1. Introduction

Under the “carbon peaking and carbon neutrality” goals, reducing carbon emissions in the construction industry is not only essential for achieving a green transformation of urban renewal but also a necessary condition for sustainable development [

1]. Technological advancements and policy optimization in the construction industry are particularly significant in urban renewal. Considering that urban renewal nowadays is an important development direction of urban planning, construction, and governance, it is vital to investigate the impact of building and construction renewal strategies on carbon emissions [

2,

3,

4].

Prefabricated buildings (PBs), also known as offsite construction, originate from the manufacturing domain and transform the construction process into industrialization. The basic categories of prefabrication, defined by the percentage of offsite, include component, non-volumetric, volumetric, and modular. In comparison with traditional construction methods, PBs can effectively reduce the negative effects of construction projects on the environment and promote low-carbon construction and development [

5]. Specifically, technological advancements and policy optimization for carbon emission reduction in PBs help fulfill the transition towards low-carbon urban development. For example, Liu et al. [

6] examined the effect of prefabricated building supply chains on carbon reduction. Buildings with prefabrication have been widely promoted for achieving the “carbon peaking and carbon neutrality” goals. Thus, in urban renewal, it is essential to use PBs for renovating existing structures, implementing PBs in new construction projects, and minimizing carbon emissions, as presented in studies such as Liu et al. [

6].

The need for a distinct carbon emission framework for urban renewal, compared with conventional construction, arises from the unique complexities and opportunities inherent in redeveloping existing urban areas. Conventional frameworks often focus narrowly on the operational energy efficiency and embodied carbon of new structures on greenfield sites, overlooking critical factors specific to renewal projects. Urban renewal involves interacting with existing infrastructure, embodied carbon in standing structures, dense site logistics, and socioeconomic impacts. Demolishing existing buildings releases significant embodied carbon without accounting for this “carbon debt”, whereas adaptive reuse preserves it. Renewal projects also face challenges like constrained site access, requiring inefficient material transport and extended construction phases with higher ongoing emissions from equipment and worker commutes. Furthermore, renewal occurs within functioning communities, where temporary relocations or service disruptions can increase indirect emissions (e.g., longer resident commutes). A tailored framework must prioritize carbon stewardship—emphasizing building retention, low-impact retrofits, and circular material use—while accounting for phased construction emissions, avoided carbon through reuse, and broader urban system efficiencies (e.g., integrated transit or district energy). Ignoring these factors risks underestimating the true carbon footprint of renewal or favoring carbon-intensive demolition over sustainable refurbishment, undermining climate goals in cities where renewal is most critical.

However, the potential of carbon emission reduction from prefabricated buildings (PBs) in urban renewal is shaped by multidimensional interactions, such as socioeconomic conditions, policy framework, and operational practices. Liu et al. [

6] quantified socioeconomic drivers via a structural equation model (SEM), revealing that economic conditions rank as the second-most critical driver (after technology) for PB carbon reduction. Socioeconomic conditions determine both the scale of construction activities and the adoption of low-carbon technologies, e.g., income levels and environmental awareness, cost efficiency, and resource optimization. Policy interventions are pivotal in overcoming market barriers and incentivizing low-carbon transitions, e.g., fiscal and regulatory tools, technical standards, and industrial restructurings. Timilsina [

7] cautions that policies like carbon taxes face political resistance in urban renewal projects, where short-term costs provoke public opposition. Operational energy use refers to energy consumed during building use, such as heating, cooling, lighting, and ventilation. The operation phases account for most buildings’ lifecycle emissions; thus, energy-efficient operation practices are essential for the energy performance of PBs. Although the potential of carbon emissions reduction from PBs has received extensive attention, specific gaps remain in the research focusing on the mechanisms influencing carbon emissions from PBs in urban renewal. Few studies examined the effect of prefabrication on urban renewal, and even fewer explored the influence mechanism of prefabrication on the “carbon peak and carbon neutrality” target. The identification of the influencing factors is beneficial for uncovering the internal mechanisms of carbon emissions from PBs in urban renewal and sets the prerequisite for the influence paths of PBs’ carbon emissions. This paper aims to analyze the factors and mechanisms influencing carbon emissions from PBs in urban renewal and provide references for governments and relevant construction enterprises on the strategies of sustainable urban renewal.

2. Research Background

The problem of the existing building stock in cities has become increasingly prominent, and the issue of carbon emissions from urban buildings has become more serious. Urban renewal has evolved from physical revitalization to a strategic approach for reducing carbon emissions in existing building stocks. Ramnarine et al. propose urban digital twins (e.g., the CANVAS framework) to optimize carbon-neutral transitions, demonstrating how Energy Use Intensity (EUI) can decrease in Tokyo’s Nihonbashi district through operational improvements and photovoltaic integration [

8]. PBs have become an important practical pathway for achieving low-carbon transformation and sustainable development in the urban renewal process. Guo and Zhang emphasized “green renewal” as a financial strategy, linking spatial patterns—such as building aspect ratios and density—to reduced residential energy consumption in Chinese cities [

3]. A series of studies have been conducted in the fields of urban renewal and carbon emissions from PBs. Urban renewal, an important tool for optimizing urban spatial structure and enhancing urban functions through renovating existing buildings and improving infrastructure, has become a crucial approach for achieving the low-carbon transformation of cities. Xiao et al. developed an integrated analysis framework to discover that the construction of New-type Urbanization has reduced the carbon emissions of urban buildings [

9]. Zhang et al. used Building Information Modeling (BIM) to construct a carbon budget estimation system that aims to achieve low-carbon urban renewal [

10]. Urban development has gradually shifted from large-scale incremental construction in the past to emphasizing the optimization of both renovated and newly constructed buildings. PBs play a crucial role in this transformation process. In the policy documents promoting urban renewal, many countries emphasize that PBs should be actively encouraged to achieve the green transformation of construction projects. An increasing number of studies focus on PBs in the context of urban renewal. Li et al. incorporated PBs and atmospheric pollutants into the same research framework to explore the significant role of PBs in energy conservation and emission reduction [

11].

Regarding carbon reduction for PBs, various research methods exist for studying carbon emission issues. Hao et al. developed a carbon emission calculation model for the materialization stage of PBs, including three stages, i.e., production, transportation, and construction. The production of concrete and steel reinforcement account for 42.43% to 41.04% of the total carbon emissions of PBs in the materialization stage [

12]. Telesca et al. [

13] found that prefabricated materials that contain adhesive products are beneficial for resource conservation and environmental protection. Ding et al. documented a 20.11% reduction in carbon emissions per unit volume (764.87 kg/m

3 vs. cast-in-place components) due to efficient material use. Ma et al. quantify this at 336 kg/m

2 for semi-prefabricated projects versus 368 kg/m

2 for conventional methods, with material production dominating emissions (85%) [

14]. Wang et al. revealed PBs reduce energy consumption by 7.54% and carbon emissions by 7.17% (81.08 kg CO

2/year·m

2), primarily during operation and construction phases, while lowering costs by 10.62% [

15]. Dong et al. [

16] conducted a case study of a private residential building in Hong Kong and found that prefabricated concrete helps reduce carbon emissions in construction. Ding et al. developed a carbon emission measurement system for the materialization phase of PBs, showing that the total carbon emissions per unit volume of all prefabricated components were 764.87 kg/m

3, which was 20.11% lower than that of cast-in-place components in a PB project [

17].

Studies also examined the factors influencing carbon emission reduction in PBs. Based on the theory of Environment–Economy–Energy system, Zhu and Li identified five influencing factors for carbon emission reduction in the materialization stage of PBs, including government policy, management mode, technology level, economic input, and energy structure [

18]. Zhan et al. analyzed the factors influencing the production stage of PBs, which include four aspects, i.e., material selection, energy consumption, material storage, and carbon emissions [

19].

In addition, policy and governance frameworks are critical for scaling PBs. Cabannes documented PB in 1700+ cities globally, enabling community-driven projects that enhance service delivery and governance [

20]. Sinervo et al. highlighted PB’s role in environmental sustainability, such as funding green urban regeneration and climate adaptation. In Brazil, PB redistributed resources to marginalized neighborhoods but faced constraints like inadequate funding and institutional resistance [

21]. Leshinka et al. identified PPPs as vital for financing sustainable cities, integrating governance, innovation, and stakeholder engagement (“Public–Private–People Partnerships”) [

22]. Zhang et al. noted financial pressure drives PPP adoption in China, particularly for economic infrastructure [

23].

In sum, scholars have conducted extensive research on urban renewal theory and carbon emission accounting of PBs. However, few studies examined the mechanisms of carbon emission reduction from PBs in urban renewal. Urban renewal projects frequently entail complicated site conditions, renovation of existing buildings, and owners’ needs for the quality of the living environment. These attributes lead to considerable differences in the carbon emission reduction paths and influencing factors of PBs compared with traditional construction projects. A systematic framework needs to be developed to illustrate the influencing mechanism of PB’s carbon emissions and carbon emission reduction potential in urban renewal scenarios.

3. Methodology

Firstly, this study selected the most relevant literature on the carbon emission of PBs in the context of urban renewal from the Web of Science (WOS) database and identified the factors influencing PBs’ impact on carbon emission reduction. The keywords are “carbon emission/energy consumption”, “community renovation/urban renewal/old residential building”, and “prefabricated building/precast/modular/volumetric”. After retrieval, a total of 97 papers were obtained. Subsequently, the abstracts of the papers were read to conduct a preliminary screening of the documents, and 30 documents with relevant content were selected. Then, the publications with the most citations were finalized. Finally, through two rounds of screening, 14 documents were chosen as the core documents for the induction of influencing factors. The key influencing factors of carbon emission reduction in the context of urban renewal were identified and categorized into social economy, policy and regulation, building operation, and materialization of PBs.

Secondly, hypotheses were proposed to make assumptions about the relationships between the influencing factors of the carbon emissions from PBs in the context of urban renewal. This study developed a hypothetical model to explore the mechanisms influencing carbon emission reduction from PBs in urban renewal, in order to examine the internal relationships among variables and factors of social economy, policy and regulation, building operation, and materialization of PBs. A pilot study was conducted to verify the hypothesis model and the observed indicators. Five experts with over 10 years of work experience on prefabrication have been invited to check the description, clarity, relevance, and feasibility of all observed indicators, and to modify the questions and hypotheses based on participant feedback. The pilot study was also used to finalize the instrument and research plan for the main study. The SEM was used to develop the hypothesized paths among latent variables. Next, the developed model is evaluated, and the hypotheses are tested.

Subsequently, a questionnaire survey was conducted from September to November 2024 to gather expert insights on the perceived significance of factors influencing carbon emissions from prefabricated buildings (PBs) in urban renewal projects. Utilizing a purposive and snowball sampling approach, targeted respondents (n = 120) were recruited from key stakeholder groups directly involved in China’s urban renewal and prefabricated construction sector. Participants comprised professionals, including architects, project managers, construction engineers, sustainability consultants, developers, policy makers, and researchers with a minimum of 5 years of relevant experience and direct involvement in at least one urban renewal or PB project. The questionnaire employed a Likert five-point scale to measure the perceived influence level of each factor, where 1 = No significant influence, 2 = Weak influence, 3 = Moderate influence, 4 = Strong influence, and 5 = Significant influence. It consisted of three parts: (1) Introductory Remarks, outlining the research purpose and significance; (2) Respondent Demographics, capturing detailed information such as company type (e.g., construction firm, design institute, real estate developer, government agency), respondent category, educational attainment, current position, years of field experience, and number of urban renewal/PB projects participated in; and (3) Core Questionnaire Body, focusing specifically on the impact of various factors related to PBs in urban renewal on carbon emissions and general understanding of these p prefabricated projects in urban renewal.

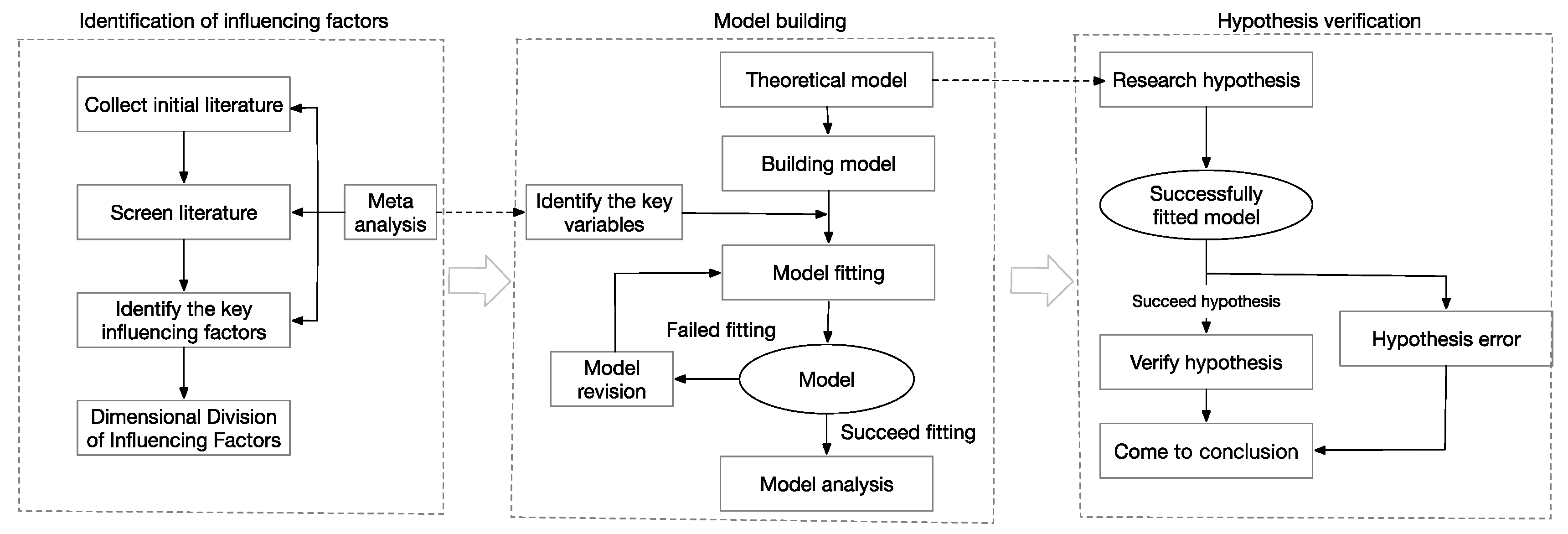

The overall design concept is to formulate questions based on the influencing factor framework identified in the above Meta-analysis across four dimensions: social economy, policy and regulations, building operation, and the materialization of PBs. The materialization of PBs can be further categorized into four parts: production, transportation, assembly, and demolition. Based on the collected survey data, the accuracy and reliability of the data were tested. A fitness analysis was conducted on the effects of various factors influencing carbon emissions from PBs in urban renewal based on the SEM. The overall methodology roadmap is shown in

Figure 1.

4. Results of the Data Analysis

4.1. Dimensions of Influencing Factors of Carbon Emission Reduction from PBs in Urban Renewal Based on Meta-Analysis

This study selected publications related to the carbon emissions of PBs in urban renewal by using search field titles, abstracts, and keywords that contain “urban renewal”, “carbon emissions of PBs”, and “sustainable development” and were published during the years 2015–2024. In total, 14 papers are chosen as the essential literature for identifying the influencing factors of carbon emissions from PBs. Through the meta-analysis of the selected literature, it is found that the research on the carbon emissions of PBs in urban renewal is relatively more focused on the manufacturing and construction stages of PBs. Only a few studies consider the operational stage of PBs, primarily focusing on aspects like lighting and heating. Some studies also examine the impact of policy regulations and the social economy on the overall carbon emissions system. Based on the identified influencing factors from the meta-analysis, it was found that the initial number of these factors was quite large and that certain coupling relationships existed among them. Incorporating the literature review of the projects and the characteristics of literature concerning carbon emissions from PBs in urban renewal, the initial influencing factors were summarized. Ultimately, the system of factors influencing carbon emissions from PBs in urban renewal was established, as specifically illustrated in

Table 1.

4.2. Hypothetical Model of the Influence Mechanism of Carbon Emission Reduction from PBs in Urban Renewal

Based on existing research and relevant policy documents, the following hypotheses are proposed concerning the influencing mechanisms among the four dimensions: socioeconomic factors, policy regulations, building operation, and the materialization aspects of PBs mentioned earlier [

14,

28,

36].

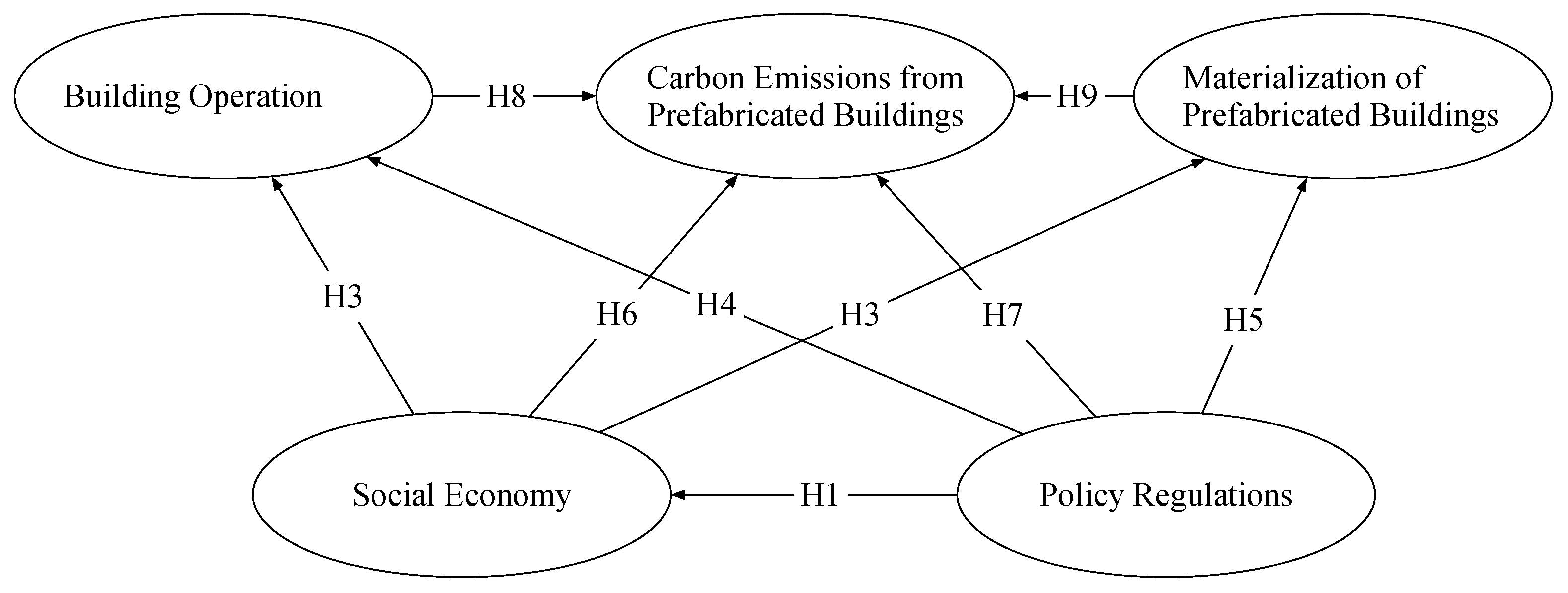

H1. Policy and regulations have a positive impact on social economy factors.

H2. Social economy factors have a positive impact on building operations.

H3. Social economy factors have a positive impact on the materialization aspects of buildings.

H4. Policy and regulations have a positive impact on building operations.

H5. Policy and regulations have a positive impact on the materialization aspects of PBs.

In addition to the influence of four dimensions, each dimension may also impact the final carbon emissions of PBs in urban renewal. Based on an analysis of existing research and relevant policy documents, the following hypotheses are proposed regarding the influencing mechanisms between each dimension and the total carbon emissions [

25,

37]:

H6. Social economy factors have a positive impact on the carbon emissions of PBs in urban renewal.

H7. Policy regulations have a positive impact on the carbon emissions of PBs in urban renewal.

H8. Building operation has a positive impact on the carbon emissions of PBs in urban renewal.

H9. The materialization aspects of PBs have a positive impact on the carbon emissions of PBs in urban renewal.

Based on the above analysis, research hypotheses can be formulated regarding the relationships among the four dimensions of socioeconomic factors, policy regulations, building operation, and the materialization aspects of PBs, as well as the impact of these four dimensions on the total carbon emissions of PBs in the context of urban renewal. According to the nine hypotheses mentioned above, the hypothesized model is shown in

Figure 2.

4.2.1. Results of Validity and Reliability Test

In total, 39 paper questionnaires and 231 online questionnaires were gathered, resulting in 270 valid questionnaires and an 80.12% response rate. The profile of the respondents is presented in

Table 2. Nearly 70% of the respondents have over 4 years of work experience. All of the respondents have participated in one or more PB projects. 71.8% of the respondents have a bachelor’s or higher degree. The remaining 28.2% of the respondents mainly come from construction and manufacturing companies with experience in prefabrication production, transport, and construction. The profile of the respondents suggests all respondents have relevant experience in prefabrication and justifies the validity of the data collection.

Using the statistical software SPSS 26.0, the Cronbach’s α coefficient for the total scale measuring carbon emissions of PBs in urban renewal is calculated to be 0.964, which exceeds 0.90, indicating an excellent overall reliability of the questionnaire. By calculating the Cronbach’s α coefficients for each sub-scale, it is found that the coefficients of the investigated variables are all greater than 0.70. Thus, the reliability levels for each dimension of the questionnaire are also relatively high.

In the next step, by deleting a certain measurement item, a change in the Cronbach’s α coefficient is observed, as shown in

Table 3. The total scale of the carbon emissions of PBs in the context of urban renewal has a high level of reliability, strong stability, and sufficient reliability; thus, the next step of the validity test can be carried out.

4.2.2. Results of the Confirmatory Factor Analysis

As shown in

Table 4, the KMO value for the investigated variables and the significance of Bartlett’s sphericity test indicate that the questionnaire can be utilized for SEM analysis.

According to calculations performed with SPSS 26.0, the results show that the characteristic roots of the first five factors exceed 1, and the cumulative contribution rate reaches 72.383%, surpassing 60%. At the same time, the factor loadings of all items are greater than 0.400. Therefore, all five latent variables outlined in the theoretical model above pass this test, which is shown in

Table 5.

The four initial single-factor models were evaluated using the maximum likelihood method with Amos 27 software. The operational results are shown in

Table 6. All indicators meet the requirements, indicating that the four sub-models of social economy, policy regulations, building operation, and materialization carbon of PBs possess strong fitting properties. Therefore, each sub-item effectively measures the conditions of its corresponding dimension, and the scale of each sub-dimension demonstrates strong structural validity.

When testing for discriminant validity, the AVE method is generally employed. If the square root of the AVE value of each latent variable exceeds its correlation coefficient with other latent variables, then there is strong discriminant validity between the two dimensions. As shown in

Table 7 and

Table 8, the correlation coefficient for each dimension satisfies the research requirements. Therefore, the observed variables with strong discriminant validity confirm the validity of the scale used in this paper.

4.3. Analysis of the Influence Mechanism

4.3.1. Analysis of the Degree of Fitting

Once the theoretical models for each sub-dimension have successfully passed the reliability and validity tests, it is essential to evaluate the goodness of fit for the overall structural model.

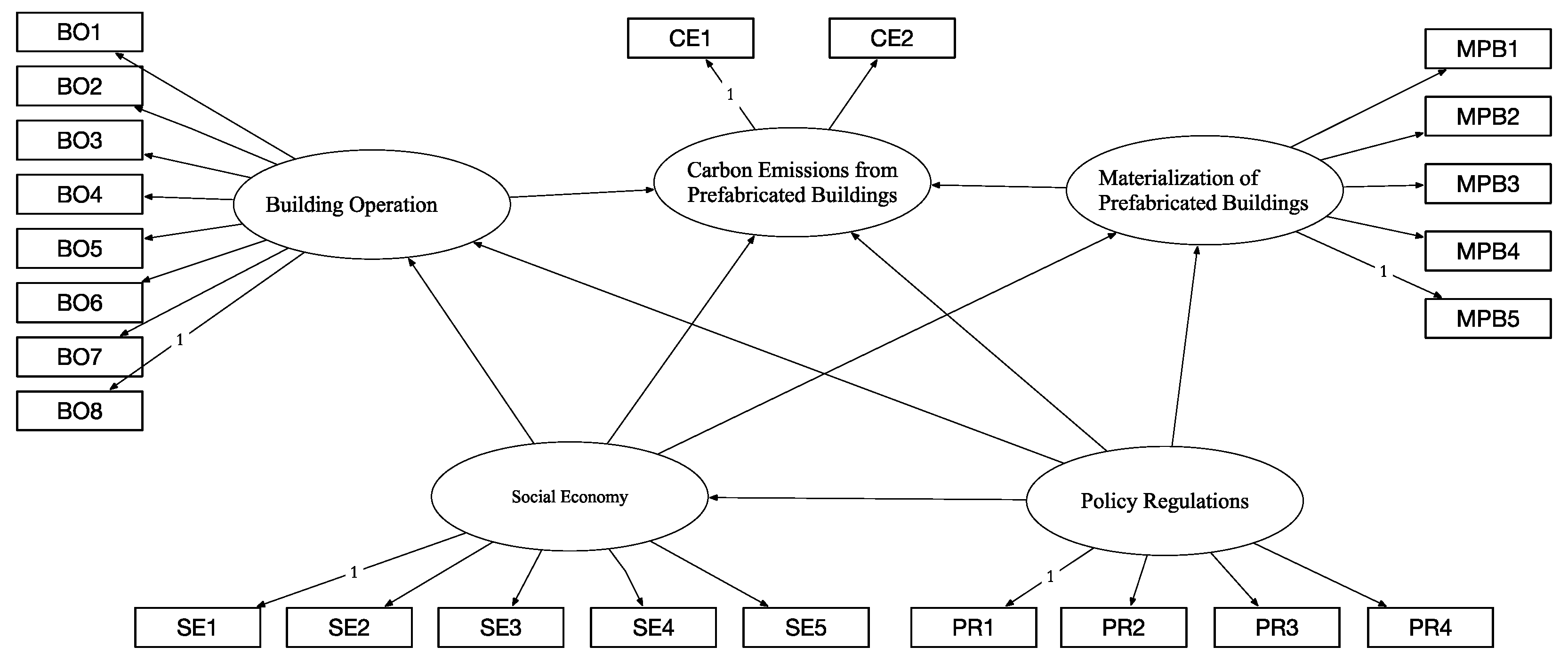

Combining with the theoretical model and research hypotheses of the carbon emissions of PBs in urban renewal, this paper analyzes the influence relationships among variables in social economy, policy regulations, building operation, materialization of PBs, and carbon emissions, and finally proposes a structural equation model, as shown in

Figure 3.

Amos 24.0 was used to analyze the degree of fit between this structural equation model and the data sample. Three commonly used types of indices—absolute fit indices, incremental fit indices, and parsimony fit indices—are selected to evaluate the goodness of fit for the structural model. The results of the calculation and analysis using the maximum likelihood method are shown in

Table 9.

4.3.2. Analysis of Hypothesis Testing

The calculated results using the maximum likelihood method are shown in

Table 10 and

Table 11. Through the structural equation, this paper identified the path relationships among the latent variables on carbon emissions from PBs in urban renewal. As shown in

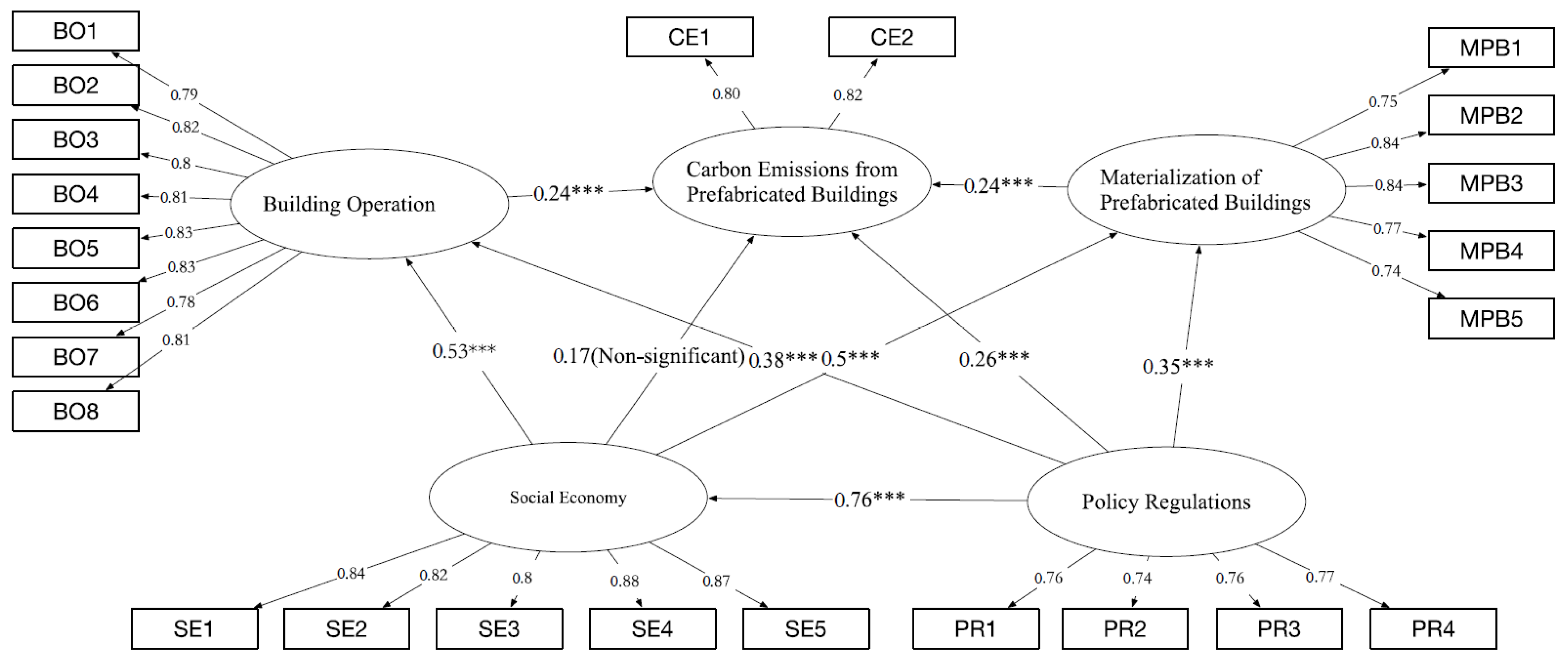

Table 10, the path relationship coefficients among the latent variables in the model are used to test the causal relationship hypotheses among the latent variables. The standardized results of the overall model are shown in

Figure 4. The results of the path analysis show that the standardized path coefficients for all observed variables range from 0.65 to 0.99. The four dimensions of the socioeconomic aspect, policy and regulations, building operation, and the materialization of carbon of PBs significantly impact the carbon emissions of PBs in urban renewal. The results of the path analysis show that all the hypotheses except for H6 are valid.

5. Discussion

In the context of urban renewal, the mechanisms driving carbon emission reduction in prefabricated buildings (PBs) reveal a complex, interconnected system. Policies and regulations (PR) emerge as a primary catalyst, evidenced by a standardized path coefficient of 0.263. This significance stems from the hybrid effect of policy instruments—subsidies, taxes, R&D incentives, and public awareness campaigns—which collectively enhance prefabrication adoption and emission reduction, aligning with findings by Shi et al. [

38] and Yan et al. [

37]. Critically, industrial policies (e.g., fiscal, technical, and ecological measures) can elevate PB market shares by up to 52% and reduce emissions by 12.56 million tons, as demonstrated in Xi’an’s system dynamics simulations [

33]. However, mandatory policies alone risk neglecting quality and safety; thus, a blend of incentives and mandates is optimal for sustainable PB development [

39].

PR’s influence extends beyond direct impacts (path coefficient: 0.263) to potent indirect pathways via socioeconomic factors, with a notably higher coefficient of 0.76. This corroborates Tumminia et al. [

34], showing that policy-driven incentives shape public and corporate willingness to adopt PBs. Socioeconomic factors (SE), while lacking a direct emissions pathway, exert substantial indirect effects through building operations (BO) and materialization processes (MP). For instance, SE boosts low-carbon PB development by channeling investments into R&D and new energy technologies [

39], with Liu et al. confirming economy-driven factors as secondary only to technological innovation in emission reduction [

6]. Path analysis further reveals that SE’s mediated impact—via BO and MP—accounts for >90% of its total effect, underscoring the necessity of “through-path” methodologies to capture indirect relationships [

40]. In sum, while social economy factors shape where or why prefabricated units are deployed, they do not change the carbon footprint of prefabrication in manufacturing and transporting modules, or the carbon footprint of a factory-made wall panel. Their impact is indirect, but the emissions themselves arise from technical/logistical decisions, not social goals. Social factors can influence emissions indirectly from both policy incentives and design compromises. Social equity goals might accelerate the adoption of PB for affordable housing, indirectly scaling low-carbon technologies. In addition, community demands might reduce floor space, lowering material use.

Building operations (BOs) and materialization (MP) are unequivocal focal points for direct emission reduction. BOs contribute 28% of global carbon emissions, but hybrid renewable systems (e.g., BIPVs + wind turbines) can slash operational emissions by 65.9%. Meanwhile, MP’s embodied carbon varies from 2% to 80% of a building’s lifecycle emissions, emphasizing centralized production’s role in minimizing waste and energy inefficiency [

41]. Zhu and Li [

18] identified MP-stage optimization as critical, while BIM and building performance simulations (BPSs) enable precise quantification of these impacts.

Urban renewal uniquely amplifies PBs’ advantages over traditional buildings. Demolition–reuse cycles in renewal projects exacerbate waste in conventional construction, whereas PBs’ modular design reduces material waste by 30–50% [

42]. Traditional urban renewal often erodes regional cultural identity through uniform demolition, but PBs align with renewal goals by balancing efficiency with heritage conservation. Empirical studies confirm that economic investments—particularly public-private partnerships (PPP)—accelerate low-carbon PB transitions via spatial spillover effects, enhancing infrastructure efficiency and industrial upgrading. For example, road PPP projects boost low-carbon economic efficiency by 15–20% more than traditional investments [

43].

6. Conclusions

This paper uses the meta-analysis method to summarize the framework of factors influencing carbon emissions from PBs in the context of China’s urban renewal. The identified factors influencing carbon emissions of PBs in urban renewal can be categorized into four dimensions: social economy, policy regulations, building operation, and the embodied carbon of PBs. There are 22 influencing factors in these four dimensions. SEM was used to test the hypothesized model using the data collected from the questionnaire survey. The results confirm the existence of the pathway from policy regulations to carbon emissions, with a standardized estimated value of 0.263 for the path coefficient. Policy regulations were proven to have an impact on social economy, building operations, and the materialization of carbon of PBs, with path coefficients of 0.758, 0.377, and 0.345, respectively. In addition, the building operation has a positive correlation with carbon emissions, with a standardized estimated path coefficient value of 0.244. Building operations are influenced by both the social economy aspect and policy regulations, with path coefficients of 0.532 and 0.377. The standardized estimated value of the path for the materialization of PBs to the carbon emissions coefficient is 0.239. The building operation is influenced by both the social economy and policy regulations, with path coefficients of 0.496 and 0.345. The direct influence of socioeconomic factors on carbon emissions is insignificant, while it exerts its effect on PBs’ carbon emissions through the building operation and materialization stage. The findings help shed light on the potential action plans for achieving sustainable urban renewal in the building and construction sector.

Despite the findings of the study, some shortcomings still exist in this paper. This paper explores the relationships among various influencing factors from a macroscopic perspective. There is a lack of investigation into the action paths of factors at the microscopic level and their interrelationships regarding carbon emission reduction in PBs in urban renewal. Future research also needs to investigate the transmission mechanisms and action paths of macro-influencing factors, such as social economy and policy regulations, on the carbon emissions of PBs at the building or community level.

Author Contributions

Conceptualization, X.Q.; methodology, X.Z.; software, X.Q.; validation, S.Z., X.Q. and X.Z.; formal analysis, X.Z.; investigation, X.Q. and Y.Z.; resources, X.Q. and Y.Z.; data curation, Y.Z. and X.Z.; writing—original draft preparation, X.Q.; writing—review and editing, S.Z.; visualization, S.Z.; supervision, X.Z.; project administration, X.Z.; funding acquisition, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge that this study is funded by the BIT Science and Technology Innovation Program “Think Tank” Promotion Plan (No: 2024CX13044) and Beijing Social Science Foundation Decision Project (No: 22JCC117).

Data Availability Statement

Data generated or analyzed during the study are available from the corresponding author by request.

Acknowledgments

Thanks to the authors for their contributions and to the funders for their financial support.

Conflicts of Interest

Author Yongwei Zhang was employed by the company China Resources Land (Beijing) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SEM | Structural Equation Model |

| SE | Social Economy |

| PR | Policy Regulations |

| BO | Building Operation |

| MPB | Materialization of Prefabricated Buildings |

| KMO | Kaiser Meyer Olkin |

| GFI | Goodness of Fit Index |

| AGFI | Adjusted Goodness of Fit Index |

| CFI | Comparative Fit Index |

| RMSEA | Root Mean Square Error of Approximation |

| AVE | Average Variance Extracted |

| CR | Composite Reliability |

| NFI | Normed Fit Index |

| IFI | Incremental Fit Index |

| PNFI | Parsimony Normed Fit Index |

| PGFI | Parsimony Goodness of Fit Index |

References

- Liu, Y.; Sang, M.; Xu, X.; Shen, L.; Bao, H. How Can Urban Regeneration Reduce Carbon Emissions? A Bibliometric Review. Land 2023, 12, 1328. [Google Scholar] [CrossRef]

- Chen, H.; Qi, S.; Tan, X. Decomposition and Prediction of China’s Carbon Emission Intensity Towards Carbon Neutrality: From Perspectives of National, Regional and Sectoral Level. Sci. Total Environ. 2022, 825, 153839. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhang, Z.; Burçin, B.; Lin, Q. Novel Issues for Urban Energy-Saving Management: Renewal of Leftover Space. Sustain. Energy Technol. Assess. 2023, 55, 102934. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, Z. Reducing Carbon Emissions through Green Renewal: Insights from Residential Energy Consumption in Chinese Urban Inventory Districts from an Evidence-Based Decision-Making Perspective. Humanit. Soc. Sci. Commun. 2024, 11, 13. [Google Scholar] [CrossRef]

- Li, C.Z.; Tam, V.W.Y.; Zhou, M.; Liu, L.; Wu, H. Quantifying the Coupling Coordination Effect between the Prefabricated Building Industry and Its External Comprehensive Environment in China. J. Clean. Prod. 2024, 434, 140238. [Google Scholar] [CrossRef]

- Liu, W.; Fan, G.; Liu, Z. Driving Factors in Carbon Emission Reduction in Prefabricated Building Supply Chains Based on Structural Equation Modelling. Sustainability 2024, 16, 3150. [Google Scholar] [CrossRef]

- Timilsina, G.R.; Fisher, C.; Oppermann, K.; Rogers, S.; Strand, J.; Agnolucci, P.; Montes, M.; Leon, O. Price-Based Mechanisms for Climate Change Mitigation and the Role of Results-Based Climate Finance? 2022. Available online: https://www.tcafwb.org/sites/default/files/2023-02/Price-based%20Mechanisms%20for%20Climate%20Change%20Mitigation%20and%20RBCF.pdf (accessed on 23 March 2025).

- Ramnarine, I.D.; A Sherif, T.; Alorabi, A.H.; Helmy, H.; Yoshida, T.; Murayama, A.; Yang, P.P.-J. Urban revitalization pathways toward zero carbon emissions through systems architecting of urban digital twins. Environ. Plan. B Urban Anal. City Sci. 2025. [Google Scholar] [CrossRef]

- Xiao, Y.; Huang, H.; Qian, X.-M.; Zhang, L.-Y.; An, B.-W. Can New-Type Urbanization Reduce Urban Building Carbon Emissions? New Evidence from China. Sustain. Cities Soc. 2023, 90, 104410. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, Y.Q.; Song, S.D.; Sun, L.L. An Urban Renewal Design Method Based on Carbon Emissions and Carbon Sink Calculations: A Case Study on an Environmental Improvement Project in the Suzhou Industrial Investment Science and Technology Park. Buildings 2024, 14, 2962. [Google Scholar] [CrossRef]

- Li, Y.L.; Gao, Y.; Meng, X.X.; Liu, X.L.; Feng, Y.C. Assessing the Air Pollution Abatement Effect of Prefabricated Buildings in China. Environ. Res. 2023, 239, 12. [Google Scholar] [CrossRef] [PubMed]

- Hao, Z.B.A.; Wang, Y.S.; Fan, Z.Y.; Yan, H.; Shen, T. Research on Carbon Emissions Measurement During Materialization Stage of Prefabricated Buildings: A Case Study of Urban Renewal Project in Guangzhou. In Proceedings of the International Conference on Construction and Real Estate Management (ICCREM), Virtual, 17–18 December 2022; American Society of Civil Engineers: New York, NY, USA, 2022; pp. 156–169. [Google Scholar]

- Telesca, A.; Marroccoli, M.; Calabrese, D.; Valenti, G.L.; Montagnaro, F. Flue Gas Desulfurization Gypsum and Coal Fly Ash as Basic Components of Prefabricated Building Materials. Waste Manag. 2013, 33, 628–633. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Sun, D.; Deng, Y.; Meng, X.; Li, M. Analysis of Carbon Emissions of Prefabricated Buildings from the Views of Energy Conservation and Emission Reduction. Nat. Environ. Pollut. Technol. 2021, 20, 39–44. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Gao, W.; Kuroki, S. Life Cycle Environmental and Cost Performance of Prefabricated Buildings. Sustainability 2020, 12, 2609. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.; Chu, P.; Poon, C.S. Comparing Carbon Emissions of Precast and Cast-in-Situ Construction Methods—a Case Study of High-Rise Private Building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, S.; Luo, L.; Liao, L. A Building Information Modeling-Based Carbon Emission Measurement System for Prefabricated Residential Buildings During the Materialization Phase. J. Clean. Prod. 2020, 264, 121728. [Google Scholar] [CrossRef]

- Zhu, R.; Li, L.H. SEM-Based Analysis of Carbon Emission Reduction Pathway Study During the Materialization Stage of Prefabricated Buildings: Evidence from Shenyang and Guiyang, China. J. Environ. Public Health 2022, 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Z.; Xia, P.; Xia, D. Study on Carbon Emission Measurement and Influencing Factors for Prefabricated Buildings at the Materialization Stage Based on LCA. Sustainability 2023, 15, 13648. [Google Scholar] [CrossRef]

- Cabannes, Y. The impact of participatory budgeting on basic services: Municipal practices and evidence from the field. Environ. Urban. 2015, 27, 257–284. [Google Scholar] [CrossRef]

- Sinervo, L.-M.; Bartocci, L.; Lehtonen, P.; Ebdon, C. Toward sustainable governance with participatory budgeting. J. Public Budg. Account. Financ. Manag. 2024, 36, 1–19. [Google Scholar] [CrossRef]

- Leshinka, P.S.; Tembo, M.; Mwanaumo, E.M. The Role of Public-Private Partnerships in Developing Sustainable Cities: Framework, Opportunities, Mechanisms. Int. J. Innov. Interdiscip. Res. (IJIIR) 2023, 1, 1–15. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, L.; Wu, J.; Wang, S. Factors Affecting Local Governments’ Public–Private Partnership Adoption in Urban China. Sustainability 2019, 11, 6831. [Google Scholar] [CrossRef]

- Cheng, J.; Li, L.P.; Zhang, R.; Tian, L.; Liu, Y.H. Identification of Key Drivers and Path Transmission of Carbon Emissions from Prefabricated Buildings: Based on System Dynamics. Buildings 2025, 15, 562. [Google Scholar] [CrossRef]

- Wu, G.B.; Yang, R.; Li, L.; Bi, X.; Liu, B.S.; Li, S.Y.; Zhou, S.X. Factors Influencing the Application of Prefabricated Construction in China: From Perspectives of Technology Promotion and Cleaner Production. J. Clean. Prod. 2019, 219, 753–762. [Google Scholar] [CrossRef]

- Du, Q.; Pang, Q.; Bao, T.; Guo, X.; Deng, Y. Critical Factors Influencing Carbon Emissions of Prefabricated Building Supply Chains in China. J. Clean. Prod. 2021, 280, 124398. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.; Kulatunga, A.K.; Zhang, G.M. A Comparative Life Cycle Assessment of Prefabricated and Traditional Construction—A Case of a Developing Country. J. Build. Eng. 2023, 72, 19. [Google Scholar] [CrossRef]

- Onyszkiewicz, J.; Sadowski, K. Proposals for the Revitalization of Prefabricated Building Facades in Terms of the Principles of Sustainable Development and Social Participation. J. Build. Eng. 2022, 46, 22. [Google Scholar] [CrossRef]

- Wang, X.; Du, Q.; Lu, C.; Li, J. Exploration in carbon emission reduction effect of low-carbon practices in prefabricated building supply chain. J. Clean. Prod. 2022, 368, 133153. [Google Scholar] [CrossRef]

- Bonamente, E.; Cotana, F. Carbon and Energy Footprints of Prefabricated Industrial Buildings: A Systematic Life Cycle Assessment Analysis. Energies 2015, 8, 12685–12701. [Google Scholar] [CrossRef]

- He, Y.; Wang, Y.T.; Song, Z.Y.; Yu, H.W.; Xue, Y.B. Study on Carbon Emissions from the Renovation of Old Residential Areas in Cold Regions of China. Sustainability 2023, 15, 3018. [Google Scholar] [CrossRef]

- Luo, X.Y.; Ren, M.Y.; Zhao, J.H.; Wang, Z.T.; Ge, J.; Gao, W.J. Life Cycle Assessment for Carbon Emission Impact Analysis for the Renovation of Old Residential Areas. J. Clean. Prod. 2022, 367, 17. [Google Scholar] [CrossRef]

- Han, Q.Y.; Chang, J.J.; Liu, G.W.; Zhang, H. The Carbon Emission Assessment of a Building with Different Prefabrication Rates in the Construction Stage. Int. J. Environ. Res. Public Health 2022, 19, 2366. [Google Scholar] [CrossRef] [PubMed]

- Tumminia, G.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M.; Antonucci, V. Life Cycle Energy Performances and Environmental Impacts of a Prefabricated Building Module. Renew. Sustain. Energy Rev. 2018, 92, 272–283. [Google Scholar] [CrossRef]

- Teng, Y.; Pan, W. Estimating and Minimizing Embodied Carbon of Prefabricated High-Rise Residential Buildings Considering Parameter, Scenario and Model Uncertainties. Build. Environ. 2020, 180, 15. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, F.; Yang, X. The Efficiency of the Chinese Prefabricated Building Industry and Its Influencing Factors: An Empirical Study. Sustainability 2022, 14, 10695. [Google Scholar] [CrossRef]

- Yan, W.; Guo, C.; Li, L. Evaluating the Effect of Prefabricated Building Incentive Policies Using Structural Equation Modeling: A Chinese Empirical Study. Buildings 2024, 14, 1304. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, Z.; Li, B.; Hertogh, M.; Wang, S. Evolutionary Analysis of Prefabrication Implementation in Construction Projects under Low-Carbon Policies. Int. J. Environ. Res. Public Health 2022, 19, 12511. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.; Han, D.; Gozgor, G.; Mahalik, M.K.; Sahoo, B.K. The impact of climate policy uncertainty on renewable and non-renewable energy demand in the United States. Renew. Energy 2022, 197, 654–667. [Google Scholar] [CrossRef]

- Zhou, F.; Ning, Y.B.; Guo, X.R.; Guo, S.D. Analyze Differences in Carbon Emissions from Traditional and Prefabricated Buildings Combining the Life Cycle. Buildings 2023, 13, 874. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y.W.; Feng, W.M.; Fang, Y.; Feng, A.Q. Factors That Influence the Quantification of the Embodied Carbon Emission of Prefabricated Buildings: A Systematic Review, Meta-Analysis and the Way Forward. Buildings 2022, 12, 1265. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Hou, X.; Li, W.; Li, D.; Peng, J. Public–private partnerships and carbon reduction targets: Evidence from PPP investments in energy and environmental protection in China. Environ. Dev. Sustain. 2023, 27, 6567–6597. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).