Study of the Possibility of Transition to More Stringent Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan

Abstract

1. Introduction

2. Materials and Methods

- -

- -

3. Results

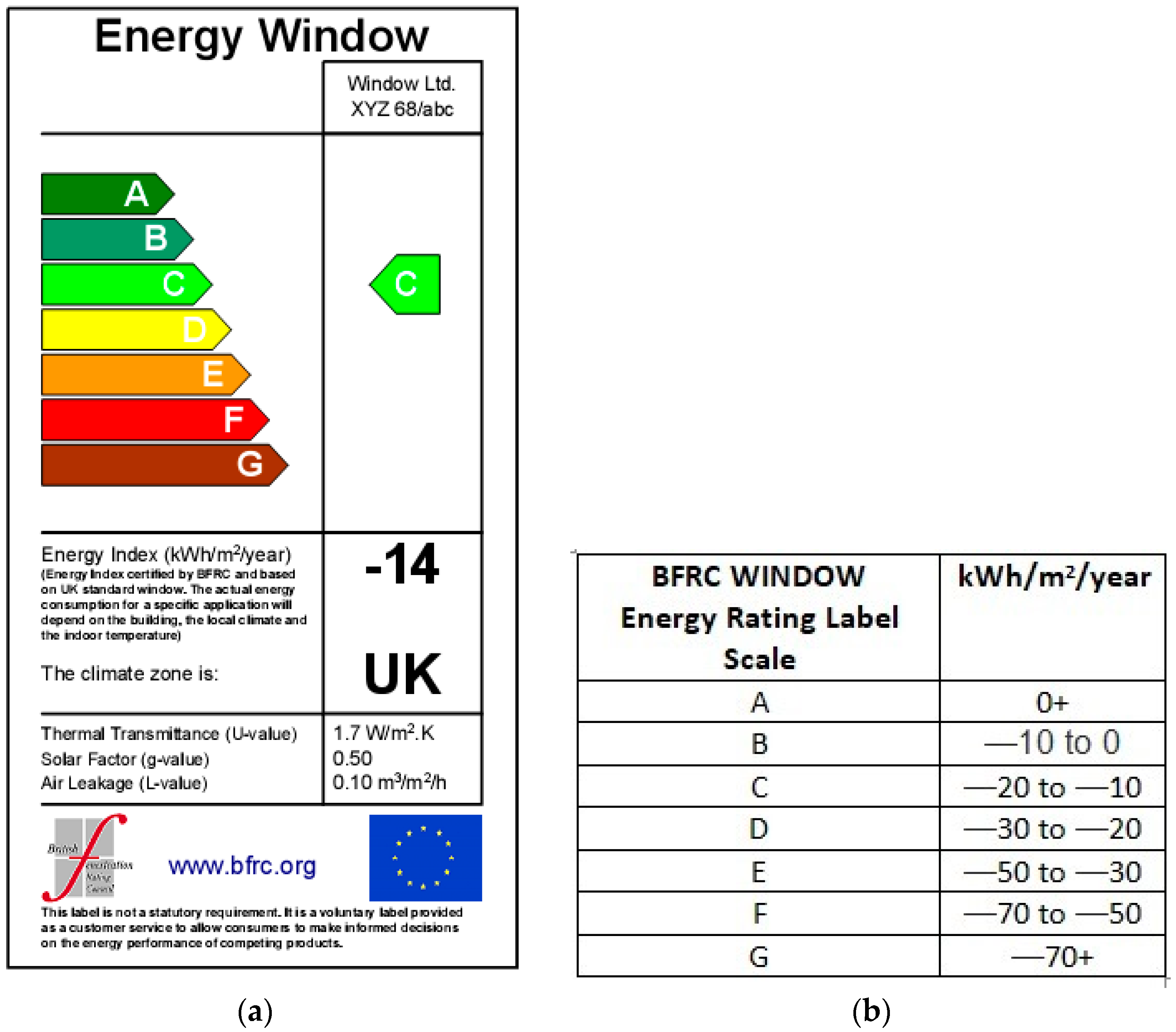

- (a)

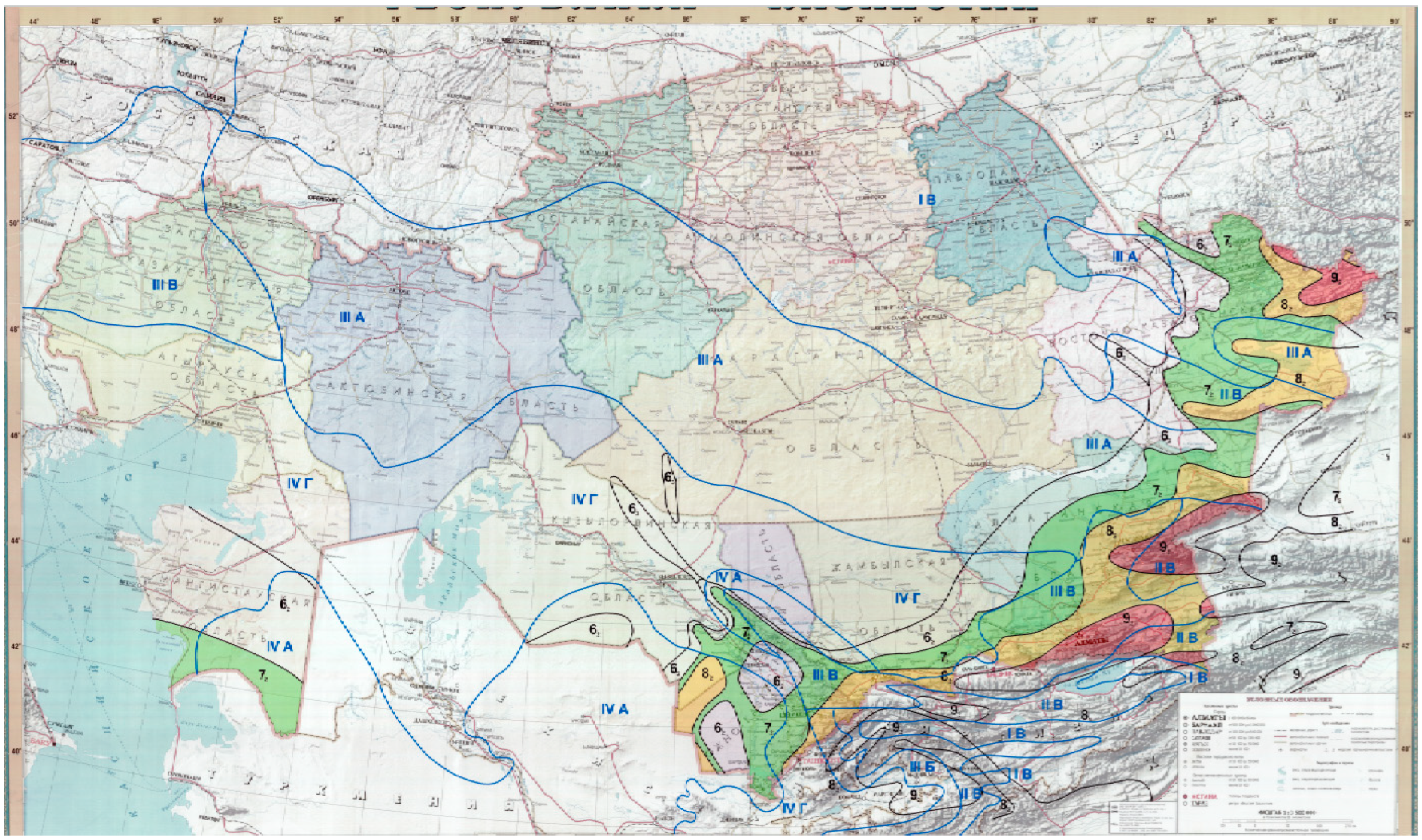

- For construction areas with Dd ≤ 3500 °C × day, it is recommended to use windows with a reduced heat transfer resistance of R ≥ 0.6 m2 × °C/W for construction areas relative to the regions and settlements of the cities of Taraz, Turkestan, Aktau, Shymkent, and the nearest points to them. These characteristics can be accepted for glazing balconies, loggias, and verandas in all climatic regions.

- (b)

- For the construction area with Dd = 3500÷5200 °C × day, it is recommended to use energy-efficient windows with R ≥ 0.8 m2 × °C/W for the construction area relative to the regions and settlements of the cities of Almaty, Aralsk, Atyrau, Bakanas, Bakhta, Beineu, Ganyushkino, Zhalpaktal, Zharkent, Kazaly, Karaulkeldi, Kyzylorda, Taipak, Taldykorgan, Uil, Ulanbel, Usharal, Shalkar, Emba, and the nearest points to them.

- (c)

- For construction areas with Dd ≥ 5200 °C × days, it is recommended to use energy-efficient windows with a heat transfer resistance of RFr ≥ 1.0 m2 × °C/W for construction areas relative to the regions and settlements of the cities of Aktobe, Amangeldy, Astana, Atbasar, Balkhash, Ertis, Zhezkazgan, Zhympity, Zaisan, Karaganda, Karkaraly, Karsakpay, Katon-Karagay, Kokpekty, Kokshetau, Kostanay, Kyzylzhar, Pavlodar, Petropavlovsk, Semipalatinsk, Torgay, Uralsk, Ust-Kamenogorsk, Yrgiz, and the nearest points to them.

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yessengabulov, S. Dissertation for the degree of Candidate of Technical Sciences on the topic. In Energy-Efficient Exterior Walls with Organized Air Exchange; Moscow, Russia, 2009. Available online: https://www.dissercat.com/content/energoeffektivnye-naruzhnye-steny-s-organizovannym-vozdukhoobmenom?ysclid=mcnpfoqnbi531033583 (accessed on 22 June 2025).

- Dastenova, G.D. Production of Building Materials, Products and Structures, Written on the Topic: Increasing the Moisture regime of Modern Porous Concrete External Wall Blocks (Increasing the Moisture Regime of Modern Expanded Clay Concrete Blocks). Dissertation Work for the Degree of Master of Engineering and Technology in the Specialty 6M073000, L.N. Gumilyov Eurasian National University, Astana, Kazakhstan, 2019. [Google Scholar]

- Terekhova, I.A. Recommendations on the Possible Application in Kazakhstan of International Methods for the Certification and Energy Labeling of Building Materials, Products, and Structures with the Aim of Improving the Energy Efficiency of Buildings; UNDP/GEF RK: New York, NY, USA, 2011. [Google Scholar]

- Orynbasarov, A.S. The Existing Market for Basic Building Materials, Products, and Elements of External Enclosing Structures Manufactured in Kazakhstan and Their Technical Characteristics; UNDP/GEF RK: New York, NY, USA, 2011. [Google Scholar]

- GOST 23166-99; Window Blocks. General Technical Conditions. UNDP: New York, NY, USA, 2016.

- SN RK 2.04-21-2004; Energy Consumption and Thermal Protection of Civil Buildings. UNDP: New York, NY, USA, 2004.

- SN RK 2.04-07-2022; Thermal Protection of Buildings. UNDP: New York, NY, USA, 2022.

- SP RK 2.04-01-2017; Building Climatology. UNDP: New York, NY, USA, 2017.

- Abdurafikov, R.; Spiridonov, A.V. How to Evaluate Energy Efficient Windows, Energy Saving Journal, No. 8, 2013. Available online: https://bik.sfu-kras.ru/elib/view?id=PRSV-/%D0%90%2013-122448&ysclid=mcnpoh3qss238328811 (accessed on 22 June 2025).

- Deshko, V.I.; Buiak, N.A.; Bilous IYu Hurieiev, M.V.; Holubenko, O.O. Assessment of the influence of vacuum replacement on energy consumption and conditions of comfort in building on the basis of dynamic modeling. Power Eng. Econ. Tech. Ecol. 2018, 3, 52–62. [Google Scholar] [CrossRef]

- Galyamichev, A. Bearing Capacity of a Glass Facade Systems, Including Stiffness of Nodes and Work of Filling. In Proceedings of the STCCE: International Scientific Conference on Socio-Technical Construction and Civil Engineering 2022: Lecture Notes in Civil Engineering, Kazan, Russia, 21–29 April 2022; Springer Nature: Cham, Switzerland, 2022; Volume 291, pp. 43–63. [Google Scholar] [CrossRef]

- Burmaka, V.; Tarasenko, M.; Kozak, K.; Omeiza, L.A.; Sabat, N. Effective use of daylight in office rooms. J. Daylighting 2020, 7, 154–166. [Google Scholar] [CrossRef]

- Burmaka, V.; Tarasenko, M.; Kozak, K.; Khomyshyn, V. Definition of a composite in ex of glazing rooms, Eastern-European. J. Enterp. Technol. 2018, 4, 22–28. [Google Scholar] [CrossRef]

- Yessengabulov, S. Assessment and Analysis of Energy Efficiency and Economic Benefits from the Introduction of Energy-Efficient Translucent Structures; UNDP/GEF Kazakhstan: New York, NY, USA, 2015. [Google Scholar]

- Yessengabulov, S. Conclusion on the Possibilities of Transitioning to Stricter Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan; UNDP/GEF RK: New York, NY, USA, 2015. [Google Scholar]

- Yessengabulov, S. Conclusion on the Feasibility of Energy Labeling of Translucent Structures; UNDP/GEF Kazakhstan: New York, NY, USA, 2015. [Google Scholar]

| No. | Classes | Thermal Resistance, m2∙°C/W |

|---|---|---|

| 1 | A1 | 0.80 and more |

| 2 | A2 | 0.75–0.79 |

| 3 | B1 | 0.70–0.74 |

| 4 | B2 | 0.65–0.69 |

| 5 | C1 | 0.60–0.64 |

| 6 | C2 | 0.55–0.59 |

| 7 | D1 | 0.50–0.54 |

| 8 | D2 | 0.45–0.49 |

| 9 | E1 | 0.40–0.44 |

| 10 | E2 | 0.35–0.39 |

| No. | Item | Degree Days Dd, °C, Day/Duration of Heating Period, , Day | Standardized Values of Heat Transfer Resistance SPK Roreq, m2 · °C/W |

|---|---|---|---|

| Akmola region | |||

| 1 | Astana | 6286/216 | 0.62 |

| 2 | Atbasar | 6496/218 | 0.64 |

| 3 | Kokshetau | 6163/217 | 0.61 |

| Aktobe region | |||

| 4 | Aktobe | 5623/203 | 0.57 |

| 5 | Amankeldi | 5858/202 | 0.59 |

| 6 | Yrgyz | 5358/188 | 0.55 |

| 7 | Karaulkeldy | 4850/188 | 0.51 |

| 8 | Wil | 4974/187 | 0.52 |

| 9 | Shalkar | 5057/188 | 0.53 |

| 10 | Emba | 5187/195 | 0.54 |

| Almaty region | |||

| 11 | Almaty | 3641/167 | 0.42 |

| 12 | Bakanas | 4412/173 | 0.48 |

| 13 | Zharkent | 3623/161 | 0.42 |

| 14 | Taldykorgan | 4148/175 | 0.46 |

| 15 | Usharal | 4521/178 | 0.49 |

| Atyrau region | |||

| 16 | Atyrau | 4160/177 | 0.46 |

| 17 | Ganyushkino | 3863/174 | 0.44 |

| East Kazakhstan region | |||

| 18 | Bakhty | 4851/181 | 0.51 |

| 19 | Semipalatinsk | 5806/203 | 0.59 |

| 20 | Zaisan | 6587/192 | 0.64 |

| 21 | Katon-Karagai | 5934/230 | 0.60 |

| 22 | Kokpekty | 6508/212 | 0.64 |

| 23 | Ust-Kamenogorsk | 5871/206 | 0.59 |

| Zhambyl region | |||

| 24 | Taraz | 3477/164 | 0.41 |

| 25 | Ulanbel | 4001/171 | 0.45 |

| West Kazakhstan region | |||

| 26 | Zhympity | 5219/194 | 0.54 |

| 27 | Taipak | 4484/183 | 0.49 |

| 28 | Uralsk | 5400/200 | 0.56 |

| 29 | Zhalpaktal | 4719/188 | 0.50 |

| Karaganda region | |||

| 30 | Balkhash | 5235/189 | 0.54 |

| 31 | Zhezkazgan | 5432/194 | 0.56 |

| 32 | Karagandy | 5971/214 | 0.60 |

| 33 | Karkaraly | 6188/225 | 0.61 |

| 34 | Karsakpai | 5656/202 | 0.57 |

| 35 | Kyzylzhar | 5615/197 | 0.57 |

| Kostanay region | |||

| 36 | Kostanai | 6227/214 | 0.62 |

| 37 | Torgay | 5782/196 | 0.58 |

| Kyzylorda region | |||

| 38 | Aralsk | 4582/179 | 0.49 |

| 39 | Kazaly | 4263/174 | 0.47 |

| 40 | Kyzylorda | 3965/168 | 0.45 |

| Mangistau region | |||

| 41 | Beineu | 3758/167 | 0.43 |

| 42 | Fort-Shevchenko | 3007/155 | 0.38 |

| Pavlodar region | |||

| 43 | Ertis | 6377/214 | 0.63 |

| 44 | Pavlodar | 6212/212 | 0.62 |

| North Kazakhstan region | |||

| 45 | Petropavlovsk | 6571/222 | 0.64 |

| South Kazakhstan region | |||

| 46 | Turkestan | 3069/149 | 0.38 |

| 47 | Shymkent | 2660/143 | 0.35 |

| Translucent Constructions | |||||||

|---|---|---|---|---|---|---|---|

| Filling of the Light Aperture | In Wooden or PCV Glazing | In Aluminum Glazing | |||||

| Ror, × °C/W | t | k | Ror, × °C/W | t | K | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 | Double glazing of ordinary glass in twin glazing | 0.4 | 0.75/0.7 | 0.62 | -- | 0.70 | 0.62 |

| 2 | Double glazing with hard selective coating in twin glazing | 0.55 | 0.75 | 0.65 | -- | 0.70 | 0.65 |

| 3 | Double glazing of ordinary glass in separate bindings | 0.44 | 0.65/0.6 | 0.62 | 0.34 * | 0.8/0.6 (0.8) | 0.62 |

| 4 | Double glazing with hard selective coating in separate bindings | 0.57 | 0.65 | 0.60 | 0.45 | 0.60 | 0.60 |

| 5 | Glass hollow glass blocks (with joint width of 6 mm) with dimensions, mm: | ||||||

| 194 × 194 × 98 | 0.31 | 0.9 | 0.40 (without binding) | ||||

| 244 × 244 × 98 | 0.33 | 0.9 | 0.45 (without binding) | ||||

| 6 | Box section profile glass | 0.31 | 0.9 | 0.50 (without binding) | |||

| 7 | Double organic glass for skylights | 0.36 | 0.9 | 0.9 | — | 0.90 | 0.90 |

| 8 | Triple organic glass for skylights | 0.52 | 0.9 | 0.83 | — | 0.90 | 0.83 |

| 9 | Triple glazing made of ordinary glass in split-jointed bindings | 0.55 | 0.5/-- | 0.70 | 0.46 | 0.5/-- | 0.70 |

| 10 | Triple glazing with hard selective coating in split-jointed glazing bars | 0.60 | 0.50 | 0.67 | 0.50 | 0.50 | 0.67 |

| 11 | Single glazing unit in a single pane of glass: | ||||||

| plain | 0.38 | 0.8/-- | 0.76 | 0.34 | 0.8/-- | 0.76 | |

| with hard selective coating | 0.51 | 0.8/-- | 0.75 | 0.43 | 0.8/-- | 0.75 | |

| with soft selective coating | 0.56 | 0.8/-- | 0.54 | 0.47 | 0.8/-- | 0.54 | |

| 12 | Double-glazed unit in a single pane of glass: | ||||||

| ordinary (with 8 mm glass spacing) | 0.51 | 0.80/- | 0.74 | 0.43 | 0.80/-- | 0.74 | |

| ordinary (with 12 mm glass spacing) | 0.54 | 0.80/- | 0.74 | 0.45 | 0.80/- | 0.74 | |

| with hard, selective coating | 0.58 | 0.80/- | 0.68 | 0.48 | 0.80/- | 0.68 | |

| soft, selective coating | 0.68 | 0.80/- | 0.48 | 0.52 | 0.80/- | 0.48 | |

| with hard, selective coating and argon filling | 0.65 | 0.80/- | 0.68 | 0.53 | 0.80/- | 0.68 | |

| 13 | Ordinary glass and single glazing unit in separate glass bindings: | ||||||

| ordinary | 0.56 | 0.60/- | 0.63 | — | 0.60 | 0.63 | |

| hard, selective coated | 0.65 | 0.60/- | 0.51 | — | 0.60 | 0.58 | |

| with soft, selective coating | 0.72 | 0.60/- | 0.51 | — | 0.60 | 0.38 | |

| with hard, selective coating and argon filling | 0.69 | 0.60/- | 0.58 | — | 0.60 | 0.58 | |

| Climatic Regions | Climatic Sub-Areas | Average Monthly Air Temperature in January, °C | Average Wind Speed for Three Winter Months, m/s | Average Monthly Air Temperature in July, °C | Average Monthly Relative Humidity in July, % |

|---|---|---|---|---|---|

| I | IA | From minus 32 and below | — | From 0 to 19 | — |

| IB | From minus 28 and below | 5 and more | From 0 to 13 | St. 75 | |

| IC | From minus 14 to minus 28 | — | From 12 to 21 | — | |

| ID | From minus 14 to minus 28 | 5 and more | From 0 to 14 | St. 75 | |

| IE | From minus 14 to minus 32 | — | From 10 to 20 | — | |

| II | IIA | From minus 4 to minus 14 | 5 and more | From 8 to 12 | St. 75 |

| IIB | From minus 3 to minus 5 | 5 and more | From 12 to 21 | St. 75 | |

| IIC | From minus 4 to minus 14 | — | From 12 to 21 | — | |

| IID | From minus 5 to minus 14 | 5 and more | From 12 to 21 | St. 75 | |

| III | IIIA | From minus 14 to minus 20 | — | From 21 to 25 | — |

| IIIB | From minus 5 to minus 2 | — | From 21 to 25 | — | |

| IIIC | From minus 5 to minus 2 | — | From 21 to 25 | — | |

| IV | IVA | From minus 10 to 2 | — | From 28 and less | — |

| IVB | From 2 to 6 | — | From 22 to 28 | 50 and more in 15 h | |

| IVC | From 0 to 2 | — | From 25 to 28 | — | |

| IVD | From minus 15 to 0 | — | From 25 to 28 | — |

| Indicator | At Degree-Days of Heating Period RK | ||

|---|---|---|---|

| Up to 3500 | Up to 3500 to 5200 | 5200 and More | |

| Current normative values of heat transfer resistance of translucent constructions | 0.4 | 0.5 | 0.6 |

| Recommended values of heat transfer resistance of translucent constructions | 0.6 | 0.8 | 1.0 |

| Window Energy Efficiency Labels | Window Energy Efficiency Class | |

|---|---|---|

| Classes | R, m2 × °C/W |  |

| A | 1.0 and more | |

| 0.95 ÷ 0.99 | ||

| B | 0.90 ÷ 0.94 | |

| 0.85 ÷ 0.89 | ||

| C | 0.80÷ 0.84 | |

| 0.75 ÷ 0.79 | ||

| D | 0.70 ÷ 0.74 | |

| 0.65 ÷ 0.69 | ||

| E | 0.60 ÷ 0.64 | |

| 0.55 ÷ 0.59 | ||

| F | 0.50 ÷ 0.54 | |

| 0.45 ÷ 0.49 | ||

| G | 0.40 ÷ 0.44 | |

| 0.35 ÷ 0.39 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yessengabulov, S.; Kozhakhmet, M.; Zharkenov, Y.; Abakanov, Y.; Dastenova, G.; Nurbayeva, M.; Kozhakhmet, A.; Zhankeldi, M.; Jexembayeva, A. Study of the Possibility of Transition to More Stringent Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan. Buildings 2025, 15, 2354. https://doi.org/10.3390/buildings15132354

Yessengabulov S, Kozhakhmet M, Zharkenov Y, Abakanov Y, Dastenova G, Nurbayeva M, Kozhakhmet A, Zhankeldi M, Jexembayeva A. Study of the Possibility of Transition to More Stringent Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan. Buildings. 2025; 15(13):2354. https://doi.org/10.3390/buildings15132354

Chicago/Turabian StyleYessengabulov, Serikbolat, Meiram Kozhakhmet, Yerkebulan Zharkenov, Yeldos Abakanov, Gulzhamal Dastenova, Marzhan Nurbayeva, Aru Kozhakhmet, Meiir Zhankeldi, and Assel Jexembayeva. 2025. "Study of the Possibility of Transition to More Stringent Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan" Buildings 15, no. 13: 2354. https://doi.org/10.3390/buildings15132354

APA StyleYessengabulov, S., Kozhakhmet, M., Zharkenov, Y., Abakanov, Y., Dastenova, G., Nurbayeva, M., Kozhakhmet, A., Zhankeldi, M., & Jexembayeva, A. (2025). Study of the Possibility of Transition to More Stringent Energy Efficiency Requirements for Translucent Structures in the Republic of Kazakhstan. Buildings, 15(13), 2354. https://doi.org/10.3390/buildings15132354