Abstract

The incorporation of fibers in cement-based materials has gained attention in the construction sector in recent decades, aiming to improve the mechanical performance of composites. This present work evaluates the influence of synthetic and natural fibers as reinforcements in cement mortars, analyzing their effects on both physical and mechanical properties through destructive and non-destructive testing. Polypropylene fibers (PPFs) were considered synthetic reinforcement, whereas alfa fibers (AFs) were selected as a sustainable alternative. Compressive strength, flexural strength and Ultrasonic Pulse Velocity (UPV) were conducted to assess mechanical behavior and material integrity as well as density, water absorption and voids content. Additionally, a statistical approach was performed to compare the properties of both types of fibers and determine their significance in improving mortar properties. The results indicate that both PPFs and AFs significantly improve the flexural strength and promote a ductile failure mode without compromising workability. Moreover, UPV measurements suggest that fiber incorporation does not adversely impair the internal homogeneity of the material. The results obtained confirm the effectiveness of fiber reinforcement, offering valuable insights regarding the potential of AF as a strong candidate for sustainable building purposes and practical applications.

1. Introduction

The use of fibers in cement-based materials has become increasingly common in recent decades as a way to improve the strength and durability of construction materials [1]. Traditionally, this reinforcement has been achieved through the use of synthetic fibers, such as steel, glass [2] or polymeric fibers [3], with polypropylene as one of the most utilized in the construction sector, recognized for its effectiveness in improving properties like tensile strength, flexural strength and crack control [4,5]. Nonetheless, the production of synthetic fibers involves considerable energy consumption and the use of non-renewable resources, raising concerns about environmental sustainability [6].

In this context, natural fibers (NFs), particularly plant-based fibers, have emerged as a more environmentally friendly alternative [7]. Their biodegradable, renewable nature and low environmental impact make them an attractive option to replace synthetic fibers [8]. Moreover, various studies have shown that these fibers can significantly enhance the mechanical performance of mortars, increasing compressive and flexural strength, as well as properties such as workability and Ultrasonic Pulse Velocity (UPV) [9,10,11].

However, a major challenge lies in the compatibility of cement matrices with NF. In particular, its structural composition, characterized by amorphous regions and hydrophilic behavior, can lead to increased porosity and water absorption in the composite [12,13]. Additionally, the highly alkaline environment of cement-based materials may induce premature degradation of the fibers [14]. These conditions, among others, are recognized to weaken the fiber–matrix interface, compromising mechanical performance, long-term durability, and even reduce the fresh-state workability.

In order to overcome this limitation, various chemical treatments have been developed, with alkaline treatments using sodium or calcium hydroxide solutions being among the most common. These treatments modify the fiber surface, remove impurities and improve fiber–matrix adhesion [4,15]. Properly treated, plant fibers can retain their integrity within the mortar and contribute effectively to reinforcement, even under aggressive service conditions [15].

Among the various natural fibers studied, alfa fibers, extracted from the leaves of esparto grass (Stipa tenacissima L.), have shown remarkable potential as reinforcements in cement-based composites [16,17]. This perennial grass, native to semi-arid regions of the western Mediterranean, has historically been used in crafts, papermaking and textiles and more recently has attracted attention for its mechanical performance in sustainable construction materials [16]. The fibers extracted from its leaves possess competitive specific strength and a morphology favorable for integration into cementitious systems, particularly after alkaline treatment [18,19]. Studies have shown that esparto fibers can significantly improve strength and mortar toughness by bridging cracks and reducing the brittleness of the material [16,17]. Moreover, its local availability and renewable nature make it a suitable reinforcement aligned with circular economy principles and environmental sustainability in the construction industry [20].

In this context and considering that the incorporation of fibers into composites can modify both mechanical and physical behaviors, the present study compares the mechanical performance of cement mortars reinforced with synthetic polypropylene fibers (PPFs) and chemically treated alfa fibers (AFs). While synthetic fibers are commonly used to enhance flexural and crack resistance through more effective stress redistribution, improvement of fracture toughness and promoting a more ductile failure mode [21], natural fibers offer a more sustainable alternative by reducing the environmental impact of these materials [22]. Hence, this research focuses on key properties such as fresh mix workability and flexural and compressive strength to determine the potential of natural fibers as sustainable reinforcement in cementitious materials, further complimented by a non-destructive technique like UPV, aimed to reveal insights on the homogeneity of the mixture. Additionally, water absorption, density and porosity were evaluated to further compare the physical properties.

This comparative study aims to provide a quantitative understanding of the performance of both reinforcement types, offering a direct comparison between PPF and AF under identical conditions using different characterization techniques, and contributes to the development of more sustainable solutions for the construction industry. The integrated approach provides novel insights into the viability of alfa fibers as reinforcement for cement mortar, promoting the utilization of locally available resources.

2. Materials and Methods

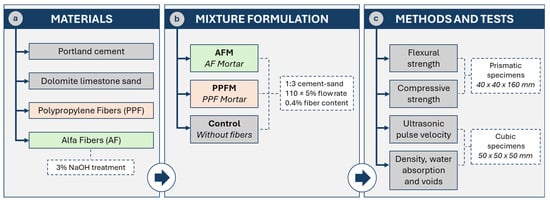

Figure 1 presents an overview of the experimental methodology adopted in this work, structured into three main categories: (a) materials; (b) mixture formulation; and (c) methods and tests. These aspects are explained in detail in the following sections.

Figure 1.

Experimental methodology followed.

2.1. Materials

2.1.1. Mortar Components

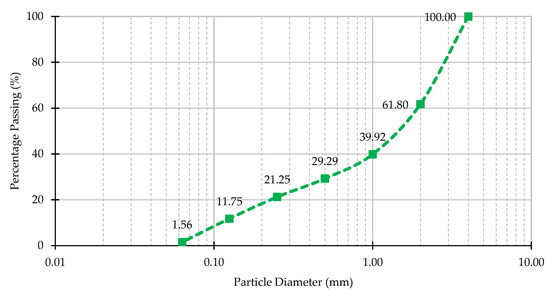

Portland Cement Type I was selected as the cementitious material for the fiber-reinforced mortars, in accordance with the classification outlined by the UNE-EN 197-1 standard [23]. Additionally, the fine aggregate used was a dolomite limestone sand sourced from southern Spain. The particle size distribution, ranging from 0 to 4 mm, is shown in Figure 2.

Figure 2.

Fine aggregate particle size distribution.

2.1.2. Synthetic and Natural Fibers

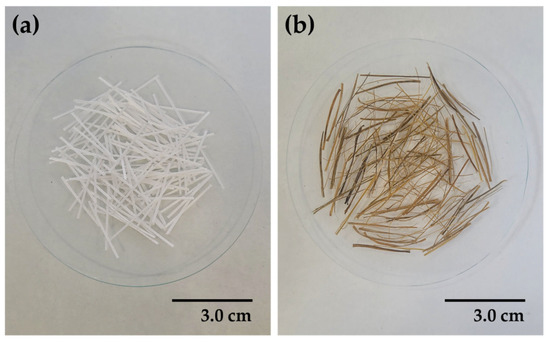

The synthetic fibers incorporated in this study were the commercially available MasterFiber 235, supplied by Master Builder Solutions, with a length of 3.0 cm. These extruded polypropylene fibers are shaped with a rough surface and a corrugated profile to promote an effective anchorage with the cementitious matrix (see Figure 3a). In contrast, the natural fibers included in the present work were manually collected and mechanically separated from alfa grass leaves to be incorporated as reinforcements in the mortar, identified for the purpose of this study as alfa fibers.

Figure 3.

Fibers incorporated in this study: (a) polypropylene fibers; (b) alfa fibers.

In order to improve the compatibility and durability of cementitious matrices, several studies have highlighted alkaline treatments as optimal procedures to successfully reduce water absorption, improve the surface roughness and increase the crystallinity of NF, thereby enhancing the mechanical performance of the composite [24,25]. In this context, the use of sodium hydroxide (NaOH) has become a widely adopted method for treating natural fibers, with concentrations typically ranging from 2% to 5%. However, studies have reported that a 5% NaOH concentration may adversely affect the inherent properties of NF [26,27]. Considering these observations and in line with the findings of previous research [28,29], a 3% NaOH concentration was selected for this study.

Based on this selection, the alfa fibers underwent alkaline treatment following the methodology proposed by Alcivar-Bastidas et al. [29,30]. The treatment consisted of soaking the AF in a 3% NaOH solution (prepared with deionized water) for 4 h, followed by soaking in common water for 10 h. Next, they were washed and rinsed, to conclude the procedure by oven-drying the fibers at 85 °C for 24 h. The treated fibers were subsequently cut to 3.0 cm using a manual procedure developed in the laboratory, in accordance with the results reported by Alcivar-Bastidas et al. [30], and to match the length of the PPF, thereby enabling more consistent comparative conditions. The final appearance of AF is shown in Figure 3b.

In addition, Table 1 presents a summary of the key properties of AF after the NaOH treatment, providing essential information regarding their reinforcing potential within mortars.

Table 1.

Properties of alfa fibers following alkaline procedure.

2.2. Mixture Formulation

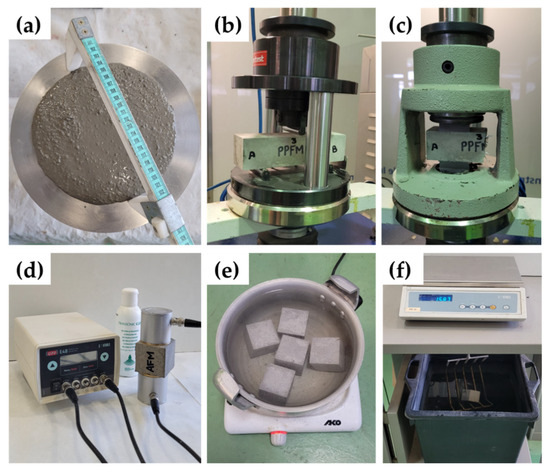

Three different mortar dosages were designed in this study, maintaining a 1:3 cement–sand ratio and adjusting the water content to accomplish a flow rate of 110 ± 5% in the flow table test (see Figure 4a), according to the methodology outlined in the UNE-EN 1015-3 [31]. This resulted in a fixed water-to-cement ratio of 0.70. The mixtures were classified as follows: (i) mortar with polypropylene fibers (PPFM), (ii) mortar with alfa fibers (AFM) and (iii) mortar without fibers (CONTROL).

Figure 4.

Procedures and tests conducted in the experimental program: (a) flow rate in fresh state; (b) flexural strength test; (c) compressive strength test; (d) UPV test; (e) boiling procedure of specimens; and (f) weighing specimen suspended in water.

There is considerable variability in the reported fiber content (FC) used in cement-based materials reinforced with NF, as well as fiber dimensions, typically expressed either by volume or weight [32]. Although several studies have indicated that the incorporation of NF can enhance the mechanical properties of cementitious composites, there is no consensus regarding an optimal FC, mainly because of the inherent variability of NF [6,33]. In this line, Table 2 provides a brief summary of selected studies employing different NF in cement-based materials, highlighting the diversity in the fiber dosages used and key findings observed. Therefore, to evaluate the reinforcement potential of AF over PPF in mortars, and following the studies listed in Table 2, the FC was defined as a percentage of the total dry materials (cement and sand) by weight to ensure consistency in the results. Considering the comparative aim of this study, chemical admixtures were excluded to isolate the effects of fiber incorporation. After casting preliminary batches, where higher FC led to reduced fresh-state workability and fiber agglomeration, a fixed FC of 0.4% was selected. This value aligns with the upper limit recommended by the PPF supplier and ensures the workability range of the fresh mortar. The final mixture proportions are listed in Table 3.

Table 2.

Natural fiber-reinforced cement mortar studies.

Table 3.

Mortar mix composition.

The mixing process was performed according to the following sequence: sand and fibers were first combined in a dry state to ensure a uniform distribution in the mortar. Next, using an automatic mixer, water and cement were mixed for 30 s, followed by a gradual addition of the sand–fiber blend and then mixed at high speed for another 30 s. After a 90 s pause, the bowl was scraped, and the mixing process continued at high speed for 60 s.

2.3. Methods and Tests

The specimens were demolded 24 h after casting and placed in a controlled humid chamber at 20 ± 2 °C and 95 ± 2% relative humidity to be tested at the corresponding ages. The characterization techniques employed in this study are summarized in Table 4, detailing the number of specimens, dimensions and testing ages considered for each evaluated parameter. Each of these tests is described in detail in the subsequent sections.

Table 4.

Summary of characterization techniques.

The mechanical and physical tests selected in this study, listed in Table 4, are widely recognized in the literature for evaluating the performance of fiber-reinforced cementitious composites [28,38,39]. Flexural strength testing is particularly relevant in applications where materials are exposed to bending or tensile stresses. The flexural response also provides insight into the energy absorption and crack-bridging capacity of fibers, which are essential for assessing post-cracking ductility and structural resilience [40]. UPV, on the other hand, is a non-destructive method that indirectly assesses material quality through wave propagation speed. It correlates with internal compactness, homogeneity and potential long-term durability, especially in fiber-modified mortars, where internal interfaces can affect wave transmission [41]. Together, these tests offer a comprehensive perspective on both mechanical performance and physical integrity, facilitating an evaluation framework that reflects real-world applicability and supports the development of more sustainable construction materials.

2.3.1. Basic Physical Properties

Porosity is a crucial physical parameter to further evaluate long-term performance of cement mortars, linked to the voids and densities of the composite materials [42]. Hence, to evaluate the influence of fibers in the matrix, this research assessed water absorption, density and void at 28 days, considering five different cubic specimens of 50 mm per mix and following the immersion and boiling approach specified by the ASTM C642-21 [43]. The specimens were oven-dried at 110 °C, until achieving constant weight, immersed in water and afterward boiled to reach saturation, allowing to calculate the porosity of the mortars (see Figure 4e,f).

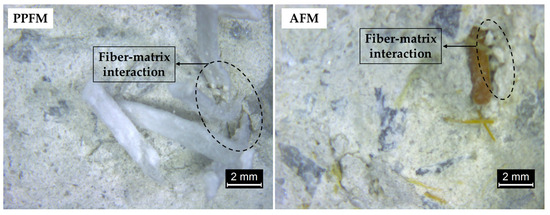

Additionally, as part of the characterization, microscopic images of the specimens were obtained using an LEICA DVM2000 digital microscope to further analyze the interaction between PPF and AF within the cementitious matrix.

2.3.2. Mechanical Properties

After being cured in the humid chamber for 7, 14 and 28 days, flexural strength (FS) was determined using prismatic specimens of 40 × 40 × 160 mm, applying the three-point loading method (see Figure 4b). Consequently, compressive strength (CS) was evaluated in each of the half-broken prisms obtained from the FS test (see Figure 4c). Both tests were performed using a PROETI universal testing machine, following the testing procedures established in the UNE-EN 196-1 [44]. The reported results represent the mean value of three specimens per mixture.

2.3.3. Ultrasonic Pulse Velocity

In line with the ASTM C597-22 [45], UPV tests were performed at 7, 14 and 28 days of curing, using five different cubic specimens of 50 mm per mortar to ensure reliability. For this purpose, the direct method was adopted by means of a UPV Tester Model 58-E0048 by CONTROLS, with a frequency of 54 kHz. The emitter was placed opposite the receiver in the cube, considering two different sides (designated as side A and side B), discarding the top face of each specimen. The measurements were conducted on the lateral faces in contact with the mold, as these sides exhibited a uniform and smoother surface compared to the top and bottom faces of the specimens, which, for the purposes of this study, were excluded due to potential surface irregularities Additionally, to promote an effective pulse transmission between the transducers and the mortar, a transonic gel was utilized (see Figure 4d).

3. Results

3.1. Visual Inspection

A preliminary inspection was conducted to evaluate the effect of fiber incorporation in both the fresh and hardened states of mortar. The workability of the mixtures in the fresh state was not impaired by the addition of either PPF or AF, achieving the target flow rate in this study with no signs of segregation observed. In the hardened state, none of the specimens used for testing exhibited any significant differences in appearance, suggesting adequate fiber dispersion in the composite. Moreover, the surfaces were smooth and uniform, indicating a homogeneous mixture across the different mortars, as shown in Figure 5 and Figure 6. These qualitative observations were systematically analyzed to support the following mechanical and physical results.

Figure 5.

Visual aspect of prismatic 40 × 40 × 160 mm specimens: (a) PPFM; (b) AFM; and (c) CONTROL.

Figure 6.

Visual aspect of 50 mm cubic specimens: (a) PPFM; (b) AFM; and (c) CONTROL.

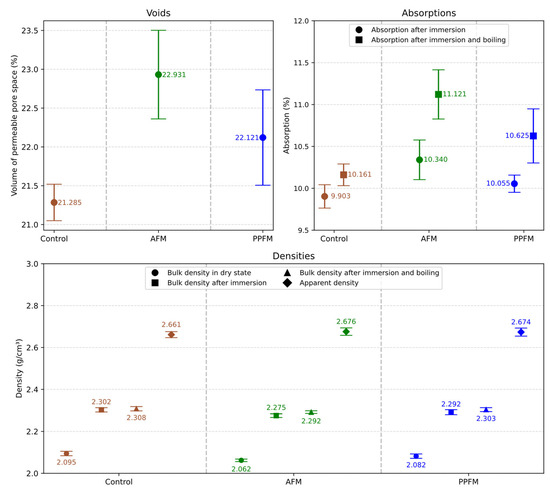

3.2. Basic Physical Characterization

Figure 7 presents the basic physical properties of the evaluated mortars (i.e., CONTROL, AFM and PPFM) in terms of void content, water absorption and density, highlighting the influence of the incorporated fibers. The modified mortars, particularly the one reinforced with synthetic fibers (i.e., PPFM), exhibit notably higher volumes of permeable pore space and increased absorption values, indicating a greater water retention capacity. Conversely, the incorporation of fibers shows minimal impact on both densities, likely due to the relatively low fiber dosage employed in the mixes, which was insufficient to (significantly) alter the mass-to-volume ratio of the mortars.

Figure 7.

Basic characterization of mortars.

Additionally, Figure 8 presents microscopic visualization of the PPFM and AFM specimens, providing insights into the interfacial transition zone between fibers and the cementitious matrix. These images offer qualitative information regarding fiber dispersion, surface adhesion and the integrity of the cement paste. While the images suggest adequate fiber–matrix interaction that may contribute to the mechanical performance, they also reveal minor voids and interfacial gap dispersion, which likely explain the observed minor increase in porosity, when compared to the fiber-reinforced mortars with the CONTROL mixture.

Figure 8.

Microscopic images of fiber-reinforced mortars.

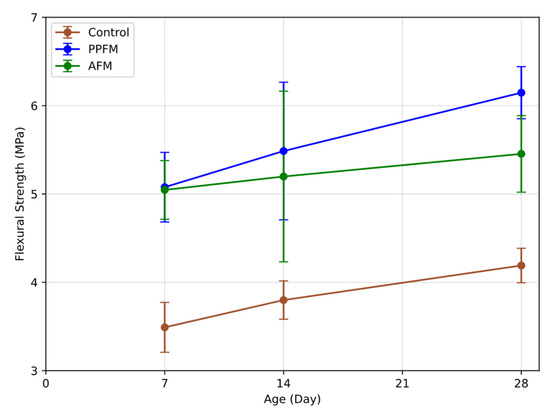

3.3. Flexural Strength

Flexural strength is a critical mechanical property of cement mortars, as it reflects the material’s ability to resist bending and cracking under tensile stresses, which are often more severe and detrimental than compressive loads in many structural applications [46,47]. In fiber-reinforced mortars, assessing FS becomes especially important because it directly indicates the contribution of fibers in enhancing the post-crack load-bearing capacity and crack-bridging behavior of the composite [48,49]. Unlike compressive strength, which may not fully capture the ductility or toughness improvements introduced by fiber reinforcement, flexural strength tests reveal how effectively fibers control crack propagation, increase energy absorption and maintain structural integrity under bending stresses [50,51]. Therefore, evaluating flexural performance is essential for quantifying the reinforcement effectiveness and ensuring the reliability of fiber-enhanced cementitious composites in practical applications.

Figure 9 shows the variation in FS of the three evaluated cement mortar mixtures (i.e., CONTROL, AFM and PPFM) measured at curing ages of 7, 14 and 28 days. The reference mixture, represented in brown, consistently exhibits the lowest flexural strength across all curing periods, starting at approximately 3.5 MPa on day 7 and gradually increasing to almost 4.2 MPa by day 28. In contrast, both fiber-reinforced mortars show significantly improved performances. The AFM mixture, shown in green, starts at around 5.0 MPa and sees a modest increase over time, reaching approximately 5.5 MPa at 28 days. The most notable improvement is observed in the PPFM mixture, represented in blue, which begins with a flexural strength of about 5.1 MPa on day 7 and continues to increase more sharply than the others, reaching over 6.1 MPa by day 28. Although both fiber-reinforced mixtures outperform the CONTROL one, the overlapping error bars between AFM and PPFM at each curing age suggest that the differences in flexural strength between the two fiber types are not statistically significant. The preceding indicates that although polypropylene fiber shows a slightly higher average performance, both fiber additions offer comparable enhancements within the observed variability.

Figure 9.

Impact of fiber reinforcement on the flexural strength of cement mortars.

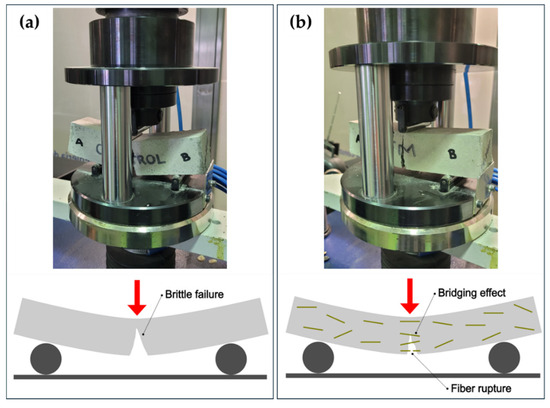

After 28 days of curing, the PPFM exhibited an improved flexural strength of 46.7% compared to the plain mix and only 12.7% higher than the AFM. In contrast, the AFM showed a 30.2% increase over CONTROL, demonstrating the positive effect of chemically treated alfa fibers and highlighting their competitive performance compared to synthetic fibers in terms of load-bearing capacity. Additionally, it is worth noting that the FS tests revealed evident differences in the failure modes of the fiber-reinforced mixtures and CONTROL mortars. As expected for cement-based materials, the CONTROL specimens exhibited a brittle fracture. In contrast, the PPFM and AFM specimens demonstrated more ductile behavior, displaying a noticeable bridging effect after initial cracking and partial structural integrity post-failure. These differences are illustrated in Figure 10.

Figure 10.

Failure mode during flexural test: (a) CONTROL specimen; (b) AFM specimen.

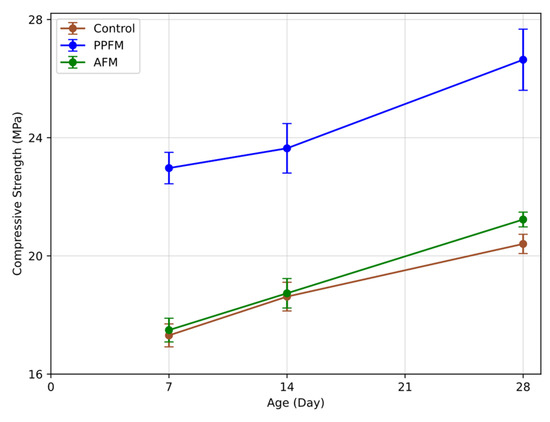

3.4. Compressive Strength

Compressive strength is a fundamental mechanical property that measures the maximum load a material can withstand before failure under uniaxial compression, serving as a critical indicator of a material’s structural integrity and load-bearing capacity [52,53]. This property is crucial for cement-based composites, such as mortars, due to their direct influence on the performance and durability of structural and non-structural components [54,55]. Analyzing the impact of fiber reinforcement on the CS of cement mortars is essential because fibers, depending on their type and content, can significantly alter the microstructure and mechanical behavior of the matrix [56,57]. The inclusion of fibers may enhance the post-cracking behavior, mitigate shrinkage and improve toughness, but their influence on compressive strength is complex and not always positively correlated, making rigorous experimental evaluation crucial. Understanding these effects helps optimize fiber-reinforced cementitious materials for both structural and functional applications, ensuring reliability and efficiency in construction practices.

Figure 11 presents the evolution of CS in the three evaluated cement mortar mixtures (i.e., CONTROL in brown, AFM in green and PPFM in blue) measured at curing ages of 7, 14 and 28 days. All mixtures exhibit a progressive increase in strength with curing time, reflecting continued hydration and matrix densification. The CONTROL mixture starts at around 17.3 MPa on day 7 and reaches just above 20.4 MPa by day 28. The AF-modified mortar slightly improves over the CONTROL at each stage, achieving approximately 21.2 MPa by day 28, suggesting a modest contribution of natural fibers to compressive behavior. In contrast, the PPFM mixture consistently demonstrates the highest compressive strength, starting near 23.0 MPa on day 7 and rising to approximately 26.6 MPa on day 28. This superior performance indicates that polypropylene fibers provide a more effective reinforcement mechanism under compressive loading, likely due to better bonding and stress distribution.

Figure 11.

Impact of fiber reinforcement on the compressive strength of cement mortars.

In contrast to the results observed in flexural resistance, the enhancement in compressive strength with alfa fibers was moderate. At 28 days, the AFM exhibited a 4.1% increase compared to the CONTROL, whereas the PPFM achieved a higher improvement of 30.5%, highlighting the comparatively greater effectiveness of synthetic fibers in this parameter. Additionally, the error bars indicate some overlap between the CONTROL and AFM results, suggesting that the enhancement from natural fibers may not be statistically significant, whereas PPFM offers a clear and consistent advantage.

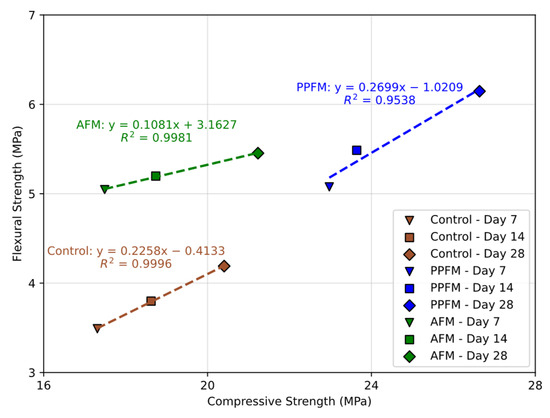

The combined analysis of flexural strength (Figure 9) and compressive strength (Figure 11) reveals distinct performance trends for the fiber-reinforced cement mortars. As expected, the PPFM mixture demonstrated consistent improvements in both flexural and compressive strengths, indicating its broad applicability in enhancing overall mechanical performance. On the other hand, the AFM mixture exhibited a substantial gain in flexural strength but only a statistically insignificant improvement in compressive strength. This suggests that while AFM contributes significantly to the material’s behavior under bending (highlighting the tensile reinforcement efficiency of alfa fibers), its impact under pure compression is limited. Therefore, AFM is recommended for concrete elements subjected primarily to tensile or flexural stresses, such as rigid pavement slabs, cantilevered balconies and thin-shell structures, where resistance to cracking and bending governs service performance and long-term durability. It is important to note that flexural strength, while influenced by tensile behavior, is not directly proportional to tensile strength, as it arises from a complex stress state involving tension, compression and shear.

A final analysis of the flexural and compressive strengths is presented in Figure 12. This plot illustrates the correlations between FS and CS for each of the three evaluated cement mortars. According to Figure 12, a clear positive correlation exists in all mixtures, with high coefficients of determination (R2 > 0.95). This strong relationship ensures the reliability of the results and indicates that an increase in one typically corresponds to an augment in the other. These results align well with findings reported in the literature, confirming expected behavior [2,58,59].

Figure 12.

Relationship between compressive and flexural strengths.

3.5. UPV Results

The UPV test is a reliable non-destructive method used to evaluate the internal condition of materials by measuring the time it takes for ultrasonic waves to travel through them [60,61]. Hence, the UPV test provides valuable information about diverse properties such as homogeneity, strength and stiffness [62,63]. Performing UPV measurements along different paths (or across various faces of a sample) allows for detecting directional differences in wave propagation, which is essential for evaluating anisotropy or isotropic compliance [64,65]. Anisotropy refers to the variation in material properties depending on the measurement direction [66,67]. In the case of fiber-reinforced cement mortars, the UPV test is critical because these materials often possess complex internal structures due to the presence and orientation of fibers, which strongly influence mechanical behavior [68,69]. Commonly, fiber-reinforced mortars and other cement-based materials are considered (and, thus, modeled) as mainly isotropic materials [70,71]. In practice, however, many of these materials exhibit nearly anisotropic characteristics because of randomly distributed fibers, insufficient alignment during casting or poor workability that prevents consistent fiber orientation [72,73].

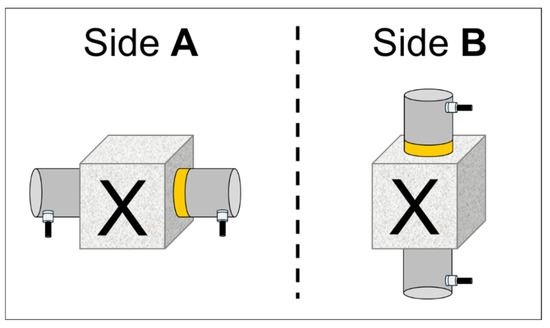

In this regard, evaluating the UPV in multiple directions helps determine whether the material exhibits isotropic or anisotropic behavior. As shown in Figure 13, two ultrasonic pulse transmission paths were assessed in this study. Considering this, Figure 14 presents the results of the pulse velocity measurements.

Figure 13.

Ultrasonic pulse transmission paths for concrete quality evaluation.

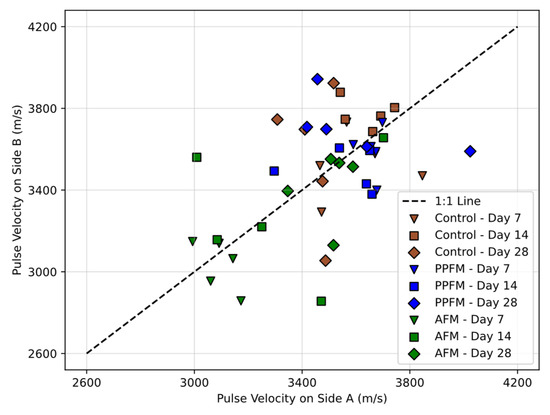

Figure 14.

Directional dependence of UPV: anisotropy analysis results.

Figure 14 shows the UPV measurements taken along two orthogonal directions (i.e., Side A and Side B according to Figure 13) for the three types of evaluated cement mortars (i.e., unreinforced reference mixture with brown markers, AFM with green markers and PPFM with blue markers), each tested at curing ages of 7, 14 and 28 days. Figure 14 also includes a dashed 1:1 reference line, representing the ideal case where the pulse velocity measured on Side A is equal to that on Side B, indicating perfectly isotropic behavior, where material properties are the same in all directions. In this context, the closer an experimental data point lies to the 1:1 line, the more similar the wave velocities are in both directions, suggesting that the material behaves isotropically. Conversely, the farther a data point deviates from the 1:1 line, the greater the difference in wave velocities between the two directions, indicating a higher degree of anisotropy. This visual comparison provides a straightforward way to assess the directional dependence of the material’s internal structure and mechanical response. Overall, the widespread scattering of data points around this line across all mixtures and curing ages reveals notable discrepancies between pulse velocities on different sides of the specimens. This directional dependency in wave propagation clearly indicates that all mixtures exhibit anisotropic behavior. The results highlight that the intrinsic structure of fiber-reinforced and plain cement mortars significantly influences measurement direction on UPV values, confirming that cementitious materials inherently possess anisotropic characteristics.

The observed anisotropic behavior in all evaluated mortar mixtures can be hypothesized to stem from heterogeneities and microstructural inconsistencies inherent in the materials. Even in the unreinforced CONTROL mixture, anisotropy may arise from casting effects, shrinkage-induced microcracking or preferential alignment of hydration products during curing. These factors collectively result in directional dependence of mechanical wave transmission, leading to the anisotropic response observed in UPV measurements. In fiber-reinforced mortars, such anisotropy is likely amplified by the random orientation and uneven dispersion of fibers, which locally alter the density and stiffness of the matrix, thereby affecting wave propagation differently along various directions.

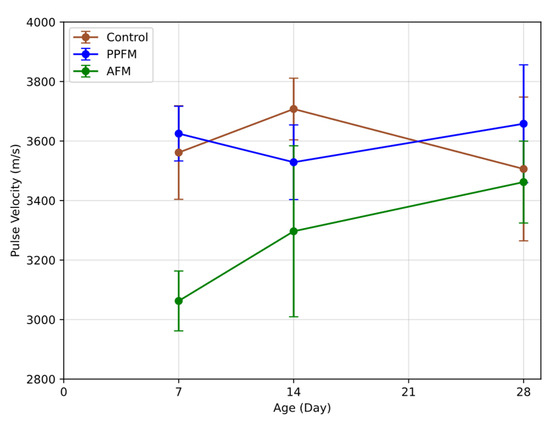

Figure 15 shows the UPV results for each type of cement mortar at different curing ages, with values averaged between both measurement sides. This graph reveals that the CONTROL and PPFM mixtures exhibit overlapping error bars across all ages, suggesting that including PPF did not significantly alter the pulse velocity compared to the unmodified mortar. Furthermore, both these mixtures show minimal variation over time, with no distinct increasing or decreasing trend, implying a relatively stable internal structure during curing. Conversely, the AFM mixture demonstrates consistently lower pulse velocity values at early ages, followed by a steady increase up to day 28, eventually approaching the values of the CONTROL one. This progressive increase in pulse velocity for AFM may indicate gradual densification or refinement of the internal microstructure. The initially low UPV could reflect higher porosity or microcracking introduced by the modification, while the subsequent improvement suggests “healing” or structural refinement, highlighting a different temporal development in the internal structure compared to the other mixtures. From a construction perspective, these results imply that AFM may not be suitable for applications requiring early-age strength or rapid formwork removal. Nonetheless, its improving performance over time denotes potential for use in non-urgent structural elements or contexts where long-term durability is prioritized over early strength.

Figure 15.

Evolution of pulse velocity over curing time.

The ASTM C597-22 standard recommends determining the stiffness of the cement-based materials through the UPV test by employing Equation (1). This expression allows the calculus of the Dynamic Modulus of Elasticity (). Accordingly, mortar concrete is assumed to be a perfectly elastic material. In that case, it is also possible to compute the Shear Modulus (G) and Bulk Modulus (K) via Equation (2) and Equation (3), respectively [74].

where

- , and are stiffness-related quantities (Pa).

- ρ is the bulk density after immersion (kg/m3).

- is the pulse velocity (m/s).

- is the Poisson’s ratio (-).

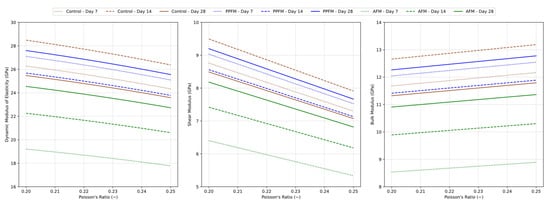

Figure 16 illustrates the variation in , G and K with respect to different assumed values ranging from 0.20 to 0.25. Since direct measurements of were not conducted in this investigation, this typical range for cementitious materials was adopted to analyze the sensitivity of these elastic properties [75,76,77]. As observed in the leftmost plot, decreases slightly with increasing across all mixes and curing ages. The CONTROL mixture consistently exhibits the highest , followed by PPFM and then AFM, suggesting superior stiffness in conventional mixes and a beneficial, albeit slightly reduced, effect from synthetic fibers compared to natural ones. The middle plot shows that G also decreases with increasing . Again, the CONTROL mixture demonstrates the highest values, while AFM presents the lowest. In contrast, the rightmost plot reveals an increase in K with augmenting , as expected from its formulation. Here, the CONTROL and PPFM mixtures show relatively higher K compared to AFM. Overall, it is clear that AFMs are the less stiff mortars, suggesting that AFMs are more deformable and less capable of resisting mechanical stresses, making them less suitable for structural elements that require high rigidity and load-bearing capacity.

Figure 16.

, and calculated for varying .

Figure 16 also displays the evolution of stiffness-related moduli concerning curing age, revealing distinct trends among the different mortars. For the AFM, a consistent increase in stiffness is observed as curing progresses from 7 to 28 days, indicating continuous microstructural development and hydration over time. In contrast, the CONTROL mixture shows an initial increase in stiffness from 7 to 14 days, followed by a reduction by day 28, while the PPFM mixture exhibits an inverse trend (i.e., initially decreasing from 7 to 14 days and then increasing by day 28). These non-linear trends in the PPFM and CONTROL mixtures directly result from the variations in the averaged pulse velocity values (as seen in Figure 15) used in the modulus calculations, which influence the estimated elastic properties. Interestingly, despite this inconsistency in the stiffness evolution, both the CONTROL and PPFM mixtures demonstrate a clear and steady increase in flexural and compressive strengths over time, as shown in Figure 9, Figure 11 and Figure 12. The preceding suggests that while stiffness moduli derived from pulse velocity measurements may fluctuate due to localized inhomogeneities, the overall mechanical performance of the mortars in terms of strength continues to improve with curing age, reaffirming the reliability of direct strength testing over indirect stiffness estimation in assessing long-term performance.

4. Discussion

The experimental results demonstrated that the inclusion of fiber, both PPF and AF, enhanced the mechanical behavior of mortars, particularly in terms of FS. These findings, as expected, support the initial hypothesis regarding the contribution of fiber reinforcement towards tensile performance and load-bearing capacity of composites. The increase in FS is consistent with previous studies, which attributed these improvements to mechanisms related to load transfer and energy dissipation facilitated by the presence of fibers in the matrix [78,79], thereby promoting ductile failure modes, as highlighted previously in Figure 10. Notably, the overall performance of AFM was comparable to that of PPF, indicating the technical feasibility of substituting or partially replacing synthetic fibers with natural fibers, particularly for non-structural components in the building sector (i.e., composite panels, masonry walls or plastering), as have been proposed by other authors [80,81]. Moreover, it is compared against existing regulatory thresholds for structural mortars, such as those specified in ASTM C270 [82], which sets a minimum compressive strength of 12.4 MPa for Type S mortar, and ASTM C1329 [83], which requires a minimum flexural bond strength of 0.7 MPa. These findings, while aligned with typical non-structural requirements, may also open the door to broader applications in cementitious elements where moderate strength and enhanced sustainability are desired, pending further validation under specific design and service conditions.

Fiber-reinforced mortars exhibited a modest increase in CS compared to the CONTROL mixture, which aligns with previous research works, indicating that fibers present a limited role in enhancing compressive properties. For instance, Lertwattanaruk and Suntijitto [84] reported a reduction in compressive resistance with the utilization of both coconut fiber and oil palm fiber in cement mortars. A similar trend was observed by the research group of Juarez et al. [85] with lechugilla fiber and flax fiber, negatively affecting mechanical strength of cementitious composites.

Compared to other studied natural fibers, AF demonstrated a comparable reinforcing effect and enhancement of the mechanical behavior. The research group of Ramli et al. [86] reported experimental improvements of 13% and 9% in compressive and flexural strengths, respectively, with the utilization of coconut fibers in concrete. Likewise, Zakaria et al. [87] reported an increase in flexural performance with jute fiber-reinforced concrete but an unexpected drop in compressive resistance. Hence, after the results obtained with AFM and considering the dosage used in this study (0.4%), it can be stated that alfa fibers improved mechanical performance, highlighting their potential as a sustainable alternative for building materials.

Moreover, previous studies have stated negative effects on the physical properties of composites after the utilization of NF. For instance, Okeola et al. [88] reported an increase in porosity with sisal fiber-reinforced concrete. Similarly, Teixeira et al. [89] highlighted an increase in water absorption with curaua fibers in cementitious composites. In this line, the outcomes for density, water absorption and voids in the present study exhibited no significant adverse effect associated with the incorporation of fibers. Both PPFM and AFM presented comparable values to the CONTROL mortar, indicating the compactness of the composite.

Additionally, UPV further supported this assumption, with all mixtures presenting homogeneous values. The uniform fiber distribution observed in the fresh state and the absence of macro-defects suggest appropriate mixing and compatibility between fibers and cement matrix, as discussed in the visual inspection. This is particularly relevant for natural fibers, as poor dispersion in the matrix is considered one of the major drawbacks for their use as cement-based material reinforcement [90].

4.1. Limitations of the Study

While the findings reported in this study suggest the viability of natural fibers as a suitable reinforcement material in cementitious mortars, some limitations must be acknowledged. On one hand, the experimental program was restricted to a single fiber content (0.4%), which limits the deep understanding of how variations in alfa fiber dosage influence the overall performance of the mortar. Additionally, the exclusive use of one type of natural fiber restricts the comprehension and applicability of the findings towards other plant-based fibers, which may differ in morphology and chemical composition. Furthermore, while physical and mechanical properties were prioritized to evaluate the feasibility of fiber-reinforced mortars, this study did not include long-term performance tests, such as carbonation, freeze–thaw cycles or chloride ion penetration, which are essential for durability assessments under aggressive environmental conditions. Nonetheless, these aspects are considered within the future research lines discussed in the following sections.

4.2. Future Research Lines

The results highlighted alfa fibers as a promising alternative to synthetic fibers, aligning with ongoing efforts to promote sustainability in the construction sector. In this line, the use of industrial or agricultural by-products as a replacement for conventional materials in cement-based composites has been widely proposed by several authors [27,91,92]. Nevertheless, the authors recognize the need for a broader comparative analysis, encompassing various fiber types, both synthetic and natural, to better understand the influence of fiber characteristics on the different properties of the composite. In addition, the implementation of the life-cycle assessment and life-cycle cost analysis methodologies is recommended to evaluate the environmental and economic implications (of using these fibers), respectively [53,93]. This would allow for validation of their contribution not only in terms of technical performance but also from a feasible perspective concerning ecological footprint and resource efficiency.

Likewise, microstructural characterization is proposed to further analyze the fiber–matrix interface, including techniques such as scanning electron microscopy and mercury intrusion porosimeter. Moreover, as previously mentioned, it is essential to advance the investigation towards understanding the long-term performance of AF in cementitious matrices. Therefore, the next stage should include durability testing, such as accelerated aging (e.g., carbonation and freeze–thaw cycles) and resistance to aggressive agents (e.g., chloride and acid resistance).

Considering this, a critical and timely line of research is the investigation of directional dependency of cement-based materials and their constitutive modeling, particularly given the anisotropy observed in both fiber-reinforced and plain cement mortars. This inherent anisotropy challenges the assumptions of isotropy commonly embedded in conventional modeling frameworks. As such, there is a pressing need to advance current constitutive models to accurately capture the direction-dependent mechanical responses of these materials. Promising approaches to address this complexity include the use of Bézier-based multi-step simulations to describe curved fiber paths and complex geometries [94]. Alongside this is the integration of finite element methods or discrete element methods, which can account for localized interactions, discontinuities and evolving damage patterns [95]. These modeling tools, when appropriately calibrated and validated, hold significant potential to enhance predictive capabilities and guide the design of more resilient cementitious composites.

5. Conclusions

This study evaluated the mechanical performance of fiber-reinforced cement mortars, comparing the effect of polypropylene fibers (PPFs) and alkali-treated alfa fibers (AFs), contributing to the expanding research field on the use of NF in cement-based materials. Based on the results obtained, the following conclusions can be drawn:

- PPF mortars exhibited the highest compressive strength values, confirming the superior performance of synthetic fibers in resisting axial loads. Nonetheless, AF mortars achieved satisfactory compressive strengths, above those of the CONTROL mixes, demonstrating that they may represent a suitable solution for certain building applications.

- Both fiber types improved flexural performance compared to the reference mix, with better energy absorption and visible joining effects. Fiber incorporation enhances the flexural resistance of the composites, promoting a more ductile failure mode compared to the brittle behavior observed in the non-reinforced, supporting their potential in crack control and toughness enhancement.

- Mortars reinforced with AF exhibited slightly lower UPV values compared to those containing PPF, suggesting a marginal increase in porosity or internal heterogeneities. This behavior is attributed to the inherent hydrophilic nature of natural fibers, as reflected in the results of the physical properties. Nevertheless, all UPV values remained within the acceptable range for good-quality mortars.

- Despite the somewhat lower mechanical performance, AF mortars offer a promising sustainable alternative. The use of treated alfa fibers contributes to circular economy strategies and reduces reliance on non-renewable synthetic materials.

- The improved flexural behavior of AFM suggests the potential of AF not only as a sustainable alternative but also as a technically viable option for use in base layers, overlays and other cementitious components subjected to flexural or fatigue loads in pavement applications and transportation infrastructure designed based on moduli of rupture criteria.

- The UPV tests confirmed the directional dependence of the evaluated mortars, thus confirming the anisotropic nature of wave propagation in both fiber-reinforced and plain cement mortars. These findings highlight the inherent anisotropy of cement-based materials, which is driven by their internal structure, and underscore the critical importance of considering directional variability in constitutive modeling and engineering design.

Overall, the findings confirm that alkali-treated alfa fibers can be effectively used to enhance certain mechanical properties of cement mortars. While the authors acknowledge the need for further investigation into the feasibility of alfa fibers as a full substitute for industrial fibers, the comparable performance exhibited by AF and PPF supports the potential use of NF as a viable alternative to synthetic reinforcement, particularly in applications where flexural behavior and environmental impact are key design criteria.

Author Contributions

Conceptualization, A.A.-M. and M.J.M.-E.; methodology, A.A.-M. and O.G.-B.; software, R.P.-M.; validation, O.G.-B. and R.P.-M.; formal analysis, A.A.-M.; investigation, A.A.-M. and R.P.-M.; resources, A.A.-M. and M.J.M.-E.; data curation, A.A.-M. and R.P.-M.; writing—original draft preparation, A.A.-M. and O.G.-B.; writing—review and editing, M.J.M.-E. and R.P.-M.; visualization, M.J.M.-E.; supervision, M.J.M.-E.; project administration, M.J.M.-E.; funding acquisition, M.J.M.-E. All authors have read and agreed to the published version of the manuscript.

Funding

This research is part of project C-ING-071-UGR23 funded by the Consejería de Universidad, Investigación e Innovación and by ERDF Andalusia Program 2021–2027.

Data Availability Statement

The raw data underlying the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to express their gratitude to Cayetano García del Moral S.L. and Master Builders Solutions for providing the esparto and the polypropylene fibers, respectively, used in this research work.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| NFs | Natural fibers |

| PPFs | Polypropylene fibers |

| AFs | Alfa fibers |

| PPFM | Mortar with polypropylene fibers |

| AFM | Mortar with alfa fibers |

| FC | Fiber content |

| FS | Flexural strength |

| CS | Compressive strength |

| UPV | Ultrasonic Pulse Velocity |

References

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B.S. A Comprehensive Review on the Use of Natural Fibers in Cement/Geopolymer Concrete: A Step towards Sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Abdollahnejad, Z. Effect of Different Lengths and Dosages of Recycled Glass Fibres on the Fresh and Hardened Properties of SCC. Mag. Concr. Res. 2018, 70, 1175–1188. [Google Scholar] [CrossRef]

- Ravichandran, D.; Prem, P.R.; Kaliyavaradhan, S.K.; Ambily, P.S. Influence of Fibers on Fresh and Hardened Properties of Ultra High Performance Concrete (UHPC)—A Review. J. Build. Eng. 2022, 57, 104922. [Google Scholar] [CrossRef]

- Wang, S.; Li, Z.; Fan, L.; Zhang, Z.; Yin, S.; Yuan, J.; He, H.; Lin, H.; Lin, W.; Dai, X.; et al. A Study on the Mechanical and Economic Performance Comparison of Ceramsite Concrete Based on Fiber Selection and Optimization. Sci. Rep. 2024, 14, 31939. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, Y. Fiber-Reinforced Mechanism and Mechanical Performance of Composite Fibers Reinforced Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2020, 35, 121–130. [Google Scholar] [CrossRef]

- Arvizu-Montes, A.; Martinez-Echevarria, M.J. Vegetable Fibers in Cement Composites: A Bibliometric Analysis, Current Status, and Future Outlooks. Materials 2025, 18, 333. [Google Scholar] [CrossRef]

- Pons Ribera, S.; Hamzaoui, R.; Colin, J.; Bessette, L.; Audouin, M. Valorization of Vegetal Fibers (Hemp, Flax, Miscanthus and Bamboo) in a Fiber Reinforced Screed (FRS) Formulation. Materials 2023, 16, 2203. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Abedi, M.; Hassanshahi, O.; Rashiddel, A.; Ashtari, H.; Seddik Meddah, M.; Dias, D.; Arjomand, M.A.; Keong Choong, K. A Sustainable Cementitious Composite Reinforced with Natural Fibers: An Experimental and Numerical Study. Constr. Build. Mater. 2023, 378, 131093. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, Y.X.; Yang, C.; Ding, Y. Recent Advances in Experimental Studies of the Mechanical Behaviour of Natural Fibre-reinforced Cementitious Composites. Struct. Concr. 2016, 17, 564–575. [Google Scholar] [CrossRef]

- Shah, I.; Li, J.; Yang, S.; Zhang, Y.; Anwar, A. Experimental Investigation on the Mechanical Properties of Natural Fiber Reinforced Concrete. J. Renew. Mater. 2022, 10, 1307–1320. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Achour, A.; Ghomari, F.; Belayachi, N. Properties of Cementitious Mortars Reinforced with Natural Fibers. J. Adhes. Sci. Technol. 2017, 31, 1938–1962. [Google Scholar] [CrossRef]

- Santana, H.A.; Amorim Júnior, N.S.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M.R. Vegetable Fibers Behavior in Geopolymers and Alkali-Activated Cement Based Matrices: A Review. J. Build. Eng. 2021, 44, 103291. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Mobasher, B.; Filho, R.D.T. Cracking Mechanisms in Durable Sisal Fiber Reinforced Cement Composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- El-Abbassi, F.E.; Assarar, M.; Ayad, R.; Bourmaud, A.; Baley, C. A Review on Alfa Fibre (Stipa Tenacissima L.): From the Plant Architecture to the Reinforcement of Polymer Composites. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105677. [Google Scholar] [CrossRef]

- Belkadi, A.A.; Aggoun, S.; Amouri, C.; Geuttala, A.; Houari, H. Effect of Vegetable and Synthetic Fibers on Mechanical Performance and Durability of Metakaolin-Based Mortars. J. Adhes. Sci. Technol. 2018, 32, 1670–1686. [Google Scholar] [CrossRef]

- Garrouri, S.; Lakhal, W.; Benazzouk, A.; Sediki, E. Potential Use of Alfa Fibers in Construction Material: Physico-Mechanical and Thermal Characterisation of Reinforced Specimen. Constr. Build. Mater. 2022, 342, 127787. [Google Scholar] [CrossRef]

- Messas, T.; Achoura, D.; Abdelaziz, B.; Mamen, B. Experimental Investigation on the Mechanical Behavior of Concrete Reinforced with Alfa Plant Fibers. Fract. Struct. Integr. 2022, 16, 102–113. [Google Scholar] [CrossRef]

- Krobba, B.; Bouhicha, M.; Kenai, S.; Courard, L. Formulation of Low Cost Eco-Repair Mortar Based on Dune Sand and Stipa Tenacissima Microfibers Plant. Constr. Build. Mater. 2018, 171, 950–959. [Google Scholar] [CrossRef]

- Ling, Y.; Zhang, P.; Wang, J.; Chen, Y. Effect of PVA Fiber on Mechanical Properties of Cementitious Composite with and without Nano-SiO2. Constr. Build. Mater. 2019, 229, 117068. [Google Scholar] [CrossRef]

- Fode, T.A.; Jande, Y.A.C.; Kim, Y.-D.; Ham, M.-G.; Lee, J.; Kivevele, T.; Rahbar, N. Effects of Different Lengths and Doses of Raw and Treated Sisal Fibers in the Cement Composite Material. Sci. Rep. 2025, 15, 1603. [Google Scholar] [CrossRef]

- Asociacion Española de Normalización. UNE-EN 197-1:2011: Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements, 1st ed.; AENOR: Madrid, Spain, 2011. [Google Scholar]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Katoh, M.; Ueki, T.; Waterhouse, G.I.N.; Li, Y. Influence of Alkali Treatment on Internal Microstructure and Tensile Properties of Abaca Fibers. Ind. Crops Prod. 2015, 65, 27–35. [Google Scholar] [CrossRef]

- Mayakun, J.; Klinkosum, P.; Chaichanasongkram, T.; Sarak, S.; Kaewtatip, K. Characterization of a New Natural Cellulose Fiber from Enhalus Acoroides and Its Potential Application. Ind. Crops Prod. 2022, 186, 115285. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Yuan, X. Improving the Mechanical Properties of Natural Fibre Fabric Reinforced Epoxy Composites by Alkali Treatment. J. Reinf. Plast. Compos. 2012, 31, 425–437. [Google Scholar] [CrossRef]

- Laverde, V.; Marin, A.; Benjumea, J.M.; Rincón Ortiz, M. Use of Vegetable Fibers as Reinforcements in Cement-Matrix Composite Materials: A Review. Constr. Build. Mater. 2022, 340, 127729. [Google Scholar] [CrossRef]

- Arvizu-Montes, A.; Alcivar-Bastidas, S.; Martínez-Echevarría, M.J. Experimental Study on the Effect of Abaca Fibers on Reinforced Concrete: Evaluation of Workability, Mechanical, and Durability-Related Properties. Fibers 2025, 13, 75. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological Performance of Açaí Natural Fibre Reinforced Cement-Based Mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Alcivar-Bastidas, S.; Petroche, D.M.; Martinez-Echevarria, M.J. The Effect of Different Treatments on Abaca Fibers Used in Cementitious Composites. J. Nat. Fibers 2023, 20. [Google Scholar] [CrossRef]

- Asociación Española de la Normalización. UNE-EN 196-1:2018: Methods of Testing Cement—Part 1: Determination of Strength, 1st ed.; AENOR: Madrid, Spain, 2018; ISBN UNE-EN 1015-3. [Google Scholar]

- Ferrández, D.; Zaragoza-Benzal, A.; Pastor Lamberto, R.; Santos, P.; Michalak, J. Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers. Appl. Sci. 2024, 14, 6226. [Google Scholar] [CrossRef]

- García, G.; Cabrera, R.; Rolón, J.; Pichardo, R.; Thomas, C. Natural Fibers as Reinforcement of Mortar and Concrete: A Systematic Review from Central and South American Regions. J. Build. Eng. 2024, 98, 111267. [Google Scholar] [CrossRef]

- Helaili, S.; Guizani, A.; Khadimallah, M.A.; Chafra, M. Natural Cellulosic Alfa Fiber (Stipa Tenacissima L.) Improved with Environment-Friendly Treatment Cementitious Composites with a Stable Flexural Strength. Civ. Eng. Archit. 2023, 11, 1632–1644. [Google Scholar] [CrossRef]

- Sathiparan, N.; Rupasinghe, M.N.; Bhasura, H.M.P. Performance of Coconut Coir Reinforced Hydraulic Cement Mortar for Surface Plastering Application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Rashmi Nayak, J.; Bochen, J.; Gołaszewska, M. Experimental Studies on the Effect of Natural and Synthetic Fibers on Properties of Fresh and Hardened Mortar. Constr. Build. Mater. 2022, 347, 128550. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; Antunes, M.L.P.; Rangel, E.C.; Fediuk, R. Technological Perspective for Use the Natural Pineapple Fiber in Mortar to Repair Structures. Waste Biomass Valorization 2021, 12, 5131–5145. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The Hornification of Vegetable Fibers to Improve the Durability of Cement Mortar Composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Ghavami, K.; England, G.L.; Scrivener, K. Development of Vegetable Fibre–Mortar Composites of Improved Durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Safiuddin, M.; Abdel-Sayed, G.; Hearn, N. Flexural and Impact Behaviors of Mortar Composite Including Carbon Fibers. Materials 2022, 15, 1657. [Google Scholar] [CrossRef]

- Espinosa, A.B.; Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Ortega-López, V. Utility of Ultrasonic Pulse Velocity for Estimating the Overall Mechanical Behavior of Recycled Aggregate Self-Compacting Concrete. Appl. Sci. 2023, 13, 874. [Google Scholar] [CrossRef]

- Al-jabali, H.M.; Edris, W.F.; Al-Tamimi, M.; Al Sayed, A.A.-K.A.; Selouma, T.I. Evaluation of the Degradation of Mortar with Volcanic Tuff Replacement via Destructive and Non-Destructive Testing. Case Stud. Constr. Mater. 2025, 22, e04308. [Google Scholar] [CrossRef]

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. 1st ed. ASTM International: West Conshohocken, PA, USA, 2022; ISBN ASTM C597-22.

- Asociación Española de la Normalización UNE. UNE-EN 1015-3: Methods of Test For Mortar For Masonry. Part 3: Determination of Consistence of Fresh Mortar (By Flow Table), 1st ed.; AENOR: Madrid, Spain, 2000. [Google Scholar]

- ASTM C597-22; Standard Test Method for Ultrasonic Pulse Velocity Through Concrete. 1st ed. ASTM International: West Conshohocken, PA, USA, 2022; ISBN ASTM C597-22.

- Wang, Q.; Zhang, L.; Zhang, A. The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross. Coatings 2025, 15, 459. [Google Scholar] [CrossRef]

- Kaptan, K.; Cunha, S.; Aguiar, J. The Effect of Activation Methods on the Mechanical Properties of Cement Mortars with Recycled Powder from Concrete Waste as a Cement Partial Replacement: A Review. Sustainability 2025, 17, 4502. [Google Scholar] [CrossRef]

- Sun, H.; Zou, H.; Ren, J.; Xu, G.; Xing, F. Synthesis of a Novel Graphene Oxide/Belite Cement Composite and Its Effects on Flexural Strength and Interfacial Transition Zone of Ordinary Portland Cement Mortars. Constr. Build. Mater. 2023, 402, 133009. [Google Scholar] [CrossRef]

- Naenudon, S.; Vilaivong, A.; Zaetang, Y.; Tangchirapat, W.; Wongsa, A.; Sata, V.; Chindaprasirt, P. High Flexural Strength Lightweight Fly Ash Geopolymer Mortar Containing Waste FIber Cement. Case Stud. Constr. Mater. 2022, 16, e01121. [Google Scholar] [CrossRef]

- Abdulrahman, P.I.; Bzeni, D.K.; Ahmed, S.M. Pull-off and Slant-Shear Tests for Evaluating Bond Strength in Polymer-Modified Cement Mortar Reinforced with Polypropylene Fibers. J. Build. Eng. 2025, 104, 112259. [Google Scholar] [CrossRef]

- Aminul Haque, M.; Chen, B.; Riaz Ahmad, M.; farasat ali shah, S. Mechanical Strength and Flexural Parameters Analysis of Micro-Steel, Polyvinyl and Basalt Fibre Reinforced Magnesium Phosphate Cement Mortars. Constr. Build. Mater. 2020, 235, 117447. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R.; Duque, J. Development of a Machine Learning (ML)-Based Computational Model to Estimate the Engineering Properties of Portland Cement Concrete (PCC). Arab J. Sci. Eng. 2024, 49, 14351–14365. [Google Scholar] [CrossRef]

- Pineda, A.; Peñabaena-Niebles, R.; Martínez-Arguelles, G.; Polo-Mendoza, R. Development of OptiCon: A Mathematical Model with a Graphical User Interface for Designing Sustainable Portland Cement Concrete Mixes with Budget Constraint. Inventions 2025, 10, 22. [Google Scholar] [CrossRef]

- Abdelli, K.; Deboucha, W.; Leklou, N.; Alengaram, U.J.; Oudjit, M.N. Effect of Curing Temperature on the Early and Later Ages Behaviour of Metakaolin Blended Cement Mortars: Hydration Heat and Compressive Strength. Aust. J. Civ. Eng. 2024, 22, 94–107. [Google Scholar] [CrossRef]

- Al Safi, A.A. Blast Furnace Slag-Based Geopolymer Mortars Cured at Different Conditions: Modeling and Optimization of Compressive Strength. Eur. J. Environ. Civ. Eng. 2021, 25, 1949–1961. [Google Scholar] [CrossRef]

- Li, T.; Liu, X.; Zhang, J.; Shi, F.; Zhao, M.; Shen, X.; Zhu, J.; Lyu, K.; Shah, S.P.; Bao, T. Effect of Air Void Structure and Mechanical Properties of High Strength Fiber Reinforced Mortar Composed with Different Construction Sand Species Based on X-CT Technology. Mech. Adv. Mater. Struct. 2024, 31, 2873–2888. [Google Scholar] [CrossRef]

- Frayyeh, Q.; Swaif, A. Mechanical Properties of Fly Ash Geopolymer Mortar Reinforced with Carbon Fibers. MATEC Web Conf. 2018, 162, 02028. [Google Scholar] [CrossRef][Green Version]

- Choucha, S.; Benyahia, A.; Ghrici, M.; Said Mansour, M. Correlation between Compressive Strength and Other Properties of Engineered Cementitious Composites with High-Volume Natural Pozzolana. Asian J. Civ. Eng. 2018, 19, 639–646. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Abdalla, A.A.; Kurda, R.; Qadir, W.S.; Mahmood, W.; Ghafor, K. Soft Computing Techniques to Estimate the Uniaxial Compressive Strength of Mortar Incorporated with Cement Kiln Dust. Innov. Infrastruct. Solut. 2023, 8, 300. [Google Scholar] [CrossRef]

- Lee, T.; Lee, J. Setting Time and Compressive Strength Prediction Model of Concrete by Nondestructive Ultrasonic Pulse Velocity Testing at Early Age. Constr. Build. Mater. 2020, 252, 119027. [Google Scholar] [CrossRef]

- Sathiparan, N.; Jayasundara, W.G.B.S.; Samarakoon, K.S.D.; Banujan, B. Prediction of Characteristics of Cement Stabilized Earth Blocks Using Non-Destructive Testing: Ultrasonic Pulse Velocity and Electrical Resistivity. Materialia 2023, 29, 101794. [Google Scholar] [CrossRef]

- Ndagi, A.; Umar, A.A.; Hejazi, F.; Jaafar, M.S. Non-Destructive Assessment of Concrete Deterioration by Ultrasonic Pulse Velocity: A Review. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012015. [Google Scholar] [CrossRef]

- do Nascimento Moura, M.A.; Moreno, A.L.; dos Santos Ferreira, G.C. Ultrasonic Testing on Evaluation of Concrete Residual Compressive Strength: A Review. Constr. Build. Mater. 2023, 373, 130887. [Google Scholar] [CrossRef]

- Setiawan, M.R.; Fatkhan; Latief, F.D.E.; Fauzi, U. Characterization of Diabase Core Anisotropy: Integrating Ultrasonic Measurements and Digital Rock Physics. J. Appl. Geophys. 2025, 238, 105698. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.; Yi, J.; Zhang, J. Effects of Coral Aggregate Properties on the Ultrasonic Pulse Velocity of Concrete. J. Build. Eng. 2023, 80, 107935. [Google Scholar] [CrossRef]

- Wang, C.; Chen, B.; Vo, T.L.; Rezania, M. Mechanical Anisotropy, Rheology and Carbon Footprint of 3D Printable Concrete: A Review. J. Build. Eng. 2023, 76, 107309. [Google Scholar] [CrossRef]

- Cortez, J.; Browning, J.; Marquardt, C.; Clunes, M.; Carmona, N.; Benson, P.; Koor, N. Variable Elastic Anisotropy Controls Stress in Shallow Crown Pillars. Rock Mech. Bull. 2025, 100212. [Google Scholar] [CrossRef]

- Liu, B.; Liu, X.; Li, G.; Geng, S.; Li, Z.; Weng, Y.; Qian, K. Study on Anisotropy of 3D Printing PVA Fiber Reinforced Concrete Using Destructive and Non-Destructive Testing Methods. Case Stud. Constr. Mater. 2022, 17, e01519. [Google Scholar] [CrossRef]

- Liu, B.; Chen, Y.; Li, D.; Wang, Y.; Geng, S.; Qian, K. Study on the Fracture Behavior and Anisotropy of 3D-Printing PVA Fiber-Reinforced Concrete. Constr. Build. Mater. 2024, 447, 138051. [Google Scholar] [CrossRef]

- Nguyen, G.D.; Korsunsky, A.M. Development of an Approach to Constitutive Modelling of Concrete: Isotropic Damage Coupled with Plasticity. Int. J. Solids Struct. 2008, 45, 5483–5501. [Google Scholar] [CrossRef]

- Kurumatani, M.; Terada, K.; Kato, J.; Kyoya, T.; Kashiyama, K. An Isotropic Damage Model Based on Fracture Mechanics for Concrete. Eng. Fract. Mech. 2016, 155, 49–66. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, Q.; Wu, S.; Zheng, H.; Sun, W. Modification Effect of Nanosilica and Polypropylene Fiber for Extrusion-Based 3D Printing Concrete: Printability and Mechanical Anisotropy. Addit. Manuf. 2022, 56, 102944. [Google Scholar] [CrossRef]

- Meza de Luna, A.; Shaikh, F.U.A. Anisotropy and Bond Behaviour of Recycled Polyethylene Terephthalate (PET) Fibre as Concrete Reinforcement. Constr. Build. Mater. 2020, 265, 120331. [Google Scholar] [CrossRef]

- Słota-Valim, M. Static and Dynamic Elastic Properties, the Cause of the Difference and Conversion Methods—Case Study. Nafta-Gaz 2015, 71, 816–826. [Google Scholar] [CrossRef]

- Tang, C.-W. Effect of Presoaking Degree of Lightweight Aggregate on the Properties of Lightweight Aggregate Concrete. Comput. Concr. 2017, 19, 69–78. [Google Scholar] [CrossRef]

- Nik Hasni, N.A.H.; Alisibramulisi, A.; Hassan, R.; Saari, N.; Krishnamoorthy, R.R.; Adnan, S.H. Numerical Analysis of Splitting Tensile Strength of Steel Fibre Reinforced Concrete under Static Loading. J. Adv. Ind. Technol. Appl. 2022, 3, 64–77. [Google Scholar] [CrossRef]

- Guerrero-Bustamante, O.; Guillen, A.; Moreno-Navarro, F.; Rubio-Gámez, M.C.; Sol-Sánchez, M. Suitable Granular Road Base from Reclaimed Asphalt Pavement. Materials 2025, 18, 854. [Google Scholar] [CrossRef]

- Thapa, K.; Sedai, S.; Paudel, J.; Gyawali, T.R. Investigation on the Potential of Eulaliopsis Binata (Babiyo) as a Sustainable Fiber Reinforcement for Mortar and Concrete. Case Stud. Constr. Mater. 2024, 20, e03115. [Google Scholar] [CrossRef]

- de Azevedo, A.; Cruz, A.; Marvila, M.; de Oliveira, L.; Monteiro, S.; Vieira, C.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymer 2021, 13, 2493. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A Review of Recent Developments in Structural Applications of Natural Fiber-Reinforced Composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Stochino, F.; Majumder, A.; Frattolillo, A.; Valdes, M.; Martinelli, E. Jute Fiber Reinforcement for Masonry Walls: Integrating Structural Strength and Thermal Insulation in Sustainable Upgrades. J. Build. Eng. 2025, 104, 112210. [Google Scholar] [CrossRef]

- ASTM C270-25; Standard Specification for Mortar for Unit Masonry. 1st ed. ASTM International: West Conshohocken, PA, USA, 2025; ISBN ASTM C597-22.

- ASTM C1329-05; Standard Specification for Mortar Cement. 1st ed. ASTM International: West Conshohocken, PA, USA, 2012; ISBN ASTM C597-22.

- Lertwattanaruk, P.; Suntijitto, A. Properties of Natural Fiber Cement Materials Containing Coconut Coir and Oil Palm Fibers for Residential Building Applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Juárez-Alvarado, C.A.; Magniont, C.; Escadeillas, G.; Terán-Torres, B.T.; Rosas-Diaz, F.; Valdez-Tamez, P.L. Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sustainability 2022, 14, 14397. [Google Scholar] [CrossRef]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and Durability of Coconut-Fiber-Reinforced Concrete in Aggressive Environments. Constr. Build. Mater. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.; Shaid, A. A Comparative Study of the Mechanical Properties of Jute Fiber and Yarn Reinforced Concrete Composites. J. Nat. Fibers 2020, 17, 676–687. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Teixeira, R.S.; Santos, S.F.; Christoforo, A.L.; Payá, J.; Savastano, H.; Lahr, F.A.R. Impact of Content and Length of Curauá Fibers on Mechanical Behavior of Extruded Cementitious Composites: Analysis of Variance. Cem. Concr. Compos. 2019, 102, 134–144. [Google Scholar] [CrossRef]

- Boulos, L.; Foruzanmehr, M.R.; Tagnit-Hamou, A.; Robert, M. The Effect of a Zirconium Dioxide Sol-Gel Treatment on the Durability of Flax Reinforcements in Cementitious Composites. Cem. Concr. Res. 2019, 115, 105–115. [Google Scholar] [CrossRef]

- Padavala, S.S.A.B.; Noolu, V.; Paluri, Y.; Harinder, D.; Akula, U.K. Performance Evaluation of Concrete Blended with Industrial and Agricultural Wastes Reinforced with Hybrid Fibres—A Feasibility Study. Sci. Rep. 2025, 15, 6662. [Google Scholar] [CrossRef]

- Chen, H.; Chow, C.L.; Lau, D. Developing Green and Sustainable Concrete in Integrating with Different Urban Wastes. J. Clean. Prod. 2022, 368, 133057. [Google Scholar] [CrossRef]

- Guerrero-Bustamante, O.; Camargo, R.; Duque, J.; Martinez-Arguelles, G.; Polo-Mendoza, R.; Acosta, C.; Murillo, M. Designing Sustainable Asphalt Pavement Structures with a Cement-Treated Base (CTB) and Recycled Concrete Aggregate (RCA): A Case Study from a Developing Country. Designs 2025, 9, 65. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A Generalized 2D Bézier-Based Solution for Stress Analysis of Notched Epoxy Resin Plates Reinforced with Graphene Nanoplatelets. Thin-Walled Struct. 2021, 169, 108484. [Google Scholar] [CrossRef]

- Duarte, C.A.; Hamzeh, O.N.; Liszka, T.J.; Tworzydlo, W.W. A Generalized Finite Element Method for the Simulation of Three-Dimensional Dynamic Crack Propagation. Comput. Methods Appl. Mech. Eng. 2001, 190, 2227–2262. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).