Finite Element Model Updating of Large-Span-Cable-Stayed Bridge Based on Response Surface

Abstract

1. Introduction

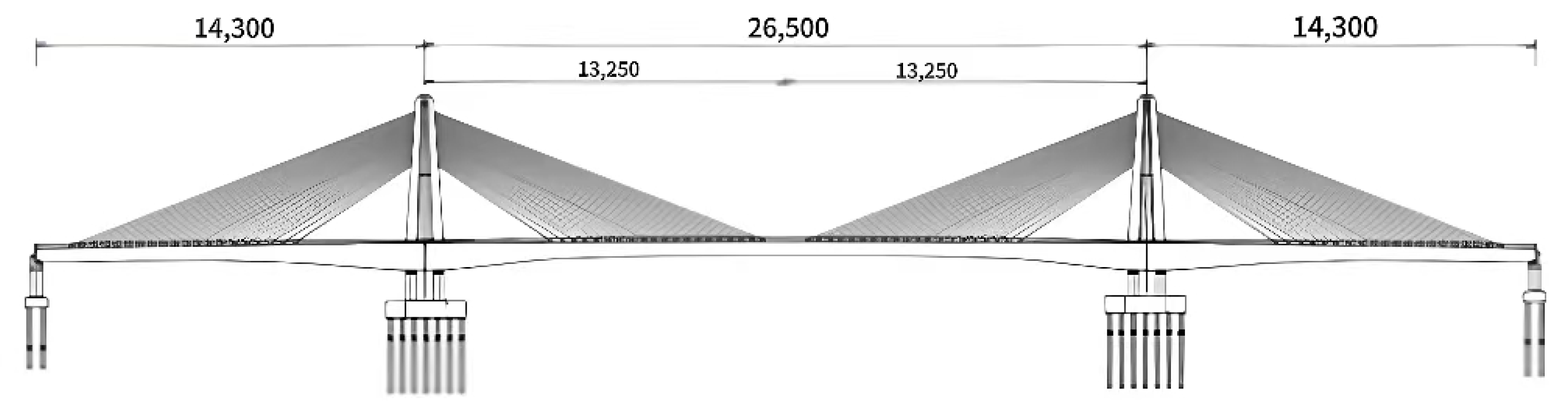

2. FE Model Updating Using the Response Surface Method

2.1. Experimental Design

2.2. Parameter Significance Test

- —Sum of squares of deviations caused by experimental error.

- —Sum of squares of deviations caused by individual factors.

- —Degrees of freedom for factors.

- —Degrees of freedom for deviation.

- , , the impact of the updated parameter A on the response is significant,

- , , the effect of the updated parameter A on the response is not significant, so it is excluded.

2.3. Fitting the Response Surface and Precision Check

- —total variance,

- —sum of squared errors,

- —Regression sums of squares,

- —Total degrees of freedom in the model,

- —Predicted Residual Sum of Squares

2.4. Optimization Solution

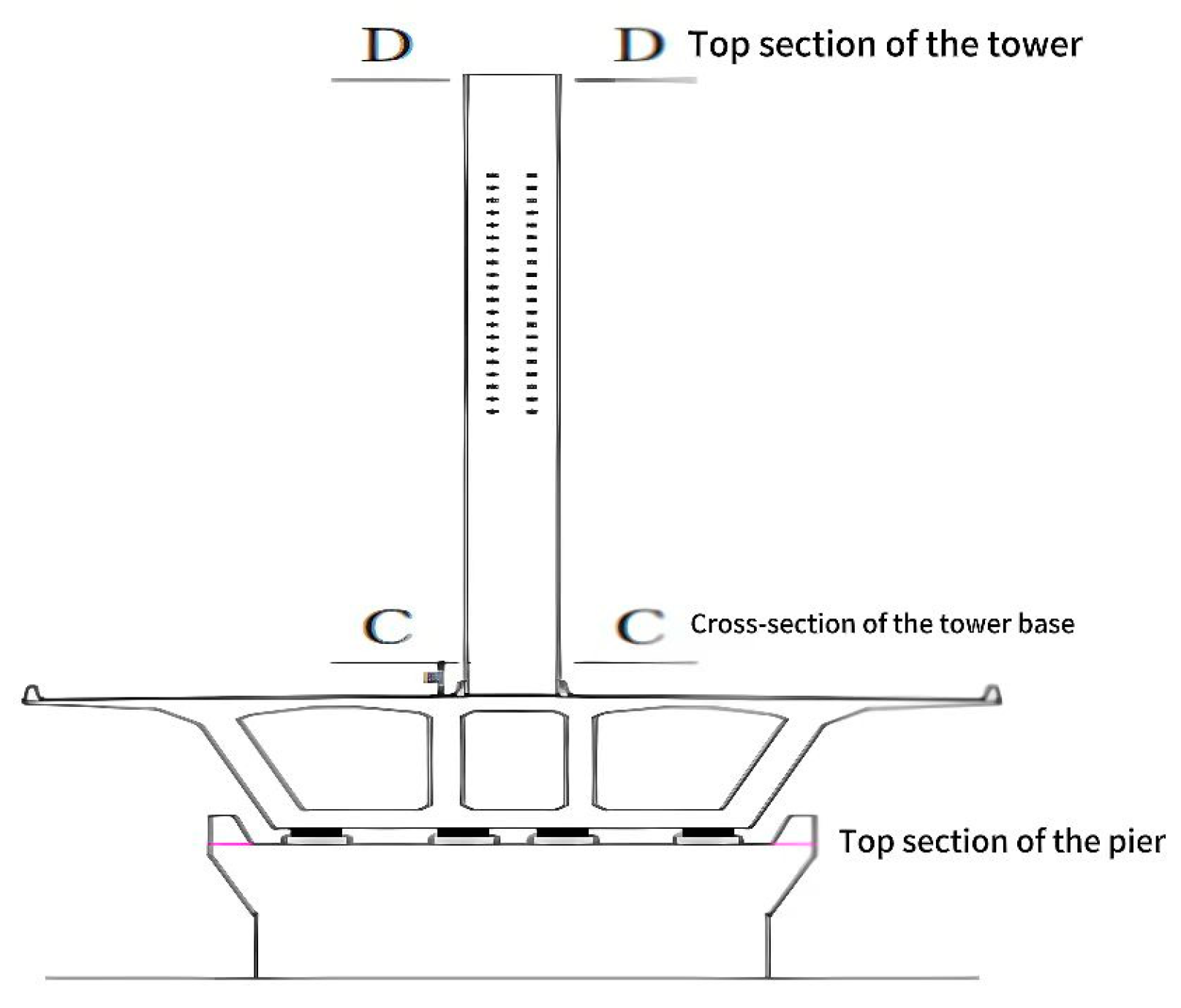

3. Project Overview

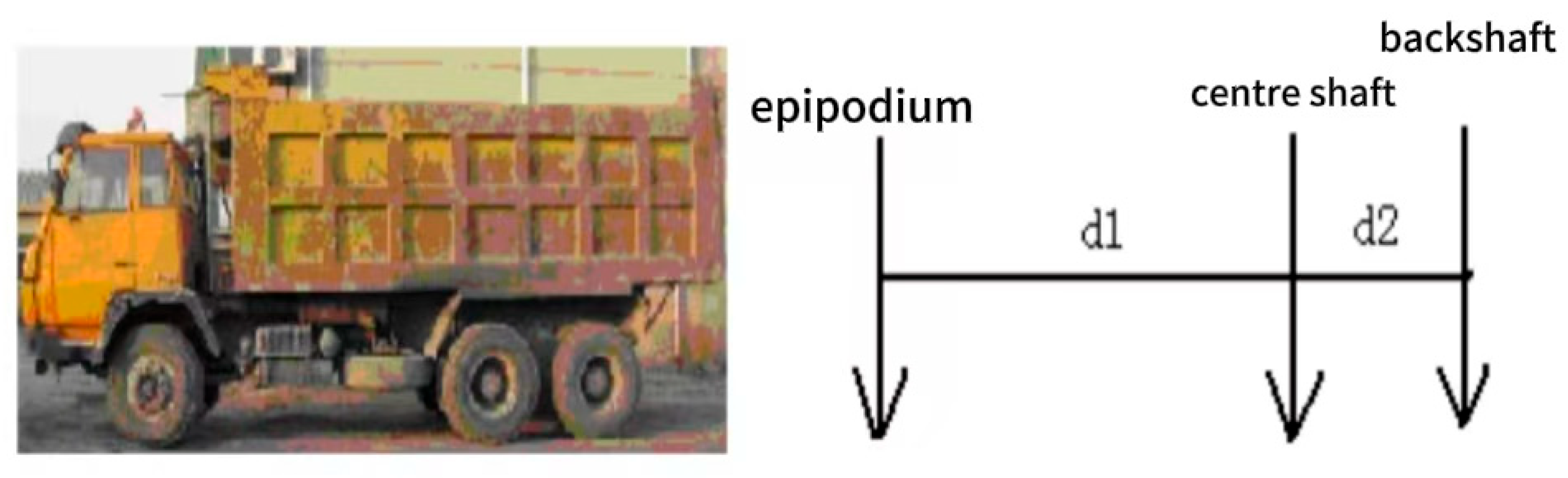

4. Static and Dynamic Load Testing

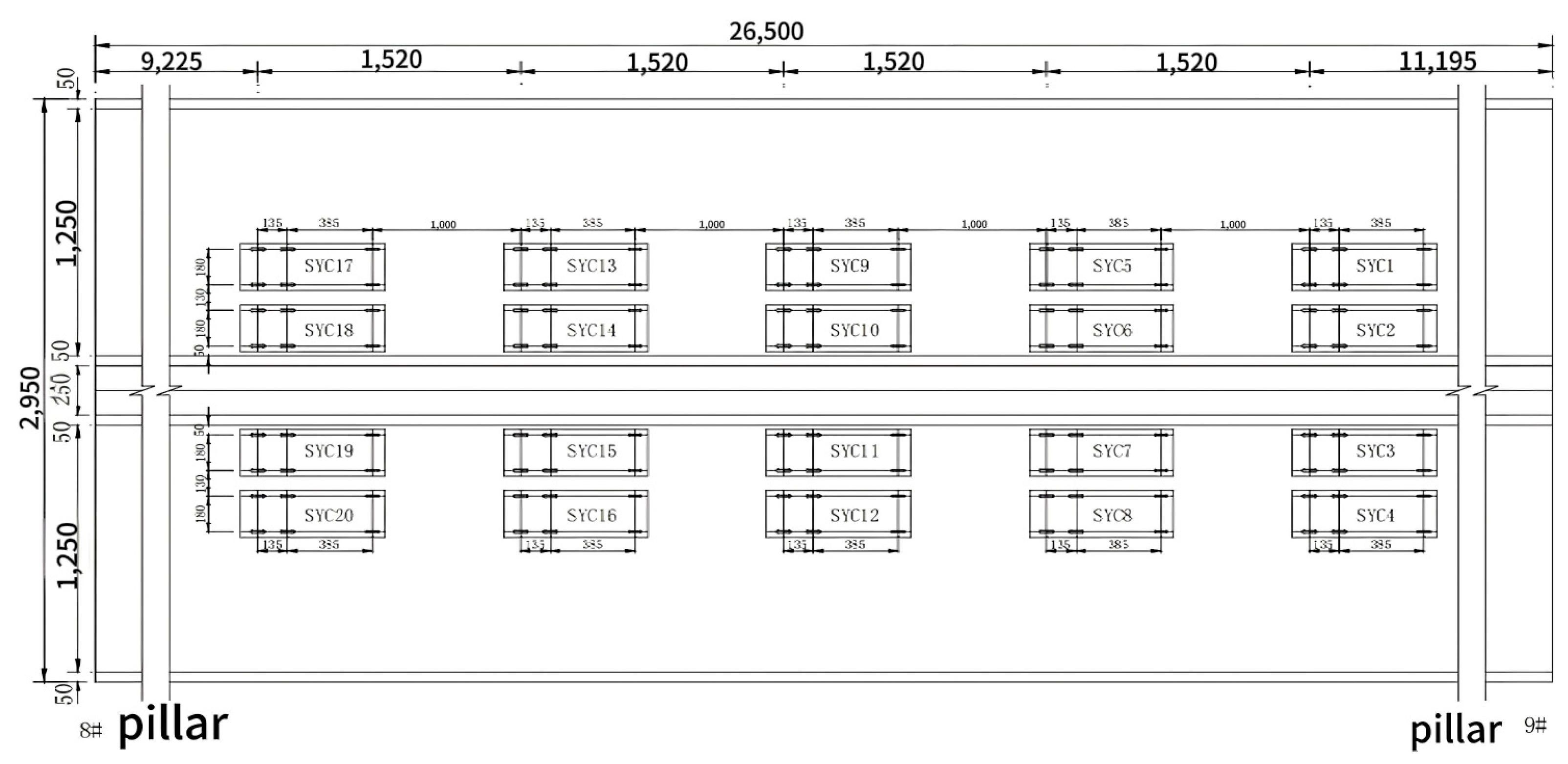

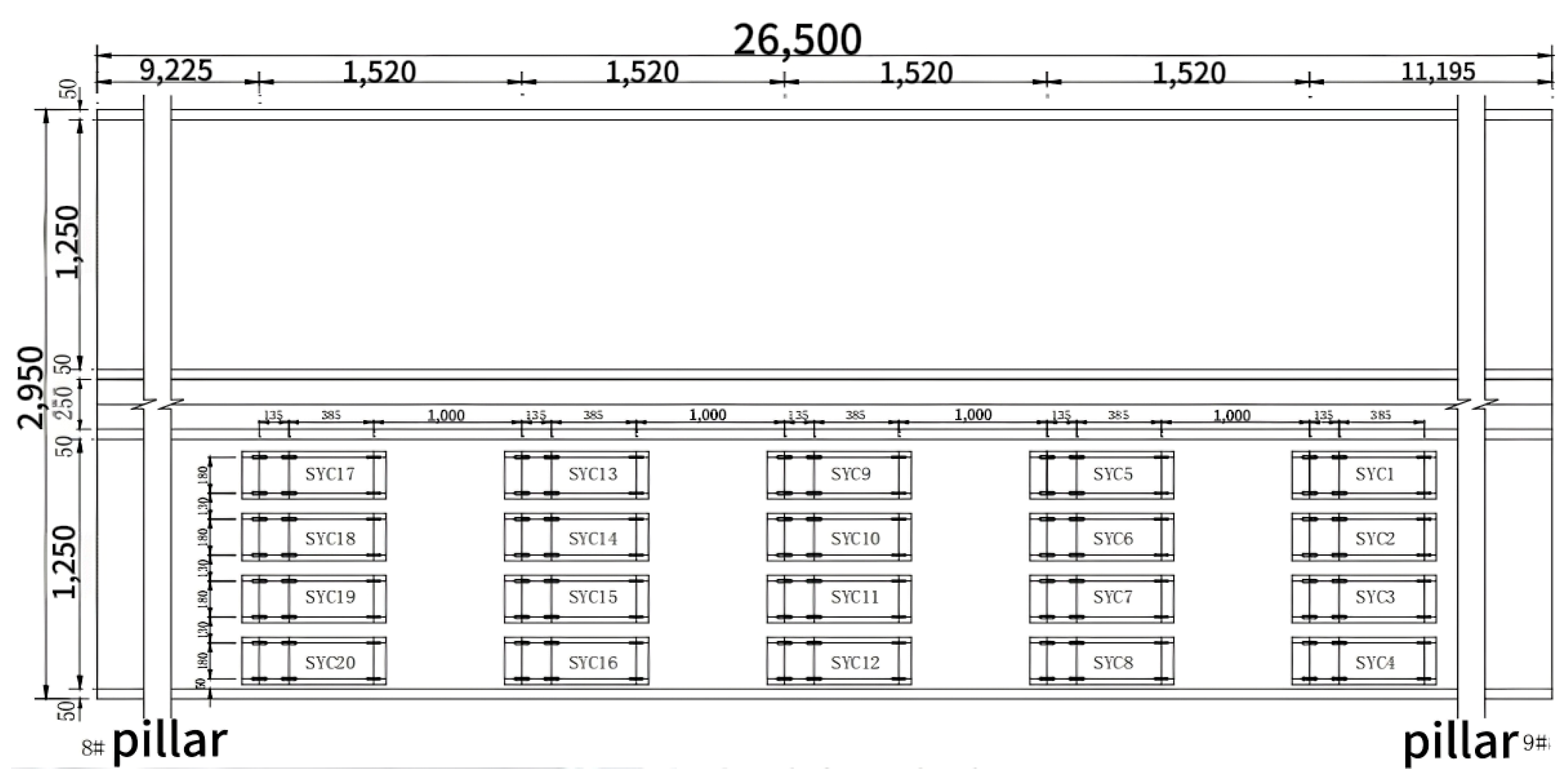

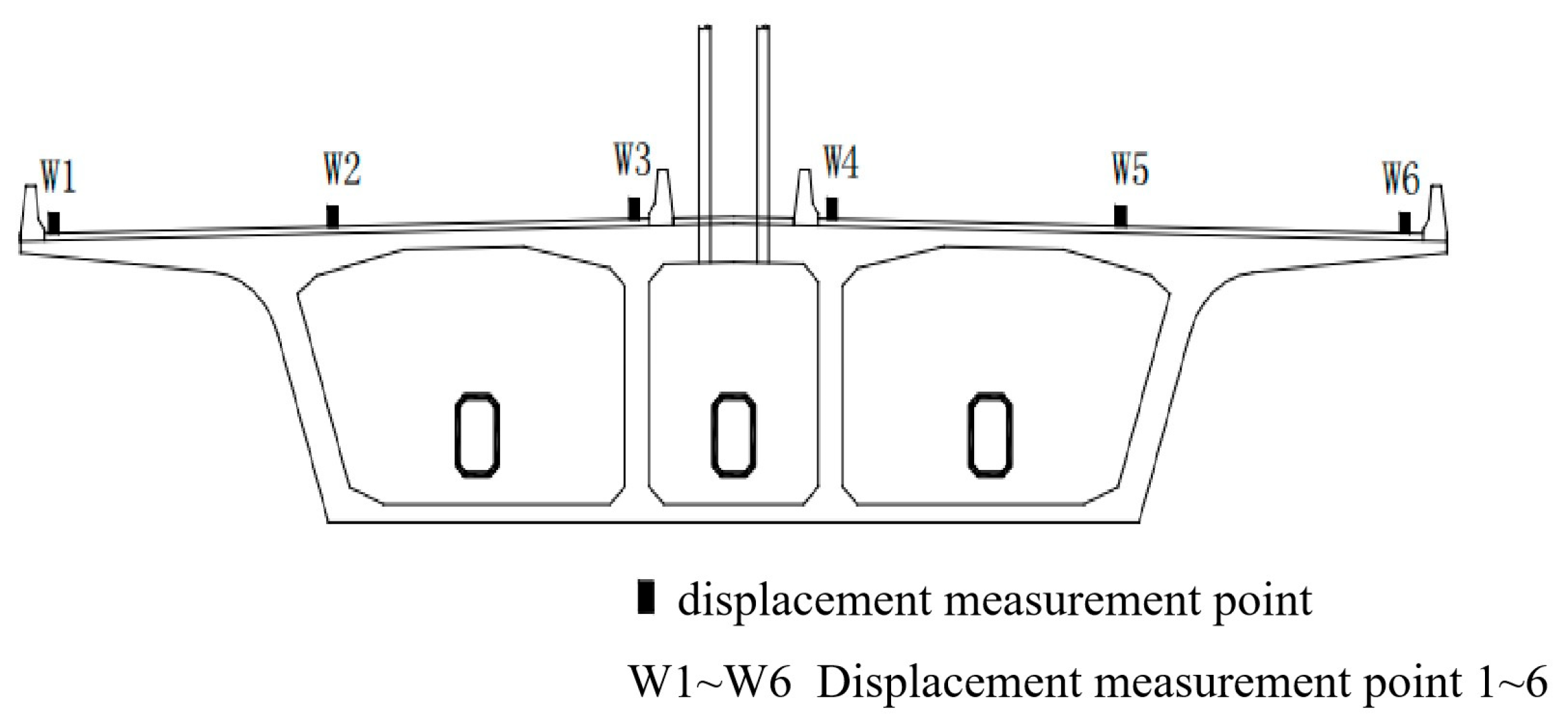

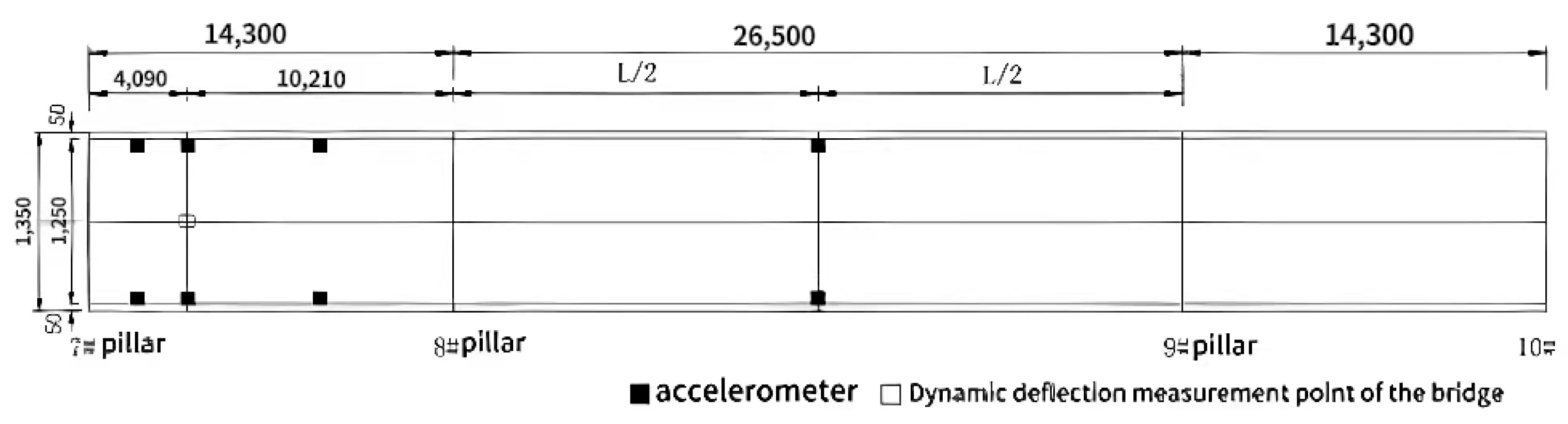

4.1. Static Load Testing

4.2. Dynamic Load Test

5. FE Model Updating

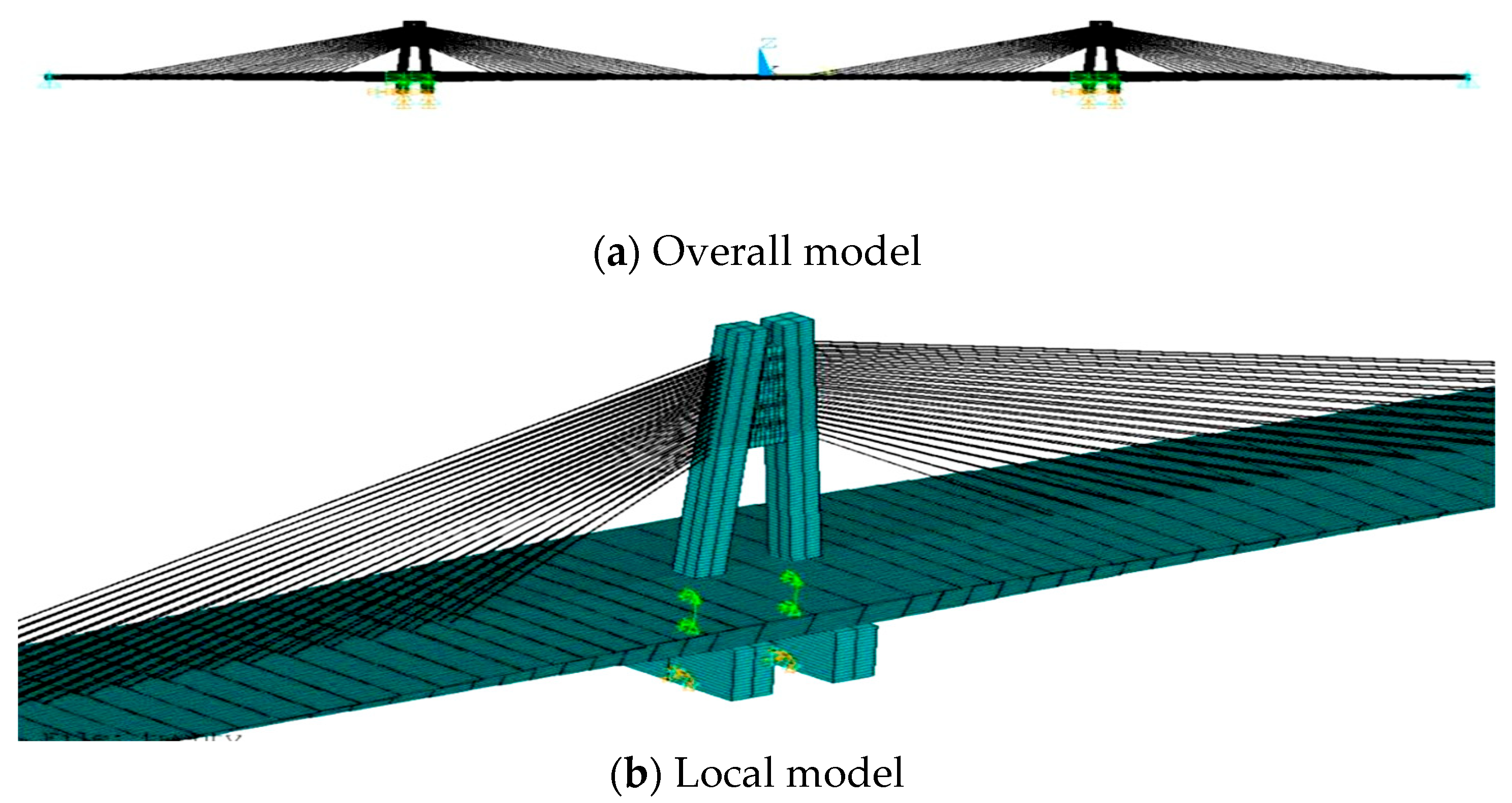

5.1. Initial FE Model

5.2. Selection of Eigenvalues

5.3. Experimental Design of the Case Study

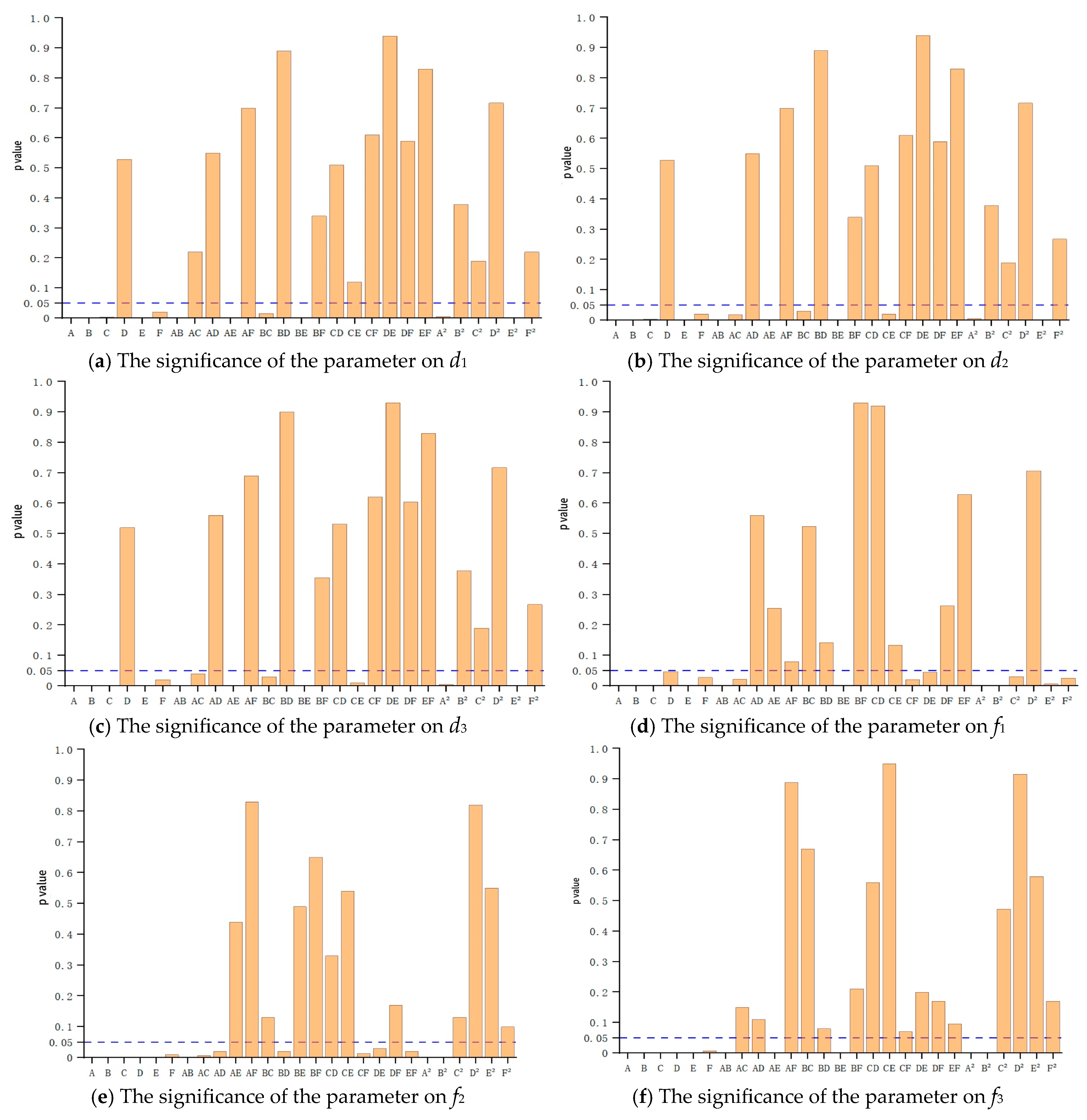

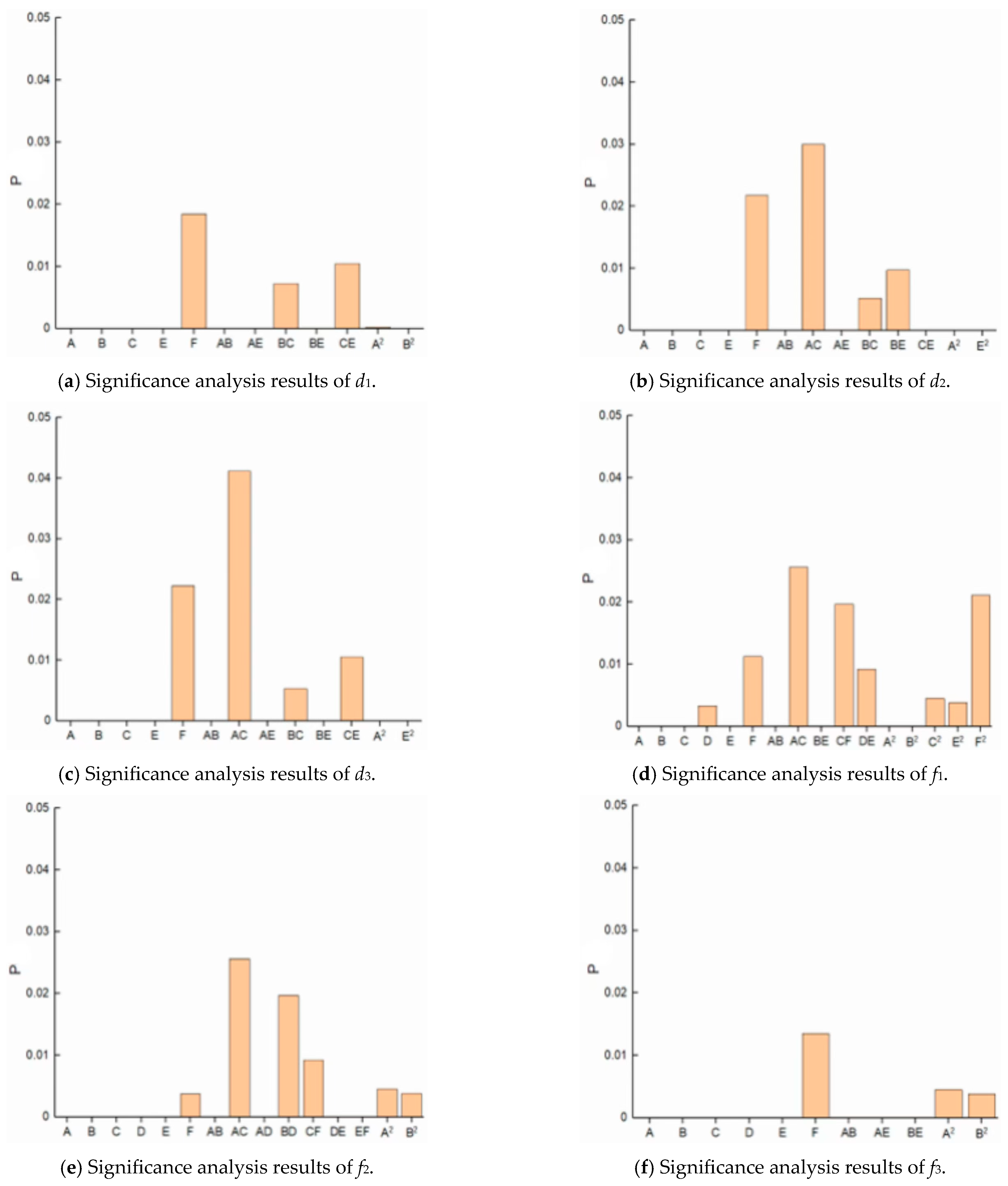

5.4. Parameter Significance Test of the Case Study

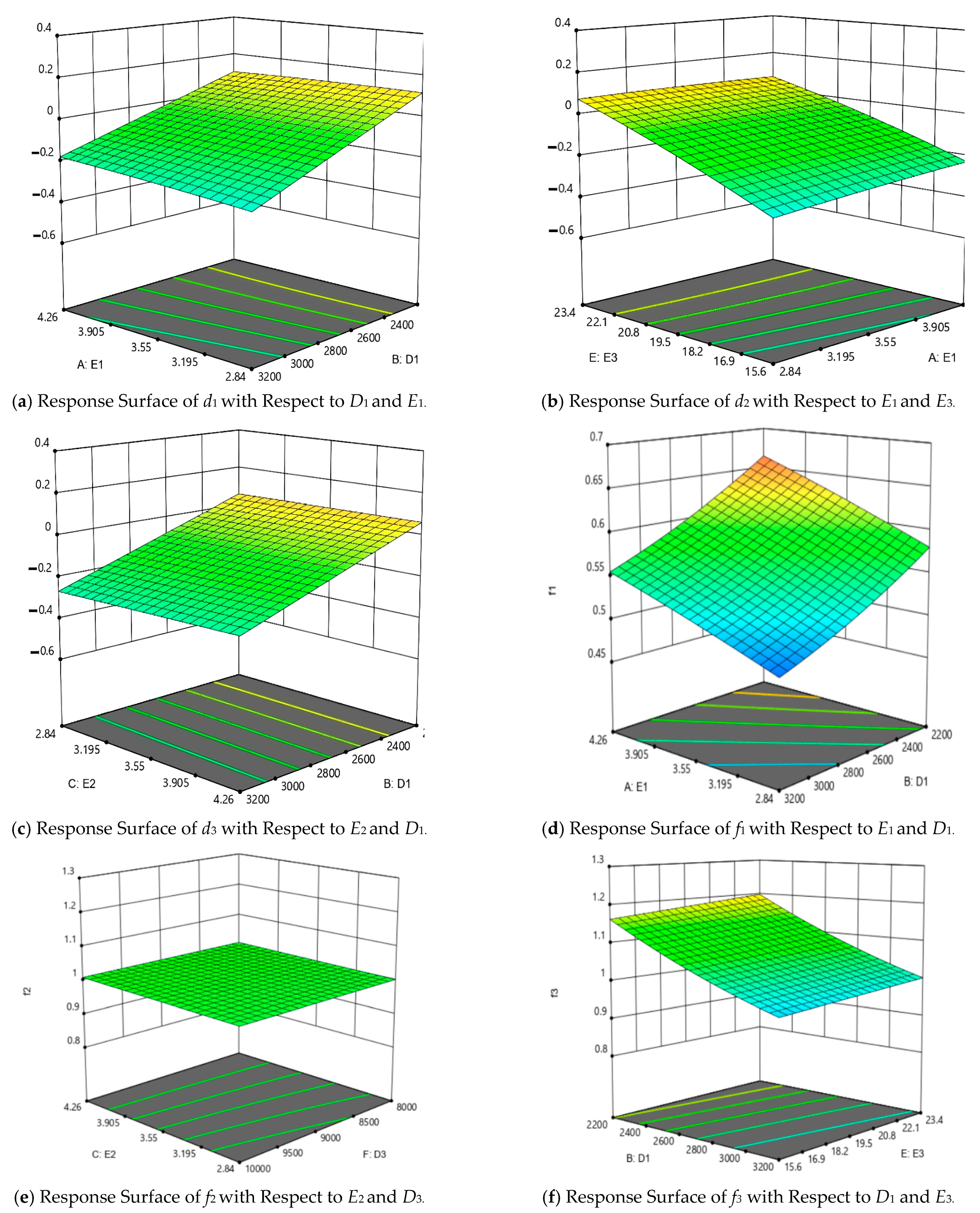

5.5. Fitting and Accuracy Verification of the Response Surface

5.6. Response Surface Function

5.7. Result Verification

5.7.1. Static Response Verification

5.7.2. Dynamic Response Verification

6. Conclusions

- (1)

- The p-values for the elastic modulus and density of the main beam and main tower, as well as the elastic modulus of the cable, are all below 0.05, indicating that their impact on the response is significant. The p-value for the cable’s density is greater than 0.05, indicating that its impact on the corresponding response is not significant.

- (2)

- The updated FE model more closely resembles the actual cable-stayed bridge, with the relative error of the static response reduced by over 50% and the relative error of the dynamic response now within 3%. It is evident that the model updating based on the response surface method is effective.

- (3)

- The model updating method that utilizes the response surface method is effective. This approach can be applied to the FE model updating real bridge structures and utilized in subsequent tasks, including health monitoring and damage assessment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Z.; Huang, B.; Fan, J.; Chen, H. Homotopy based stochastic finite element model updating with correlated static measurement data. Measurement 2023, 210, 112512. [Google Scholar] [CrossRef]

- Ren, W.-X.; Peng, X.-L. Baseline finite element modeling of a large span cable-stayed bridge through field ambient vibration tests. Comput. Struct. 2005, 83, 536–550. [Google Scholar] [CrossRef]

- Yi, J.; Lunhua, B.; Yuntao, J.; Junjin, L.; Dongmei, Y. Study of load Tests for long-span Continuous Rigid Frame Bridge. J. Build. Sci. Eng. 2017, 34, 105–111. [Google Scholar]

- Gang, L. Research on Finite Element Method Updating for Beam Bridge Based on Static and Dynamic Response Surface. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2018. [Google Scholar]

- Han, Z.; Wang, H.; Shao, Z.; Fu, H.; Jiang, H.; Wang, W. Finite difference method–based calculation of gravity deformation curve for the large-span beam of heavy-duty vertical lathe. Adv. Mech. Eng. 2016, 8, 1687814016646072. [Google Scholar] [CrossRef]

- Ren, W.-X.; Chen, H.-B. Finite element model updating in structural dynamics by using the response surface method. Eng. Struct. 2010, 32, 2455–2465. [Google Scholar] [CrossRef]

- Zhou, Y. Research on Model Correction Method Based on Response Surface and Its Application in Damage Identification of Continuous Girder Bridge. Master’s Thesis, Sichuan Agricultural University, Yaan, China, 2020. [Google Scholar] [CrossRef]

- Xu, Z.; Xin, J.; Tang, Q. Finite Element Model Updating Based on Response Surface Method and Sparrow Search Algorithm. Sci. Technol. Eng. 2021, 21, 9094–9101. [Google Scholar]

- Ma, Y.; Liu, Y.; Liu, J. Multi-scale Finite Element Model Updating of CFST Composite Truss Bridge Based on Response Surface Method. J. China Highw. Transp. 2019, 32, 51–61. [Google Scholar] [CrossRef]

- Lu, P.; Li, D.; Shi, Q.; Chen, Y. Prediction method of Static Load Test Results of Variable Section Bridge Based on Dynamic Load Test Data. J. China Highw. Transp. 2022, 35, 213–221. [Google Scholar] [CrossRef]

- Ren, W.X.; Lin, Y.Q.; Peng, X.L. Field load tests and numerical analysis of Qingzhou cable-stayed bridge. J. Bridge Eng. 2007, 12, 261–270. [Google Scholar] [CrossRef]

| Material | Elastic Modulus/(×104 MPa) | Density (kg/m3) | |

|---|---|---|---|

| Main beam | C60 Concrete | 3.55 | 2600 |

| Main tower | C60 Concrete | 3.55 | 2600 |

| Cable | Epoxy Coated Steel Strand | 19.5 | 8500 |

| Deflection (cm) | First Vertical Natural Frequency (Hz) | Second Vertical Natural Frequency (Hz) | Third Vertical Natural Frequency (Hz) | |

|---|---|---|---|---|

| Measured value | −5.5 | 0.586 | 1.074 | 1.172 |

| Calculated value | −9.5 | 0.568 | 1.027 | 1.092 |

| Error | 72.7% | 3.07% | 4.38% | 6.82% |

| Updating Parameters | Initial Value | Minimum Value | Maximum Value |

|---|---|---|---|

| 104 MPa) | 3.55 | 2.84 | 4.26 |

| (kg/m3) | 2600 | 2200 | 3200 |

| 104 MPa) | 3.55 | 2.84 | 4.26 |

| (kg/m3) | 2600 | 2200 | 3200 |

| 104 MPa) | 19.5 | 15.6 | 23.4 |

| (kg/m3) | 8500 | 8000 | 10,000 |

| Samples | 104 MPa) | (kg/m3) | 104 MPa) | (kg/m3) | 104 MPa) | (kg/m3) |

|---|---|---|---|---|---|---|

| 1 | 3.78 | 2395 | 2.84 | 2678.78 | 23.40 | 10,000 |

| 2 | 2.91 | 2200 | 3.01 | 2775 | 19.54 | 8860 |

| 3 | 2.88 | 2670 | 3.88 | 3030 | 18.06 | 10,000 |

| 4 | 3.48 | 3200 | 3.68 | 3200 | 19.62 | 8000 |

| … | … | … | … | … | … | … |

| 35 | 4.26 | 3062.84 | 3.05 | 2985 | 22.62 | 8980 |

| 36 | 3.75 | 2938.96 | 3.76 | 2770 | 18.56 | 9220 |

| 37 | 3.61 | 2200 | 4.26 | 2602.68 | 15.60 | 9550 |

| 38 | 2.84 | 3200 | 2.98 | 3200 | 15.60 | 9960 |

| Samples | (m) | (m) | (m) | (Hz) | (Hz) | (Hz) |

|---|---|---|---|---|---|---|

| 1 | 0.18907 | 0.16116 | 0.13952 | 0.62072 | 1.0929 | 1.1773 |

| 2 | 0.11761 | 0.08285 | 0.05601 | 0.58204 | 1.0148 | 1.0913 |

| 3 | −0.12124 | −0.15648 | −0.18369 | 0.52696 | 0.9235 | 0.98392 |

| 4 | −0.20253 | −0.23294 | −0.25652 | 0.51821 | 0.91904 | 0.97834 |

| … | … | … | … | … | … | … |

| 35 | −0.02534 | −0.05112 | −0.07120 | 0.57408 | 1.0243 | 1.0934 |

| 36 | −0.15755 | −0.18678 | −0.20953 | 0.55163 | 0.9894 | 1.0462 |

| 37 | −0.05346 | −0.08451 | −0.10871 | 0.61601 | 1.1173 | 1.1727 |

| 38 | −0.46964 | −0.50687 | −0.53575 | 0.46886 | 0.83386 | 0.88289 |

| Response Surface Function | ||||||

|---|---|---|---|---|---|---|

| R-squared | 0.9999 | 0.9999 | 0.9999 | 1.0 | 1.0 | 0.9999 |

| Adj R-squared | 0.9998 | 0.9998 | 0.9998 | 0.9999 | 0.9999 | 0.9999 |

| Pred R-squared | 0.9996 | 0.9996 | 0.9996 | 0.9998 | 0.9999 | 0.9999 |

| Updated Parameter | Initial Value | Updated Value | Change Range |

|---|---|---|---|

| 104 MPa) | 3.55 | 4.26 | 20.0% |

| (kg/m3) | 2600 | 2758.6 | 6.1% |

| 104 MPa) | 3.55 | 2.84 | −20.0% |

| (kg/m3) | 2600 | 3017.3 | 16.1% |

| 104 MPa) | 19.5 | 20.7 | 6.2% |

| (kg/m3) | 8500 | 9854 | 15.9% |

| Symmetric Loading | Measured Values (mm) | Initial Values (mm) | Updated Values (mm) | Relative Error Before Updating (%) | Relative Error After Updating (%) |

|---|---|---|---|---|---|

| Level 1 | −15.0 | −11.7 | −13.5 | 22.00 | 10.00 |

| Level 2 | −29.9 | −25.9 | −26.1 | 13.38 | 12.71 |

| Level 3 | −37.4 | −44.9 | −39.1 | 20.05 | 4.55 |

| Level 4 | −45.3 | −58.0 | −50.7 | 28.04 | 11.92 |

| Level 5 | −53.8 | −68.3 | −59.7 | 26.95 | 10.97 |

| Order | Initial Value (Hz) | Measured Value (Hz) | Updated Value (Hz) | Relative Error Before Updating (%) | Relative Error After Updating (%) |

|---|---|---|---|---|---|

| 0.576 | 0.586 | 0.595 | 1.7 | 1.5 | |

| 1.026 | 1.074 | 1.073 | 4.5 | 0.1 | |

| 1.091 | 1.172 | 1.141 | 6.9 | 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Wu, J.; Li, J.; Wang, W.; Wang, T.; Yuan, Y.; Wang, J. Finite Element Model Updating of Large-Span-Cable-Stayed Bridge Based on Response Surface. Buildings 2025, 15, 2247. https://doi.org/10.3390/buildings15132247

Lv Y, Wu J, Li J, Wang W, Wang T, Yuan Y, Wang J. Finite Element Model Updating of Large-Span-Cable-Stayed Bridge Based on Response Surface. Buildings. 2025; 15(13):2247. https://doi.org/10.3390/buildings15132247

Chicago/Turabian StyleLv, Yanjun, Juchao Wu, Junlong Li, Wei Wang, Tongning Wang, Ye Yuan, and Jianing Wang. 2025. "Finite Element Model Updating of Large-Span-Cable-Stayed Bridge Based on Response Surface" Buildings 15, no. 13: 2247. https://doi.org/10.3390/buildings15132247

APA StyleLv, Y., Wu, J., Li, J., Wang, W., Wang, T., Yuan, Y., & Wang, J. (2025). Finite Element Model Updating of Large-Span-Cable-Stayed Bridge Based on Response Surface. Buildings, 15(13), 2247. https://doi.org/10.3390/buildings15132247