1. Introduction

In the 21st century, climate change is a critical challenge, intensified by the high environmental impact of traditional construction [

1,

2]. Given this reality, it is crucial for the construction industry to evolve toward more sustainable practices. The search for sustainable alternatives in construction presents itself as a critical solution to reduce environmental impact [

3]. It is not merely about carrying out construction projects but doing so in a way that promotes harmony between societal development and the environment.

The increasing energy demand, exacerbated by the depletion of fossil resources and climate change, necessitates a more efficient and effective use of energy in residential and commercial buildings, industrial construction sectors, transportation, and service industries [

4].

In recent years, there has been a considerable increase in energy consumption in buildings due to various factors, including climate change, population growth, and the pursuit of improved living conditions in general [

5]. A significant portion of the energy consumed in buildings is allocated to heating and cooling loads, which can account for around 30% of a country’s total consumption [

6]. These thermal loads are largely attributed to heat loss or gain through the building envelope. Reducing heat transfer through the envelope can effectively decrease the energy consumption in buildings. In this context, a passive and highly effective method to reduce environmental loads is to apply thermal insulation to the external walls of the building. However, it is important to consider that increasing the thickness of the insulation reduces the heat transfer load but also raises the installation cost [

7]. Therefore, it is essential to determine the optimum thickness that minimizes the total cost for insulation and HVAC energy use of the building throughout its lifecycle [

8], especially considering the impact of climate change and the future rise in temperatures.

Associated with the above, there are various alternative solutions, such as energy optimization methods through simulations, where iterative processes can be used to optimize various components of any type of building related to its energy efficiency, economic optimization, and ecological impact [

9,

10]. The selection of the optimal insulation thickness is crucial, as excessive insulation may not justify its additional cost and could even be counterproductive in certain climates by increasing the cooling load [

11,

12]. The main optimization methodologies include energy modeling and simulation using software such as DesignBuilder (which uses EnergyPlus), TRNSYS, Dest, or IDA ICE, which allow simulation of the building’s energy performance [

11,

13]. These simulations consider variables such as building orientation, window-to-wall ratio (WWR), internal heat gains, and material properties, enabling the identification of the optimal thermal insulation for the building envelope. To optimize the results of multiple simulations, algorithms such as non-dominated sorting genetic algorithm II (NSGA II), genetic algorithms (GAs), or particle swarm optimization (PSO) are commonly used [

11,

14]. These algorithms, often coupled with energy simulations and artificial neural networks (ANNs), aim to minimize multiple objectives simultaneously, such as energy consumption and cost, among others [

13].

Another approach to determine the optimal thickness of thermal insulation is the use of analytical methods, which involve solving heat transfer equations across the building envelope. For example, the finite difference method and Fourier transform techniques are commonly used to solve these equations under steady or periodic conditions [

15,

16].

A complementary approach is Life Cycle Assessment (LCA), an essential methodology to evaluate the total environmental impact of construction materials and systems throughout the entire life cycle of a building—from production to end-of-life. Considering the embodied carbon of materials is increasingly important, as materials with higher embodied carbon may not be offset by lower operational energy consumption [

15,

17].

Another approach is the Life Cycle Cost Analysis (LCCA) method, a widely used and proven methodology globally, which serves as a useful tool for economic evaluation that contributes to achieving sustainable goals, attaining long-term performance by improving operational costs in buildings [

18]. This approach goes beyond merely considering the initial costs and also evaluates the long-term implications. The main aim of LCCA is to balance the economic and environmental impact. By assessing the direct and indirect costs associated with a project, from raw material extraction to the eventual demolition of the structure, it provides a more comprehensive perspective. This holistic approach enables construction professionals to make informed decisions that benefit both economic profitability and environmental sustainability.

A concrete example of applying LCCA is in precisely the determination of the optimum thickness of insulation in walls [

19,

20,

21]. Instead of automatically opting for the most cost-effective solution in the short term, LCCA considers energy costs over time, as well as the environmental impact associated with energy consumption. This can lead to the choice of a thicker insulation which, although initially more expensive, results in significant savings over the building’s lifecycle, as well as a reduction in carbon emissions. Generally, the alternative that presents the lowest total cost over its life cycle is considered the most economical and, therefore, may be the preferred option [

22]. The recent research presents 47 examples of studies defining the optimum thermal insulation thickness for walls using the LCCA methodology, highlighting the scientific interest in this method from various research institutions worldwide, demonstrating its suitability for different types of walls and thermal insulation applications [

23]. Furthermore, the authors of the study [

21] emphasize the importance of considering solar radiation for warmer regions of the world, particularly those with extreme solar climates due to their proximity to the equator. This parameter is crucial, and the need to include it in the LCCA methodology to determine the optimum insulation thickness is discussed [

21,

24]. Considering the effect of solar radiation to correct degree days tends to be a complicated task due to the number of meteorological and geographical factors in the building’s location [

4]. Therefore, it is necessary to take into account both the different orientations of the studied wall and the corresponding hourly variations in global solar radiation for each orientation [

25]. Solar radiation directly impacts the exterior walls, generating a thermal load that must be controlled by the thermal insulation system [

26]. The intensity of solar radiation, local climatic conditions, and seasonal variations are key factors that impact the amount of heat to be mitigated. Heat transfer through walls is responsible for 20–40% of the cooling load for different buildings in various climatic zones [

27]. In regions with high temperatures and prolonged sun exposure, more effective insulation is required to reduce unwanted heat gain.

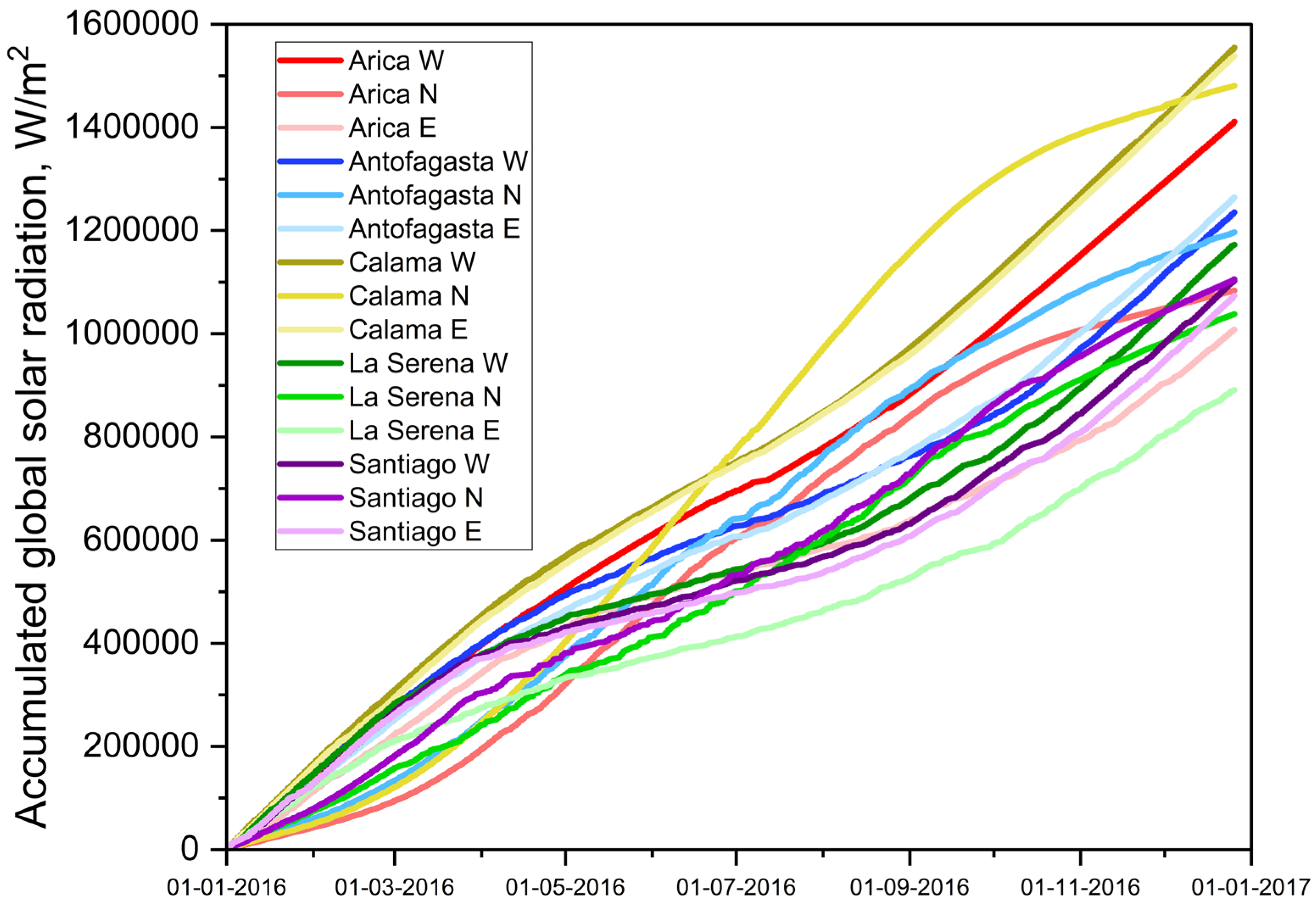

One of the countries characterized by an extremely solar climate is Chile, specifically in the north of the country, where the annual average values of global horizontal solar radiation can reach up to 2400–2800 kWh/m

2 [

28].

The design of thermal envelope elements for buildings in Chile is based on national construction regulations that set maximum permissible values for thermal transmittance (U) in different geographical locations [

29,

30]. However, these regulations do not consider various local geophysical and geographical aspects [

31]. Therefore, it is essential to determine the optimum insulation thickness, which in turn will allow the determination of an optimum U-value for the thermal envelope elements of buildings using the LCCA methodology. This approach is a suitable alternative for customized project designs in different geographical zones of Chile.

When using the LCCA methodology to define the optimum thickness of thermal insulation for walls in northern Chile, it is necessary to determine the influence of solar radiation, as this can significantly affect the determination of the optimum insulation thickness in these extremely hot areas [

32] for mass walls and its effect on the energy demand for heating and cooling of a typical house in the area. In this context, the main objective of this research will be to analyze the necessity of considering solar radiation in the calculation of the optimum thermal insulation thickness for mass walls through the LCCA methodology in the cities of northern Chile.

3. Results and Discussion

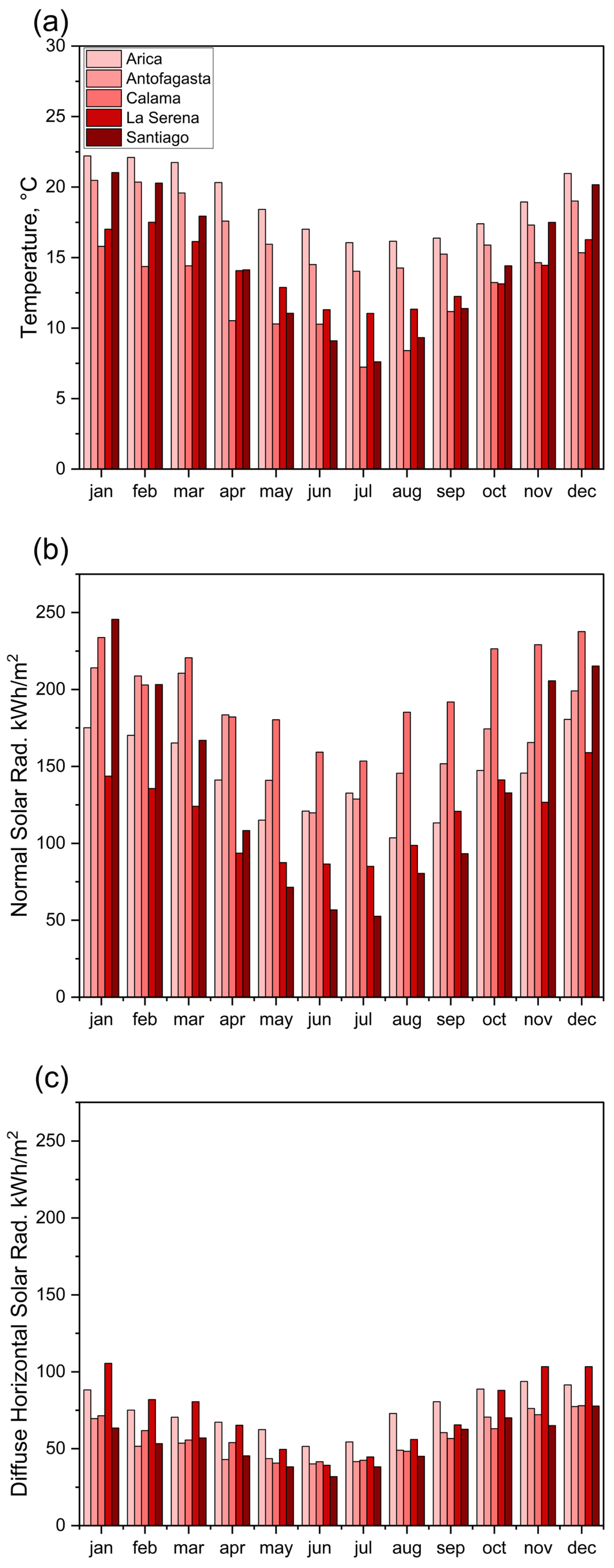

The results section is divided into three parts. The first part considers variable threshold temperatures for cooling and heating (θc and θh), presenting the optimum thicknesses obtained using the LCCA method with the sol–air temperature (θsa), taking into account the effect of solar radiation, and the method using ambient temperature (θo), which does not consider it. The second part of the results presents an analysis of the same parameters, but with constant cooling and heating thresholds throughout the year for each city. In the third part, the results of the validation of the optimum thicknesses are presented alongside the results of the energy demand simulation in the study cities for a typical house in the study area.

3.1. Optimum Thermal Insulation Thicknesses for Variable Threshold Temperatures

Table 9 presents the results of the optimum thickness (x) obtained for each city, method, and orientation of the studied wall, along with the annual sums of CDDs and HDD. A notable difference can be observed between the annual values of CDDs based on sol–air temperature compared to CDDs based on ambient temperature in all the cities studied. The west orientation in all cities is characterized by having the maximum CDDs θsa. Due to the orographic aspects of Chile, the presence of the high Andes mountains in the eastern part of the country influences the modelling of global solar radiation. As in the Northern Hemisphere, in summer, the east and west facades receive more radiation than the south facades [

53], which is why the CDDs θsa of the west wall is greater than that of the south wall. Furthermore, the solar radiation simulation takes into account the hourly variable effect of cloud cover [

34], which influences the final CDDs results calculated based on sol–air temperature. The values of CDDs θo are almost negligible, as the cooling limit thresholds were developed based on the adaptive thermal comfort model.

In the case of HDDs, considering the effect of solar radiation on average decreases the annual value of HDD θo by 16% in all cities for three orientations, with a minimum decrease in the city of Calama. This result is logical due to the transition to θsa considering solar gains. The variation in HDD θsa by orientation is not as notable in almost all cities (

Table 9).

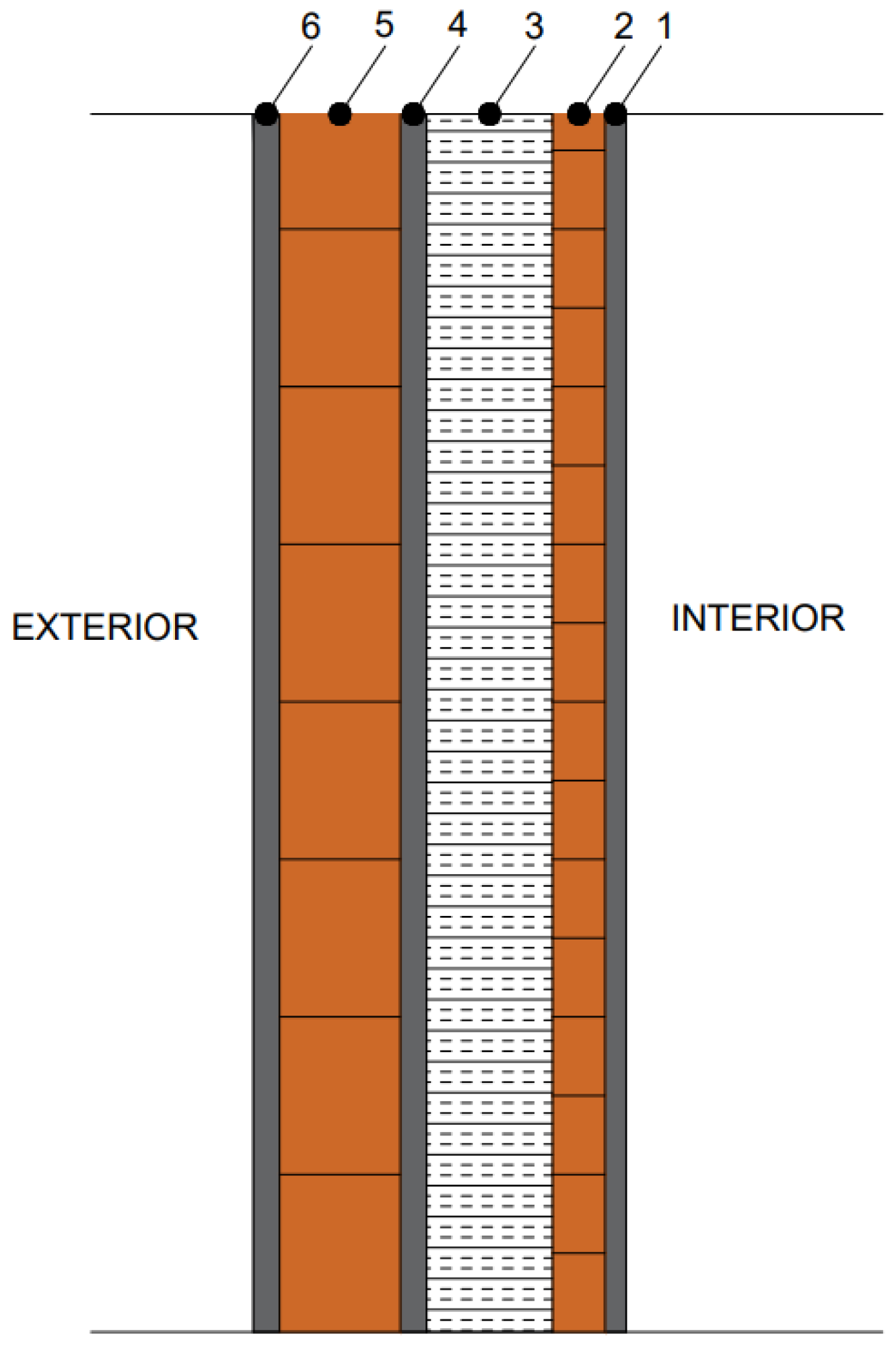

Regarding the optimum thicknesses of EPS thermal insulation for the analyzed wall construction solution (

Table 9), the greatest differences between optimum thicknesses were identified in Arica and Calama when comparing those that considered solar radiation and those that did not. In Antofagasta, the optimum insulation thickness considering the effect of solar radiation was on average 1.5 cm greater than the optimum thickness based on degree days calculated with ambient temperature. In Santiago, this difference reached 2.6 cm, and in La Serena, a minimum of 0.4 cm was observed (

Table 10). The highest value of optimum thickness for the west orientation of the wall is related to the specific characteristics of the solar climate in Chile, which were previously mentioned, explaining the differences in the degree day results. Therefore, the effect of considering solar radiation is notable in the LCCA methodology for calculating the optimum thickness of thermal insulation in different geographical locations.

Table 10 presents the results of the average optimum thickness for three orientations exposed to solar radiation and for the south orientation, which was taken as the ambient temperature (θo). In this way, an optimum thickness of thermal insulation was obtained for each city, considering the effect of solar radiation in some cases and not in others.

Table 10 details the final optimum thicknesses using variable threshold temperatures for the case where solar radiation is considered—average value by three orientations (

and the case where it is ignored (

. Additionally, Δ denotes the difference between methods, either absolute or percentage.

From

Table 10, it can be observed that the greatest variations in optimum thickness between methods occurred in Arica, with 39%, and to a lesser extent in Calama, with 21%. In both cases, the absolute thickness variations exceeded 4 cm. For the rest of the cities studied, the influence was considerably smaller, especially in La Serena, where there was only a 2% increase. This underscores the importance of considering the sol–air temperature when defining the optimum wall insulation thicknesses using the LCCA method for Arica and Calama, due to their more severe solar regime compared to other cities. The same recommendation should be applied to other regions of the world that have a climate similar to these cities.

3.2. Optimum Thicknesses of Thermal Insulation for Constant Threshold Temperatures

Table 11 includes the result of the optimum thickness, denoted by x

cte, for the case where the threshold temperatures are constant in each city, considering the heating and cooling limits indicated in

Table 3.

Table 11 highlights the low thicknesses in Arica and Antofagasta using the θo temperature, which is attributed to the low sums of CDDs and HDDs. Additionally, it is important to mention that in general, the obtained thicknesses were slightly higher compared to those that considered the effect of solar radiation.

Table 12 details the final thicknesses using constant threshold temperatures, differentiating between the case that considers solar radiation—average value by three orientations (

and the case that ignores it (

. Additionally, Δ denotes the difference between methods, either in absolute or percentage terms.

From

Table 12, it can be observed that the use of constant threshold temperatures slightly increases the average optimum thicknesses of thermal insulation in all study cases. Additionally, the percentage variations are quite similar to those obtained with variable threshold temperatures.

It is important to note that the use of constant temperatures simplifies the calculations but may underestimate or overestimate the actual heating and cooling needs due to the absence of seasonal variations. This can result in significant differences in insulation thickness, especially in extreme climates. On the other hand, variable threshold temperatures, adjusted monthly according to the ECS methodology, provide a more accurate and adapted representation of real conditions, improving the precision of the analysis.

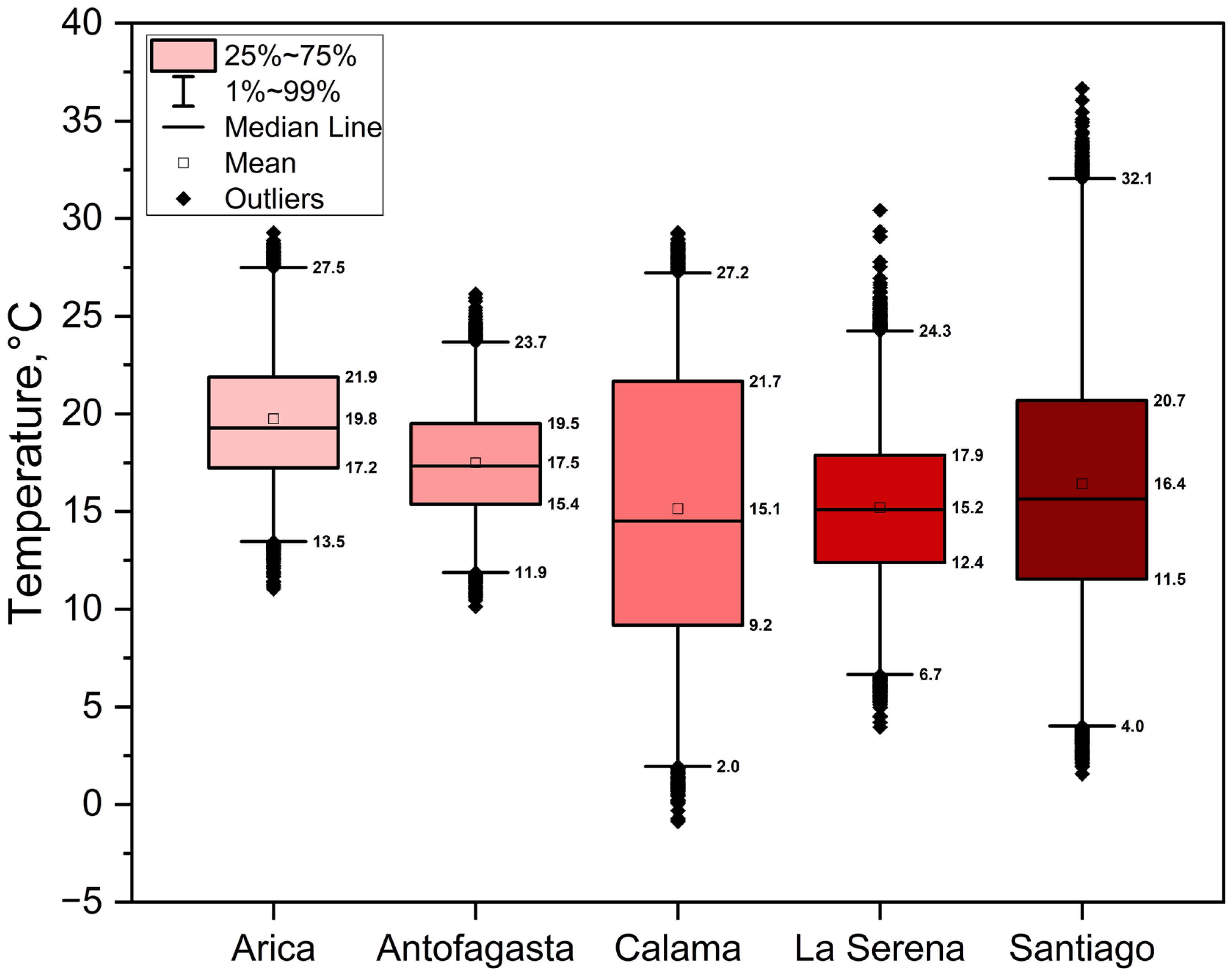

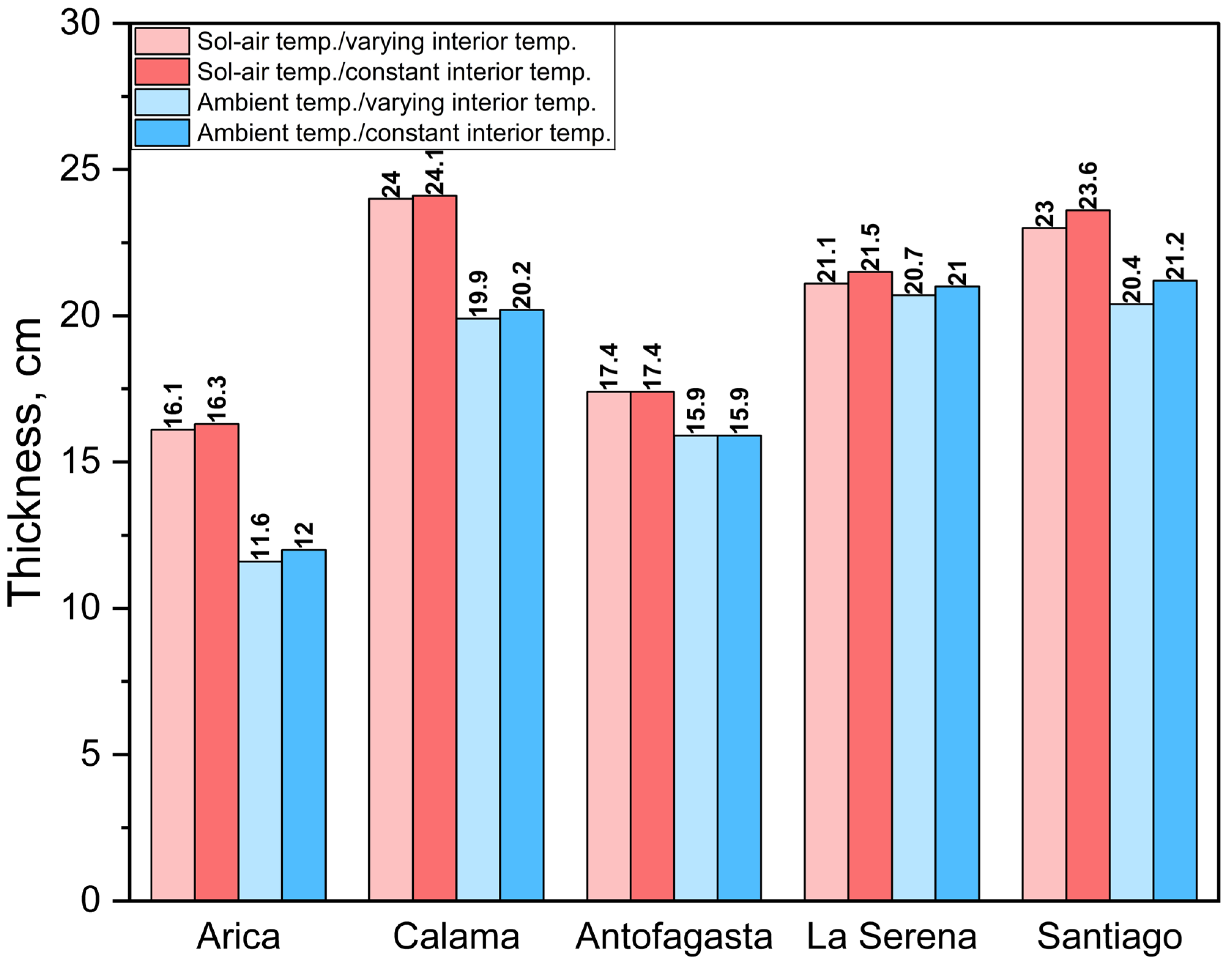

Figure 9 provides a graphical comparison of the optimum thicknesses of EPS thermal insulation in walls for the five study cities and all the methods used. In general, the greatest thicknesses are recorded in Calama and Santiago, where values can reach up to 24 cm, considering both variable and constant temperatures, as well as the effect of solar radiation.

The high thicknesses in Calama and Santiago are related to more extreme climatic conditions in summer and winter compared to the other cities. Therefore, the thermal insulation must address both heating and cooling issues.

According to the ECS, to comply with the maximum allowable thermal transmittance (U-value) in different climatic zones of the country, the wall configuration studied requires only 0.01 cm of insulation in the cities of Arica and Antofagasta. Therefore, even without additional insulation, the proposed solution already meets national requirements in those locations. In contrast, in Santiago and La Serena, the minimum insulation thickness required to meet standards is 2.6 cm, while in Calama it is 9.7 cm of EPS. Consequently, the insulation thicknesses obtained through the Life Cycle Cost Analysis (LCCA) methodology significantly exceed the values established by current national energy efficiency regulation.

The results suggest that considering solar radiation and using variable threshold temperatures better reflect thermal comfort needs. Additionally, the importance of selecting an appropriate technique for calculating degree days for the LCCA methodology to estimate the optimum thickness of thermal insulation has been discussed in previous works [

21,

30]. Another aspect is that for cities with a solar climate similar to Arica and Calama, it is important to consider global solar radiation to estimate the optimum wall thickness, as demonstrated in recent studies from different parts of the world [

23,

25,

54]. However, the main problem lies in the availability of information on global solar radiation from different orientations and inclinations of building envelope elements. Although it is possible to use real measurement data of global solar radiation, this approach is quite complex and requires extensive instrumentation. Another alternative is the calculation of solar radiation for clear skies, as in the study by [

4], but without considering geophysical aspects that affect the variation in global solar radiation, such as the presence of clouds, variation in atmospheric aerosols, etc. Therefore, the example presented in this work, using global solar radiation data from the Solar Explorer [

34], represents a good alternative for considering the effects of solar radiation in various tasks and calculations related to building climatology in Chile.

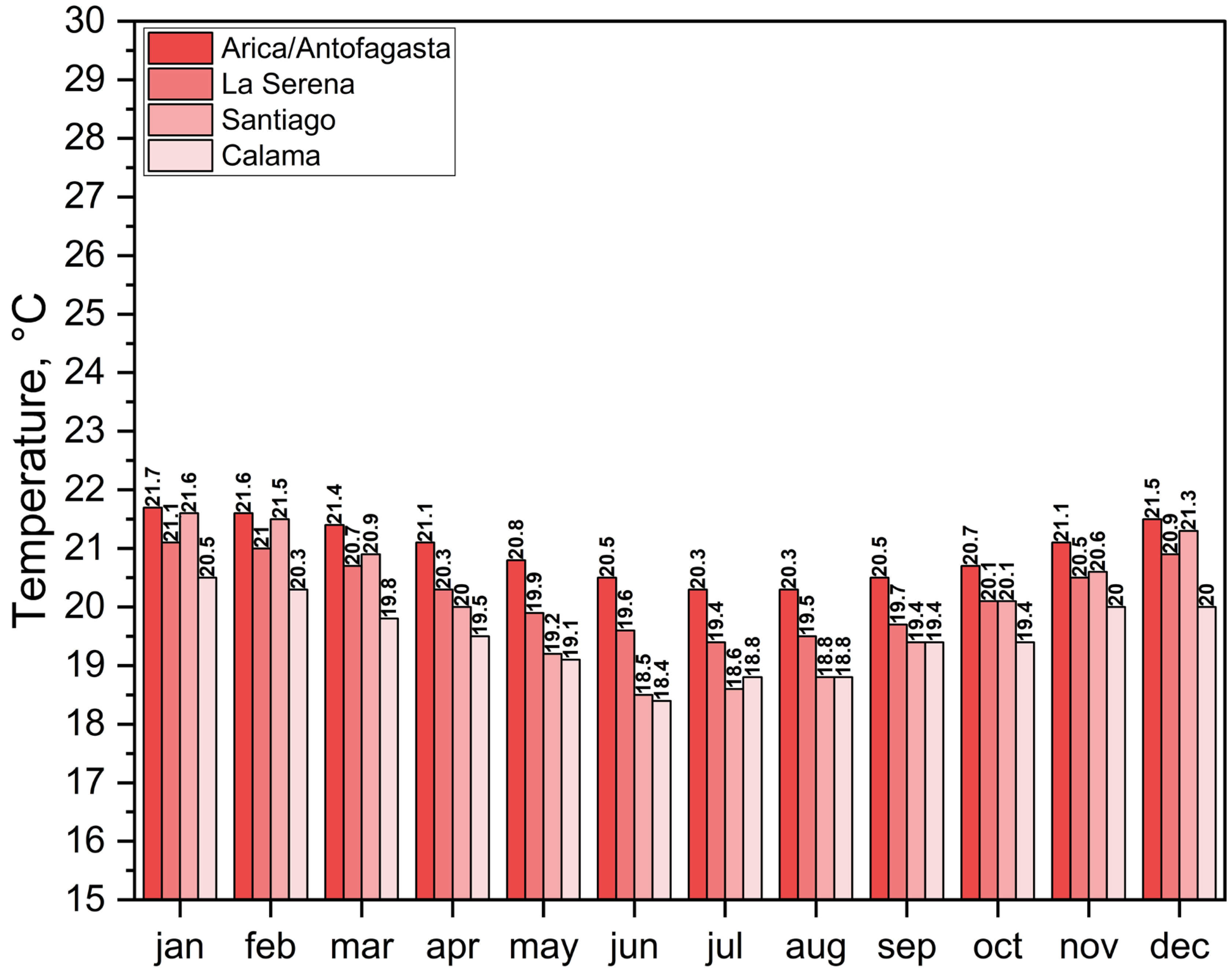

Additionally, it is logical to deduce that for roofs, considering the effect of solar radiation will be mandatory in climate zones that are not as severe as those presented in this study. However, this will require additional studies and will depend on the initial construction solution of the roof in the search for the optimum insulation thickness. The consideration of constant temperatures increases the optimum thicknesses in all cases, as a constant annual temperature does not reflect the monthly variations in adaptive thermal comfort temperatures in each city with its corresponding climate, as illustrated in

Figure 5 and

Figure 6. Therefore, the application of constant temperatures can lead to a slight increase in the optimum thickness and unnecessary use of material. Although this difference is not significant, it can raise the carbon footprint of materials used in a construction project. Hence, the use of variable adaptive thermal comfort temperatures is appropriate for calculating HDDs and CDDs in the analyzed climates (hot arid, Mediterranean types) and should be included in the estimations of optimum wall and roof thicknesses using the LCCA methodology. Differences in insulation thicknesses can be quite notable (

Figure 9), but to analyze the real effect on the energy demand of a project, the following section will be presented.

3.3. Validation Results of Optimum Insulation Thicknesses Through Energy Simulation

In the previous section, optimum insulation thickness values were established considering the effect of solar radiation and without this effect. This section presents the results of the annual energy demand simulation for heating and cooling of the studied house located in five cities for five optimum EPS thicknesses considering the effect of solar radiation, without this consideration, and for a wall with a constant insulation thickness of 3 cm (control case). The energy demand simulation was performed only for optimum thicknesses with constant threshold temperatures (see

Figure 9). All energy demand results for heating and cooling of the studied house can be seen in

Table 13. For all cities, for the studied wall, considering the effect of solar radiation and without considering it in the LCCA methodology, there is not much difference in the results.

It can be highlighted that the results obtained from the energy simulation are within the range of permissible values for residential houses according to Chilean building standard ECS [

38]. Thus, for the cities of Arica and Antofagasta, the energy demand values of a residential home for cooling and heating should not exceed 10 kWh/m

2 and 15 kWh/m

2, respectively. For the city of Calama and for climatic zone H, cooling demand must be around 0 kWh/m

2 and for heating not exceed 120 kWh/m

2. In La Serena and Santiago, the permissible value of the cooling demand must be less than 10 kWh/m

2 and for heating no greater than 77 kWh/m

2 and 71 kWh/m

2, respectively.

The greatest difference is observed in the city of Calama, where increasing the EPS thickness for walls from 20.2 cm to 24.1 cm would help reduce the annual heating demand from 25.9 kWh/m2 to 22.7 kWh/m2; however, this would increase the cooling demand by 0.5 kWh/m2. This is likely related to the high thermal mass of the studied wall type. On the other hand, in Arica, an increase of 12 cm of insulation in walls up to 16.3 cm also results in a slight increase in cooling demand, which is also related to the high thermal mass of the studied wall and applied to the analyzed house.

Similar results regarding the increase in cooling energy demand with the increase in wall thermal mass were observed in a study conducted in Saudi Arabia under arid climate conditions comparable to those of the present study [

55]. Likewise, other researchers in Saudi Arabia working under extreme desert climates emphasize the importance of achieving a balance between thermal insulation and thermal mass to ensure cooling-efficient building designs [

56]. In another study focused on public buildings, the authors observed that increasing the thermal mass of envelope components had only a modest effect on mitigating indoor overheating during periods of high outdoor temperatures [

57].

In all studied cities, the use of the optimum thickness estimated based on the LCCA methodology reduces the total demand for heating and cooling by an average of 6–48%, similar to what was observed in a study conducted in Turkey [

4]. Additionally, for these cities, the use of the optimum thermal insulation thickness for the analyzed house significantly reduces (46–86%) the heating demand.

In the case of the cities of Arica and Antofagasta, increasing the insulation from 3 cm to the optimum values defined by the LCCA methodology does not generate benefits in the energy efficiency of the analyzed house project. Therefore, the application of additional thermal insulation in cities with these climatic conditions is not as necessary for the analyzed house and wall type.

Despite significant differences in the optimum thermal insulation thickness obtained with or without considering the effect of solar radiation for the studied wall and house type, the energy demand simulation did not show significant differences in the variation in the energy performance of the studied house. Moreover, for cities with warmer and milder climates, the use of the optimum insulation thickness for the studied mass wall did not provide any energy benefit but rather the opposite effect. This highlights the importance of more in-depth studies on the application of the LCCA methodology to define optimum insulation thicknesses in different climatic zones for mass walls and to assess the feasibility of integrating this variable to improve the LCCA methodology.

4. Conclusions

An analysis of the effect of global solar radiation on the optimum thickness of thermal insulation for exterior walls in northern Chile was conducted using the LCCA methodology. A specific type of mass wall was analyzed, and the main conclusions were as follows:

The consideration of the sol–air temperature in determining the optimum insulation thickness for the studied wall is especially relevant in Arica and Calama. In Arica, this effect increases the insulation thickness by 39%, and in Calama, by 21%, with variable monthly temperatures indoors. For other cities, the difference was not significant. Although only one type of wall was analyzed, the results are sufficient to demonstrate the importance of solar radiation in the LCCA methodology for defining the optimum wall thickness.

The use of constant threshold temperatures for heating and cooling tends to increase the optimum insulation thickness studied, although not significantly, as these are based on averages derived from an adaptive thermal comfort model for the analyzed cities. This simplification facilitates the calculation but may not accurately reflect actual needs due to seasonal variations. It is recommended to use variable threshold temperatures adjusted monthly according to the adaptive thermal comfort model to obtain more precise and specific results. However, constant threshold temperatures can be useful for preliminary studies.

On the other hand, it was demonstrated that for the studied house, the influence of solar radiation on the results of the search for the optimum insulation thickness does not have a significant effect on its energy efficiency, due to the type of mass wall studied in this research. However, the LCCA methodology provides good results for optimum thermal insulation in cities such as Calama, La Serena, and Santiago, where the energy demand for heating predominates over cooling. Considering solar radiation and using the sol–air temperature instead of the ambient air temperature to define the optimal thermal insulation thickness through the Life Cycle Cost Analysis (LCCA) methodology helps reduce the cooling and heating energy demand of the studied house by 36% to 41% in the city of La Serena, and by 42% to 47% in the city of Calama.

For the cities of Arica and Antofagasta, the use of the optimum thickness defined based on the LCCA methodology did not provide energy improvements in the studied house, raising questions about the applicability of this methodology for mass walls and requiring future studies. Additionally, future studies should focus on roofs with high heat capacity and the consideration of the effect of solar radiation, which could undoubtedly affect the results of the LCCA methodology for determining the optimum insulation thickness and the energy performance of house and building projects.