133. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, B.; Liu, B.; Zeng, Z.; Zhang, Y.; Zheng, Y. Shrinkage cracking and strength deterioration of red clay under cyclic drying and wetting. Alex. Eng. J. 2022, 61, 2574–2588. [Google Scholar] [CrossRef]

- Zhao, C.; Lei, M.; Jia, C.; Liang, G.; Shi, Y. Mechanical characteristics of red sandstone subjected to freeze–thaw cycles and increasing amplitude cyclic load. Rock Mech. Rock Eng. 2024, 57, 3237–3256. [Google Scholar] [CrossRef]

- Yan, C.; Ma, H.; Tang, Z.; Ke, W. A two-dimensional moisture diffusion continuous model for simulating dry shrinkage and cracking of soil. Int. J. Geomech. 2022, 22, 04022172. [Google Scholar] [CrossRef]

- Zhang, S.; Yue, J.; Huang, X.; Zhao, L.; Wang, Z. Study on Cracking Law of Earthen Soil under Dry Shrinkage Condition. Materials 2022, 15, 8281. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.; Bian, H.; Hattab, M.; Yang, Z. Numerical modelling of desiccation shrinkage and cracking of soils. Eur. J. Environ. Civ. Eng. 2023, 27, 3525–3545. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, B.; Zhao, J.; Wang, Y.; Jia, C.; Zhang, Q. An improved model for discrete element method simulation of spatial gradient distributions of freeze-thaw-induced damage to sandstone. Comput. Geotech. 2024, 171, 106412. [Google Scholar] [CrossRef]

- Yu, S.; Ren, X.; Zhang, J. Modeling the rock frost cracking processes using an improved ice–Stress–Damage coupling method. Theor. Appl. Fract. Mech. 2024, 131, 104421. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Q.; Jia, C.; Lei, M.; Zhao, C.; Pang, R.; Li, Z.; Zang, T. Experimental and DEM simulations of the mechanical properties of rock under freeze–thaw cycles. Cold Reg. Sci. Technol. 2023, 211, 103866. [Google Scholar] [CrossRef]

- Zheng, Y.; Jia, C.; Lei, M.; Huang, J.; Shi, C. Investigation of the constitutive damage model of rock under the coupled effect of freeze–thaw cycles and loading. Rock Mech. Rock Eng. 2024, 57, 1861–1879. [Google Scholar] [CrossRef]

- G/BT 50123-2019; Standard for Geotechnical Testing Method. Construction Ministry of PRC: Beijing, China, 2019.

- Dong, M.; Deng, Y.; Fu, Y. Cracking behavior and deterioration of strength characteristics of silty clay under drying-wetting cycles. Bull. Eng. Geol. Environ. 2025, 84, 205. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, H.; Wang, G.; Yang, Y.; Ouyang, M. Development Characteristics and Mechanism of Crack in Expansive Soil under Wet–Dry Cycling. Appl. Sci. 2024, 14, 6499. [Google Scholar] [CrossRef]

- Yu, H.C.; Zeng, L.; Wu, X.Y.; Gao, Q.F.; Bian, H.B.; Luo, J.T.; Zhang, H.R. Classification of cracking potential for clayey soils based on cyclic wet-dry tests. Environ. Earth Sci. 2025, 84, 198. [Google Scholar] [CrossRef]

- Li, T.; He, Y.; Liu, G.; Li, B.; Hou, R. Experimental study on cracking behaviour and strength properties of an expansive soil under cyclic wetting and drying. Shock Vib. 2021, 2021, 1170770. [Google Scholar] [CrossRef]

- Gao, Y.; Hao, D.; Zhu, Y.; Chen, R.; Liu, X.; Guo, R. Experimental Investigation of Desiccation Cracking of Jilin Ball Clay Under Wet–Dry Cycles. Geotech. Geol. Eng. 2024, 42, 2767–2782. [Google Scholar] [CrossRef]

| Specific Gravity (Gs) | Water Content (%) | Dry Density (g/cm3) | Initial Porosity Ratio | Plasticity Limit (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|---|---|---|

| 2.71 | 15.7 | 1.45 | 0.97 | 20.54 | 35.78 | 15.24 |

| Number of Wet–Dry Cycles N/(Times) | Dry Density ρd (g/cm3) | Initial Water Content w/(%) | Thickness H/(cm) |

|---|---|---|---|

| 5 | 12 | 1.50 | 2 |

| 14 | 1.50 | 2 | |

| 16 | 1.50 | 2 | |

| 18 | 1.50 | 2 | |

| 20 | 1.50 | 2 | |

| 16 | 1.40 | 2 | |

| 16 | 1.45 | 2 | |

| 16 | 1.50 | 2 | |

| 16 | 1.55 | 2 | |

| 16 | 1.60 | 2 | |

| 16 | 1.50 | 0.5 | |

| 16 | 1.50 | 1 | |

| 16 | 1.50 | 1.5 | |

| 16 | 1.50 | 2 | |

| 16 | 1.50 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.; Sun, M.; Li, G.; Zhang, J. Crack Development in Compacted Loess Subjected to Wet–Dry Cycles: Experimental Observations and Numerical Modeling. Buildings 2025, 15, 2625. https://doi.org/10.3390/buildings15152625

Xi Y, Sun M, Li G, Zhang J. Crack Development in Compacted Loess Subjected to Wet–Dry Cycles: Experimental Observations and Numerical Modeling. Buildings. 2025; 15(15):2625. https://doi.org/10.3390/buildings15152625

Chicago/Turabian StyleXi, Yu, Mingming Sun, Gang Li, and Jinli Zhang. 2025. "Crack Development in Compacted Loess Subjected to Wet–Dry Cycles: Experimental Observations and Numerical Modeling" Buildings 15, no. 15: 2625. https://doi.org/10.3390/buildings15152625

APA StyleXi, Y., Sun, M., Li, G., & Zhang, J. (2025). Crack Development in Compacted Loess Subjected to Wet–Dry Cycles: Experimental Observations and Numerical Modeling. Buildings, 15(15), 2625. https://doi.org/10.3390/buildings15152625