A Review on the Aging Behavior of BADGE-Based Epoxy Resin

Abstract

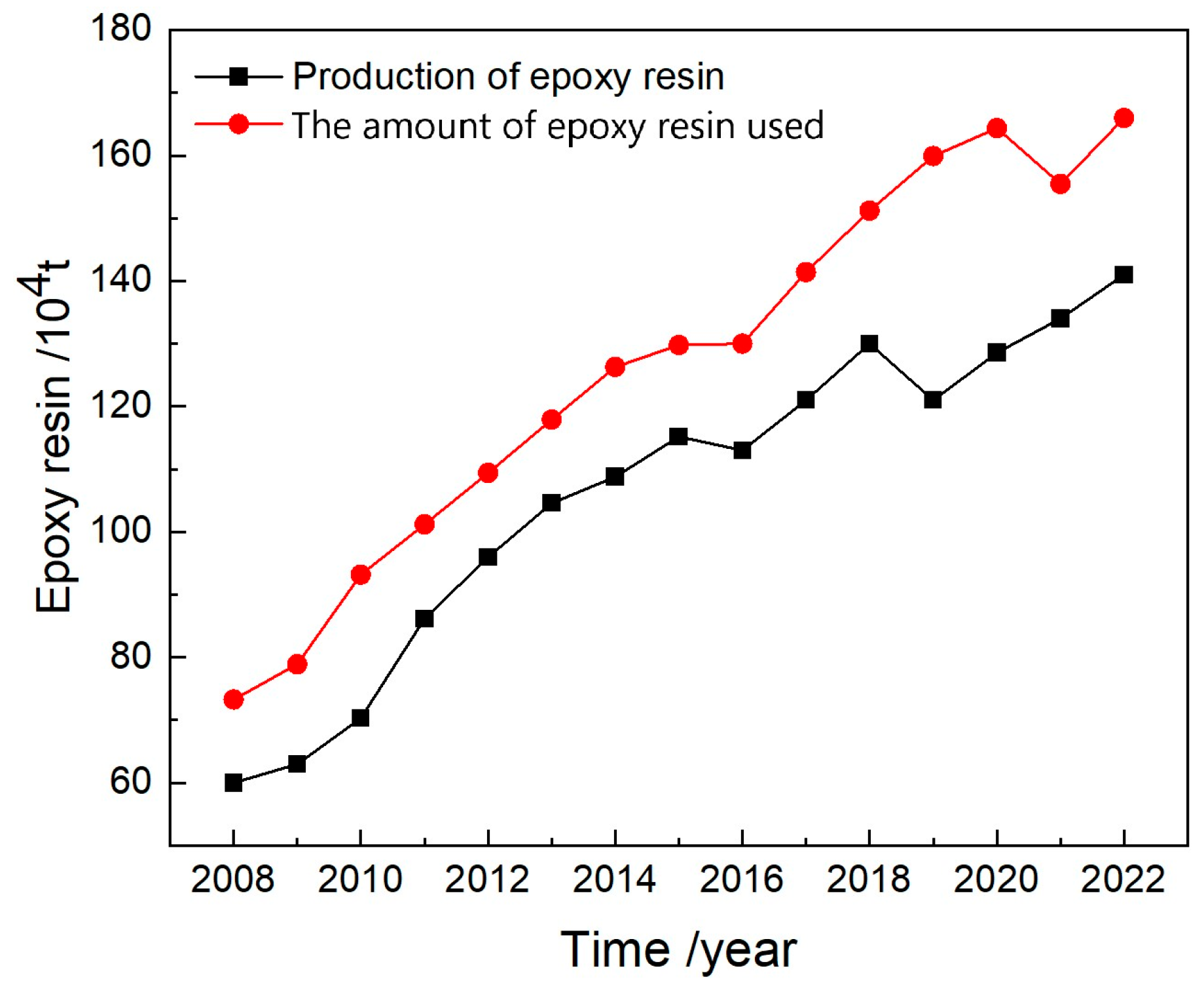

1. Introduction

2. Artificial Accelerated Aging Test

3. Aging Performance of BADGE-Based Epoxy Resin

3.1. Thermal Oxidative Aging

3.2. Hot and Humid Aging

3.3. Photochemical Oxidative Aging

4. Aging Performance of Filled BADGE-Based Epoxy Resin

5. Aging Performance of BADGE-Based Composite (FRP)

6. Aging Durability Prediction

6.1. Arrhenius Method

6.2. Other Aging Durability Prediction Methods

7. Conclusions

- During service, BADGE-based epoxy resin is susceptible to various environmental factors (such as temperature, air, rain, ultraviolet light, and corrosive media), leading to different aging phenomena. These factors result in changes to the microstructure, mechanical properties, and dynamic mechanical performance—for example, molecular chain breakage and weakening of the crosslinked structure after aging; the tensile strength, flexural strength, etc., may decrease by more than 30%; and the Tg shows a decline—thereby affecting its durability. Researching different forms of aging provides valuable insights into assessing the service life of BADGE-based epoxy resin. However, current research has predominantly considered aging factors in isolation, and there is a scarcity of studies investigating the aging performance of materials under the coupling effects of multiple factors.

- Adding fillers to BADGE-based epoxy resin as a matrix can improve the aging performance of composites, such as increasing the Tg and reducing weight loss, and also reduce costs. However, this often leads to a decrease in mechanical properties. For instance, the addition of fillers may increase the water absorption rate of the material and reduce its elastic modulus, compressive strength, and tensile strength. The performance changes are related to the type and characteristics of the fillers. Therefore, exploring the optimal filler content that maintains the material’s aging performance within acceptable limits is essential. Currently, the fillers used are primarily inorganic materials such as SiO2, Al2O3, and fly ash. In future research, other types of fillers should also be investigated to expand the scope of material improvement.

- Compared to pure BADGE-based epoxy resin, fiber-reinforced BADGE composites show improved aging resistance, with enhanced tensile properties and stiffness. The interfacial bonding effect between fibers and the resin matrix exhibits a significant positive correlation with the composites’ anti-aging performance. However, there has been limited focus on the aging of the resin–fiber interface. It is crucial to understand the degradation of the internal interface that occurs during the aging process.

- The prediction of the performance of BADGE-based epoxy resin after aging is primarily based on accelerated aging tests and empirical formulae to establish aging models; however, these models lack validation through long-term natural aging test data. Therefore, there may be significant errors in the prediction.

- Conduct natural aging tests on BADGE-based epoxy resin and epoxy resin-based composites under multiple factors. Most studies focus on the aging behavior of materials under heat–oxygen, wet–heat, and photo-oxygen conditions. However, the real-world environments of materials are far more complex, involving multiple conditions acting together. Therefore, aging studies incorporating multifactor coupling more accurately reflect the actual aging process of materials, and the results can provide a more precise analysis of their durability.

- Design natural aging tests under real environmental conditions. Artificial aging tests still differ significantly from natural environments, meaning the material degradation results obtained through these tests may have some degree of error. The aging models built from such data must also be validated and adjusted using long-term natural aging data. However, there is a lack of research on natural aging, and it is essential to conduct long-term studies on natural aging to analyze the aging process and predict the durability of materials, such as BADGE-based epoxy resin, more systematically.

- Establish a relationship between artificial and natural aging tests. Natural aging tests are unsuitable for large-scale aging studies. It is possible to compare the data of material degradation under similar aging conditions in both natural and accelerated aging environments. This comparison could help establish a correlation between the two methods, allowing for quick, convenient, and accurate determination of material aging performance.

- Research modification methods for BADGE-based epoxy resin and the interface performance between the modified matrix and the added materials. As aging progresses and the interface degrades, the material’s durability can be affected. However, there has been limited research on the interface between the matrix and added materials, so this area should be prioritized. Additionally, other effective modification methods should be explored to promote the development of BADGE-based epoxy resins.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Capricho, J.C.; Fox, B.; Hameed, N. Multifunctionality in epoxy resins. Polym. Rev. 2020, 60, 1–41. [Google Scholar] [CrossRef]

- Mi, X.; Liang, N.; Xu, H.; Wu, J.; Jiang, Y.; Nie, B.; Zhang, D. Toughness and its mechanisms in epoxy resins. Prog. Mater. Sci. 2022, 130, 100977. [Google Scholar] [CrossRef]

- Lee, H.; Neville, K. Book Review-Handbook of Epoxy Resins. Ind. Eng. Chem. 1967, 59, 16–17. [Google Scholar] [CrossRef]

- Zhiyan Consulting. 2025–2031 Market Development Situation and Industrial Demand Research Report on China’s Electronic Grade Epoxy Resin Industry; Zhiyan Consulting: Beijing, China, 2024. [Google Scholar]

- Wang, M.; Xu, X.; Ji, J.; Ji, J.; Yang, Y.; Shen, J.; Ye, M. The hygrothermal aging process and mechanism of the novolac epoxy resin. Compos. Part B Eng. 2016, 107, 1–8. [Google Scholar] [CrossRef]

- Siedlaczek, P.; Sinn, G.; Peter, P.; Jandl, J.; Hantal, G.; Wriessnig, K.; Wendner, R.; Lichtenegger, H. Hygrothermal aging of particle-filled epoxy-based composites. Polym. Degrad. Stab. 2023, 208, 110248. [Google Scholar] [CrossRef]

- Cavasin, M.; Sangermano, M.; Thomson, B.; Giannis, S. Exposure of glass fiber reinforced polymer composites in seawater and the effect on their physical performance. Materials 2019, 12, 807. [Google Scholar] [CrossRef] [PubMed]

- Xian, G.; Karbhari, V.M. Segmental relaxation of water-aged ambient cured epoxy. Polym. Degrad. Stab. 2007, 92, 1650–1659. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.M.; Chamberlain, D.A. Remediation and protection of masonry structures with crystallising moisture blocking treatment. Int. J. Build. Pathol. Adapt. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- ASTM D7444; Standard Practice for Heat and Humidity Aging of Oxidatively Degradable Plastics. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D7028; Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM: West Conshohocken, PA, USA, 2008.

- JIS K 7148-1:2022; Plastics-Epoxy Resins-Part 1: Determination of Degree of Crosslinking of Crosslinked Epoxy Resins by Differential Scanning Calorimetry (DSC). JSA: Tokyo, Japan, 2022.

- GB/T 15905-1995; Rubber, Vulcanized-Test Method of Damp Heat Aging. Standards Press of China: Beijing, China, 1995.

- ASTM D4329; Standard Practice for Exposure of Plastics to Ultraviolet Radiation. ASTM: West Conshohocken, PA, USA, 2021.

- ISO 4892-1; Plastics-Methods of Exposure to Laboratory Light Sources-Part 1: General Guidance. ISO: Geneva, Switzerland, 2024.

- ISO 4611; Plastics-Determination of the Effects of Exposure Todamp Heat, Water Spray and Salt Mist. ISO: Geneva, Switzerland, 2010.

- Frigione, M.; Rodriguez-Prieto, A. Can accelerated aging procedures predict the long term behavior of polymers exposed to different environments. Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Barbosa, A.P.C.; Fulco, A.P.P.; Guerra, E.S.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.B.; Melo, J.D.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. Part B Eng. 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Odegard, G.M.; Bandyopadhyay, A. Physical aging of epoxy polymers and their composites. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1695–1716. [Google Scholar] [CrossRef]

- Yu, B.; Jiang, Z.; Yang, J. Long-term moisture effects on the interfacial shear strength between surface treated carbon fiber and epoxy matrix. Compos. Part A Appl. Sci. Manuf. 2015, 78, 311–317. [Google Scholar] [CrossRef]

- Qin, G.; Na, J.; Mu, W.; Tan, W.; Yang, J.; Ren, J. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP-aluminum alloy joints. Compos. Part B Eng. 2018, 154, 43–55. [Google Scholar] [CrossRef]

- Gao, Y.L.; Cui, W.G.; Mou, W.; Xiong, J.P. Study on thermo-oxidation aging performance of epoxy adhesive. New Chem. Mater. 2011, 39, 72–74. [Google Scholar]

- Yang, Y.; Xian, G.; Li, H.; Sui, L. Thermal aging of an anhydride-cured epoxy resin. Polym. Degrad. Stab. 2015, 118, 111–119. [Google Scholar] [CrossRef]

- Moussa, O.; Vassilopoulos, A.P.; Castro, J.D.; Keller, T. Long-term development of thermophysical and mechanical properties of cold-curing structural adhesives. J. Appl. Polym. Sci. 2013, 127, 2490–2496. [Google Scholar] [CrossRef]

- Jeong, Y.; Lopez, M.M.; Bakis, C.E. Effects of sustained loading and temperature on a concrete–epoxy bonded interface. J. Mater. Civ. Eng. 2020, 32, 04020016. [Google Scholar] [CrossRef]

- Yi, J.H.; Wang, L.; Shang, B.; He, J.X.; Lei, J.L. Molecular dynamics modeling of the thermo-oxidative degradation in epoxy resin. Polym. Bull. 2023, 36, 505–513. [Google Scholar]

- Gibhardt, D.; Buggisch, C.; Meyer, D.; Fiedler, B. Hygrothermal aging history of amine-epoxy resins: Effects on thermo-mechanical properties. Front. Mater. 2022, 9, 826076. [Google Scholar] [CrossRef]

- Cao, Y.; Qian, X.; Liu, C.; Yang, J.; Xie, K.; Zhang, C. Controllable preparation of a novel epoxy/anhydride system with polyether-Polyester semi-interpenetrating structure and the excellent hydrothermal aging resistance properties. Polym. Degrad. Stab. 2019, 168, 108935. [Google Scholar] [CrossRef]

- Fiore, V.; Di, B.G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Lettieri, M.; Frigione, M. Natural and artificial weathering effects on cold-cured epoxy resins. J. Appl. Polym. Sci. 2011, 119, 1635–1645. [Google Scholar] [CrossRef]

- Mohamed, E.A.; Wu, H.-C. Flexural behavior of epoxy under accelerated hygrothermal conditions. Fibers 2017, 5, 25. [Google Scholar] [CrossRef]

- Cruz, R.; Correia, L.; Dushimimana, A.; Cabral-Fonseca, S.; Sena-Cruz, J. Durability of epoxy adhesives and carbon fibre reinforced polymer laminates used in strengthening systems: Accelerated ageing versus natural ageing. Materials 2021, 14, 1533. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.H.; Li, H.B. Effects of hydrothermal aging on properties of epoxy resin. Ordnance Mater. Sci. Eng. 2010, 33, 41–43. [Google Scholar]

- Ni, X.X.; Li, X.G.; Zhang, S.P.; Qiu, D.J. Aging behavior of epoxy-adhesive in typical atmospheric environments. Corros. Prot. 2010, 31, 276–278. [Google Scholar]

- De’nève, B.; Shanahan, M. Water absorption by an epoxy resin and its effect on the mechanical properties and infra-red spectra. Polymer 1993, 34, 5099–5105. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K.; Chen, L.; He, C.; Zhang, Y. Hydrothermal effects on the thermomechanical properties of high performance epoxy/clay nanocomposites. Polym. Eng. Sci. 2006, 46, 215–221. [Google Scholar] [CrossRef]

- Peng, B.; Pan, R.; Shan, Y.M. The aging resistance performance of the epoxy structural adhesive for structure strengthening. Ind. Constr. 2009, 39, 94–96. [Google Scholar]

- Yang, L. Wet-Hot Aging Properties Research on Joints of Segmental Precast Member with Glue Joint. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2017. [Google Scholar]

- Luo, H.; Kim, J.K.; Schubert, E.F.; Cho, J.; Sone, C.; Park, Y. Analysis of high-power packages for phosphor-based white-light-emitting diodes. Appl. Phys. Lett. 2005, 86, 243505. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Kishi, H.; Arimura, K.; Idesaki, A.; Kakibe, T.; Matsuda, S. Effect of γ-ray irradiation on epoxy network polymers with different curing agents. Polym. Adv. Technol. 2022, 33, 3740–3749. [Google Scholar] [CrossRef]

- Zhang, G.; Pitt, W.; Goates, S.; Owen, N. Studies on oxidative photodegradation of epoxy resins by IR-ATR spectroscopy. J. Appl. Polym. Sci. 1994, 54, 419–427. [Google Scholar] [CrossRef]

- Morsch, S.; Liu, Y.; Lyon, S.B.; Gibbon, S.; Gabriele, B.; Malanin, M.; Eichhorn, K. Examining the early stages of thermal oxidative degradation in epoxy-amine resins. Polym. Degrad. Stab. 2020, 176, 109147. [Google Scholar] [CrossRef]

- Delor-Jestin, F.; Drouin, D.; Cheval, P.-Y.; Lacoste, J. Thermal and photochemical ageing of epoxy resin-Influence of curing agents. Polym. Degrad. Stab. 2006, 91, 1247–1255. [Google Scholar] [CrossRef]

- Fu, C.Y. Research on Properties Evolution and Fatigue Properties of Resin Matrix Composites After UV Aging. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2020. [Google Scholar]

- Liu, J.; Jia, B.Y.; Tian, L.; Sun, Y.; Zheng, X.W.; Zhang, Z.M.; Yin X., Y.; Liu, H.C. Effect of UV aging on comprehensive properties of bisphenol a epoxy resin. Sci. Technol. Eng. 2022, 22, 8701–8707. [Google Scholar]

- Moosburger-will, J.; Greisel, M.; Horn, S. Physical aging of partially crosslinked RTM6 epoxy resin. J. Appl. Polym. Sci. 2014, 131, 205–212. [Google Scholar] [CrossRef]

- Mi, Y.; Liu, L.; Deng, S.; Gui, L.; Ouyang, W. Electrothermal aging characteristics of epoxy resin under bipolar exponential decay pulse voltage and its insulation life evaluation based on Cole-Cole model. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 784–791. [Google Scholar] [CrossRef]

- Tang, S. Effect of Sample Size on the Long-Term Properties of Epoxy Resins Immersed in Water and Alkaline Solution. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Lang, J.; Li, M.; Niu, H.; Yang, W.; Chen, Y.; Wang, K.; Feng, Y.; Li, S. Study on the post-curing reaction of epoxy resin during aging. In Proceedings of the 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), Shanghai, China, 7–10 May 2023; pp. 1–4. [Google Scholar]

- Sivasankaraiah, T.; Lokavarapu, B.R.; Rajesh, J.V. Post-curing effect on flexural strength of glass epoxy composites. Mater. Today Proc. 2021, 38, 3320–3331. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Torres-Giner, S.; Boronat, T.; Montanes, N. Optimization of the curing and post-curing conditions for manufacturing partially bio-based epoxy resins with improved toughness. Polymers 2019, 11, 1354. [Google Scholar] [CrossRef]

- Coniglio, N.; Nguyen, K.; Kurji, R.; Gamboa, E. Characterizing water sorption in 100% solids epoxy coatings. Prog. Org. Coat. 2013, 76, 1168–1177. [Google Scholar] [CrossRef]

- Moghtadernejad, S.; Barjasteh, E.; Johnson, Z.; Stolpe, T.; Banuelos, J. Effect of thermo-oxidative aging on surface characteristics of benzoxazine and epoxy copolymer. J. Appl. Polym. Sci. 2021, 138, 50211. [Google Scholar] [CrossRef]

- Ai, J.; Cheng, W.; Wang, P.; Qian, W.; Chen, Q. Silica solid particles toughening, strengthening, and anti-aging on epoxy resin. J. Appl. Polym. Sci. 2021, 138, 50331. [Google Scholar] [CrossRef]

- Vu, C.M.; Van Vu, T. Influence of SiO2@ PANI Core/Shell Particles on Mechanical Properties, Electrical Properties, and Thermal Aging of Epoxy Resin. Silicon 2024, 16, 25–33. [Google Scholar] [CrossRef]

- Tcherbi-Narteh, A.; Hosur, M.; Triggs, E.; Owuor, P.; Jelaani, S. Viscoelastic and thermal properties of full and partially cured DGEBA epoxy resin composites modified with montmorillonite nanoclay exposed to UV radiation. Polym. Degrad. Stab. 2014, 101, 81–91. [Google Scholar] [CrossRef]

- Pattanaik, A.; Mukharjee, M.; Mishra, S.C. Effect of environmental aging conditions on the properties of fly ash filled epoxy composites. Adv. Compos. Mater. 2020, 29, 1–30. [Google Scholar] [CrossRef]

- Fan, H.; Zhao, J.; Zhang, J.; Li, H.; Zhang, S.; Sun, J.; Xin, F.; Liu, F.; Qin, Z.; Tang, W. TiO2/SiO2/kaolinite hybrid filler to improve the flame retardancy, smoke suppression and anti-aging characteristics of epoxy resin. Mater. Chem. Phys. 2022, 277, 125576. [Google Scholar] [CrossRef]

- Panchal, P.; Mekonnen, T.H. Tailored cellulose nanocrystals as a functional ultraviolet absorbing nanofiller of epoxy polymers. Nanoscale Adv. 2019, 1, 2612–2623. [Google Scholar] [CrossRef]

- Wang, W.J.; Li, H.X.; Zhang, S.W. Wet and heat ageing resistance of the building structural adhesives. Build. Struct. 2007, 37, 386–388. [Google Scholar]

- Li, Q.; Hu, Q.Y.; Pan, Z.H.; Liu, W.; Ma, W.S. Study on modified epoxy resin filled with waste bakelite powder. China Adhes. 2022, 31, 8–14. [Google Scholar]

- Brun, E.; Rain, P.; Teissedre, G.; Guillermin, C.; Rowe, S. Hygrothermal Aging of a Filled Epoxy Resin. In Proceedings of the 2007 IEEE International Conference on Solid Dielectrics, Winchester, UK, 8–13 July 2007; IEEE: Winchester, UK, 2007; pp. 239–242. [Google Scholar]

- Yan, D.; Li, M.Y.; Jiang, J.L.; Zhang, Y.; Li, D.Q. Thermal conductivity of epoxy composite filled with Al2O3. Plastics 2017, 46, 110–113. [Google Scholar]

- Wang, Y.D.; Zheng, Y.P.; Song, S.; Yao, D. Effect of particle size and content of SiO2 solvent-free nanofluid on mechanical and thermal properties of epoxy resin. J. Mater. Eng. 2021, 49, 156–163. [Google Scholar]

- Goyanes, S.; König, P.; Marconi, J. Dynamic mechanical analysis of particulate-filled epoxy resin. J. Appl. Polym. Sci. 2003, 88, 883–892. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Reddy, K.R.; Nazari, A. Effect of elevated in-service temperature on particulate-filled epoxy polymers’ mechanical properties and microstructure. Polym. Degrad. Stab. 2019, 170, 108994. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Nguyen, K.T.; Hota, G. Aging of particulate-filled epoxy resin under hygrothermal conditions. Constr. Build. Mater. 2020, 249, 118846. [Google Scholar] [CrossRef]

- Xu, L.; Tu, Y.M.; Cui, H.; Zhou, S. Effect of aging cycle on T800 carbon fiber/epoxy resin composites in seawater environment. J. Mater. Eng. 2022, 50, 89–94. [Google Scholar]

- Tran, P.; Nguyen, Q.T.; Lau, K.T. Fire performance of polymer-based composites for maritime infrastructure. Compos. Part B Eng. 2018, 155, 31–48. [Google Scholar] [CrossRef]

- Lan, Z.; Deng, J.; Xu, Z.; Ye, Z.; Nie, Y. Study of heat treatment effect on mechanical properties of epoxy resin reinforced with fiber glass. Polymers 2023, 15, 2734. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.D.; An, T.; Zou, T.C.; Gong, T.C. Effect of hygrothermal environment on mechanical properties and damage mechanism of CFRP. J. Mater. Eng. 2019, 47, 84–91. [Google Scholar]

- Li, B.; Shi, D.W.; Wi, J.H. Preparation and properties of flax fiber reinforced epoxy resin composites for automobile interior decoration. Wool. Text. J. 2022, 50, 13–17. [Google Scholar]

- Kajorn, S.; Gupta, R.K.; Gangarao, H.V. Effect of aging environment on degradation of glass-reinforced epoxy. J. Compos. Constr. 2002, 6, 61–69. [Google Scholar]

- Wang, Y.; Meng, Z.; Zhu, W.; Wan, B.; Bai, Y. Hygrothermal aging behavior and aging mechanism of carbon nanofibers/epoxy composites. Constr. Build. Mater. 2021, 294, 123538. [Google Scholar] [CrossRef]

- Wang, B.; Ci, S.; Zhou, M.; Di, C.; Yu, J.; Zhu, B.; Qiao, K. Effects of hygrothermal and salt mist ageing on the properties of epoxy resins and their composites. Polymers 2023, 15, 725. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gangarao, H.; Liang, R.; Liu, W. A critical review of the durability and prediction models of fiber-reinforced polymer composites under various environmental conditions. J. Reinf. Plast. Compos. 2016, 35, 179–211. [Google Scholar] [CrossRef]

- Capela, C.; Oliveira, S.; Ferreira, J. Fatigue behavior of short carbon fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 164, 191–197. [Google Scholar] [CrossRef]

- Wang, D.X.; Sun, Y.; Xie, K.Y.; Li, H.; Wang, X.B.; Duan, J.; Shao, M. Long term aging and failure behaviors of carbon fiber reinforced polymer composites in simulated marine environments. Acta Mater. Compos. Sin. 2022, 39, 1353–1362. [Google Scholar]

- Vukovic, F.; Walsh, T.R. Moisture ingress at the molecular scale in hygrothermal aging of fiber–epoxy interfaces. ACS Appl. Mater. Interfaces 2020, 12, 55278–55289. [Google Scholar] [CrossRef]

- Abanilla, M.A.; Yan, L.; Karbhari, V.M. Durability characterization of wet layup graphite/epoxy composites used in external strengthening. Compos. Part B 2005, 37, 200–212. [Google Scholar] [CrossRef]

- Qiao, K.; Zhu, B.; Gao, X.P.; Xie, B.; Yuan, H.; Wu, Y.M.; Zhang, C.L. Influence of artificial accelerating UV aging on carbon fiber reinforced epoxy composite. J. Funct. Mater. 2012, 43, 2989–2992. [Google Scholar]

- Jia, Y.X.; Xu, L.; Ao, Q.Y.; Zhang, W.Z.; Wang, T.; Wei, J. Effects of different thermal-oxidative environments on mechanical properties of T800 carbon fiber/epoxy resin composites. J. Mater. Eng. 2022, 50, 156–161. [Google Scholar]

- Silva, M.A.; Da, F.B.S.; Biscaia, H. On estimates of durability of FRP based on accelerated tests. Compos. Struct. 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Ageing of carbon/epoxy and carbon/vinyl ester composites used in the reinforcement and/or the repair of civil engineering structures. Compos. Part B Eng. 2012, 43, 2020–2030. [Google Scholar] [CrossRef]

- Wang, G.J.; Sun, Y.N.; Jiang, W.L. Aging behavior of glass fiber reinforced epoxy resin composite in warm-wet and ultraviolet irradiation environment. Mater. Mech. Eng. 2018, 42, 11–15+20. [Google Scholar] [CrossRef]

- Meyer, M.R.; Friedman, R.J.; Schutte, H.D.; Latour, R.A. Long-term interface durability in FRP composites after exposure to simulated physiologic saline environments. J. Biomed. Mater. Res. 1994, 28, 1221–1231. [Google Scholar] [CrossRef]

- Gerritse, A. Assessment of long-term performance of FRP bars in concrete structures. In Proc, Durability of Fiber Reinforced Polymers (FRP) Composites for Construction; Universite de Sherbrooke: Sherbrooke, Canada, 1998; pp. 285–297. [Google Scholar]

- Anderson, B.J. Thermal stability of high-temperature epoxy adhesives by thermogravimetric and adhesive strength measurements. Polym. Degrad. Stab. 2011, 96, 1874–1881. [Google Scholar] [CrossRef]

- Eldridge, A.; Fam, A. Environmental aging effect on tensile properties of GFRP made of furfuryl alcohol bioresin compared to epoxy. J. Compos. Constr. 2014, 18, 04014010. [Google Scholar] [CrossRef]

- Aiello, M.; Leone, M.; Aniskevich, A.; Starkova, O.A. Moisture effects on elastic and viscoelastic properties of CFRP rebars and vinyl ester binder. J. Mater. Civ. Eng. 2006, 18, 686–691. [Google Scholar] [CrossRef]

- Chang, X.L.; Yu, Y.F.; Zhang, Y.H.; Long, B.; Kuan, H.U.; Zhao, F. Storage life prediction of NEPE propellant based on hygrothermal aging experiment. Aerospace 2010, 27, 57–60. [Google Scholar]

- Zhang, X.J.; Chang, X.L.; Chen, X.S.; Fan, S.F. Hygrothermal aging testing and life assessment for solid rocket motor adhesive interface. J. Solid. Rocket. Technol. 2013, 36, 27–31. [Google Scholar]

- Li, X.J.; Sun, S.; Liu, L.X.; Hui, T.L.; Yu, W.T.; Yang, Y.D.; Tang, X.J.; Wan, L.; Zhu, X.X. Prediction of nitrile butadiene rubber storage life for spacecraft based on hygrothermal aging test. Spacecr. Environ. Eng. 2022, 39, 539–544. [Google Scholar]

- Huang, C.; Tao, C.H.; Wang, Z.B.; Fan, J.J.; Hou, X.Q. T300/648 composite material hygrothermal aging behavior and life prediction of storage. J. Ordnance Equip. Eng. 2013, 34, 137–140. [Google Scholar]

- Gao, J.Y.; Hong, B.; Gao, Z.D.; Ji, Y.; Li, X.Q. Study on the hydrothermal aging law of carbon fiber reinforced epoxy resins. Thermosetting Resin. 2018, 33, 56–59. [Google Scholar]

- Meshgin, P.; Choi, K.-K.; Taha, M.M.R. Experimental and analytical investigations of creep of epoxy adhesive at the concrete–FRP interfaces. Int. J. Adhes. Adhes. 2009, 29, 56–66. [Google Scholar] [CrossRef]

- Kim, Y.J.; Hossain, M.; Yoshitake, I. Cold region durability of a two-part epoxy adhesive in double-lap shear joints: Experiment and model development. Constr. Build. Mater. 2012, 36, 295–304. [Google Scholar] [CrossRef]

- Yu, D.C. Study on the Joint Durability of Bridge Precast Section Beams by Freeze-Thaw and Carbonization in North Hebei Region. Master’s Thesis, Hebei University of Architecture, Zhangjiakou, China, 2020. [Google Scholar]

- Ali, A.H.; Benmokrane, B.; Mohamed, H.M.; Manalo, A.; El-Safty, A. Statistical analysis and theoretical predictions of the tensile-strength retention of glass fiber-reinforced polymer bars based on resin type. J. Compos. Mater. 2018, 52, 2929–2948. [Google Scholar] [CrossRef]

- Liu, X.D.; Su, Q.Y.; Zhu, J.; Song, X. The aging behavior and life prediction of CFRP rod under hygrothermal environment. Polymers 2023, 15, 2490. [Google Scholar] [CrossRef]

| Aging Test Category | Main Test Environmental Parameters | Test Purpose or Application |

|---|---|---|

| Thermo-oxidative aging | Temperature: 70–180 °C; oxygen concentration: around 21%. | Evaluate the durability and life of materials in high-temperature and oxygen environments. |

| Hygrothermal aging | Temperature: 40–85 °C; relative humidity (RH): 60–95%. | To evaluate the durability and service life of materials under a high-temperature and high-humidity environment. |

| Photo-oxidation aging | Oxygen concentration: around 21%; light intensity and wavelength: variable; temperature: room temperature. | Study of material performance changes under solar light and oxygen exposure. |

| Physical and chemical aging | Stress and chemical substances are determined based on practical applications. | Evaluate the durability and service life of epoxy resins and their composites. |

| Electrical–thermal aging | Temperature and current: range should be determined according to the application environment. | The durability of materials in an electrothermal environment is simulated with different temperatures and currents. |

| Salt fog aging | Temperature: 35–50 °C; RH: ≥95%; salt spray concentration: 5–10%. | Simulate salt spray corrosion in marine environments to test the material’s corrosion resistance. |

| Thermal cycling aging | Temperature cycle: high-temperature and low-temperature cycle. | Study the material’s relevant performance changes under temperature cycling. |

| Oxygen exposure aging | High-oxygen environment, according to the application environment. | Evaluate the material’s oxidation stability in a high-oxygen environment. |

| Electron beam irradiation | Irradiation using high-energy electron beams. | Study the performance changes in materials under a radiation environment. |

| Component | Environment | Water Absorption | Performance Change | Ref. |

|---|---|---|---|---|

| BADGE/PEI | 70 °C, RH 75% for 34 d | The water absorption increased rapidly in the first 14 d and then stabilized, and the water absorption rate is 1.55% | Tg decreased by 5 °C; the flexural modulus decreased by 35% in the first 7 d and then stabilized; the bending strength was reduced by 31%. | [30] |

| BADGE/DEA | Wet–heat cycle 625 times at 25, 100, 180 °C and RH 100% | — | The flexural strength decreases by 16.5% and 39% at 100 °C and 180 °C, respectively; the stiffness changes are similar, approximately 11–33% lower. | [31] |

| BADGE/AA | 20 °C, RH 100%, 2 years | The water absorption is fast in the early stage and then tends to be stable; the maximum water absorption is 5% | The tensile properties decrease with time and reduce by 25% after 2 years. | [32] |

| BADGE/DDS | 80 °C, RH 90%, 900 h | In the early stage, the growth rate is fast, with a balance of 5.15% | The tensile strength decreased by 40%, and the storage modulus decreased by 38.8%. | [33] |

| BADGE/PA | One-year atmospheric environmental aging experiment | — | The shear strength decreases exponentially, with a maximum decrease of 53.1%. The tensile strength decreases linearly and decreases by 50% after one year. | [34] |

| Component | Aging Form | Performance Changes Due to Post-Curing | Ref. |

|---|---|---|---|

| Epoxy resins BADGE/PA | Thermo-oxidative aging | The shear strength increases in the first 5 days of aging and then decreases continuously; the higher the temperature, the greater the decrease. | [22] |

| BADGE/DETA | Thermo-oxidative aging | The tensile strength and stiffness at 60 °C increase by 7 days before aging, and the stiffness increases by about 15%. | [24] |

| BADGE/DDS | Thermo-oxidative aging | When the temperature is within 40–140 °C, the post-curing increases the bending strength. | [51] |

| BADGE/DEA | Photo-oxidation aging | The curing degree reaches the maximum after 7 d of aging, and the tensile and flexural strength reach the peak on the 7th day, which increase by 6.2% and 6.7%, respectively; the tensile modulus rises to the peak on the 3rd day, increasing by 4.1%, and then shows a decreasing trend. | [45] |

| BADGE/EDA | Thermo-oxidative aging | A post-curing phenomenon at higher temperatures (80, 90 °C) strengthens the flexural strength. | [52] |

| MIX ID | Conditioned (RH 98%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| RT | 40 °C | 60 °C | |||||||

| 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | |

| Compressive strength retention (%) | |||||||||

| F0 | 100 | 98.03 | 96.17 | 97.59 | 96.39 | 93.87 | 94.97 | 92.78 | 91.14 |

| F20 | 100 | 97.11 | 96.00 | 98.11 | 95.77 | 94.44 | 96.77 | 94.99 | 92.66 |

| F40 | 100 | 99.22 | 97.76 | 98.65 | 97.76 | 96.86 | 97.65 | 96.52 | 95.40 |

| F60 | 100 | 97.72 | 96.29 | 99.29 | 96.58 | 95.44 | 97.29 | 95.58 | 93.44 |

| Tensile strength retention (%) | |||||||||

| F0 | 100 | 97.64 | 95.54 | 97.64 | 96.06 | 93.18 | 94.49 | 93.18 | 89.76 |

| F20 | 100 | 96.89 | 96.19 | 96.19 | 95.50 | 92.73 | 94.46 | 92.73 | 91.00 |

| F40 | 100 | 98.25 | 95.80 | 96.75 | 95.10 | 93.01 | 94.76 | 91.96 | 91.26 |

| F60 | 100 | 98.55 | 96.62 | 97.10 | 94.20 | 93.82 | 94.69 | 92.27 | 91.30 |

| Flexural strength retention (%) | |||||||||

| F0 | 100 | 97.33 | 93.93 | 98.62 | 94.85 | 91.82 | 95.77 | 92.92 | 88.88 |

| F20 | 100 | 95.57 | 94.41 | 98.46 | 95.57 | 92.68 | 95.38 | 92.87 | 89.02 |

| F40 | 100 | 97.41 | 94.81 | 99.53 | 94.58 | 94.10 | 96.93 | 94.10 | 90.57 |

| F60 | 100 | 96.21 | 94.95 | 98.11 | 94.64 | 94.01 | 95.27 | 94.32 | 91.17 |

| Fiber Type | Dosage | Aging Form | Aging Properties of BADGE | Aging Properties of Fiber-BADGE | Ref. |

|---|---|---|---|---|---|

| Glass fiber | 47 wt% glass fiber | Chemical aging | The tensile strength decreases with an increase in aging time; the E change is insignificant at approximately 0.45 GPa. | The tensile strength has been dramatically improved and remains superior to that of the resin after aging. The E is 2.8 GPa. | [74] |

| Carbon nanofibers | 0.25–2 wt% carbon nanofibers | Hygrothermal aging | Temperature promotes moisture absorption, and the trend conforms to Fick’s law. The tensile strength, E, and δ decrease gradually; Tg decreases by 25.6%. | Water absorption is lower than that of the resin. The tensile strength, E, and δ after aging at 0.5 wt% are 18.4%, 7.5%, and 11.6% higher than those of the resin, and the Tg is 65.3 °C. | [75] |

| Glass fiber | The fiber volume content is 55 ± 5%. | Photo-oxidation aging | The color changes noticeably, and the mass loss rate is 0.32%. The tensile and flexural strengths of the aged material at 28 days are 54.9 and 89.8 MPa, respectively, which represent a decrease of 2.3% and 2%. | Fiber delays the oxidation of materials, and its tensile and flexural strength are much higher than those of epoxy resin. Tg decreased less than that of resin. | [45] |

| Carbon fiber | The fiber volume content is 58% | Hygrothermal aging | Water absorption conforms to Fick’s law and stabilizes at 1.1%; as the aging process develops, the density gradually decreases. | Flexural and impact strength are strengthened, with values of 760 MPa and 310 J/m2, respectively, after aging, which decreases by 5.4% and 19%. | [76] |

| Material | Aging Form | Model | Index | Prediction Result | Ref. |

|---|---|---|---|---|---|

| BADGE and filled BADGE | Hygrothermal aging | Arrhenius | Tensile, flexural, and compressive strength | After aging at 30 °C for 100 years, the strength retention rate is above 70%. | [68] |

| BADGE-based GFRP | Hygrothermal aging | Arrhenius | Tensile strength | After 100 years of service at 3, 10, and 20 °C, the strength retention rates are 65%, 61%, and 50%, respectively. | [90] |

| BADGE-based CFRP | Hygrothermal aging | Generalized Eyring | Shear strength | Based on the failure criterion of a 30% loss of shear strength, the storage life at 20 °C and 60% RH is 31 years. | [95] |

| BADGE-based CFRP | Hygrothermal aging | Generalized Eyring | Flexural strength | Taking a 30% decrease in flexural strength as the failure criterion, the life at 20 °C and RH 90% is 11.4 years. | [96] |

| BADGE-based GFRP | Chemical aging | Arrhenius | Tensile strength | After 200 years of aging in an alkaline solution at 10 °C and 30 °C, the tensile strength retention rates are 83% and 69%, respectively. | [100] |

| BADGE-based CFRP | Hygrothermal aging | Arrhenius | Shear strength | After aging at 8.1, 15.8, and 21.8 °C, the shear strength retention rate remains stable at approximately 73%. When the shear strength retention rate reaches 90%, it takes 1442, 881, and 611 days. | [101] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W.; Jiang, X.; He, R.; Zheng, Y.; Dai, D.; Huang, L.; Yao, X. A Review on the Aging Behavior of BADGE-Based Epoxy Resin. Buildings 2025, 15, 2450. https://doi.org/10.3390/buildings15142450

He W, Jiang X, He R, Zheng Y, Dai D, Huang L, Yao X. A Review on the Aging Behavior of BADGE-Based Epoxy Resin. Buildings. 2025; 15(14):2450. https://doi.org/10.3390/buildings15142450

Chicago/Turabian StyleHe, Wei, Xinshuo Jiang, Rong He, Yuchao Zheng, Dongli Dai, Liang Huang, and Xianhua Yao. 2025. "A Review on the Aging Behavior of BADGE-Based Epoxy Resin" Buildings 15, no. 14: 2450. https://doi.org/10.3390/buildings15142450

APA StyleHe, W., Jiang, X., He, R., Zheng, Y., Dai, D., Huang, L., & Yao, X. (2025). A Review on the Aging Behavior of BADGE-Based Epoxy Resin. Buildings, 15(14), 2450. https://doi.org/10.3390/buildings15142450