Investigating Prefabricated Construction Technology Innovation Dynamics: Evidence from a Patent Analysis in China

Abstract

1. Introduction

2. PCT Innovation Review

3. Research Design

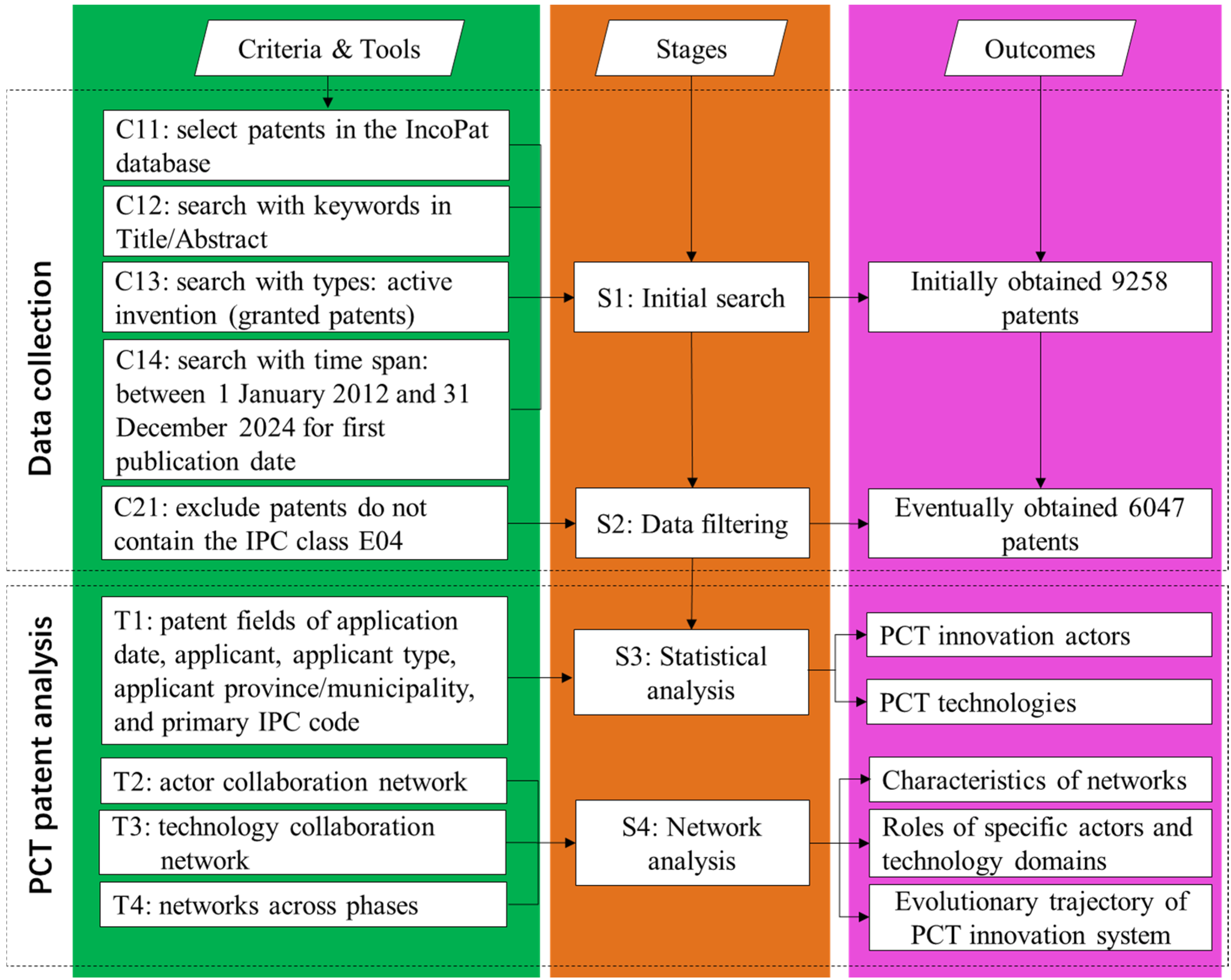

3.1. Research Method

3.2. Data Collection

3.3. Data Analysis

4. Results

4.1. Framework of PCT Innovation System

4.1.1. PCT Innovation Actors

- Geographical distribution of PCT innovation actors

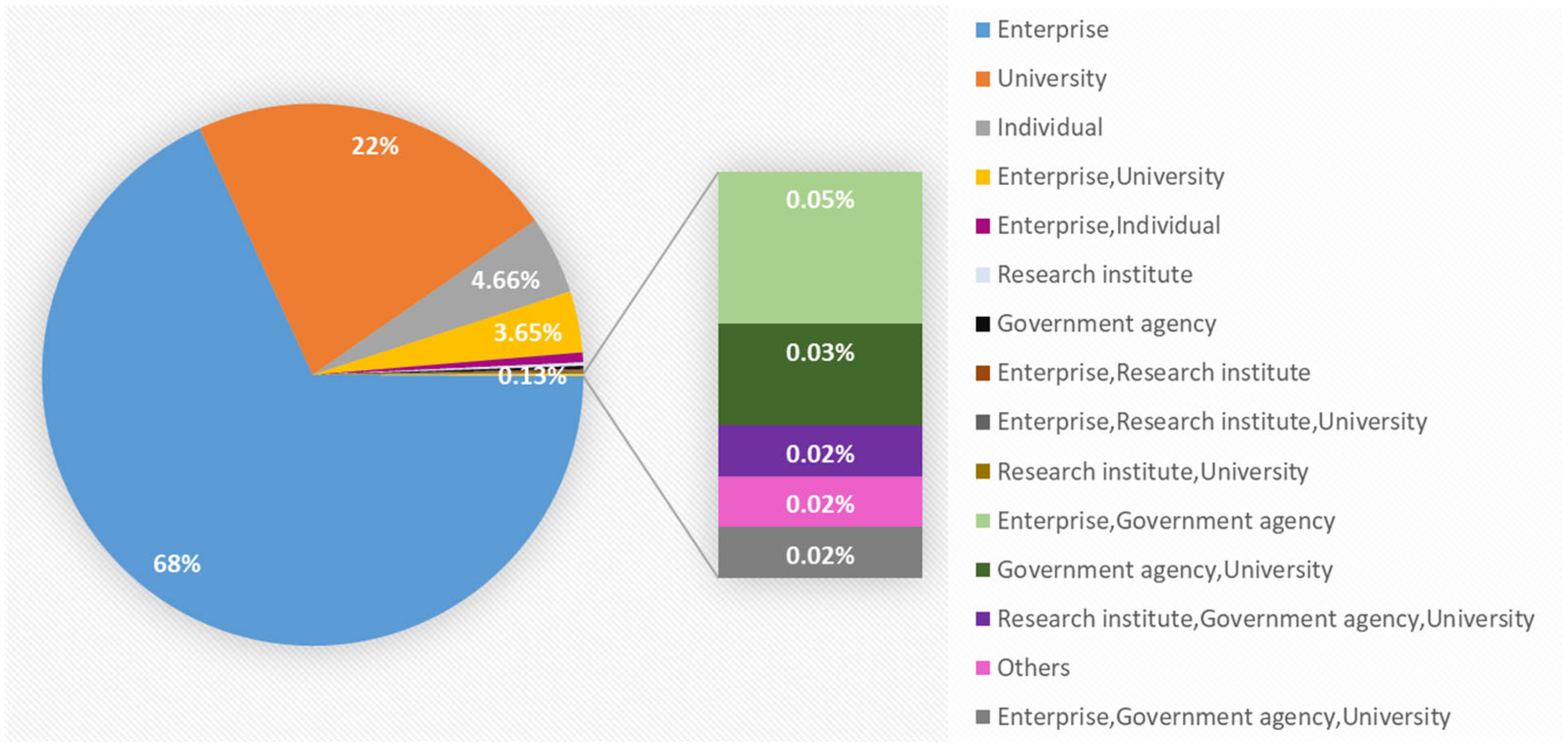

- Types of PCT innovation actors

- Top 15 PCT innovation actors

4.1.2. PCT Domains

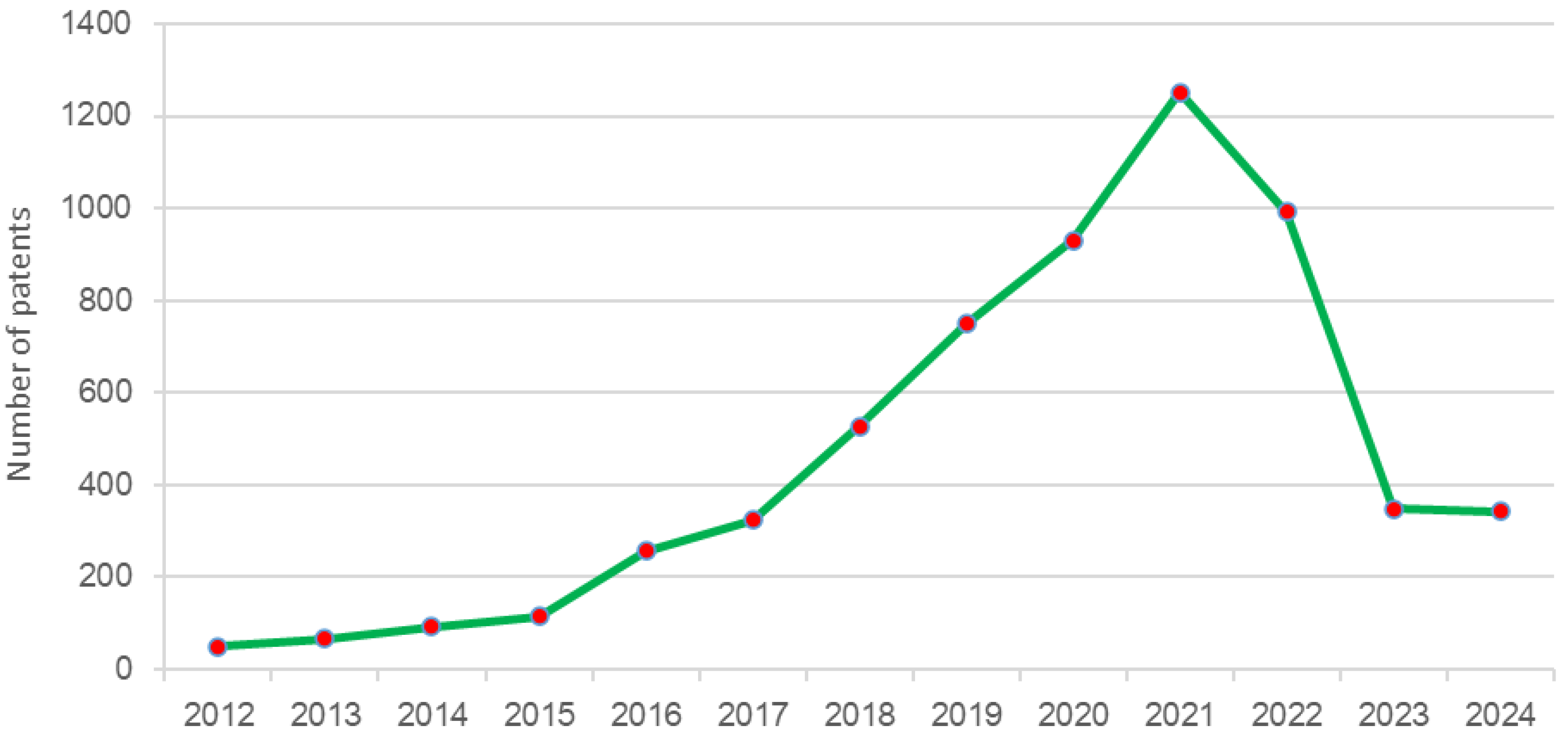

- Temporal distribution of PCT patent applications

- Technological classifications of PCT patents

4.2. Collaborations Within PCT Innovation System

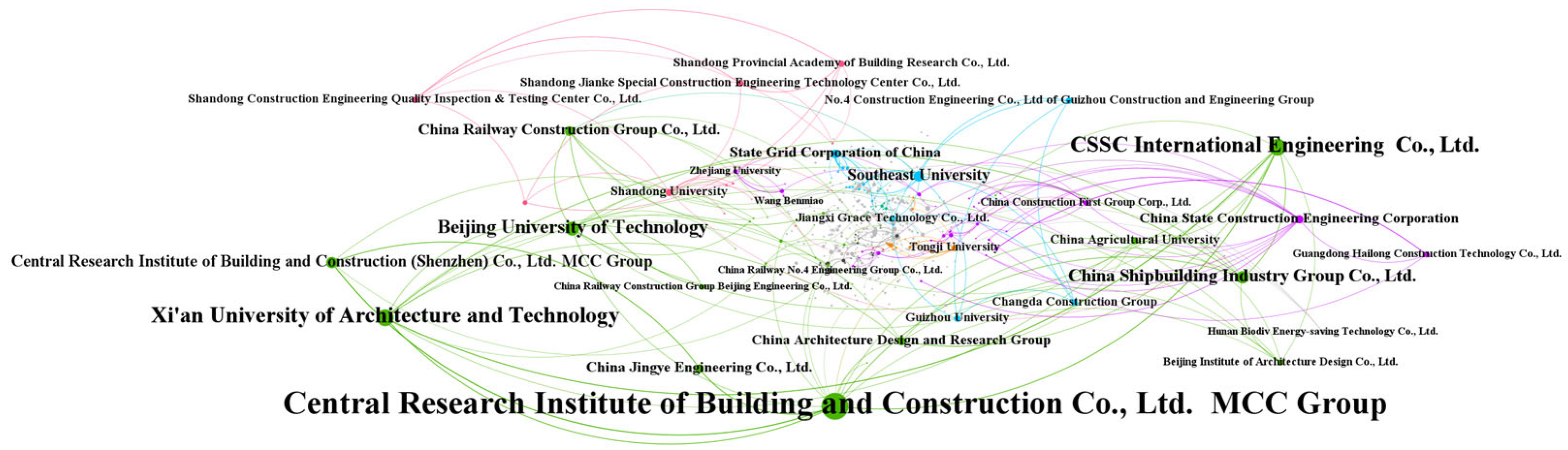

4.2.1. Collaboration Network of Innovation Actors

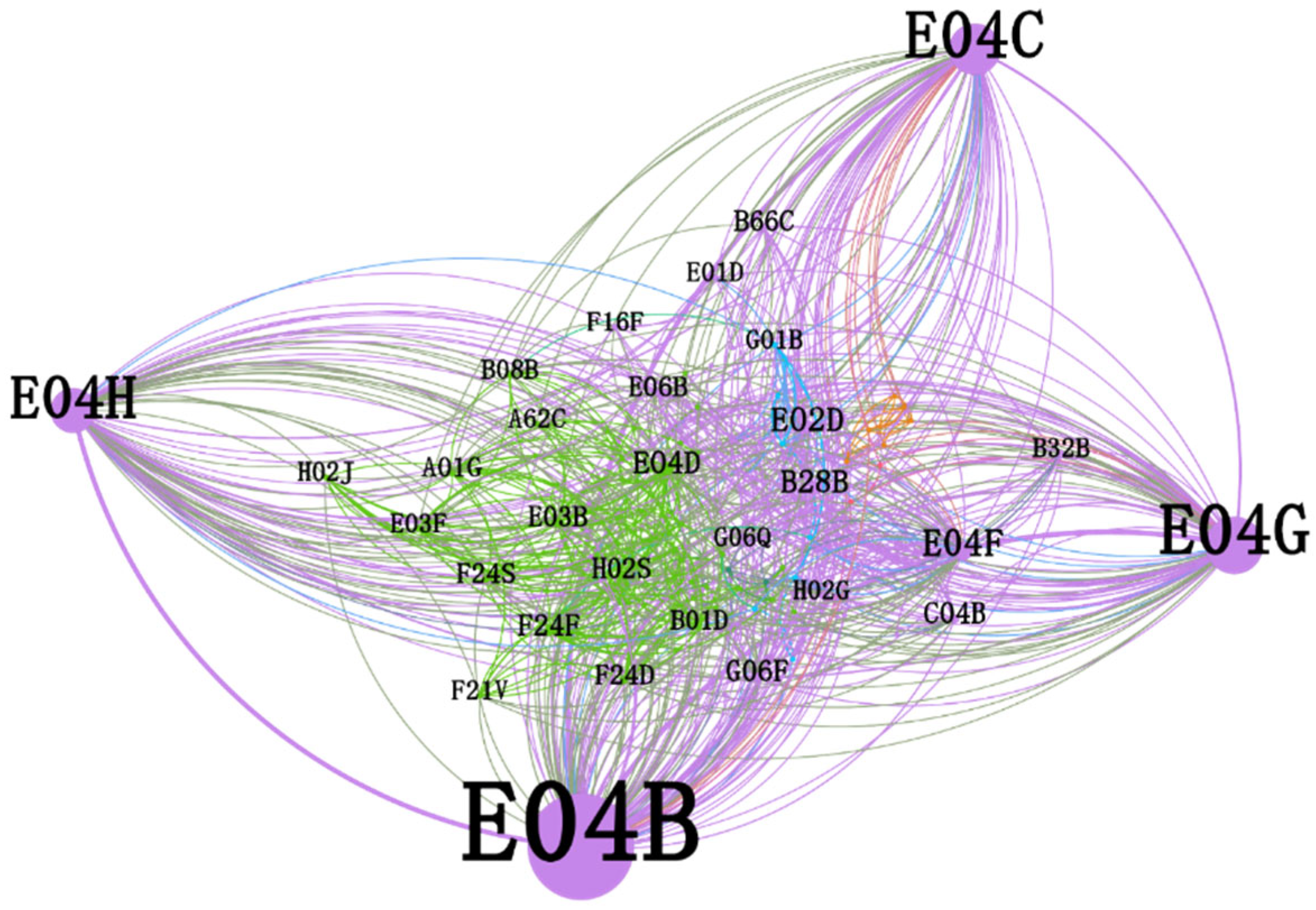

4.2.2. Technology Collaboration Network

4.3. Evolution of PCT Innovation System

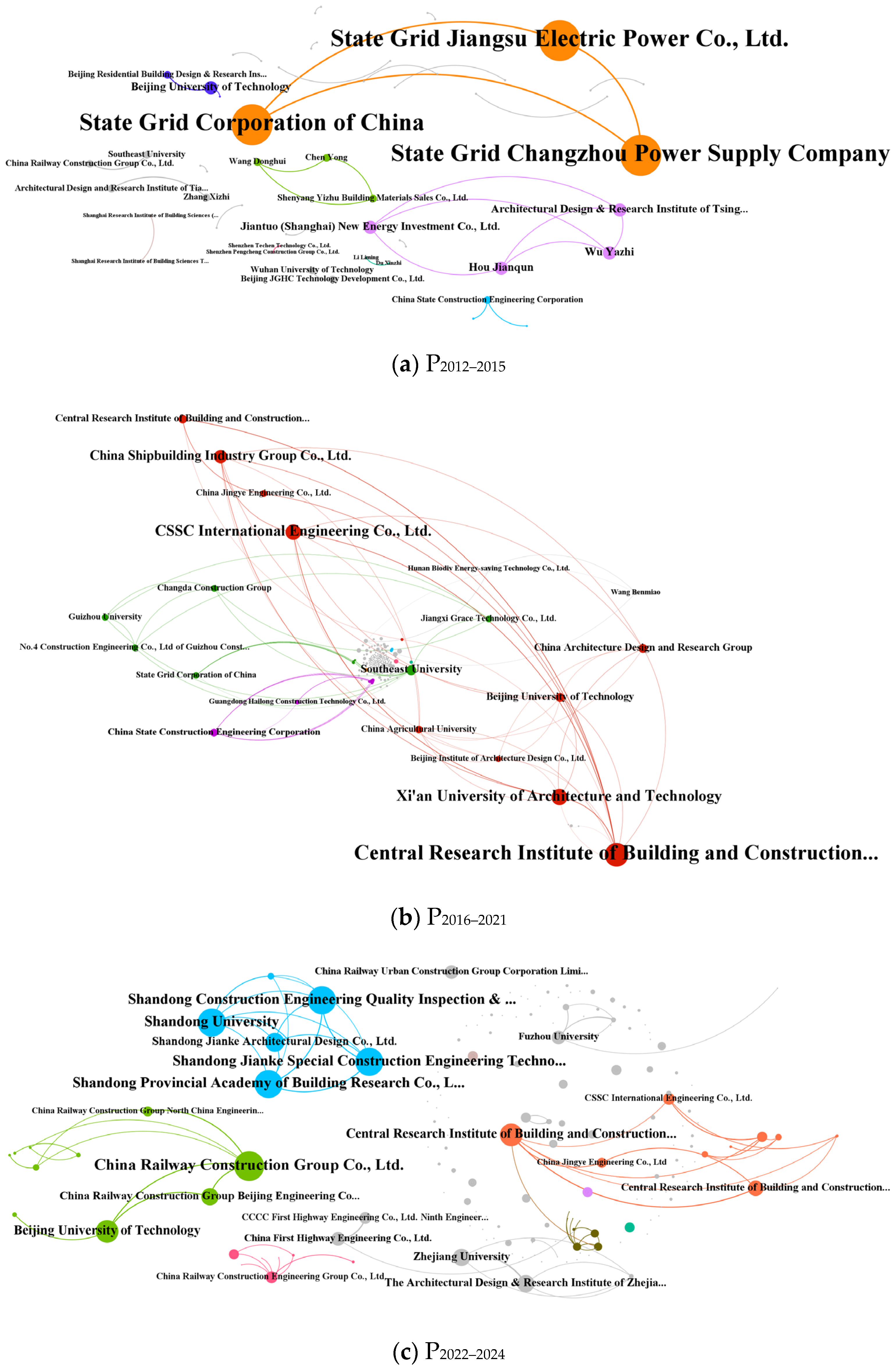

4.3.1. Dynamics of Actor Collaboration Network

4.3.2. Dynamics of Technology Collaboration Network

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical Evaluation of Off-Site Construction Research: A Scientometric Analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Goh, M.; Goh, Y.M. Lean Production Theory-Based Simulation of Modular Construction Processes. Autom. Constr. 2019, 101, 227–244. [Google Scholar] [CrossRef]

- Ping, T.; Pan, W.; Zhang, Z. Developing a Systematic Performance Measurement Framework for Benchmarking Steel Modular Building Construction. Eng. Constr. Archit. Manag. 2023, 32, 1837–1856. [Google Scholar] [CrossRef]

- Ho, C.; Kim, Y.W.; Zabinsky, Z.B. Prefabrication Supply Chains with Multiple Shops: Optimization for Job Allocation. Autom. Constr. 2022, 136, 104155. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A Quantitative Assessment of Greenhouse Gas (GHG) Emissions from Conventional and Modular Construction: A Case of Developing Country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, X.; Yu, T.; Wang, Y. Mapping the Dynamics of China’s Prefabricated Building Policies from 1956 to 2019: A Bibliometric Analysis. Build. Res. Inf. 2020, 49, 216–233. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A Holistic Review of Off-Site Construction Literature Published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Wang, Y.; Xue, W.; Tan, Y. A Systematic Overview of Prefabricated Construction Policies in China. J. Clean. Prod. 2021, 280, 124371. [Google Scholar] [CrossRef]

- Li, T.; Li, Z.; Dou, Y. Diffusion Prediction of Prefabricated Construction Technology under Multi-Factor Coupling. Build. Res. Inf. 2023, 51, 333–353. [Google Scholar] [CrossRef]

- Li, C.Z.; Li, S.; Li, X.; Wu, H.; Xiao, B.; Tam, V.W.Y.; Asiedu-Kwakyewa, C. A Scientometric Review of Management of Prefabricated Construction from 2011–2021. Buildings 2022, 12, 1515. [Google Scholar] [CrossRef]

- Dang, J.; Motohashi, K. Patent Statistics: A Good Indicator for Innovation in China? Patent Subsidy Program Impacts on Patent Quality. China Econ. Rev. 2015, 35, 137–155. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site Logistics Planning and Control for Engineer-to-Order Prefabricated Building Systems Using BIM 4D Modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Salama, T.; Salah, A.; Moselhi, O.; Al-Hussein, M. Near Optimum Selection of Module Configuration for Efficient Modular Construction. Autom. Constr. 2017, 83, 316–329. [Google Scholar] [CrossRef]

- Liu, G.; Li, K.; Zhao, D.; Mao, C. Business Model Innovation and Its Drivers in the Chinese Construction Industry during the Shift to Modular Prefabrication. J. Manag. Eng. 2017, 33, 04016051. [Google Scholar] [CrossRef]

- Gasparri, E.; Aitchison, M. Unitised Timber Envelopes. A Novel Approach to the Design of Prefabricated Mass Timber Envelopes for Multi-Storey Buildings. J. Build. Eng. 2019, 26, 100898. [Google Scholar] [CrossRef]

- Du, H.; Huang, P.; Jones, P. Modular Facade Retrofit with Renewable Energy Technologies: The Definition and Current Status in Europe. Energy Build. 2019, 205, 109543. [Google Scholar] [CrossRef]

- Pan, M.; Pan, W. Determinants of Adoption of Robotics in Precast Concrete Production for Buildings. J. Manag. Eng. 2019, 35, 05019007. [Google Scholar] [CrossRef]

- Li, X.; Wu, L.; Zhao, R.; Lu, W.; Xue, F. Two-Layer Adaptive Blockchain-Based Supervision Model for off-Site Modular Housing Production. Comput. Ind. 2021, 128, 103437. [Google Scholar] [CrossRef]

- Benjaoran, V.; Dawood, N. Intelligence Approach to Production Planning System for Bespoke Precast Concrete Products. Autom. Constr. 2006, 15, 737–745. [Google Scholar] [CrossRef]

- Xue, X.; Zhang, X.; Wang, L.; Skitmore, M.; Wang, Q. Analyzing Collaborative Relationships among Industrialized Construction Technology Innovation Organizations: A Combined SNA and SEM Approach. J. Clean. Prod. 2018, 173, 265–277. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X.; Wu, C.; Luo, X.; Wang, Y. Interorganizational Diffusion of Prefabricated Construction Technology: Two-Stage Evolution Framework. J. Constr. Eng. Manag. 2020, 146, 04020114. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, Y.; Zhang, W. Capabilities for Collaborative Innovation of Technological Alliance: A Knowledge-Based View. IEEE Trans. Eng. Manag. 2021, 68, 1734–1744. [Google Scholar] [CrossRef]

- Kaplan, S.; Vakili, K. The Double-Edged Sword of Recombination in Breakthrough Innovation. Strateg. Manag. J. 2015, 36, 1435–1457. [Google Scholar] [CrossRef]

- Laursen, K.; Salter, A. Open for Innovation: The Role of Openness in Explaining Innovation Performance among U.K. Manuf. Firms. Strateg. Manag. J. 2006, 27, 131–150. [Google Scholar] [CrossRef]

- Vakili, K.; Zhang, L. High on Creativity: The Impact of Social Liberalization Policies on Innovation. Strateg. Manag. J. 2018, 39, 1860–1886. [Google Scholar] [CrossRef]

- De Faria, P.; Lima, F.; Santos, R. Cooperation in Innovation Activities: The Importance of Partners. Res. Policy 2010, 39, 1082–1092. [Google Scholar] [CrossRef]

- Zeng, S.X.; Xie, X.M.; Tam, C.M. Relationship between Cooperation Networks and Innovation Performance of SMEs. Technovation 2010, 30, 181–194. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Grigoroudis, E.; Campbell, D.F.J.; Meissner, D.; Stamati, D. The Ecosystem as Helix: An Exploratory Theory-Building Study of Regional Co-Opetitive Entrepreneurial Ecosystems as Quadruple/Quintuple Helix Innovation Models. R D Manag. 2018, 48, 148–162. [Google Scholar] [CrossRef]

- Xue, X.; Tan, X.; Ji, A.; Xue, W. Measuring the Global Digital Technology Innovation Network in the Construction Industry. IEEE Trans. Eng. Manag. 2024, 71, 11138–11165. [Google Scholar] [CrossRef]

- Wu, H.; Shen, G.; Lin, X.; Li, M.; Zhang, B.; Li, C.Z. Screening Patents of ICT in Construction Using Deep Learning and NLP Techniques. Eng. Constr. Archit. Manag. 2020, 27, 1891–1912. [Google Scholar] [CrossRef]

- Pan, X.; Zhong, B.; Wang, X.; Xiang, R. Text Mining-Based Patent Analysis of Bim Application in Construction. J. Civ. Eng. Manag. 2021, 27, 303–315. [Google Scholar] [CrossRef]

- Cuellar, S.; Grisales, S.; Castaneda, D.I. Constructing Tomorrow: A Multifaceted Exploration of Industry 4.0 Scientific, Patents, and Market Trend. Autom. Constr. 2023, 156, 105113. [Google Scholar] [CrossRef]

- Xie, H.; Xin, M.; Lu, C.; Xu, J. Knowledge Map and Forecast of Digital Twin in the Construction Industry: State-of-the-Art Review Using Scientometric Analysis. J. Clean. Prod. 2023, 383, 135231. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, Y.; Cao, D. Artificial Intelligence in Construction: Topic-Based Technology Mapping Based on Patent Data. Autom. Constr. 2025, 172, 106073. [Google Scholar] [CrossRef]

- Hou, J.; Tang, S.; Zhang, Y. A Novel Technology Life Cycle Analysis Method Based on LSTM and CRF. Scientometrics 2024, 129, 1173–1196. [Google Scholar] [CrossRef]

- CDA: A Clustering Degree Based Influential Spreader Identification Algorithm in Weighted Complex Network-All Databases. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/WOS:000430792700013 (accessed on 13 June 2025).

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key Constraints and Mitigation Strategies for Prefabricated Prefinished Volumetric Construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Tan, Y.; Wang, Y.; Zhang, Y. Exploring a Body of Knowledge for Promoting the Sustainable Transition to Prefabricated Construction. Eng. Constr. Archit. Manag. 2021, 28, 2637–2666. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X.; London, K. Understanding Stakeholders in Off-Site Manufacturing: A Literature Review. J. Constr. Eng. Manag. 2019, 145, 03119003. [Google Scholar] [CrossRef]

| IPC Class | Description | Number of Patents | Percentage |

|---|---|---|---|

| E04 | Building structures (e.g., prefabricated components, prefabricated walls, connection joints)—Representing the core PCT domain. | 5651 | 95.02% |

| B66 | Lifting/Hoisting equipment (e.g., tower cranes, elevators, construction lifts)—Supporting component hoisting and positioning during assembly processes. | 64 | 1.08% |

| E02 | Earthworks and foundation engineering (e.g., subgrade, underground structures, shoring systems)—Critical for early-stage groundwork and structural support. | 57 | 0.96% |

| G06 | Computing and digital technologies (e.g., BIM, construction information systems, intelligent scheduling)—Providing the PC infrastructures. | 36 | 0.61% |

| B28 | Concrete/Gypsum/Cement processing (e.g., precast concrete production, curing techniques)—Pertaining to PC material fabrication. | 32 | 0.54% |

| C04 | Cement/Refractory and inorganic materials (e.g., low-carbon concrete, PC binding materials)—Innovative directions in component material. | 31 | 0.52% |

| F24 | HVAC and thermal systems (e.g., modular mechanical installations, integrated equipment)—Mechanical–electrical assembly techniques. | 23 | 0.39% |

| G01 | Measurement and inspection (e.g., assembly quality control, structural displacement monitoring)—Precision assurance methods. | 20 | 0.34% |

| E01 | Road construction and maintenance (e.g., prefabricated pavement, modular urban infrastructure)—Prefabricated municipal engineering applications. | 17 | 0.29% |

| E06 | Building envelope systems (e.g., windows/doors, curtain walls, integrated interior systems)—Prefabricated interior and exterior enclosure solutions. | 16 | 0.27% |

| Total | 5947 | 98.35% |

| Average Degree | Average Weighted Degree | Graph Density | Modularity | Average Clustering Coefficient |

|---|---|---|---|---|

| 2.014 | 3.048 | 0 002 | 0.948 | 0.75 |

| Node | Degree | Weighted Degree | Closeness Centrality | Betweenness Centrality | Eigenvector Centrality |

|---|---|---|---|---|---|

| Central Research Institute of Building and Construction Co., Ltd. MCC Group (Beijing, China) | 15 | 77 | 0.2458 | 9485.0833 | 1 |

| CSSC International Engineering Co., Ltd. (Beijing, China) | 9 | 47 | 0.2129 | 233.5833 | 0.8445 |

| Xi’an University of Architecture and Technology (Xi’an, China) | 10 | 47 | 0.2131 | 386.8333 | 0.8679 |

| Beijing University of Technology (Beijing, China) | 12 | 38 | 0.2252 | 6394 | 0.8882 |

| China Shipbuilding Industry Group Co., Ltd. (Beijing, China) | 7 | 34 | 0.2116 | 0 | 0.7830 |

| Central Research Institute of Building and Construction (Shenzhen) Co., Ltd. MCC Group (Shenzhen, China) | 4 | 30 | 0.2007 | 12.5 | 0.2119 |

| Southeast University (Nanjing, China) | 15 | 28 | 0.1800 | 4772 | 0.4212 |

| China Railway Construction Group Co., Ltd. (Beijing, China) | 10 | 26 | 0.2035 | 6328 | 0.2870 |

| China Jingye Engineering Co., Ltd. (Beijing, China) | 2 | 23 | 0.1978 | 0 | 0.1663 |

| State Grid Corporation of China (Beijing, China) | 17 | 23 | 0.1567 | 2175 | 0.4119 |

| Average Degree | Average Weighted Degree | Graph Density | Modularity | Average Clustering Coefficient |

|---|---|---|---|---|

| 10.4 | 90.1 | 0 065 | 0.082 | 0.803 |

| Node | Degree | Weighted Degree | Closeness Centrality | Betweenness Centrality | Eigenvector Centrality |

|---|---|---|---|---|---|

| E04B | 134 | 4211 | 0.8641 | 5552.9103 | 1 |

| E04G | 89 | 2178 | 0.6943 | 1921.5570 | 0.8109 |

| E04C | 81 | 1928 | 0.6709 | 1606.5570 | 0.7597 |

| E04H | 82 | 1663 | 0.6737 | 1484.6164 | 0.7869 |

| E04F | 68 | 550 | 0.636 | 976.3313 | 0.6831 |

| E02D | 30 | 348 | 0.5520 | 64.8562 | 0.4513 |

| B28B | 21 | 293 | 0.5354 | 32.3566 | 0.3189 |

| E04D | 41 | 290 | 0.5740 | 329.0952 | 0.5318 |

| G06F | 22 | 178 | 0.5372 | 45.8933 | 0.3490 |

| F24F | 34 | 175 | 0.5599 | 162.6989 | 0.4506 |

| Phases | Average Degree | Average Weighted Degree | Network Diameter | Graph Density | Modularity | Average Clustering Coefficient |

|---|---|---|---|---|---|---|

| P2012–2015 | 1.388 | 1.755 | 2 | 0.029 | 0.88 | 0.872 |

| P2016–2021 | 1.866 | 2.912 | 5 | 0.003 | 0.954 | 0.781 |

| P2022–2024 | 1.873 | 2.419 | 7 | 0.005 | 0.969 | 0.791 |

| Phases | Average Degree | Average Weighted Degree | Network Diameter | Graph Density | Modularity | Average Clustering Coefficient |

|---|---|---|---|---|---|---|

| P2012–2015 | 4.455 | 21.727 | 3 | 0.212 | 0.154 | 0.794 |

| P2016–2021 | 8.899 | 62.348 | 3 | 0.065 | 0.093 | 0.811 |

| P2022–2024 | 8.034 | 45.983 | 3 | 0.07 | 0.027 | 0.814 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Huang, A.; Dou, Y. Investigating Prefabricated Construction Technology Innovation Dynamics: Evidence from a Patent Analysis in China. Buildings 2025, 15, 2300. https://doi.org/10.3390/buildings15132300

Wang Y, Huang A, Dou Y. Investigating Prefabricated Construction Technology Innovation Dynamics: Evidence from a Patent Analysis in China. Buildings. 2025; 15(13):2300. https://doi.org/10.3390/buildings15132300

Chicago/Turabian StyleWang, Yuna, Anqi Huang, and Yudan Dou. 2025. "Investigating Prefabricated Construction Technology Innovation Dynamics: Evidence from a Patent Analysis in China" Buildings 15, no. 13: 2300. https://doi.org/10.3390/buildings15132300

APA StyleWang, Y., Huang, A., & Dou, Y. (2025). Investigating Prefabricated Construction Technology Innovation Dynamics: Evidence from a Patent Analysis in China. Buildings, 15(13), 2300. https://doi.org/10.3390/buildings15132300