Research and Prospects of Airtightness of Biological Laboratory Enclosures: Influencing Factors and Evaluation Methods

Abstract

1. Introduction

2. Current Status of Research Worldwide and in China

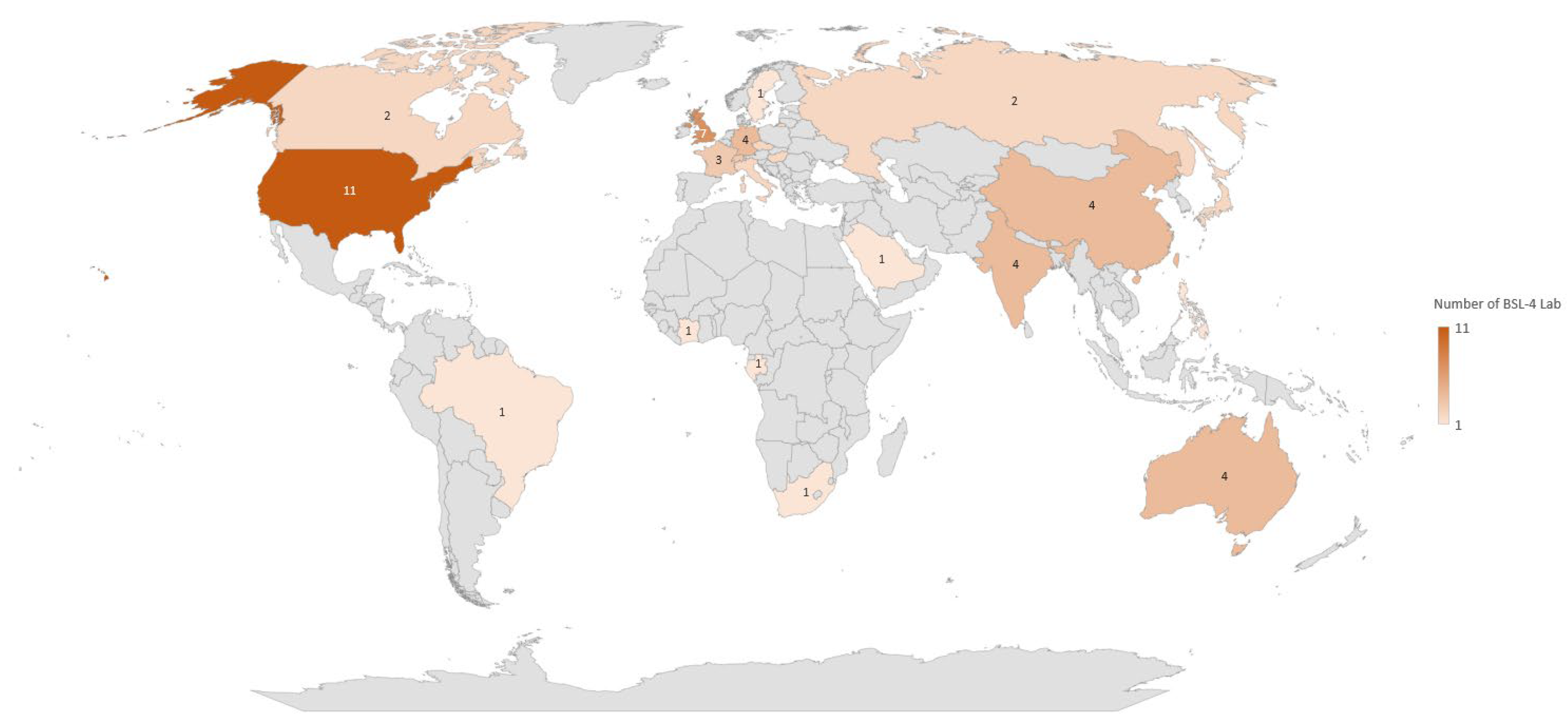

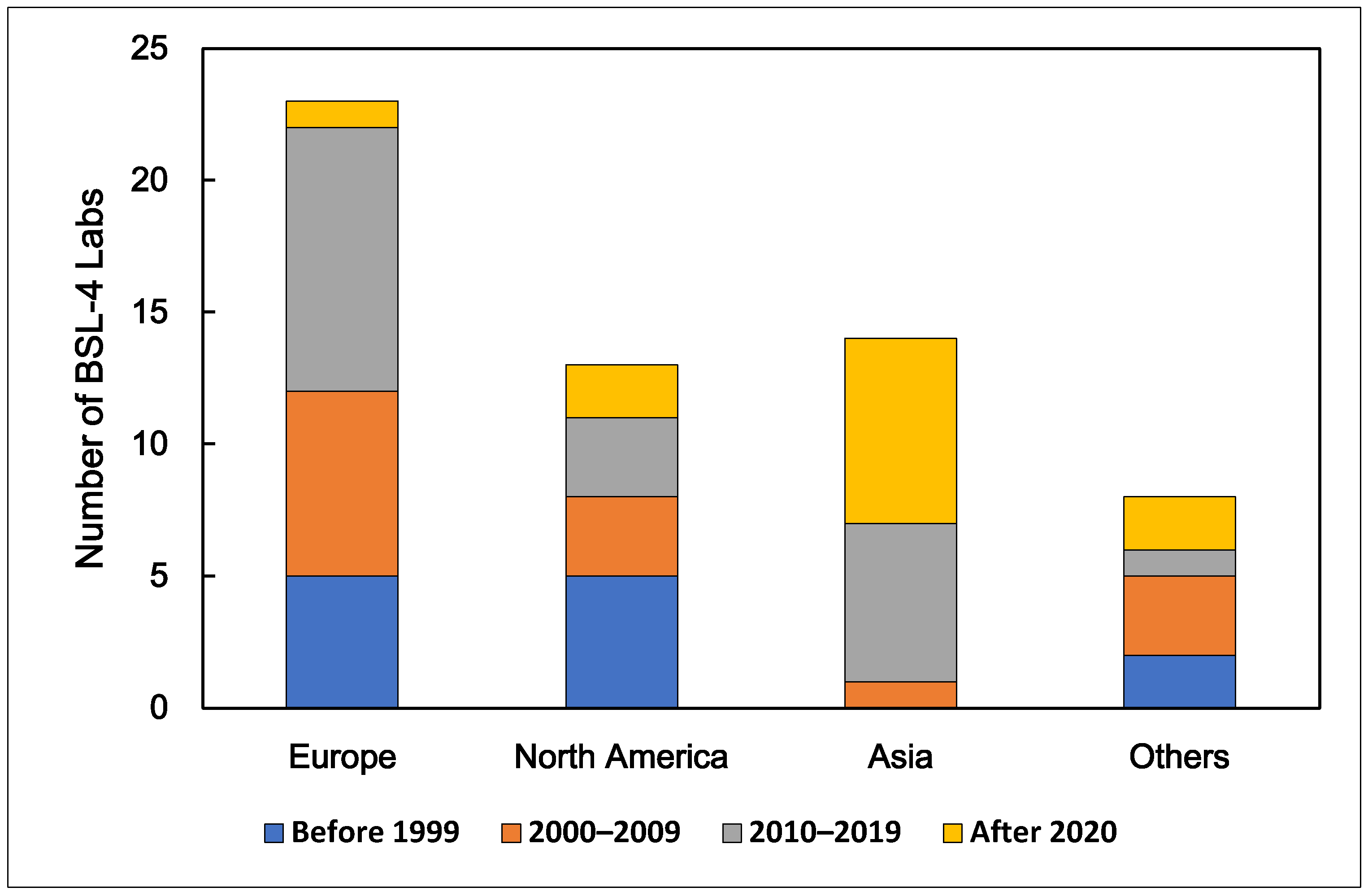

2.1. Development of Biosafety Laboratories Worldwide

2.2. Research Status in China

3. Airtightness of Concrete Structures

3.1. Concrete Material Properties

3.1.1. Mixing Ratio Design

3.1.2. Material Additives

3.2. Construction Technology

4. Airtightness of Steel Structures

4.1. Selection of Enclosure Structure and Components

4.2. Welding Performance and Welding Materials

- (1)

- Differences in melting points make heat treatment difficult. The melting of the base material cannot be synchronized; if the melting point difference is too great, it may prevent successful welding of the materials.

- (2)

- Differences in electromagnetic properties lead to unstable arc combustion during arc welding.

- (3)

- Different linear expansion coefficients can easily cause welding stress concentration or cracks, which is also one of the key reasons why welded joints may fail to meet airtightness requirements.

- (4)

- Differences in thermal conductivity and specific heat capacity prevent the formation of the melt pool from being synchronized. Different rates of heat transfer result in increased thermal stress.

4.3. Welding Process

- (1)

- Laser Welding.

- (2)

- Arc Welding.

5. Evaluation of Concrete, Steel Enclosures, and Use of Other Materials

5.1. Comprehensive Evaluation of Concrete and Steel Enclosures

5.2. Lifecycle Cost-Benefit Evaluation of Enclosure Systems

5.3. Other Materials Applied in the BSL-4 Laboratories

- (1)

- Composite Materials

- (2)

- Epoxy Coatings and Sealants

- (3)

- Glass and Acrylic Panels

- (4)

- High-Performance Gaskets and Membranes

- (5)

- Nanotechnology-Enhanced Materials

- (6)

- Fire-Resistant and Thermal Barriers

6. Airtightness Test Methods and Evaluation Criteria

6.1. Airtightness Test Methods

6.2. Airtightness Testing Standards

6.2.1. International Standards

6.2.2. China’s Standards

- (1)

- Pressure Decay Method

- (2)

- Constant Pressure Method

7. Other Measures to Improve Airtightness

7.1. Setting the Airtight Valve and Airtight Door

7.1.1. Airtight Valve

7.1.2. Airtight Doors

7.2. Through-Wall Equipment and Sealing Measures

7.3. Adopting the Dynamic Pressure Control Design Method

7.4. Microbial Testing of Laboratory Tightness

8. Conclusions

- (1)

- From the operation practice of P4 laboratories, the number of high-level biosafety laboratories in China needs to be further increased, with plans to form a reasonable national network of high-level biosafety laboratories by 2025. There are still some safety loopholes in the management of P4 facilities, which need to be unified. In order to improve the accuracy and effectiveness of enclosure structure airtightness testing, relevant national standards still need to be formulated and revised. Currently, China particularly needs to accumulate information related to the long-term operational reliability of P4 facilities, including laboratory design, building materials, construction processes, construction supervision, and qualification certification. Relevant regulations and standards still need to be further improved. In the future, China can draw on the mature experiences and relevant standards of other countries in the construction of high-level biosafety laboratories to improve its national standards, laboratory management, and maintenance, providing references for the biosafety construction and application of high-level biosafety laboratories in China. Given the high requirements for the construction and management of high-level biosafety laboratories and the significant investment costs involved, it is advisable to first strengthen support for the development of key technologies and related disciplines, gradually forming and leveraging their capabilities and advantages.

- (2)

- The airtightness of concrete is closely related to its capillary porosity, with influencing factors including material proportions and forming processes. Admixtures significantly affect concrete airtightness. Water-reducing agents improve the airtightness of concrete specimens; defoamers refine pores and reduce concrete permeability; air-entraining agents enhance airtightness, but increased dosage leads to a temporary decrease followed by an increase in permeability coefficient; when compressive strength and permeability coefficient decrease, airtightness agent dosage increases.

- (3)

- Stainless steel enclosure structures are airtight, corrosion-resistant, high-pressure resistant, and easy to disinfect and clean. They are widely used in high-level biosafety laboratories. A stainless steel plate seam-welded enclosure structure is the preferred option for remodeling projects, with low cost and a short construction period. Color steel plate enclosure structures for non-airborne biological factors of the laboratory to ensure airtightness are usually made of 304 stainless steel, after welding, molding, aging treatment, CNC machining, sandblasting and painting, and other processes. The welding performance of steel structures is affected by the physical and chemical properties of the base material, chemical composition, welding material selection, process, structural design, use conditions, and other aspects. Welding material selection affects the welding quality; the chemical composition matching, strength, corrosion resistance, process performance, anti-porosity, and crack resistance need to be considered. Different welding methods to obtain the organization and properties of the welded joints include new technologies such as K-TIG welding, hybrid laser welding, dual-arc welding, and magnetron electro slag welding to improve productivity and joint strength.

- (4)

- Airtightness test methods include the pressure decay method, helium mass spectrometry leak detection method, soap method, heating method, flow method, water pressure method, etc., among which the pressure decay method and helium mass spectrometry leak detection method are more recommended. In developed countries, the research on the airtightness of the enclosure structure is sufficient, and the relevant building codes are more complete, with higher requirements for airtightness. China’s research on building airtightness is still in the primary stage, and the current national standards still need to be further improved.

- (5)

- From a holistic perspective, to systematically improve China’s biosafety laboratory infrastructure, a three-phase roadmap is proposed. In the short term, interdisciplinary training programs (e.g., biosafety engineering) should be prioritized to build technical capacity. For the mid-term, piloting regional laboratories incorporating hybrid materials could optimize cost/performance ratios. Long-term efforts should focus on establishing a centralized database for airtightness performance metrics, enabling data-driven standardization. This tiered approach balances immediate needs, incremental innovation, and sustainable governance for future biosafety challenges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BSL-4 | Biosafety Level 4 |

| P4 | Physical Containment Level 4 (equivalent to BSL-4) |

| CNAS | China National Accreditation Service for Conformity Assessment |

| GB | Guobiao (Chinese National Standards) |

| ISO | International Organization for Standardization |

| ASTM | American Society for Testing and Materials |

| EN | European Standard |

| JIS | Japanese Industrial Standards |

| ATTMA | Air Tightness Testing & Measurement Association |

| CGSB | Canadian General Standards Board |

| ACH50 | Air Changes per Hour at 50 Pa |

| ELA | Equivalent Leakage Area |

| CFM | Cubic Feet per Minute |

Appendix A

| Region | Country | Number | Name of Laboratory and Organization | Year of Construction | Area (m2) |

|---|---|---|---|---|---|

| Europe | UK | 7 | Centre for Emergency Preparedness and Response, Public Health England (PHE) | 1974 | 105 |

| Defence Science and Technology Laboratory (Dstl), Ministry of Defense | 2005 | 335 | |||

| High Containment Large Animal Facility (HCLAF), Pirbright Institute | 2015 | 257 | |||

| The Francis Crick Institute Containment 4 facility (formerly NIMR), The Francis Crick Institute | 2016 | 298 | |||

| Centre for Infections (CFL), United Kingdom Health Security Agency (UKHSA) | 2013 | 30 | |||

| National Institute for Biological Standards and Control (NIBSC), The Medicines and Healthcare Products Regulatory Agency, Department of Health & Social Care | 1975 | 118 | |||

| Public Health England (PHE) Harlow, United Kingdom Health Security Agency (UKHSA) | 2024 | unknown | |||

| Germany | 4 | Institute for Virology, Philipps University of Marburg | 2007 | 152 | |

| Bernhard Nocht Institute for Tropical Medicine (BNI) | 2014 | 400 | |||

| Centre for Biological Threats and Special Pathogens, Robert Koch Institute, Federal Ministry of Health | 2018 | 330 | |||

| Friedrich Loeffler Institute (FLI), Federal Research Institute for Animal Health | 2015 | 405 | |||

| France | 3 | DGA Maîtrise NRBC, General Directorate of Armaments (DGA) | 2013 | 178 | |

| Institut de Recherche Biomédicale des Armées (IRBA), Army Health Service (SSA) | 2015 | 240 | |||

| Jean Mérieux-Inserm (Institut national de la santé et de la recherche médicale), French National Institute of Health and Medical Research | 1999 | 400 | |||

| Switzerland | 3 | Spiez Laboratory | 2014 | 118 | |

| Laboratory of Virology, Geneva University Hospitals | unknown | 36 | |||

| Institute of Medical Virology, University of Zurich | unknown | 25 | |||

| Italy | 2 | National Institute for Infectious Diseases Lazzaro Spallanzani (IRCCS) | 2000 | unknown | |

| Laboratory of Clinical Microbiology, Virology and Bioemergencies (CLIMVIB), Luigi Sacco University Hospital, University of Milan | unknown | unknown | |||

| Czech Republic | 2 | Laboratory for Biological Monitoring and Protection, National Institute for Nuclear, Chemical, and Biological Protection | 2007 | 28 | |

| Department for Biological Defence, Military Institute of Health | 2007 | 50 | |||

| Hungary | 2 | National Biosafety Laboratory (OKI), National Public Health Institute (former National Center for Epidemiology) | 2002 | 163 | |

| Szentágothai Research Center, University of Pécs | 2017 | 55 | |||

| Russia | 2 | State Research Center of Virology and Biotechnology (VECTOR), Russian Federal Service for Surveillance on Consumer Rights Protection and Human Wellbeing | 1980 | 1440 | |

| 48th Central Scientific Research Institute Sergiev Posad, Ministry of Defense | 1979 | unknown | |||

| Sweden | 1 | Folkhälsomyndigheten (FOHM), Public Health Agency of Sweden | 2001 | 136 | |

| North America | US | 11 | Integrated Research Facility at Rocky Mountain Lab (IRF, RML), National Institutes of Health (NIH), National Institute of Allergy and Infectious Diseases (NIAID) | 2008 | 1145 |

| The Betty Slick and Lewis J. Moorman, Jr. Laboratory Complex, Texas Biomedical Research Institute | 1970 | 114 | |||

| Center for Biodefense and Emerging Infectious Diseases Shope Laboratory, The University of Texas Medical Branch | 2003 | 186 | |||

| Galveston National Laboratory, The University of Texas Medical Branch | 2010 | 1022 | |||

| National Bio and Agro-Defense Facility (NBAF), US Department of Homeland Security, US Department of Agriculture | 2024 | 4084 | |||

| High Containment Core (HCC) (formerly the Viral Immunology Center), Georgia State University | 1988 | 60 | |||

| Special Pathogens Branch, Centers for Disease Control and Prevention (CDC) | 1988 | 533 | |||

| National Biodefense Analysis and Countermeasures Center (NBACC), US Department of Homeland Security | 2008 | 980 | |||

| Integrated Research Facility at Fort Detrick (IRF - Frederick), National Institutes of Health (NIH), National Institute of Allergy and Infectious Diseases (NIAID) | 2013 | 1305 | |||

| US Army Medical Research Institute of Infectious Diseases (USAMRIID), US Army Medical Research and Materiel Command, Department of Defense | 1969 | 1186 | |||

| National Emerging Infectious Diseases Laboratories (NEIDL), Boston University | 2017 | 1202 | |||

| Canada | 2 | Vaccine and Infectious Disease Organization, Centre for Pandemic Research, University of Saskatchewan | 2024 | unknown | |

| National Microbiology Laboratory (NML), Public Health Agency of Canada | 1999 | 185 | |||

| Asia | China | 4 | High-Level Biosafety Primate Experimental Center, Institute of Medical Biology, Chinese Academy of Medical Sciences | 2019 | 3000 |

| Wuhan Institute of Virology, Chinese Academy of Sciences | 2016 | 200 | |||

| Chinese Center for Disease Control and Prevention, National Health Commission | Under construction | Pending | |||

| Chinese National High Containment Facilities for Animal Diseases Control and Prevention, Harbin Veterinary Research Institute | 2018 | 17000 | |||

| India | 4 | Microbial Containment Complex (MCC), National Institute of Virology | 2012 | 848 | |

| National Institute of High-Security Animal Diseases (NIHSAD), Indian Council of Agricultural Research | 2000 | unknown | |||

| Advanced Biological Defence Research Centre (ABDRC) | Under construction | Pending | |||

| Rajiv Gandhi Centre for Biotechnology (RGCB) | Under construction | Pending | |||

| Japan | 2 | Murayama Annex, National Institute of Infectious Diseases (NIID) | 2015 | unknown | |

| National Research Center for the Control and Prevention of Infectious Diseases, Nagasaki University | 2021 | unknown | |||

| Taiwan, China | 1 | Institute of Preventive Medical Research (IPMR), National Defense University | unknown | unknown | |

| Korea | 1 | Osong BSL-4 Laboratory, Korea Centers for Disease Control and Prevention Agency | 2017 | 300 | |

| Saudi Arabia | 1 | National Health Laboratory, Saudi Ministry of Health | Pending | Pending | |

| Singapore | 1 | Defence Science Organisation (DSO) National Laboratories | 2025 | Pending | |

| Philippines | 1 | Virology Institute of the Philippines | 2024 | Pending | |

| Africa | South Africa | 1 | Special Pathogens Unit, National Institute for Communicable Diseases (NICD) | 1979 | unknown |

| Gabon | 1 | International Center for Medical Research of Franceville (CIRMF) | 2008 | unknown | |

| Côte d’Ivoire | 1 | Institut Pasteur de Côte d’Ivoire | Pending | Pending | |

| Oceania | Australia | 4 | Australian Centre for Disease Preparedness (formerly Australian Animal Health Laboratory), Commonwealth Scientific and Industrial Research Organization (CSIRO) | 1985 | 567 |

| Emerging Infections and Biohazard Response Unit (EIBRU), Westmead Hospital | 2007 | 86 | |||

| Queensland Health Forensic and Scientific Services (QHFSS) | 2007 | 150 | |||

| National High-Security Quarantine Laboratory (NHSQL), Peter Doherty Institute for Infection and Immunity | 2014 | 90 | |||

| South America | Brazil | 1 | Pan American Foot and Mouth Disease Center (PANAFTOSA) | 2021 | unknown |

References

- Lu, J.; Wang, R.; Cao, G. Protection zone and air tightness requirements for level-4 biosafety laboratories. HVAC 2018, 48, 15–20. [Google Scholar] [CrossRef]

- Furuyama, W.; Nanbo, A. Introduction of high containment laboratories in abroad. Uirusu 2022, 72, 139–148. [Google Scholar] [CrossRef]

- Song, Q.; Ding, C.; Chen, F.; Zhang, Z. Construction and development status of international biosafety level 4 laboratory and suggestions to China. World Sci. Technol. Res. Dev. 2021, 43, 169–181. [Google Scholar] [CrossRef]

- National Development and Reform Commission (NDRC); Ministry of Science and Technology (MOST). High-level Biosafety Laboratory System Construction Plan (2016-2025). China Pharm. Biotechnol. 2017, 12, 83. [Google Scholar]

- Yuan, Z. Current status and future challenges of high-level biosafety laboratories in China. J. Biosaf. Biosecur. 2019, 1, 123–127. [Google Scholar] [CrossRef]

- Tang, S.; Liu, W. Research on factors influencing the gas permeability of concrete. In Proceedings of the 26th National Conference on Structural Engineering, Changsha, China, 20 October 2017. [Google Scholar]

- Liu, Z.; Sun, W.; Zhou, X. Research on rapid testing method for gas diffusion coefficient of concrete. Concrete 2005, 11, 4–6+10. [Google Scholar] [CrossRef]

- Yang, J.; Liu, C.; Jiang, J. Application of stainless steel envelope to high-level bio-safety laboratories. HVAC 2021, 51, 70–72. [Google Scholar] [CrossRef]

- ISO 9972:2015; Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- ASTM E779-19; Standard Test Method for Determining Air Leakage Rate by Fan Pressurization. ASTM International: West Conshohocken, PA, USA, 2019.

- Li, Y.; Lu, Y.; Cao, G. Discussion and research on correlation of two air tightness testing methods in high-level biosafety laboratory envelope air tightness tests. HVAC 2023, 03, 31–36. [Google Scholar] [CrossRef]

- Speranza, E.; Caballero, I.; Honko, A.N.; Johnson, J.C.; Bohannon, J.K.; DeWald, L.E.; Gerhardt, D.M.; Sword, J.; Hensley, L.E.; Bennett, R.S.; et al. Previremic identification of Ebola or Marburg virus infection using integrated host-transcriptome and viral genome detection. mBio 2020, 11, e01157-20. [Google Scholar] [CrossRef]

- GB 19489-2008; General Requirements for Laboratory Biosafety. China National Accreditation Center for Conformity Assessment (CNAC). China CDC: Beijing, China, 2008; pp. 7–11, 23–24.

- China Daily. China Builds World-Class Virus Lab to Study Deadliest Pathogens. 2017. Available online: http://world.chinadaily.com.cn/2017-02/23/content_34074282.htm (accessed on 23 February 2017).

- Hu, L.; Jin, A.-J.; Zhang, K. Biological protection test of facilities and key equipment in BSL-4 laboratory. Chin. Med. Biotechnol. 2018, 13, 104–109. [Google Scholar] [CrossRef]

- GB 50346-2011; Technical Specification for Biosafety Laboratory Construction. China Academy of Building Research: Beijing, China, 2012; pp. 5–9, 32.

- Chen, W.; Su, Y.; Chen, Z.; Li, W.; Yin, Y.; Wen, L.; Li, R.; Chen, W. Innovative practice of key technologies in nucleic acid detection laboratory of gas membrane building structure. Sci. Discov. 2022, 10, 7–16. [Google Scholar] [CrossRef]

- Wang, G.; Fang, J.; Yan, C.; Huang, D.; Hu, K.; Zhou, K. Advancements in smart building envelopes: A comprehensive review. Energy Build. 2024, 312, 114190. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Li, W. Gas permeability and microstructure evolution of fiber-reinforced concrete under negative pressure. Build. Environ. 2022, 215, 108921. [Google Scholar] [CrossRef]

- Liu, M. Effect of Low Vacuum Environment on Gas Permeability of Concrete and Its Mechanism. Ph.D. Thesis, Tongfang Knowledge Network (Beijing) Technology Co., Ltd., Beijing, China, 2023. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, X.; Che, J.; Chen, S.; Leng, B. Study on the effect of admixtures on airtightness of concrete. New Build. Mater. 2023, 50, 148–150. [Google Scholar] [CrossRef]

- Huang, C.; Ding, B.; Ou, Z.; Feng, R. Influence of defoamer on the properties and pore structure of cementitious grout for rebar sleeve splicing. Buildings 2023, 13, 170. [Google Scholar] [CrossRef]

- Cai, J. Study on the effect of defoamer and the process of “First Elimination and then Introduction” on the apparent bubbles of concrete structure. Guangdong Build. Mater. 2024, 40, 15–18. [Google Scholar] [CrossRef]

- Bai, G.; Li, X.; Lu, X.; Chen, X.; Liu, Y. The preparation and properties of airtight agent for concrete and its microstructure analysis. New Build. Mater. 2018, 45, 102–107. [Google Scholar] [CrossRef]

- Lian, X. Construction technology of gas-tightness high performance concrete with bucket-based. China Concr. Cem. Prod. 2016, 5, 80–82. [Google Scholar] [CrossRef]

- Yang, G. Application of concrete pouring construction technology in civil engineering construction. Brick-Tile 2024, 9, 169–171. [Google Scholar] [CrossRef]

- Wu, W. Pouring and vibrating of concrete. J. Liaoning Prov. Coll. Commun. 2005, 4, 14–15. [Google Scholar] [CrossRef]

- Zhang, G. Research on the influence of welding materials on process quality. South. Agric. Mach. 2020, 51, 157–158. [Google Scholar] [CrossRef]

- Gorshkova, O. New technologies in welding production. Sovrem. Naukoemkie Tekhnol. (Mod. High Technol.) 2021, 2, 14–18. [Google Scholar] [CrossRef]

- Liu, G.; Chen, S. A review of the welding process of dissimilar steel. China High-Tech Enterp. 2016, 25, 83–84. [Google Scholar] [CrossRef]

- EN 13829:2000; Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method. European Committee for Standardization (CEN): Brussels, Belgium, 2000.

- ISO 10648-2:1994; Containment Enclosures: Part 2: Classification According to Leak Tightness and Associated Checking Methods. International Organization for Standardization: Geneva, Switzerland, 1994.

- World Health Organization. Laboratory Biosafety Manual, 4th ed.; World Health Organization: Geneva, Switzerland, 2020; Available online: https://www.who.int/publications/i/item/9789240011311 (accessed on 20 December 2020).

- Kumar, A.P.; Singh, R.P. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2008, 33, 1180–1223. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Recent advances in graft copolymerization and applications of chitosan: A review. ACS Sustain. Chem. Eng. 2014, 2, 2637–2652. [Google Scholar] [CrossRef]

- Panta, J.; Rider, A.N.; Wang, J.; Yang, C.H.; Hugh Stone, R.; Taylor, A.C.; Brack, N.; Cheevers, S.; Zhang, Y.X. High-performance carbon nanofiber reinforced epoxy-based nanocomposite adhesive materials modified with novel functionalization method and triblock copolymer. Compos. Part B Eng. 2023, 249, 110401. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Huang, L.; Ding, X.; Chen, Z.; Ren, C.; Hao, W.; Ma, L.; Zhang, D. Photothermally activated self-healing coatings for corrosion protection: A review. Prog. Org. Coat. 2023, 185, 107886. [Google Scholar] [CrossRef]

- Kalogeras, I.M.; Hagg Lobland, H.E. The nature of the glassy state: Structure and transitions. J. Mater. Educ. 2012, 34, 69–94. [Google Scholar]

- Rastogi, P.; Kaushal, R. Acrylic polymers in healthcare applications. Polym. Adv. Technol. 2018, 29, 41–54. [Google Scholar] [CrossRef]

- Ahmed, S.; Salehi, S.; Ezeakacha, C.; Teodoriu, C. Experimental investigation of elastomers in downhole seal elements: Implications for safety. Polym. Test. 2019, 76, 350–364. [Google Scholar] [CrossRef]

- Yang, S.T.; Liu, Y.; Wang, Y.W.; Cao, A. Biosafety and bioapplication of nanomaterials by designing protein-nanoparticle interactions. Small 2013, 9, 1635–1653. [Google Scholar] [CrossRef] [PubMed]

- Nel, A.; Xia, T.; Madler, L.; Li, N. Toxic potential of materials at the nanolevel. Science 2006, 311, 622–627. [Google Scholar] [CrossRef] [PubMed]

- Morgan, A.B.; Wilkie, C.A. Flame Retardant Polymer Nanocomposites; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Schartel, B. Phosphorus-based flame retardancy mechanisms—Old hat or a starting point for future development? Materials 2010, 3, 4710–4745. [Google Scholar] [CrossRef]

- Zheng, X.; Cooper, E.; Gillott, M.; Wood, C. A practical review of alternatives to the steady pressurisation method for determining building airtightness. Renew. Sustain. Energy Rev. 2020, 132, 110049. [Google Scholar] [CrossRef] [PubMed]

- JIS A 2201:2018; Method for Measurement of Air Permeability of Buildings. Japanese Standards Association: Tokyo, Japan, 2018.

- ATTMA TS1:2022; Measuring Air Permeability of Building Envelopes (Dwellings and Non-Dwellings). Air Tightness Testing & Measurement Association: Northampton, UK, 2022.

- CAN/CGSB-149.15:2020; Determination of the Airtightness of Building Envelopes by the Fan Depressurization Method. Canadian General Standards Board: Ottawa, ON, Canada, 2020.

- Zhou, Q.; Meng, L.; Chen, Q. Case analysis of biosafety level-4 mode laboratory design. HVAC 2022, 7, 69–73. [Google Scholar] [CrossRef]

- Liu, W.; Song, J.; Zhao, H.; Cui, Z.; Zhang, S.; Qiao, Y.; Cao, C.; Li, W. Mechanically stable and superhydrophobic nano-SiO2@silane/silicate coating for enhanced impermeability of mortar. Constr. Build. Mater. 2025, 470, 140541. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, J.T.; Chen, J.B.; Chai, H.Y.; Zhu, C.Y.; Tang, H.A.; Gan, Y. Study on contaminant distribution in a mobile BSL-4 laboratory based on multi-region directional airflow. Environ. Sci. Pollut. Res. 2022, 29, 12100–12114. [Google Scholar] [CrossRef] [PubMed]

- Cao, G.; Wang, R.; Zhai, P. Discussion on building envelope air tightness test of high-level biosafety laboratories. HVAC 2016, 12, 74–79. [Google Scholar] [CrossRef]

- Van Linden, S.; Van Den Bossche, N. Airtightness of sealed building joints: Comparison of performance before and after artificial ageing. Build. Environ. 2020, 180, 107010. [Google Scholar] [CrossRef]

- Xia, H.; Huang, Y.; Ma, H.; Liu, B.; Xie, W.; Song, D.; Yuan, W. Biosafety Level 4 Laboratory User Training Program, China. Emerg. Infect. Dis. 2019, 25, 1457–1464. [Google Scholar] [CrossRef]

- Richmond, J.Y.; McKinney, R.W. (Eds.) Biosafety in Microbiological and Biomedical Laboratories, 6th ed.; U.S. Department of Health and Human Services: Washington, DC, USA, 2020. Available online: https://www.cdc.gov/labs/bmbl/index.html (accessed on 20 December 2020).

- Le Duc, J.W.; Anderson, K.; Bloom, M.E.; Estep, J.E.; Feldmann, H.; Geisbert, J.B.; Geisbert, T.W.; Hensley, L.; Holbrook, M.; Jahrling, P.B.; et al. Framework for leadership and training of biosafety level 4 laboratory workers. Emerg. Infect. Dis. 2009, 15, e73. [Google Scholar] [CrossRef] [PubMed]

- Klimpel, D.; Meyer, V.; Rziha, H.-J. Testing the integrity of high-containment laboratories: Aerosol challenge studies with Bacillus atrophaeus spores. Appl. Biosaf. 2013, 18, 67–74. [Google Scholar] [CrossRef]

- Dimmick, R.L.; Fogl, W.F.; Chatigny, M.A. Potential for accidental microbial aerosol transmission in the biology laboratory. In Proceedings of a Conference Held at the Asilomar Conference Center, Pacific Grove, CA, USA, 22-24 Januray 1973; Hellman, A., Oxman, M.N., Pollack, R., Eds.; Biohazards in biological research; Cold Spring Harbor Laboratory: New York, NY, USA, 1973; pp. 246–266. [Google Scholar]

| Region | Country | No. | Representative Facilities | Year | Area (m2) | Airtightness Standards /Techniques | Key Challenges |

|---|---|---|---|---|---|---|---|

| Europe | UK | 7 | Public Health England (PHE) | 1974 | 105 | ISO 9972:2015, EN 13829:2000; Stainless steel welding, Epoxy coatings | Common: High initial costs (materials and welding); Specific: Aging infrastructure requires specialized retrofitting. |

| Germany | 4 | Bernhard Nocht Institute (BNI) | 2014 | 400 | Airtight concrete additives, Dynamic pressure control systems | Common: High operational costs; Specific: Stringent energy efficiency requirements increase the complexity of HVAC systems. | |

| North America | USA | 11 | NIH Integrated Research Facility (IRF) | 2008 | 1145 | ASTM E779-19; Composite materials, HEPA filtration systems | Common: Regulatory compliance burdens; Specific: Large facility size amplifies joint leakage risks. |

| Asia | China | 4 | Wuhan Institute of Virology | 2016 | 200 | GB 19489-2008; Steel/concrete hybrid structures | Common: Technician training deficiencies; Specific: Thermal expansion mismatch in hybrid structures. |

| India | 4 | Microbial Containment Complex (MCC) | 2012 | 848 | ISO 10648-2; Gasket-sealed doors | Common: Funding gaps; Specific: Tropical climate accelerates gasket degradation. | |

| Africa | South Africa | 1 | NICD Special Pathogens Unit | 1979 | N/A | Limited data; Reliance on international collaborations | Common: Resource constraints; Specific: Outdated facilities require donor-funded upgrades. |

| Oceania | Australia | 4 | Australian Centre for Disease Preparedness | 1985 | 567 | Laser welding technology, Smart pressure monitoring | Common: High operational costs; Specific: Geographical isolation increases parts replacement time. |

| Name | Principle of Action | Material Efficacy | Other |

|---|---|---|---|

| Water reducing agent | A typical surfactant that adsorbs at the gas/liquid interface, effectively reducing surface tension and increasing the strength of the liquid films between foam bubbles, thereby improving foam stability. | Incorporation of water-reducing agents is beneficial to improve the airtightness of concrete specimens, among which the sulfonate water-reducing agent is the most effective one [21]. | The uneven size and irregular shape of foam may affect the mechanical properties of concrete. |

| Defoamer | Using defoamers can refine the pore size and thus reduce the gas permeability of concrete. | As the dosage of defoamer increases, the workability of the concrete mixture decreases. Additionally, the difference in setting time decreases, while the compressive strength ratio first increases and then decreases. The permeability coefficient of hardened concrete shows a decrease followed by an increase. Organosilicon defoamer has a notably stronger effect on enhancing concrete airtightness [21]. | Mercury pressure test results indicate that the defoamer increased the pore volume of the paste in the pore size range of 6–30 nm, while it decreased the pore volume in the range of 30–60 µm. However, in the pore size range of 60–300 µm, the pore volume increased at defoamer dosages of 0.0025% and 0.0075%, and the pore volume of the cement slurry first reduced and then slightly increased at defoamer dosages of 0.005% and 0.001% [22]. |

| Air-entraining agent | Adding an air-entraining agent can effectively improve the airtightness of concrete. | As the dosage of the air-entraining agent increases, the permeability coefficient of the concrete specimen first decreases and then increases. | Cai (2024) [23] studied the joint effects of defoamers and air-entraining agents, proposing that the process of “first elimination, then air-entraining” can effectively regulate the air content of concrete, thus controlling the apparent quality of concrete components. |

| Air sealing agent | The amount of air sealing agent has a greater impact on the strength and air permeability coefficient of concrete. | Increasing the dosage of air sealing agent reduces the compressive strength and air permeability coefficient of concrete, while the lowest dosage of air sealing agent results in slightly poorer concrete flowability. | Bai et al. (2018) [24] prepared a new type of concrete airtightness agent using the pre-emulsified seed emulsion polymerization method, which is beneficial for improving the strength and airtightness of concrete. |

| PHE All-Stainless-Steel Enclosure | Wuhan Steel/Concrete Hybrid Enclosure | |

|---|---|---|

| Initial Construction: | ||

| Total Cost | USD 950–1600/m2 | USD 370–600/m2 |

| Material Cost | 304 Stainless steel: USD 650–900/m2 (316 L: +20–30%) Epoxy coating: USD 50–80/m2 | Structural steel (Q235/Q355): USD 150–250/m2 Concrete (C30–C50): USD 80–120/m2 Fireproofing: USD 30–50/m2 |

| Process Cost | Laser welding: USD 150–200/m2 Precision joints: USD 100–150/m2 | Conventional welding: USD 60–100/m2 Formwork: USD 50–80/m2 |

| Cost Multiple | 2–3× | 1× (baseline) |

| Post-Construction Maintenance: | ||

| Inspection Frequency | Every 10 years | Every 5 years |

| Maintenance Cost | Coating refurbishment: USD 50–80/m2/cycle Weld inspection | Crack repair: USD 20–40/m2/cycle Joint sealing |

| Region | Policy Drivers | Funding Profile | Dominant Enclosure Structure | Airtightness Impact | Cost Ratio * |

|---|---|---|---|---|---|

| EU | EN 13829:2000 lifecycle requirements Strict decontamination protocols | High public health budgets 20-year depreciation cycles | Laser-welded stainless steel | Ultra-low leakage Excellent chemical resistance | 1.0× (Baseline) |

| USA | ASTM E779-19 joint testing mandates Defense-funded biosafety priorities | Mixed federal/private funding Emphasis on rapid deploy ability | Composite panel systems | Moderate leakage Reliant on gasket seals | 0.8× |

| China | GB 19489-2008 attenuation limits “Localized innovation” subsidies | State capital projects 5-year budget cycles | Steel/concrete hybrid | Variable performance Thermal cracking risks | 0.6× |

| India | ISO 10648-2 compliance for aid projects Tropical climate adaptations | International grants (e.g., WHO) < USD 50 m project caps | Gasket-sealed color steel | High leakage Frequent gasket replacement | 0.3× |

| Africa | Donor-mandated EU/US standards Emergency outbreak response needs | >80% foreign-funded < USD 20 m/total facility | Modular prefabricated units | Poor long-term sealing Reliant on silicone sealants | 0.2× |

| Method Name | Recommended Rating | Method Description | Reason for Recommendation |

|---|---|---|---|

| Pressure Decay Method | ★★★★★ | Apply a certain pressure to the product or system being tested, record the initial pressure value, then turn off the gas or liquid supply source and measure the pressure change over a period of time to determine airtightness. | This method enables quantitative airtightness assessment and is the most widely adopted in BSL-4 laboratories. It is suitable for testing the airtightness of high-level biosafety laboratories, such as BSL-3 or BSL-4 laboratories. |

| Helium Mass Spectrometry Leak Detection Method | ★★★★★ | Apply gas around the product or test sample and use a leak detector to detect gas leakage, thereby assessing its airtightness performance. | The most reliable method, offering advantages of high accuracy, fast response, locatable leaks, and environmental adaptability. However, it requires a specialized helium mass spectrometry leak detector, which is relatively expensive. |

| Soap Liquid Method | ★★★★☆ | Apply soap liquid to the surface of the tested component, then fill it with gas at a certain pressure. The gas will blow soap bubbles through the leakage point, thus exposing the leakage location and observing whether there are bubbles generated to determine the airtightness. | Simple and easy, safe and reliable, can determine the leak location. However, the bubble formation can be influenced by leakage size and pressure difference. If the leakage volume is small, bubble formation takes longer, and bubbles may be too small or fragile to observe. |

| Heating Method | ★★★★☆ | Utilizing the thermal expansion and contraction properties of gas, the component is heated to expand the internal gas, then observe whether there are bubbles or water column formation to determine the airtightness. | Simple to operate, no complex equipment required, and bubbles or water columns can be directly observed. However, it is unsuitable for temperature-sensitive equipment and lacks sensitivity for detecting small leaks. Often used for chemical laboratory equipment. |

| Flow Rate Method | ★★★★☆ | Intermittently inject gas at a certain pressure into the tested component, use a mass flowmeter or volume flowmeter to detect changes in gas flow rate, and determine whether the leakage rate of the component is within the required acceptable range. | This system has a simple design, wide applicability, accurate test results, and can quantitatively assess airtightness performance. However, it can only detect overall airtightness and cannot locate the leakage position. |

| Water Pressure Method | ★★★☆☆ | Based on the principle of pressure, the component is submerged in water, subjected to a certain water pressure, and observed for water ingress or the formation of bubbles to determine its airtightness. | This method is simple and easy to perform, enabling direct visualization of leak points. However, once water enters the component, it may cause irreparable damage, and the water must be dried, wasting manpower and resources. |

| Criteria | ISO 9972:2015 [9] | EN 13829:2000 [31] | ASTM E779-19 [10] | JIS A 2201:2018 [46] | ATTMA TS1 (2022) [47] | CAN/CGSB-149.15 (2020) [48] |

|---|---|---|---|---|---|---|

| Regional Scope | International benchmark standard | Mandatory in EU member states | Mainstream in North America | Japan-specific | UK construction standard | Canadian national standard |

| Test Method | Single-mode fan pressurization | Dual-mode (Method A/B) | Single-point/Multi-point options | ISO 9972 + Japanese adaptation | Residential/Non-residential classification | Single-zone/Multi-zone testing |

| Metrics | Q50 (m3/h) ACH50 (h−1) A50 (m2) | Same as ISO 9972 | CFM50 (ft3/min) ACH50 (h−1) ELA (in2) | Q50 (m3/h) ACH50 (h−1) C-value (cm2/m2) | Q50 (m3/h) ACH50 (h−1) ELA (m2) | Q50 (m3/h) ACH50 (h−1) ELA (cm2) |

| Equations | Q = C·(ΔP)^n ACH50 = Q50/V A50 = Q50/(0.61·√50) | Same as ISO 9972 | Imperial unit adaptation ELA = CFM50/(0.61·√50) | Same as ISO 9972 C-value = ELA/floor area | Same as ISO 9972 | Same as ISO 9972 Climate zone adjustments |

| Compliance | Referenced by other standards | Incorporated in EU regulations | Used for US certification | Japanese Building Code reference | UK Building Regulations | Canadian National Building Code |

| Special Notes | None | Design verification method B | Single point allowed | Mandatory C-value reporting | Building type differentiation | Adaptation to extreme climates |

| Clause No. | Airtightness Requirements | |

|---|---|---|

| GB 19489 | 6.4.8 | The airtightness of the enclosure of the laboratory protection zone shall meet the following requirements: under the condition of closing all access to the test room and maintaining the temperature in the room at the upper limit of the design range, when the air pressure in the room rises to 500 Pa, the natural decay of the air pressure within 20 min shall be less than 250 Pa. |

| GB 50346 | 10.1.6 No.3 | Level 4 biosafety laboratories shall use the primary laboratory pressure decay test method under both positive and negative pressure conditions. |

| 3.3.2 | The relative negative pressure of the main laboratory room is −500 Pa, and after 20 min of natural decay, the relative negative pressure should not exceed −250 Pa. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, G.; Shi, X.; Hu, R.; Wang, X.; Zhan, J. Research and Prospects of Airtightness of Biological Laboratory Enclosures: Influencing Factors and Evaluation Methods. Buildings 2025, 15, 2314. https://doi.org/10.3390/buildings15132314

Peng G, Shi X, Hu R, Wang X, Zhan J. Research and Prospects of Airtightness of Biological Laboratory Enclosures: Influencing Factors and Evaluation Methods. Buildings. 2025; 15(13):2314. https://doi.org/10.3390/buildings15132314

Chicago/Turabian StylePeng, Geqing, Xiaoshuang Shi, Ruihan Hu, Xiaoli Wang, and Jinsheng Zhan. 2025. "Research and Prospects of Airtightness of Biological Laboratory Enclosures: Influencing Factors and Evaluation Methods" Buildings 15, no. 13: 2314. https://doi.org/10.3390/buildings15132314

APA StylePeng, G., Shi, X., Hu, R., Wang, X., & Zhan, J. (2025). Research and Prospects of Airtightness of Biological Laboratory Enclosures: Influencing Factors and Evaluation Methods. Buildings, 15(13), 2314. https://doi.org/10.3390/buildings15132314