Study on the Mechanical Response of FSP-IV Steel Sheet Pile Cofferdam and the Collaborative Mechanism of Sediment Control Technology in the Nenjiang Water Intake Project

Abstract

1. Introduction

2. Research Background

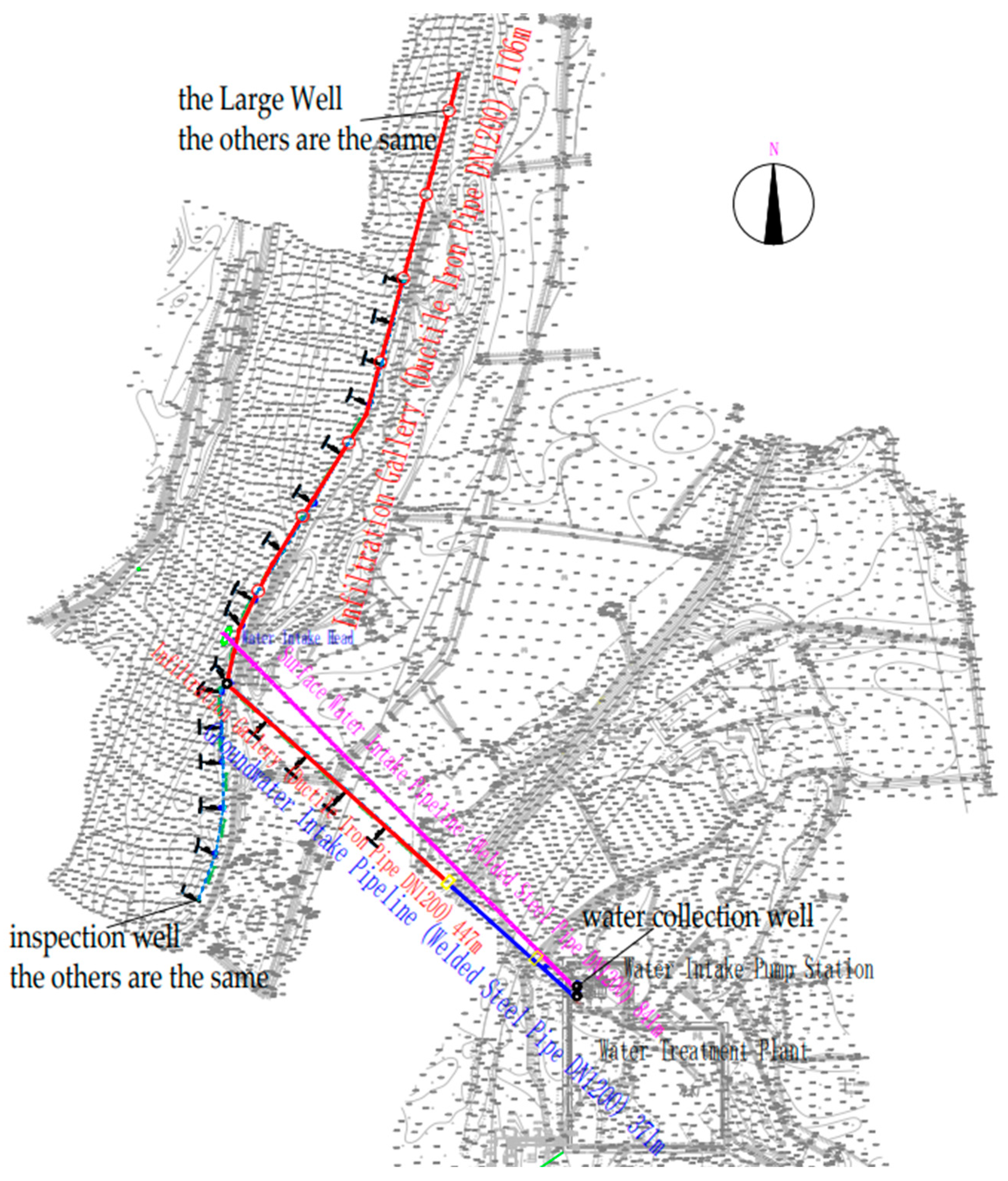

2.1. Project Overview

2.2. Geological Environmental Characteristics

3. Mechanical Response of the Infiltration Channel Steel Sheet Pile Cofferdam

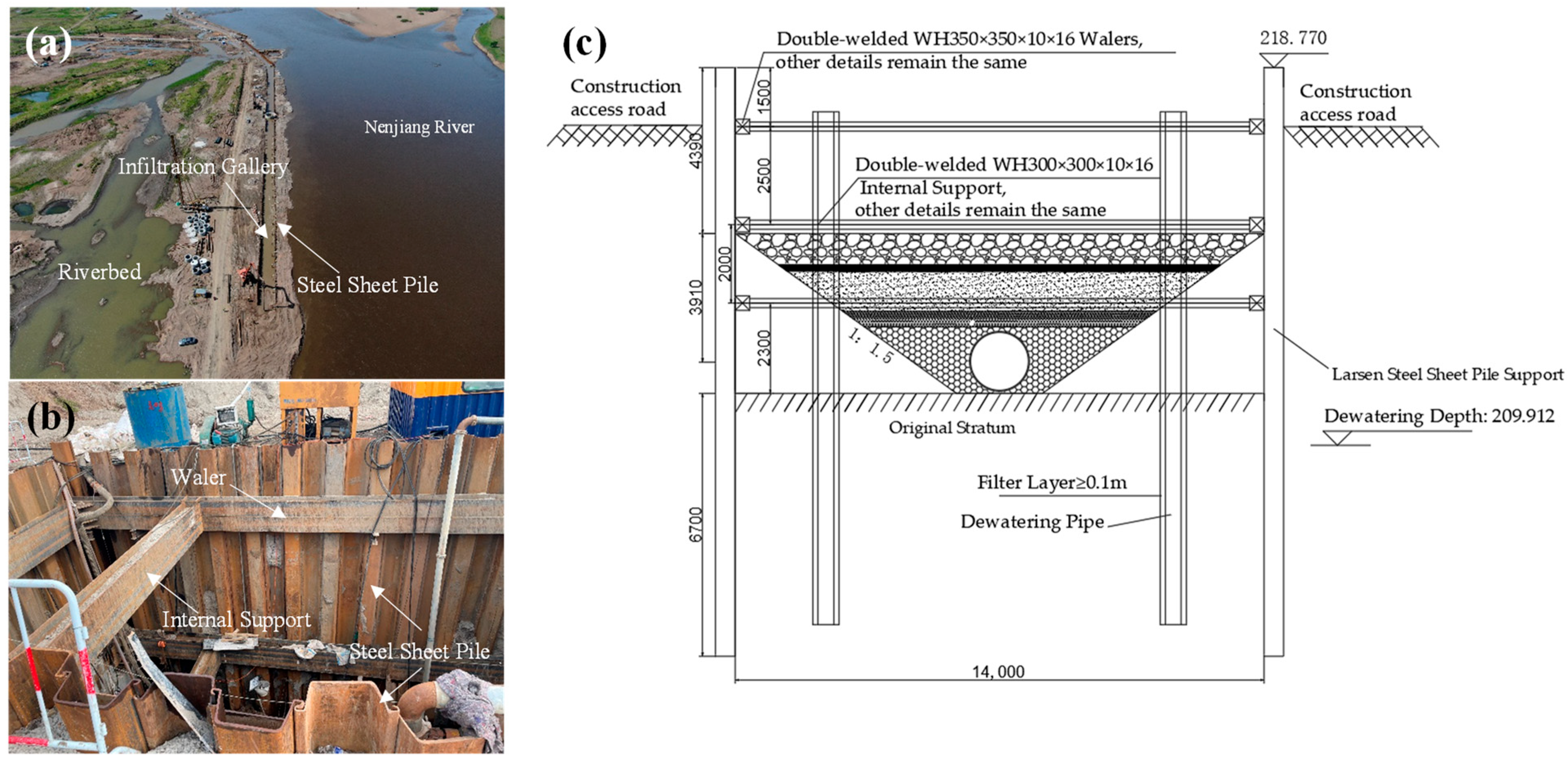

3.1. Basic Characteristics of the Infiltration Channel Steel Sheet Pile Cofferdam

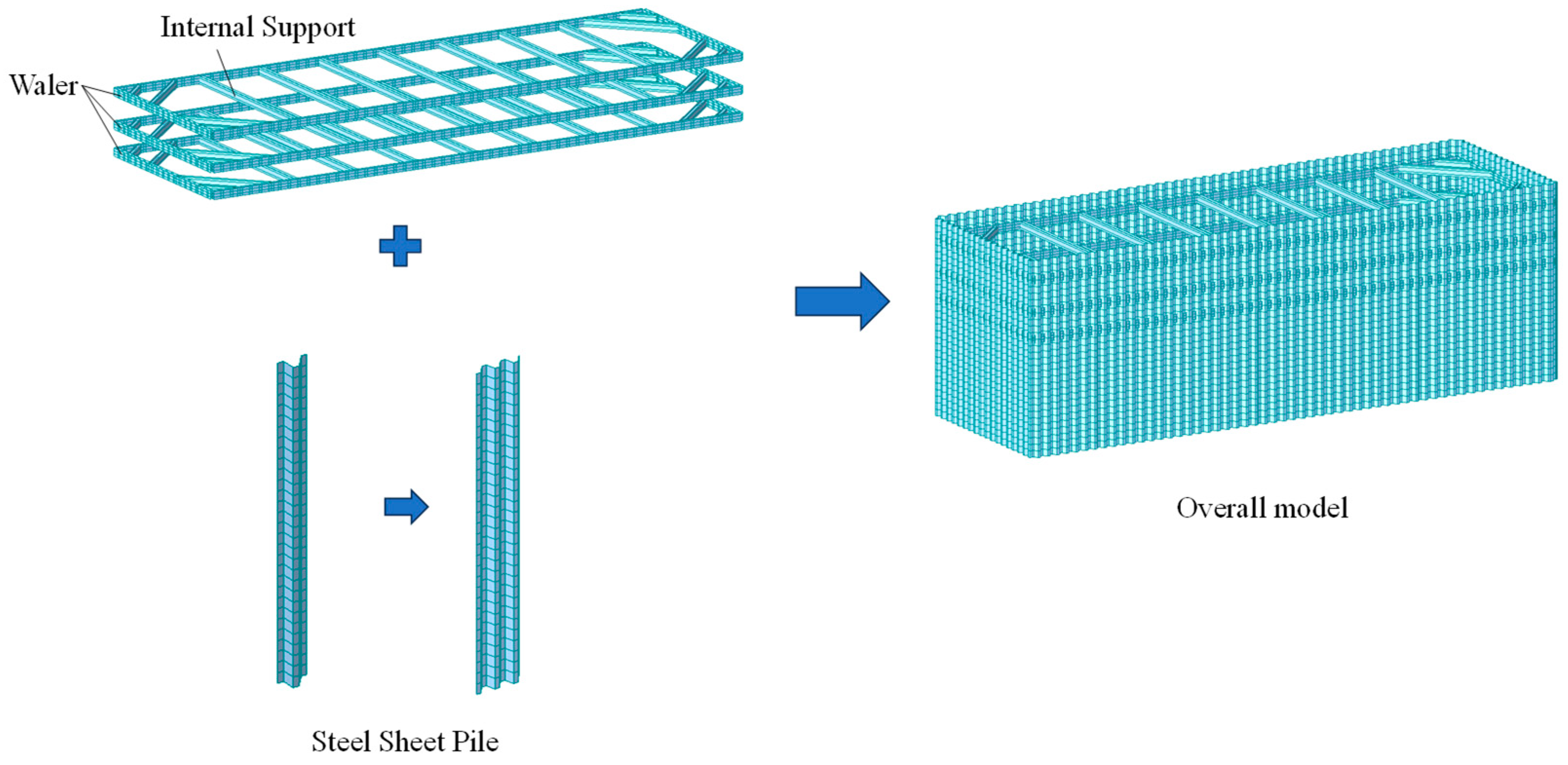

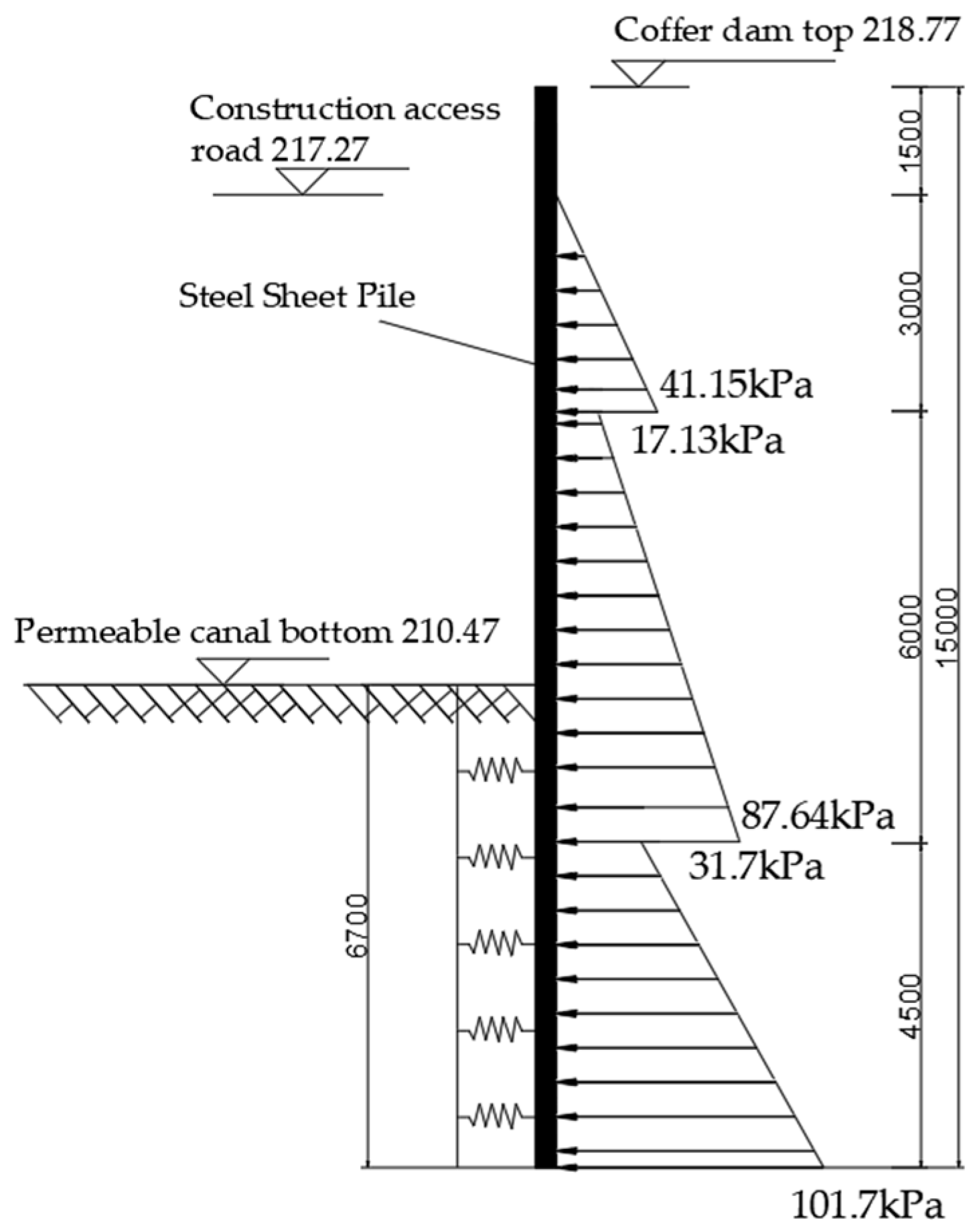

3.2. Calculation Model and Parameters

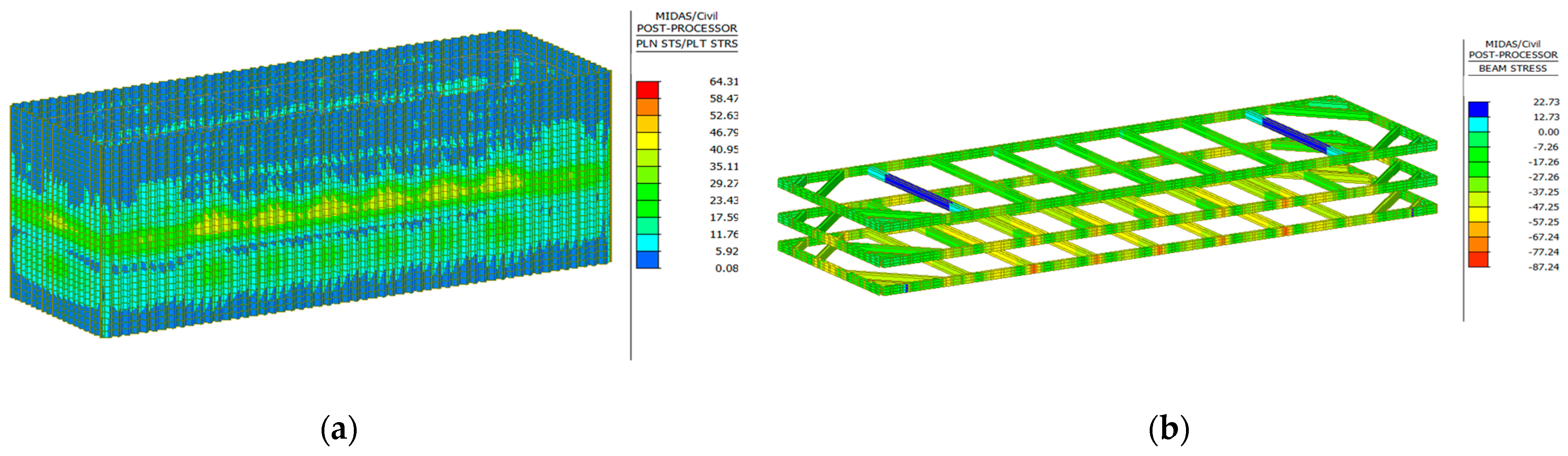

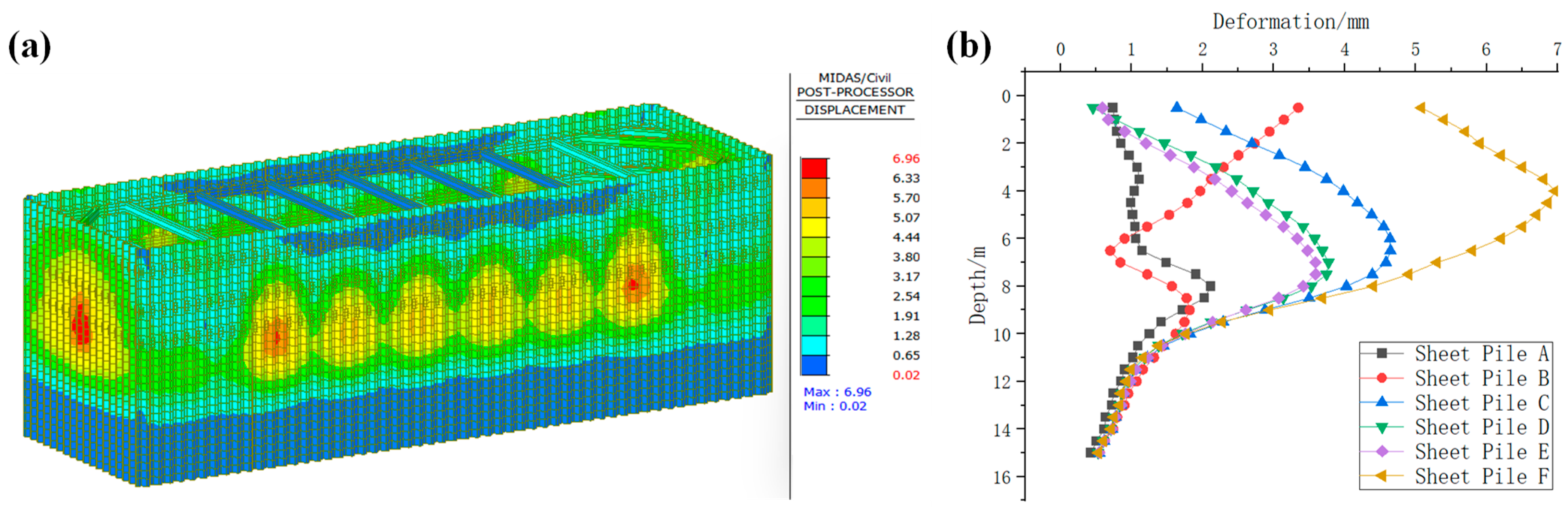

3.3. Calculation Results and Analysis

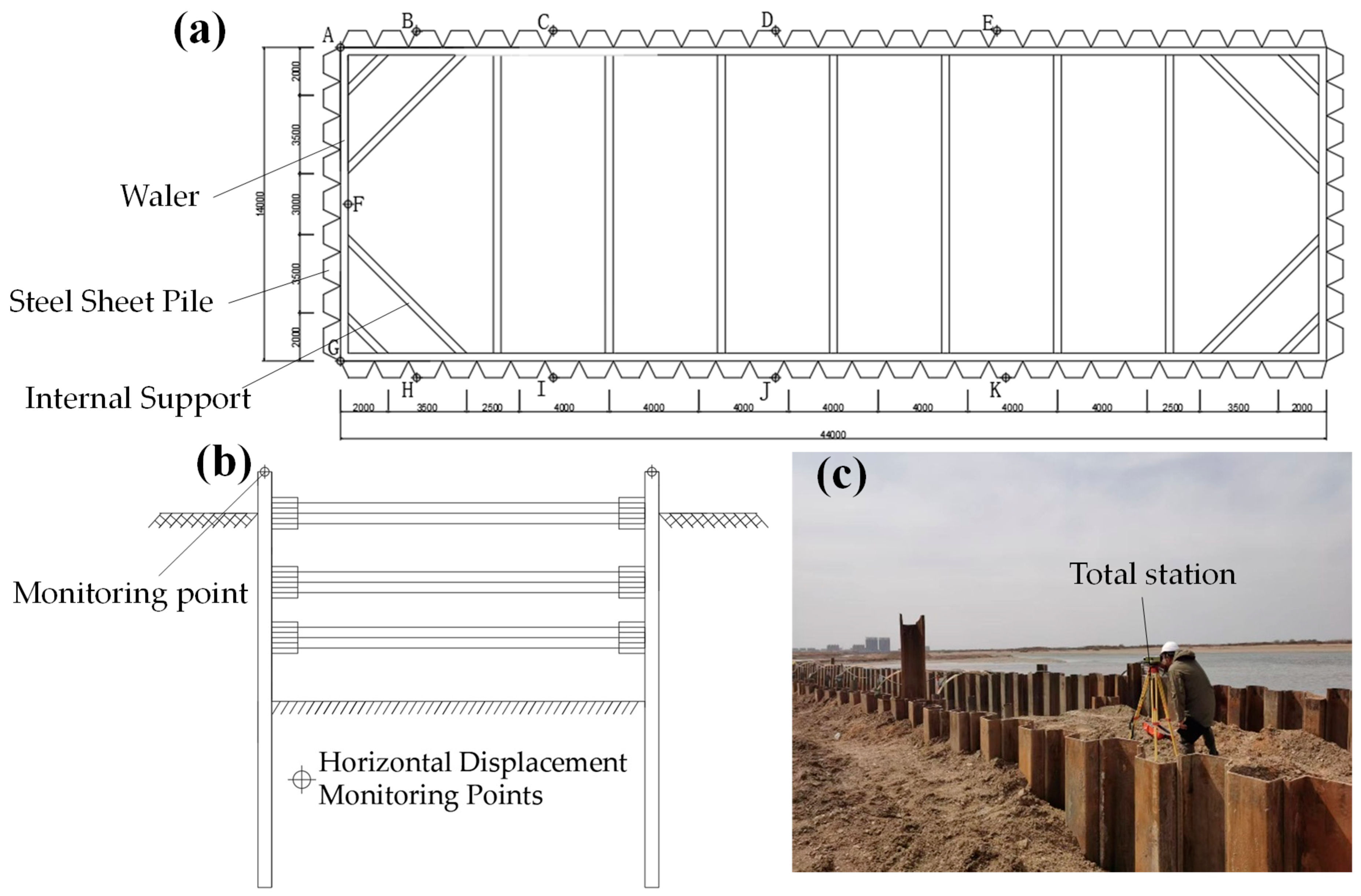

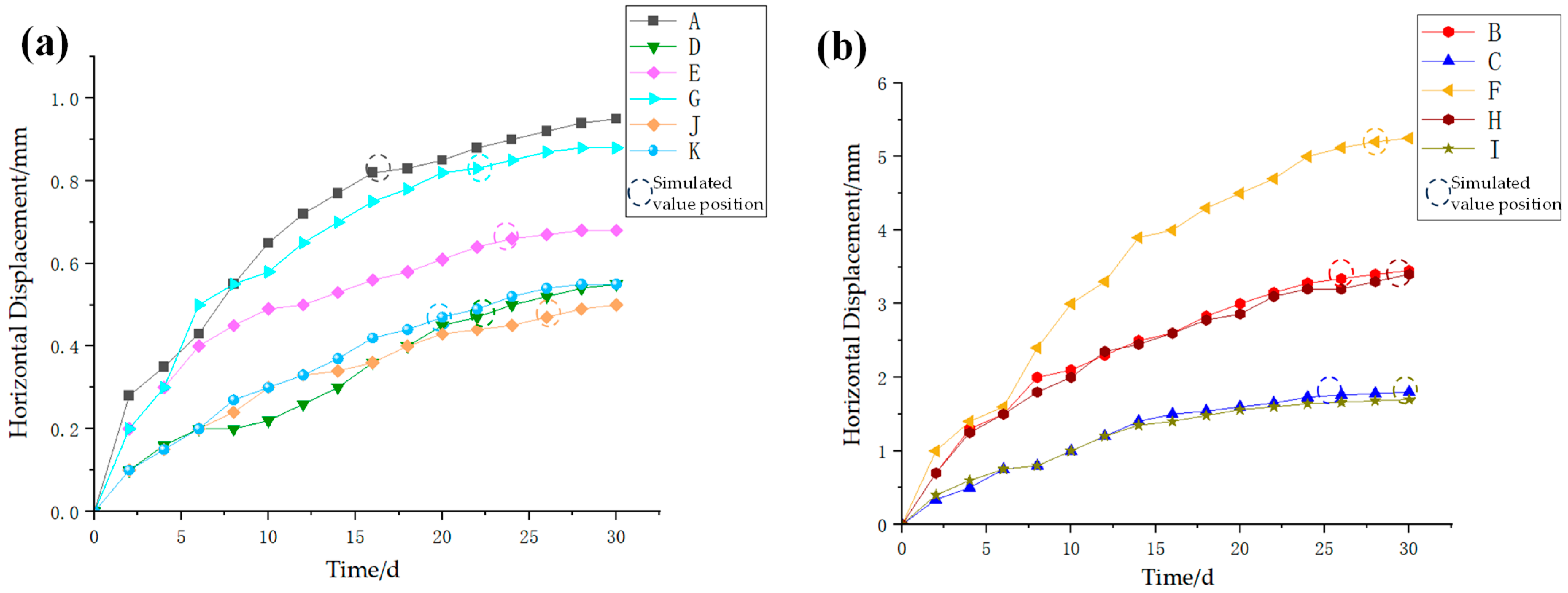

3.4. On-Site Monitoring

4. Key Sediment Control Technologies for the Water Intake Project

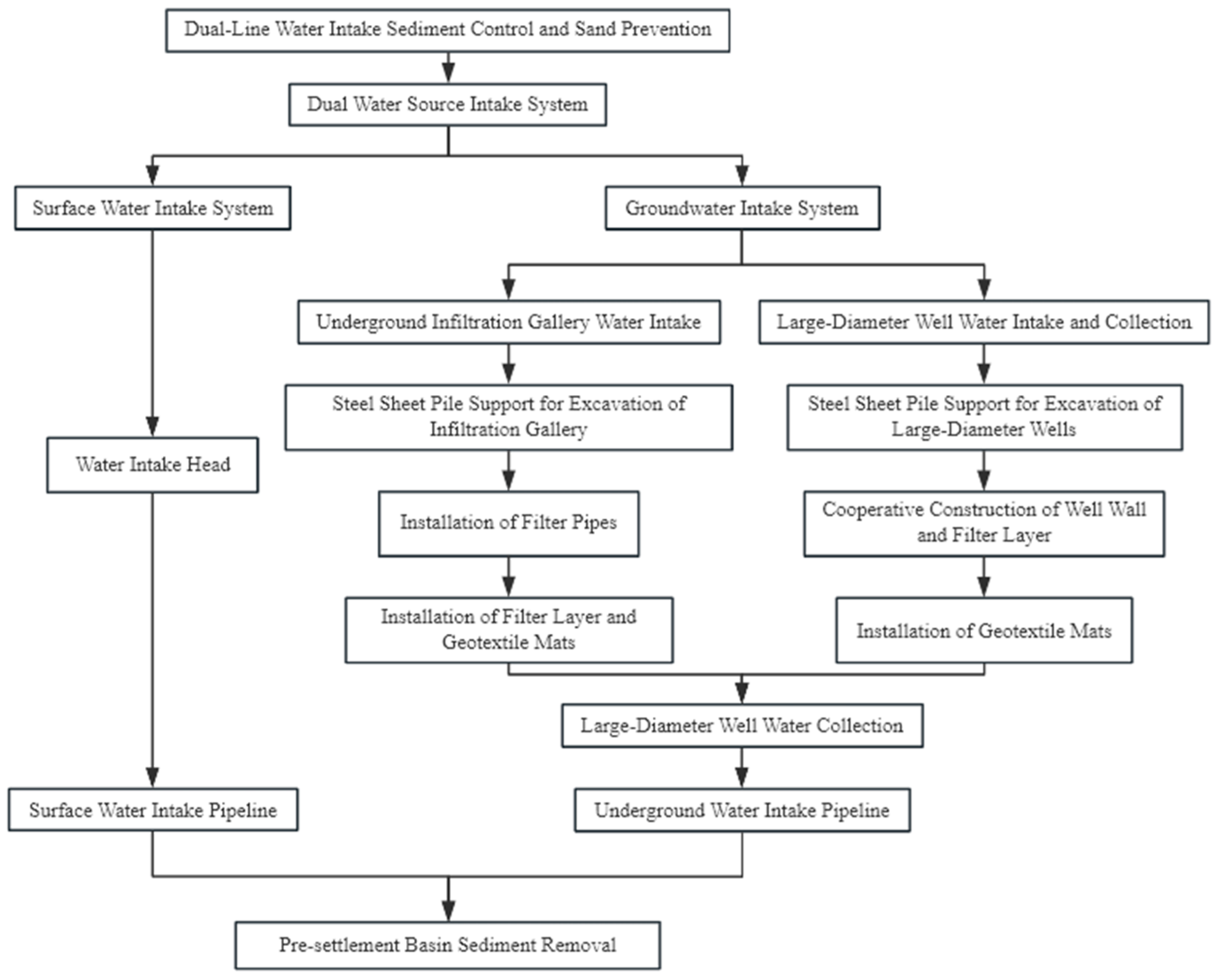

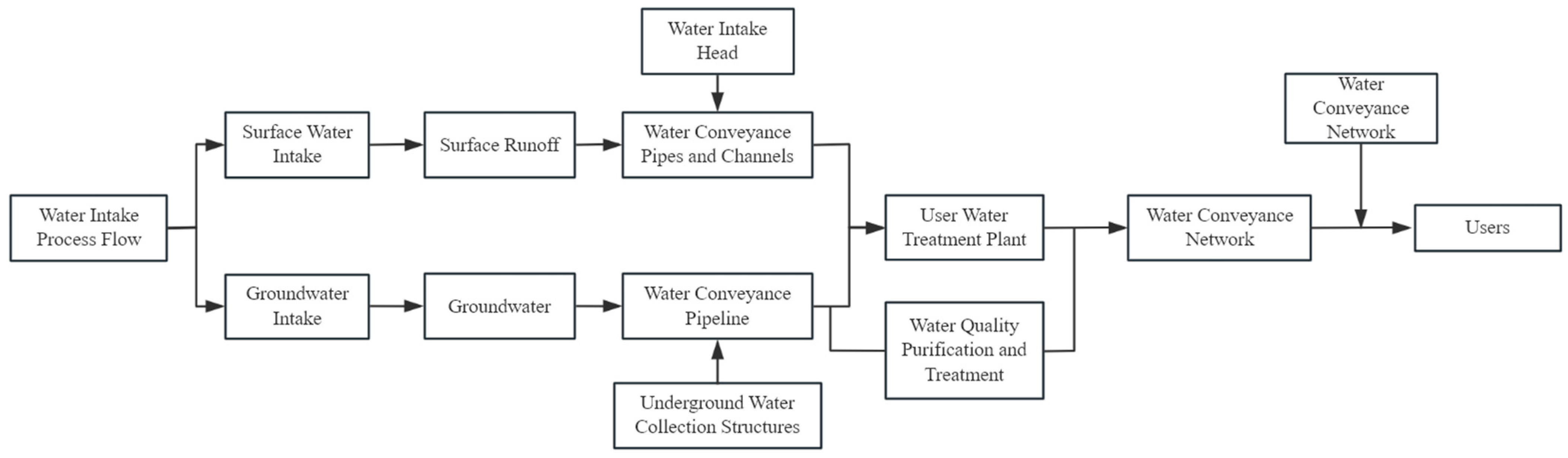

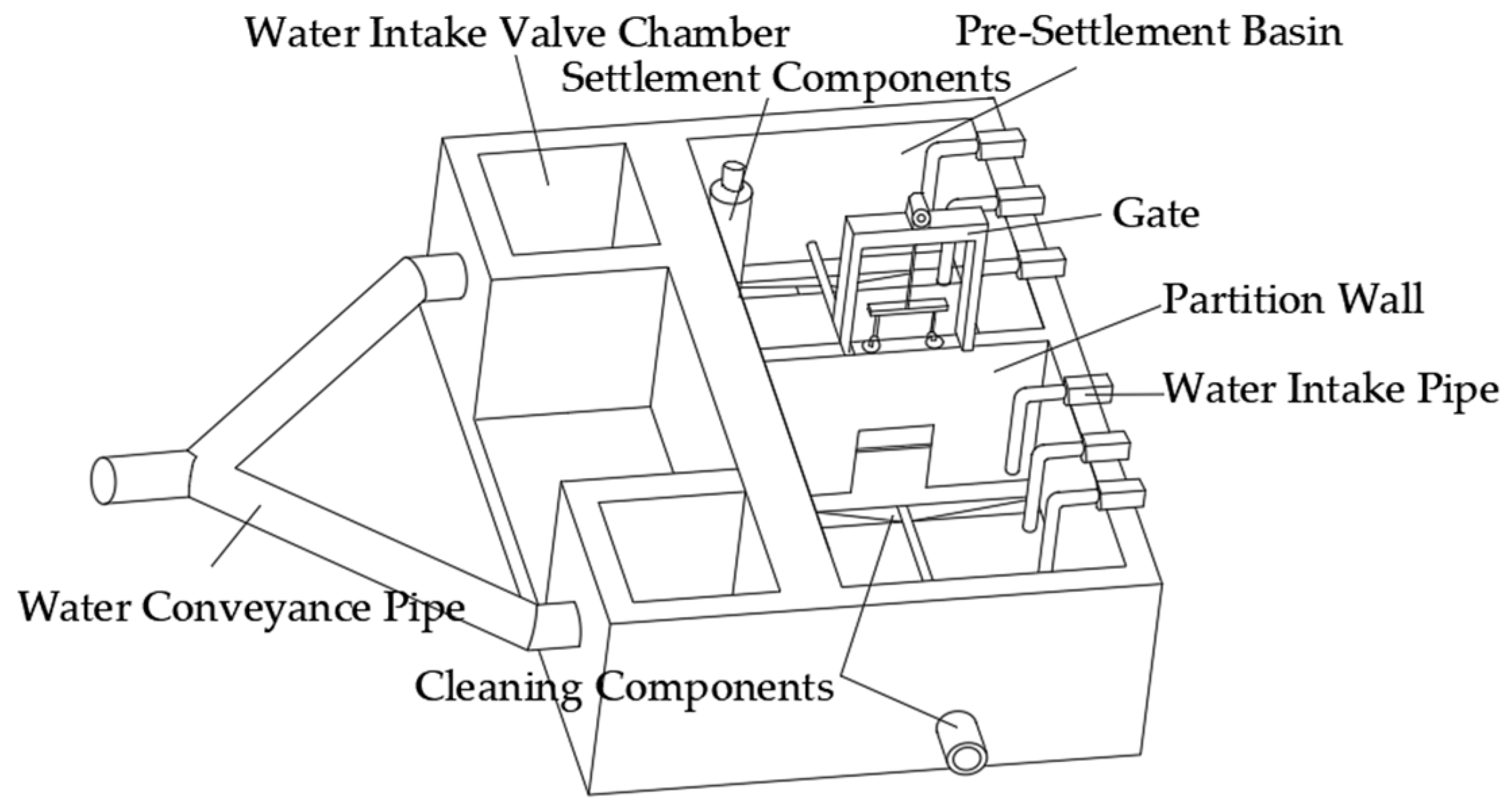

4.1. Sediment Control and Sand Settlement-Guided Dual-Line Water Intake Process

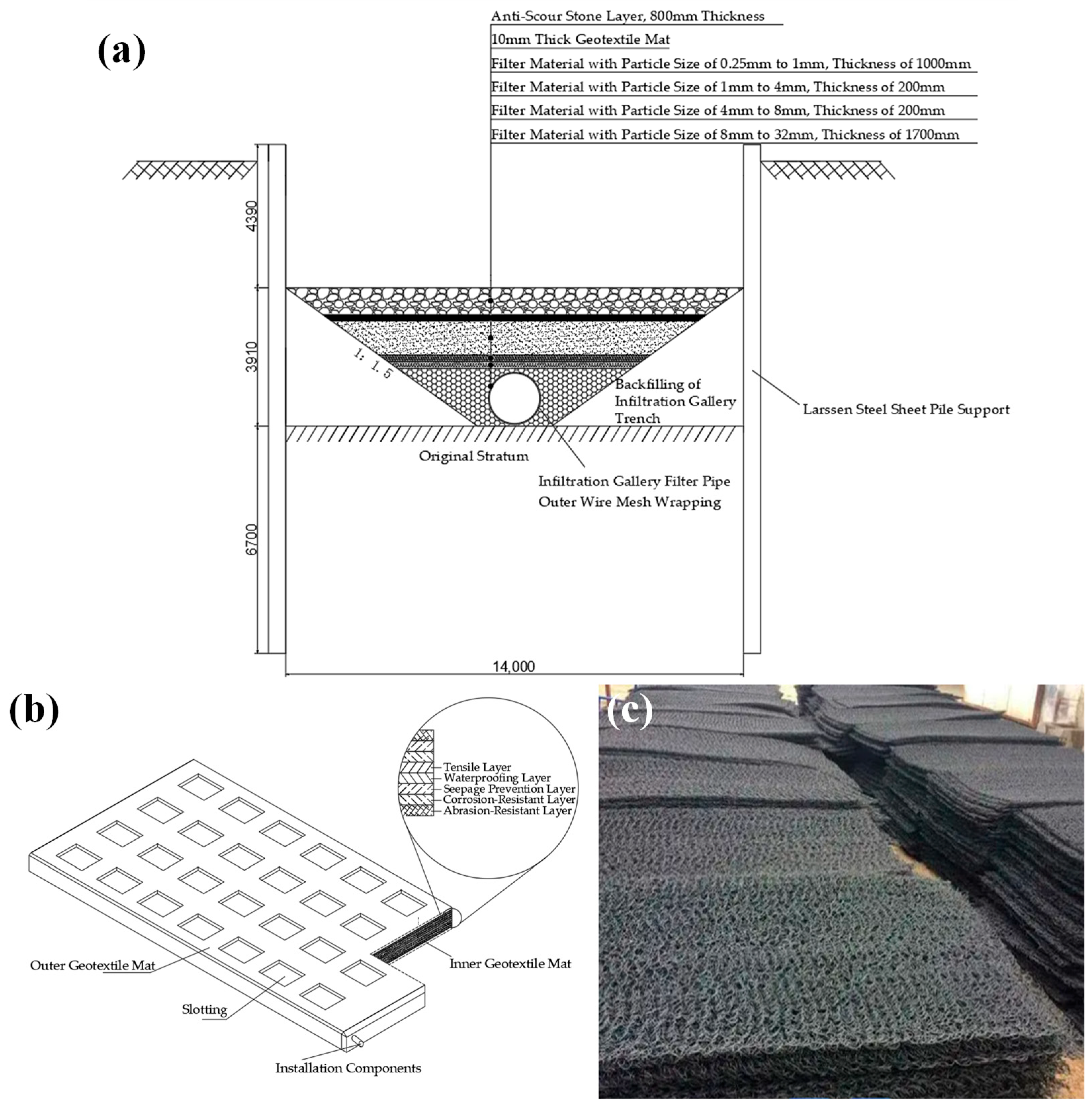

4.2. Key Construction Technologies for Layered Placement of Composite Reverse Filtration Layers in Infiltration Channel Water Intake

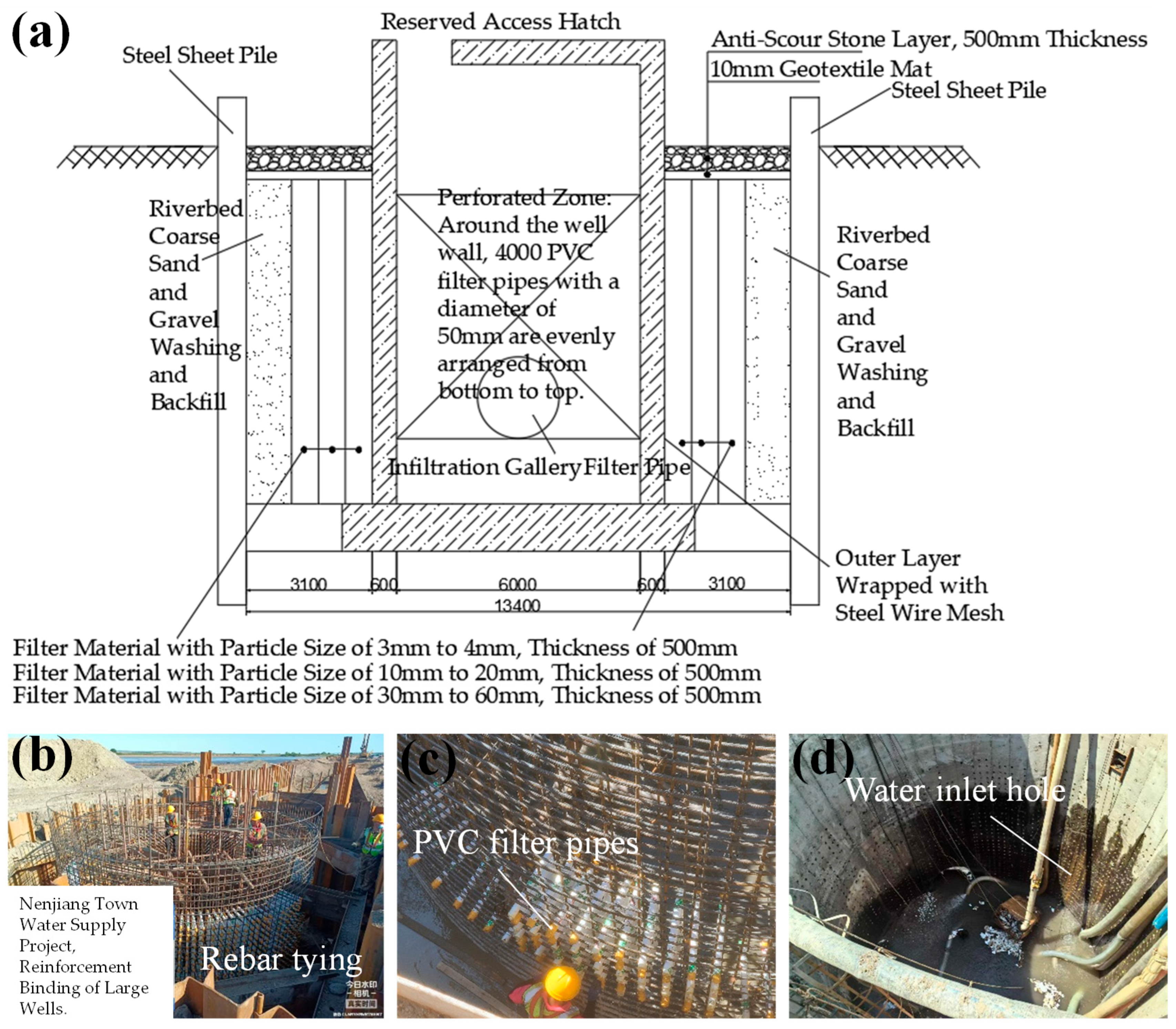

4.3. Key Construction Technologies for the Collaborative Construction of the Infiltration Filter Layer and Well Casing Structure of the Large Well Water Intake Structure

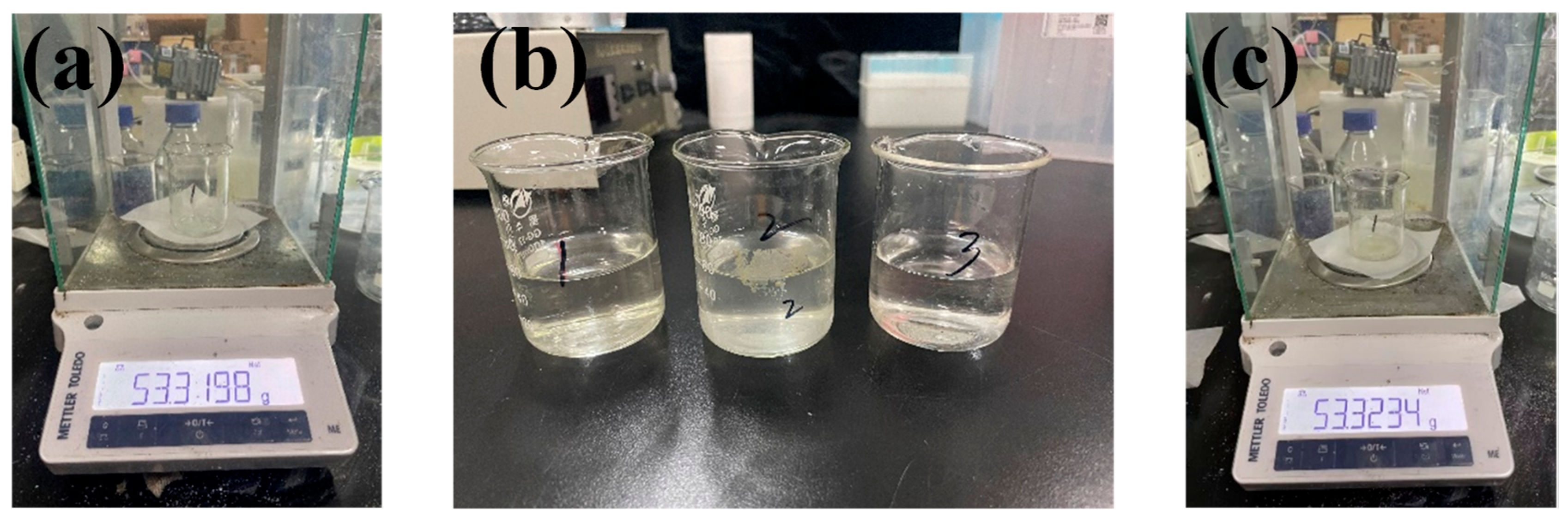

4.4. Sediment Control and Sand Settlement Effectiveness in Water Intake Projects

5. Conclusions

- (1)

- The stress peak of the FSP-IV steel sheet pile supporting structure in the excavation of the infiltration channel foundation pit (64.3 MPa) is concentrated at the center of the pit at depths of 5.5–8.0 m. The maximum horizontal displacement (6.96 mm) occurs at the middle of the side span at the F pile. The internal support stress increases with depth, reaching 87.2 MPa at the bottom, with significant stress concentration at the connection between the surrounding girder and the piles. The lack of support or excessive spacing between supports leads to insufficient local stiffness at the side span center (Point F, with a displacement of 5.3 mm) and the right-angle region (Points B/H), which is the main cause of displacement exceeding the limit. Field monitoring verified the reliability of the numerical model.

- (2)

- The sediment control and sand settlement integrated system for the water intake infiltration channel achieves a 75% reduction in sand content and a significant decrease in standard deviation through the dual-line water intake method, the layered placement of reverse filtration layers in the infiltration channel, and the collaborative construction technology of the intake holes and reverse filtration layers. This system ensures both water quality stability and continuous water supply, forming a systematic technological solution for water intake from rivers with a high sediment content.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Liu, W.; Hu, A.; Li, F.; Yang, Z. Application of Steel Sheet Pile in Deep Foundation Pit Support of Collapsible Loess Regions. Earth Environ. Sci. 2020, 474, 02088. [Google Scholar] [CrossRef]

- Marazuela, M.; Garcia, A.; Santamarta, J.C.; Gasco, S.; Cruz, N.; Hofmann, T. Stormwater management in urban areas using dry gallery infiltration systems. Sci. Total Environ. 2022, 823, 153705. [Google Scholar] [CrossRef] [PubMed]

- Anderson, E.I. Yield Equations for Bed-Mounted Infiltration Galleries. J. Irrig. Drain. Eng. 2023, 149, 060230031-6. [Google Scholar] [CrossRef]

- Lewis, J.R.; Farr, S.J. Design and construction of a sheet pile earth retention system in soft clays. IFCEE 2015 2015, 1536–1549. [Google Scholar] [CrossRef]

- Zhu, M.; Ebrahimi, A.; Viswanath, M.; Brussel, L.; Beech, J. Design and monitoring of a sheet pile wall installed in soft industrial waste. IFCEE 2015 2015, 627–635. [Google Scholar] [CrossRef]

- Wang, J.; Xiang, H.; Yan, J. Numerical simulation of steel sheet pile support structures in foundation pit excavation. Int. J. Geomech. 2019, 19, 05019002. [Google Scholar] [CrossRef]

- Ouyang, w.; Yang, Y.; Wan, J.; Liu, S. Second-order analysis of steel sheet piles by pile element considering nonlinear soil-structure interactions. Adv. Steel Constr. 2020, 16, 354–362. [Google Scholar] [CrossRef]

- Veylon, G.; Stoltz, G.; Mériaux, P.; Faure, Y.; Touze-Foltz, N. Performance of geotextile filters after 18 years’ service in drainage trenches. Geotext. Geomembr. 2016, 44, 515–533. [Google Scholar] [CrossRef]

- Erat, B.; Barbaros, E.; Taştan, K. Experimental and Numerical Investigation on Flow and Scour Upstream of Pipe Intake Structures. Arab. J. Sci. Eng. 2024, 49, 5973–5987. [Google Scholar] [CrossRef]

- Chowdhury, S.S.; Deb, K.; Sengupta, A. Estimation of design parameters for braced excavation: Numerical study. Int. J. Geomech. 2013, 13, 234–247. [Google Scholar] [CrossRef]

- Azzam, W.R.; Elwakil, A.Z. Performance of axially loaded-piled retaining wall: Experimental and numerical analysis. Int. J. Geomech. 2017, 17, 04016049. [Google Scholar] [CrossRef]

- Denisov, G.V.; Lalin, V.V.; Abramov, D.S. Preservation of Lock Joints in Steel Sheet Piling During Vibratory Driving. Soil Mech. Found. Eng. 2014, 51, 29–35. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, Z.; Li, F.; Chen, W. The prediction of water level based on support vector machine under construction condition of steel sheet pile cofferdam. Concurr. Comput. Pract. Exp. 2021, 33, e6003. [Google Scholar] [CrossRef]

- Athanasopoulos, G.A.; Vlachakis, V.S.; Pelekis, P.C. Installation and performance of a steel sheet pile wall for supporting an excavation in urban environment. Geotech. Spec. Publ. 2011, 3370–3380. [Google Scholar] [CrossRef]

- Lee, F.; Hong, S.; Gu, Q.; Zhao, P. Application of large three-dimensional finite-element analyses to practical problems. Int. J. Geomech. 2011, 11, 529–539. [Google Scholar] [CrossRef][Green Version]

- Zhou, X.; Liu, C.; Qian, Y. Design of very long steel sheet pile cofferdam for deep water foundation and key construction techniques. World Bridge 2020, 48, 20–24. Available online: https://kns.cnki.net/kcms2/article/abstract?v=4OORb77KhuLGF1cpZsZbp69TOcraROLxoDMVVq5gLNK2l15UBlQAzH29ghSRi7gcB3KLLzdpEOhG2Ttc2L5b1tBJ0uYLhrlC1FrHxZrGRjV_nNvHBCDzcwEIPswp7RAjzclMJN_PU3Q6jrxPNT4eXPsE_ESbT5VHSPADZEd4FijMkSkR3fobubK1CVMyqd0BNrTX9GJvtS4=&uniplatform=NZKPT&language=CHS (accessed on 19 June 2025). (In Chinese).[Green Version]

- Rad, M. Reliability based analysis and optimum design of laterally loaded piles. Period. Polytech. Civ. Eng. 2017, 61, 491–497. [Google Scholar] [CrossRef]

- Lv, G.; Liu, Z.; Yu, X.; Zhang, F.; Meng, Q.; Hu, X. Numerical modeling and analysis of steel sheet pile cofferdams, considering the construction sequence. Buildings 2025, 15, 407. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Zhang, F.; Meng, Q.; Liu, Z. Study on the calculation model of mutually embedded displacement between miscellaneous fill and soft soil. Bull. Eng. Geol. Environ. 2024, 83, 348. [Google Scholar] [CrossRef]

- Huang, Y.; Fei, Z.; Kang, A.; Zhang, D.; Jin, K. Research on Effective Embedded Depth of Bottomless Steel Sheet Pile Cofferdam in Rock. Bridge Constr. 2023, 53, 103–110. (In Chinese) [Google Scholar] [CrossRef]

- Xue, R.; Bie, S.; Guo, L.; Zhang, P. Stability analysis for cofferdams of pile wall frame structures. KSCE J. Civ. Eng. 2019, 23, 4010–4021. [Google Scholar] [CrossRef]

- Xu, C.; Tian, J.; Wang, G.; Lian, H.; Wang, R.; Hu, X. Numerical Analysis of Water–Sediment Flow Fields within the Intake Structure of Pumping Station under Different Hydraulic Conditions. Water 2024, 16, 779. [Google Scholar] [CrossRef]

- Sesler, K.; Missimer, T.M. Technical feasibility of using seabed galleries for seawater RO facility intakes and pretreatment: Om al misk island site, red sea, saudi Arabia. In Proceedings of the AMTA/AWWA Membrane Technology Conference and Exposition, San Antonio, TX, USA, 25–28 February 2013; pp. 484–496. [Google Scholar]

- Zheng, W.; Lichwa, J.; D’Alessio, M.; Ray, C. Fate and transport of TNT, RDX, and HMX in streambed sediments: Implications for riverbank filtration. Chemosphere 2009, 76, 1167–1177. [Google Scholar] [CrossRef] [PubMed]

- Taylor, J.; Geogre, C. Geology and ground water of the azapa valley, province of tarapaca, Chile. Econ. Geol. 1949, 44, 40–62. [Google Scholar] [CrossRef]

- Amin, M.I.; Qazi, R.; Downing, T.E. Efficiency of Infiltration Galleries as a Source of Water in Arid Lands. Water Int. 1983, 8, 158–165. [Google Scholar] [CrossRef]

- Xu, C.; Du, C.; Yang, Y.; Shen, P.; Li, M. Long-term permeability tests on clogging and permeability of nonwoven geotextile filtering silty clay. J. Text. Inst. 2022, 114, 1704–1715. [Google Scholar] [CrossRef]

- Michell, F.; Ettema, R.; Muste, M. Case Study: Sediment Control at Water Intake for Large Thermal-Power Station on a Small River. J. Hydraul. Eng. 2006, 132, 440–449. [Google Scholar] [CrossRef]

- GB 18306-2015; Seismic ground motion parameters zonation map of China. Institute of Geophysics, China Earthquake Administration: Beijing, China, 2015. Available online: https://www.gb18306.net (accessed on 6 May 2025).

- Tan, H. Design and Construction of Steel Sheet Pile Cofferdam for Deep Water Piers of Long Bridge. Highway 2024, 69, 153–157. [Google Scholar]

- Yang, S.; Liu, X.; Feng, Y.; Wang, Z.; Liu, Z. Research on Steel Sheet Pile Cofferdam Technology in Deep Water Dense Sandstone Strata. Highway 2021, 66, 184–188. Available online: https://link.cnki.net/urlid/11.1668.U.20210111.0919.066 (accessed on 19 June 2025).

- Li, H. Comparison of Structural Performance between Deep Water Reverse and Forward Construction Methods for Steel Sheet Pile Cofferdam. China Railw. 2022, 11, 55–62. [Google Scholar] [CrossRef]

- Huang, K.; Feng, R. Deep pit foundation steel sheet pile supporting scheme of the 274# pile cap for super large bridge over the coastal expressway and the North Jiangsu irrigation canal. In Proceedings of the 5th International Conference on Material and Manufacturing Technology, Kuala Lumpur, Malaysia, 8–9 May 2014; Trans Tech Publications Ltd.: Kuala Lumpur, Malaysia, 2014; pp. 341–345. [Google Scholar] [CrossRef]

- JGJ120-2012; Building Foundation pit Support Design Regulations. China Academy of Building Research: Beijing, China, 2012. Available online: https://www.mohurd.gov.cn/gongkai/zc/wjk/art/2012/art_17339_210547.html (accessed on 11 May 2025.).

| Stratum Type | Density (kN/m3) | Cohesion (kPa) | Internal Friction Angle (°) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| Mixed Fill Soil | 10.0 | 0 | 0 | 40 | 0.3 |

| Gravel | 18 | 8 | 25 | 80 | 0.26 |

| Sandstone | 20.0 | 20 | 20 | 2000 | 0.22 |

| Depth of Calculation Point/(m) | m/(MN/m4) | Design Width of Sheet Pile, b/(m) | Design Height of Sheet Pile, h/(m) | Stage I Soil Spring Stiffness, k1 (kN/m) | Stage II Soil Spring Stiffness, k2 (kN/m) | Stage III Soil Spring Stiffness, k3 (kN/m) |

|---|---|---|---|---|---|---|

| 4 | 10,400 | 0.2 | 0.5 | 0 | 0 | 0 |

| 4.5 | 10,400 | 0.2 | 0.5 | 520 | 0 | 0 |

| 5 | 10,800 | 0.2 | 0.5 | 1060 | 0 | 0 |

| 5.5 | 10,800 | 0.2 | 0.5 | 1600 | 0 | 0 |

| 6 | 10,800 | 0.2 | 0.5 | 2140 | 0 | 0 |

| 6.5 | 10,800 | 0.2 | 0.5 | 2680 | 540 | 0 |

| 7 | 10,800 | 0.2 | 0.5 | 3220 | 1080 | 0 |

| 7.5 | 10,800 | 0.2 | 0.5 | 3760 | 1620 | 0 |

| 8 | 10,800 | 0.2 | 0.5 | 4300 | 2160 | 0 |

| 8.5 | 10,800 | 0.2 | 0.5 | 4840 | 2700 | 216 |

| 9 | 10,800 | 0.2 | 0.5 | 5380 | 3240 | 756 |

| 9.5 | 10,800 | 0.2 | 0.5 | 5920 | 3780 | 1296 |

| 10 | 10,800 | 0.2 | 0.5 | 6460 | 4320 | 1836 |

| 10.5 | 10,800 | 0.2 | 0.5 | 7000 | 4860 | 2376 |

| 11 | 8000 | 0.2 | 0.5 | 7400 | 5260 | 2776 |

| 11.5 | 8000 | 0.2 | 0.5 | 7800 | 5660 | 3176 |

| 12 | 8000 | 0.2 | 0.5 | 8200 | 6060 | 3576 |

| 12.5 | 8000 | 0.2 | 0.5 | 8600 | 6460 | 3976 |

| 13 | 8000 | 0.2 | 0.5 | 9000 | 6860 | 4376 |

| 13.5 | 8000 | 0.2 | 0.5 | 9400 | 7260 | 4776 |

| 14 | 8000 | 0.2 | 0.5 | 9800 | 7660 | 5176 |

| 14.5 | 8000 | 0.2 | 0.5 | 10,200 | 8060 | 5576 |

| 15 | 8000 | 0.2 | 0.5 | 10,600 | 8460 | 5976 |

| System Component | System Characteristics |

|---|---|

| Surface Water System | Direct water intake from the Nenjiang River during the wet season, equipped with intake head and intake pipeline. |

| Groundwater System | During the dry season, groundwater is collected through infiltration galleries in the floodplain and transported to the pump station. |

| Intake Pump Station | Combined pump station for both surface water and groundwater, sharing pressurization equipment and water transport systems. |

| Water Transportation Pipeline | Surface water and groundwater pipelines are laid in parallel, converging into the water treatment plant. |

| Geotextile Mat | Tensile Strength (Longitudinal) | Tensile Strength (Transverse) | Abrasion Resistance | Permeability Coefficient (Inner Layer) | Porosity |

|---|---|---|---|---|---|

| Traditional geotextile mat | 16 kN/m | 16 kN/m | 420 cycles | 1.0× 10−2 cm/s | ≥60% |

| New-generation geotextile mat | ≥25 kN/m | ≥20 kN/m | ≥500 cycles | 1.2 × 10−2 cm/s | ≥75% |

| Geotextile Mat | Initial Permeability Coefficient (cm/s) | 24 h Permeability Coefficient Decrease Rate | Clogging Status | Material Failure Conditions |

|---|---|---|---|---|

| Traditional geotextile mat | 1.0 × 10−2 | 42.7% | Yes | Severe surface sedimentation |

| New-generation geotextile mat | 1.2 × 10−2 | 9.4% | No | No significant damage |

| Water Sample | Serial Number | Sand Content | Average Value | Standard Deviation | Range | Confidence Interval (95%) |

|---|---|---|---|---|---|---|

| Intake head water sample | 1 | 0.0146 g | 0.0144 g | 0.0001732 | 0.0003 | [0.01397, 0.01483] |

| 2 | 0.0143 g | |||||

| 3 | 0.0143 g | |||||

| Pre-settlement pool water sample | 1 | 0.0038 g | 0.0036 g | 0.0001528 | 0.0003 | [0.00325, 0.00325] |

| 2 | 0.0036 g | |||||

| 3 | 0.0035 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wu, L.; Luo, R.; Wei, L.; Chen, F. Study on the Mechanical Response of FSP-IV Steel Sheet Pile Cofferdam and the Collaborative Mechanism of Sediment Control Technology in the Nenjiang Water Intake Project. Buildings 2025, 15, 2610. https://doi.org/10.3390/buildings15152610

Zhang Z, Wu L, Luo R, Wei L, Chen F. Study on the Mechanical Response of FSP-IV Steel Sheet Pile Cofferdam and the Collaborative Mechanism of Sediment Control Technology in the Nenjiang Water Intake Project. Buildings. 2025; 15(15):2610. https://doi.org/10.3390/buildings15152610

Chicago/Turabian StyleZhang, Ziguang, Liang Wu, Rui Luo, Lin Wei, and Feifei Chen. 2025. "Study on the Mechanical Response of FSP-IV Steel Sheet Pile Cofferdam and the Collaborative Mechanism of Sediment Control Technology in the Nenjiang Water Intake Project" Buildings 15, no. 15: 2610. https://doi.org/10.3390/buildings15152610

APA StyleZhang, Z., Wu, L., Luo, R., Wei, L., & Chen, F. (2025). Study on the Mechanical Response of FSP-IV Steel Sheet Pile Cofferdam and the Collaborative Mechanism of Sediment Control Technology in the Nenjiang Water Intake Project. Buildings, 15(15), 2610. https://doi.org/10.3390/buildings15152610