Study on Comprehensive Benefit Evaluation of Rural Houses with an Additional Sunroom in Cold Areas—A Case Study of Hebei Province, China

Abstract

1. Introduction

1.1. Overview

1.2. Literature Review

- ①

- Applicability of the research results of the energy-saving renovation of agricultural houses: Most existing studies only focus on the optimization of a typical rural house in a certain area, but in fact, rural houses in a region are multi-type in nature due to the differences in their construction ages, their envelope structure performances, the income levels of the residents, and other factors, leading to optimizations of the design of rural house sunshine rooms and energy-saving changes to the envelope structure. Each house’s energy-saving demands and economic demands are different [17] and therefore, research on the optimal design of sunrooms for existing rural houses and energy-saving changes to the enclosure structure needs to be conducted according to the different types and different remaining lifecycles of the building. This will meet the actual needs of rural residents and be suitable for classification research [18].

- ②

- Limitations of existing sunshine room research in China: At present, research on the optimal design of the transparent envelope structure of sunshine rooms in China is only focused on glass material, and there are few studies that have comprehensively researched and analyzed the energy-saving potential, cost savings, suitability, and convenience of other transparent envelope materials for sunshine rooms in the Chinese building materials market.

Innovations of the Thesis

- ①

- Construction of a Typical Rural House Classification Model in Hebei Province Based on Subjective–Objective Integration

- ②

- Comprehensive Benefit Evaluation and Optimal Selection of Transparent Materials for Rural House Sunspaces Based on Full Lifecycle

2. Materials and Methods

- ①

- Field mapping

- ②

- Interview and questionnaire

- ③

- Temperature test

2.1. Classification of Existing Rural Houses

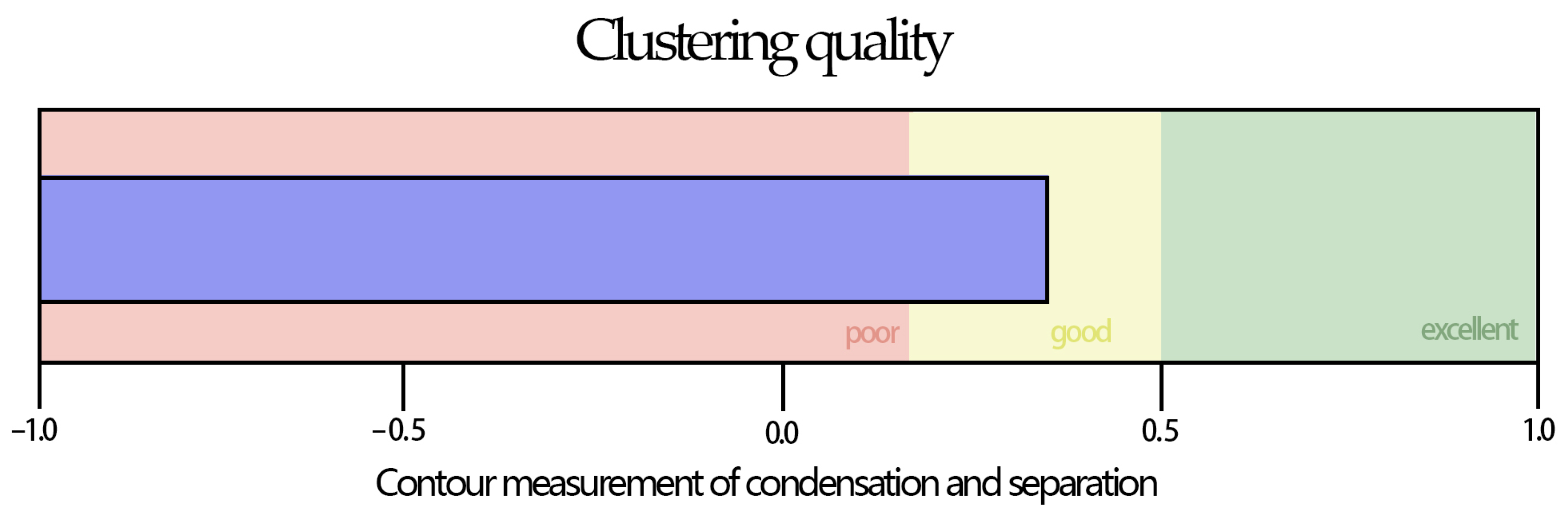

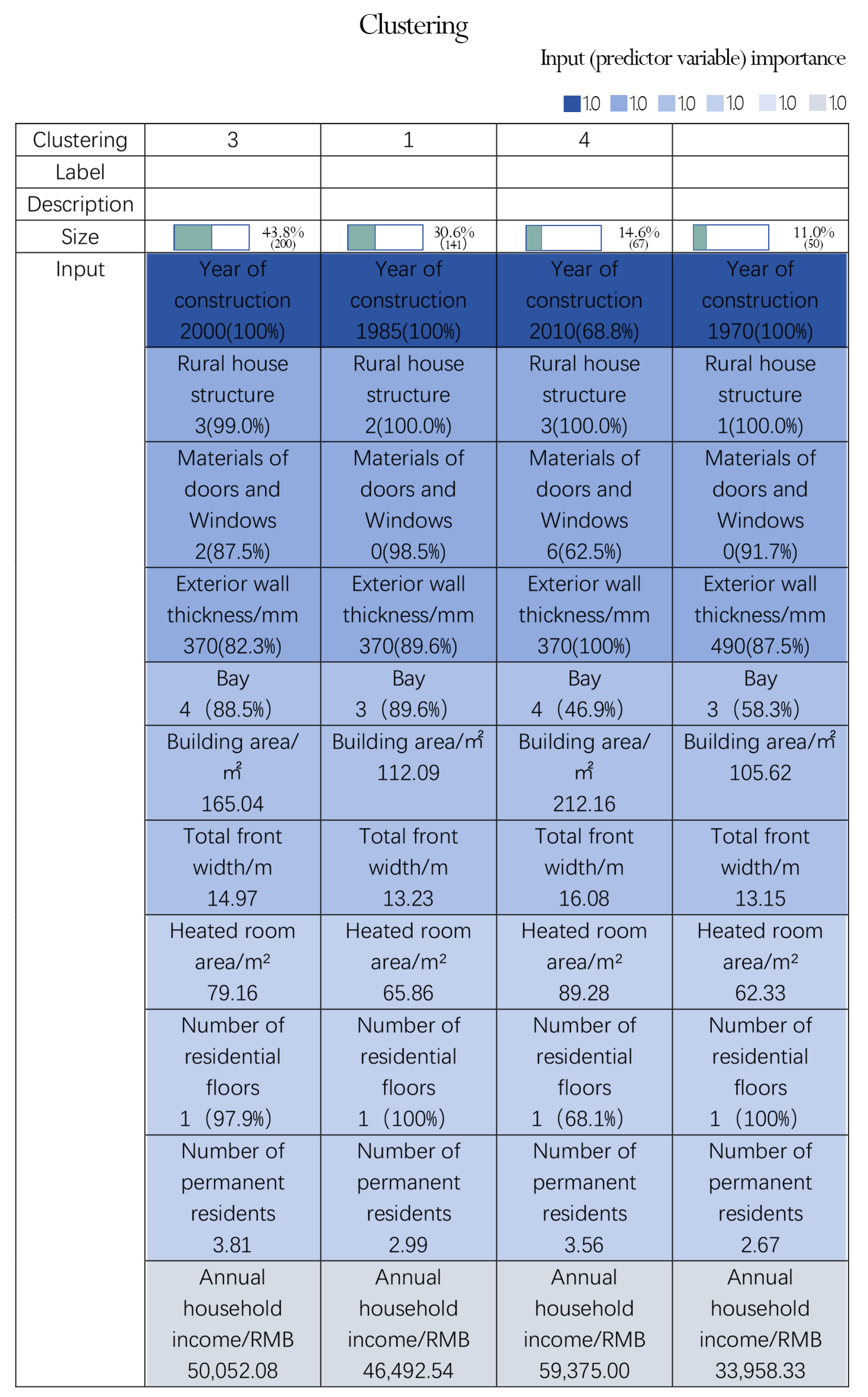

2.2. Rural House Clustering Results

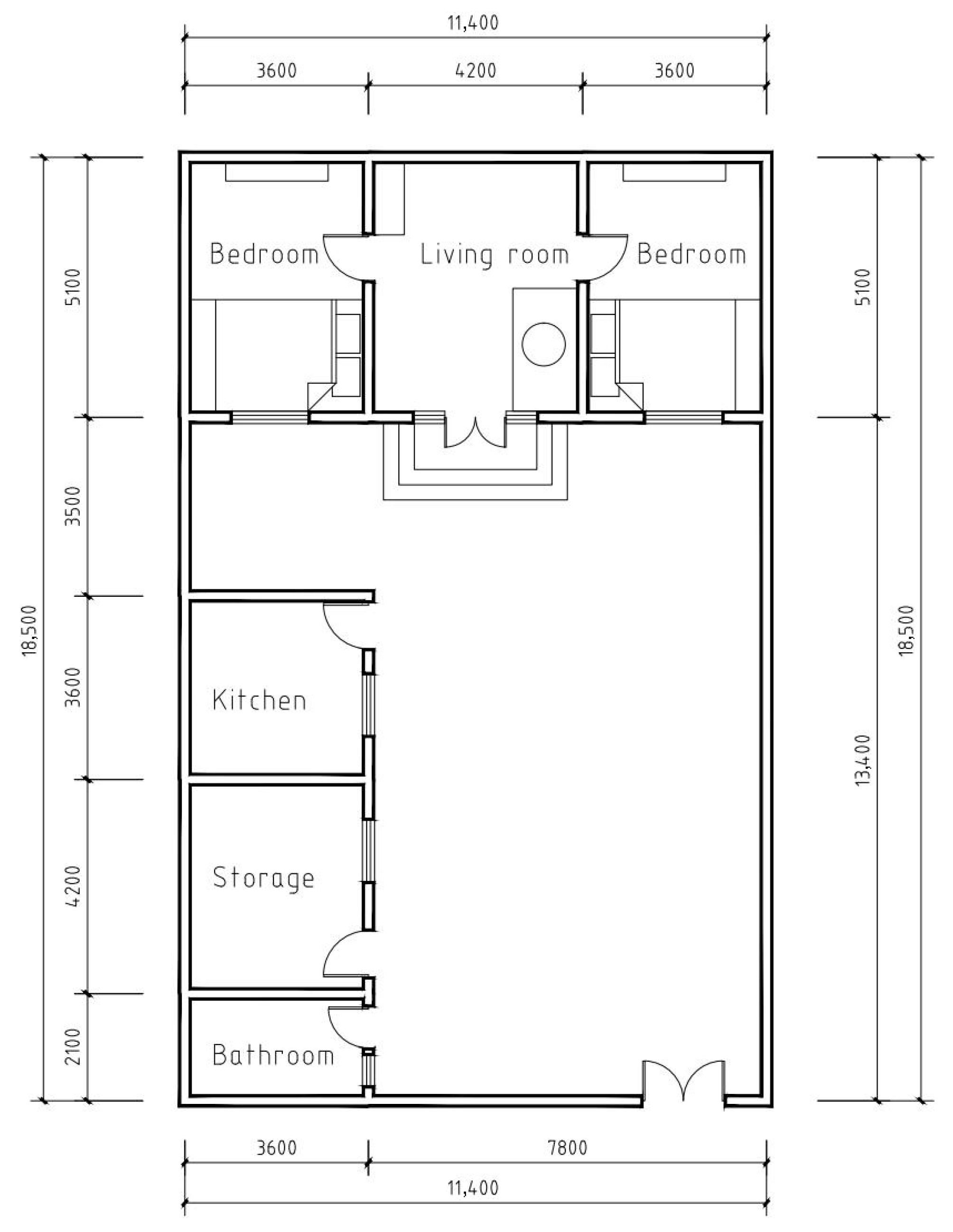

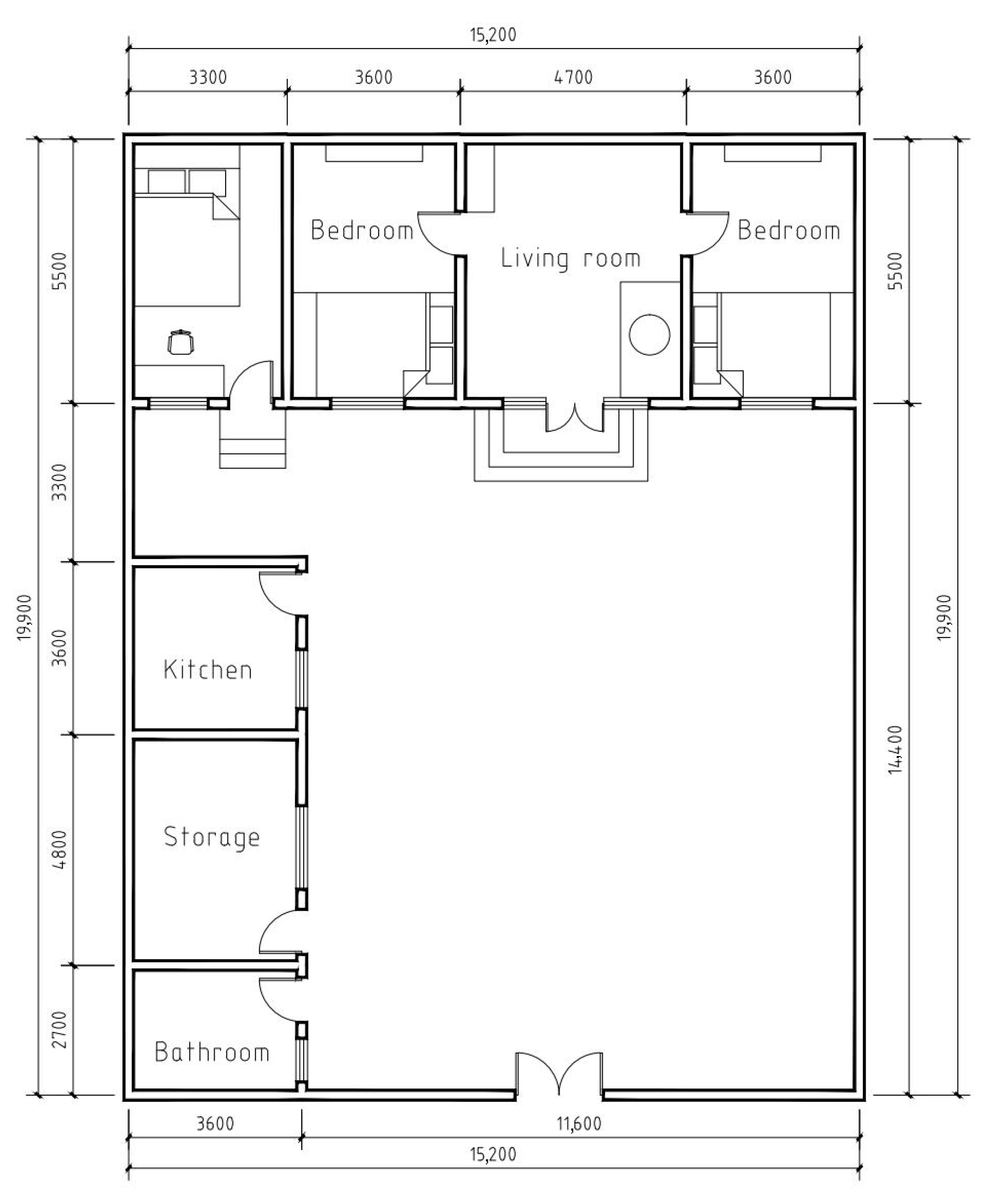

2.3. Parameters of the Rural House Building Model

2.4. Additional Sunshine Room Status

2.5. Climate and Parameter Setting

2.6. Benefit Evaluation of Agricultural Houses with an Additional Sunshine Room

- Selection of Evaluation Period

- 2.

- Cost composition

- ①

- Economic cost

- ②

- Environmental cost

- 3.

- Benefit composition

- ①

- Economic benefits

- ②

- Environmental benefits

2.6.1. Environmental Benefit Evaluation

2.6.2. Evaluation of Economic Benefit

- (1)

- Incremental Cost

- (2)

- Incremental benefit

- (3)

- Benefit evaluation

2.7. Analysis of Adaptation Between Sunshine Room and Different Rural Houses

3. Results

- Classification of rural houses:

- 2.

- Suggestions to optimize the benefits include the following:

- ①

- Adobe rural houses in the 1980s: Due to the short remaining service lives of the main body, a sunspace design scheme with a shorter dynamic payback period (that is, faster investment recovery) is mor suitable.

- ②

- Brick–wood structure rural houses in the 1980s–1990s: The main body has a moderate remaining service life, and a broken bridge aluminum alloy double-glass sunspace scheme is preferred.

- ③

- Brick–concrete structure rural houses in the 1990s: The main body has a long remaining service life and design schemes with a higher energy-saving rate and longer service life of the sunspace itself are more applicable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Dimension | Representative Prior Studies | This Study |

|---|---|---|

| Research Scope | ||

| Climate Region | Mediterranean, Jilin | Cold Regions of China (Hebei–Tianjin) |

| Building Typology | Urban residences, single farmhouse | Multi-type rural housing clusters (458 dwellings → 3 archetypes) |

| Benefit Assessment | ||

| Energy Saving | Energy-saving rate | Energy-saving rate |

| Economic Metrics | Static payback period | Dynamic PP + NPV |

| Ecological Impact | Implied via energy data | Carbon reduction + LCA |

| Decision Framework | ||

| Optimization Approach | Single-objective approach | Clustering hierarchy + multi-objective synergy |

| Output Format | Parameter suggestions | Typology-specific priority methodology |

References

- Liu, Y. Research on Energy-Saving Renovation Design of Rural Residential Roofs from the Perspective of Winter Thermal Comfort. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2021. [Google Scholar]

- Zhou, G.G. Multi-Objective Optimization Research on Envelope Structure of Low-Carbon Rural Dwellings in Hot Summer and Cold Winter Regions. Master’s Thesis, Zhongnan University of Economics and Law, Wuhan, China, 2023. [Google Scholar]

- Cheng, H.; Yao, C.Q.; Li, X. Verification and Optimization of Spatial Performance of Solar Energy Utilization in Qinghai Huangyuan Residential Buildings. South. Archit. 2024, 10, 94–104. [Google Scholar]

- Guan, Z.Z.; Zhang, W.X.; Xue, Y.B. Design Optimization Strategies and Benefit Analysis of Attached Sunspaces for Existing Rural Houses in Yimeng Mountain Area. Build. Energy Effic. (Chin. Engl. Ed.) 2024, 52, 157–163. [Google Scholar]

- Bataineh, K.M.; Fayez, N. Analysis of thermal performance of building attached sunspace. Energy Build. 2011, 43, 1863–1868. [Google Scholar] [CrossRef]

- Aelenei, D.; Leal, H.; Aelenei, L. The Use of Attached-sunspaces in Retrofitting Design: The Case of Residential Buildings in Portugal. Energy Procedia 2014, 48, 1436–1441. [Google Scholar] [CrossRef]

- Ulpiani, G.; Giuliani, D.; Romagnoli, A.; di Perna, C. Experimental monitoring of a sunspace applied to a NZEB mock-up: Assessing and comparing the energy benefits of different configurations. Energy Build. 2017, 152, 194–215. [Google Scholar] [CrossRef]

- Chiesa, G.; Simonetti, M.; Ballada, G. Potential of attached sunspaces in winter season comparing different technological choices in Central and Southern Europe. Energy Build. 2017, 138, 377–395. [Google Scholar] [CrossRef]

- Lopez, M.S.; Castro, S.S.; Manso, A.N.; Marigorta, E.B. Heat collection in an attached sunspace. Renew. Energy 2020, 145, 2144–2150. [Google Scholar] [CrossRef]

- Kottia, S.; Telia, D.; Jamesa, P. Quantifying Thermal Bridge Effects and Assessing Retrofit Solutions in a Greek Residential Building. Procedia Environ. Sci. 2017, 38, 306–313. [Google Scholar] [CrossRef]

- Jin, H.; Zhou, C.Y. Energy Efficiency Analysis of Integrated Solar Houses in Rural Cold Regions. J. Harbin Inst. Technol. 2008, 40, 2007–2010. [Google Scholar]

- Yang, Y.X. Thermal Transfer Process and Energy Efficiency Evaluation of Attached Sunspaces in Southern Liaoning Rural Dwellings. Master’s Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Wu, H.J. Research on Solar Energy Rural Houses in Cold Regions. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2009. [Google Scholar]

- Zhao, J.; Liu, D.; Lu, S. Research on the Indoor Thermal Environment of Attached Sunspace Passive Solar Heating System Based on Zero-State Response Control Strategy. Appl. Sci. 2022, 12, 855. [Google Scholar] [CrossRef]

- Cao, P.; Sun, Q.; Li, H.; Jiao, Y. Optimization Analysis of an Energy-Saving Renovation Scheme for Building Envelopes of Existing Rural Houses Based on a Comprehensive Benefit Evaluation. Buildings 2024, 14, 454. [Google Scholar] [CrossRef]

- Wang, C.H.; Yang, Y.; Wei, G.L. Optimization of Attached Sunspaces for Rural Dwellings in Cold Regions Based on Benefit Evaluation. Build. Sci. 2023, 39, 130–138. [Google Scholar]

- Shao, S.Y. Research on Energy-Saving Renovation Strategies for Rural Dwellings in Eastern Hebei Based on Thermal Comfort. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2021. [Google Scholar]

- Tang, Z.Y.; Chen, Y.; Wang, C.W.; Jia, Q. Research on Renovation Design of Traditional Dwellings in Guanzhong Region from the Perspective of Ecological Integration. Eng. Technol. Res. 2024, 9, 194–198. [Google Scholar]

- Zhang, C. Applicable Technologies and Economic Analysis of Energy-saving Retrofits for Existing Rural Buildings in Guanzhong Region. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2012. [Google Scholar]

- GB/T 42074-2022; Classification of Climate Seasons. China Standard Press: Beijing, China, 2022.

- Li, S. Multi-objective Optimization of Attached Sunspaces for Rural Dwellings in Severe Cold Regions Integrating Design and Technology. Master’s Thesis, Hebei University of Engineering, Handan, China, 2024. [Google Scholar]

- Diao, L.; Sun, Y.; Chen, Z.; Chen, J. Modeling energy consumption in residential buildings: A bottom-up analysis based on occupant behavior pattern clustering and stochastic simulation. Energy Build. 2017, 147, 47–66. [Google Scholar] [CrossRef]

- Barthelmes, V.M.; Li, R.; Andersen, R.K.; Bahnfleth, W.; Corgnati, S.P.; Rode, C. Profiling occupant behaviour in Danish dwellings using time use survey data. Energy Build. 2018, 177, 329–340. [Google Scholar] [CrossRef]

- Liu, J.; Zou, Y.; Song, B. Investigation on the Current Situation and Energy-saving Approaches of Rural Residential Buildings in Severe Cold and Cold Regions. Build. Sci. 2012, 28, 1–5. [Google Scholar]

- Zhu, K. Research on Energy Consumption Benchmark in Energy-Saving Renovation of Existing Residential Buildings in Chongqing from the Typological Perspective. Master’s Thesis, Chongqing University, Chongqing, China, 2023. [Google Scholar]

- Zhou, H. Statistical and Evaluation Study on Heating Energy Consumption of Rural Houses in Cold Regions. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Sun, R.; Lü, J.; Ren, S. Investigation and Analysis of Energy Consumption of Rural Residences in Northeast China. Build. Energy Environ. 2011, 30, 45–48+92. [Google Scholar]

- Qian, Z. Research on the Application Strategy of Thermal Buffer Space in the Renovation of Rural Houses in Zhangbei Area Oriented by Nearly Zero-Energy Consumption. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2024. [Google Scholar]

- Liu, Y. Analysis of Carbon Emissions of Vernacular Rural Dwellings in the Regions along the Yellow River in Inner Mongolia and Research on Carbon Reduction Strategies. Master’s Thesis, Inner Mongolia University of Science and Technology, Baotou, China, 2023. [Google Scholar]

- Giusti, L.; Almoosawi, M. Impact of building characteristics and occupants’ behaviour on the electricity consumption of households in Abu Dhabi (UAE). Energy Build. 2017, 151, 534–547. [Google Scholar] [CrossRef]

- Chang, W. Research and Testing on the Energy-saving Performance of External Windows. Master’s Thesis, Jilin Jianzhu University, Changchun, China, 2016. [Google Scholar]

- Luo, G.H. Empirical Study on Improving Thermal Comfort of Rural Households in Alpine Regions Using Solar Energy. Master’s Thesis, Lanzhou University, Lanzhou, China, 2011. [Google Scholar]

- He, Q.; Liu, D.L.; Zhu, X.R. Field Study on Indoor Thermal Environment of Tibetan Dwellings in Western Sichuan Plateau. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2015, 47, 402–406. [Google Scholar]

- GB/T 50824-2013; Energy Efficiency Design Standard for Rural Residential Buildings. China Architecture & Building Press: Beijing, China, 2013.

- GB 50736-2012; Design Code for Heating, Ventilation and Air-Conditioning of Civil Buildings. China Architecture & Building Press: Beijing, China, 2012.

- Yang, Y. Research on Optimization of Sunspaces and Energy-Saving Envelope Retrofitting Strategies for Rural Dwellings in Hebei-Tianjin Region. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2023. [Google Scholar]

- GB 50068-2018; Unified Standard for Reliability Design of Building Structures. China Architecture & Building Press: Beijing, China, 2018.

- GB/T 51366-2019; Standard for Calculation of Building Carbon Emissions. China Architecture & Building Press: Beijing, China, 2019.

- Luo, Z.X. Research on Calculation Methods and Emission Reduction Strategies for Building Life Cycle Carbon Dioxide Emissions. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. [Google Scholar]

- Fang, C.X.; Yin, L.X.; Liu, M.Y. Impact of “Coal-to-Gas” Transition in Thermal Power and Central Heating on Air Pollution Control in Beijing. Energy Conserv. Environ. Prot. 2021, 10, 78–80. [Google Scholar]

- Li, X.R.; Han, Y.P.; Zhao, Z.N. Selection of Heating Methods for Residential Areas. Build. Energy Environ. 2000, 2, 18–21. [Google Scholar]

- Ge, X.; Lai, Q.; Jiang, W. Life Cycle Assessment of a Novel Polycarbonate Production Process. J. Inner Mongolia Univ. Sci. Technol. 2019, 38, 404–408. [Google Scholar]

- Wu, D.R. Life Cycle Cost-Benefit Analysis of Energy-Saving Retrofits for Existing Building Envelopes. Master’s Thesis, Beijing Forestry University, Beijing, China, 2020. [Google Scholar]

- Wang, W.W. Economic Evaluation of Energy-saving Retrofits for Existing Residential Buildings. Wall Mater. Innov. Build. Energy Conserv. 2010, 6, 50–53+4. [Google Scholar]

- Sun, R. Research on Prefabricated Renovation Design of Civil Houses in Beiqijia. Master’s Thesis, Tsinghua University, Beijing, China, 2017. [Google Scholar]

| Serial Number | Survey Category | Research Method | Specific Research Content |

|---|---|---|---|

| 1 | Basic information of residents | Questionnaire | Number of permanent residents of the household, major industries, annual household income |

| 2 | Information on the construction of rural houses | Questionnaire Field mapping | Age of Construction, Yard Form, Number of Building Floors, Building Area, Functional Layout, Form of Enclosure Structure |

| 3 | Indoor thermal environment of rural house | Experimental | Outdoor air temperature, relative humidity, wind speed, solar radiation intensity of rural house |

| 4 | Habits and wishes of residents | Questionnaire | Heating area, heating cost, room rate, energy-saving renovation intention |

| Variable Attributes | Variable Name | Variable Encoding | Variable Description | References |

|---|---|---|---|---|

| Continuous variables | Number of permanent residents | Number of permanent residents | Unit: People | Diao et al. [22]: Modeling energy consumption in residential buildings: a bottom-up analysis based on occupant behavior pattern clustering and stochastic simulation. |

| Annual household income | Annual household income | Unit: Yuan/year | Barthelmes et al. [23]: Profiling occupant behaviour in Danish dwellings using time use survey data. | |

| Floor area | Floor area | Unit: m | Liu Jing [24]: Investigation on the Current Situation and Energy-saving Approaches of Rural Residential Buildings in Severe Cold and Cold Regions | |

| Width of main room face | Width of the main room | Unit: m | Zhu Kedi [25]: Research on Energy Consumption Benchmark in Energy—saving Renovation of Existing Residential Buildings in Chongqing from the Typological Perspective. | |

| Heating area | Heating area | Unit: m | Zhou Heming [26]: Statistical and Evaluation Study on Heating Energy Consumption of Rural Houses in Cold Regions. | |

| Categorical variable | Age of construction | 1970 1985 2000 2010 | Before 1980 1980–1990 1990–2010 2010 onwards | Zhu Kedi [25]: Research on Energy Consumption Benchmark in Energy—saving Renovation of Existing Residential Buildings in Chongqing from the Typological Perspective. |

| Number of building floors | 1 2 | 1 floor 2 floors | Sun Ruijun et al. [27]: Investigation and Analysis of Energy Consumption of Rural Residences in Northeast China. | |

| Cubicles | 3 4 5 | 3 cubicles 4 cubicles 5 rooms | Qian Zhijun [28]: Research on the Application Strategy of Thermal Buffer Space in the Renovation of Rural Dwellings in Zhangbei Region Oriented towards Near—Zero Energy Consumption. | |

| Rural house construction | 1 2 3 | Adobe walls Brick and wood construction Brick–concrete construction | Liu Yaqi [29]: Analysis of Carbon Emissions of Vernacular Rural Dwellings in the Regions along the Yellow River in Inner Mongolia and Research on Carbon Reduction Strategies. | |

| Exterior wall thickness | 240 370 490 | Wall thickness 240 mm Wall thickness 370 mm Wall thickness 490 mm | Giusti et al. [30]: Impact of building characteristics and occupants’ behaviour on the electricity consumption of households in Abu Dhabi (UAE). | |

| Materials for doors and windows | 0 2 4 6 | Wood-framed single glass Windows Aluminum alloy single-glass window Aluminum alloy double-glass window Plastic steel window | Chang Wentao [31]: Research and Testing on the Energy-saving Performance of External Windows. |

| Residence Feature | Adobe Rural House from 80 Years Ago | 1980s–1990s Brick-and-Wood Rural House | 1990–2010s Brick Rural House | Brick Rural House from 10 Years Ago |

|---|---|---|---|---|

| Number of permanent residents | 2–3 people | 2–3 people | 3–4 people | 3–4 people |

| Annual household income | About CNY 45,000 Medium annual income | Around CNY 30,000 Lower annual income | About CNY 50,000 Medium annual income | About CNY 60,000 Higher annual income |

| Years of construction | Before 1980 | 1980–1990 | 1990–2010 | 2010 onwards |

| Floor area | About 110 m2 | About 110 m2 | About 160 m2 | Around 200 m2 |

| Number of layers | 1 layer | Floor 1 | 1 layer, very few 2 layers | 1 layer, very few 2 layers |

| Kaina | 3 bays | 3 bays, 4 bays | 3 bays, 4 bays | 4 bays, 5 bays |

| Rural house construction | Civil construction Stone and wood construction | Brick and wood construction | Few brick-and-wood structures Most masonry | Brick-mix |

| Exterior wall thickness | 490 mm | 370 mm | 240 mm, 370 mm | 240 mm, 370 mm |

| Material for doors and Windows | Wooden frame single glass | Wooden frame single glass | Mostly aluminum alloy single glass A few aluminum alloy double glass | Aluminum alloy windows Plastic steel windows |

| Heating method | Earth kang and stove Gas wall hanging stove | Earth kang, stove Gas wall hanging stove | Earth kang, stove Gas wall hanging stove | Stove Gas wall-mounted stove |

| Heating area | About 60 m2 | Around 70 m2 | Around 80 m2 | About 90 m2 |

| Heating costs | About CNY 1500 | Around CNY 2000 | Around CNY 3000 | More than CNY 3000 |

| Photograph |  |  |  |  |

| Make Up | Less | Medium | More | Less |

| Type of Rural Building | Structure Type | Heat Transfer Coefficient | Materials | Thickness |

|---|---|---|---|---|

| W·(m2·K) | mm | |||

| Pre-1980s Adobe rural house | Exterior wall | 1.46 | Solid clay bricks | 240 |

| Adobe | 240 | |||

| Mixed mortar | 10 | |||

| Roofing | 0.96 | Roof shingles | 10 | |

| Grass mud | 80 | |||

| Grass mat | 50 | |||

| Wooden frame construction | - | |||

| Wooden keel | - | |||

| Suspended ceiling layer | 10 | |||

| Interior walls | 1.82 | Mixed mortar | 20 | |

| Solid clay brick | 240 | |||

| Mixed mortar | 20 | |||

| Ground | 2.74 | Cement mortar | 20 | |

| Concrete bedding | 60 | |||

| Tamped plain earth | 100 | |||

| Doors and Windows | 4.75 | Wood frame +6 mm single glass | ||

| 1980s–1990s Brick and wood rural homes | Exterior wall | 1.54 | Solid clay brick | 370 |

| Mixed mortar | 20 | |||

| Roofing | 0.96 | Roof shingles | 10 | |

| Grass mud | 80 | |||

| Grass mat | 100 | |||

| Wooden house frame structure | - | |||

| Wooden keel | - | |||

| Suspended ceiling layer | 10 | |||

| Interior walls | 1.82 | Mixed mortar | 20 | |

| Solid clay brick | 240 | |||

| Mixed mortar | 20 | |||

| Ground | 2.74 | Cement mortar | 20 | |

| Concrete bedding | 60 | |||

| The plain soil is compacted | 100 | |||

| Doors and Windows | 4.75 | Wood frame +6 mm single glass | ||

| Post-1990s Brick-and-mix rural homes | Exterior wall | 1.49 | Cement mortar | 20 |

| Solid clay brick | 370 | |||

| Mixed mortar | 20 | |||

| Roofing | 2.87 | Roof shingles | 10 | |

| Grass mud | 50 | |||

| Reinforced concrete hollow floor slabs | 130 | |||

| Light steel keel | - | |||

| Suspended ceiling layer | 10 | |||

| Interior walls | 1.82 | Mixed mortar | 20 | |

| Solid clay brick | 240 | |||

| Mixed mortar | 20 | |||

| Ground | 2.74 | Cement mortar | 20 | |

| Concrete bedding | 60 | |||

| Tamped plain earth | 100 | |||

| Doors and Windows | 5.7 | Aluminum frame +6 mm single glass | ||

| Warming Gallery Form | Single Pane | Double Glazing | Plastic Sheeting | Sun Panels |

|---|---|---|---|---|

| Geographic location | Luoxiaoying Village, Hengshui City | Duan Zhuang Village, Shijiazhuang City | Houshuangtuo Village, Qinhuangdao city | Yaozhuangzi Village, Cangzhou City |

| House features |  |  |  |  |

| SIZE | Depth 1.5 M | Depth 1.68 M | 2.6 M depth | Depth 1.7 M |

| Spending | USD 1739.46 | USD 1739.46 | USD 217.43 | USD 1739.46 |

| Interior temperature before renovation | 11–16 °C | 17 °C | 10–15 °C | 17–20 °C |

| Indoor temperature after renovation | 12–19 °C | 18–20 °C | 14–19 °C | 19–22 °C |

| Material | Unit Price (CNY) | Unit Price (USD) |

|---|---|---|

| Regular hollow glass window | 280/m2 | 40.59/m2 |

| Low-e hollow glass window | 370B/m2 | 53.63/m2 |

| Square steel tube skeleton | 23/m | 3.33/m2 |

| Round steel skeleton | 12/m | 1.74/m2 |

| 3 mm solid PC board | 70/m2 | 10.15/m2 |

| 6 mm single-layer broken bridge aluminum glass window | 140/m2 | 20.29/m2 |

| 10 mm hollow PC board | 30/m2 | 4.35/m2 |

| Parameter Name | Parameter Setting |

|---|---|

| Meteorological parameters | Typical annual Meteorological hourly data of Tianjin (CSWD) |

| Main function rooms | Winter 18 °C (Heating period: “15 November–15 March”) |

| Interior design temperature and time | 28 °C in summer, (Cooling period: “1 June–31 August”) [35] |

| Number of air changes | 0.5 h |

| Category | Designed Service Life (Years) |

|---|---|

| Temporary building structures | 5 |

| Easily replaceable structural components | 25 |

| Ordinary houses and structures | 50 |

| Landmark buildings and particularly important building structures | 100 |

| Natural GAS | Unit | Electricity | Unit | |

|---|---|---|---|---|

| CO2 | 55.54 [38] | tCO2/TJ | 1.10 [39] | kgCO2e/kWh |

| SO2 | 0.1 [38] | g/m3 | 0.117 [40] | g/kWh |

| NOx | 0.63 [41] | g/m3 | 0.168 [40] | g/kWh |

| Soot | 0.24 [41] | g/m3 | 0.017 [40] | g/kWh |

| Type of Rural Homes | Sunroom Category | Building Material Category | Amount Used | Unit | Carbon Emission Factor | Carbon Emission | Carbon Reduction |

|---|---|---|---|---|---|---|---|

| kgCO2e/Units | kgCO2e | kgCO2e | |||||

| Pre-1980s adobe rural house | Plastic sheathed sunroom | PE film | 101.8 | m2 | 0.31 [38] | 101.26 | 3268.71 |

| Round steel skeleton | 0.034 | t | 2050 [38] | ||||

| 3 mm PC board Sunshine room | 3 mm PC board | 50.9 | m2 | 4.93 [42] | 462.09 | 2667.36 | |

| Square steel tube skeleton | 0.103 | t | 2050 [38] | ||||

| 10 mm hollow PC board sunroom | 10 mm hollow PC board | 50.9 | m2 | 1.97 [42] | 311.42 | 3392.90 | |

| Square steel tube skeleton | 0.103 | t | 2050 | ||||

| Broken bridge aluminum alloy single glass sunroom | Broken bridge aluminum alloy single-glass window | 50.9 | m2 | 40 [41] | 2066.54 | 2733.28 | |

| Broken bridge aluminum alloy double glass sunshine room | Broken bridge aluminum alloy hollow window | 50.9 | m2 | 65.9 [39] | 3456.11 | 3594.59 | |

| Broken bridge Aluminum Low-e Sunroom | Broken bridge aluminum Low-e window | 50.9 | m2 | 77.3 [39] | 4036.37 | 3912.72 | |

| 1980s–90s brick-and-wood rural homes | Plastic sheeting sunroom | PE film | 197.6 | m2 | 0.31 | 200.66 | 7115.36 |

| Circular steel skeleton | 0.068 | t | 2050 | ||||

| 3 mm PC board Sunshine room | 3 mm PC board | 98.8 | m2 | 4.93 | 909.38 | 5361.23 | |

| Square steel tube skeleton | 0.206 | t | 2050 | ||||

| 10 mm hollow PC board sunroom | 10 mm hollow PC board | 98.8 | m2 | 1.97 | 616.94 | 6863.73 | |

| Square steel tube skeleton | 0.206 | t | 2050 | ||||

| Broken bridge aluminum alloy single glass sunroom | Broken bridge aluminum alloy single-glass window | 49.4 | m2 | 40 | 2005.64 | 5492.46 | |

| Broken bridge aluminum alloy double glass sunshine room | Broken bridge aluminum alloy hollow window | 49.4 | m2 | 65.9 | 3354.26 | 7276.17 | |

| Broken bridge aluminum Low-e Sunroom | Broken bridge aluminum Low-e window | 49.4 | m2 | 77.3 | 3917.42 | 7921.28 | |

| After 1990s brick-and-mix rural homes | Plastic sheeting sunroom | PE film | 378 | m2 | 0.31 | 354.57 | 13,701.14 |

| Round steel skeleton | 0.116 | t | 2050 | ||||

| 3 mm PC board sunshine room | 3 mm PC board | 126 | m2 | 4.93 | 1125.48 | 11,072.14 | |

| Square steel tube skeleton | 0.246 | t | 2050 | ||||

| 10 mm hollow PC board sunroom | 10 mm hollow PC board | 126 | m2 | 1.97 | 752.52 | 14,189.03 | |

| Square steel tube skeleton | 0.246 | t | 2050 | ||||

| Broken bridge aluminum alloy single glass sunroom | Broken bridge aluminum alloy single-glass window | 63 | m2 | 40 | 2557.80 | 11,352.28 | |

| Broken bridge aluminum alloy double glass sunshine room | Broken bridge aluminum alloy hollow window | 63 | m2 | 65.9 | 4277.70 | 15,023.15 | |

| Broken bridge aluminum Low-e Sunroom | Broken bridge aluminum Low-e window | 63 | m2 | 77.3 | 4995.90 | 16,332.20 |

| Type of Rural Residence | Sunroom Category | SO2 | NOx | Soot/g |

|---|---|---|---|---|

| g | g | g | ||

| Pre-1980s Adobe rural house | Plastic wrap sunroom | 163.48 | 1029.93 | 392.36 |

| 3 mm PC board sunshine room | 89.85 | 965.96 | 401.02 | |

| 10 mm hollow PC board sunshine room | 120.63 | 1210.44 | 498.32 | |

| Broken bridge aluminum alloy single-glass sunshine room | 91.66 | 991.00 | 411.68 | |

| Broken bridge aluminum alloy double-glass sunshine room | 126.78 | 1285.32 | 529.83 | |

| Broken bridge aluminum Low-e sunroom | 138.01 | 1399.04 | 576.70 | |

| 1980s–90s Brick and wood rural homes | Plastic sheeting sunroom | 355.87 | 2241.97 | 854.08 |

| 3 mm PC board sunshine room | 148.95 | 2032.67 | 864.72 | |

| 10 mm hollow PC board sunshine room | 212.93 | 2538.28 | 1065.81 | |

| 1980s–90s Brick and wood rural homes | Broken bridge aluminum alloy single-glass sunshine room | 152.48 | 2082.77 | 886.11 |

| Broken bridge aluminum alloy double-glass sunshine room | 225.57 | 2691.22 | 1130.12 | |

| Broken bridge Aluminum Low-e sunroom | 248.48 | 2921.45 | 1224.92 | |

| Post-1990s Brick-and-mix rural homes | Plastic sheeting sunroom | 685.25 | 4317.07 | 1644.60 |

| 3 mm PC board sunroom | 362.68 | 4039.27 | 1683.66 | |

| 10 mm hollow PC board sunroom | 498.14 | 5080.22 | 2095.70 | |

| Broken bridge aluminum alloy single-glass sunshine room | 369.26 | 4148.95 | 1731.07 | |

| Broken bridge aluminum alloy double-glass sunshine room | 522.88 | 5391.96 | 2227.33 | |

| Broken bridge aluminum Low-e sunroom | 570.23 | 5856.64 | 2418.09 |

| CO2 | SO2 | NOx | Dust | |

|---|---|---|---|---|

| RMB/kg | RMB/kg | RMB/kg | RMB/kg | |

| Charging standard | 0.06 | 4.8 | 4.8 | 0.03 |

| Type of Rural Homes | Sunroom Category | CO2 | SO2 | NOx | Soot | Total |

|---|---|---|---|---|---|---|

| RMB | RMB | RMB | RMB | RMB | ||

| Pre-1980s Adobe rural house | Plastic sheathed sunroom | 190.04 | 0.78 | 4.94 | 0.012 | 195.77 |

| 3 mm PC plate sunroom | 132.32 | 0.43 | 4.64 | 0.012 | 137.40 | |

| 10 mm hollow PC board sunshine room | 184.89 | 0.58 | 5.81 | 0.015 | 191.30 | |

| Broken bridge aluminum alloy single-glass sunshine room | 40.00 | 0.44 | 4.76 | 0.012 | 45.21 | |

| Broken bridge aluminum alloy double-glass sunshine room | 8.31 | 0.61 | 6.17 | 0.016 | 15.11 | |

| Broken bridge aluminum Low-e sunshine room | −7.42 | 0.66 | 6.72 | 0.017 | −0.02 | |

| 1980s–1990s brick-and-wood rural homes | Plastic sheeting sunroom | 414.88 | 1.71 | 10.76 | 0.026 | 427.38 |

| 3 mm PC plate sunroom | 267.11 | 0.71 | 9.76 | 0.026 | 277.61 | |

| 10 mm hollow PC board sunshine room | 374.81 | 1.02 | 12.18 | 0.032 | 388.04 | |

| Broken bridge aluminum alloy single-glass sunshine room | 209.21 | 0.73 | 10.00 | 0.027 | 219.97 | |

| Broken bridge aluminum alloy double-glass sunshine room | 235.31 | 1.08 | 12.92 | 0.034 | 249.34 | |

| Broken bridge aluminum Low-e sunshine room | 240.23 | 1.19 | 14.02 | 0.037 | 255.48 | |

| Post-1990s brick-and-mix rural homes | Plastic sheeting sunroom | 800.79 | 3.29 | 20.72 | 0.049 | 824.85 |

| 3 mm PC plate sunroom | 596.80 | 1.74 | 19.39 | 0.051 | 617.98 | |

| 10 mm hollow PC board sunshine room | 806.19 | 2.39 | 24.39 | 0.063 | 833.03 | |

| Broken bridge aluminum alloy single-glass sunshine room | 527.67 | 1.77 | 19.91 | 0.052 | 549.40 | |

| Broken bridge aluminum alloy double-glass sunshine room | 644.73 | 2.51 | 25.88 | 0.067 | 673.19 | |

| Broken bridge aluminum Low-e sunshine room | 680.18 | 2.74 | 28.11 | 0.073 | 711.10 |

| Material | Unit Price | Materials | Unit Price |

|---|---|---|---|

| PO plastic wrap | 4 RMB/m | Regular hollow glass window | CNY 280/m |

| 3 mm solid PC board | 70 RMB/m | Low-e hollow glass window | CNY 370/m |

| 6 mm broken bridge aluminum single-glass window | 140 RMB/m | Square steel tube skeleton | CNY 23/m |

| 10 mm hollow PC board | 30 RMB/m | Round steel skeleton | CNY 12/m |

| Type of Rural Houses | Sunroom Type | Number of Repairs | Single Repair Cost | Initial Investment Cost | Incremental Cost Present Value |

|---|---|---|---|---|---|

| Repairs | CNY | CNY | CNY | ||

| Pre-1980s Adobe rural house | Plastic sheathed sunroom | 1 | 1283.62 | 1283.62 | 2446.14 |

| 3 mm PC board sunshine room | 0 | 0 | 5758.28 | 5484.08 | |

| 10 mm hollow PC board sunroom | 0 | 0 | 3672.12 | 3497.26 | |

| Broken bridge aluminum alloy single-glass sunshine room | 0 | 0 | 7826.56 | 7453.87 | |

| Broken bridge aluminum alloy double-glass sunshine room | 0 | 0 | 14,953.12 | 14,241.07 | |

| Broken bridge aluminum Low-e sunroom | 0 | 0 | 19,534.48 | 18,604.27 | |

| 1980s–1990s brick-and-wood rural house | Plastic sheeting sunroom | 3 | 1277.74 | 1277.74 | 4702.95 |

| 3 mm PC board sunroom | 1 | 5655.38 | 5655.38 | 11,638.80 | |

| 10 mm hollow PC board sunroom | 1 | 3628.02 | 3628.02 | 7466.48 | |

| Broken bridge aluminum alloy single-glass sunroom | 0 | 0 | 7620.76 | 7257.87 | |

| Broken bridge aluminum alloy double-glass sunshine room | 0 | 0 | 14,541.52 | 13,849.07 | |

| Broken bridge aluminum Low-e sunroom | 0 | 0 | 18,990.58 | 18,086.27 | |

| Post-1990s brick-and-mix rural homes | Plastic sheeting sunroom | 5 | 1488.00 | 1488.00 | 7877.06 |

| 3 mm PC board sunroom | 1 | 6904.00 | 6904.00 | 12,556.07 | |

| 10 mm hollow PC board sunshine room | 1 | 4334.00 | 4334.00 | 7882.10 | |

| Broken bridge aluminum alloy single-glass sunshine room | 0 | 0 | 9520.00 | 9066.67 | |

| Broken bridge aluminum alloy double-glass sunshine room | 0 | 0 | 18,340.00 | 17,466.67 | |

| Broken Bridge Aluminum Low-e sunroom | 0 | 0 | 24,010.00 | 22,866.67 |

| Type of Rural Residences | Sunroom Type | Annual Saving for Heating Energy Consumption | Annual Saving for Cooling Energy Consumption | Annual Gas Saving | Annual Energy Saving | Total Incremental Benefit Present Value |

|---|---|---|---|---|---|---|

| /kW·h | /kW·h | /m3 | /kW·h | CNY | ||

| Pre-1980s Adobe rural house | Plastic wrap sunroom | 1634.81 | 0.00 | 163.48 | 0.00 | 4789.77 |

| 3 mm PC board sunroom | 1720.68 | −224.88 | 172.07 | −70.28 | 4641.39 | |

| 10 mm hollow PC board sunroom | 2132.43 | −253.31 | 213.24 | −79.16 | 5797.20 | |

| Broken bridge aluminum alloy single-glass sunroom | 1766.79 | −232.53 | 176.68 | −72.66 | 4762.90 | |

| Broken bridge aluminum alloy double-glass sunroom | 2268.19 | −273.60 | 226.82 | −85.50 | 6158.88 | |

| Broken bridge aluminum Low-e sunroom | 2468.83 | −297.76 | 246.88 | −93.05 | 6703.76 | |

| 1980s–1990s brick-and-wood rural homes | Plastic sheeting sunroom | 1779.34 | 0.00 | 177.93 | 0.00 | 10,944.74 |

| 3 mm PC board sunroom | 1869.60 | −307.65 | 186.96 | −96.14 | 10,351.27 | |

| 10 mm hollow PC board sunroom | 2294.91 | −336.49 | 229.49 | −105.15 | 12,859.69 | |

| Broken bridge aluminum alloy single-glass sunroom | 1915.90 | −315.49 | 191.59 | −98.59 | 10,606.78 | |

| Broken bridge aluminum alloy double-glass sunshine room | 2433.46 | −357.08 | 243.35 | −111.59 | 13,635.01 | |

| Broken bridge aluminum Low-e sunroom | 2636.30 | −381.23 | 263.63 | −119.13 | 14,792.51 | |

| Post-1990s brick-and-mix rural homes | Plastic sheeting sunroom | 2284.16 | 0.00 | 228.42 | 0.00 | 22,139.13 |

| 3 mm PC board sunroom | 2411.20 | −328.83 | 241.12 | −102.76 | 21,435.80 | |

| 10 mm hollow PC board sunroom | 2991.26 | −363.98 | 299.13 | −113.74 | 26,851.21 | |

| Broken bridge aluminum alloy single-glass sunroom | 2479.89 | −341.61 | 247.99 | −106.75 | 22,026.32 | |

| Broken bridge aluminum alloy double-glass sunshine room | 3180.55 | −393.19 | 318.06 | −122.87 | 28,513.98 | |

| Broken bridge aluminum Low-e sunroom | 3452.40 | −424.38 | 345.24 | −132.62 | 30,965.40 |

| Rural Home Type | Sunroom Type | Net Present Value | Dynamic Payback Period | Cost-Effectiveness Ratio |

|---|---|---|---|---|

| CNY | Year | |||

| pre-80s Adobe rural house | Plastic sheathed sunroom | 2343.63 | 2.80 | 1.96 |

| 3 mm PC board sunroom | −842.69 | 12.38 | 0.85 | |

| 10 mm hollow PC board sunshine room | 2299.94 | 6.50 | 1.66 | |

| Broken bridge aluminum alloy single-glass sunshine room | −2690.97 | 16.11 | 0.64 | |

| Broken bridge aluminum alloy double-glass sunshine room | −8082.19 | 23.01 | 0.43 | |

| Broken bridge aluminum Low-e sunroom | −11,900.51 | 27.06 | 0.36 | |

| 1980s–1990s brick-and-wood rural homes | Plastic sheeting sunroom | 6241.79 | 2.56 | 2.33 |

| 3 mm PC board sunroom | −1287.53 | 11.49 | 0.89 | |

| 10 mm hollow PC board sunroom | 5393.21 | 6.09 | 1.72 | |

| Broken bridge aluminum alloy single-glass sunshine room | 3348.91 | 14.87 | 1.46 | |

| Broken bridge aluminum alloy double-glass sunshine room | −214.06 | 21.39 | 0.98 | |

| Broken bridge aluminum Low-e sunshine room | −3293.76 | 25.26 | 0.82 | |

| Post-1990s brick-and-mix rural homes | Plastic wrap sunroom | 14,262.07 | 2.33 | 2.81 |

| 3 mm PC board sunroom | 8879.73 | 10.72 | 1.71 | |

| 10 mm hollow PC board sunroom | 18,969.11 | 5.51 | 3.41 | |

| Broken bridge aluminum alloy single-glass sunroom | 12,959.65 | 14.15 | 2.43 | |

| Broken bridge aluminum alloy double-glass sunshine room | 11,047.31 | 20.42 | 1.63 | |

| Broken bridge aluminum Low-e Sunroom | 8098.73 | 24.17 | 1.35 |

| Option | Sunroom Scheme |

|---|---|

| Economic option | Plastic sheathed sunroom |

| Standard option | 10 mm hollow PC board sunroom |

| Preferential option | 3 mm PC board sunroom |

| Option | Sunroom Scheme |

|---|---|

| Economic option | Plastic sheathed sunroom |

| Standard option | 10 mm hollow PC board sunroom |

| Preferential option | Broken bridge aluminum alloy double-glass sunshine room |

| Option | Sunroom Scheme |

|---|---|

| Economic option | 10 mm hollow PC board sunroom |

| Standard option | Broken bridge aluminum alloy double-glass sunshine room |

| Preferential option | Broken bridge aluminum Low-e sunlight room |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Duan, T.; Yang, Y.; Wang, C. Study on Comprehensive Benefit Evaluation of Rural Houses with an Additional Sunroom in Cold Areas—A Case Study of Hebei Province, China. Buildings 2025, 15, 2343. https://doi.org/10.3390/buildings15132343

Zhu X, Duan T, Yang Y, Wang C. Study on Comprehensive Benefit Evaluation of Rural Houses with an Additional Sunroom in Cold Areas—A Case Study of Hebei Province, China. Buildings. 2025; 15(13):2343. https://doi.org/10.3390/buildings15132343

Chicago/Turabian StyleZhu, Xinyu, Tiantian Duan, Yang Yang, and Chaohong Wang. 2025. "Study on Comprehensive Benefit Evaluation of Rural Houses with an Additional Sunroom in Cold Areas—A Case Study of Hebei Province, China" Buildings 15, no. 13: 2343. https://doi.org/10.3390/buildings15132343

APA StyleZhu, X., Duan, T., Yang, Y., & Wang, C. (2025). Study on Comprehensive Benefit Evaluation of Rural Houses with an Additional Sunroom in Cold Areas—A Case Study of Hebei Province, China. Buildings, 15(13), 2343. https://doi.org/10.3390/buildings15132343