1. Introduction

In response to the increasing demand for more refined and intelligent project management within the construction industry, the integration of Building Information Modeling (BIM) and Artificial Intelligence (AI) has gradually become a prominent focus of academic research. Broadly, BIM is defined as a digital methodology for generating and managing built asset data throughout its lifecycle, facilitating collaborative decision-making. Narrowly, it refers to a technology centered on 3D models to design, visualize, and simulate building characteristics [

1]. AI technologies, especially machine learning and optimization algorithms, have been widely applied in various fields. In the context of construction schedule management, AI helps to analyze historical project data, predict potential project delays, optimize scheduling strategies, and adjust resource allocation through intelligent algorithms. These capabilities significantly improve the efficiency and effectiveness of project management process in the construction [

2]. Machine Learning (ML) is predominantly applied for schedule forecasting and risk identification; Genetic Algorithms (GA) is widely utilized for multi-objective schedule optimization; and Reinforcement Learning (RL) is emerging as a promising approach for dynamic scheduling and real-time adjustment [

3]. In the past, Gantt charts have been used as a fundamental tool of project schedule management for visualizing task timelines and monitoring overall progress in construction. When construction projects grow in complexity, the limitations of conventional Gantt charts become more pronounced, underscoring the need for optimization [

4]. Conventional scheduling methodologies exhibit intrinsic static limitations, hindering responsiveness to dynamic execution variables (e.g., abrupt weather shifts, supply chain interruptions, or emergent site risks) and inducing schedule delays [

5]. Empirical studies indicate that approximately 85% of large-scale construction projects experience schedule overruns, predominantly attributable to inflexible progress planning and lagging response mechanisms. These findings collectively highlight a functional deficiency in prevailing scheduling tools—particularly Gantt charts—regarding dynamic adaptability and real-time optimization capabilities [

6]. The integration of BIM with AI technologies offers a robust solution that enables dynamic task adjustments, real-time progress tracking, and automated optimization of task sequencing and resource allocation. This not only shorten construction periods and reduce costs but also drives innovation and supports digital transformation within the construction industry [

7]. The convergence of AI and BIM is reshaping architectural, engineering, and construction (AEC) practices. Recent empirical studies further demonstrate transformative potential in two domains: (1) Digital Twin (DT) platforms integrate IoT sensor data with BIM for predictive maintenance, as evidenced by Liu et al. (2024) who achieved a 15% reduction in equipment downtime through real-time structural health monitoring [

8]; (2) Sustainable design optimization has been enhanced by AI-BIM fusion, with tools like Hypar enabling early-stage carbon footprint simulation that narrows the performance gap between predicted and actual energy use by up to 20% [

9]. As intelligent technologies advance, the integration of BIM and AI in schedule management, particularly for optimizing Gantt chart, offers significant research value and practical significance [

10].

Current research on the integration of BIM and AI in schedule management mainly focuses on developing integrated frameworks that harness BIM’s three-dimensional data and AI’s optimization capabilities to enable more intelligent scheduling. Existing studies [

11,

12] show that AI optimization algorithms are widely applied in Gantt charts optimization, where they generate optimal task schedules by accounting for factors such as project resource constraints, task dependencies, and time windows [

13]. In addition to optimization, AI is also used for schedule forecasting and risk management, where machine learning models analyze historical data to identify potential delays and adjust task sequences in Gantt charts [

14]. Optimization problems in schedule management are often multi-objective in nature. AI technologies, through multi-objective optimization algorithms, allow simultaneous consideration of factors such as construction duration, resource utilization, and budget constraints [

15]. Some studies explored integration of BIM and AI in real-time progress monitoring systems that continuously update the BIM model’s data for tracking actual construction progress by comparing it against planned schedules, identifying deviations, and adjusting tasks promptly [

16]. Although there are considerable progress on integrating BIM and AI both theoretically and practically, existing methods still exhibit shortcomings in dynamic adjustments and flexibility when responding to project changes. Many optimization methods rely on static models, which fail to adequately consider uncertainties in project execution—such as weather changes and workforce scheduling issue—resulting in outcomes that lack adaptability and flexibility. [

17] Furthermore, while the technologies performs well in theory, their practical applications often present challenges. The complexity of BIM and AI technologies, combined with high operational requirements, presents technical barriers for construction personnel, many of whom lack professional knowledge for effective implementation [

18].

Although there has been research on the application of AI in project management, most studies focus on the application in individual areas, such as cost control and schedule adjustment. Existing literature seldom addresses how AI can comprehensively consider multiple factors (such as material supply, personnel scheduling, and equipment utilization) to optimize the overall management of a project. Therefore, a clear gap exists in the current research, specifically the lack of an AI framework for the comprehensive analysis of multiple variables in construction projects. Therefore, this study aims to develop a platform that integrates BIM and AI technologies with the capability of dynamic optimization and real-time feedback mechanisms to monitor project progress in real-time. A core innovation is the three-engine architecture—integrating the Task Engine, 4-in-1 Network Diagram Engine, and Blueprint Engine—to manage multi-variable complexities in construction project management. Real-time data is inputted into the AI optimization model to dynamically adjust the schedule. A framework using a prototype system is proposed, and the framework was later tested in a water conveyance tunnel project for a reservoir in China. This project is large scale, with a long construction cycle and a relatively complex stakeholder relationship in its structure. Business operations are complex, and multi-party collaboration presents challenges, making it crucial to refine optimization analysis in progress management.

This paper aims to investigate the following questions: (1) How can AI technology be utilized to predict and optimize the schedule of construction projects? (2) Within a multi-variable analysis framework, how can AI identify potential risks in a project and issue early warnings? (3) What is the effectiveness of AI prediction models in practical construction projects, and can they significantly improve project management efficiency? The structure of this paper is as follows: first, past research related to project schedule management is reviewed, and the latest advancements on using BIM and AI are discussed. Next, the development of a theoretical framework is illustrated, which involves a platform composing of three functional layers and two key technologies. Then, a case study is conducted to test the framework, followed by a discussion. Finally, the conclusions, limitations, and suggestions for future research are presented.

2. Literature Review

2.1. The Application of BIM in Schedule Manage

With the rapid development of Building Information Modeling (BIM) technology, its application in construction project management, particularly in schedule management, has become a focal point for both research and practice. Moon et al. (2019) [

19] proposed a BIM-based schedule information management framework to improve the efficiency and accuracy of construction projects through the integration of multiple dimensions. However, despite the emphasis on the advantages of BIM technology in schedule management, effectively implementing these frameworks in practical projects remains a challenge. In an attempt to provide a comprehensive digital schedule management platform, Stas and Abrishami [

20] developed a framework to link the schedule plan to the BIM model, by mapping the Work Breakdown Structure (WBS) to model components, associating construction processes with model elements, and integrating resource allocation with component attributes. The limitation of this approach lies in the fact that as the project scale increases, the complexity of the model may make it difficult to update and track schedule information.

To address such issues, Bortolini et al. [

21] proposed a framework to enhance project effectiveness through dynamic visualization mechanisms such as 4D construction process simulation, progress comparison between actual and planned schedules, and optimized site layout-making the project’s progress more intuitive and transparent [

22]. Although this approach provides more intuitive support for schedule management, how to effectively adjust schedules and provide decision support across different stages remains a research direction that deserves attention.

Meanwhile, Chen et al. [

23] showed that BIM technology significantly improves the visualization of schedule information, typically enhancing it by over 40%. This improved visualization provides project teams with a clearer view of the project timelines, thereby increasing the efficiency of collaborative work. From these studies, it is evident that BIM technology plays a crucial role in schedule management. By enabling precise data integration and real-time visualization, BIM greatly enhances the transparency, predictability, and overall collaborative efficiency in construction projects. The BIM technological advancements have led to greater accuracy, lower risk, and are accelerating the digital transformation and intelligent development of the construction industry [

24]. However, maintaining data consistency and accuracy in multidimensional schedule data analysis remains a key issue that needs to be further addressed.

2.2. Four-Dimensional BIM Model and BIM Collaborative Management Platform

To address the issue of maintaining data consistency and accuracy in multidimensional schedule data analysis encountered in previous research, subsequent researchers, based on BIM technology, integrated the 4D BIM model with project schedules and 3D models, thereby achieving dynamic visualization of the construction process. Hamledari et al. [

25] introduced a comprehensive 4D-BIM schedule management method designed to improve the efficiency and accuracy of schedule management in construction projects., Using 4D modeling, this model integrates the project schedule with the 3D model. Through simulation and optimization of construction sequence, potential conflicts in the workflow are identified and resolved. It incorporates conflict detections within construction processes to ensure seamless task coordination. Additionally, it supports dynamic optimization of site layout, allowing for layout adjustments based on the actual site conditions during project execution, contributing to improved construction efficiency and better space utilization [

26]. However, the real-time application of the 4D BIM model (e.g., using Revit (version 2024 or later) for schedule integration) still faces challenges related to data synchronization and management efficiency, particularly under the dynamic changes in resource management and site conditions.

Four-dimensional BIM tracks progress at the component level, allowing for more precise control of individual construction units. By integrating real time process monitoring, it allows for continuous tracking of construction progress, timely detection of deviations, and the implementation of analysis and warnings. This ensures the project stay on plan [

27]. Through optimized schedule adjustment, managers can quickly revise construction plans based on real-time data and alerts, reducing schedule deviations [

28]. Nevertheless, the existing 4D BIM technology still requires further development to better address the real-time changes and coordination needs in complex projects. As a result, some researchers have proposed a new concept of a collaborative management platform that integrates various BIM functions for more efficient management.

The BIM-based collaborative management platform enhances the efficiency and effectiveness of construction collaboration. The platform architecture consists of four layers: the data management layer, the business process layer, the application service layer, and the user interaction layer. The data management layer serves as the centralized storage and governance of project data, ensuring data integrity and security. The business processing layer handles and analyzes the core project management business to ensure the efficiency of platform operation. The application service layer provides various management tools and services, such as schedule planning, construction management, and resource scheduling. The user interaction layer serves as the interface for project team members to interact with the platform, ensuring intuitive use and real-time access to platform functions. The core functional modules of the platform include schedule planning, on-site construction management, resource scheduling, and quality and safety management, empowering the project team with precise control over every project aspect. The schedule planning module supports schedule arrangements and adjustments; the construction management module provides real-time on-site monitoring and feedback; the resource scheduling management module optimizes resource allocation; and the quality and safety management module ensures compliance with safety protocols and quality standards. The integration of these functional modules significantly improves collaboration, transparency, and overall project management efficiency [

29].

Application effectiveness analysis shows that the collaborative management platform significantly enhances information sharing efficiency and the quality of collaborative decision-making in practical applications. By enabling project teams to access and share project information in real-time, the platform supports a more scientific and timely decision-making process. This, in turn, contributes to optimized resource allocation, increased construction efficiency, and reduced project risks. The platform also plays a vital role in driving digital transformation and fostering innovation in construction management practices while promoting the standardization of management workflows [

30].

2.3. Applications of Artificial Intelligence in Schedule Management

Artificial Intelligence (AI), as an emerging technology, is being increasingly applied in the schedule management of construction projects. Braun et al. (2015) [

31] proposed a computer vision-based progress monitoring method for progress monitoring, automated tracking and real-time updates through advanced image processing technologies. The core of this method lies in the diversified deployment of image acquisition systems, incorporating fixed cameras for long-term monitoring, drone-based aerial imagery, and mobile device-based flexible data collection. The multi-source approach enables comprehensive and accurate real-time image data capture across the construction site. High-efficiency algorithms capable of component recognition, construction status determination, and progress evaluation is also developed for image processing and analysis. This system achieves an accuracy of component recognition up to 98%, with an accuracy of construction status determination of 90%. The system provides high-precision analysis outputs and reliable data to support decision-making in project management. In addition, the system can also automatically analyze key progress indicators and provide real-time feedback on construction progress.

In addition, an intelligent decision support system proposed by Pan et al. [

32] is designed to enhance decision-making efficiency and risk response capabilities in project management. The system is structured around three-layer architecture comprising the data collection layer, the analysis layer, and the decision support layer. The data collection layer gathers real-time data from the project site, including schedule, resources, and risks. The data is then processed to analysis layer using advanced data analytical algorithms to extract insights for decision-making. The decision support layer leverages the insights to provide project managers with relevant recommendations and optimization strategies.

The system’s core functionality centers on three main features: schedule status assessment, risk analysis and warning, and plan optimization recommendations. Schedule status assessment enables real-time tracking of project progress and prediction of potential schedule deviations. Risk analysis and warning feature identifies potential risks and issues early warnings, allowing managers to take proactive measures. Plan optimization recommendations provide suggestions for optimal resource allocation and making adjustments based on the current conditions, thereby improving the efficiency and effectiveness of project execution [

33].

2.4. Integrated Applications of BIM and Artificial Intelligence

Advancement of BIM and AI offers a great opportunity to transform the construction industry, which has been critiqued for its poor performance in efficiency, scalability, and accuracy. By leveraging AI’s ability to process vast and diverse datasets, BIM systems can evolve into more intelligent and autonomous platforms. Zhang et al. [

34] pointed out that integrating BIM and AI technologies offers a variety of models, and the three models are as follows: (1) AI integration for real-time BIM data collection and update; (2) AI-powered management and analysis of BIM data; and (3) AI-driven automation of BIM tasks.

To the first model, the dynamic natures of a building’s lifecycle necessitates continuous updates to its BIM data. Traditional methods often struggle to capture and update information in real-time. This model addresses this issue by using AI technologies to automatically identify and update BIM data using diverse data sources-such as site videos, images, audio, text, and 3D point clouds [

35]. AI technologies can extract meaningful information from these data sources, automatically recognizing and categorizing building materials, elements, and components, and input the results into the BIM system. For example, computer vision technologies can analyze live imagery to monitor construction progress, while indoor image analysis can support indoor positioning data collection, greatly enhancing the timeliness and precision of BIM updates [

36].

Regarding the second model, as vast volumes of building information accumulate and continuously build up throughout its life cycle, manual management and analysis of such information become increasingly difficult and inefficient. AI technology is used as a powerful tool to automatically manage and analyze BIM data to enable advanced analytics to unlock greater value from the information [

37]. During the design phase, AI can help identify and resolve design conflicts; in the operation and maintenance phase, AI can assist in verifying records and refining work orders by analyzing operational data. AI can enhance BIM’s analytical capabilities by supporting tasks such as energy performance forecasting and sustainable design optimization. Moreover, the integration of AI with BIM expands the analytical capabilities of the building systems, enabling optimization, prediction, evaluation, simulation, decision-making, and feedback—ultimately providing more informed and science-based project decisions [

38].

The third model primarily involves the use of AI technologies to perform automated tasks in construction, especially BIM-based activities particularly through robotic systems. AI-supported robots can autonomously execute standardized, repetitive, or high-risk construction tasks by interacting with BIM models and data platforms [

39]. These robotic systems are not solely dependent on pre-programmed instructions; their behaviors can adapt dynamically to real-time site conditions, thus enhancing the efficiency, precision, and safety of construction works [

40]. The integration of AI and BIM facilitates seamless connection between design and construction processes, accelerating construction progress and reducing labor requirements [

41].

Apart from that, BIM serves not only as a modeling tool but as a centralized knowledge repository integrating geometric and semantic data, while AI enhances its capabilities by automating manual tasks, reducing time and errors. For instance, data-driven design enables BIM models to adapt dynamically to changing conditions, and AI-powered rule-based compliance checks validate designs against regulations, ensuring adherence to standards [

42]. Concurrently, BIM tools generate event logs with big data characteristics, which can be mined to support design performance evaluation, activity prediction, and social network analysis, thereby improving decision quality and efficiency [

43].

Finally, Digital Twin technology synchronizes virtual BIM models with physical assets via IoT devices and AI algorithms, enabling real-time monitoring, simulations of building behaviors, and predictive analytics for lifecycle management. This integration facilitates problem diagnosis, trend prediction, and operational efficiency improvements [

44]. Collectively, these advancements position BIM as a dynamic platform for innovation in design, sustainability, and smart building management.

2.5. Summary of This Chapter

In the conclusion, we have provided a comprehensive overview of the application of BIM technology in construction project management, presenting the core methodologies, advantages, limitations, and the evolutionary relationships of various research directions in tabular form (

Table 1).

3. Methodology

Based on a thorough literature review of applications of BIM and AI in construction as well as technology advancements of integrating BIM and AI.

3.1. Framework Development

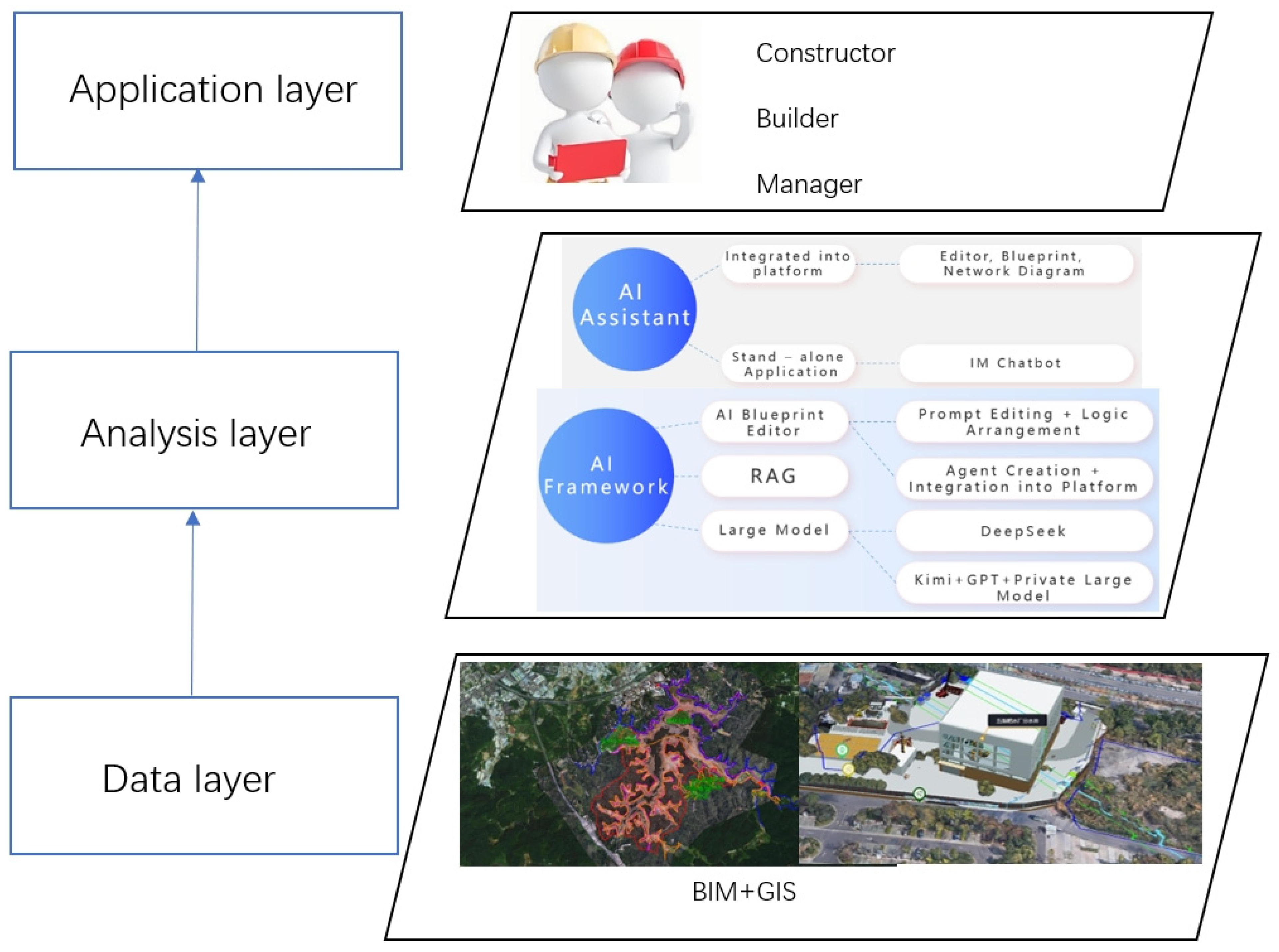

While existing studies highlight the potential of BIM-AI integration, practical challenges such as dynamic adaptability and technical complexity remain unresolved. To address these gaps, this study proposes a practical framework that integrates BIM and AI technologies for optimizing schedule management. The framework is structured into three layers: data layer, analysis layer, and application layer (

Figure 1). To further illustrate the novelty of the proposed framework and its improvements in decision-making capabilities compared to existing methods, the table presents the enhancements at each layer and their impact on project management decisions (

Table 2).

3.1.1. Data Layer

The data layer forms the cornerstone of our framework, meticulously designed to gather, integrate, and manage information from diverse sources. It revolves around the BIM model, systematically collecting data from every project phase to guarantee consistency and comprehensiveness. This layer does not merely capture geometric information but also amasses engineering parameters, material specifications, and construction methods. In this way, it provides a holistic foundation that seamlessly supports the subsequent analysis layer.

Complementing the BIM model data is real-time information harvested from the construction site through an array of sensors and monitoring devices. This live data enables the tracking of dynamic variables such as construction progress, resource consumption, and personnel scheduling, offering an immediate reflection of the site’s actual conditions. When combined with historical project data, it becomes an invaluable asset for training AI models. The analysis of past project trends and outcomes allows the system to pinpoint potential risk factors and enhance the accuracy of forecasts.

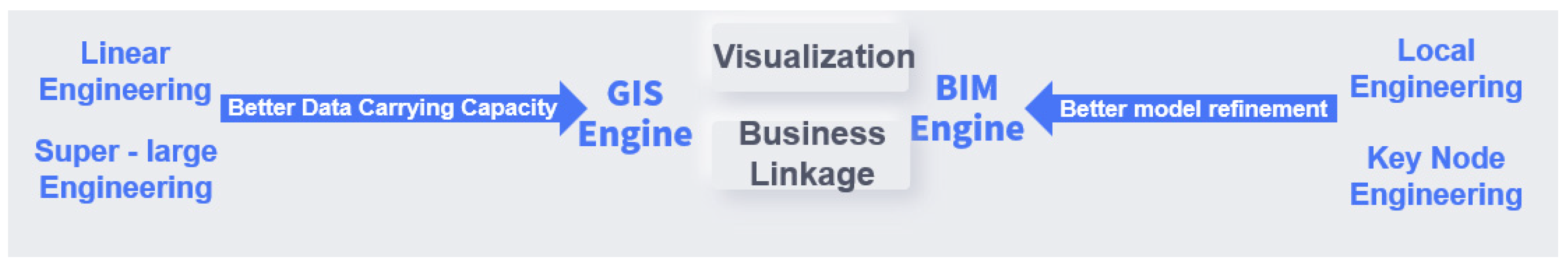

To further augment spatial intelligence within the framework, we have incorporated several advanced technologies. The integration of BIM and GIS technology brings locational precision and visualization capabilities to the table, ensuring smooth progress even in complex environmental conditions [

45]. The integration of BIM and GIS faces significant challenges, including data interoperability issues due to differing semantic frameworks and geometric representations, scale discrepancies between detailed building models and broader geographic contexts, and the absence of standardized protocols for seamless data exchange [

46]. However, the careful selection and optimization of AI models play a pivotal role in ensuring the efficient operation of the analysis layer. Accurate predictions and analyses can only be achieved through the appropriate choice of models. Additionally, a real-time feedback mechanism has been established, allowing for continuous refinement of predictions as new data becomes available. This integration of BIM model data, real-time information, historical data, and advanced technologies collectively forms a solid and dynamic data foundation, guaranteeing the timeliness and accuracy required for effective schedule management throughout the entire system.

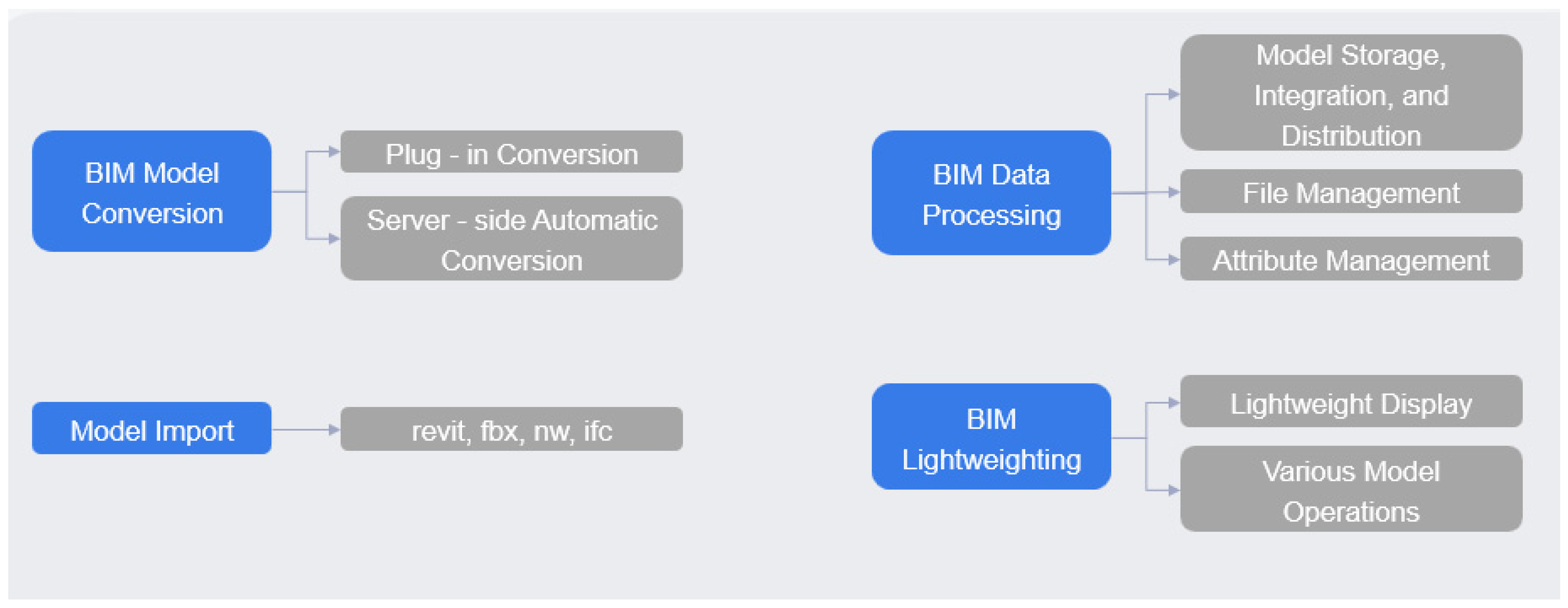

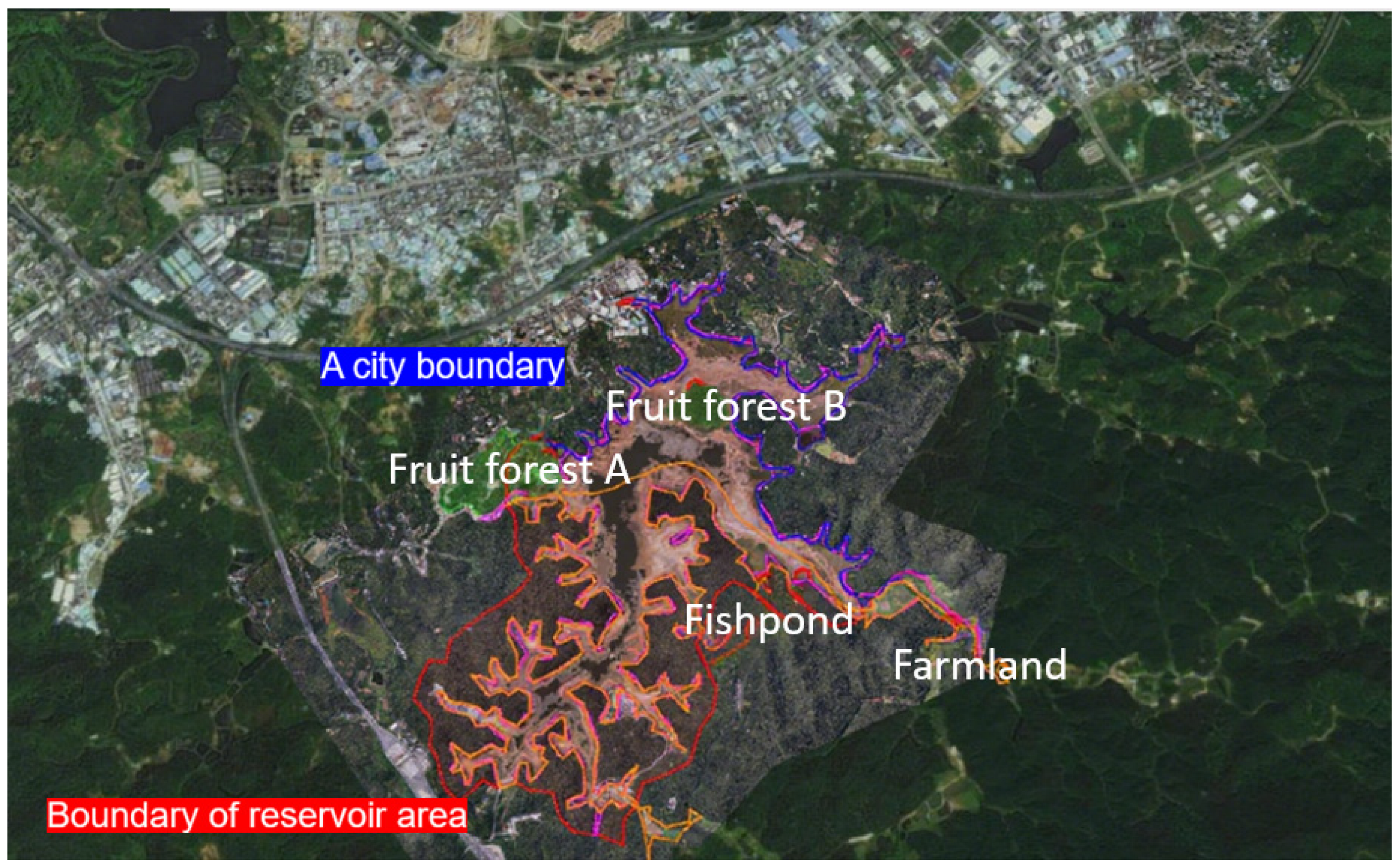

The BIM + GIS system is a smart spatial management system integrating BIM and GIS technology. This hybrid system provides more accurate spatial data and a comprehensive project view. By combining BIM’s detailed modeling capabilities with geographic context provided by GIS including topography, climate, and traffic, this hybrid technology offers comprehensive spatial context (

Figure 2) within the framework interface. The BIM + GIS model that requires lightweight conversion from the modeling software to the platform supports two methods: direct local conversion via software plugins and server-based conversion through online platforms. The former offers more options and ensures better confidentiality, while the latter offers faster processing with reduced local resource usage. The cloud-based conversion method requires no waiting time because it uploads the model source file directly, with the platform server handling the conversion in the background (

Figure 3). This BIM + GIS hybrid technology enhances the spatial accuracy of construction planning, facilitates land-use analysis, and improves risk assessment by contextualizing projects with real-world environments.

3.1.2. Analysis Layer

At the analysis layer, the core is the processing capability of AI algorithms. These algorithms conduct comprehensive analysis of data using multidimensional approaches and construct predictive models to provide scientific basis for project schedule planning and adjustments [

47].

The analysis layer is the core engine of the framework, responsible for transforming the collected data into actionable insights using AI technologies such as machine learning and deep learning. Initially, AI algorithms analyze data to automatically generate the construction schedule network diagrams. These are then enhanced using multidimensional analyses that integrate variables such as material supply, personnel scheduling, and equipment usage to identify and mitigate potential risks. By identifying potential risks in advance, AI enables appropriate corresponding countermeasures to be taken for improving the accuracy and efficiency of schedule management.

The analysis layer also performs real-time progress analysis and constructs predictive models to assess schedule risks. By leveraging both historical trends and live site data, AI algorithms can predict potential delays and resource shortages, issue early warnings and enabling proactive interventions. This predictive capability enhances accuracy and responsiveness of schedule management, helping project managers make timely, data-driven decisions.

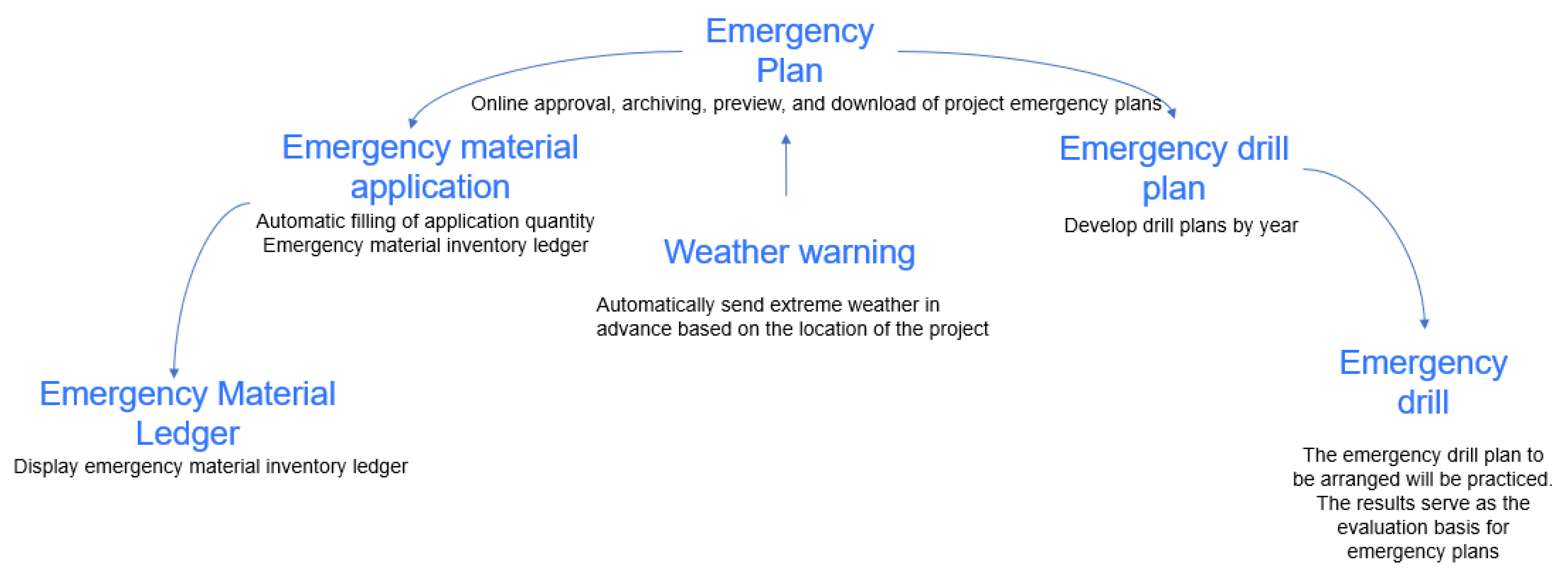

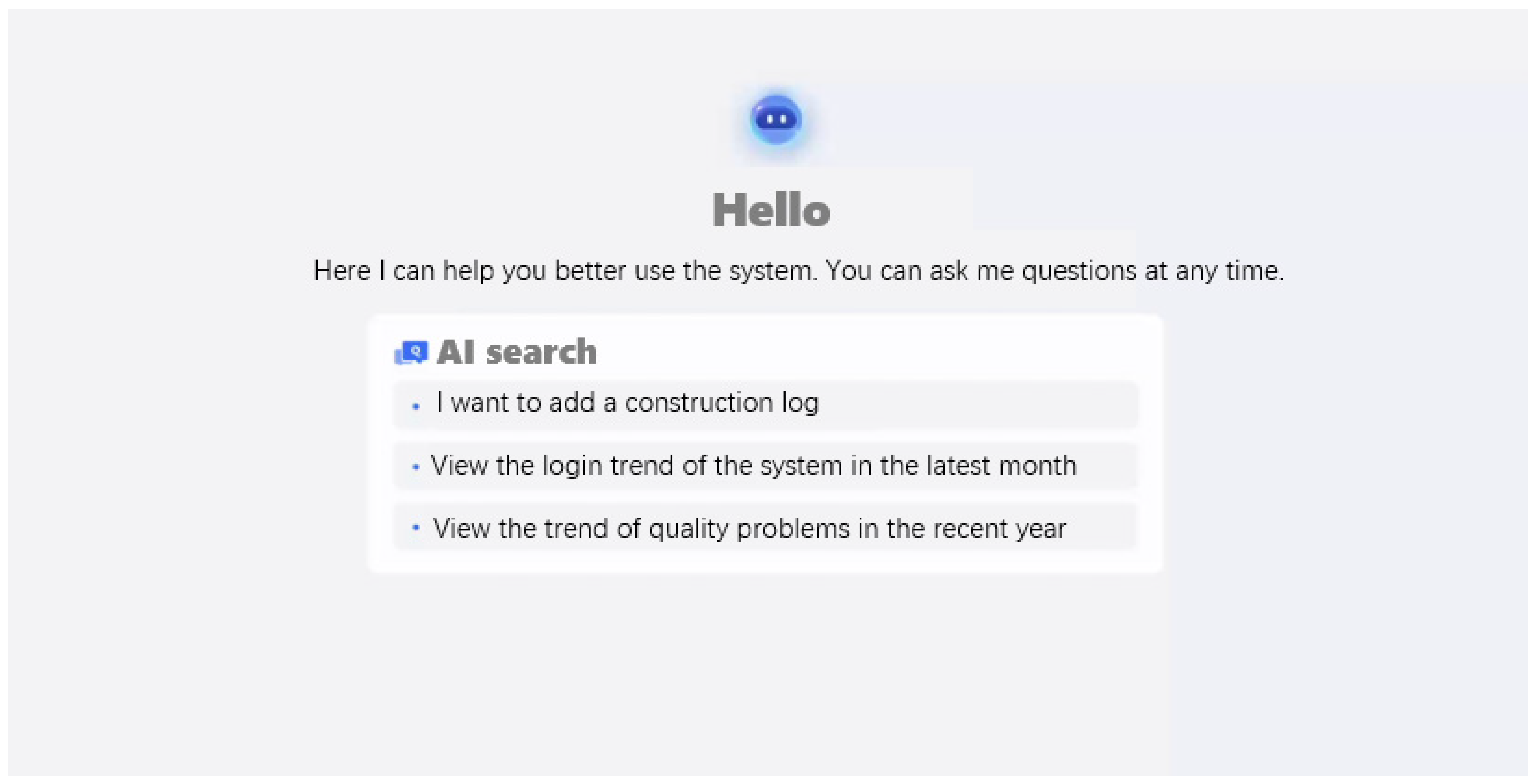

3.1.3. Application Layer

Visualization technology enables intuitive presentation of BIM data and AI-driven analytical results, enhancing comprehension of real-time project scheduling [

48]. Consequently, this study incorporates visualization techniques at the application layer to support dynamic progress monitoring. The application layer serves as the interface between the system and its users, providing visualization and intelligent decision support. It integrates the outputs from the data and analysis layers and employs various management tools to form an efficient and intuitive schedule management system. This system can transform complex schedule information into easy-to-understand visual presentations. Through dynamic visualizations, the application layer maps construction progress directly onto the building model, allowing stakeholders to intuitively grasp the project status. Real-time progress tracking is supported by AI-enhanced dashboards to display updated schedule and highlight deviations. The application layer also incorporates early warning mechanisms and predictive analytics to support strategic planning and agile adjustments, ensuring timely project delivery and maintaining quality standards. By improving controllability of the project schedule, the application layer plays a key role in ensuring efficient schedule management and fostering collaboration among all parties. For instance, in the case of extreme weather material scheduling, the model’s processing scheme, which helps address these challenges, is illustrated in the following figure (

Figure 4).

3.1.4. Framework Assessment

To critically address scalability concerns raised during peer review, a systematic evaluation matrix was established to quantify the framework’s performance across four key dimensions: (1) Project scale adaptability, (2) Big-data processing capacity, (3) Cross-platform deployment flexibility, and (4) System boundary interoperability. Quantitative thresholds were derived from industry benchmarks and stress-test simulations, defining measurable criteria for each scalability attribute. The validation metrics presented in

Table 3 provide empirically testable requirements for framework implementation under varying operational constraints (

Table 3).

3.2. AI Model Selection and Optimization

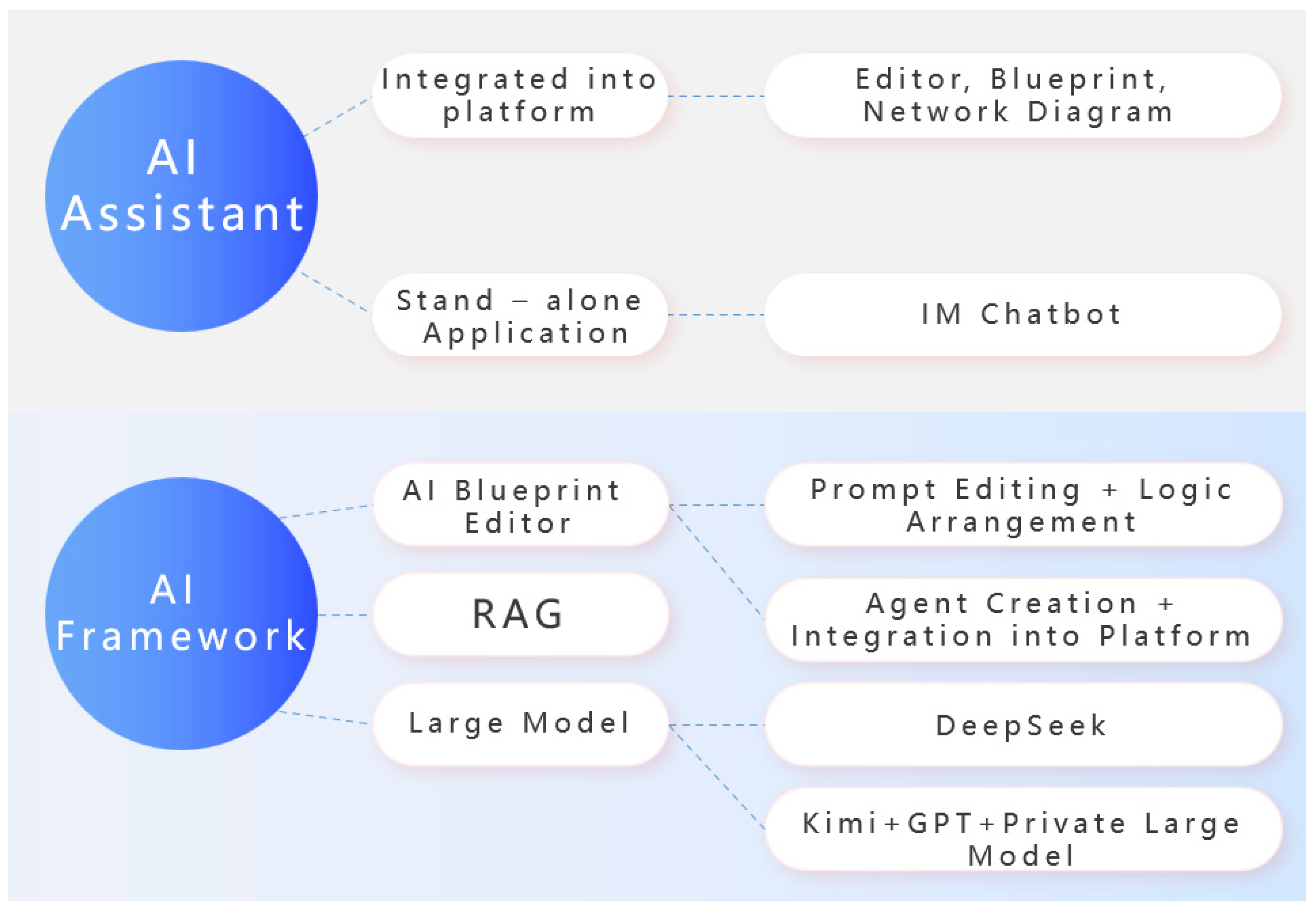

The selection and optimization of AI models (

Figure 5) serve as the backbone of our analysis layer, meticulously tailored to address the unique demands of each project. Our framework leverages a diverse array of AI algorithms, spanning from traditional regression models to cutting-edge deep learning networks, each chosen for their specific strengths in optimizing critical project parameters such as schedule, cost, and resource allocation. The integration of DeepSeek technology further enhances our capabilities, providing advanced analytical power that traditional models might lack. This sophisticated selection process is complemented by our AI Blueprint Editor, which allows for precise prompt editing and logic arrangement, ensuring that the models are not only selected but also finely tuned to the project’s intricacies (

Table 4). The models are trained on a rich tapestry of data, combining historical project records with real-time information gathered through sensors and monitoring devices. This dual data approach enables the models to learn from past experiences while remaining responsive to current dynamics on the construction site. The adaptive optimization feature is particularly noteworthy, as it permits continuous refinement of predictions as new data streams in. This iterative learning capability ensures that our system does not just react to changes but anticipates them, maintaining its effectiveness throughout the project lifecycle.

Furthermore, our AI Framework is designed with flexibility and scalability in mind. The ability to integrate AI models into various platforms, whether as a stand-alone application or embedded within existing systems like editors, blueprints, and network diagrams, demonstrates our commitment to versatility. The combination of Kimi + GPT + Private Large Model offers a powerful solution that can be customized to meet specific project requirements. This integration is not merely technical but strategic, as it allows for the creation of specialized agents that can be seamlessly incorporated into the platform, enhancing its functionality and adaptability. The real-time feedback mechanism, supported by RAG (Retrieval-Augmented Generation), ensures that these models remain aligned with the project’s evolving needs. By continuously updating and optimizing based on incoming data, the models provide increasingly accurate predictions and analyses, thereby significantly enhancing the overall reliability and effectiveness of our schedule management system. This sophisticated interplay of model selection, optimization, and integration positions our framework as a robust solution for navigating the complexities of modern construction projects.

4. Case Study

This study adopted an empirical case study to test the feasibility and practicality of the proposed framework. A practical system based on the proposed framework was developed in collaboration with a local technology company and tested on a water reservoir tunnel project in China. The project has a long construction period and a complex construction phase, involving multiple collaborations and exhibiting typical characteristics of large-scale infrastructure. It accurately reflects the common challenges faced in progress management within the current infrastructure sector, such as schedule delays, resource misallocation, and delayed site feedback. The selection of this project helps validate the adaptability and effectiveness of the proposed BIM + AI + GIS cloud platform in real-world engineering environments.

The system began by constructing a comprehensive 3D project model using BIM technology. The model includes detailed information about building structures, materials, construction procedures resource configuration, milestones, and their interdependencies. This virtual environment enabled project managers to gain a holistic view of project progress, identify potential challenges, and anticipate bottlenecks in advance, thereby allowing for early issue detection and optimized solutions for resource allocation. In addition, the BIM model provided accurate spatial information and structural data that serve as an input for subsequent AI algorithm analysis.

To support real-time monitoring, the system with support of GIS engine deployed IoT devices across construction site to continuously collect data, including construction progress, personnel location, and equipment usage (

Figure 6). This data included construction progress, personnel positioning, equipment usage, and material consumption. Sensors transmitted data to the centralized cloud server at one-minute intervals, ensuring high frequency updates and precise tracking of on-site activities. Leveraging this data, AI algorithms conducted in-depth analysis to identify early indicators of schedule delays, such as uneven resource allocation or progress deviations. For example, by combining historical and real-time data, the system could predict potential delays in a specific construction phase and provide optimized adjustment strategies to assist managers in making quick decisions.

In project scheduling and management, AI technology has played a powerful role. However, the strengths and weaknesses of its various models differ across different application scenarios. Deep Learning (DL), with its ability to automatically extract features and recognize complex data patterns, has demonstrated outstanding performance in fields such as large-scale high-dimensional data processing, time series analysis, image recognition, and natural language processing. Nevertheless, Deep Learning models require large amounts of labeled data and computational resources, and their training process is relatively slow. Furthermore, the lack of interpretability of these models limits their use in applications where high precision and transparency are crucial. In contrast, Support Vector Machines (SVM) perform excellently in small sample learning and high-dimensional data classification, particularly in solving both linear and non-linear classification problems. However, SVMs are computationally expensive and lack robustness to noisy data, which may affect their practical application performance. XGBoost, as an efficient ensemble learning method, improves predictive accuracy through multiple iterations of training weak learners. It is capable of handling missing values and noisy data. However, it is highly sensitive to parameter tuning and can easily overfit when there are many outliers in the data. Convolutional Neural Networks (CNN) have demonstrated exceptional efficiency in image processing, particularly in image classification and object detection tasks, where they hold a unique advantage. However, CNNs require large amounts of data and computational resources, and their performance is inferior to other algorithms when handling non-image data. Recurrent Neural Networks (RNN) excel at handling sequential data, especially in time series analysis and natural language processing tasks, where they are able to effectively retain historical information and make reasonable predictions. However, RNNs frequently face issues such as gradient vanishing or exploding when processing long-term dependencies, affecting their ability to learn key features in long time series data. In summary, the selection of the appropriate AI technology should be based on the specific application scenario, with Deep Learning and XGBoost performing exceptionally well in large-scale data processing, while SVM and RNN are more suitable for specific tasks, especially when dealing with smaller datasets. By combining the strengths of different AI techniques, the accuracy and flexibility of project scheduling and management systems can be effectively enhanced. The advantages of each model are summarized in the table below (

Table 5).

In order to more precisely adapt to the diverse needs of the project, this study selected multiple advanced AI models in the analysis layer, including Random Forest, Long Short-Term Memory (LSTM) networks, and Transformer models, to address various levels of schedule prediction, resource scheduling, and risk assessment tasks. The model selection process fully considered the compatibility between the characteristics of each model and the project’s specific requirements, as outlined below: these AI models were carefully selected and further optimized through transfer learning and fine-tuning to meet the specific characteristics of the project. The introduction of transfer learning enables the models to acquire prior knowledge from related fields, thereby accelerating the training process and enhancing predictive performance. During the fine-tuning process, techniques such as Grid Search and Bayesian Optimization were employed in combination with hyperparameter tuning methods to identify the optimal hyperparameter configuration, maximizing the model’s predictive accuracy and generalization ability. Through these optimization strategies, we are able to ensure that the performance of each model is best suited to the data characteristics of the project, thereby improving the accuracy of schedule prediction and resource allocation and providing a solid data foundation for project management.

The training of the AI models utilized a total of over 20,000 data samples, including on-site construction logs, material entry and exit records, meteorological data, personnel scheduling data, and more.

Data preprocessing methods:

Missing value imputation;

Feature normalization;

Time series slicing.

Cross-validation method:

5-fold cross-validation was used to evaluate the generalization ability of the models.

Hardware platform:

NVIDIA A100 GPU servers with 4 GPUs running in parallel for each machine.

Training time:

The LSTM model took approximately 2.5 h per training epoch.

The Transformer model required about 3.2 h per epoch.

In total, around 30 epochs were trained to achieve optimal convergence.

The following are the key indicators of model prediction accuracy and usability (

Table 6).

For robust data storage and efficient processing, the system server was hosted on a cloud computing platform. This cloud platform enabled scalable storage of vast datasets from various construction nodes and facilitated rapid data analysis system-wide. To improve operational efficiency, the system also developed an all-scenario no-code development environment that enabled non-programmers to configure workflows. When combined with AI technology, this environment enabled automated identification of schedule risks and provided intelligent decision support to project managers.

The platform supports both desktop and mobile access, allowing stakeholders to view project progress, receive system alerts, and provide feedback at any time and from any location. This multi-terminal design significantly enhanced the system’s real-time responsiveness and flexibility, empowering managers to make informed decisions in real time (

Figure 7).

During the actual testing, the system successfully helped project managers identify and resolve potential problems across multiple construction phases. By combining BIM and AI technologies, the system provided more accurate schedule predictions and effectively shortened the decision-making cycle. Managers could monitor live project progress in real-time and make quick adjustments to construction plans or reallocate resources when progress deviations occurred, thereby avoiding risks of project delays.

While the system demonstrated significant improvements in schedule optimization, the system revealed several limitations during testing. Key aspects such as personnel management, skills matching, and workload balance were not comprehensively addressed. The success of a project not only depends on schedule adherence but also on optimal resource utilization and the alignment of workforce skills, and these aspects remain crucial for future development. Additionally, the platform’s interface, while rich in content, may be overwhelming for users without technical expertise, due to the complexity and abundance of interface content. Although the platform provides timely recommendations, practical constraints on-site can delay the implementation of suggested changes, limiting the system’s full potential.

To support project operations, the system incorporated a three-engine system, comprising a 4-in-1 network diagram engine, task engine, and blueprint engine, unified by an AI assistant. This setup allowed project data to be effectively categorized and distributed, enabling different personnel to access relevant information based on their specific responsibilities and work requirements.

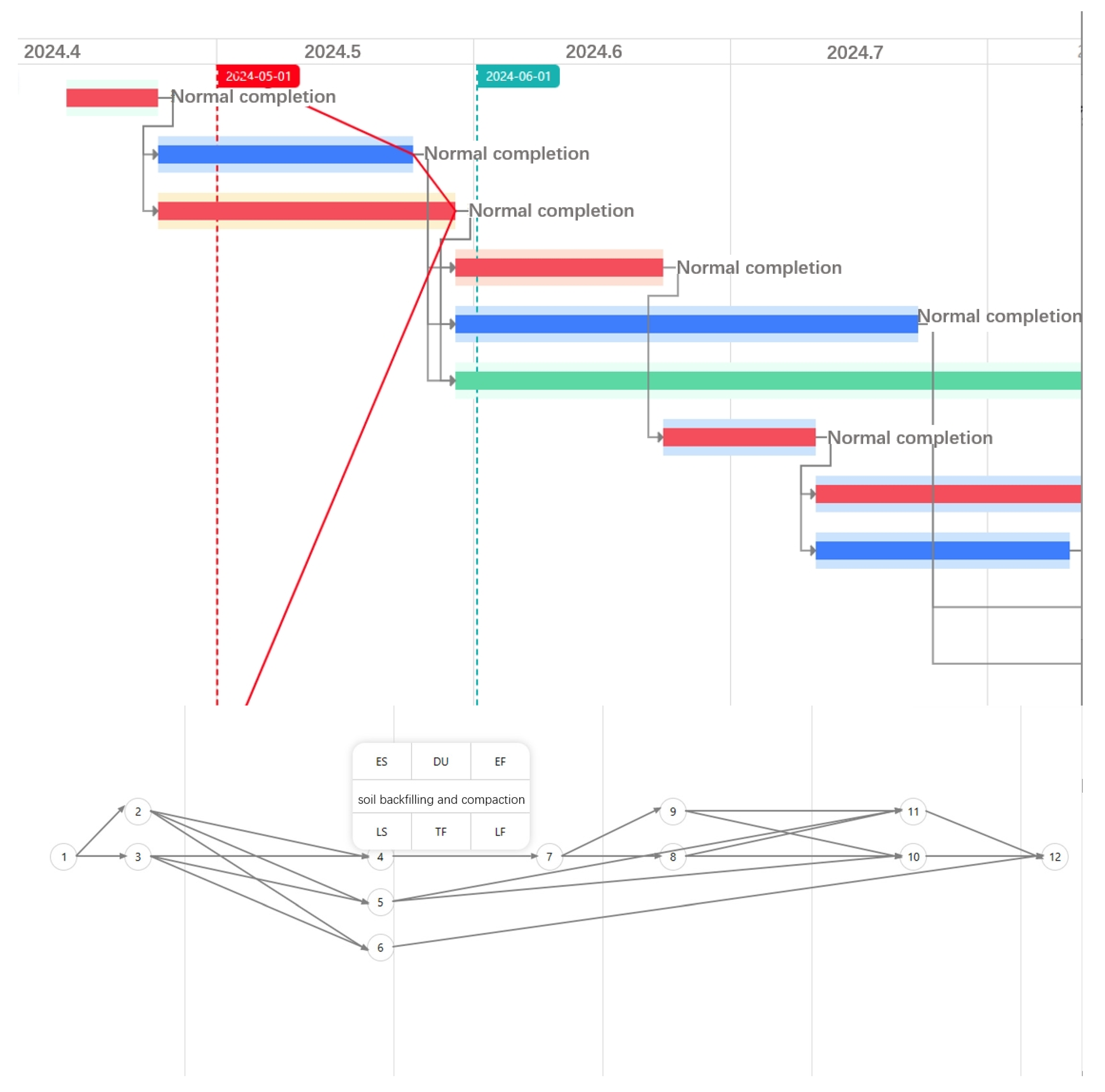

5. Results: 4-in-1 Network Diagram Engine

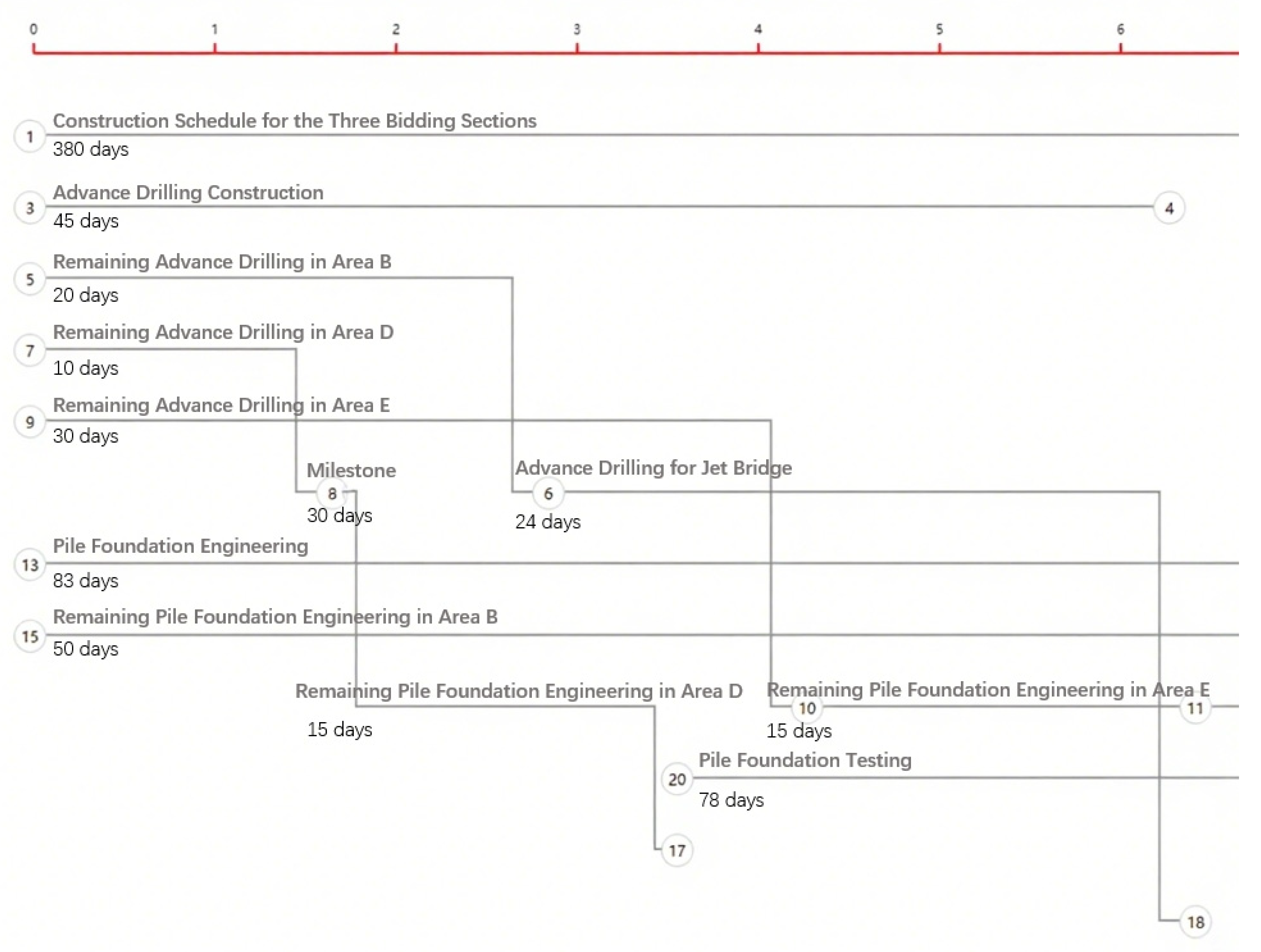

The 4-in-1 Network Diagram Engine (

Figure 8) integrated four essential project management tools—“Gantt Chart + Timeline Network Diagram + Double-Coding Network Diagram + PERT Chart”—into a unified, data-driven platform. With one-click switching, users could seamlessly transition between views, enabling dynamic and intuitive progress monitoring for large and complex projects, such as the one featured in this case study. Designed to handle tens of thousands of data points, this engine ensures high performance and real time responsiveness. This scalability met the rigorous demands of schedule management, offering both visual flexibility and operational efficiency.

Each diagram mode offered tailored functionality:

Gantt Chart Mode: Displayed task start/end times, dependencies, and progress at a glance, allowing project managers to monitor timelines and identify delays quickly;

Timeline Network Diagram Mode: Presented the timelines and highlights chronological task relationships with precision, helping teams adjust the schedule efficiently;

Double-Coding Network Diagram Mode: Displayed task dependencies and multiple constraint-based paths using nodes and arrows, ideal for complex scheduling as shown in the case study;

PERT Chart Mode: Applied statistical analysis to model uncertainty, offering likelihood-based estimates for task and project completion times.

At the core of the engine was data-driven automation, which automatically generated and updated diagrams based on large-scale datasets of the case project-eliminating manual adjustments, reducing human error and increasing productivity. Furthermore, the engine provided instant updates and smooth transitions, even with over 100,000 task entries/data points, preventing lags that could derail timely decision-making. To support interoperability, the engine also allowed for seamless data import and export with tools such as Microsoft Project and Primavera P6, enabling cross-platform data migration and ensuring smooth project management processes.

In addition, integrated AI algorithms analyzed both historical and real time data to generate optimized scheduling plans, identify potential risks, and provided proactive adjustment recommendations. This significantly improved the efficiency, accuracy, and adaptability of project planning and execution.

Overall, the 4-in-1 Network Diagram Engine provided robust support for large-scale, data-intensive schedule management. It demonstrated that the schedule management system in the case study could efficiently process and display vast amounts of data with great details, reducing resource waste due to data processing lags. We compared the use of software with the use of traditional methods, and obtained the following table (

Table 7). We compare the system proposed in this paper with synchro, MS project, Alice, and other tools in terms of availability, adaptability, and performance (

Table 8).

5.1. Task Engine

The Task Engine utilized a visual, drag-and-drop task distribution and transmission method, enabling the rapid completion of task presetting. It supported the configuration of custom branching logic for different task flows, allowing precise and flexible rule configuration through aggregation conditions and function formulas. To support different task requirements, the engine enabled the combination of functional modules into composite tasks, supporting various task types across different business types. Custom reminder configurations were set based on task types and urgency levels, with built-in time-based notification rules tailored to the project’s dynamic requirements.

In this case study, the Task Engine played a crucial role in managing complex task workflows. By enabling precise task workflow design, the Task Engine efficiently handled dependencies between different project stages, ensuring seamless coordination, minimizing errors and inefficiency commonly seen in traditional manual task management. The system supported not only sequential execution but also parallel processing conditional branching, and loop execution, all configurable via an intuitive graphical interface. This visual approach reduced configuration complexity and empowered users to clearly define, adjust, and maintain complex workflows.

A key feature of the Task Engine was its deep integration with forms systems. In real-world applications, task execution was often closely tied to the input, validation, and processing of form data. The Task Engine facilitated automated task progression based on form interactions. The automatic linkage mechanism allowed dynamic automatic data transmission, where data input, validation, and approval, were autonomously driven by the form’s contents. For example, in the case study, upon submission of an approval form, the Task Engine automatically verified conditions and triggered the next task step if requirements were met. This tight coupling between data flow and task flow eliminated the need for manual intervention ensures smooth, error-free task transitions.

The Task Engine also supported fully customizable task flows, allowing teams to tailor workflows to specific business needs. Users created exclusive task flow templates, defined execution sequences, set dependencies, and applied conditional logics to adapt to changing priorities or external conditions. In the case study, for instance, certain tasks were time-sensitive, while others required dynamic rescheduling. The Task Engine’s custom progress control parameters allowed for this level of flexibility, empowering the management team to finetune the project timelines in real time, in accordance with task priority and business requirements.

5.2. Blueprint Engine

The Blueprint Engine was a versatile tool designed to support a variety of scenarios, from simple workflow management to complex, multi-level task coordination. Whether it was internal enterprise approval processes, automated customer service handling, or event triggered state management in large-scale systems, the Blueprint Engine provided a unified framework that helped users quickly designed, built, adjusted, and optimized workflows across diverse business contexts.

In the case study, the Blueprint Engine demonstrated its powerful capabilities through visual logical orchestration and a flexible event-triggered mechanism. It enabled precise control over project workflows, ensuring tasks follow planned schedules, and deviations are detected and addressed promptly, and project delivery was both timely and efficient. Given that schedule management often involved multiple stages and task dependencies, each with its own sequence and time requirements, the Blueprint Engine’s drag-and-drop interface simplified the orchestration of complex workflows. Project managers could visually define the execution order, set dependencies, and monitor real-time progress, all while maintaining a clear overview of each task’s status and interconnections.

In scenarios where parallel tasks must proceed simultaneously, the Blueprint Engine used visual nodes to provides a transparent and intuitive representation of each project phase, ensuring synchronized execution and timely completion. Additionally, the engine integrated seamlessly with external systems, enabling real-time data exchange. For example, in this case study, the Blueprint Engine could adjust construction schedules automatically based on material delivery data from external suppliers. When delays occurred, the engine immediately activated predefined logic, such as reallocating resources, shifting timelines, or notifying relevant personnel, allowing for swift and informed responses for resolutions.

Moreover, the Blueprint Engine also supported integration with AI assistants, enhancing its capacity to monitor progress and respond intelligently in real-time and automatically generate warning notifications. If a task’s actual completion time exceeded the scheduled time, the AI could trigger a “delay” event, prompting the system to automatically update the schedule, reallocated resources and alerted the project manager. This proactive warning system enabled timely intervention and minimized the risk of cascading delays across the project.

5.3. Application Framework

We have implemented a multi-level architecture on the platform, starting at the group level, with subsequent layers for company or command center levels, and down to the project level. This architecture consolidates construction data from various project sections, enabling owners to have a clearer understanding of the status of each section, thereby facilitating more informed decision-making. During actual usage, we often encounter situations where integration with other systems is required. Therefore, we have developed standardized data interfaces that allow for seamless integration with various third-party systems, including OA systems and various business management systems. This enables owners to manage data centrally on a single platform. All business management data flows within the platform and can be interconnected with BIM-GIS data, supporting bidirectional communication. When building the platform, processes, forms, and permissions are customizable according to the enterprise’s specific requirements. The use of the aforementioned engines within this platform has significantly enhanced the efficiency of progress management at the group level (

Figure 9).

5.4. Validation and Interviews

To validate the practical application value of the proposed BIM and AI integrated theoretical framework, this study conducted 15 semi-structured interviews to collect feedback from industry experts and participants in engineering projects. The interview questions were developed to explore the opportunities and challenges of integrating BIM and AI in schedule management as week as their implications and public acceptance. The interview questions serve as a guideline, and respondents were asked to provide explanation and informative examples when answering.

Table 9 summarizes the interview questions in the study. The interview protocol was designed to ensure methodological transparency, including participant recruitment, interview procedures, and data analysis methods.

This study adopted a purposive sampling strategy to ensure the inclusion of three stakeholder groups: technical experts (four individuals), including researchers and developers in the fields of BIM and AI; project management practitioners (six individuals), such as project managers and construction team leaders; and system end-users (five individuals), including on-site engineers, schedule managers, and construction supervisors. A total of 15 interviews were conducted. The interviewee selection aimed to cover a broad spectrum of stakeholders involved in BIM and AI integration in schedule management to enhance the study’s applicability.

The interviews were conducted using a semi-structured format, with questions tailored to the roles and experiences of the interviewees. Each interview lasted approximately 45–60 min and was recorded with the interviewees’ consent. To minimize researcher bias, the interviewer followed a standardized protocol and avoided leading questions. The interviews were transcribed verbatim, and thematic analysis was performed using open coding to identify key themes. Thematic saturation was achieved when no new themes emerged from the data.

The interview findings were analyzed using thematic analysis, and the results were organized into four main themes: practical effects and user acceptance, technical challenges and management issues, optimization directions for platform functionality, and feasibility of industry-wide promotion.

Practical Effects and User Acceptance: 12 of the 15 interviewees recognized the innovative value of BIM-AI integration in schedule management, highlighting data-driven optimization and improved decision-making. However, 40% of end-users noted interface complexity and mobile system lag under poor signal conditions.

Technical Challenges and Management Issues: 10 interviewees identified technical limitations, particularly in handling uncertainties like extreme weather. In total, 70% of project management practitioners cited resource allocation challenges due to varying skill levels and delays in executing complex instructions.

Optimization Directions for Platform Functionality: 50% of end-users suggested interface simplification, while 40% of technical experts recommended improving mobile system stability. 60% of interviewees emphasized strengthening data security mechanisms.

Feasibility of Industry-Wide Promotion: 11 interviewees acknowledged the framework’s potential for industry-wide promotion but noted the need for validation across different project types. In total, 70% of technical experts recommended pilot studies on various projects, and 60% of project management practitioners emphasized the need for training programs.

The interview findings of this study demonstrate the practical application value of the proposed BIM and AI integration framework in schedule management. Through thematic analysis, four main themes were identified: practical effects and user acceptance, technical challenges and management issues, optimization directions for platform functionality, and feasibility of industry-wide promotion. The findings align with prior research (e.g., Pan et al., 2023 [

10]), which emphasizes that BIM-AI integration can streamline complex workflows, shorten operation times, reduce risks, and optimize resource allocation. This study further reveals that the developed framework facilitates tactical decision-making, enabling continuous optimization of project operations throughout the entire project lifecycle under changing conditions.

However, several implementation bottlenecks were also confirmed, echoing challenges highlighted by Zhang et al. (2022) [

34], such as delay in real-time data processing and user operational inefficiencies. Delays in real-time data processing occasionally caused delayed warnings, suggesting the need to integrate edge computing technologies to reduce latency and improve system responsiveness. End user feedback identified “insufficient personnel skill matching” as a flaw, recommending the enhancement of the human resource management module through AI-driven personnel profiling to better match worker skills with task requirements. The framework presented in this study addresses the limitations of traditional static models by offering dynamic optimization and real-time feedback mechanisms (

Table 10). However, as the current work is drawn from a single case project, future research should aim to validate the framework’s generalizability across different project types and operational environments.

6. Discussions

The study revealed that integrating BIM and AI significantly enhances project scheduling efficiency, decision-making accuracy, and dynamic optimization capabilities through a three-layer framework of data collection, intelligent analysis, and visualized application.

The integration of BIM and AI represents a pivotal advancement in construction management theory, offering a robust solution to bridge the gap between static project planning and dynamic progress optimization. Unlike traditional methods that rely on static models and manual adjustments, our framework leverages AI’s machine learning capabilities to analyze BIM data in real-time, enabling predictive analytics and multi-objective optimization. This aligns with Pan et al. (2023) [

10], who emphasized that BIM-AI integration can streamline workflows and optimize resource allocation throughout the project lifecycle. Additionally, our framework addresses the limitations highlighted by Zhang et al. (2022) [

34] by incorporating edge computing technologies to reduce latency and improve system responsiveness, thus enhancing the practicality of BIM-AI integration in real-world scenarios.

Moreover, this study contributes to the theoretical foundation of intelligent construction management by introducing a novel 4-in-1 Network Diagram Engine and a Blueprint Engine. By embedding AI-driven predictive models within BIM’s data-rich environment, the framework theoretically redefines collaborative decision-making processes, aligning with emerging paradigms of Digital Twin integration (Jiang et al., 2021) [

44]. For example, these tools not only facilitate intuitive visualization and multi-dimensional analysis of progress data but also streamline complex task workflows, reducing errors and delays caused by manual interventions. The 4-in-1 Network Diagram Engine integrates Gantt charts, timeline network diagrams, double-coding network diagrams, and PERT charts into a unified platform, allowing users to dynamically switch between views and optimize scheduling strategies. In terms of schedule accuracy, the deviation was reduced by 42% compared to traditional Gantt charts, validated through 12 key milestones. Decision-making efficiency saw a 30% improvement in response time, with real-time chart updates processing over 100,000 data points and reducing the average response time from 45 min to 15 min. This innovation addresses the need for more efficient and flexible project management tools as identified by Nusen et al. (2021) [

11] and R.F. Tavares Neto et al. (2013) [

12].

From a practical standpoint, the proposed framework offers significant benefits for construction project management. Project managers can monitor progress in real-time, dynamically adjust resources, and continuously optimize task sequences, thereby enhancing both efficiency and quality. The system’s ability to identify potential delays and provide optimized adjustment strategies empowers managers to make quick, data-driven decisions. Furthermore, the platform’s multi-terminal design allows stakeholders to access project information anytime and anywhere, improving collaboration and transparency. However, it is important to note that while the framework demonstrates strong applicability in progress optimization and overall control, there is room for improvement in areas such as personnel skill matching, workload balancing, and user interface design to ensure broader adoption and effectiveness in diverse project environments.

7. Conclusions

This paper examines the application value of a dynamic optimization framework that deeply integrates BIM (Building Information Modeling) and AI (Artificial Intelligence) technologies in schedule management. The study found that the synergistic integration of BIM and AI significantly enhances efficiency and decision-making in scheduling.

BIM provides comprehensive project data and visualization models, serving as data-rich foundation. AI contributes through intelligent algorithms capable of data analysis, prediction, and multi-objective optimization. Together, they effectively bridges the gap between static project planning and dynamic progress optimization. BIM’s high-precision 3D models and real-time data streams fuel AI algorithms, while AI leverages machine learning to improve forecasting accuracy and optimize resource scheduling.

The BIM + GIS visualization platform and the 4-in-1 Network Diagram Engine further enhance this integration by enabling the intuitive visualization and multi-dimensional analysis of progress data. These tools facilitate collaborative decisions and real time task dispatch across all project stakeholders. Furthermore, in complex scenarios such as tunnel segment construction sequencing, the engine’s multi-view flexibility outperformed standalone tools, reducing the number of planning iterations by 60%. The drag-and-drop workflow automation of the task engine has led to measurable improvements in various aspects of task management. Workflow efficiency has been enhanced by 35%, with customized task flows (approval processes) reducing processing times from an average of 48 h to 31 h. Error avoidance has been significantly improved, with automatic form data association reducing task conversion errors by 88%, based on audits of over 500 tasks. The engine’s scalability allows for parallel processing of over 200 concurrent tasks without delay, as verified during peak operation testing at construction sites. User feedback indicates a 25% reduction in administrative coordination time, as reported by field engineers in a survey (n = 15). However, mobile delays remain an issue in weak signal areas, with response times reaching up to 8 s. The introduction of the Blueprint Engine adds another layer of functionality by streamlining automated management of complex task flows, reducing errors and delays caused by manual interventions. The event-triggered automation of the Blueprint Engine has demonstrated significant effectiveness in dynamic scheduling. AI-driven early warning systems have reduced cascading delays by 63%, with material delay alerts prompting a 3 h acceleration in resource adjustments. Real-time synchronization with vendor systems has shortened schedule adjustment time by 50%. Additionally, 78% of AI-generated resource reallocation recommendations were implemented, preventing a potential 14-day delay. However, despite the notable performance of the AI system, a 22% execution gap in recommendations remained, attributed to disparities in personnel skill levels. Among these engines, the combined BIM and AI progress management method demonstrates strong applicability. Project managers can monitor project progress in real-time, dynamically adjust resources, and continuously optimize task sequences, enhancing both efficiency and quality of the project.

This research provides empirical evidence and a validated framework for the theoretical proposition that deep integration of BIM (as a rich data source and visualization platform) and AI (for dynamic prediction and optimization) is essential for bridging the persistent gap between static project planning and the dynamic realities of construction execution. Furthermore, it demonstrates how real-time data feeds from BIM and IoT, combined with AI processing, can create a feedback loop enabling continuous schedule adaptation, thus advancing the theoretical understanding of dynamic control systems in construction management. Building on this, the study proposes and validates a novel, integrated framework, which provides a blueprint for future implementations of BIM-AI integration in schedule management. Additionally, we develop and demonstrate the efficacy of the “4-in-1 Network Diagram Engine” as a methodological tool for unifying disparate project management views (Gantt, network, resource, etc.) and enabling multi-dimensional analysis within a single platform, thereby enhancing collaborative decision-making.

However, while this framework performs excellently in progress optimization and effectively promotes overall control, several limitations remain. First, the current framework does not adequately address the variation in team members’ professional skills. This can lead to suboptimal resource allocation, where tasks may not be assigned to the most suitable personnel. Future iterations could integrate AI-driven dynamic skill profiling with optimization logic to generate competency-based task assignments. Reinforcement learning algorithms could further calibrate these assignments through continuous performance feedback. Additionally, the system lacks flexibility in dynamically balancing work loads, which may lead to overburdening or underutilization of certain roles-ultimately affecting operational efficiency. Second, the system interface may present usability challenges for users without a strong technical background. Data input and result interpretation processes are not sufficiently intuitive and straightforward; they may necessitate extensive training before users can operate the system proficiently. Future system designs should place more emphasis on user experience, making the interface more user-friendly, ensuring that users of varying technical skill levels can navigate the system with ease. Future designs must prioritize user experience (UX) principles, implementing AI-assisted interaction simplification. Lastly, delays in personnel scheduling often lead to lags in the implementation of AI-generated optimization plans. To address this, future systems should enable more agile personnel reallocation and tighter integration between human resources and optimization logic to ensure timely execution of plans. Future systems should incorporate agile reallocation mechanisms and tighter human–AI coordination, potentially via AI agents that proactively alert managers to reallocation needs based on real-time progress data, thereby accelerating decision-making.