AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

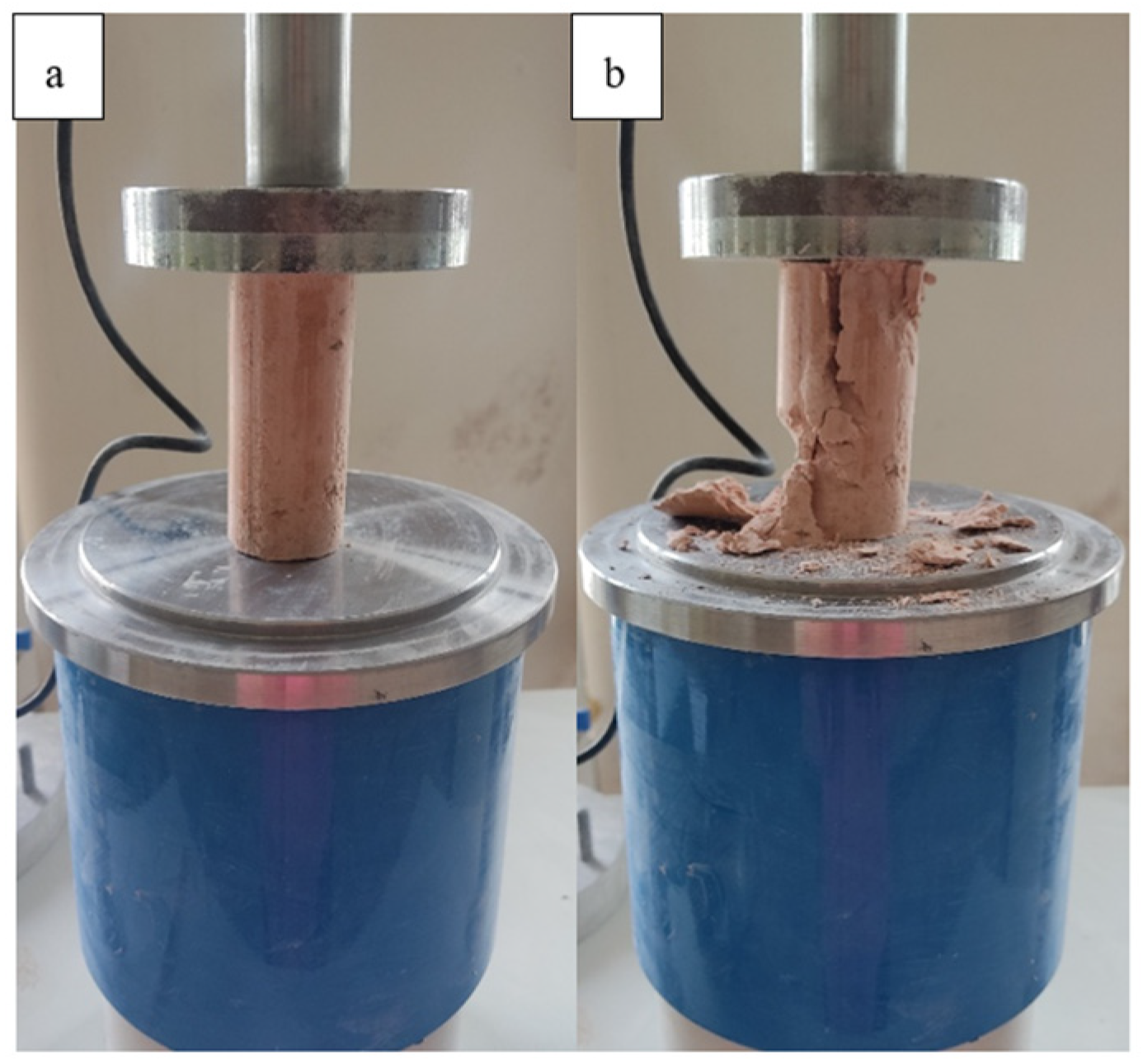

2.3. Methods

3. Experimental Analysis

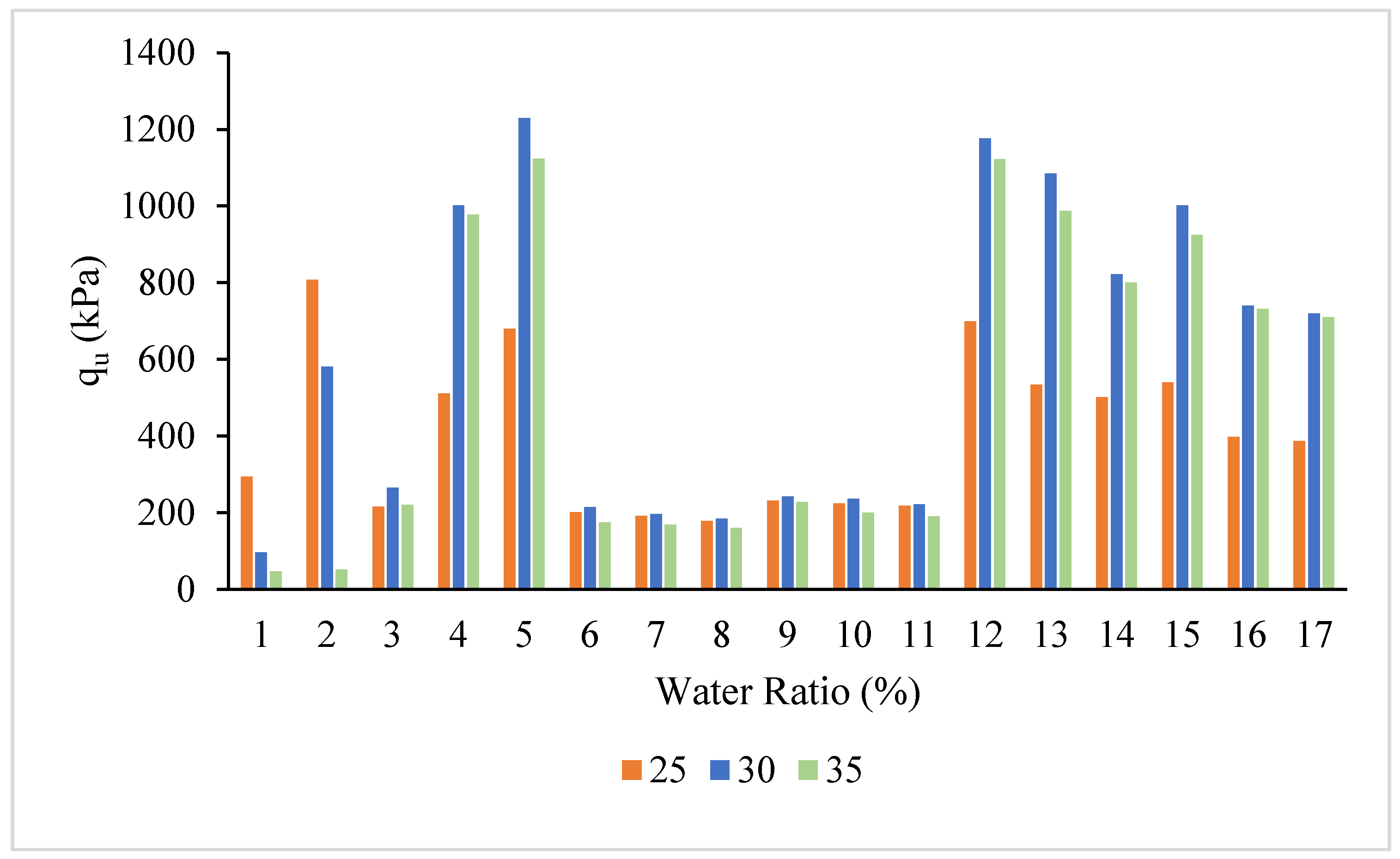

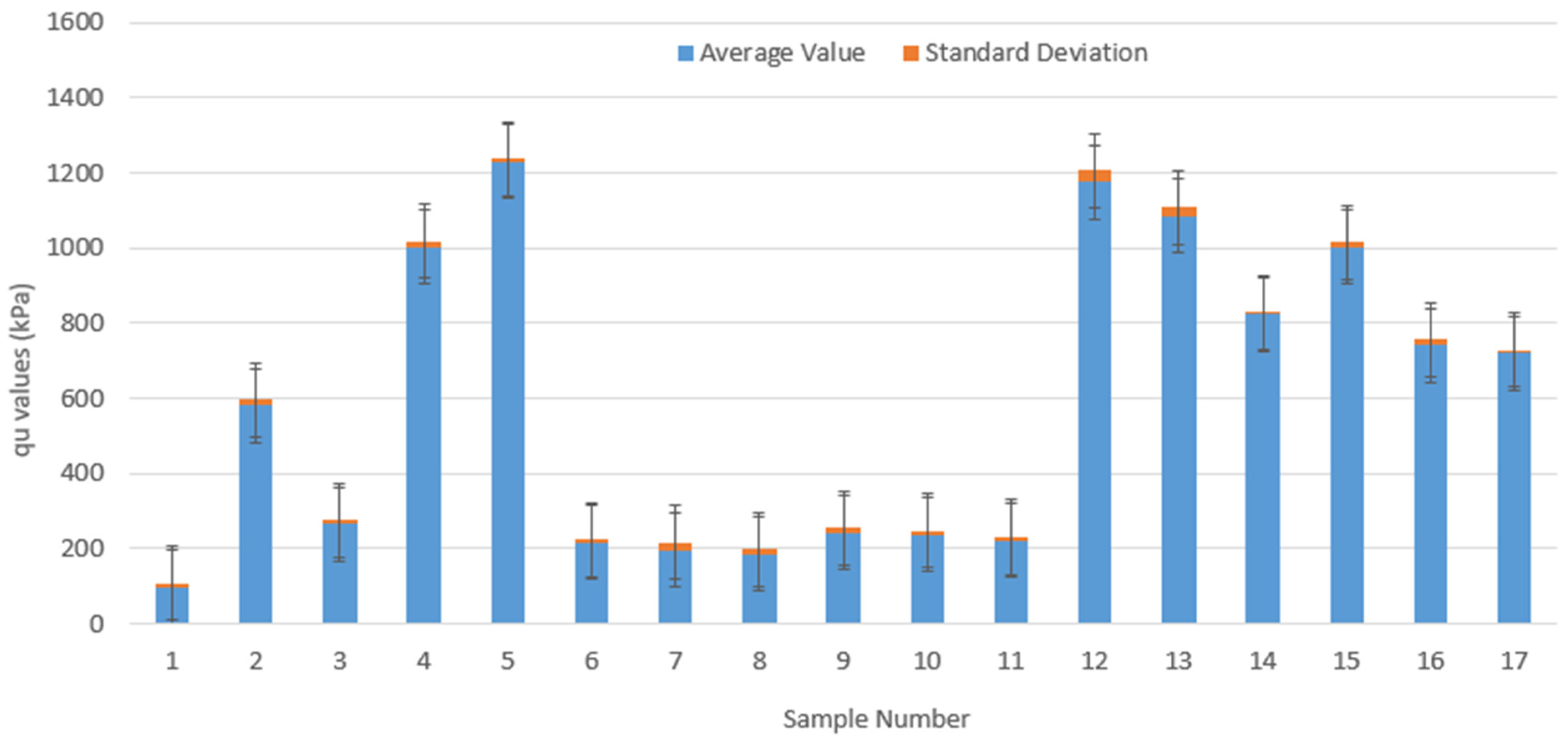

3.1. Changes in Unconfined Compressive Strength Before Curing

3.2. Changes in Unconfined Compressive Strength After Curing

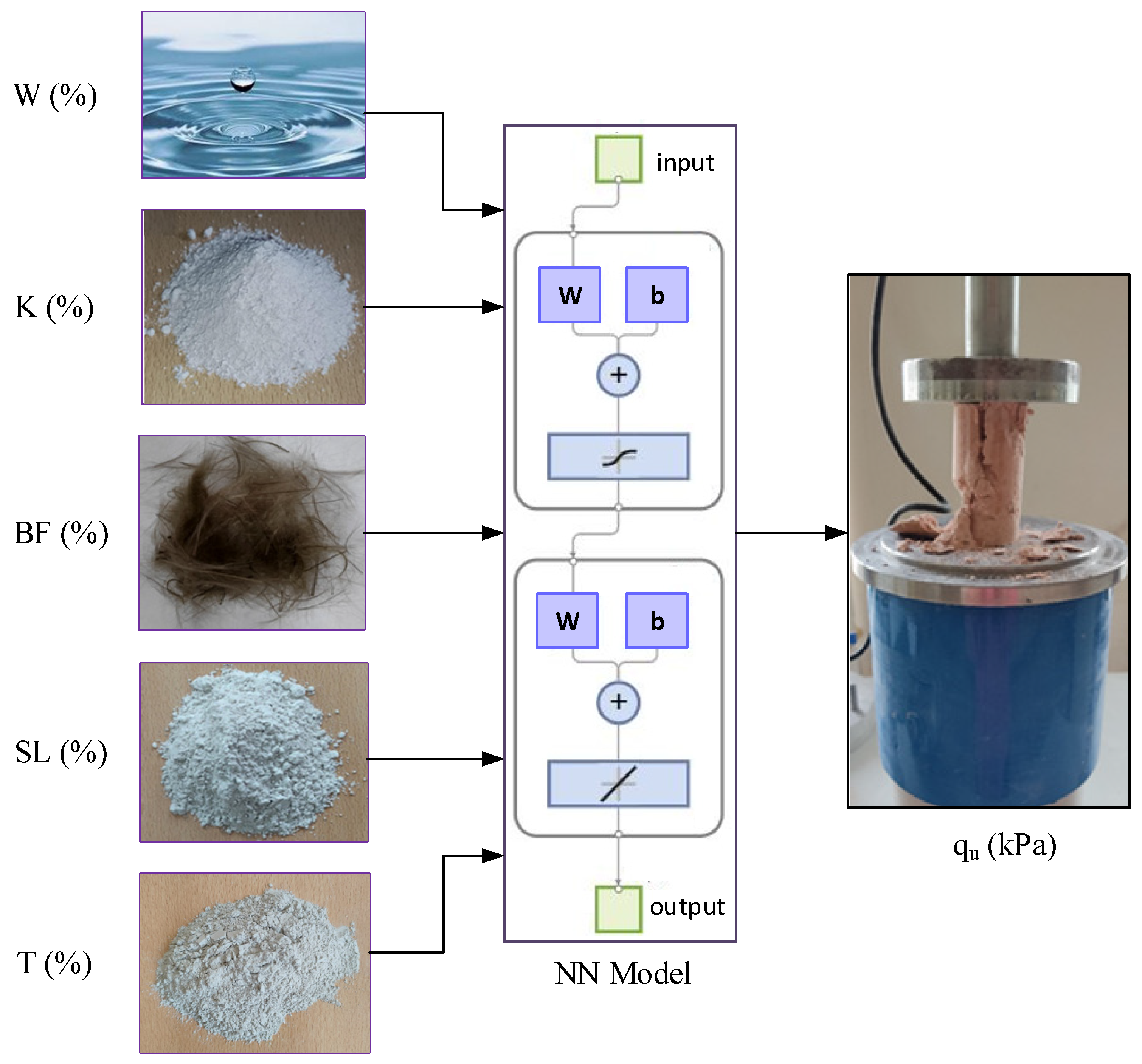

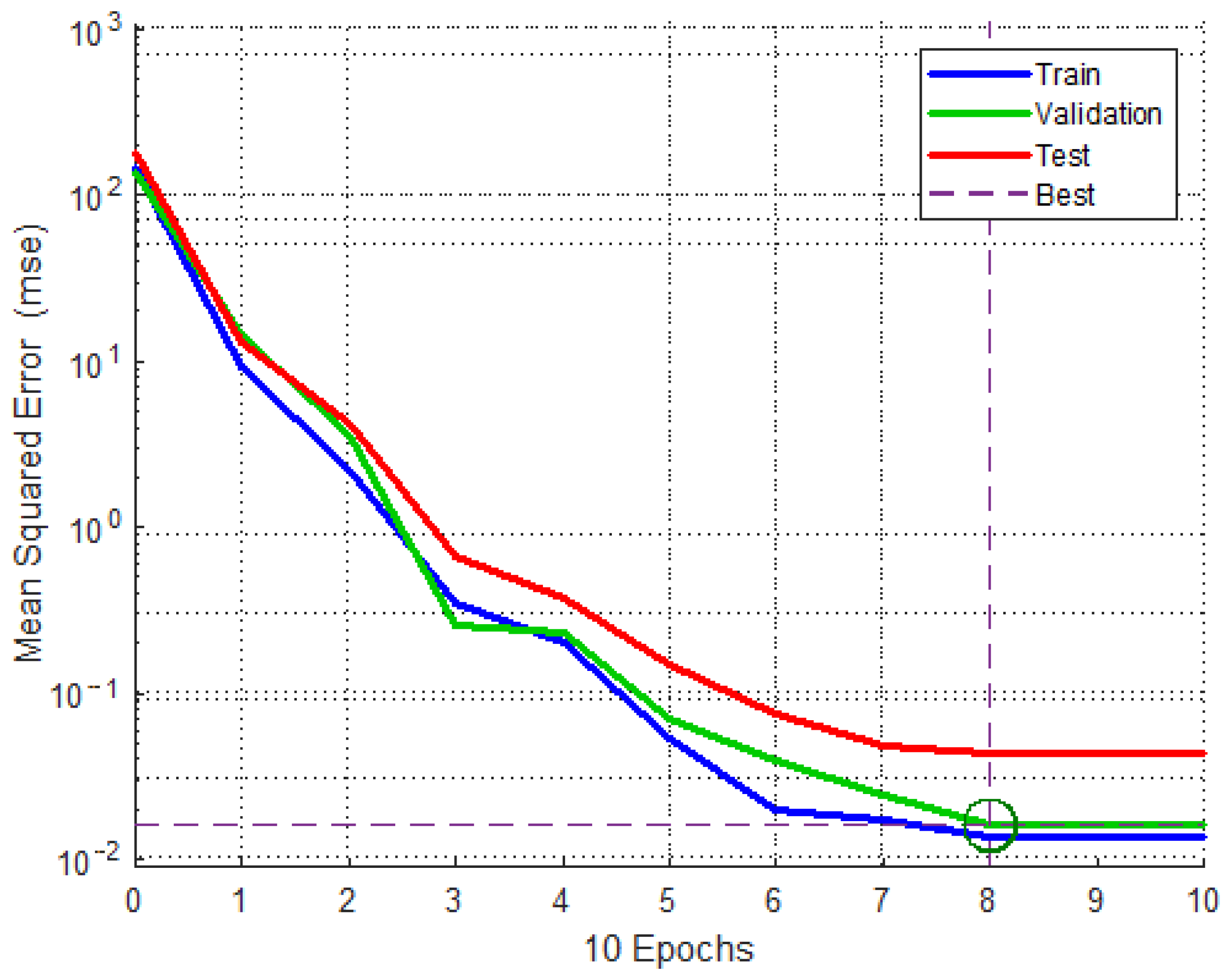

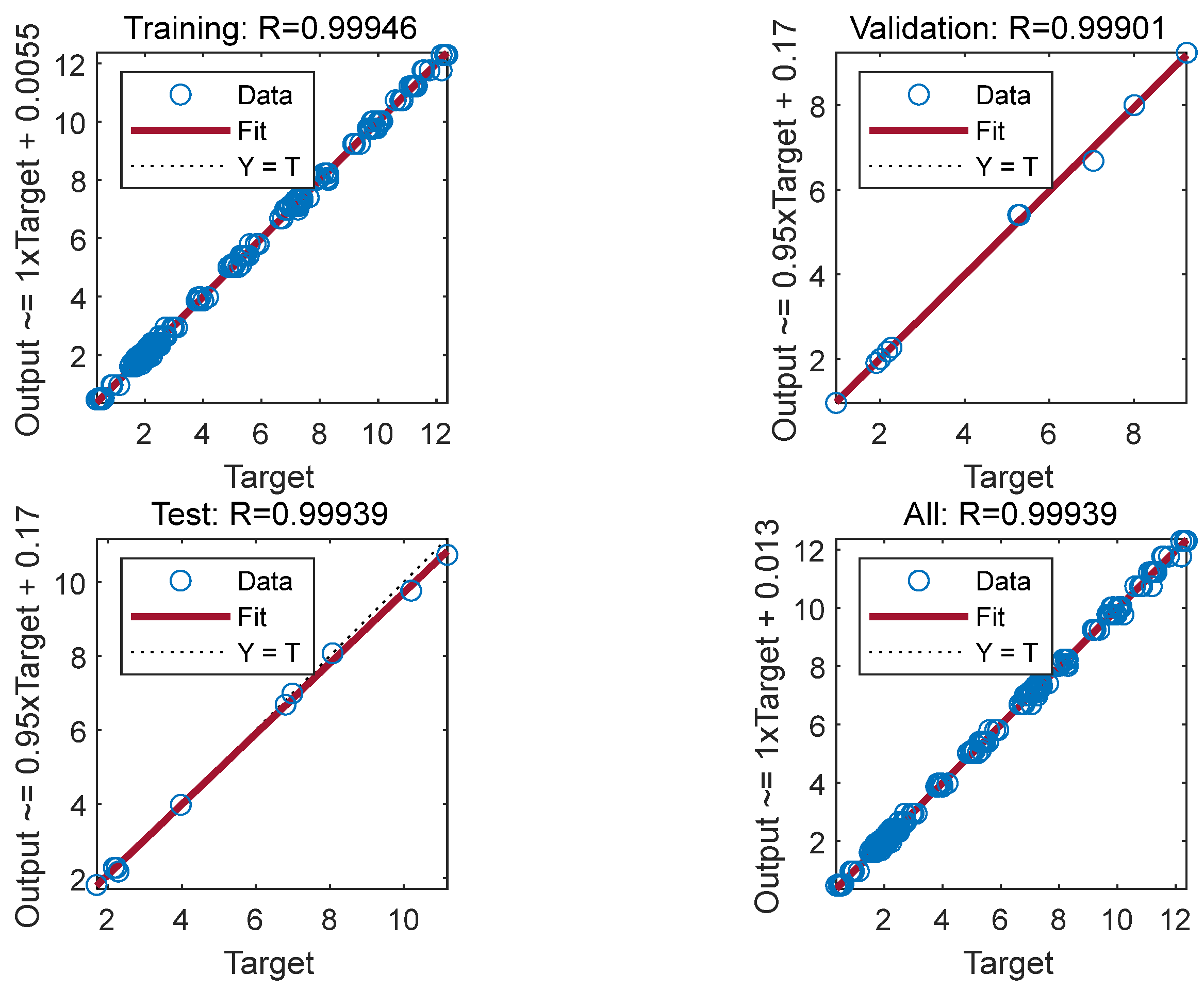

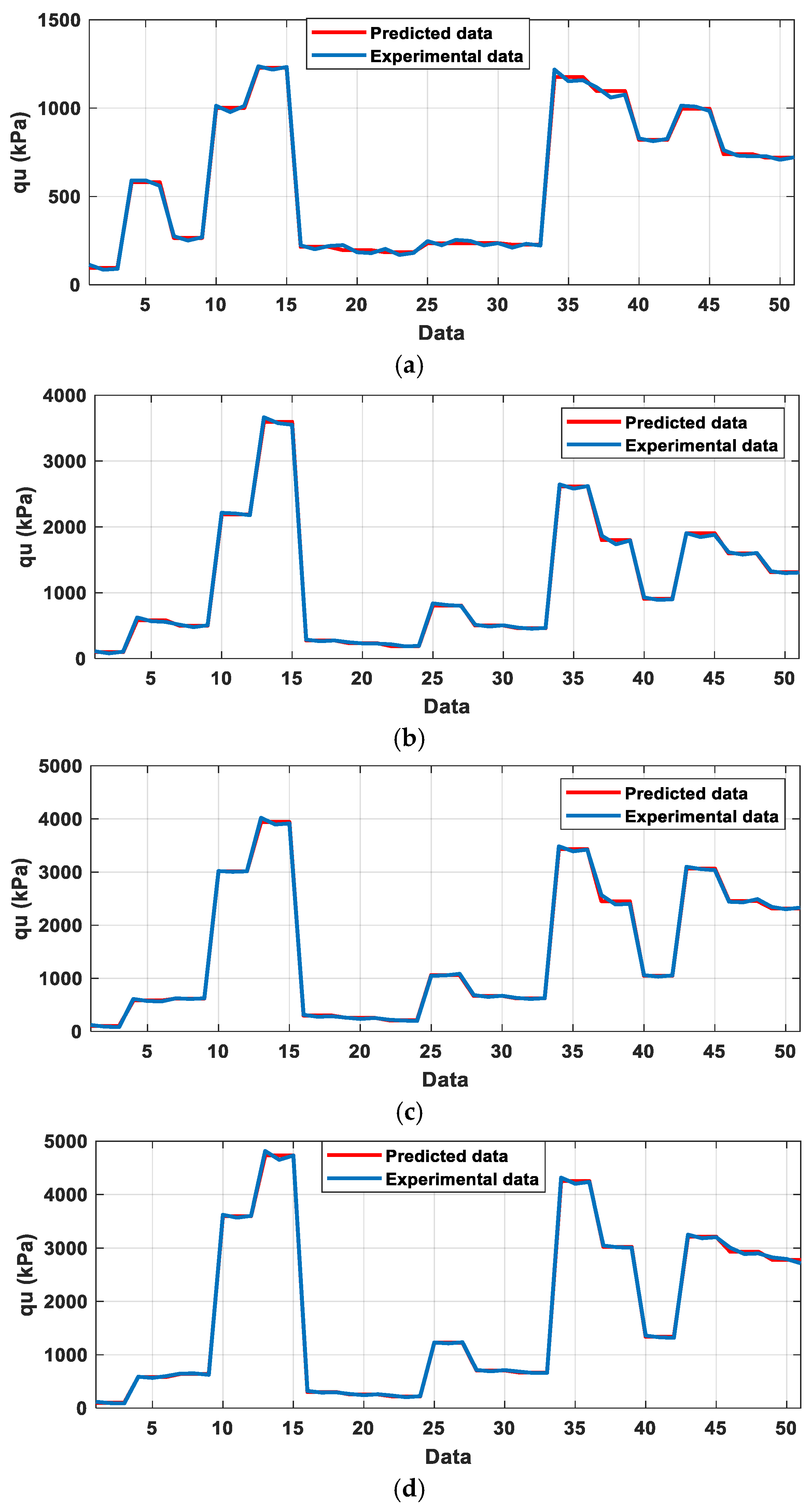

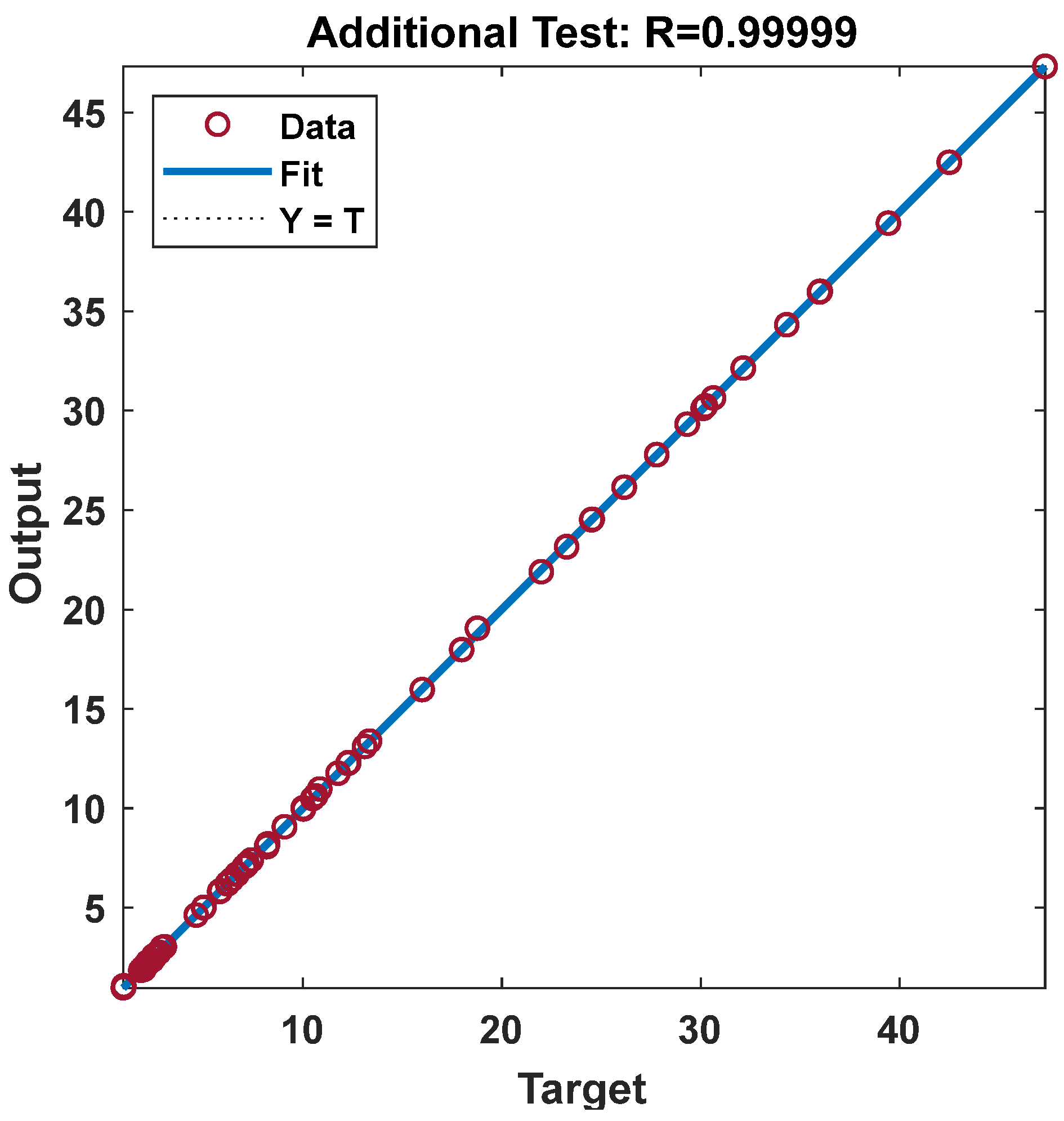

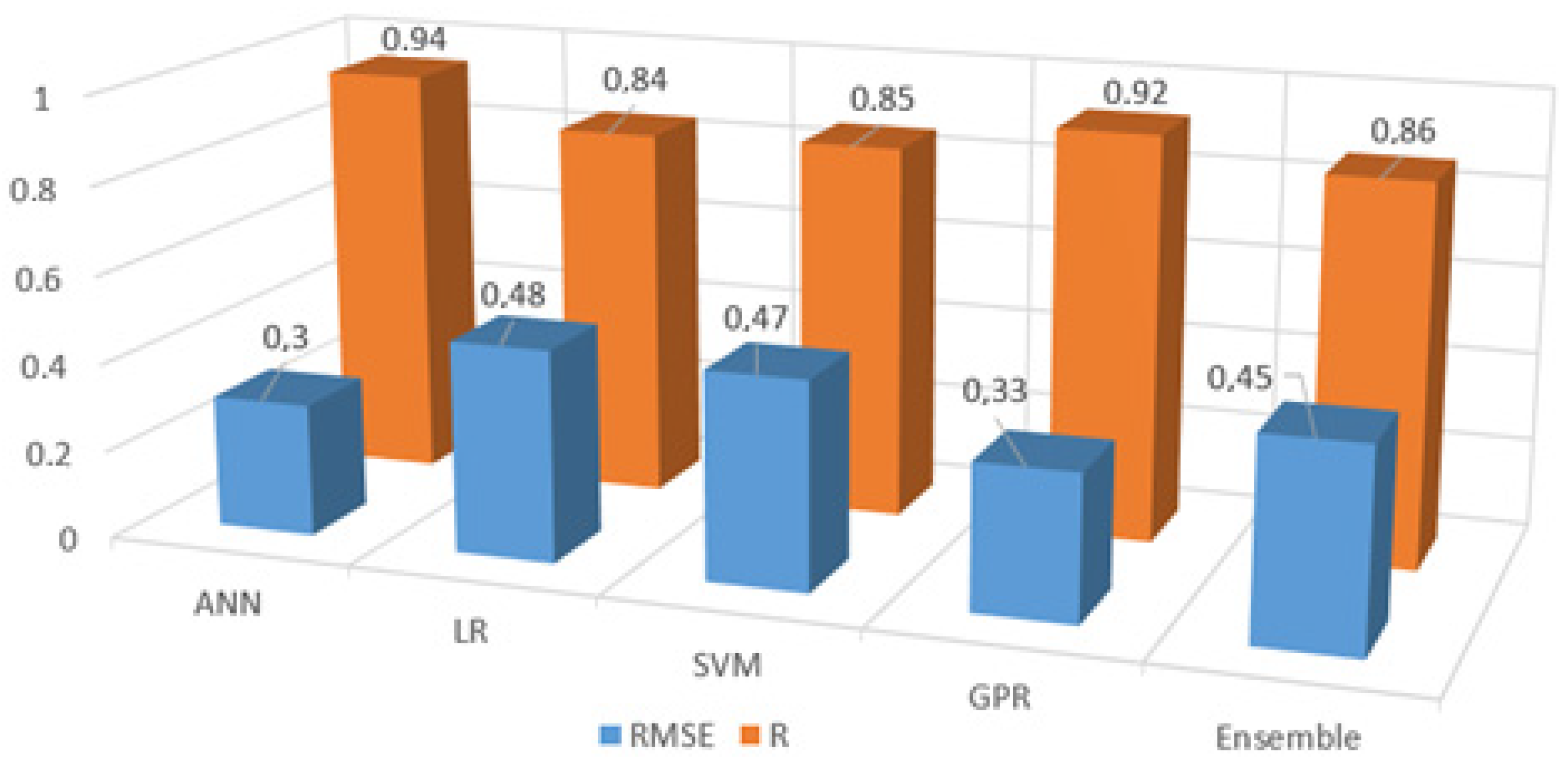

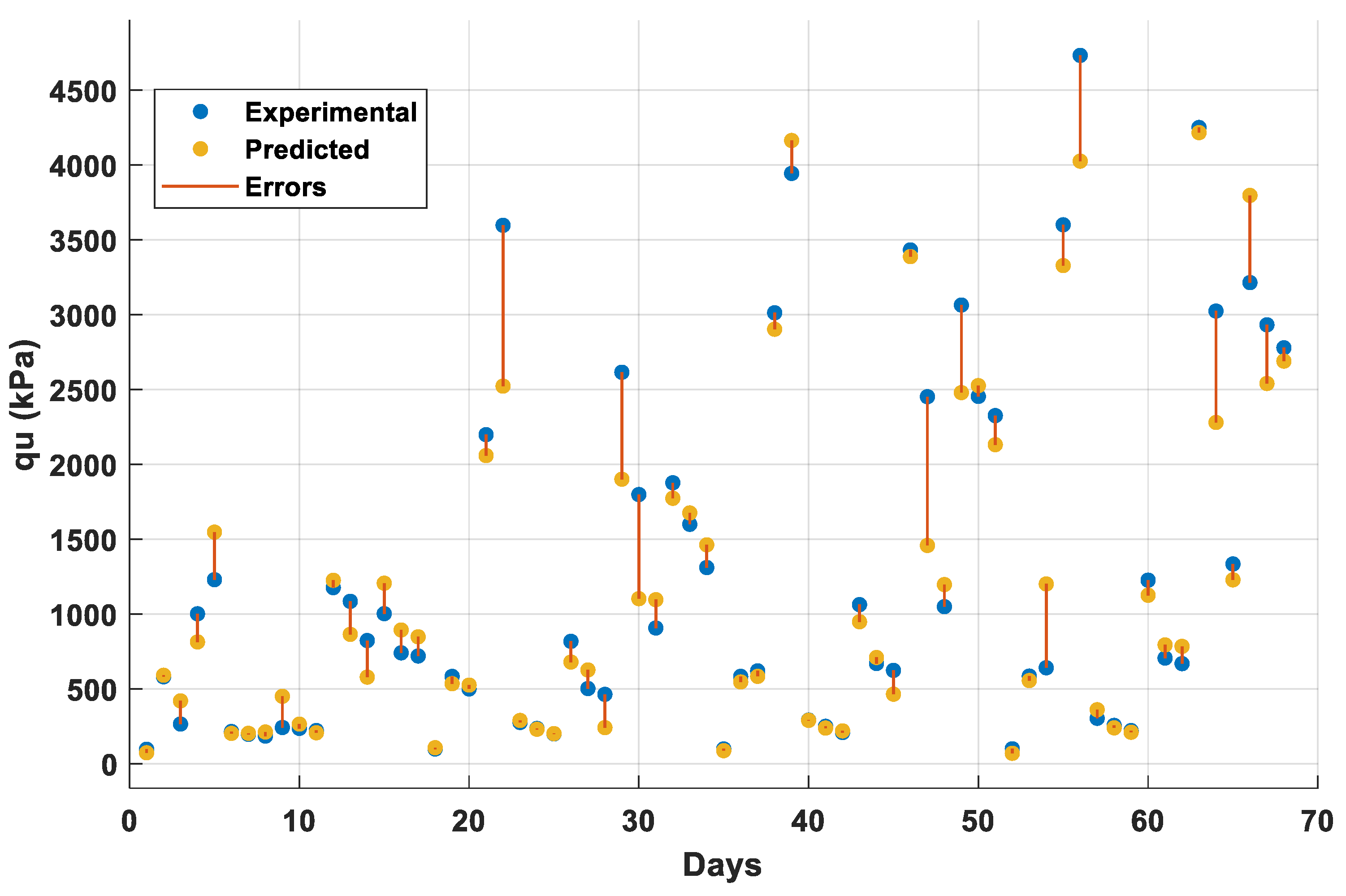

4. ANN-Based Strength Prediction for Basalt-Fiber-Reinforced Clay

- Input layer, where data is fed into the system,

- Hidden layer, where input data is processed based on its features,

- Output layer, where the processed data is presented after being analyzed by the neurons in the hidden layer.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hossain, K.M.A.; Mol, L. Some engineering properties of stabilized clayey soils incorporating natural pozzolans and industrial wastes. Constr. Build. Mater. 2011, 25, 3495–3501. [Google Scholar] [CrossRef]

- Driss, A.A.E.; Harichane, K.; Ghrici, M.; Mohammed, A.S. Enhancing geotechnical properties of expansive clay with lime and natural pozzolana: Experimental and microstructural analysis. Arab. J. Sci. Eng. 2025, 1–23. [Google Scholar] [CrossRef]

- Azadegan, O.; Jafari, S.H.; Li, J. Compaction characteristics and mechanical properties of lime/cement treated granular soils. Electron. J. Geotech. Eng. 2012, 17, 2275–2284. [Google Scholar]

- Lin, B.; Cerato, A.B.; Madden, A.S.; Madden, M.E.E. Effect of fly ash on the behavior of expansive soils: Microscopic analysis. Environ. Eng. Geosci. 2013, 19, 85–94. [Google Scholar] [CrossRef]

- Mahamedi, A.; Khemissa, M. Cement stabilization of compacted expansive clay. Online J. Sci. Technol. 2013, 3, 33–38. [Google Scholar]

- Voottipruex, P.; Jamsawang, P. Characteristics of expansive soils improved with cement and fly ash in Northern Thailand. Geomech. Eng. 2014, 6, 437–453. [Google Scholar] [CrossRef]

- Asgari, M.R.; Baghebanzadeh Dezfuli, A.; Bayat, M. Experimental study on stabilization of a low plasticity clayey coil with cement/lime. Arab. J. Geosci. 2015, 8, 1439–1452. [Google Scholar] [CrossRef]

- Goodarzi, A.R.; Goodarzi, S.; Akbari, H.R. Assessing geo-mechanical and micro-structural performance of modified expansive clayey soil by silica fume as ındustrial waste. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2015, 39, 333–350. [Google Scholar]

- Zhu, J.; Saberian, M.; Perera, S.T.A.M.; Roychand, R.; Li, J.; Wang, G. Reusing COVID-19 disposable nitrile gloves to improve the mechanical properties of expansive clay subgrade: An innovative medical waste solution. J. Clean. Prod. 2022, 375, 134086. [Google Scholar] [CrossRef]

- Aslan Topçuoğlu, Y.; Gürocak, Z. Changes in the strength of high-plasticity clays after stabilization: An experimental study. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 1109–1123. [Google Scholar] [CrossRef]

- Al-Gharbawi, A.S.; Najemalden, A.M.; Fattah, M.Y. Expansive soil stabilization with lime, cement, and silica fume. Appl. Sci. 2022, 13, 436. [Google Scholar] [CrossRef]

- Raja, K.; Venkatachalam, S.; Vishnuvardhan, K.; Krishnan, R.S.R.; Selvan, V.T.; Vetriselvan, N. A review on soil stabilization using rice husk ash and lime sludge. Mater. Today Proc. 2022, 65, 1205–1212. [Google Scholar] [CrossRef]

- Bulut, Ü. Pozzolanic Activity of Perlite. Ph.D. Thesis, İstanbul Technical University, İstanbul, Turkey, 2007. [Google Scholar]

- Kavlak, Y. Use of Isparta-Gelincik Pumice in Stabilization of Highway Flexible Pavement Subgrade. Master’s Thesis, Süleymen Demirel University, Isparta, Turkey, 2008. [Google Scholar]

- Bulut, Ü.; Tanaçan, L. Pozzolanic activity of perlite. İTÜ Derg. Archit. Plan. Des. 2009, 8, 81–89. [Google Scholar]

- Çalik, U.; Şadoglu, E. Engineering properties of expansive clayey soil stabilized with lime and perlite. Geomech. Eng. 2014, 6, 403–418. [Google Scholar] [CrossRef]

- Yılmaz, F. Fineness effect of pozzolanic additive on strength in soil stabilization. AKU J. Sci. Eng. 2017, 17, 1048–1054. [Google Scholar] [CrossRef]

- Çimen, Ö.; Coşan, F.Ş. Volkanik tüf ve amorf silikanin kilin mühendislik özelliklerine etkisi. Mühendislik Bilim. Ve Tasarım Derg. 2019, 7, 459–466. [Google Scholar] [CrossRef]

- Çimen, Ö.; Dereli, B.; Keleş, E. Comparison of the effect of pumice of three different regions to high plasticity clay. BEU J. Sci. 2020, 9, 427–433. [Google Scholar][Green Version]

- Czigány, T.; Vad, J.; Pölöskei, K. Basalt fiber as a reinforcement of polymer composites. Period. Polytech. Mech. Eng. 2005, 49, 3–14. [Google Scholar][Green Version]

- Gao, L.; Hu, G.; Xu, N.; Fu, J.; Xiang, C.; Yang, C. Experimental study on unconfined compressive strength of basalt fiber reinforced clay soil. Adv. Mater. Sci. Eng. 2015, 561293. [Google Scholar] [CrossRef]

- Ndepete, C.P.; Sert, S. Use of basalt fibers for soil improvement. Acta Phys. Pol. 2016, 130, 355–356. [Google Scholar] [CrossRef]

- Kenan, A.; Özocak, A. Bazalt fiber katkısının siltli zeminlerin kayma direncine etkisi. In Proceedings of the 2nd International Symposium on Natural Hazards and Disaster Management, Melbourne, Australia, 26–27 July 2018; pp. 918–924. [Google Scholar]

- Sungur, A.; Yazıcı, M.F.; Keskin, S.N. Experimental research on the engineering properties of basalt fiber reinforced clayey soil. Eur. J. Sci. Technol. Spec. Issue 2021, 28, 895–899. [Google Scholar]

- Gürocak, Z.; Aslan Topçuoğlu, Y. The effect of basalt fiber use on the unconfined compressive strength of low plasticity clay. Gümüşhane Univ. J. Sci. Technol. 2023, 13, 688–701. [Google Scholar]

- Zhao, N.; Wu, H.; Huang, Z. Strength behavior of red clay reinforced by basalt chopped fiber. Arab. J. Geosci. 2021, 14, 15. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, J.S.; Wang, X.; Ding, Y.; Chen, X.B.; Liu, T. Experimental study on mechanical properties of basalt fiber-reinforced silty clay. J. Cent. South Univ. 2022, 29, 1945–1956. [Google Scholar] [CrossRef]

- Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on mechanical properties and microstructure of basalt fiber-modified red clay. Sustainability 2023, 15, 4411. [Google Scholar] [CrossRef]

- Chen, J.; Mu, J.; Chen, A.; Long, Y.; Zhang, Y.; Zou, J. Experimental Study on the Properties of Basalt Fiber–Cement-Stabilized Expansive Soil. Sustainability 2024, 16, 7579. [Google Scholar] [CrossRef]

- Özdemir, T.; Polat, G.E.; Azdeniz, O.; Boz, A.; Sezer, A. Strength properties of clay soil reinforced with basalt fiber and lime. In Proceedings of the 16th National Congress of Soil Mechanics and Foundation Engineering, Osaka, Japan, 12–16 September 2016; Volume 16, pp. 1025–1035. [Google Scholar]

- Wang, Y.; Sun, S.; Ye, W.; Li, F.; Ding, H. Laboratory test of expansive soil improved by lime–basalt fiber reinforcement. In Proceedings of the Transportation Research Congress 2016: Innovations in Transportation Research Infrastructure, Beijing, China, 6–8 June 2016. [Google Scholar]

- Boz, A.; Sezer, A.; Özdemir, T.; Hızal, G.E.; Azdeniz Dolmacı, O. Mechanical properties of lime-treated clay reinforced with different types of randomly distributed fibers. Arab. J. Geosci. 2018, 11, 122. [Google Scholar] [CrossRef]

- Cao, Z.; Ma, O.; Wang, H. Effect of basalt fiber addition on static-dynamic mechanical behaviors and microstructure of stabilized soil compositing cement and fly ash. Hindawi Adv. Civ. Eng. 2019, 1–20. [Google Scholar] [CrossRef]

- Ma, Q.Y.; Cao, Z.M.; Yuan, P. Experimental research on microstructure and physical-mechanical properties of expansive soil stabilized with fly ash, sand, and basalt fiber. Adv. Mater. Sci. Eng. 2018, 1–13. [Google Scholar] [CrossRef]

- Shen, M. Laboratory experimental study on improvement of silty soil lime and basalt fiber in Hangjiahu. J. Innov. Dev. 2023, 2, 115–118. [Google Scholar] [CrossRef]

- Tabarsa, A.; Latifi, N.; Osouli, A.; Bagheri, Y. Unconfined compressive strength prediction of soils stabilized using artificial neural networks and support vector machines. Front. Struct. Civ. Eng. 2021, 15, 520–536. [Google Scholar] [CrossRef]

- Chumacero, J.M.G.; Torres, P.L.A.; La Portilla, C.C.C.; Perez, S.P.M. Influence of artificial intelligence on the optimization of the dosage of natural hydraulic lime, plastic and metallic fibers on the geological characteristics of a treated soil. Rev. Ing. De Construcción 2023, 38. [Google Scholar] [CrossRef]

- Garg, A.; Bordoloi, S.; Mondal, S.; Ni, J.J.; Sreedeep, S. investigation of mechanical factor of soil reinforced with four types of fibers: An integrated experimental and extreme learning machine approach. J. Nat. Fibers 2020, 17, 650–664. [Google Scholar] [CrossRef]

- Tiwarii, N.; Satyam, N. Coupling effect of pond ash and polypropylene fiber on strength and durability of expansive soil subgrades: An integrated experimental and machine learning approach. J. Rock Mech. Geotech. Eng. 2021, 13, 1101–1112. [Google Scholar] [CrossRef]

- Ndepete, C.P.; Sert, S.; Beycioğlu, A.; Katanalp, B.Y.; Eren, E.; Bağrıaçık, B.; Topolinski, S. Exploring the effect of basalt fibers on maximum deviator stress and failure deformation of silty soils using ANN, SVM and FL supported by experimental data. Adv. Eng. Softw. 2022, 172, 103211. [Google Scholar] [CrossRef]

- Sungur, A.; Yazıcı, M.F.; Keskin, N. Prediction of the shear strength of glass fiber-reinforced clay soil by adaptive neuro-fuzzy inference system (ANFIS). El-Cezeri 2022, 9, 1255–1264. [Google Scholar]

- Sert, S.; Arslan, E.; Ocakbaşı, P.; Ekinci, E.; Garip, Z.; Özocak, A.; Bol, E.; Ndepete, C.P. Stabilization of expansive clays with basalt fibers and prediction of strength by machine learning. Arab. J. Sci. Eng. 2024, 49, 13651–13670. [Google Scholar] [CrossRef]

- Jeremiah, J.J.; Abbey, S.J.; Booth, C.A.; Kashyap, A. Results of application of artificial neural networks in predicting geo-mechanical properties of stabilised clays—A review. Geotechnics 2021, 1, 147–171. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Alaneme, G.U.; Onyia, M.E.; Bui Van, D.; Diomonyeka, M.U.; Nnadi, E.; Ogbonna, C.; Odum, L.O.; Aju, D.E.; Abel, C.; et al. Comparative modeling of strength properties of hydrated-lime activated rice-husk-ash (HARHA) modified soft soil for pavement construction purposes by artificial neural network (ANN) and fuzzy logic (FL). J. Kejuruter. 2021, 33, 365–384. [Google Scholar]

- Tinoco, J.; Correia, A.A.S.; Venda Oliveira, P.J. Soil-cement mixtures reinforced with fibers: A data-driven approach for mechanical properties prediction. Appl. Sci. 2021, 11, 8099. [Google Scholar] [CrossRef]

- Raja, M.N.A.; Shukla, S.K.; Khan, M.U.A. An intelligent approach for predicting the strength of geosynthetic-reinforced subgrade soil. Int. J. Pavement Eng. 2022, 23, 3505–3521. [Google Scholar] [CrossRef]

- Rabbani, A.; Samui, P.; Kumari, S. Optimized ANN-based approach for estimation of shear strength of soil. Asian J. Civ. Eng. 2023, 24, 3627–3640. [Google Scholar] [CrossRef]

- Duong, N.T.; Tran, K.Q. Estimation of seepage velocity and piping resistance of fiber-reinforced soil by using artificial neural network-based approach. Neural Comput. Appl. 2023, 35, 2443–2455. [Google Scholar] [CrossRef]

- Vahedi, J.; Koohmishi, M. Assessing the strength of lime-treated clayey soil reinforced with PET: A ML-based data-derived approach. Results Eng. 2025, 25, 103913. [Google Scholar] [CrossRef]

- Thapa, I.; Ghani, S.; Asteris, P.G. Neural network coupled with nature-inspired optimization algorithms for prediction of microstructural and mechanical properties of nano-silica treated fine-grained soil. Model. Earth Syst. Environ. 2025, 11, 69. [Google Scholar] [CrossRef]

- Kumar, A.; Sinha, S. Machine learning-based hybrid regularization techniques for predicting unconfined compressive strength of soil reinforced with multiple additives. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 228. [Google Scholar] [CrossRef]

- Sharma, L.K.; Umrao, R.K.; Singh, R.; Singh, T.N. Artificial Neural Network Approach to Evaluate Geotechnical Properties of Lime-Treated Mountain Soil: A Slope Stabilization Perspective. Transp. Infrastruct. Geotechnol. 2025, 12, 1–37. [Google Scholar] [CrossRef]

- Güven, I.H. (General Directorate of Mineral Research and Exploration, Ankara, Turkey). Doğu Pontidler’in Jeolojisi ve 1/250,000 Ölçekli Kompliasyonu. Report of the General Directorate of Mineral Research and Exploration. Unpublished work. 1993. [Google Scholar]

- Aslan Topçuoğlu, Y. The Effect of Different Additive Materials on the Engineering Properties of Soils. Ph.D. Thesis, Fırat University, Elazığ, Turkey, 2020. [Google Scholar]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber-a review. J. Text. Inst. 2015, 107, 923–937. [Google Scholar] [CrossRef]

- Aslan Topçuoğlu, Y.; Gürocak, Z. The effect of basalt fiber reinforcement at different ratios on the unconfined compressive strength of kaolin. Niğde Ömer Halisdemir Üniversitesi Mühendislik Bilim. Derg. 2024, 13, 169–175. [Google Scholar] [CrossRef]

- ASTM D698-12e2; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- Aydın, S. Improvement of the Geotechnical Properties of Yenikent (Ankara) Settlement Area Clays with Lime and Fly Ash. Master’s Thesis, Gazi University, Ankara, Turkey, 2010. [Google Scholar]

- Ghabaee, S. Curing Time Effects on the Bearing Capacity of Stabilized Bentonite with Lime. Master’s Thesis, Istanbul Technical University, Istanbul, Turkey, 2015. [Google Scholar]

- ASTM D2166M-16; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Guldemir, N.H.; Alkan, A. Classification of optical coherence tomography images via deep learning. Firat Univ. J. Eng. Sci. 2021, 33, 607–615. [Google Scholar]

- Sengur, D. Pedagogical othering and suicide: A preventive model proposal with machine learning approaches. Int. Online J. Educ. Sci. 2023, 15, 414–427. [Google Scholar]

- Demir, T.; Duranay, Z.B.; Demirel, B.; Yildirim, B. Artificial neural network evaluation of concrete performance exposed to elevated temperature with destructive-non-destructive tests. Neural Comput. Appl. 2024, 36, 17079–17093. [Google Scholar] [CrossRef]

- Alqahtani, F. Ai-powered image security: Utilizing autoencoders for advanced medical image encryption. CMES-Comput. Model. Eng. Sci. 2024, 141, 1709. [Google Scholar] [CrossRef]

- Duranay, Z.B. Neural network based harmonic elimination in single-phase inverters. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2023, 42, 543–564. [Google Scholar] [CrossRef]

- Rabab’ah, S.R.; Taamneh, M.M.; Abdallah, H.M.; Nusier, O.K.; Ibdah, L. Effect of adding zeolitic tuff on geotechnical properties of lime-stabilized expansive soil. KSCE J. Civ. Eng. 2021, 25, 4596–4609. [Google Scholar] [CrossRef]

- Yilmaz, F.; Kuvat, A.; Kamiloğlu, H.A. Optimizing and investigating durability performance of sandy soils stabilized with alkali activated waste tuff-fly ash mixtures. Sādhanā 2023, 48, 185. [Google Scholar] [CrossRef]

- Abutaqa, A.; Mohsen, M.O.; Aburumman, M.O.; Senouci, A.; Taha, R.; Maherzi, W.; Qtiashat, D. Eco-Sustainable Cement: Natural Volcanic Tuffs’ Impact on Concrete Strength and Durability. Buildings 2024, 14, 2902. [Google Scholar] [CrossRef]

| Sample Number | Sample Code | Explanations |

|---|---|---|

| 1 | K | Clay |

| 2 | K + BF 1% | Clay + Basalt Fiber (1%) |

| 3 | K + BF 1% + SL 3% | Clay + Basalt Fiber (1%) + Slaked Lime (3%) |

| 4 | K + BF 1% + SL 6% | Clay + Basalt Fiber (1%) + Slaked Lime (6%) |

| 5 | K + BF 1% + SL 9% | Clay + Basalt Fiber (1%) + Slaked Lime (9%) |

| 6 | K + BF 1% + T 10% | Clay + Basalt Fiber (1%) + Tuff (10%) |

| 7 | K + BF 1% + T 20% | Clay + Basalt Fiber (1%) + Tuff (20%) |

| 8 | K + BF 1% + T 30% | Clay + Basalt Fiber (1%) + Tuff (30%) |

| 9 | K + BF 1% + SL 3% + T 10% | Clay + Basalt Fiber (1%) + Slaked Lime (3%) + Tuff (10%) |

| 10 | K + BF 1% + SL 3% + T 20% | Clay + Basalt Fiber (1%) + Slaked Lime (3%) + Tuff (20%) |

| 11 | K + BF 1% + SL 3% + T 30% | Clay + Basalt Fiber (1%) + Slaked Lime (3%) + Tuff (30%) |

| 12 | K + BF 1% + SL 6% + T 10% | Clay + Basalt Fiber (1%) + Slaked Lime (6%) + Tuff (10%) |

| 13 | K + BF 1% + SL 6% + T 20% | Clay + Basalt Fiber (1%) + Slaked Lime (6%) + Tuff (20%) |

| 14 | K + BF 1% + SL 6% + T 30% | Clay + Basalt Fiber (1%) + Slaked Lime (6%) + Tuff (30%) |

| 15 | K + BF 1% + SL 9% + T 10% | Clay + Basalt Fiber (1%) + Slaked Lime (9%) + Tuff (10%) |

| 16 | K + BF 1% + SL 9% + T 20% | Clay + Basalt Fiber (1%) + Slaked Lime (9%) + Tuff (20%) |

| 17 | K + BF 1% + SL 9% + T 30% | Clay + Basalt Fiber (1%) + Slaked Lime (9%) + Tuff (30%) |

| Sample Number | Sample Code | K (%) | BF (%) | SL (%) | T (%) |

|---|---|---|---|---|---|

| 1 | K | 100 | 0 | 0 | 0 |

| 2 | K + BF 1% | 99 | 1 | 0 | 0 |

| 3 | K + BF 1% + SL 3% | 96 | 1 | 3 | 0 |

| 4 | K + BF 1% + SL 6% | 93 | 1 | 6 | 0 |

| 5 | K + BF 1% + SL 9% | 90 | 1 | 9 | 0 |

| 6 | K + BF 1% + T 10% | 89 | 1 | 0 | 10 |

| 7 | K + BF 1% + T 20% | 79 | 1 | 0 | 20 |

| 8 | K + BF 1% + T 30% | 69 | 1 | 0 | 30 |

| 9 | K + BF 1% + SL 3% + T 10% | 86 | 1 | 3 | 10 |

| 10 | K + BF 1% + SL 3% + T 20% | 76 | 1 | 3 | 20 |

| 11 | K + BF 1% + SL 3% + T 30% | 66 | 1 | 3 | 30 |

| 12 | K + BF 1% + SL 6% + T 10% | 83 | 1 | 6 | 10 |

| 13 | K + BF 1% + SL 6% + T 20% | 73 | 1 | 6 | 20 |

| 14 | K + BF 1% + SL 6% + T 30% | 63 | 1 | 6 | 30 |

| 15 | K + BF 1% + SL 9% + T 10% | 80 | 1 | 9 | 10 |

| 16 | K + BF 1% + SL 9% + T 20% | 70 | 1 | 9 | 20 |

| 17 | K + BF 1% + SL 9% + T 30% | 60 | 1 | 9 | 30 |

| Sample Number | Sample Code | Unconfined Compressive Strength, qu (kPa) | ||

|---|---|---|---|---|

| Water Ratio (%) | ||||

| 25 | 30 | 35 | ||

| 1 | K | 294.08 | 96.07 | 47.09 |

| 2 | K + BF 1% | 807.40 | 580.53 | 51.89 |

| 3 | K + BF 1% + SL 3% | 215.75 | 264.78 | 220.41 |

| 4 | K + BF 1% + SL 6% | 510.37 | 1001.21 | 977.02 |

| 5 | K + BF 1% + SL 9% | 680.28 | 1229.23 | 1124.05 |

| 6 | K + BF 1% + T 10% | 201.52 | 214.65 | 175.25 |

| 7 | K + BF 1% + T 20% | 190.88 | 195.87 | 168.54 |

| 8 | K + BF 1% + T 30% | 178.25 | 184.11 | 160.87 |

| 9 | K + BF 1% + SL 3% + T 10% | 231.58 | 241.58 | 227.14 |

| 10 | K + BF 1% + SL 3% + T 20% | 223.81 | 235.74 | 200.30 |

| 11 | K + BF 1% + SL 3% + T 30% | 217.30 | 221.40 | 190.68 |

| 12 | K + BF 1% + SL 6% + T 10% | 698.77 | 1176.11 | 1121.87 |

| 13 | K + BF 1% + SL 6% + T 20% | 534.20 | 1084.57 | 987.59 |

| 14 | K + BF 1% + SL 6% + T 30% | 501.32 | 822.48 | 800.57 |

| 15 | K + BF 1% + SL 9% + T 10% | 540.11 | 1002.19 | 924.41 |

| 16 | K + BF 1% + SL 9% + T 20% | 397.59 | 740.02 | 731.02 |

| 17 | K + BF 1% + SL 9% + T 30% | 386.75 | 719.10 | 710.31 |

| Sample Number | Sample Code | Post-Curing Unconfined Compressive Strength, qu (kPa) | ||

|---|---|---|---|---|

| 28 Days | 42 Days | 56 Days | ||

| 1 | K | 97.89 | 98.35 | 99.21 |

| 2 | K + BF 1% | 582.99 | 583.14 | 584.95 |

| 3 | K + BF 1% + SL 3% | 499.42 | 619.97 | 640.72 |

| 4 | K + BF 1% + SL 6% | 2198.14 | 3012.55 | 3600.47 |

| 5 | K + BF 1% + SL 9% | 3597.13 | 3943.56 | 4731.80 |

| 6 | K + BF 1% + T 10% | 275.23 | 291.54 | 302.87 |

| 7 | K + BF 1% + T 20% | 235.12 | 249.58 | 255.65 |

| 8 | K + BF 1% + T 30% | 198.75 | 208.11 | 220.74 |

| 9 | K + BF 1% + SL 3% + T 10% | 817.25 | 1062.43 | 1225.88 |

| 10 | K + BF 1% + SL 3% + T 20% | 501.87 | 669.08 | 705.53 |

| 11 | K + BF 1% + SL 3% + T 30% | 462.97 | 623.15 | 668.18 |

| 12 | K + BF 1% + SL 6% + T 10% | 2615.20 | 3432.45 | 4250.53 |

| 13 | K + BF 1% + SL 6% + T 20% | 1797.95 | 2451.75 | 3023.83 |

| 14 | K + BF 1% + SL 6% + T 30% | 906.41 | 1048.86 | 1334.24 |

| 15 | K + BF 1% + SL 9% + T 10% | 1876.73 | 3063.95 | 3214.08 |

| 16 | K + BF 1% + SL 9% + T 20% | 1599.19 | 2454.04 | 2932.13 |

| 17 | K + BF 1% + SL 9% + T 30% | 1310.30 | 2325.48 | 2778.73 |

| Average Values of qu | ||||||||||||||

| 264.78 | 1001.21 | 1229.23 | 214.65 | 195.87 | 184.11 | 241.58 | 235.74 | 221.4 | 1176.11 | 1084.57 | 822.48 | 1002.19 | 740.02 | 719.1 |

| Standard Deviations of qu | ||||||||||||||

| 10.49 | 16.41 | 8.31 | 9.63 | 20.41 | 14.13 | 12.92 | 10.45 | 8.9 | 29.71 | 24.09 | 6.77 | 12.99 | 15.62 | 8.69 |

| Source of Variation | Sum of Squares (SS) | Degrees of Freedom | Mean Square | F-Value |

|---|---|---|---|---|

| Between Groups | 33,137,057.17 | 2 | 16,568,528.58 | 401.24 |

| Within Groups | 25,147,826.93 | 609 | 41,293.64 | |

| Total | 58,284,884.09 | 611 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslan Topçuoğlu, Y.; Duranay, Z.B.; Gürocak, Z.; Güldemir, H. AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength. Buildings 2025, 15, 2433. https://doi.org/10.3390/buildings15142433

Aslan Topçuoğlu Y, Duranay ZB, Gürocak Z, Güldemir H. AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength. Buildings. 2025; 15(14):2433. https://doi.org/10.3390/buildings15142433

Chicago/Turabian StyleAslan Topçuoğlu, Yasemin, Zeynep Bala Duranay, Zülfü Gürocak, and Hanifi Güldemir. 2025. "AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength" Buildings 15, no. 14: 2433. https://doi.org/10.3390/buildings15142433

APA StyleAslan Topçuoğlu, Y., Duranay, Z. B., Gürocak, Z., & Güldemir, H. (2025). AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength. Buildings, 15(14), 2433. https://doi.org/10.3390/buildings15142433