A Comparative Study on the Flexural Behavior of UHPC Beams Reinforced with NPR and Conventional Steel Rebars

Abstract

1. Introduction

2. Brief Description of Experimental Program

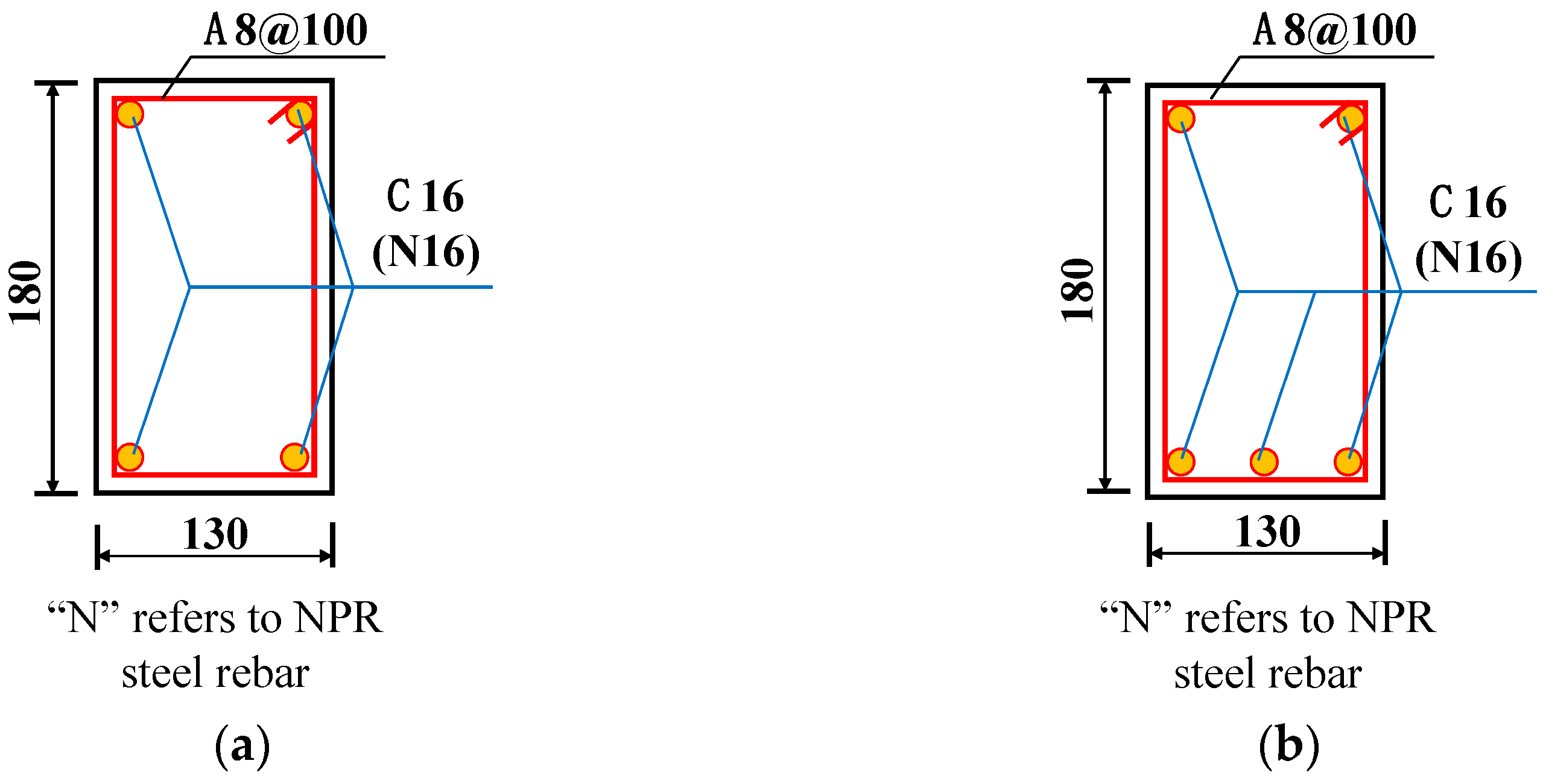

2.1. UHPC Beam Specimens Reinforced with HRB 600 Steel Rebars

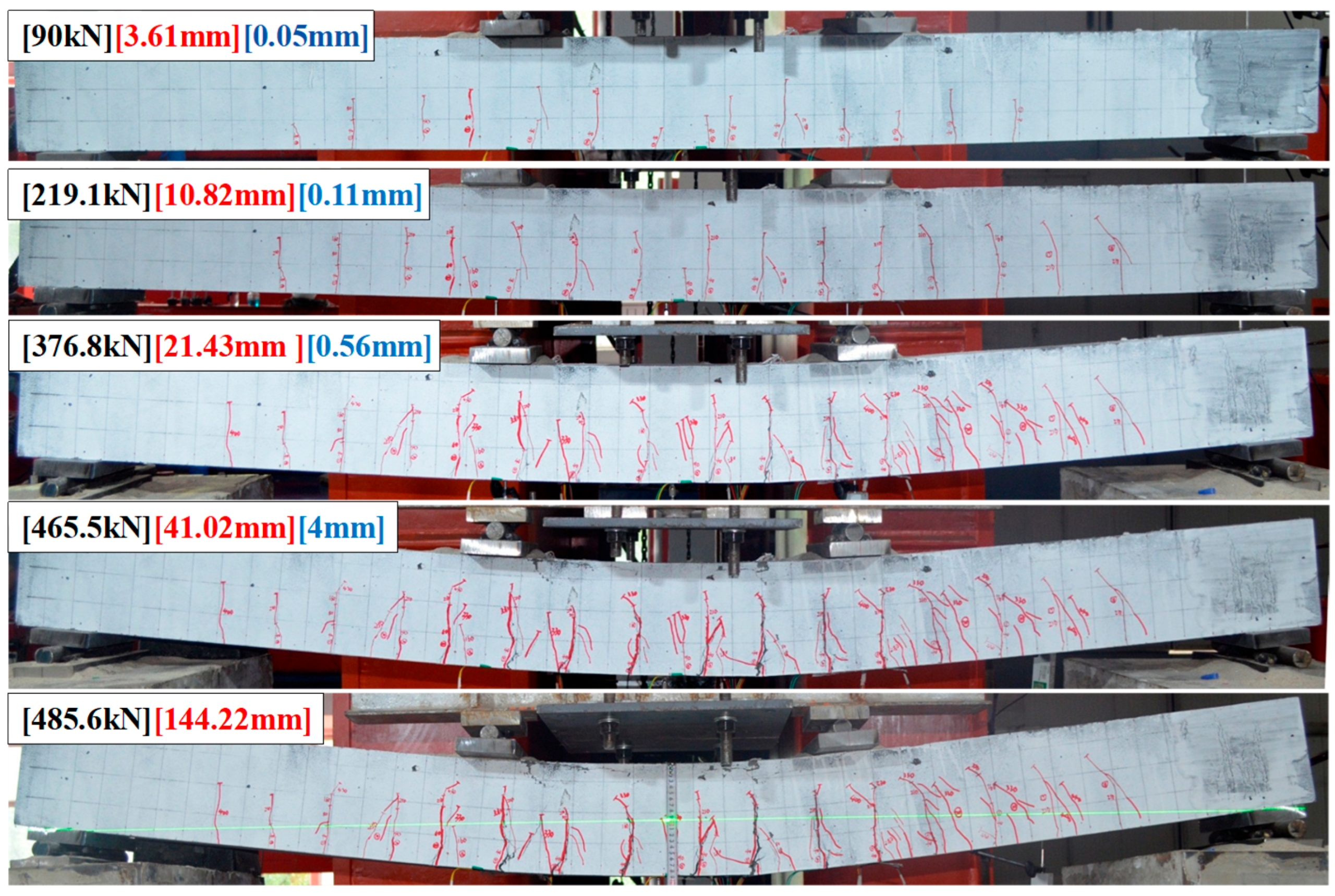

2.2. UHPC Beam Specimens Reinforced with NPR Steel Rebars

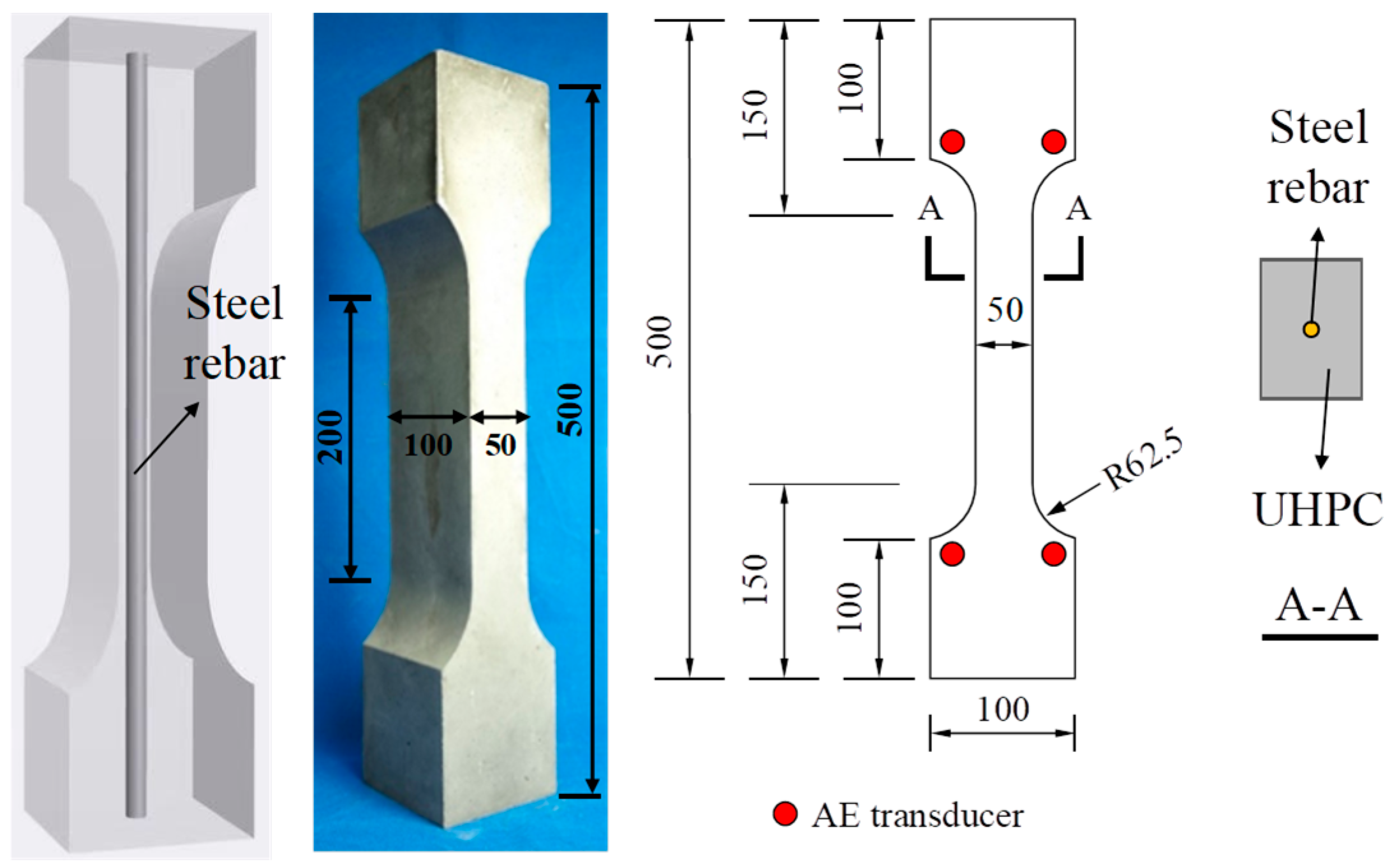

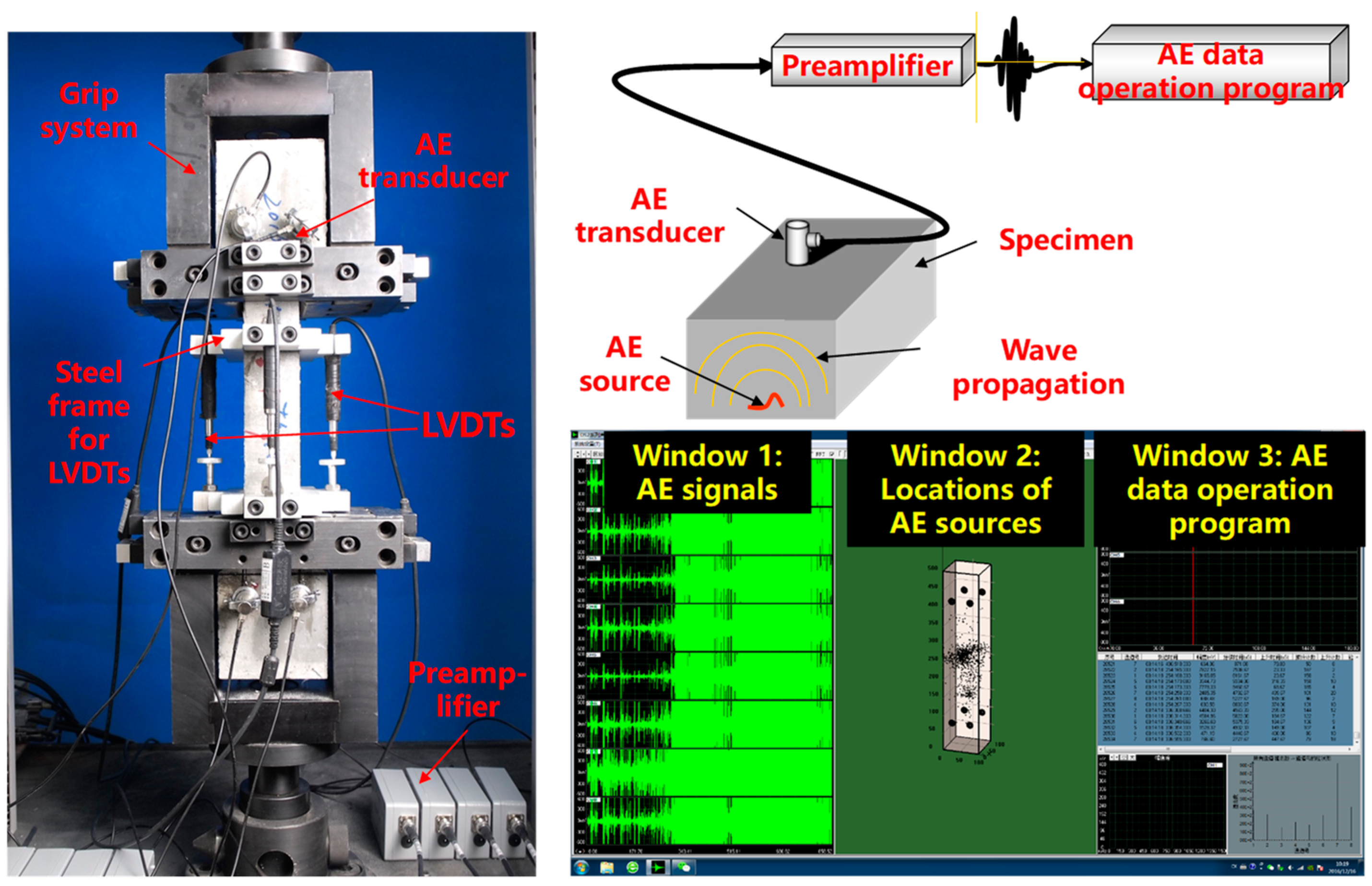

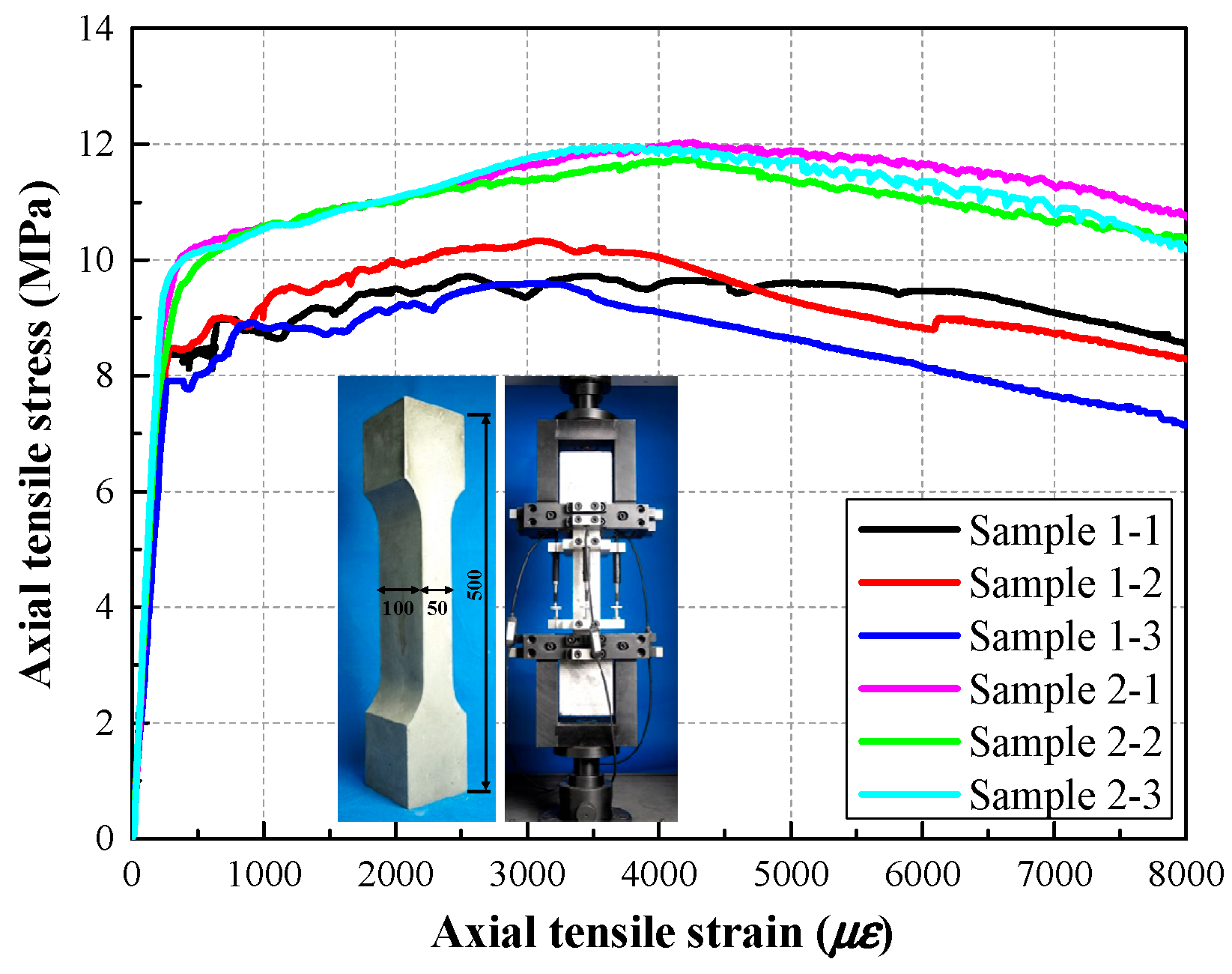

2.3. Direct Tensile Test of Reinforced UHPC

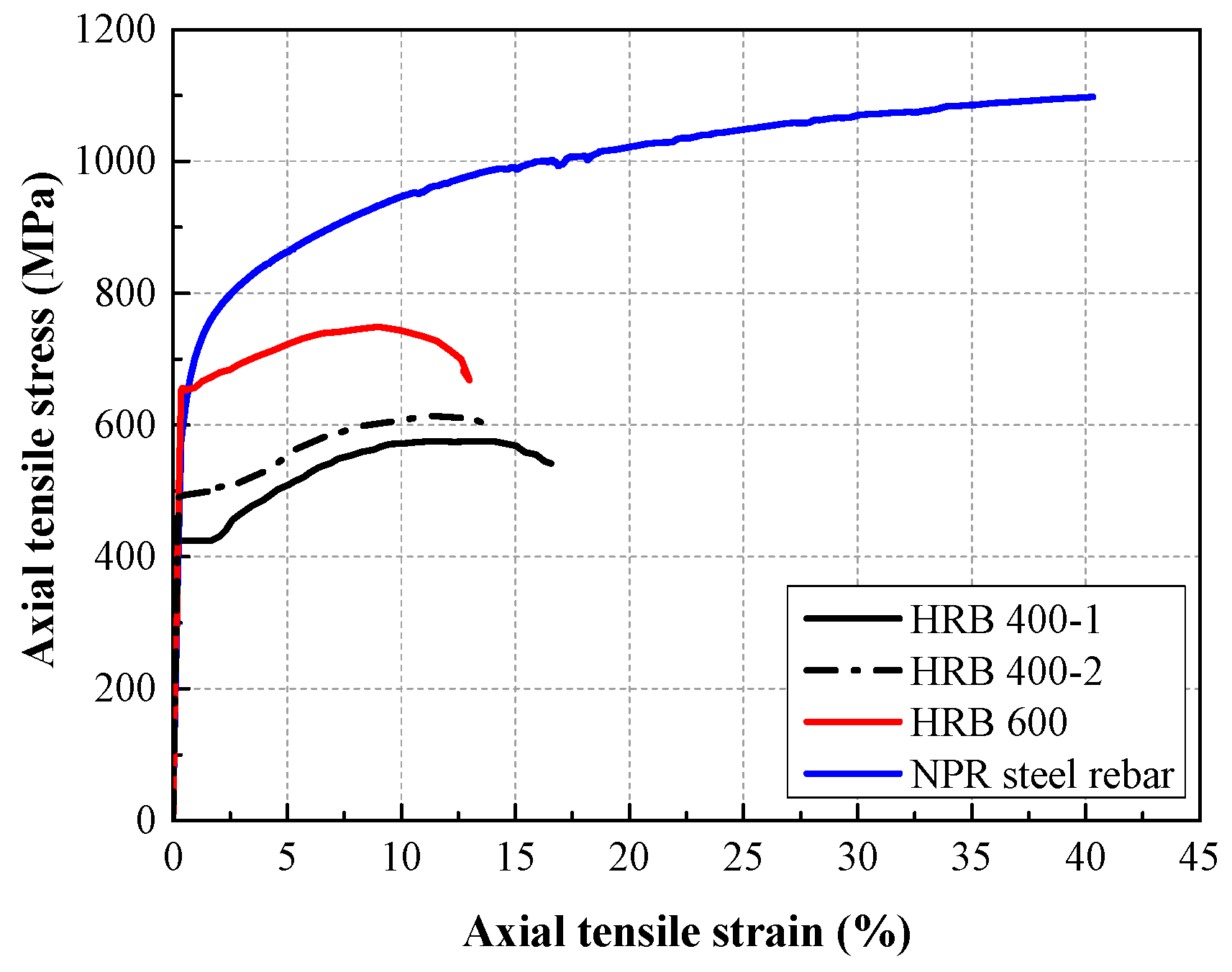

2.4. Materials Properties

3. Test Results and Discussions

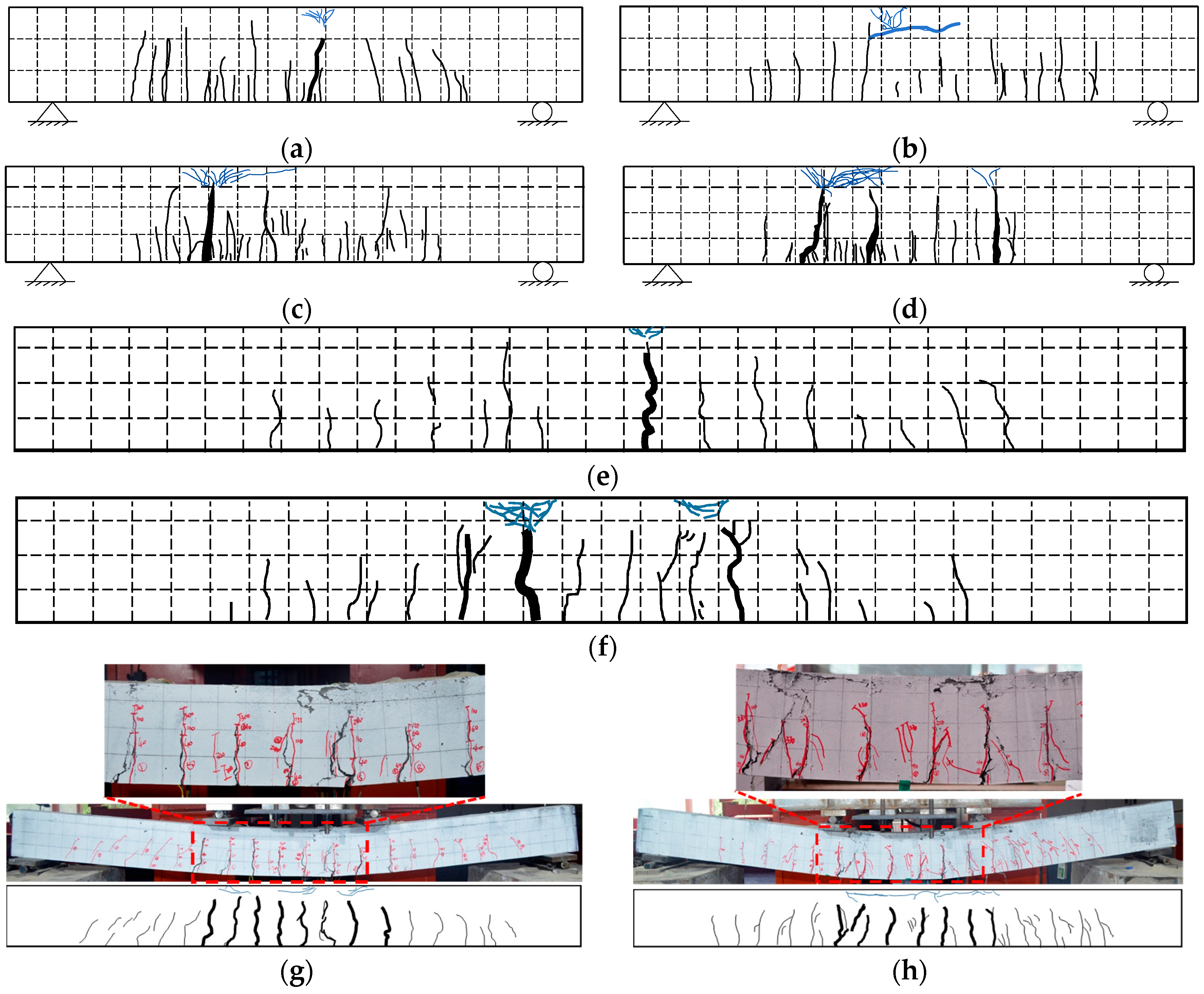

3.1. Crack Pattern of UHPC Beams

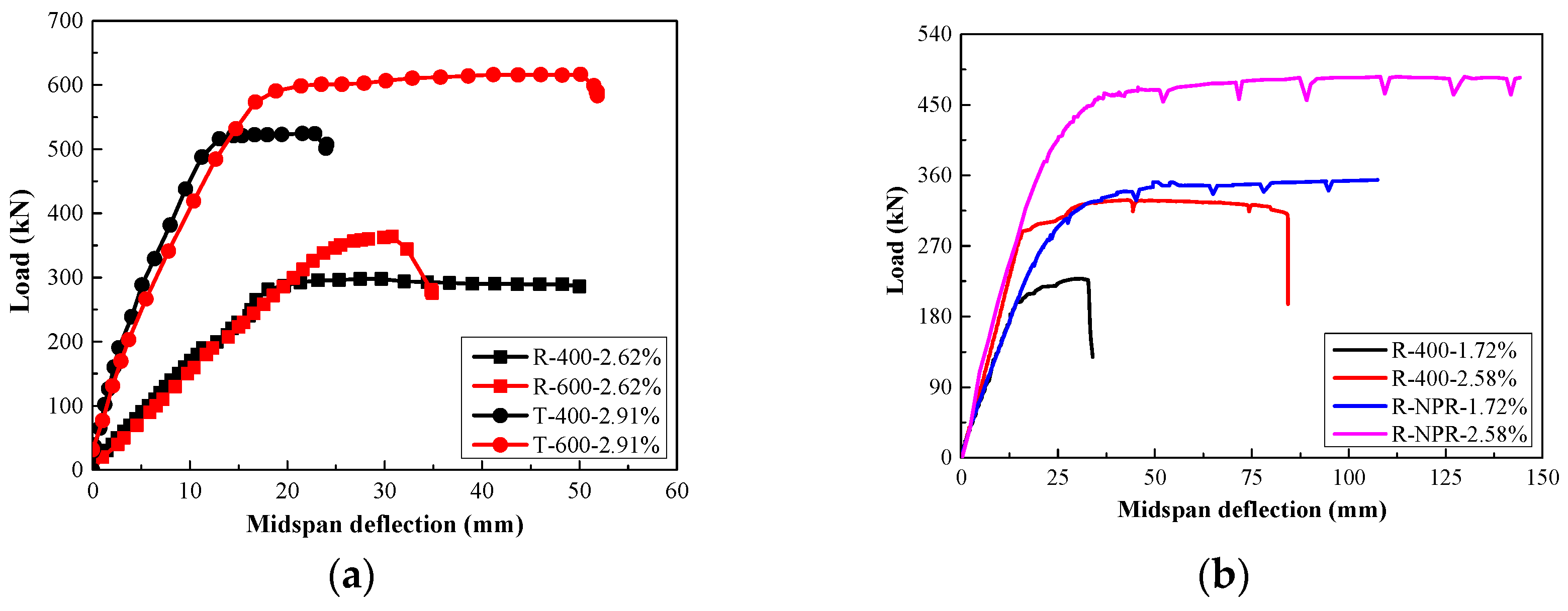

3.2. Load-Deflection Curves of UHPC Beams

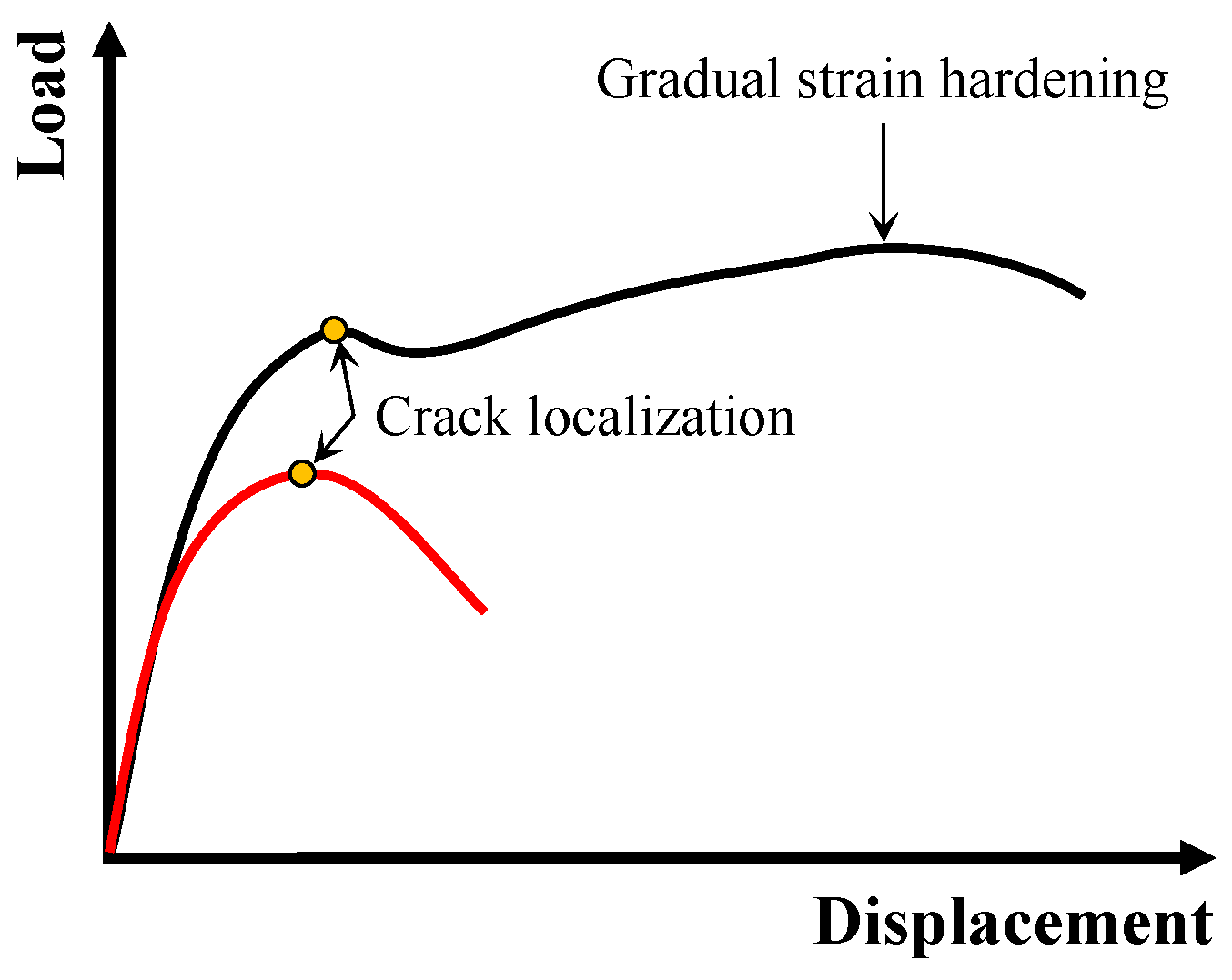

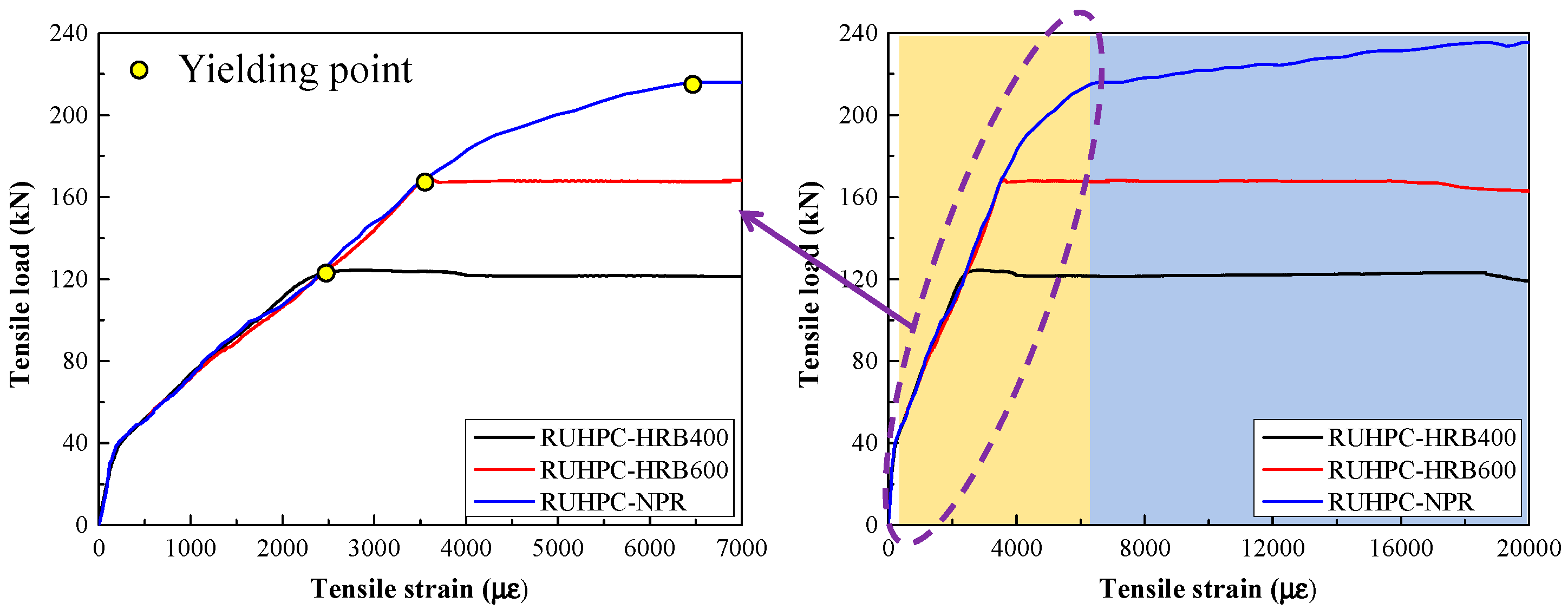

3.3. Tensile Load–Strain Curve of Direct Tensile Reinforced UHPC Specimens

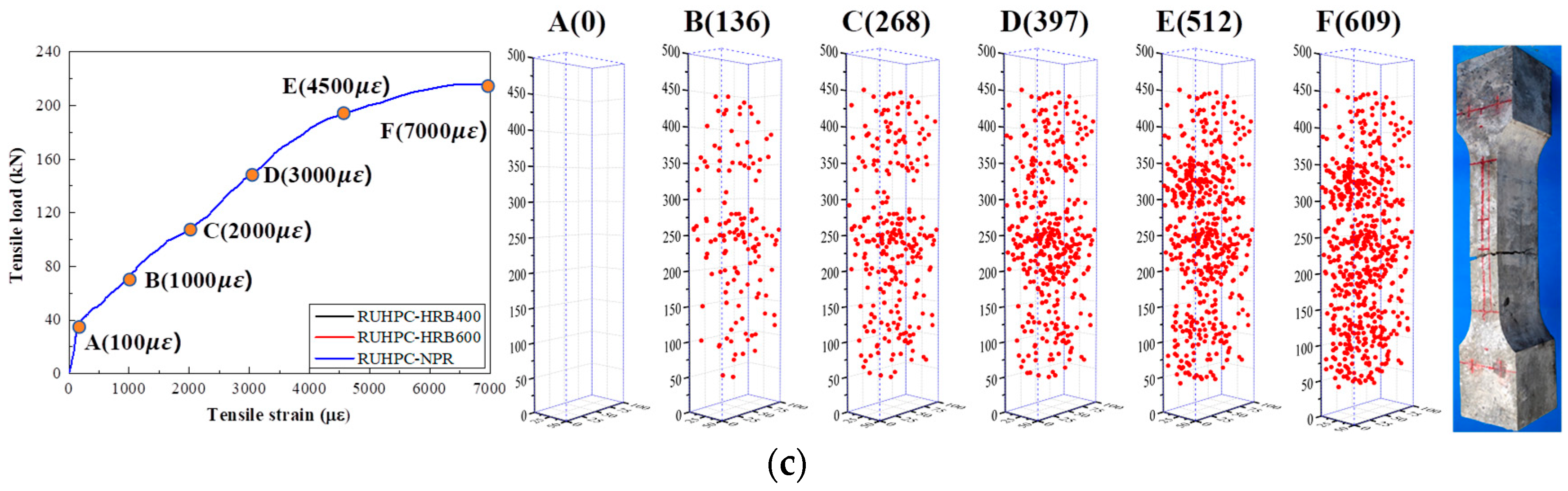

3.4. AE Evolution of Direct Tensile Reinforced UHPC Specimens

4. Damage Mechanism Analysis

5. Conclusions

- (1)

- Unlike the single main crack typical of HRB 400-reinforced UHPC beams, beams with HRB 600 rebar under balanced–reinforced failure transitioned to failure via a few (2–3) main cracks. In contrast, the NPR-reinforced UHPC beams developed multiple (6–8) uniformly distributed main cracks within the pure bending region.

- (2)

- Both the HRB 600 and NPR steel rebars significantly enhanced the load-bearing capacity and deformation ability of the reinforced UHPC beams given a certain longitudinal reinforcement ratio.

- (3)

- The AE analysis method provided robust detection of sub-0.01 mm defects while elucidating the micro-level damage evolution process in the reinforced UHPC specimens.

- (4)

- The superior and distinct tensile characteristics of NPR steel rebar could promote effective stress transfer resulting from minimizing the strain differential between the rebar and the UHPC. Besides, NPR steel rebar might mitigate localized crack deterioration while offsetting the strength reductions from fiber bridging failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, B.; Chen, W.; Liu, H. Multi-scale analysis on the tensile properties of UHPC considering fiber orientation. Compos. Struct. 2022, 280, 114835. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-T.; Yen, C.-H. Workability, fiber distribution, and mechanical properties of UHPC with hooked end steel macro-fibers. Constr. Build. Mater. 2020, 260, 119944. [Google Scholar] [CrossRef]

- Dixit, A.; Du, H.; Pang, S.D. Carbon capture in ultra-high performance concrete using pressurized CO2 curing. Constr. Build. Mater. 2021, 288, 123076. [Google Scholar] [CrossRef]

- Wang, J.-Y.; Guo, J.-Y. Damage investigation of ultra high performance concrete under direct tensile test using acoustic emission techniques. Cem. Concr. Compos. 2018, 88, 17–28. [Google Scholar] [CrossRef]

- Miao, L.; Cheng, Z.; Song, J.; Zhang, Q.; Cui, C.; Li, J. Numerical study on the effects of the mechanical degradation of UHPC layer and stud connectors on the fatigue performance of steel-UHPC composite bridge decks. Eng. Struct. 2025, 332, 120069. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Ding, R.; Nie, X.; Fan, J.-S. Seismic performance of a novel interior precast concrete beam-column joint using ultra-high performance concrete. Eng. Struct. 2020, 222, 111145. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Feng, P.; Dai, J.-G.; Zhuge, Y. Development and behavior of novel FRP-UHPC tubular members. Eng. Struct. 2022, 266, 114540. [Google Scholar] [CrossRef]

- GB 50011-2010; Standardization Administration of the People’s Republic of China (SAC). Code for Seismic Design of Buildings. Standards Press of China: Beijing, China, 2010.

- Gu, T.; Jia, L.-J.; Chen, B.; Xia, M.; Guo, H.; He, M.-C. Unified full-range plasticity till fracture of meta steel and structural steels. Eng. Fract. Mech. 2021, 253, 107869. [Google Scholar] [CrossRef]

- Brüx, U.; Frommeyer, G.; Grässel, O.; Meyer, L.W.; Weise, A. Development and characterization of high strength impact resistant Fe-Mn-(Al-, Si) TRIP/TWIP steels. Steel Res. Int. 2002, 73, 294–298. [Google Scholar] [CrossRef]

- Bandelt, M.J.; Billington, S.L. Impact of Reinforcement Ratio and Loading Type on the Deformation Capacity of High-Performance Fiber-Reinforced Cementitious Composites Reinforced with Mild Steel. J. Struct. Eng. 2016, 142, 04016084. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. A comparison of existing analytical methods to predict the flexural capacity of Ultra High Performance Concrete (UHPC) beams. Constr. Build. Mater. 2018, 172, 10–18. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, D.; Huang, Y.; Kang, S. Experimental and simulative analysis of flexural performance in UHPC-RC hybrid beams. Constr. Build. Mater. 2024, 436, 136889. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chueh, C.-Y. Cyclic behavior of UHPFRC flexural members reinforced with high-strength steel rebar. Eng. Struct. 2016, 122, 108–120. [Google Scholar] [CrossRef]

- Graybeal, B.A. Flexural Behavior of an Ultrahigh-Performance Concrete I-Girder. J. Bridge Eng. 2008, 13, 602–610. [Google Scholar] [CrossRef]

- Yan, W.; Zhang, R.; Sushant, S.; Ashour, A.; Fu, S.; Qiu, L.; Zhang, Z.; Ge, W. Experimental investigation on flexural performance of UHPC beams reinforced with steel-FRP bars. Arch. Civ. Mech. Eng. 2024, 24, 132. [Google Scholar] [CrossRef]

- Bae, Y.; Pyo, S. Effect of steel fiber content on structural and electrical properties of ultra high performance concrete (UHPC) sleepers. Eng. Struct. 2020, 222, 111131. [Google Scholar] [CrossRef]

- Shao, Y.; Billington, S.L. Impact of cyclic loading on longitudinally-reinforced UHPC flexural members with different fiber volumes and reinforcing ratios. Eng. Struct. 2021, 241, 112454. [Google Scholar] [CrossRef]

- Shao, Y.; Billington, S.L. Impact of UHPC tensile behavior on steel reinforced UHPC flexural behavior. J. Struct. Eng. 2022, 148, 04021244. [Google Scholar] [CrossRef]

- Yang, I.H.; Joh, C.; Kim, B.-S. Structural behavior of ultra high performance concrete beams subjected to bending. Eng. Struct. 2010, 32, 3478–3487. [Google Scholar] [CrossRef]

- Gao, X.-L.; Wu, K.; Guo, Y.-Q.; Zhao, Y.-C.; Guo, J.-Y. Experimental and numerical study on flexural behaviors of damaged RC beams strengthened with UHPC layer using the bonding technology of post-installed reinforcing bar. Constr. Build. Mater. 2023, 391, 131835. [Google Scholar] [CrossRef]

- Gu, J.-B.; Wang, J.-Y.; Lu, W. An experimental assessment of ultra high performance concrete beam reinforced with negative Poisson’s ratio (NPR) steel rebar. Constr. Build. Mater. 2022, 327, 127042. [Google Scholar] [CrossRef]

- Gu, J.-B.; Wang, J.-Y.; Tao, Y. Experimental assessment on cyclic flexural behavior of UHPC beam reinforced with negative Poisson’s ratio (NPR) steel rebar. Compos. Struct. 2023, 322, 117353. [Google Scholar] [CrossRef]

- Zheng, X.; Tao, Z.; He, M.; Geng, L. Investigation of the mechanical response and failure mode of high-ductility concrete (HDC) beams reinforced with negative Poisson’s ratio (NPR) steel rebar. Constr. Build. Mater. 2025, 475, 141178. [Google Scholar] [CrossRef]

- Wang, J.Y.; Gu, J.B.; Liu, C.; Huang, Y.H.; Xiao, R.C.; Ma, B. Flexural behavior of ultra high performance concrete beams reinforced with high strength steel. Struct. Eng. Mech. 2022, 81, 539–550. [Google Scholar] [CrossRef]

- GB 175-2023; Standardization Administration of the People’s Republic of China (SAC). Common Portland Cement. Standards Press of China: Beijing, China, 2023.

- Bae, Y.; Pyo, S. Ultra high performance concrete (UHPC) sleeper: Structural design and performance. Eng. Struct. 2020, 210, 110374. [Google Scholar] [CrossRef]

- Li, Y.; Aoude, H. Effect of high-strength and stainless steel reinforcement on the flexural behavior of UHPC beams. Case Stud. Constr. Mater. 2024, 20, e03271. [Google Scholar] [CrossRef]

- Shao, Y.; Billington, S.L. Predicting the two predominant flexural failure paths of longitudinally reinforced high-performance fiber-reinforced cementitious composite structural members. Eng. Struct. 2019, 199, 109581. [Google Scholar] [CrossRef]

| Test Batch | Specimen ID | Type of Cross-Section | Type of Steel Rebar | Longitudinal Reinforcement | Reinforcement Ratio |

|---|---|---|---|---|---|

| The first part of the beams | R-400-2.62% | Rectangle | HRB 400 | 3C20 | 2.62% |

| R-600-2.62% | Rectangle | HRB 600 | 3E20 | 2.62% | |

| T-400-2.91% | T-shape | HRB 400 | 4C20 | 2.91% | |

| T-600-2.91% | T-shape | HRB 600 | 4E20 | 2.91% | |

| The second part of the beams | R-400-1.72% | Rectangle | HRB 400 | 2C16 | 1.72% |

| R-400-2.58% | Rectangle | HRB 400 | 3C16 | 2.58% | |

| R-NPR-1.72% | Rectangle | NPR | 2N16 | 1.72% | |

| R-NPR-2.58% | Rectangle | NPR | 3N16 | 2.58% |

| Specimen Batch | Type of Steel Rebar | Diameter (mm) | Yielding Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| The first part of the beam specimens | HRB 400-1 | 20 | 480 | 613 | 16.6 |

| HRB 600 | 20 | 670 | 749 | 12.7 | |

| The second part of the beam specimens | HRB 400-2 | 16 | 425 | 575 | 14.0 |

| NPR steel rebar | 16 | 645 | 1097 | 40.3 | |

| Direct tensile specimens | HRB 400-2 | 16 | 425 | 575 | 14.0 |

| HRB 600 | 16 | 670 | 749 | 12.7 | |

| NPR steel rebar | 16 | 645 | 1097 | 40.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, J.-B.; Chen, Y.-H.; Tao, Y.; Wang, J.-Y.; Zhang, S.-X. A Comparative Study on the Flexural Behavior of UHPC Beams Reinforced with NPR and Conventional Steel Rebars. Buildings 2025, 15, 2358. https://doi.org/10.3390/buildings15132358

Gu J-B, Chen Y-H, Tao Y, Wang J-Y, Zhang S-X. A Comparative Study on the Flexural Behavior of UHPC Beams Reinforced with NPR and Conventional Steel Rebars. Buildings. 2025; 15(13):2358. https://doi.org/10.3390/buildings15132358

Chicago/Turabian StyleGu, Jin-Ben, Yu-Han Chen, Yi Tao, Jun-Yan Wang, and Shao-Xiong Zhang. 2025. "A Comparative Study on the Flexural Behavior of UHPC Beams Reinforced with NPR and Conventional Steel Rebars" Buildings 15, no. 13: 2358. https://doi.org/10.3390/buildings15132358

APA StyleGu, J.-B., Chen, Y.-H., Tao, Y., Wang, J.-Y., & Zhang, S.-X. (2025). A Comparative Study on the Flexural Behavior of UHPC Beams Reinforced with NPR and Conventional Steel Rebars. Buildings, 15(13), 2358. https://doi.org/10.3390/buildings15132358