Advances in Nano-Reinforced Polymer-Modified Cement Composites: Synergy, Mechanisms, and Properties

Abstract

1. Introduction

2. Effect of Polymer on the Properties of PMC

2.1. Effect of Polymer on the Workability of Cement-Based Materials

2.2. Effect of Polymer on the Mechanical Strength of Cement-Based Materials

2.3. Effect of Polymer on the Durability of Cement-Based Materials

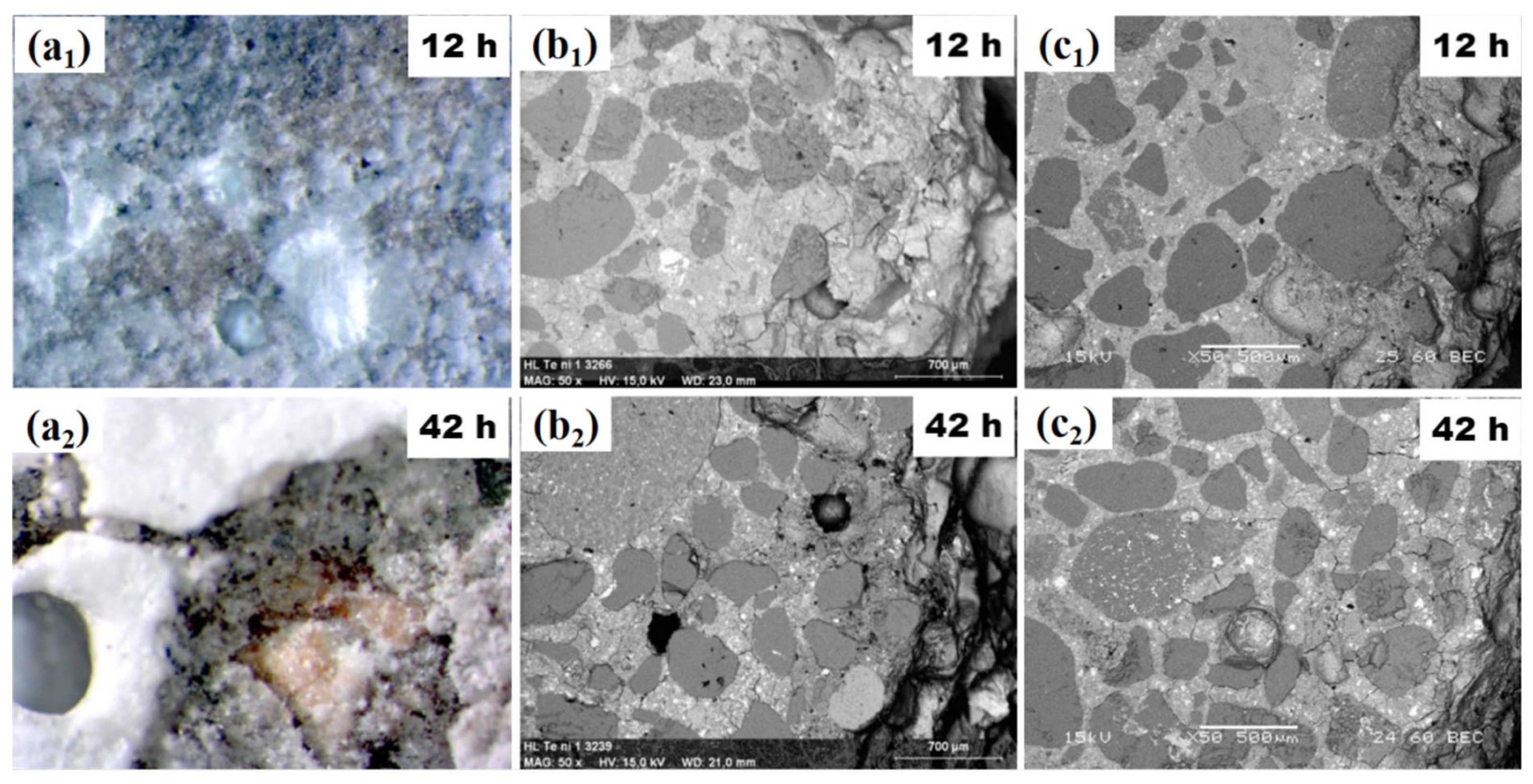

2.4. Effect of Polymer on Hydration Behavior of Silicate-Based Cement

3. Nano-Modified Cement-Based Composite (NMC)

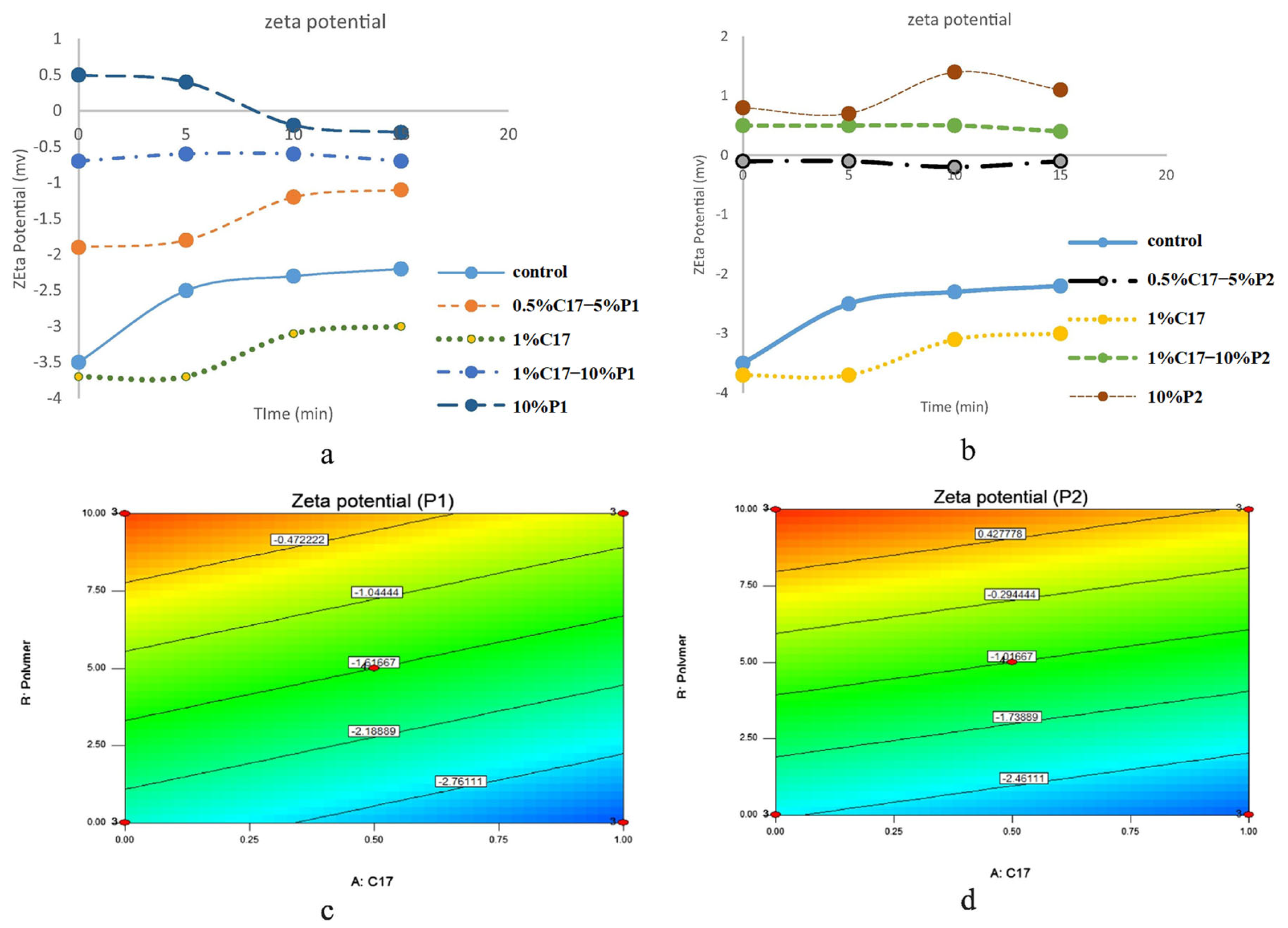

3.1. Dispersion of Nanomaterials in Aqueous System

3.2. Effect of Nanomaterials on the Properties of NMC

| Refs. | Nano Material | Body Material | Particle Size and Dosage | Consequences | Mechanisms |

|---|---|---|---|---|---|

| Senff [56] | n-SiO2 | P.O 52.5R | 9 nm, 2.5 wt% | The flow expansion diameter of mortar decreased by 19.6%, the yield stress increased by 157%. | High specific surface area, adsorbs large amounts of free water. |

| Beigi [57] | n-SiO2 | P.O II | 15 nm, 6 wt.% | The slump decreased by 10%; fc28d, 28-day split tensile strength, and ff28d increased by 17.9%, 35%, and 39.5%, respectively. | 1. Nano-filling effect; 2. Volcanic ash reaction, generating Ca(OH)2, filling pores; 3. Acting as a nano-core and bonding with C-S-H to improve the strength of the cementitious system. |

| Khaloo [58] | n-SiO2 | P.O II | 100 nm, 1.5 wt.% | Slump decreased by 29.2%, fc28d and splitting tensile strength increased by 9.0% and 10.7% respectively. | 1. SiO2 has a large specific surface area and high nanopore porosity; 2. Nanoscale nucleation promotes C-S-H growth and restricts the growth of weak crystal types such as AFt [59,60]. |

| Supit [61] | n-SiO2 | P.O I | 25 nm, 4 wt.% | Slump decreased by 60%, fc28d increased by 75.8%, water absorption and porosity decreased by 20–40% and 25% respectively. | 1. SiO2 nano-filling; 2. Volcanic ash is highly active and undergoes secondary hydration to form C-S-H, filling pores. |

| Li [62] | n-SiO2 | P.O 52.5 | 20 nm, 1 wt.% | Liquidity decreased by 20%, ff28d increased by 41%, and fc28d increased by 31%. | 1. Nano-filling; 2. High volcanic ash activity; 3. Nano-nucleation promotes hydration. |

| Zhang [63] | n-SiO2 | P. I 42.5 | 30 nm, 2 wt.% | The proportion of Ca(OH)2 in the hydration products decreased, while C-S-H increased (Figure 5c,d). | 1. Volcanic reaction and nano-filling; 2. Improved microstructure of hydration products. |

| Shang [54] | GO | P.O 42.5R | 0.08 wt.% | The yield stress increased from 25.6 Pa to 105.3 Pa, and the plastic viscosity increased from 0.84 Pa·s to 1.95 Pa·s. | The electrostatic interaction between GO and cement promotes the formation of flocculation structures. |

| Liu [64] | GO | P.O 42.5 | L * < 10 μm, 0.03 wt.% | fc28d increased by 12.4%, water resistance increased by 80%, and sulfate erosion after 3 months of fc increased by 11.3% compared to OCC. | 1. Nano-filling; 2. Nano-nucleation; 3. Nano-templating, i.e., two-dimensional layered structures regulate the distribution and morphology of hydration products. |

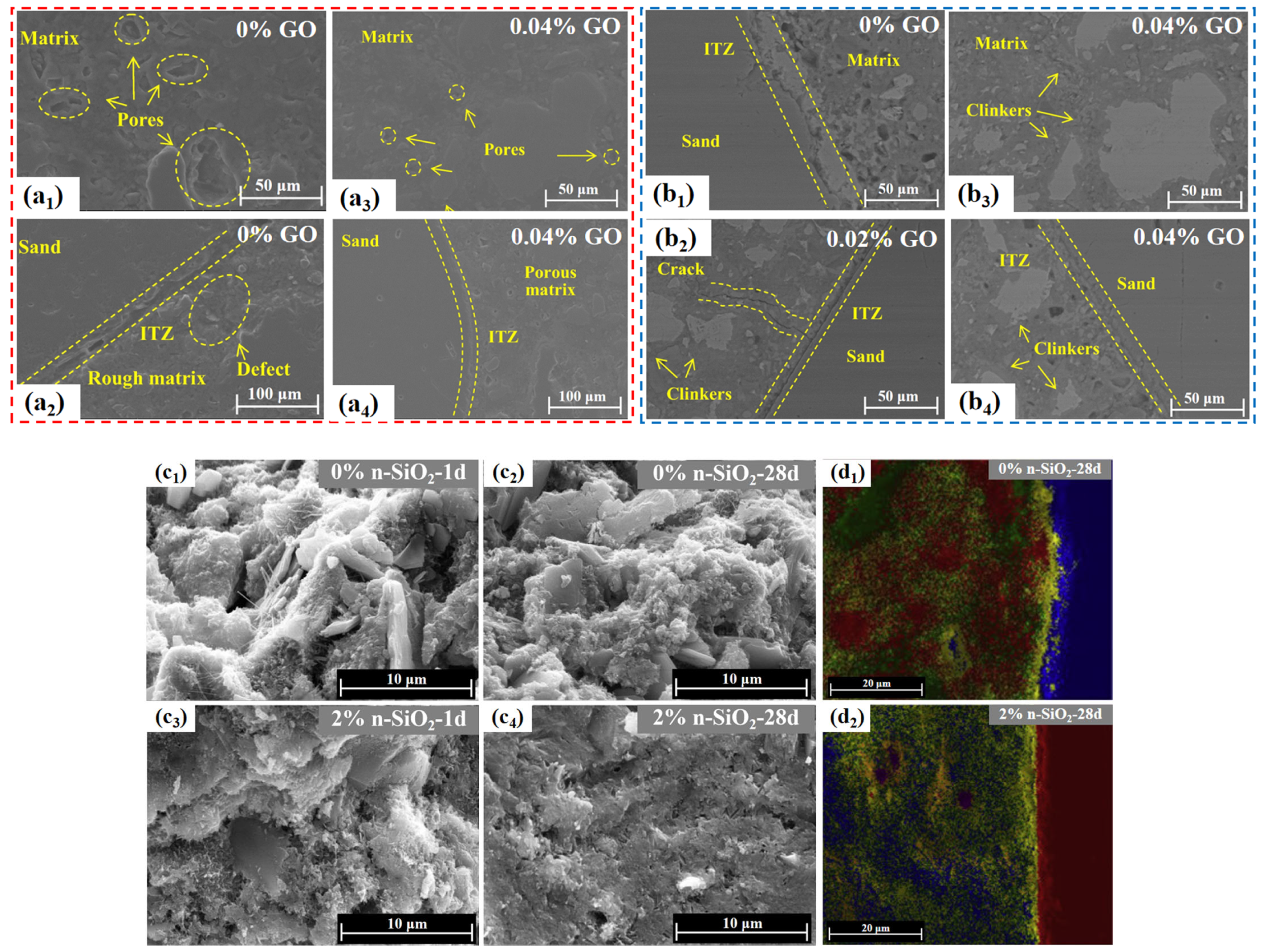

| Yan [65] | GO | P.O I | L: 3–10 μm, T * < 5 nm, 0.04 wt.% | fc3d and fc28d increased by 14.4% and 3.1%, respectively, and ITZ density increased (Figure 5a,b). | 1. High specific surface area increases interface roughness; 2. GO surface functional groups complex with Ca2+ in ITZ, enhancing interface forces; 3. Nanoscale nucleation. |

| Pan [66] | GO | P.O I | L: 1–14 μm, T: 1 nm, 0.05 wt.% | fc28d and ff28d improved by 15–33% and 41–59%, respectively. | GO surface groups can react with C-S-H or Ca(OH)2 to form strong covalent bonds at the interface, thereby improving the load transfer efficiency between the cement matrix and GO. |

| Manzur [67] | CNTs | P.O II | D *: 10–20 nm, 0.1 wt.% | Setting time reduced by approximately 25%; bond shear strength at 3, 7, and 28 days increased by 20%, 23%, and 22%, respectively. | 1. Nano-nucleation accelerates hydration; 2. The carboxyl groups on the surface of CNTs react chemically with calcium silicate hydrate (C-S-H) or Ca(OH)2; 3. Nano-filling; 4. CNTs act as a bridge between cracks and voids, ensuring load transfer. |

| Alafogianni [68] | CNTs | P.O I | D: 20–45 nm, L > 10 μm, 0.4 wt.% | Large pores reduced by 47.9%; water absorption rate reduced by 50%. | |

| Li [69] | CNTs | P.O 42.5 | 0.5 wt.% | fc and ff increased by 19% and 25%, respectively, the total porosity decreased by 64%, and pores larger than 50 nm decreased by 82%. | |

| Nasibulin [70] | CNTs | P.O 42.5 | In situ synthesis | fc28d increased by 2 times, and conductivity increased by 40 times. | CNTs act as a bridge between cement particles and hydration products. |

| Metaxa [71] | CNTs | P.O I | L: 30–100 μm, D: 100–150 nm, 0.048 wt.% | ff28d and Young’s modulus increased by 50% and 75%, respectively. | 1. Nano filling; 2. Bridging effect. |

| Wu [72] | n-CaCO3 | P.O II 42.5 | 15–105 nm, 3.2 wt.% | Liquidity decreased by 15.9%, while fc28d and ff28d increased by 9.9% and 25%, respectively. | 1. Nano-filling; 2. Providing nucleation sites to refine pores. |

| Li [69] | n-CaCO3 | P.O 52.5 | 15–80 nm, 3 wt.% | Liquidity decreased by 34%, while ff28d and fc28d increased by 40% and 17%, respectively. | |

| Vitharana [73] | TiO2 | P.O 42.5 | 20–30 nm, 1 wt.% | Fluidity decreased by 11.1%, fc7d increased by 43.7%, ff28d increased by 25%, and the weight loss rate due to reinforcement corrosion decreased by 10.54%. | |

| Hou [74] | nano-clay | White cement | L: 1.5 μm, D: 3 nm, 1wt.%, | fc7d and ff28d increased by 9.10% and 69.84% respectively, with short-term shrinkage increasing and long-term shrinkage decreasing by 3% to 6%. | 1. Accelerates early hydration and consumes a large amount of free water; 2. Nano-filling in the later stage. |

| Morsy [75] | nano metakaolin (NMK) & CNTs | P.O I | 200 × 100 × 20 nm 6 wt.%; D: 3–8 nm, 0.02 wt.% | fc28d increased by 29%. | 1. NMK undergoes an alkaline activation reaction; 2. NMK can inhibit CNT aggregation; 3. CNTs act as nucleation sites to promote hydration. |

4. Properties of NPMC

4.1. Effect of Nanomaterials on the Workability of NPMC

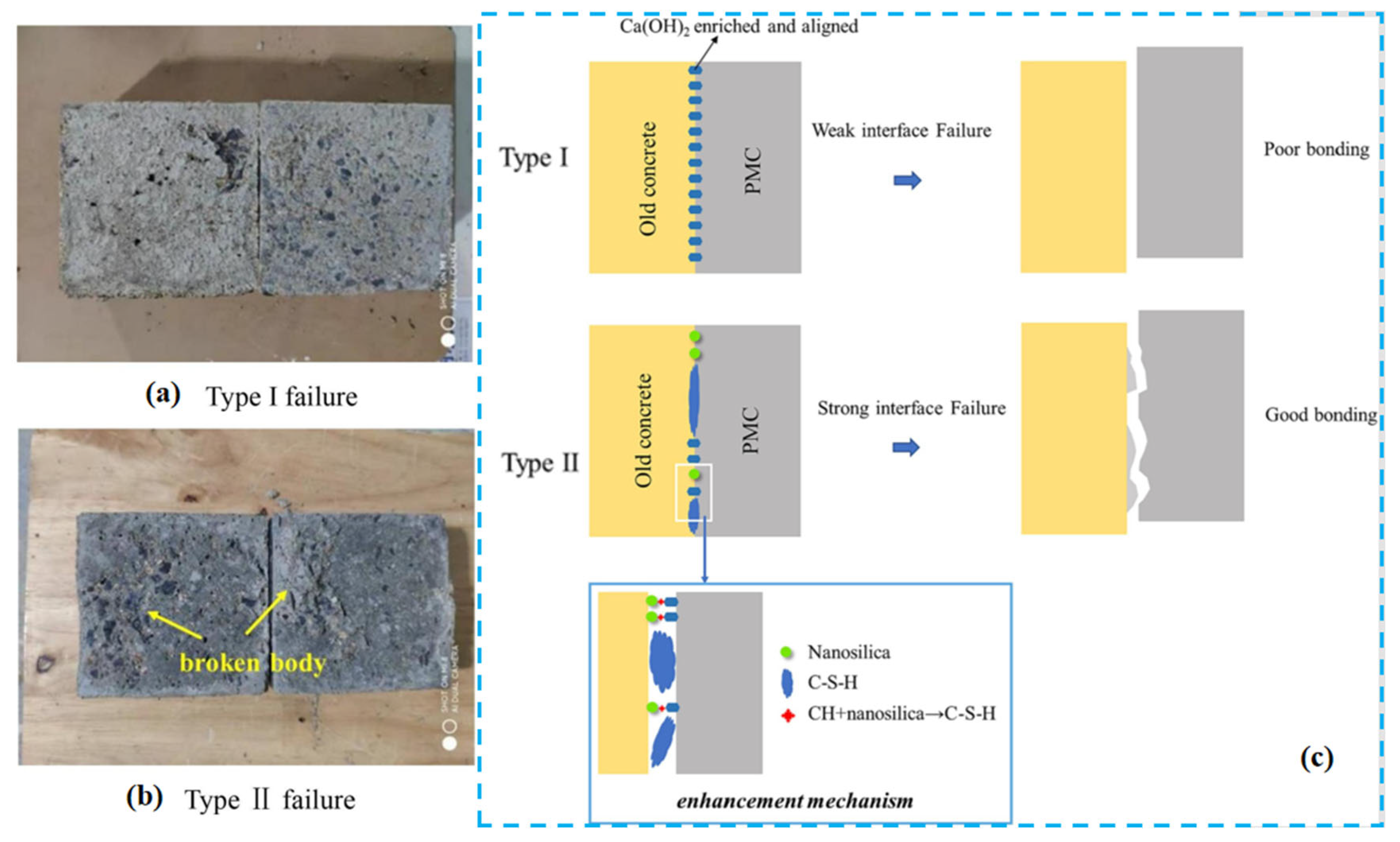

4.2. Effect of Nanomaterials on the Mechanical Properties of NPMC

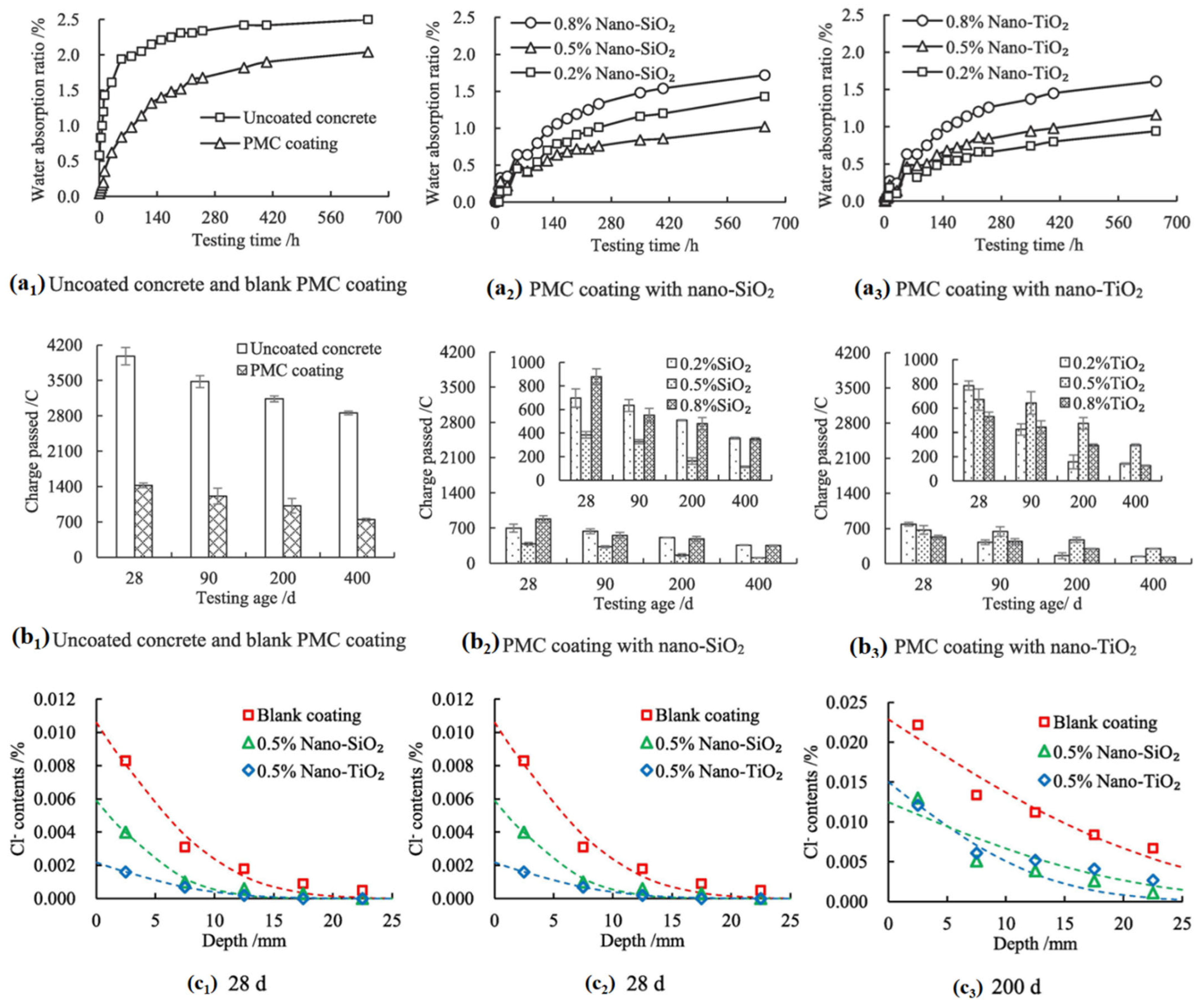

4.3. Effect of Nanomaterials on Durability of NPMC

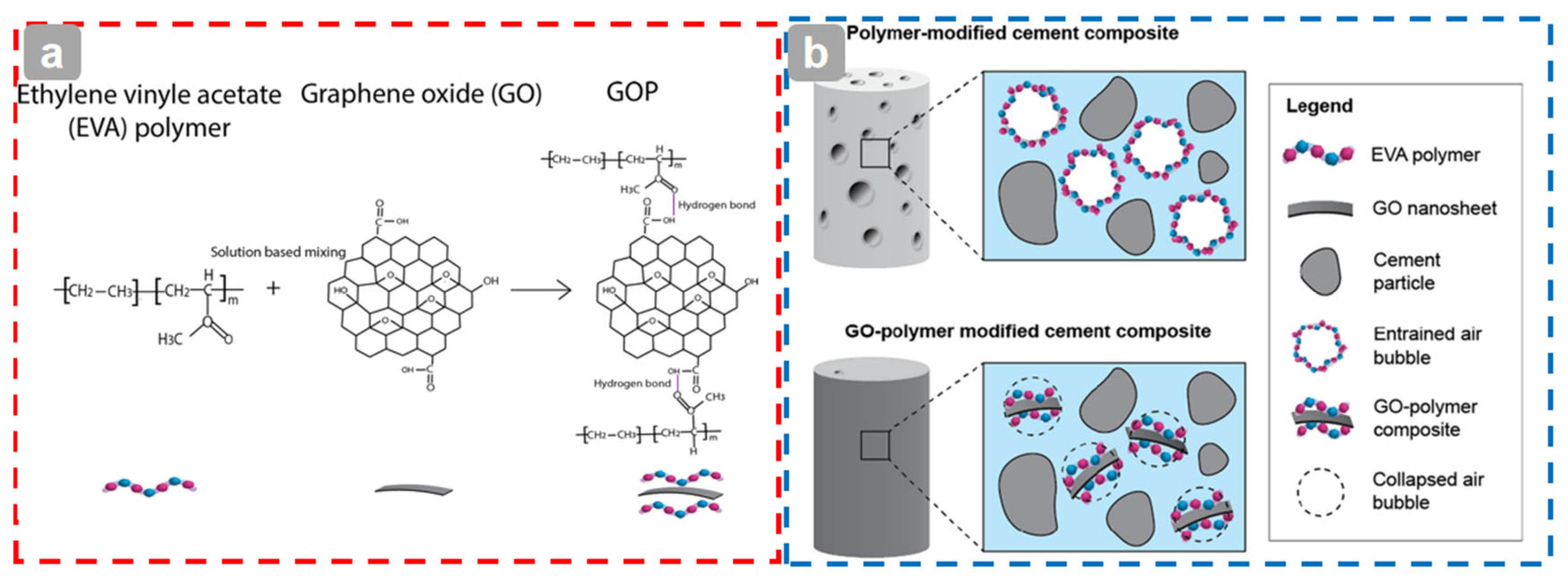

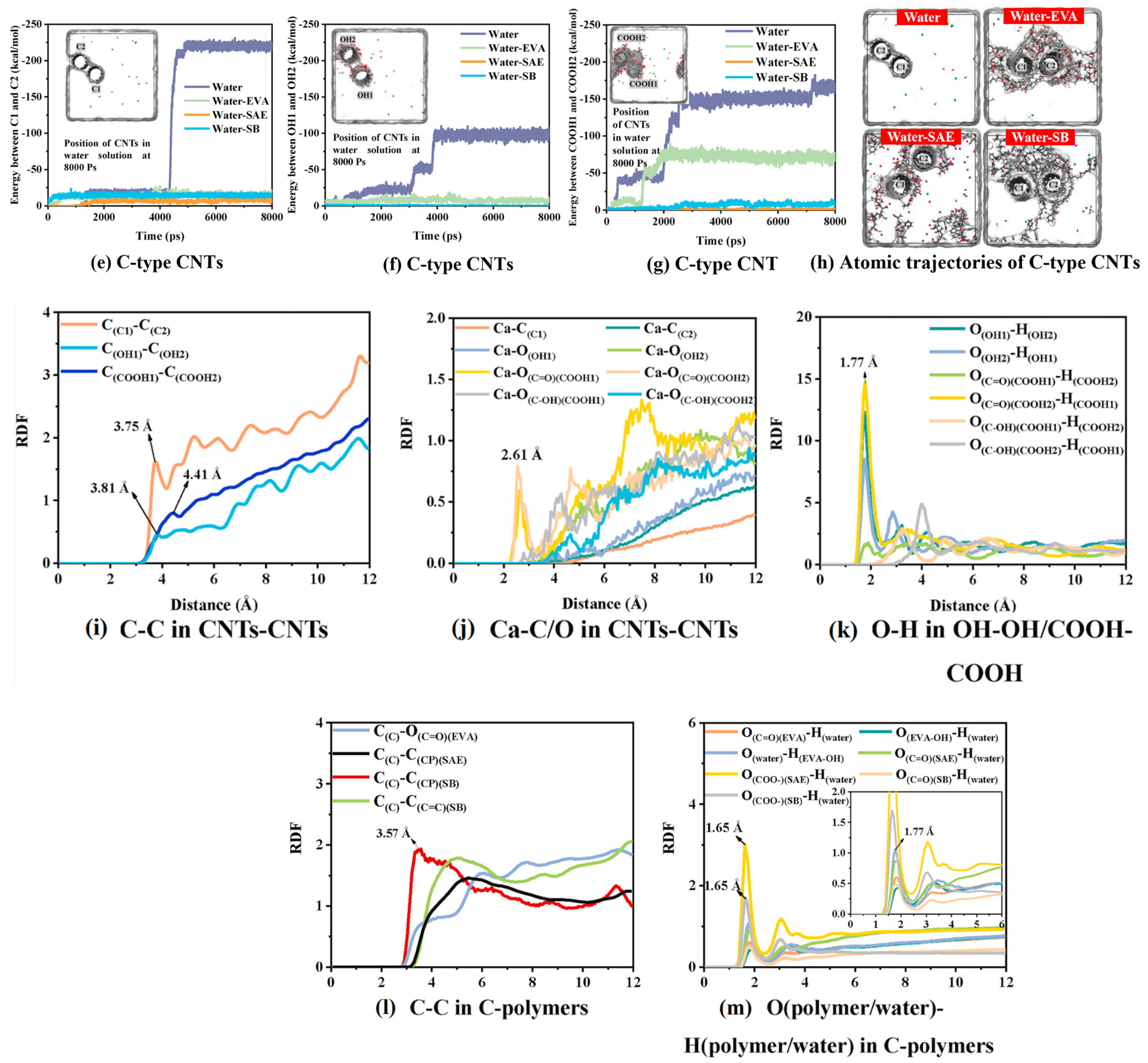

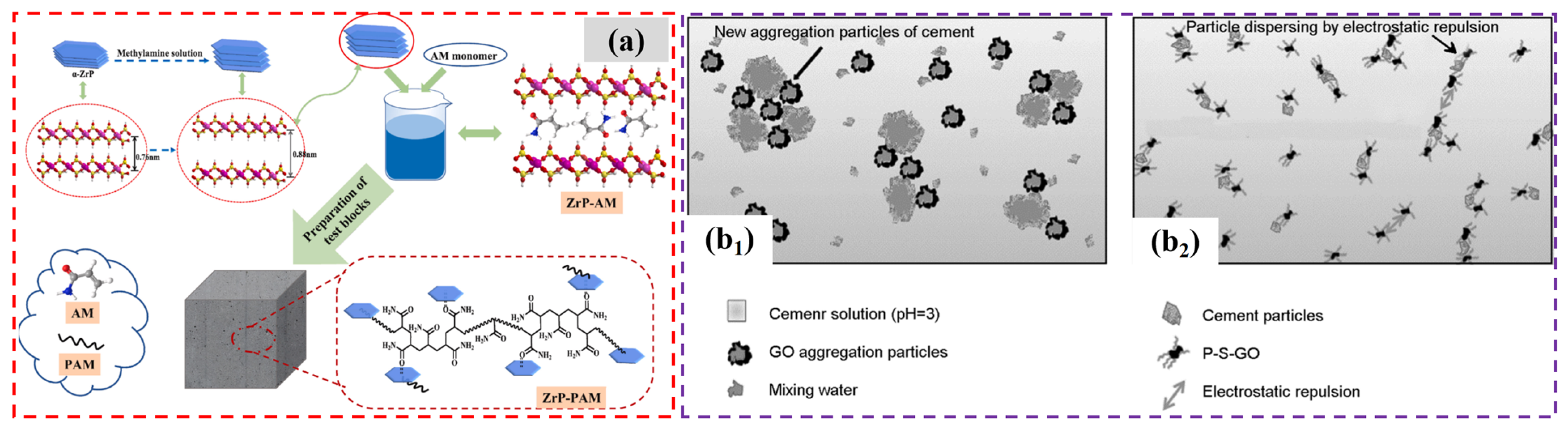

4.4. Interactions Between Nanomaterials and Polymers in NPMC

5. Conclusions and Outlook

5.1. Conclusions

5.2. Outlook

- One of the key issues constraining the application of nanomaterials in cement-based structures is high cost (e.g., GO, CNT, etc., have high production costs). Developing low-cost processes for large-scale production of nanomaterials is a prerequisite for NPMC application. Low-cost industrial solid waste can be used as raw materials for nanomaterial production; new processes can be developed or improved, such as microwave synthesis, in-situ crystallization of gel glass, and ton-scale production of water treatment composite nanomaterials.

- Improving the dispersion process of nanomaterials in cement-based systems. While existing dispersion processes can effectively disperse nanomaterials, they may damage the structure or functionality of the nanomaterials. The synthesis and optimization of new high-efficiency water-based dispersants, as well as the exploration of low-loss, high-efficiency dispersion processes, are urgent issues that need to be addressed.

- Mechanisms governing nanomaterials’ effects on microstructure and properties of PMC require further refinement. (1) Advanced characterization techniques should enable qualitative and quantitative analysis of nanomaterial effects on PMC microstructural evolution and hydration mechanisms; (2) Given the substantial hydration influence of both components, NPMC-specific hydration models can be established to investigate dynamic characteristics and reaction kinetics; (3) Current studies focus predominantly on single-phase interactions with cement-based systems, overlooking mutual polymer-nanomaterial interactions within NPMC. Pronounced interfacial interactions between specific nanomaterial surfaces and organic polymers yield hybrid-phase properties distinct from individual components, consequently altering system responses. Comprehensive understanding and utilization of these interactions will enhance synergistic optimization efficiency, enabling significant performance enhancements in cement-based materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Doğan, M.; Bideci, A. Effect of styrene butadiene copolymer (SBR) admixture on high strength concrete. Constr. Build. Mater. 2016, 112, 378–385. [Google Scholar] [CrossRef]

- Shafieyzadeh, M. Prediction of compressive strength of concretes containing silica fume and styrene-butadiene rubber (SBR) with a mathematical model. Int. J. Concr. Struct. Mater. 2013, 7, 295–301. [Google Scholar] [CrossRef]

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Khalid, N.H.A.; Mirzaa, J. Strength properties and molecular composition of epoxy-modified mortars. Constr. Build. Mater. 2015, 94, 315–322. [Google Scholar] [CrossRef]

- Assaad, J.J. Development and use of polymer-modified cement for adhesive and repair applications. Constr. Build. Mater. 2018, 163, 139–148. [Google Scholar] [CrossRef]

- Ma, H.; Li, Z. Microstructures and mechanical performance of polymer modified mortars under distinct mechanisms. Constr. Build. Mater. 2013, 47, 579–587. [Google Scholar] [CrossRef]

- Lu, Z.C.; Kong, X.M.; Zhang, C.Y.; Jansen, D.; Neubauer, J.; Goetz-Neunhoeffer, F. Effects of two oppositely charged colloidal polymers on cement hydration. Cem. Concr. Compos. 2019, 96, 66–76. [Google Scholar] [CrossRef]

- Kong, X.M.; Pakusch, J.; Jansen, D.; Emmeerling, S.; Neubauer, J.; Goetz-Neunhoeffer, F. Effect of polymer latexes with cleaned serum on the phase development of hydrating cement pastes. Cem. Concr. Res. 2016, 84, 30–40. [Google Scholar] [CrossRef]

- Jiang, L.F.; Lu, Z.C.; Kong, X.M.; Cai, Y. Surface modification of colloidal polymer particles and its effect on cement hydration. J. Chin. Ceram. Soc. 2017, 45, 601–607. (In Chinese) [Google Scholar]

- Tian, Y.; Li, Z.; Jin, X. Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: New York, NY, USA, 2010. [Google Scholar]

- Dong, S.; Yu, S.; Chen, L.; Zhuo, Q.; Wu, F.; Xie, L.; Liu, L. Comparative study on the effects of five nano-metallic oxide particles on the long-term mechanical property and durability of cement mortar. Buildings 2023, 13, 619. [Google Scholar] [CrossRef]

- Vidya, S.R.; Raghu, P.B.K.; Shantha, K.S. An experimental study on cracking evolution in concrete and cement mortar by the b-value analysis of acoustic emission technique. Cem. Concr. Res. 2012, 42, 1094–1104. [Google Scholar] [CrossRef]

- Yan, Y.; Tian, L.; Zhao, W.; Lazaro, S.A.M.; Li, X.; Tang, S. Dielectric and mechanical properties of cement pastes incorporated with magnetically aligned reduced graphene oxide. Dev. Built Environ. 2024, 18, 100471. [Google Scholar] [CrossRef]

- Mayercsik, N.P.; Shaeffer, M.; Graham-Brady, L.; Kurtis, K.E. Analysis of Portland cement mortar under impact: A combined material characterization, micromechanics modeling and dynamic testing approach. Cem. Concr. Res. 2015, 73, 190–206. [Google Scholar] [CrossRef]

- Zhang, C.; Kong, X.; Yin, J.; Fu, X. Rheology of fresh cement pastes containing polymer nanoparticles. Cem. Concr. Res. 2021, 144, 106419. [Google Scholar] [CrossRef]

- Ou, Z.H.; Ma, B.G.; Jian, S.W. Influence of cellulose ethers molecular parameters on hydration kinetics of Portland cement at early ages. Constr. Build. Mater. 2012, 33, 78–83. [Google Scholar] [CrossRef]

- Lu, Z.; Kong, X.; Zhang, C.; Xing, F.; Zhang, Y. Effect of colloidal polymers with different surface properties on the rheological property of fresh cement pastes. Colloids Surf. A 2017, 520, 154–165. [Google Scholar] [CrossRef]

- Bessaies-Bey, H.; Baumann, R.; Schmitz, M.; Radler, M.; Rouussel, N. Effect of polyacrylamide on rheology of fresh cement pastes. Cem. Concr. Res. 2015, 76, 98–106. [Google Scholar] [CrossRef]

- Abu-Tair, A.; Rigden, S.R.; Burley, E. Testing the bond between repair materials and concrete substrate. ACI Mater. J. 1996, 93, 553–558. [Google Scholar] [CrossRef] [PubMed]

- Qudoos, A.; Rehman, A.; Kim, H.G.; Ryou, J. Influence of the surface roughness of crushed natural aggregates on the microhardness of the interfacial transition zone of concrete with mineral admixtures and polymer latex. Constr. Build. Mater. 2018, 168, 946–957. [Google Scholar] [CrossRef]

- Zhou, J.; Ye, G.; Schlangen, E.; Breugel, K. Modelling of stresses and strains in bonded concrete overlays subjected to differential volume changes. Theor. Appl. Fract. Mech. 2008, 49, 199–205. [Google Scholar] [CrossRef]

- Kim, M.O. Influence of polymer types on the mechanical performance of polymer-modified cement mortars. Appl. Sci. 2020, 10, 1061. [Google Scholar] [CrossRef]

- Bureau, L.; Alliche, A.; Pilvin, P.; Paascal, S. Mechanical characterization of a styrene-butadiene modified mortar. Mater. Sci. Eng. A 2001, 308, 233–240. [Google Scholar] [CrossRef]

- Guo, S.Y.; Zhang, X.; Chen, J.Z.; Mou, B.; Shang, H.; Wang, P.; Zhang, L.; Ren, J. Mechanical and interface bonding properties of epoxy resin reinforced Portland cement repairing mortar. Constr. Build. Mater. 2020, 264, 120715. [Google Scholar] [CrossRef]

- Shi, C.; Li, M.; Ma, C.; He, T. Interfacial bonding properties of styrene-butadiene rubber and ethylene vinyl acetate emulsion-modified OPC-CAC-G repair mortar. Constr. Build. Mater. 2023, 370, 130747. [Google Scholar] [CrossRef]

- Zheng, H.; Pang, B.; Jin, Z.; Liu, S.; Zhang, Y.; Bi, J.; Chang, H.; Liu, Y.; Wang, F. mechanical performance and microstructure of waterborne polyurethane-modified cement composites as concrete repair mortar. J. Build. Eng. 2024, 84, 108394. [Google Scholar] [CrossRef]

- Li, M.; Zhong, J.; Li, G.; Zhang, Q.; Cen, F.; Gao, P. Study on the performance of polymer-modified conductive cement-based materials. Buildings 2023, 13, 2961. [Google Scholar] [CrossRef]

- Shi, C.; Zou, X.; Yang, L.; Wang, P.; Niu, M. Influence of humidity on the mechanical properties of polymer-modified cement-based repair materials. Constr. Build. Mater. 2020, 261, 119928. [Google Scholar] [CrossRef]

- Moodi, F.; Kashi, A.; Ramezanianpour, A.A.; Pourebrahimi, M. Investigation on mechanical and durability properties of polymer and latex-modified concretes. Constr. Build. Mater. 2018, 191, 145–154. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, X.; Creighton, A.T.; Peterson, M.M. Effect of styrene-butadiene rubber latex on the chloride permeability and microstructure of Portland cement mortar. Constr. Build. Mater. 2009, 23, 2283–2290. [Google Scholar] [CrossRef]

- Łukowski, P.; Dębska, D. Effect of polymer addition on performance of Portland cement mortar exposed to sulphate attack. Materials 2019, 13, 71. [Google Scholar] [CrossRef] [PubMed]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Tripathi, B. Effects of polymers on cement hydration and properties of concrete: A review. ACS Omega 2024, 9, 2014–2021. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Wang, R.; Zheng, S.; Farhan, S.; Yao, H.; Jiang, H. Research on the chemical mechanism in the polyacrylate latex modified cement system. Cem. Concr. Res. 2015, 76, 62–69. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Yin, J.; Peng, Y.; Wang, Y.; Tang, S.; Shi, Y.; Wang, Y.; Wang, L. Thermodynamics-based simulations of the hydration of low-heat Portland cement and the compensatory effect of magnesium oxide admixtures. J. Zhejiang Univ. Sci. A 2025, 26, 305–319. [Google Scholar] [CrossRef]

- Julliand, P.; Gallucci, E.; Flatt, R.; Scrivener, K. Dissolution theory applied to the induction period in alite hydration. Cem. Concr. Res. 2010, 40, 831–844. [Google Scholar] [CrossRef]

- Nicoleau, L.; Nonat, A. A new view on the kinetics of tricalcium silicate hydration. Cem. Concr. Res. 2016, 86, 1–11. [Google Scholar] [CrossRef]

- Chen, B.; Qiao, G.; Hou, D.; Wang, M.; Li, Z. Cement-based material modified by in-situ polymerization: From experiments to molecular dynamics investigation. Compos. Part B Eng. 2020, 194, 108036. [Google Scholar] [CrossRef]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon nanomaterials enhanced cement-based composites: Advances and challenges. Nanotech. Rev. 2020, 9, 115–135. [Google Scholar] [CrossRef]

- Sikora, P.; Abd Elrahman, M.; Stephan, D. The Influence of Nanomaterials on the thermal resistance of cement-based composites-A Review. Nanomaterials 2018, 8, 465. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Luo, J.; Li, Z.; Teng, F.; Zhang, J.; Gao, S.; Ma, M.; Zhou, X.; Tao, X. Dispersion of carbon nanotubes in aqueous cementitious materials: A review. Nanotechnol. Rev. 2023, 12, 20220560. [Google Scholar] [CrossRef]

- Korayem, A.H.; Tourani, N.; Zakertabrizi, M.; Sabziparvar, A.M.; Duan, W.H. A review of dispersion of nanoparticles in cementitious matrices: Nanoparticle geometry perspective. Constr. Build. Mater. 2017, 153, 346–357. [Google Scholar] [CrossRef]

- Cui, L.L. Study on Dispersion Technology of Carbon Nanotubes and Research and Development of Its Key Equipment Based on Arc Excitation. Master’s Thesis, Qingdao University of Science and Technology, Qingdao, China, 2018. (In Chinese). [Google Scholar]

- He, H.; Shuang, E.; Qiao, H.; Yang, J.; Lin, C.; He, C.; Xu, P. A general and simple method to disperse 2D nanomaterials for promoting cement hydration. Constr. Build. Mater. 2024, 427, 136217. [Google Scholar] [CrossRef]

- Ghavidel, A.K.; Zadshakoyan, M.; Arjmand, M.; Kiani, G. A novel electromechanical technique for efficient dispersion of carbon nanotubes in liquid media. Int. J. Mech. Sci. 2021, 207, 106633. [Google Scholar] [CrossRef]

- Andrievski, R.A.; Glezer, A.M. Size effects in properties of nanomaterials. Scr. Mater. 2001, 44, 1621–1624. [Google Scholar] [CrossRef]

- Yang, C.C.; Mai, Y.W. Thermodynamics at the nanoscale: A new approach to the investigation of unique physicochemical properties of nanomaterials. Mater. Sci. Eng. R 2014, 79, 1–40. [Google Scholar] [CrossRef]

- Hendon, C.H.; Rieth, A.J.; Korzynski, M.D.; Dinca, M. Grand challenges and future opportunities for metal-organic frameworks. ACS Cent. Sci. 2017, 3, 554–563. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, S.; Li, Z.; Gao, Y.; Liu, C. Mechanical strength enhancement and mechanism of hardened cement paste incorporating ZIF-8. Mater. Lett. 2020, 268, 127582. [Google Scholar] [CrossRef]

- Yuan, N.; Zhao, A.; Fang, K.; Wang, D.; Zhang, X. Diverse effects of metal-organic frameworks on microstructure and compressive strength of cement-based composites. Cem. Concr. Compos. 2022, 127, 104406. [Google Scholar] [CrossRef]

- Yin, H.; Zhu, J.; Guan, X.; Yang, Z.; Zhu, Y.; Zhao, H.; Zhang, Z.; Zhou, A.; Zhang, X.; Feng, C.; et al. Effect of MXene (Nano-Ti3C2) on early-age hydration of cement paste. J. Nanomater. 2015, 2015, 430578. [Google Scholar] [CrossRef]

- Zhu, J.; Li, G.; Feng, C.; Wang, L.; Zhang, W. Effect of delaminated MXene (Ti3C2) on the performance of cement paste. J. Nanomater. 2019, 2019, 3074206. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Zheng, D.; Yang, H.; Feng, W.; Fang, W.; Cui, H. Modification mechanism of cellulose nanocrystals in cement. Cem. Concr. Res. 2023, 165, 107089. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, J.; Zhu, X.; Fan, K.; Ma, M. A review on the effect of organic admixtures containing different functional groups on the hydration behaviors of Portland cement. Rev. Inorg. Chem. 2025. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Beigi, M.H.; Berenjian, J.; Omran, O.L.; Nik, A.S.; Nikbin, I.M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Khaloo, A.; Mobini, M.H.; Hosseini, P. Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr. Build. Mater. 2016, 113, 188–201. [Google Scholar] [CrossRef]

- Najigivi, A.; Khaloo, A.; Rashid, S.A. Investigating the effects of using different types of SiO2 nanoparticles on the mechanical performance of binary blended concrete. Compos. Part B Eng. 2013, 54, 52–58. [Google Scholar] [CrossRef]

- Hosseini, P.; Booshehrian, A.; Farshchi, S. Influence of nano-SiO2 addition on microstructure and mechanical performance of cement mortars for ferrocement. Transport. Res. Rec. 2010, 2141, 15–20. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Shaikh, F.U.A. Durability properties of high volume fly ash concrete containing nano-silica. Mater. Struct. 2015, 48, 2431–2445. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical performance of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, H.; Shen, W.; Xu, G.; Ma, B.; Ji, X. Nano-silica and silica fume modified cement mortar used as surface protection material to enhance the impermeability. Cem. Concr. Compos. 2018, 92, 7–17. [Google Scholar] [CrossRef]

- Liu, C.; Huang, X.; Wu, Y.Y.; Deng, X.; Zheng, Z. The effect of graphene oxide on the mechanical performance, impermeability and corrosion resistance of cement mortar containing mineral admixtures. Constr. Build. Mater. 2021, 288, 123059. [Google Scholar] [CrossRef]

- Yan, X.; Zheng, D.; Yang, H.; Cui, H.; Monasterio, M.; Lo, Y. Study of optimizing graphene oxide dispersion and properties of the resulting cement mortars. Constr. Build. Mater. 2020, 257, 119477. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Daun, W.H.; Wang, M.C. Mechanical performance and microstructure of a graphene oxide-cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.A.B. Potential of carbon nanotube reinforced cement composites as concrete repair material. J. Nanomater. 2016, 2016, 1421959. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dassios, K.; Tsakiroglou, C.D.; Matikas, T.E.; Barkoula, N.M. Effect of CNT addition and dispersive agents on the transport properties and microstructure of cement mortars. Constr. Build. Mater. 2019, 197, 251–261. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Nasibulin, A.G.; Shandakov, S.D.; Nasibulina, L.I.; Cwirzen, A.; Mudimela, P.R.; Habermehl-Cwirzen, K.; Grishin, D.A.; Gavrilov, Y.V.; Malm, J.E.M.; Tapper, U.; et al. A novel cement-based hybrid material. New J. Phys. 2009, 11, 023013. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Konsta-Gdoutos, M.S.; Shah, S.P. Carbon nanofiber cementitious composites: Effect of debulking procedure on dispersion and reinforcing efficiency. Cem. Concr. Compos. 2013, 36, 25–32. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Multi-scale investigation of microstructure, fiber pullout behavior, and mechanical performance of ultra-high performance concrete with nano-CaCO3 particles. Cem. Concr. Compos. 2018, 86, 255–265. [Google Scholar] [CrossRef]

- Vitharana, M.G.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Miah, M.J.; Panda, B. A study on strength and corrosion protection of cement mortar with the inclusion of nanomaterials. Sustain. Mater. Technol. 2020, 25, e00192. [Google Scholar] [CrossRef]

- Hou, S.; Duan, Z.; Ma, Z.; Singh, A. Improvement on the properties of waste glass mortar with nanomaterials. Constr. Build. Mater. 2020, 254, 118973. [Google Scholar] [CrossRef]

- Morsy, M.S.; Alsayed, S.H.; Aqel, M. Hybrid effect of carbon nanotube and nano-clay on physico-mechanical performance of cement mortar. Constr. Build. Mater. 2011, 25, 145–149. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Z.; Zhou, Y.; Du, J.; Lai, J.; Qian, K.; Ruan, S.; Bi, Y.; Qian, X. The influence of nano-silica composite superabsorbent polymer on the autogenous shrinkage of mortar. Constr. Build. Mater. 2024, 442, 137683. [Google Scholar] [CrossRef]

- Chen, W.; Song, X.; He, X.; Su, Y.; Oh, S.K.; Chen, S.; Sun, Q. Durability improvement mechanism of polymer cement protective coating based on functionalized MXene nanosheets modified polyacrylate emulsion. Prog. Org. Coat. 2024, 186, 108021. [Google Scholar] [CrossRef]

- Naseem, Z.; Shamsaei, E.; Sagoe-Crentsil, K.; Duan, W. Rheological enhancement of fresh polymer-modified cement composites via surface-modified graphene oxide. Cem. Concr. Compos. 2024, 147, 105413. [Google Scholar] [CrossRef]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.D. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Chuah, S.; Li, W.; Chen, S.J.; Sanjayan, J.G.; Duan, W.H. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments. Constr. Build. Mater. 2018, 161, 519–527. [Google Scholar] [CrossRef]

- Naseem, Z.; Shamsaei, E.; Sagoe-Crentsil, K.; Duan, W. Antifoaming effect of graphene oxide nanosheets in polymer-modified cement composites for enhanced microstructure and mechanical performance. Cem. Concr. Res. 2022, 158, 106843. [Google Scholar] [CrossRef]

- Sun, K.; Wang, S.; Zeng, L.; Peng, X. Effect of styrene-butadiene rubber latex on the rheological behavior and pore structure of cement paste. Compos. Part B Eng. 2019, 163, 282–289. [Google Scholar] [CrossRef]

- Zhou, W.; Ye, Q.; Cao, J.; Shi, S.Q.; Li, J. Performance improvement of magnesium oxychloride cement via nanoparticles-enhanced organic-inorganic hybrid network. Constr. Build. Mater. 2022, 343, 128096. [Google Scholar] [CrossRef]

- Cote, L.J.; Kim, J.; Tung, V.C.; Luo, J.; Kim, F.; Huang, J. Graphene oxide as surfactant sheets. Pure Appl. Chem. 2010, 83, 95–110. [Google Scholar] [CrossRef]

- Idrees, M.; Saeed, F.; Amin, A.; Hussain, T. Improvement in compressive strength of styrene-butadiene-rubber (SBR) modified mortars by using powder form and nanoparticles. J. Build. Eng. 2021, 44, 102651. [Google Scholar] [CrossRef]

- Fan, J.; Li, G.; Deng, S.; Deng, C.; Wang, Z.; Zhang, Z. Effect of carbon nanotube and styrene-acrylic emulsion additives on microstructure and mechanical characteristics of cement paste. Materials 2020, 13, 2807. [Google Scholar] [CrossRef] [PubMed]

- Wetzel, B.; Rosso, P.; Haupert, F.; Friedrich, K. Epoxy nanocomposites-fracture and toughening mechanisms. Eng. Fract. Mech. 2006, 73, 2375–2398. [Google Scholar] [CrossRef]

- Guo, S.Y.; Zhang, X.; Ren, J.; Chen, J.Z.; Zhao, T.J.; Li, T.W.; Zhang, L. Preparation of TiO2/epoxy resin composite and its effect on mechanical and bonding properties of OPC mortars. Constr. Build. Mater. 2021, 272, 121960. [Google Scholar] [CrossRef]

- Lin, B.; Fang, H.; Yao, Y. Bonding performance of ethylene vinyl acetate reinforced carbon nanotube repair materials. Constr. Build. Mater. 2024, 438, 137032. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Gao, S.; Zheng, Y. Improvement effects of nano-silica on bonding performance of polymer concrete for repairing damaged concrete. Constr. Build. Mater. 2023, 409, 133768. [Google Scholar] [CrossRef]

- Lu, M.; Xiao, H.; Liu, M.; Zheng, Y. Improved interfacial strength of SiO2 coated carbon fiber in cement matrix. Cem. Concr. Compos. 2018, 91, 21–28. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, J.; Zhang, J.; Zhou, X.; Teng, F.; Liu, C.; Sun, X. Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer. Nanotechnol. Rev. 2022, 11, 1778–1791. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, J.; Yuan, S.; Zhang, J.; Gao, S.; Zhu, M.; Li, Z.; Zhou, X. Fabrication of graphene oxide/fiber reinforced polymer cement mortar with remarkable repair and bonding properties. J. Mater. Res. Technol. 2023, 24, 9413–9433. [Google Scholar] [CrossRef]

- Guo, J.; Zheng, T.; Mou, F.; Qin, Y.; Wang, Z.; Zhang, S.; Li, H. A Study of composite salt erosion resistance of nano-modified cement mortar in early ages. Buildings 2025, 15, 278. [Google Scholar] [CrossRef]

- Muthalvan, R.S.; Selvaraj, L.; Avudaiappan, S.; Liseitsev, Y. Performance evaluation of super absorbent polymer modified cement mortar with nano-silica/GGBS. Case Stud. Constr. Mater. 2023, 19, e02359. [Google Scholar] [CrossRef]

- Li, G.; Ding, Y.; Gao, T.; Qin, Y.; Lv, L.; Wang, K. Chloride resistance of concrete containing nanoparticle-modified polymer cementitious coatings. Constr. Build. Mater. 2021, 299, 123736. [Google Scholar] [CrossRef]

- Yacine, B.; Ghomari, F. Latex influence on the mechanical behavior and durability of cementitious materials. J. Adhes. Sci. Technol. 2017, 31, 219–241. [Google Scholar]

- Zabihi, N.; Ozkul, M.H. The fresh properties of nano silica incorporating polymer-modified cement pastes. Constr. Build. Mater. 2018, 168, 570–579. [Google Scholar] [CrossRef]

- Meng, T.; Yu, H.; Lian, S.; Meng, R. Effect of nano-SiO2 on properties and microstructure of polymer modified cementitious materials at different temperatures. Struct. Concr. 2020, 21, 794–803. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zeng, S.; Dong, S.; Yu, X.; Yang, R.; Ou, J. Nano-core effect in nano-engineered cementitious composites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 100–109. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Fakoorpoor, S.M.; Hosseini, P.; Khaloo, A. Interactions between superabsorbent polymers and cement-based composites incorporating colloidal silica nanoparticles. Cem. Concr. Compos. 2013, 37, 196–204. [Google Scholar] [CrossRef]

- Zhang, S.W.; Wang, R.; Zhang, J.L.; Yuan, Y. Enhancing dispersion and mechanical properties of carbon nanotube-reinforced cement-based material using polymer emulsions. Cem. Concr. Compos. 2025, 157, 105910. [Google Scholar] [CrossRef]

- Yin, B.; Qi, D.; Hua, X.; Fan, F.; Han, K.; Hou, Y.; Hou, D.; Chen, B. Mechanical properties and micro-mechanism of cement-based materials strengthened by in-situ organic-inorganic polymerization. Cem. Concr. Compos. 2023, 142, 105202. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhou, R.; Liu, S.H.; Zhu, Y.; Wang, S.; Wang, J.; Guan, X. Enhanced toughness of ultra-fine sulphoaluminate cement-based hybrid grouting materials by incorporating in-situ polymerization of acrylamide. Constr. Build. Mater. 2021, 292, 123421. [Google Scholar] [CrossRef]

- Wang, J.R.; Zhang, H.B.; Zhu, Y.; Yan, Z.; Chai, H. Acrylamide in-situ polymerization of toughened sulphoaluminate cement-based grouting materials. Constr. Build. Mater. 2022, 319, 126105. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, R.J.; Wang, Q.; Liang, R.; Li, Z.; Sun, G. Cement mortar with enhanced flexural strength and durability-related properties using in situ polymerized interpenetration network. Front. Struct. Civ. Eng. 2021, 15, 99–108. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Pan, S.; Guo, Z. Synthesis and properties of a silane and copolymer-modified graphene oxide for use as a water-reducing agent in cement pastes. New Carbon Mater. 2018, 33, 131–139. [Google Scholar] [CrossRef]

- Kong, X.M.; Shi, Z.; Lu, Z. Synthesis of novel polymer nano-particles and their interaction with cement. Constr. Build. Mater. 2014, 68, 434–443. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, X.Y.; Wang, J.; Li, S.; Lv, C.; Dong, Y. Effect of fly ash on rheological properties of graphene oxide cement paste. Constr. Build. Mater. 2017, 138, 35–44. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lv, C.X.; Cui, X.; Liu, S.; Wang, X. Rheological behavior of fresh cement pastes with a graphene oxide additive. New Carbon Mater. 2016, 31, 574–584. [Google Scholar] [CrossRef]

| Refs. | Body Material | Polymer | Nano Material | Changes in Workability | Changes in Mechanical Properties | Changes in Durability |

|---|---|---|---|---|---|---|

| Naseem [78] | OPC | EVA, 3–5 wt.% | GO, 0.05 wt.% | Fluidity decreased by 5–15%. | The yield stress increased by 15% to 400%. The higher the EVA codntent, the stronger the effect. | - |

| Naseem [82] | OPC | EVA, 5 wt.% | GO, 0.05 wt.% | Slump reduction of 15% | fc28d and ft28d improved by approximately 26% and 32%, respectively. | The water absorption rate decreased by approximately 21%. |

| Idrees [86] | P.O I | SBR, 5 wt.% | n-TiO2, 2 wt.% | Fluidity decreased by 9.3%. | fc28d increased by 20%. | Water absorption decreased by 14.2%. |

| n-SiO2, 2 wt.% | Fluidity decreased by 8.0%. | fc28d increased by 48%. | Water absorption decreased by 8.6%. | |||

| Zinc-Stearate, 0.5 wt.% | Fluidity decreased by 20.0%. | fc28d increased by 24%. | Water absorption decreased by 5.7%. | |||

| Fan [87] | P.O I | SAE, 15 wt.% | CNT, 0.1 wt.% | - | fc3d, fc7d, fc28d increased by 15%, 14% and 12%; ff3d, ff7d, ff28d increased by 22%, 16% and 15%. | The capillary water absorption rate and adsorption rate decreased by 48.5% and 41.1%, respectively. |

| Guo [89] | P.O 42.5 | EP, 4.5 wt.% | n-TiO2, 2 wt.% | No significant change in rheology | fc28d, ff28d, fb28d increased by 8.8%, 7.5% and 4.5% | - |

| Gao [94] | P.O 42.5 | EVA, 8 wt.% | GO, 0.03 wt.% | Fluidity decreased by 15% and setting time was reduced by 21%. | fc28d, ff28d, fb28d increased by 8.3%, 19.1% and 36.6%. | Dry shrinkage was reduced by approximately 30%, water absorption was reduced by approximately 40%, and resistance to chloride ion permeability was also significantly improved. |

| Li [97] | P.O I | AC emulsion, 50 wt.% | n-TiO2, n-SiO2, 0.5 wt.% | - | - | Improved resistance to chloride ion penetration. |

| Chen [77] | P. I 42.5 | PA, 10 wt.% | MXene, 0.15 wt.% | Curing timel and rheology are reduced by approximately 21% and 15%. | ft and fb increased by 15%, and 10%. | Water absorption decreased by 40%. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Luo, J.; Zhang, J.; Ejaz, M.A.; Liu, L. Advances in Nano-Reinforced Polymer-Modified Cement Composites: Synergy, Mechanisms, and Properties. Buildings 2025, 15, 2598. https://doi.org/10.3390/buildings15152598

Gao Y, Luo J, Zhang J, Ejaz MA, Liu L. Advances in Nano-Reinforced Polymer-Modified Cement Composites: Synergy, Mechanisms, and Properties. Buildings. 2025; 15(15):2598. https://doi.org/10.3390/buildings15152598

Chicago/Turabian StyleGao, Yibo, Jianlin Luo, Jie Zhang, Muhammad Asad Ejaz, and Liguang Liu. 2025. "Advances in Nano-Reinforced Polymer-Modified Cement Composites: Synergy, Mechanisms, and Properties" Buildings 15, no. 15: 2598. https://doi.org/10.3390/buildings15152598

APA StyleGao, Y., Luo, J., Zhang, J., Ejaz, M. A., & Liu, L. (2025). Advances in Nano-Reinforced Polymer-Modified Cement Composites: Synergy, Mechanisms, and Properties. Buildings, 15(15), 2598. https://doi.org/10.3390/buildings15152598