Shear Performance of UHPC-NC Composite Structure Interface Treated with Retarder: Quantification by Fractal Dimension and Optimization of Process Parameters

Abstract

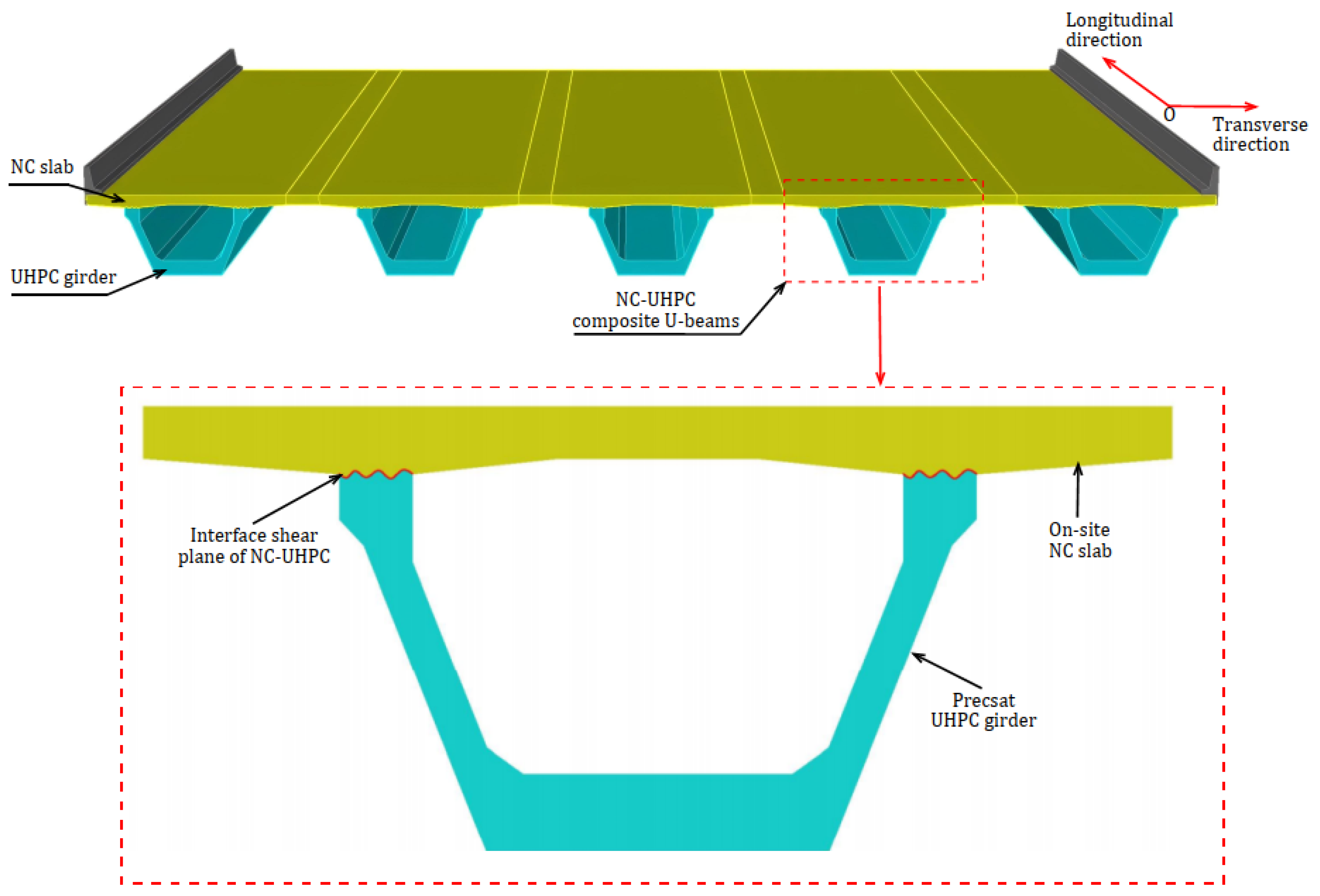

1. Introduction

2. Experiment Design and Test Methods

2.1. Materials and Mix Proportions

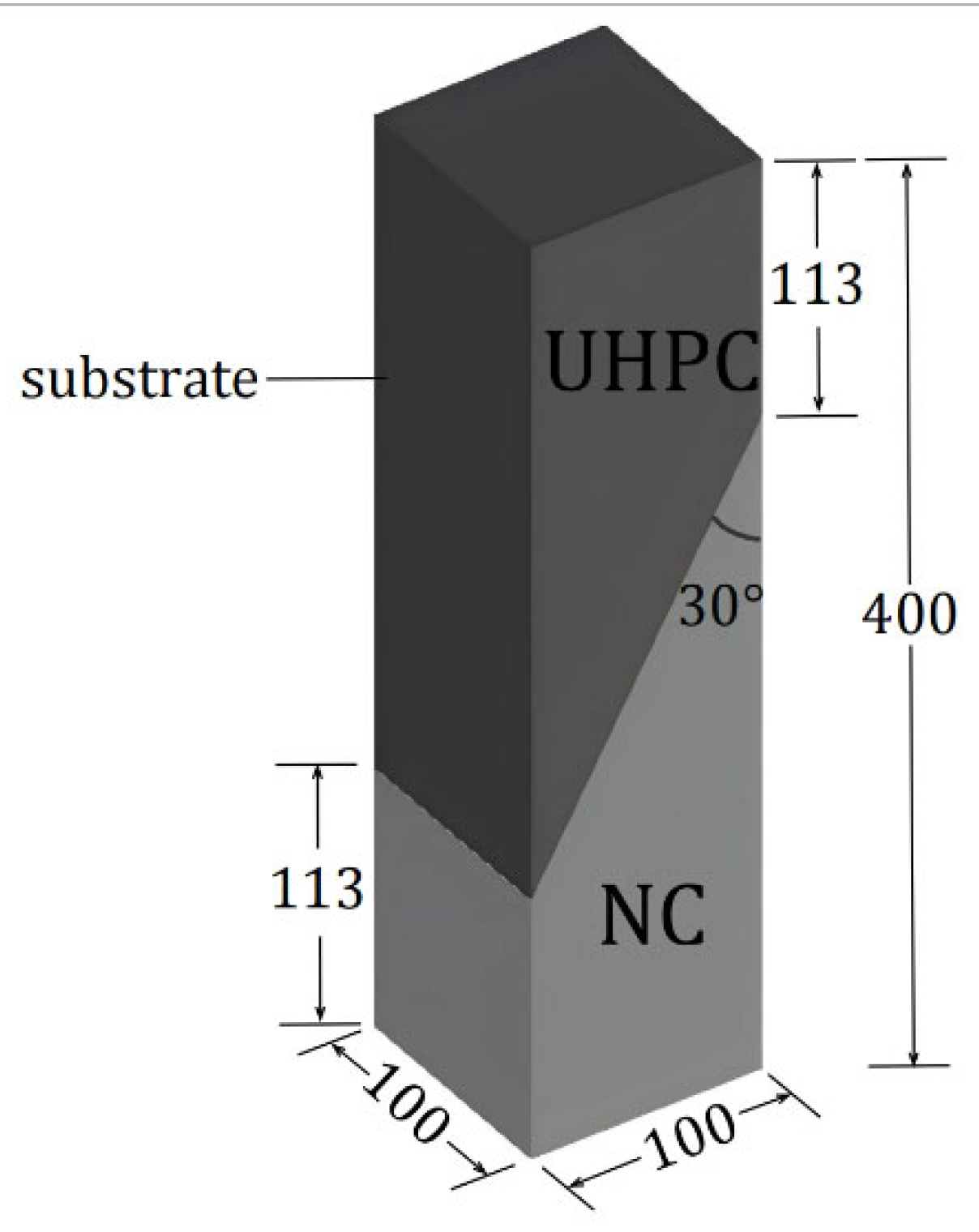

2.2. Specimen Design and Preparation

2.3. Test Methods

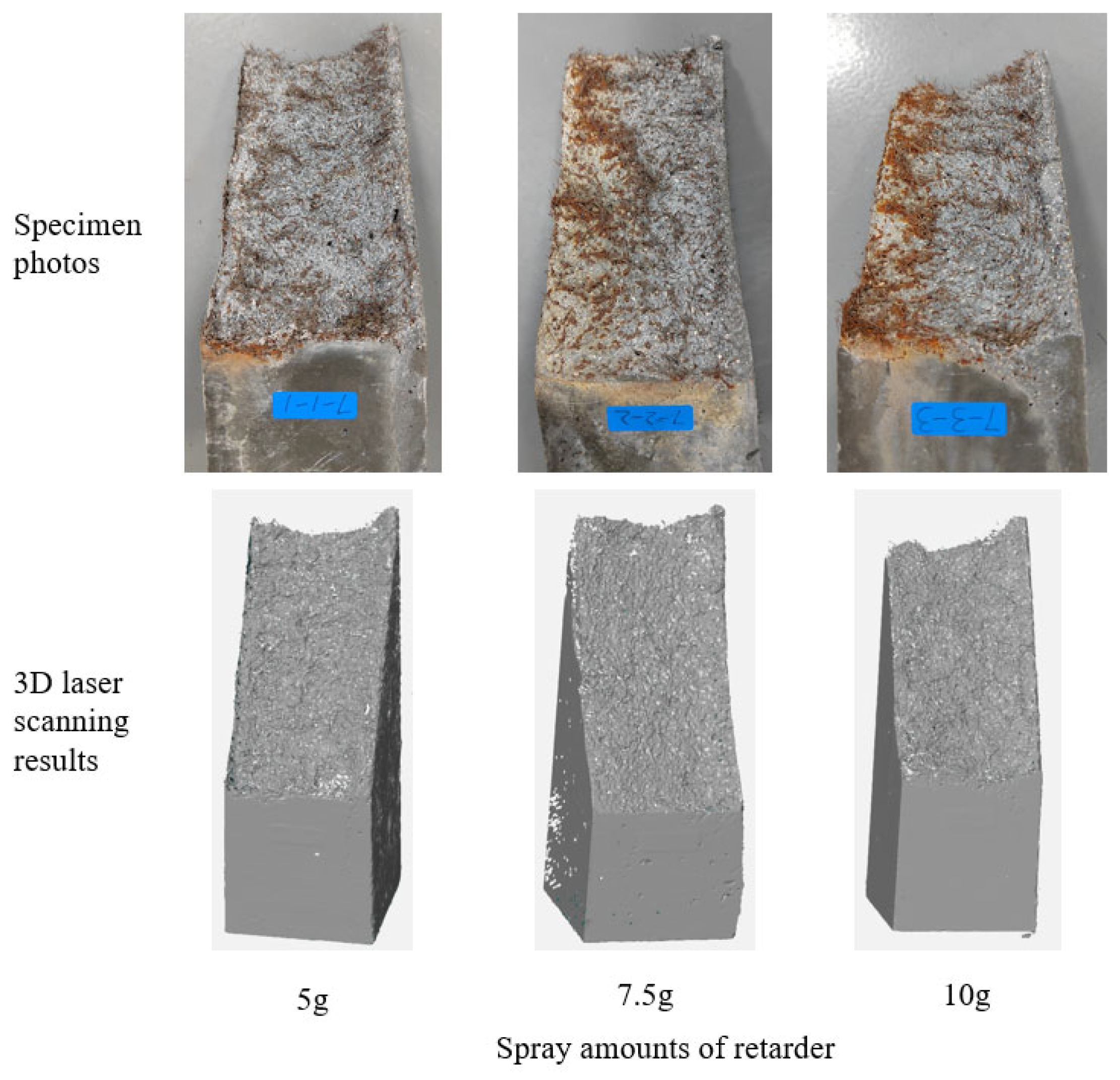

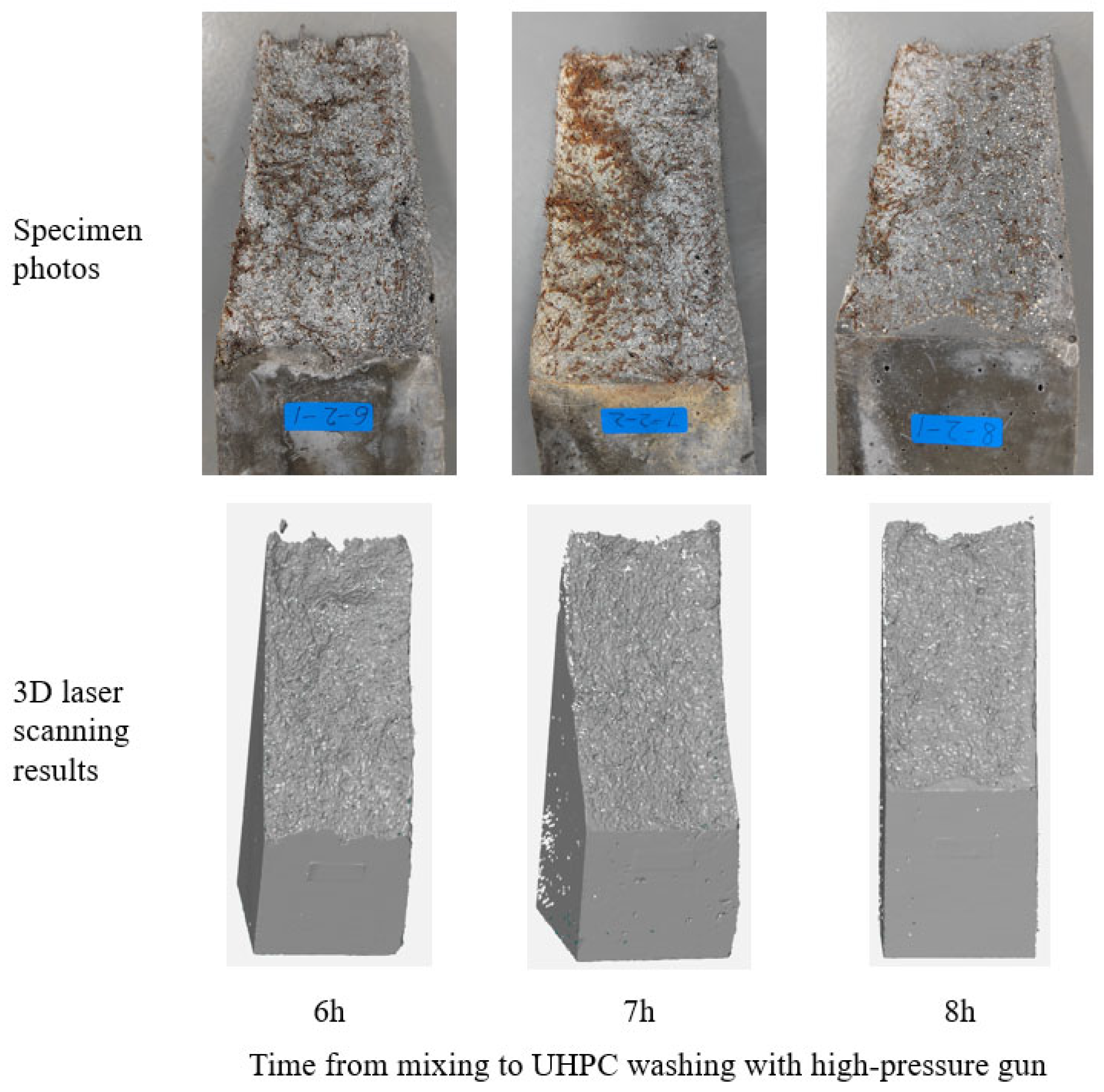

2.3.1. Laser Scanning Method for Rough Surfaces

2.3.2. Evaluation Method for Fractal Dimension of Rough Surfaces

2.3.3. Slant Shear Test

3. Experimental Results and Analysis

3.1. Test Phenomena and Failure Characteristics

3.2. Test Characteristic Values

3.3. Bond Strength-Slip Curve

3.4. Calculation of Fractal Dimension

3.5. Bond Strength of UHPC-NC Interface

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, J.D.; Wan, S.; Xiao, J.; Wang, X.; Zhou, P.; Dekemele, K. Cyclic loading test for prefabricated ultra-high performance concrete columns with bellows grouting connection. Struct. Concr. 2024, 25, 3361–3382. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, L.; Zeng, H.; Zhai, K.; Fu, J.; Jiang, H.; Pang, L. Research on the bond performance between glass fiber reinforced polymer (GFRP) bars and Ultra-high performance concrete(UHPC). J. Build. Eng. 2024, 98, 111340. [Google Scholar] [CrossRef]

- Tong, T.; Yuan, S.Q.; Liu, Z.; He, Z.Q.; Wang, J.Q. Experiments and Stress-Strain Model of Concrete Confined by UHPC Materials. J. Mater. Civ. Eng. 2023, 35, 04023006. [Google Scholar] [CrossRef]

- Feng, J.H.; Shao, X.D.; Qiu, M.H.; Li, H.H.; Gao, X.; Huang, Z.L. Reliability evaluation of flexural capacity design provision for UHPC beams reinforced with steel rebars/prestressing tendons. Eng. Struct. 2024, 300, 117160. [Google Scholar] [CrossRef]

- Luo, J.B.; Wu, G.Z.; Zhao, G.F.; Ma, Y.H.; Fang, Z.C.; Fang, S. Experimental and numerical analysis on shear performance of single embedded nut bolted shear connectors in prefabricated steel-UHPC composite structures under cyclic loading. Structures 2025, 73, 108446. [Google Scholar] [CrossRef]

- Jiang, H.B.; Chen, Z.Q.; Fang, Z.C.; Fang, S.; Tu, W.J.; Mo, F.; Xie, S.Y.; Liu, J. Rapid hardening high performance concrete (RHHPC) for bridge expansion joints: From material properties to interfacial shear performance. Constr. Build. Mater. 2025, 458, 139638. [Google Scholar] [CrossRef]

- Lin, S.; Lin, J.; Wu, Z.; Xiao, J.; Liu, L. Study on seismic performance of low yield point steel plate-ECC composite coupling beams. Structures 2025, 79, 109575. [Google Scholar] [CrossRef]

- Xiao, J.; Huang, L.; He, Z.; Qu, W.; Li, L.; Jiang, H.; Zhong, Z.; Long, X. Probabilistic models applied to concrete corrosion depth prediction under sulfuric acid environment. Measurement 2024, 234, 114807. [Google Scholar] [CrossRef]

- Shao, W.; Li, Q.M.; Zhang, W.B.; Shi, D.D.; Li, H.H. Numerical modeling of chloride diffusion in cement-based materials considering calcium leaching and external sulfate attack. Constr. Build. Mater. 2023, 401, 132913. [Google Scholar] [CrossRef]

- Yoon, I.S.; Chang, C. Quantitative Relationship between Chloride Penetration Depth and Hydraulic Conductivity of Concrete under Hydrostatic Pressure. J. Mater. Civ. Eng. 2022, 34, 04022074. [Google Scholar] [CrossRef]

- Xiao, J.; Zeng, H.; Huang, H.; Liu, L.; Li, L.; Yuan, B.; Zhong, Z. Experimental Investigation on the Influence of Strength Grade on the Surface Fractal Dimension of Concrete under Sulfuric Acid Attack. Buildings 2024, 14, 713. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.M.; Chamberlain, D.A. Remediation and protection of masonry structures with crystallising moisture blocking treatment. Int. J. Build. Pathol. Adapt. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Mobaraki, B.; Vaghefi, M. The Effect of Protective Barriers on the Dynamic Response of Underground Structures. Buildings 2024, 14, 3764. [Google Scholar] [CrossRef]

- Jiang, H.; Shao, T.; Fang, Z.; Xiao, J.; Hu, Z. Shear-friction behavior of grooved construction joints between a precast UHPC girder and a cast-in-place concrete slab. Eng. Struct. 2021, 228, 111610. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, S.; Zhang, Y.; Jiang, Y. Investigation of cracking and ductility performance of layered UHPC-NC composite members with reinforced UHPC as protective layer under bending moment. Thin-Walled Struct. 2025, 208, 112828. [Google Scholar] [CrossRef]

- Xu, J.; Wang, T.; Du, D.; Su, C.; Shi, X. Damage model of NC-UHPC interface zone in UHPC wet joint based on DIC. J. Build. Eng. 2024, 98, 111045. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Li, H. Comparative studies of the effect of ultrahigh-performance concrete and normal concrete as repair materials on interfacial bond properties and microstructure. Eng. Struct. 2020, 222, 111122. [Google Scholar] [CrossRef]

- Lyu, J.; Feng, S.; Zhang, Q.; Xiao, H. Review of factors affecting bond strength between ultra-high-performance concrete and normal strength substrate. Constr. Build. Mater. 2024, 439, 137416. [Google Scholar] [CrossRef]

- Abo El-Khier, M.; Morcous, G. Friction and Cohesion Interface Shear Factors of Ultra-High-Performance Concrete (UHPC) Cast on Hardened Conventional Concrete. Buildings 2023, 13, 1253. [Google Scholar] [CrossRef]

- Tu, W.; Cheng, Q.; Zhang, L.; Li, P.; Jiang, H.; Tian, Y.; Fang, J. Shear performance of 25 m full-scale prestressed UHPC-NC composite I-beam without stirrups. Case Stud. Constr. Mater. 2024, 21, e03942. [Google Scholar] [CrossRef]

- Tu, L.; Zhao, H.; Qiao, D.; Hu, J.; Tan, C.; Ma, J.; Hu, Z.; Qiu, H.; Shao, X. Concept and flexural performance of non-prestressed steel plate-UHPC-NC composite girder bridge. Eng. Struct. 2024, 315, 118417. [Google Scholar] [CrossRef]

- Sun, X.D.; Ma, Y.Q.; Ji, Z.M.; Fan, X.M.; Wu, H.L. Shear resistance test analysis and calculation method of shear capacity of UHPC-NC beam without web reinforcement. Adv. Struct. Eng. 2024, 27, 1810–1825. [Google Scholar] [CrossRef]

- Ganesh, P.; Ramachandra Murthy, A. Simulation of surface preparations to predict the bond behaviour between normal strength concrete and ultra-high performance concrete. Constr. Build. Mater. 2020, 250, 118871. [Google Scholar] [CrossRef]

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Constr. Build. Mater. 2020, 238, 117753. [Google Scholar] [CrossRef]

- Al-Madani, M.K.; Al-Osta, M.A.; Ahmad, S.; Khalid, H.R.; Al-Huri, M. Interfacial bond behavior between ultra high performance concrete and normal concrete substrates. Constr. Build. Mater. 2022, 320, 126229. [Google Scholar] [CrossRef]

- Tian, J.; Jiang, X.; Yang, X.; Ma, M.; Li, L. Bonding performance of the grooved interface between ultrahigh performance concrete and normal concrete. Constr. Build. Mater. 2022, 336, 127525. [Google Scholar] [CrossRef]

- Pereira Prado, L.; Carrazedo, R.; Khalil El Debs, M. Interface strength of High-Strength concrete to Ultra-High-Performance concrete. Eng. Struct. 2022, 252, 113591. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Lu, K.; Pang, Z.; Xu, Q.; Yao, Y.; Wang, J.; Miao, C. Bond strength between substrate and post-cast UHPC with innovative interface treatment. Cem. Concr. Compos. 2022, 133, 104691. [Google Scholar] [CrossRef]

- Millman, L.R.; Giancaspro, J.W. Three-Dimensional Optical Profilometry Analysis of the International Concrete Repair Institute Concrete Surface Profiles (CSPs). Aci Mater. J. 2013, 110, 519–527. [Google Scholar]

- Sengoz, B.; Topal, A.; Tanyel, S. Comparison of pavement surface texture determination by sand patch test and 3D laser scanning. Period. Polytech.-Civ. Eng. 2012, 56, 73–78. [Google Scholar] [CrossRef]

- Xiao, J.; Qu, W.J.; Jiang, H.B.; Li, L.; Huang, J.; Chen, L. Fractal characterization and mechanical behavior of pile-soil interface subjected to sulfuric acid. Fractals-Complex Geom. Patterns Scaling Nat. Soc. 2021, 29, 2140010. [Google Scholar] [CrossRef]

- Xiao, J.; Qu, W.J.; Jiang, H.B.; Dong, W.K. Three-Dimensional Fractal Characterization of Concrete Surface Subjected to Sulfuric Acid Attacks. J. Nondestruct. Eval. 2020, 39, 57. [Google Scholar] [CrossRef]

- Xiao, J.; Long, X.; Li, L.; Jiang, H.B.; Zhang, Y.W.; Qu, W.J. Study on the Influence of Three Factors on Mass Loss and Surface Fractal Dimension of Concrete in Sulfuric Acid Environments. Fractal Fract. 2021, 5, 146. [Google Scholar] [CrossRef]

- ASTM C882/C882M-20; Standard Test Method for Bond Strength of Epoxy-Resin Systems Used with Concrete by Slant Shear. ASTM: West Conshohocken, PA, USA, 2020.

- Xiao, J.; Long, X.; Qu, W.J.; Li, L.; Jiang, H.B.; Zhong, Z.C. Influence of sulfuric acid corrosion on concrete stress-strain relationship under uniaxial compression. Measurement 2022, 187, 110318. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. How Long Is the Coast of Britain? Statistical Self-Similarity and Fractional Dimension. Science 1967, 156, 636–638. [Google Scholar] [CrossRef]

- Yang, L.-l.; Xu, W.-y.; Meng, Q.-x.; Wang, R.-b. Investigation on jointed rock strength based on fractal theory. J. Cent. South Univ. 2017, 24, 1619–1626. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, Y.C.; Sun, F.Y.; Guo, M. Fractal Analysis on Asphalt Mixture Using a Two-Dimensional Imaging Technique. Adv. Mater. Sci. Eng. 2016, 2016, 8931295. [Google Scholar] [CrossRef]

- Zhou, H.W.; Xie, H. Direct Estimation of the Fractal Dimensions of a Fracture Surface of Rock. Surf. Rev. Lett. 2003, 10, 751–762. [Google Scholar] [CrossRef]

| Component | Cement | River Sand | Silica Fume | Fly Ash | Calcium Carbonate | Water-Reducing Admixture | Water | Steel Fiber |

|---|---|---|---|---|---|---|---|---|

| Mass (kg/m3) | 827.58 | 1021.27 | 203.35 | 55.8 | 33.1 | 27.52 | 191.53 | 156 |

| Design Strength Grade | Water–Cement Ratio | Sand Ratio (%) | Material Usage (m3/kg) | |||

|---|---|---|---|---|---|---|

| C40 | 0.59 | 36 | Cement | River Sand | Gravel | Water |

| 368 | 640 | 1138 | 217 | |||

| Specimen Number | Hydration Delay Duration (h) | Mass of Retarder Applied (g) |

|---|---|---|

| UN-6-5/7.5/10 | 6 | 5, 7.5, 10 |

| UN-7-5/7.5/10 | 7 | |

| UN-8-5/7.5/10 | 8 |

| Specimen ID | Average Peak Load (P/kN) | Ultimate Slip (s/mm) | Fractal Dimensions | Failure Mode |

|---|---|---|---|---|

| UN-6-5 | 412.94 | 0.3338 | 2.1357 | a, a, a |

| UN-6-7.5 | 391.50 | 0.3194 | 2.1351 | a, a, a |

| UN-6-10 | 416.56 | 0.4135 | 2.1278 | a, a, a |

| UN-7-5 | 418.06 | 0.4247 | 2.1298 | a, a, b |

| UN-7-7.5 | 385.17 | 0.2552 | 2.1241 | a, a, a |

| UN-7-10 | 389.83 | 0.3678 | 2.1168 | a, a, a |

| UN-8-5 | 325.62 | 0.2704 | 2.1193 | a, a, a |

| UN-8-7.5 | 356.87 | 0.2827 | 2.1129 | a, a, a |

| UN-8-10 | 325.07 | 0.2524 | 2.1107 | a, a, a |

| Specimen ID | Interface Bond Strength (MPa) |

|---|---|

| UN-6-5 | 20.65 |

| UN-6-7.5 | 19.58 |

| UN-6-10 | 20.83 |

| UN-7-5 | 20.90 |

| UN-7-7.5 | 19.26 |

| UN-7-10 | 19.49 |

| UN-8-5 | 16.28 |

| UN-8-7.5 | 17.84 |

| UN-8-10 | 16.25 |

| Hydration Delay Duration | 6 h | 7 h | 8 h | |

|---|---|---|---|---|

| Mass of Retarder | ||||

| 5 g | 20.65 | 20.9 | 16.28 | |

| 7.5 g | 19.58 | 19.26 | 17.84 | |

| 10 g | 20.83 | 19.49 | 16.25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, R.; He, Z.; Liu, J.; Lei, B.; Huang, L.; Xu, J.; Liu, L.; Xiao, J. Shear Performance of UHPC-NC Composite Structure Interface Treated with Retarder: Quantification by Fractal Dimension and Optimization of Process Parameters. Buildings 2025, 15, 2591. https://doi.org/10.3390/buildings15152591

Weng R, He Z, Liu J, Lei B, Huang L, Xu J, Liu L, Xiao J. Shear Performance of UHPC-NC Composite Structure Interface Treated with Retarder: Quantification by Fractal Dimension and Optimization of Process Parameters. Buildings. 2025; 15(15):2591. https://doi.org/10.3390/buildings15152591

Chicago/Turabian StyleWeng, Runcai, Zhaoxiang He, Jiajie Liu, Bin Lei, Linhai Huang, Jiajing Xu, Lingfei Liu, and Jie Xiao. 2025. "Shear Performance of UHPC-NC Composite Structure Interface Treated with Retarder: Quantification by Fractal Dimension and Optimization of Process Parameters" Buildings 15, no. 15: 2591. https://doi.org/10.3390/buildings15152591

APA StyleWeng, R., He, Z., Liu, J., Lei, B., Huang, L., Xu, J., Liu, L., & Xiao, J. (2025). Shear Performance of UHPC-NC Composite Structure Interface Treated with Retarder: Quantification by Fractal Dimension and Optimization of Process Parameters. Buildings, 15(15), 2591. https://doi.org/10.3390/buildings15152591