1. Introduction

Retractable roof structures, as a novel type of architectural system, have been widely applied in large-scale buildings such as modern stadiums, convention centers, and theaters, thanks to their flexible functionality and efficient use of space [

1,

2]. By means of mechanical or electromechanical drive systems, these roofs enable the opening and closing of panels, adapting effectively to changing climatic and environmental conditions. With ongoing advances in building technology, significant progress has been achieved in the design, construction, and intelligent control of such systems [

3,

4,

5,

6]. However, in large-span retractable systems, the complexity of structural dynamics intensifies. Stability and safety become critical concerns, especially under the influence of roof weight, wind, and snow loads [

7,

8,

9]. Consequently, the structural system must ensure robust performance throughout the operational cycle, with high durability and adaptability to external forces [

10].

To ensure long-term structural integrity and reliable operation of retractable roof systems, particularly under complex geological and environmental conditions, pile foundation ground improvement techniques play a pivotal role [

11,

12]. As a high-performance ground reinforcement solution, pile foundations enhance both bearing capacity and resistance to differential settlement, maintaining structural safety during roof motion. In areas beneath the lower track beams, piles help distribute dynamic loads and reduce localized stress concentrations, mitigating the risks of uneven foundation responses [

13,

14,

15]. Compared with conventional soil improvement methods, pile-based foundations offer higher adaptability and construction efficiency in diverse geological settings, particularly for large-span structures with heavy roofs [

16]. Integrating pile systems into the design framework effectively stabilizes the entire retractable roof mechanism and prevents structural anomalies caused by subsurface instability.

Environmental factors—such as temperature fluctuations, snow accumulation, seismic activity, and wind loads—significantly influence retractable roof performance. Researchers have conducted numerous studies to address these challenges. Cai Jianguo et al. demonstrated that thermal expansion could amplify internal forces, potentially leading to failure in flexible deployable systems, and thus proposed thermal–mechanical dynamic analyses based on finite element methods [

17,

18]. Snow load sensitivity was investigated by Cao Zhenggang et al., who applied Euler–Euler multiphase flow models to simulate snow drift on telescopic structures [

19]. Inspired by origami, Lu Jinyu et al. developed parametric models for foldable roofs [

20]. Seismic behavior and mitigation strategies, including MR dampers and tuned mass dampers (TMDs), were examined in-depth by Kim Hyunsoo, Young Rak Lee, and others [

21,

22,

23,

24]. Moreover, studies such as Qiu Hongsheng et al. highlighted the importance of pile behavior during staged construction in unstable ground, using dynamic simulations to reveal risks overlooked by static analysis [

25]. Experimental research by Guo Yuancheng et al. further illuminated soil–pile interaction mechanisms in composite foundations [

26]. Recent studies have shown that the application of artificial neural networks and hybrid metaheuristic algorithms in predicting deflection and strain in complex structural systems can complement finite element methods for large-span structures. Khatir et al. [

27] proposed an improved gradient boosting method for predicting the strain of reinforced concrete beams strengthened with near-surface mounted fiber-reinforced polymer, demonstrating the potential of machine learning techniques in traditional structural analysis methods. By combining deep learning with traditional theoretical analysis, this approach not only improves prediction accuracy but also optimizes computational efficiency. On the other hand, Osmani et al. [

28]. used a combination of artificial neural networks and analytical models to predict the deflection of tapered cellular steel beams, further validating the effectiveness of neural networks in complex structural analysis. Building on these foundations, this study proposes a semi-recessed retractable roof system that significantly improves operational stability and control precision, offering practical and theoretical value for large-scale architectural applications.

Current research on ground-supported retractable roofs primarily focuses on optimizing dynamic performance, developing intelligent control strategies, and applying new materials. However, there is still a lack of systematic studies on structural form design and static performance analysis. Therefore, this study aims to investigate the installation process and foundation reinforcement of a semi-ground-supported retractable roof structure, and proposes a design scheme that integrates efficiency, reliability, and intelligent control. By combining theoretical analysis with numerical simulation, the study explores key technical issues such as track alignment precision and foundation reinforcement of the track system. The innovation of this research lies in the proposal of a semi-ground-supported retractable roof structure, which significantly improves operational stability and control accuracy, thereby providing technical support and theoretical insights for similar large-scale public facilities.

2. Research Background

2.1. Project Overview

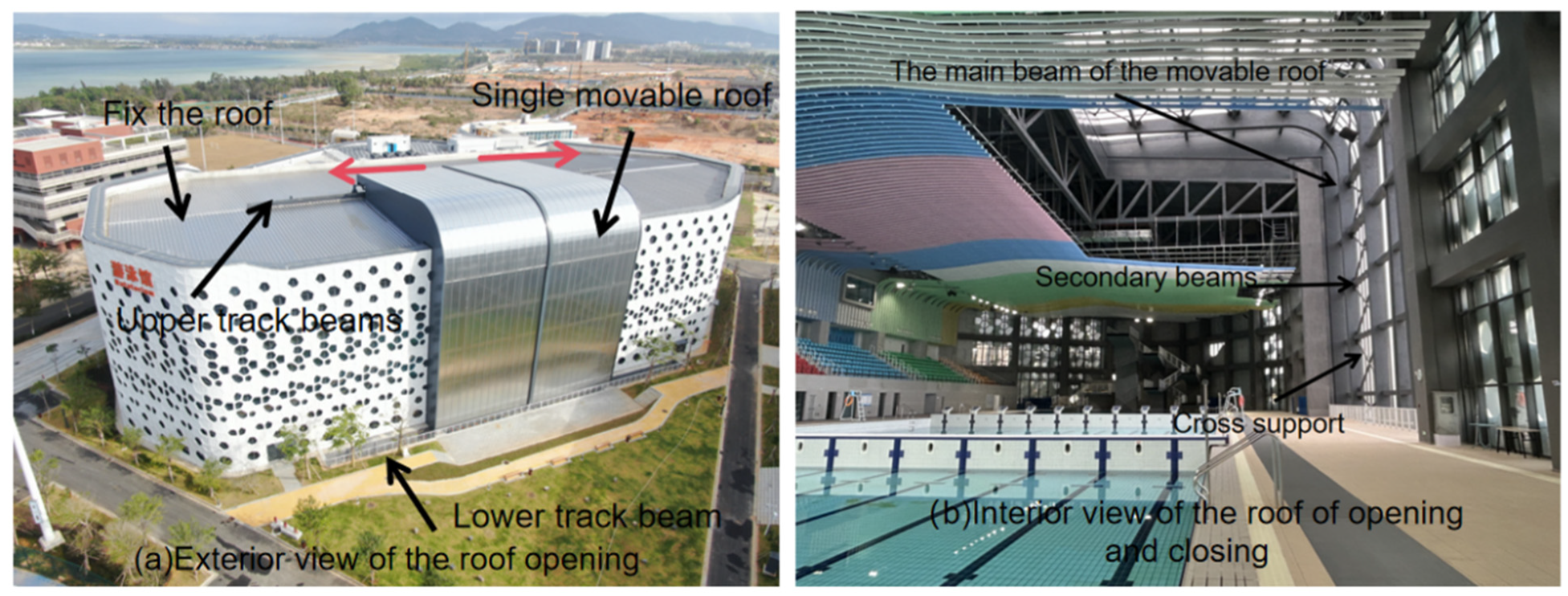

The roof steel structure of the swimming pool at the Hainan Lingshui Li’an International Education and Innovation Experimental Zone Comprehensive Sports Center adopts a movable roof structure. The roof has a longitudinal length of 100.6 m and a transverse width of 46.3 m, with the maximum height of the sliding roof reaching approximately 27.0 m. The short direction of the roof corresponds to the main truss direction, with a total of 11 main trusses. The long direction consists of track-supporting trusses and secondary trusses, with 2 track-supporting trusses and 6 secondary trusses. The fixed roof trusses are primarily composed of six types of components, with differences in span and weight. A construction effect diagram is shown in

Figure 1.

The lower end of the movable roof structure rests on a ground reinforcement groove, while the upper end is supported by the fixed roof structure. A total of 8 trolleys are arranged on the upper and lower track beams. The movable roof operates by sliding along the track beams, opening and closing horizontally from the center to both sides. The movable roof consists of two panels, each utilizing a solid web box section beam structure. Along the short direction of each roof panel, two box-section curved main beams are arranged. The main beams primarily resist bending and, based on the bending moment distribution along the beams, the main beams are designed with variable cross-sections. Secondary beams are arranged perpendicular to the main beams, with edge beams placed at the cantilevered ends of the secondary beams. The main beam structure of the movable roof is uniquely designed in an inverted L-shape. Each main beam weighs 33.3 tons, has a height of 26.2 m, and a length of 24.7 m. The primary material used for the components is Q355B steel. The ground-based movable roof structure is shown in

Figure 2.

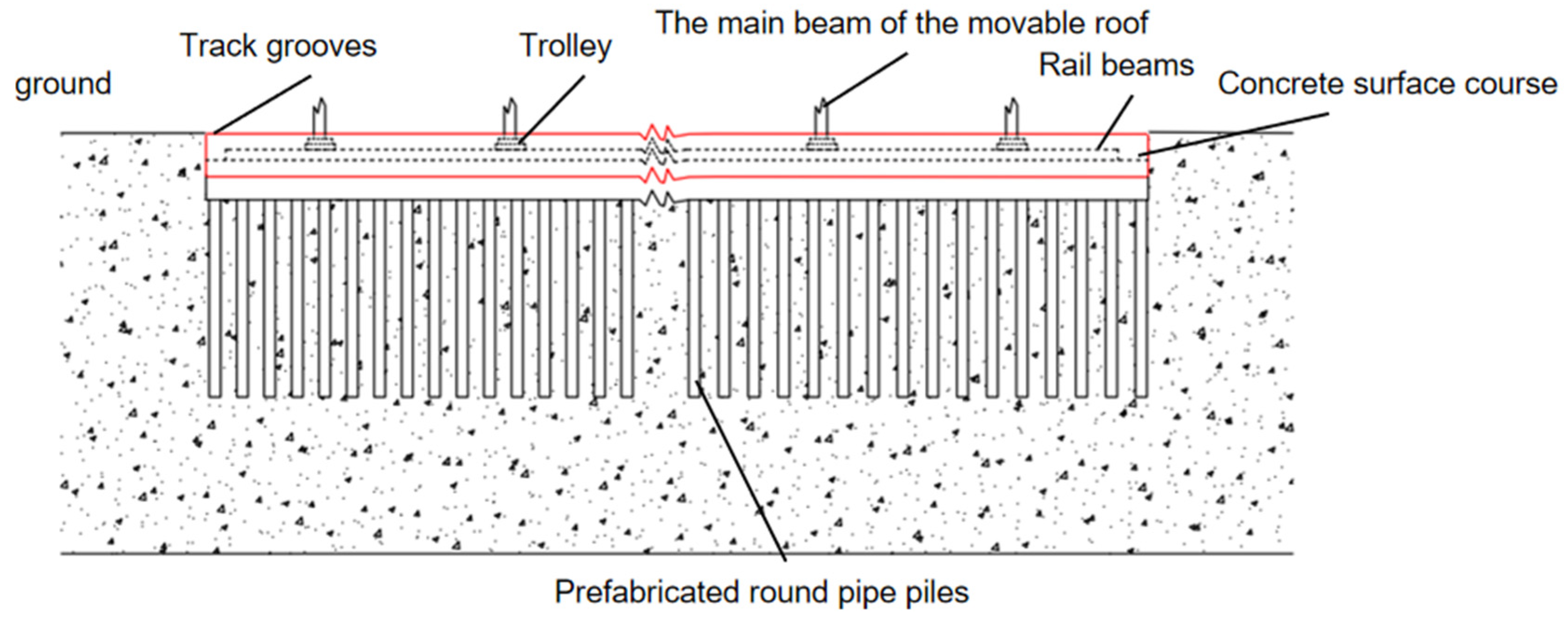

2.2. Reinforcement of the Lower Support for the Semi-Ground-Based Movable Roof

The semi-ground-supported retractable roof combines the advantages of both ground support and suspension systems, offering unique mechanical properties, cost-effectiveness, and construction convenience. Compared to the fully ground-supported system, the semi-ground-supported roof shares the load with partial ground support, enhancing structural stability and reducing material usage, thus lowering costs. In comparison to the suspension system, the semi-ground-supported roof offers better wind and seismic resistance, while simplifying the construction process, reducing high-altitude work, and shortening the construction period, providing a more efficient solution. In the roof structure, the stiffness of the track beams is crucial for the opening and closing functionality of the roof, as the deflection of the track beams can affect the normal operation of the trolleys. The load points of the roof are shown in

Figure 3.

Considering the heavy weight of the movable roof’s main beams and the unique inverted L-shape of the roof, most of the weight is concentrated on the lower track beams, which necessitates reinforcement of the lower support structure. To improve the bearing capacity of the track beam foundation and ensure the normal operation of the movable roof throughout its service life, while keeping the deflection of the track beams within a reasonable range, the lower track beam is designed with a parallel double-track layout, and special treatment is applied to the track beam foundation on the ground. The reinforcement scheme adopts a pile foundation using prefabricated reinforced concrete pipe piles, with a diameter of 40 cm and a length of 18 m, arranged with a spacing of 5 m. Two rows of pile foundations are placed in the groove, with a center-to-center distance of 80 cm between adjacent piles. The surface of the foundation is reinforced and leveled with reinforced concrete, effectively improving the bearing capacity of the parallel double-track system. The reinforcement of the lower track beam is shown in

Figure 4.

2.3. Project Implementation Plan

The construction of the swimming pool’s opening and closing roof is mainly divided into three stages: the construction of the fixed roof truss structure, the installation of track beams and trolleys, and the construction of the ground-based movable roof structure.

Step 1: Construction of Fixed Roof Truss Structure

Firstly, the assembly area is selected based on lifting requirements and site conditions, and the layout is planned accordingly. The projection lines of the truss on the ground, the axes of the upper and lower chords, and the positions of the web members are accurately located for modular assembly. The four-point lifting method is used to adjust the spatial position of the truss, ensuring precise assembly and completing welding and corrosion protection. Next, the main trusses of the fixed roof are lifted using a two-point lifting method. The crawler crane sequentially lifts the truss structure, and the main and secondary trusses are welded together. Prior to lifting, a trial lift is conducted to confirm the stability of the lifting operation and ensure the safety of the equipment during the process.

Step 2: Installation of Track Beams and Trolleys

The installation of the track beams is divided into upper and lower tracks. The upper track is supported by vertical posts, and the foundation is reinforced to ensure the track beams’ deformation remains within a reasonable range. The vertical load of the movable roof is transmitted through the secondary beams to the main beams, eventually reaching the fixed roof’s steel structure and the foundation. The horizontal load of the roof is transmitted through the supports and secondary beams to the main trusses, and then to the foundation. During trolley installation, the trolleys are prefabricated components that are directly lifted onto the track beams and secured. Considering the roof’s load-bearing characteristics, the upper track beam bears less load than the lower track beam. Therefore, the upper track is designed as a single track, while the lower track uses a parallel double-track design.

Step 3: Construction of Ground-Based Retractable Roof Structure

Subsequently, the ground-based movable roof is constructed. The main beams are assembled in segments, with attention given to controlling the flatness of the beams. During the lifting process, precision instruments are used to ensure stability, and a level is used to check the accuracy of the lifting points, ensuring that the main beam positions meet the design requirements. Finally, the installation of the secondary beams and cross supports is carried out. The spacing between the main beams is accurately measured and adjusted. The secondary beams are welded to the main beams, and the cross supports are bolted to the main beams, enhancing the overall stability of the roof structure. These steps ensure that the roof structure is solid and capable of withstanding the loads and deformations during long-term use.

3. Mechanical Response Analysis of the Movable Roof and Optimization of the Lower Track Foundation Reinforcement

3.1. Model Construction

3.1.1. Computational Model

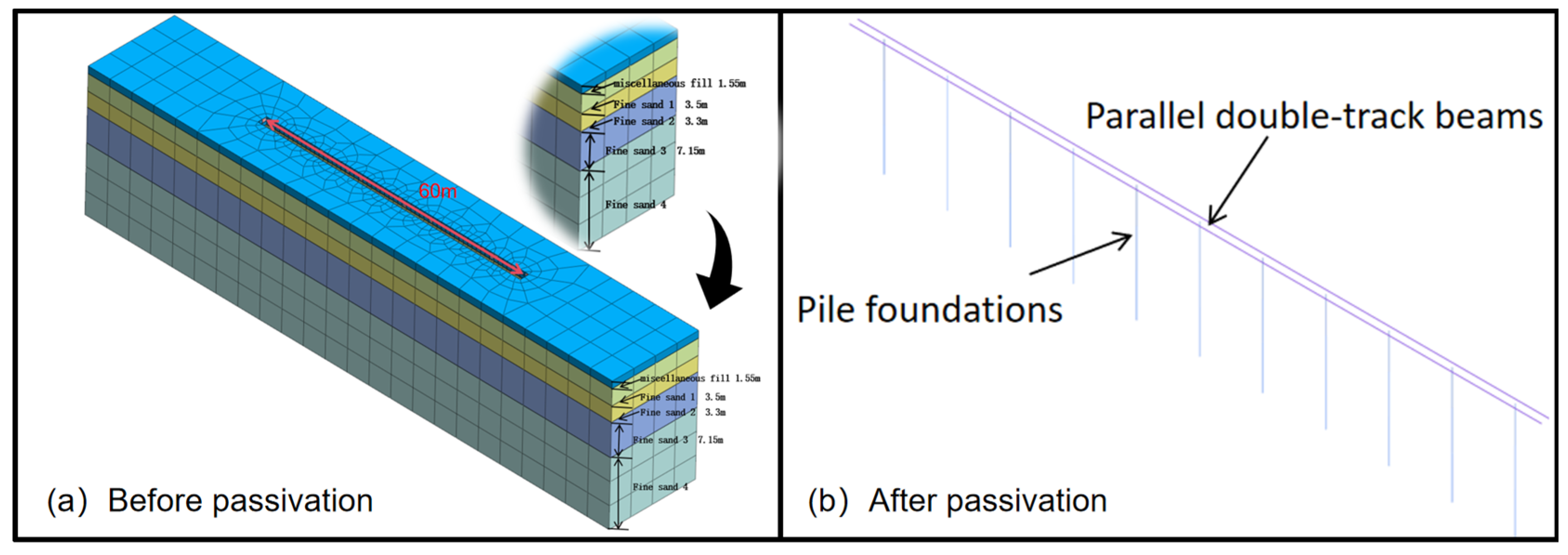

This paper performs a force analysis of the hoisting of a single movable roof main beam, the load conditions of the openable roof, and the reinforcement of the pile foundation of the lower track beam. MIDAS GEN 2025 finite element software is used to model and analyze the main structure of the openable roof and the single movable roof main beam, while MIDAS GTS finite element software is used for the modeling and numerical analysis of the lower track beam and the surrounding soil. The openable roof is analyzed under two working conditions: fully open and fully closed. In the calculations, the surrounding soil of the lower track beam is passivated, and the overall computational model is shown in

Figure 5. During the modeling process, an analysis project is first created based on the actual engineering conditions. The main structure of the openable roof is simplified into beam elements, and the hoisting cables are simulated using tension-only elements. The structural geometry is established by drawing nodes and components, and the material properties and section parameters of each component are defined: the fixed roof truss is made of rectangular steel tubes, the movable roof main beam uses a variable rectangular tube section, the secondary beams are rectangular tubes, and the diagonal braces of the movable roof are modeled with circular steel tubes. In finite element software, geometric defects and construction tolerances are simulated by defining initial geometric deviations and error ranges in the model. Geometric defects can be set by inputting node displacements, tilt angles, or bending, while construction tolerances are considered by adjusting node positions, element angles, and loading conditions during the construction stage. Additionally, tolerances can be simulated by setting statistical distributions of errors, such as normal distribution. Through nonlinear analysis, the finite element software incorporates these defects and tolerances into the calculation to accurately assess their impact on structural stability and deformation. Detailed material parameters are provided in

Table 1. Boundary conditions and support types are applied to the nodes based on the structural layout, and typical load cases such as dead load, live load, and wind load are applied for appropriate load combination analysis.

Figure 5a–c shows the fully open, fully closed, and hoisting models of the movable roof main beam, respectively.

For the substructure modeling, a 3D numerical model of the lower track beam and its foundation is established. In MIDAS GTS 2025 software, there are no specific element types; GTS divides the elements into three-dimensional, two-dimensional, and one-dimensional types, assigning grid properties to each element. Piles and track elements are one-dimensional, concrete pits are modeled as two-dimensional surface elements, and the soil is modeled as three-dimensional elements. The excavation pit has a length of 100 m, a width of 10 m, and a depth of 25 m, with the physical and mechanical parameters of the soil provided in

Table 2. The mesh is divided using element sizes of 0.5 m and 1.2 m, and automatic boundary constraints are applied to the model, considering the self-weight of the structure and line loads. Groundwater and seismic effects are not considered in this analysis.

Figure 6a,b shows the models before and after soil passivation, respectively.

3.1.2. Loads and Combinations

The main load conditions considered include the following:

Structural Dead Load (GL): This is automatically applied and calculated by the software, with a nodal enlargement factor of 1.1 taken into account.

Roof Dead Load (DL): The value is set to 1.0 kN/m2.

Roof Live Load (LL): The value is set to 0.5 kN/m2.

Wind Load (WX): This is determined using Equation (1).

Temperature Load: The roof temperature is controlled within the range of 12 °C to 36 °C.

The uniqueness of the tensioned beam structure requires consideration of the effects of temperature and wind loads, where wind suction caused by wind loads may lead to the failure of cable pre-stress. Therefore, the calculation of wind load conditions is particularly important. In MIDAS GEN, the process of adding wind loads includes defining parameters such as wind speed, building type, and its wind resistance coefficient, and calculating the wind load according to relevant standards. First, the basic information of the structure is set, and an appropriate wind load model is selected. Then, the wind load is calculated and distributed to different parts of the structure, typically including horizontal and vertical wind loads. By using the load combination function, wind loads are combined with other loads, such as dead load and live load. Finally, the analysis is run to check the structure’s stress and displacement to ensure that the structure can withstand wind loads and meet safety requirements. During the calculation, wind loads are usually determined based on factors such as wind speed, building surface area, and wind resistance coefficient, and can be optimized and adjusted as needed. The standard value of the wind load perpendicular to the building surface is as follows:

(Here, the standard value of the wind load should be provided as per the corresponding wind load code or equation, which would be referenced as Equation (1)).

where

ω0—basic wind pressure;

μs—wind load shape coefficient;

μz—height variation coefficient of wind pressure;

βz—wind vibration coefficient at height,

In this case,

Wind vibration coefficient βz is taken as 1.99;

Height variation coefficient μz is 1.00;

Shape coefficient μs is −0.8;

Basic wind pressure ω0 is 1.05 kN/m2.

Thus, the calculated wind load ωk is

ωk = −0.8 × 1.99 × 1 × 1.05 = −1.67 KN/m.

In numerical simulations, self-weight is automatically applied by the software, while roof dead and live loads are converted to nodal loads. Wind loads are applied as line loads on the model elements.

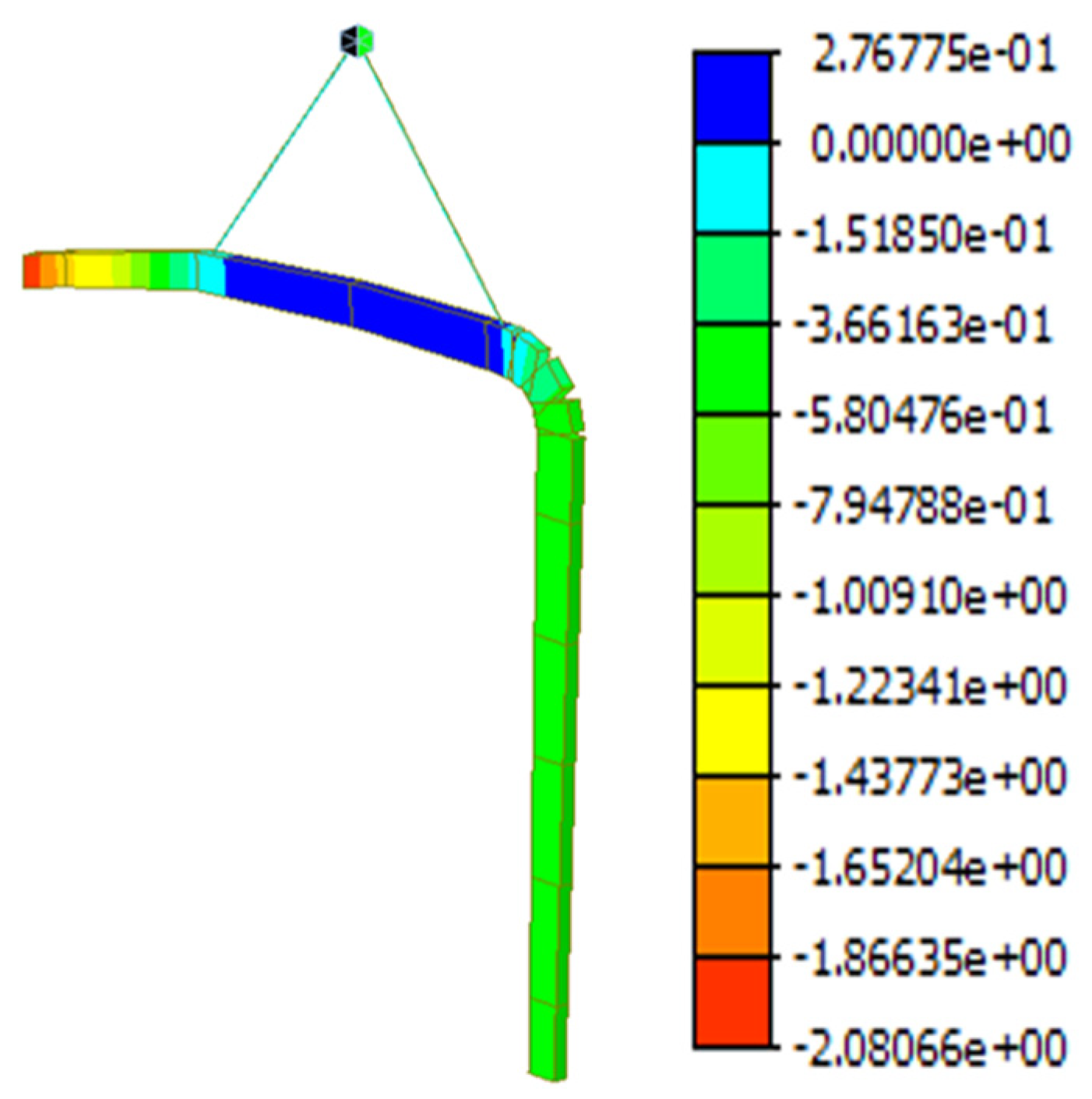

3.2. Analysis of Lifting of Variable Cross-Section Box-Type Curved Main Beams

The lifting process is analyzed using static structural analysis. A three-dimensional numerical model of the opening and closing roof is established using finite element software. The three translational directions of the space are constrained at the lifting points, and frictional effects are not considered. When analyzing the internal force distribution of each lifting unit, a dynamic load factor of 1.4 is applied to static loads, while deformation analysis is still based on the static load condition. Since the four main beams of the movable roof have the same span, mass, and member form, any one beam is selected for verification. The displacement is represented by a color gradient, where the blue areas have minimal displacement, mainly located at the top and connection areas of the beam. Due to the gravitational effects during the lifting process, the top of the beam experiences significant bending deformation, with an upward displacement of 0.27 cm. The red areas represent the maximum displacement, concentrated at the cantilevered end of the main beam, where a downward displacement of 2.08 cm occurs. This indicates that this area is highly influenced by the gravitational load during lifting, resulting in noticeable deformation. The displacement at the corner is relatively small, but it remains a critical area under concentrated force. The lifting point is located at the top of the main beam, where a vertical force is applied via lifting cables to suspend the beam. The upper part of the main beam is in tension, and the lower part is in compression, consistent with the typical loading characteristics of a cantilever structure. The lifting effect of the movable roof main beam is shown in

Figure 7.

3.3. Load Condition Analysis of the Semi-Ground-Based Movable Roof

3.3.1. Calculation Results and Analysis of the Movable Roof Under Load Conditions

Load combination factors are parameters used in structural design to adjust the impact of different types of loads on the structure. They are set based on the importance of the load, its mode of action, the probability of simultaneous occurrence, and safety requirements. Load combination factors take into account the intensity of the load and the probability of its occurrence. In finite element software, load combination factors are used to generate multiple load cases and calculate the maximum stress, displacement, and stability of the structure under different load combinations, ensuring the safety and reliability of the structure under various conditions. Our current load assumptions have certain limitations, primarily in that they do not consider the effects of seismic forces and dynamic excitations caused by mechanical movements. The nonlinearity and time variability of seismic loads may impact the stability of the roof structure, but these factors have not been included in this study. Additionally, the assumption of uniform load distribution does not account for the actual environmental load irregularities and dynamic changes, such as wind speed fluctuations and equipment movement. These simplified assumptions may lead to insufficient estimates of the structural response.

Since the roof is mostly in a fully closed state during design, the fully open state is not considered in the load state analysis to simplify the calculations. The results of the four load cases are shown in

Figure 8.

Condition 1 (Dead Load): The roof experiences downward displacement, with vertical displacement concentrated in the middle area of the fixed roof. The displacement reaches 52 mm, while the displacement on the two sides of the roof is relatively small.

Condition 2 (Dead Load + Dead Load + Live Load): The roof experiences downward displacement, with vertical displacement concentrated in the middle area of the fixed roof. Due to the addition of the dead and live loads, the displacement increases to 70 mm, while the displacement on the two sides of the roof remains relatively small.

Condition 3 (Dead Load + Dead Load + Live Load + Wind Load): Under the action of wind load, the vertical displacement of the structure decreases, with the maximum deflection being 37 mm. This indicates the upward wind suction force acting on the roof structure.

Condition 4 (Dead Load + Dead Load + Live Load + 36 °C Temperature Load): When the structure is subjected to a 36 °C temperature load, the movable roof exhibits upward arching force, indicating that the temperature load generates an upward arching force on the roof structure.

In all load states, the deformation disturbance due to dead load + live load reaches a maximum of 7 cm. Under the standard combination of dead load + live load + 36 °C temperature load, the roof exhibits a maximum arch height of 0.9 cm, resulting in a downward displacement of 3.4 cm. Both situations satisfy the design requirement that the deflection-to-span ratio does not exceed 1/250.

3.3.2. Stability Analysis

- (1)

Linear Analysis

The stability of the roof is divided into linear buckling analysis (i.e., buckling analysis) and nonlinear buckling analysis. When performing a stability analysis of the tensioned beam, a linear buckling analysis should first be conducted. The finite element basic equation for linear buckling analysis is as follows:

where

is the stiffness matrix of the structure;

is the geometric stiffness matrix or the initial stress matrix of the structure;

λ is the buckling eigenvalue, which represents the load proportionality factor (LPF)

is the eigenvector, representing the displacement vector of each node in the buckling mode of the structure.

When performing linear buckling analysis on the structure, the prestress and dead load are applied while keeping the working conditions unchanged. Afterward, the dead load and live load are proportionally amplified. The first-order buckling mode of the structure is shown in

Figure 9, with an eigenvalue of 6.3. This indicates that in an ideal linear buckling analysis, the semi-ground-based movable roof can withstand approximately 5.9 times the dead load and live load, meaning the safety factor KK is 6.3. This meets the requirement of the “Technical Code for Spatial Grid Structures” (Section 4.3.4) [

29], which specifies that the safety factor KK should be greater than 4.2.

- (2)

Nonlinear Analysis

However, linear buckling analysis assumes that the structure is defect-free and the material behaves in a linear-elastic manner. In real-world engineering, due to factors such as construction errors, material defects, and imperfections, the actual load-bearing capacity of the structure is often lower than the results obtained from linear buckling analysis. Therefore, to more accurately reflect real-world conditions, a full-process nonlinear buckling analysis is necessary. This analysis considers both the geometric and material nonlinear characteristics. Through nonlinear buckling analysis, the structure’s response from the initial state to the point where the ultimate load-bearing capacity is reached, and the gradual loss of capacity thereafter, can be obtained. This includes changes in internal forces, displacements, and stresses.

In the finite element software, the arc-length method is used for nonlinear buckling analysis. When performing nonlinear analysis, the geometric nonlinearity switch must be activated in the analysis step module, and the yield stress for Q355B steel should be set to 355 MPa in the material properties. Through nonlinear buckling analysis, the load–displacement curve of the structure is obtained, as shown in

Figure 10. Additionally, displacement contour plots for the structure under two different load combinations are presented in

Figure 11.

From the load–displacement curve in

Figure 10, it can be observed that the vertical displacement at the mid-span node increases with the load, with the deflection generated from the initial state taken as the zero displacement point. When the load is less than 2.7 times the load combination, the structure is essentially in the linear-elastic stage, and the load–displacement curve approximates a straight line. When the load reaches 3.1 times the load combination, the structure’s maximum deflection reaches 95 mm. With continued loading, when the load reaches 3.1 times the load combination, the structure’s maximum deflection increases to 142 mm, and the main beams of the movable roof experience widespread plastic deformation. The structure reaches its ultimate load-bearing capacity, and further loading leads to instability failure, as the load–displacement curve enters the descending phase.

Ultimately, the nonlinear buckling analysis indicates that the structure can withstand approximately 3.1 times the dead load and live load, meaning the safety factor K is 3.1, which satisfies the requirement of the “Technical Code for Spatial Grid Structures” (Section 4.3.4) [

29], which specifies that the K value should be greater than 2.0.

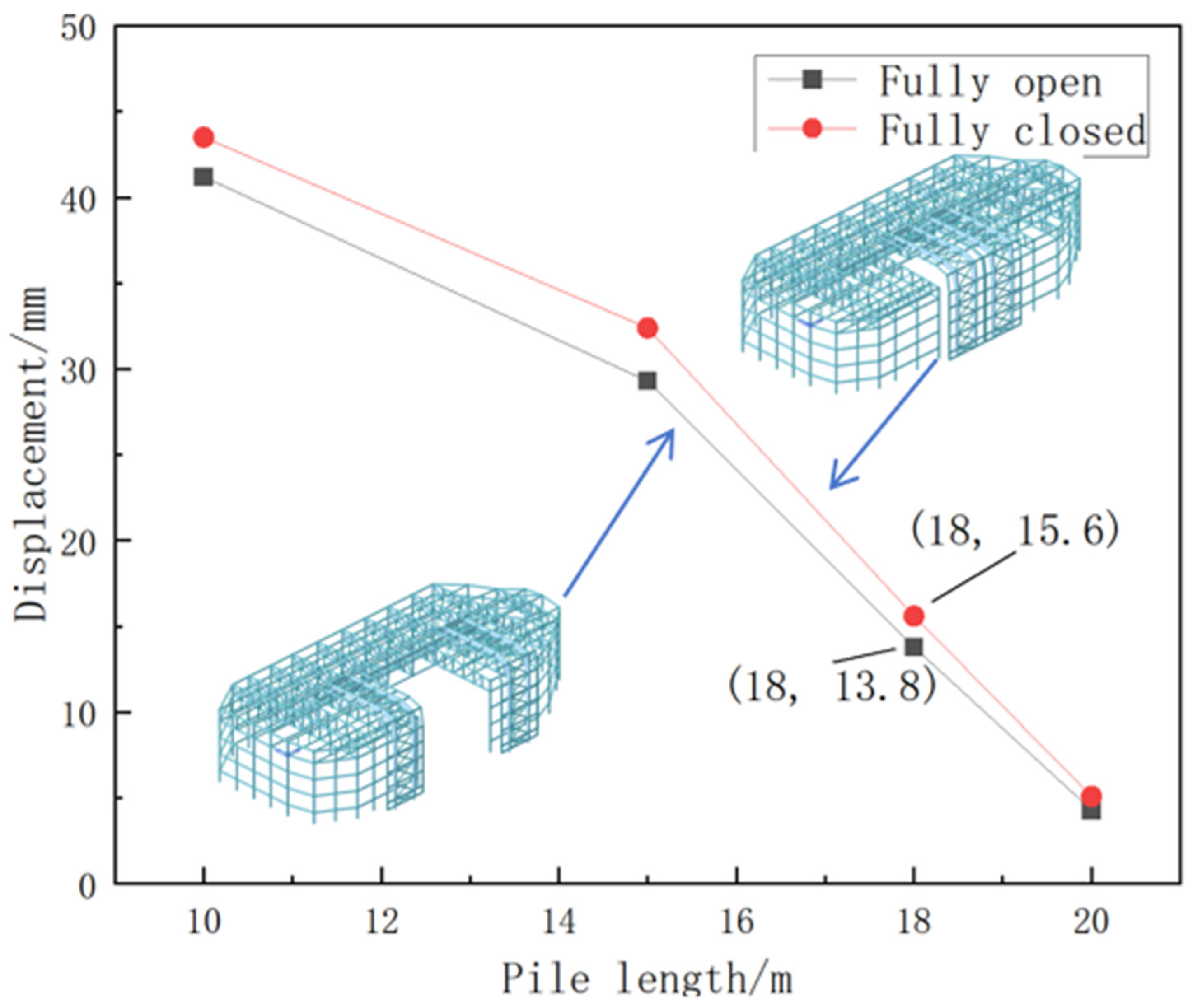

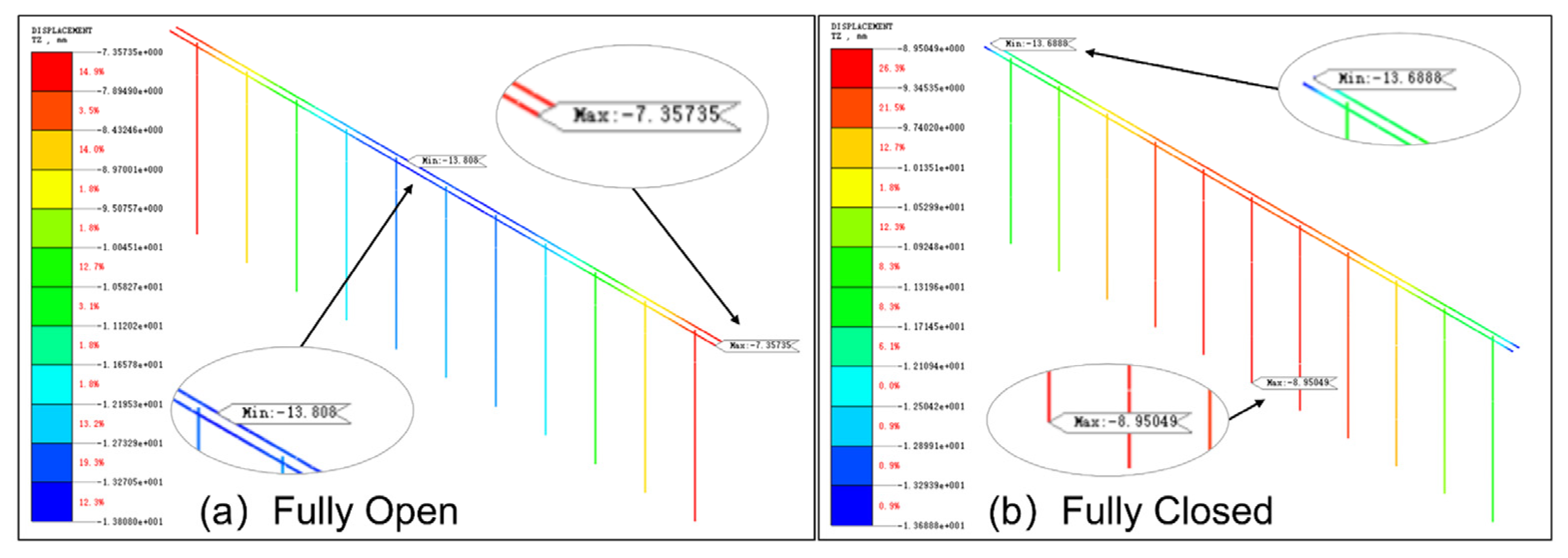

3.4. Optimization Analysis of the Lower Track Beam Pile Foundation

To ensure the safe and stable operation of the opening and closing roof structure under both the fully open and fully closed extreme conditions, a scientifically sound and reasonable reinforcement design for its track beam foundation system is essential. As the key load-bearing and guiding component in the roof opening and closing system, the load-bearing performance and deformation control of the track beam directly affect the operational accuracy and overall stability of the roof structure. According to relevant regulations, the maximum allowable deformation of the track beam during the service stage must not exceed 1/800 of its span, which in this project corresponds to a control limit of 25.25 mm. Theoretically, the pile foundation’s support stiffness and settlement control ability for the track beam are positively correlated. Increasing the pile length can effectively improve the vertical bearing capacity and horizontal lateral stiffness, thereby reducing the vertical deflection of the track beam caused by structural loads and the self-weight of the roof. To verify the rationality of this theoretical assumption, this study, under the condition of no changes to other design parameters, calculates the reaction forces at the lower support points of the structure using the software. These forces are then applied at the corresponding positions of the lower support points in the three-dimensional numerical model. The deformation response of the track beam under different pile length conditions is simulated using finite element analysis. When modeling the system, Boolean operations are used to couple the soil and pile. After the soil and piles are individually meshed, they are assigned their respective materials and properties. During the working condition simulation analysis, the upper load is first applied to the trolley. The trolley then transfers the load to the track beam. Finally, the track beam transfers the load to the soil and pile. The coupling between the soil and pile allows them to jointly bear the load and produce corresponding deformations. The results are shown in

Figure 12.

In the fully closed state, when the pile length is 10 m, the maximum vertical deformation of the track beam is 43.5 mm, far exceeding the specification limit. When the pile length is increased to 15 m, the deformation reduces to 29.3 mm, showing some improvement, but it still does not meet the specification requirements. Further increasing the pile length to 20 m results in a significant reduction in the deformation, down to 4.3 mm, indicating that the foundation stiffness has a significant impact on controlling structural deflection. However, from a practical engineering perspective, excessively long piles not only increase the project cost but also impose higher requirements on the construction period and on-site working conditions. Therefore, a balance must be sought between economic feasibility and structural performance under the premise of meeting the required structural performance. In the fully open state, the deformation of the track beam is generally lower than that in the fully closed state. As the pile length increases, the displacement values decrease. Based on theoretical analysis and simulation results, this study selects a pile length of 18 m for the optimization scheme evaluation. The simulation results show that, under this pile length condition, the maximum deformation of the track beam is 15.6 mm, which is well below the specification limit, fully satisfying the structural deformation control requirements. Compared to the 20 m pile foundation, this option saves on material and construction costs, offering good economic feasibility and engineering practicality. The deformation under this condition is shown in

Figure 13. Through the consistency verification of theoretical analysis and numerical simulation results, the nonlinear coupling relationship between pile length and track beam deflection has been further confirmed. This also provides quantifiable parameters and optimization paths for the foundation design of movable structures. Ultimately, the pile length of 18 m is recommended as the optimal design solution for reinforcing the track beam foundation, achieving a coordinated optimization of both structural safety and economic efficiency.

4. Construction Effect

This study proposes an innovative track beam reinforcement and large-span asymmetric steel structure lifting technology, designed for track beam reinforcement and large-span asymmetric steel structure design and construction. After practical application and verification, it has achieved significant engineering results. In terms of track beam reinforcement, the adoption of this technology increased the load-bearing capacity of the track beam by 40% and reduced the uneven settlement of the foundation by 25%. This effectively solved the fatigue cracks and deformation issues that the original structure had developed due to long-term use. In the Hainan Lingshui Li’an International Education and Innovation Experimental Zone Comprehensive Sports Center swimming pool project, the use of this reinforcement solution successfully extended the structure’s service life, reduced the frequency of daily maintenance, and saved approximately 20% of repair costs. During the pile foundation analysis, the costs and construction times for each pile with lengths of 10 m, 15 m, 18 m, and 20 m were compared, as shown in

Table 3.

Based on the requirements for different pile lengths, the feasibility study considered the soil conditions and the requirements for construction equipment. The 18 m pile offers the best balance between performance and cost. The installation feasibility analysis for different pile lengths is as follows: The 10 m pile: Suitable for most soil conditions, mature construction technology, low equipment requirements, and easy installation. The 15 m pile: Suitable for relatively hard soil layers, slightly higher equipment requirements, and additional equipment stability needed during construction. The 18 m pile: Suitable for deeper soils, providing good load-bearing capacity, moderate construction difficulty, and the best balance between performance and cost. The 18 m pile can effectively adapt to various geological conditions, requiring some optimization of construction equipment, but offering the most reasonable overall cost and time investment. The 20 m pile: Suitable for particularly deep soils, with higher equipment requirements, increasing the demand for equipment and technology, leading to a significant rise in construction difficulty and costs. From the above analysis, it can be seen that selecting the 18 m length achieves the best balance in terms of cost, construction period, and installation feasibility. It provides good stability during construction and, compared to longer piles, has moderate costs and construction difficulty, making it suitable for most soil conditions. Therefore, it has high practical value in engineering projects.

In the application of large-span asymmetric steel structure lifting, this technology optimized the lifting method, avoiding the need to adjust the orientation of the steel structure during the lifting process. During the construction of the opening and closing roof, the structural stability during lifting was significantly improved after applying this technology. Compared to traditional steel structures, the construction period was shortened by 15%. Additionally, this technology has unique advantages in addressing deformation issues commonly encountered in large-span steel structure designs, ensuring the long-term stability and safety of the structure. Although this technology has achieved excellent results in its application, further optimization is still needed to enhance the structure’s adaptability under extreme conditions and ensure its stability in harsh environments. Overall, the track beam reinforcement and large-span asymmetric steel structure lifting technology proposed in this study has high application value and promotion potential, providing a safer, more economical, and more efficient solution for large opening and closing roof structure projects.

5. Conclusions

This study, based on the Hainan Lingshui Swimming Pool ground-based movable roof project, utilizes finite element software to simulate the entire process of lifting the movable roof’s main beam and the upper and lower track beams. The analysis focuses on the deformation of the main beam during lifting and the deformation of the track beams in both fully open and fully closed operating states. The main conclusions are as follows.

(1) For the complex load-bearing characteristics of the variable cross-section curved main beam, the bending performance is enhanced by optimizing the cross-sectional dimensions at the corner. A modular assembly process and structural center of gravity analysis are combined with a two-point lifting technique to achieve precise alignment of the main beam units, ensuring the spatial positioning accuracy of the movable roof’s main beam and upper and lower trolleys. Finite element simulations of the lifting process show that the top of the beam experiences significant bending deformation, with an upward displacement of 0.27 cm. The maximum displacement occurs at the cantilevered end of the main beam, where the downward displacement is 2.08 cm, indicating significant deformation due to the gravitational load during lifting. The displacement at the corner is relatively small but remains a critical area under concentrated load. The lifting point is located at the top of the main beam, with vertical forces applied through the lifting cables to suspend the beam. The upper part of the beam is in tension, and the lower part is in compression, which is typical of cantilever structure loading characteristics.

(2) Mechanical response analysis of the semi-ground-based movable roof structure under three external load combinations indicates that the structure meets the specification requirements. The maximum response occurs under the dead load + live load standard combination, with a maximum mid-span deflection of 70 mm, which satisfies the applicability requirements for the movable roof structure. The linear and nonlinear stability safety factors are 5.9 and 3.2, respectively, indicating structural safety under external loads. Additionally, during normal operation, all components remain in the linear-elastic state, demonstrating a well-designed structure.

(3) For the heavy load characteristics of the lower track beams of the ground-based movable roof, the pile foundation is used to improve the bearing capacity of the track beam foundation, and the double-track beam structure is adopted to distribute the concentrated loads of the main beam. This forms a composite support system of “pile foundation + double track,” effectively controlling the deformation of the track beams and ensuring smooth operation of the movable roof. An optimization analysis of the track beam length was performed, and the results show that when the track beam length is 15 m, the deformation does not meet the required limits. When the track beam length is 20 m, the cost is too high to meet economic requirements. The optimized design adopts a pile length of 18 m for the track beam pile foundation.

Author Contributions

Z.Z.: In charge of the paper, completed construction of thesis framework system and thesis writing. A.H. and X.L.: Assisted in the related theoretical calculation analysis in the paper. S.K. and C.Z.: Assisted in the related numerical calculation in the paper. Conceptualization, Z.Z.; Data curation, A.H. and X.L.; Methodology, X.L. and C.Z.; Formal analysis, C.Z. and Z.Z.; Investigation, X.L. and C.Z.; Writing—original draft, C.Z. and A.H.; Writing—review and editing, C.Z. and X.L.; Supervision, Z.Z.; Project administration, A.H.; Resources, C.Z.; Supervision, A.H. and C.Z.; Validation, C.Z. and X.L.; Visualization, Z.Z. and C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Science and Technology Plan of Housing and Urban-Rural Construction in Anhui Province (2022-YF096), and Science and technology development project (HYB20250012, HYB20250019).

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

Author Xiaopeng Li was employed by the company First Engineering Co., Ltd. of CTCE Group. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Sokolowski, W.M.; Tan, S.C. Advanced self-deployable structures for space applications. J. Spacecr. Rocket. 2007, 44, 750–754. [Google Scholar] [CrossRef]

- De Jalon, J.G.; Bayo, E. Kinematic and Dynamic Simulation of Multibody Systems: The Real-Time Challenge; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Zhou, W.; Chen, Y.; Peng, B.; Yang, H.; Yu, H.; Liu, H.; He, X. Air damping analysis in comb microaccelerometer. Adv. Mech. Eng. 2014, 6, 373172. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Q.; Fan, F.; Shen, S. Experiments on natural snow distribution around simplified building models based on open air snow-wind combined experimental facility. J. Wind Eng. Ind. Aerodyn. 2018, 173, 1–13. [Google Scholar] [CrossRef]

- Pawlak-Jakubowska, A.; Romaniak, K. Kinematics of the retractable roofing module constructed from three roof panels. J. Build. Eng. 2021, 38, 102169. [Google Scholar] [CrossRef]

- Vlachaki, E.; Liapi, K.A. Folded surface elements coupled with planar scissor linkages: A novel hybrid type of deployable structures. Curved Layer. Struct. 2021, 8, 137–146. [Google Scholar] [CrossRef]

- Cai, J.; Feng, J.; Zhang, J. Thermoelastic buckling of steel columns with load-dependent supports. Int. J. Non-Linear Mech. 2012, 47, 8–15. [Google Scholar] [CrossRef]

- Zhou, X.; Hu, J.; Gu, M. Wind tunnel test of snow loads on a stepped flat roof using different granular materials. Nat. Hazards 2014, 74, 1629–1648. [Google Scholar] [CrossRef]

- Tominaga, Y.; Okaze, T.; Mochida, A. CFD modeling of snowdrift around a building: An overview of models and evaluation of a new approach. Build. Environ. 2011, 46, 899–910. [Google Scholar] [CrossRef]

- You, Z.; Pellegrino, S. Foldable bar structures. Int. J. Solids Struct. 1997, 34, 1825–1847. [Google Scholar] [CrossRef]

- Hong, Y.; He, B.; Wang, L.; Wang, Z.; Ng, C.; Mašín, D. Cyclic lateral response and failure mechanisms of semi-rigid pile in soft clay: Centrifuge tests and numerical modelling. Can. Geotech. J. 2017, 54, 806–824. [Google Scholar] [CrossRef]

- China Architecture & Building Press. JGJ 106-2014; Technical Code for Testing of Building Foundation Piles; China Architecture & Building Press: Beijing, China, 2014. [Google Scholar]

- Lewis, C.; King, M. Designing the world's largest dome: The National Stadium roof of Singapore Sports Hub. IES J. Part A Civ. Struct. Eng. 2014, 7, 127–150. [Google Scholar] [CrossRef]

- Lu, J.Y.; Zhang, T.; Liao, J.; Shu, G.P. Simulation and parametric analysis on movement of radial retractable roof structure. J. Vib. Shock 2015, 34, 170–175+206. (in Chinese). [Google Scholar]

- Lu, J.; Li, N.; Luo, Y. Kinematic analysis of planar deployable structures with angulated beams based on equilibrium matrix. Adv. Struct. Eng. 2011, 14, 1005–1015. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M.; Zhang, C.; Jiang, K.; Lu, M. Time-domain analyses for pile deformation induced by adjacent excavation considering influences of viscoelastic mechanism. Tunn. Undergr. Space Technol. 2019, 85, 392–405. [Google Scholar] [CrossRef]

- Cai, J.; Zhou, Y.; Zhu, Y.; Feng, J.; Xu, Y.; Zhang, J. Geometry and mechanical behaviour of radially retractable roof structures during the movement process. Int. J. Steel Struct. 2016, 16, 755–764. [Google Scholar] [CrossRef]

- Cai, J.; Xu, Y.; Feng, J.; Zhang, J. In-plane elastic buckling of shallow parabolic arches under an external load and temperature changes. J. Struct. Eng. 2012, 138, 1300–1309. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, M.; Wu, P.; Kuniya, T. Experiment Investigation and Numerical Simulation of Snowdrift on a Typical Large-Span Retractable Roof. Complexity 2019, 2019, 5984804. [Google Scholar] [CrossRef]

- Lu, J.; Hou, J.-J.; Lu, D.; Zhang, H. Development and kinematic analysis of origami-inspired retractable roof structures. Meccanica 2025, 60, 785–808. [Google Scholar] [CrossRef]

- Kim, H.S.; Kang, J.W. Vibration control of smart TMD for retractable-roof spatial structure considering closed and open roof condition. Int. J. Steel Struct. 2017, 17, 1537–1548. [Google Scholar] [CrossRef]

- Kang, J.W.; Kim, G.C.; Kim, H.S. Seismic response control of arch structures using semi-active TMD. J. Korean Assoc. Spat. Struct. 2010, 10, 103–110. [Google Scholar]

- Kim, H.S.; Kang, J.W. Seismic response control of retractable-roof spatial structure using smart TMD. J. Korean Assoc. Spat. Struct. 2016, 16, 91–100. [Google Scholar] [CrossRef]

- Lee, Y.R.; Kim, H.S.; Kang, J.W. Seismic response control performance evaluation of tuned mass dampers for a retractable-roof spatial structure. Int. J. Steel Struct. 2021, 21, 213–224. [Google Scholar] [CrossRef]

- Qiu, H.; Zhou, Y.; Ayasrah, M. Impact study of deep foundations construction of inclined and straight combined support piles on adjacent pile foundations. Appl. Sci. 2023, 13, 1810. [Google Scholar] [CrossRef]

- Guo, Y.; Lv, C.; Hou, S.; Liu, Y.; Garcea, G. Experimental Study on the Pile-Soil Synergistic Mechanism of Composite Foundation with Rigid Long and Short Piles. Math. Probl. Eng. 2021, 2021, 6657116. [Google Scholar] [CrossRef]

- Khatir, A.; Capozucca, R.; Khatir, S.; Magagnini, E.; Benaissa, B.; Cuong-Le, T. An efficient improved gradient boosting for strain prediction in near-surface mounted fiber-reinforced polymer strengthened reinforced concrete beam. Front. Struct. Civ. Eng. 2024, 18, 1148–1168. [Google Scholar] [CrossRef]

- Osmani, A.; Shamass, R.; Tsavdaridis, K.; Ferreira, F.P.V.; Khatira, A. Deflection Predictions of Tapered Cellular Steel Beams using Analytical Models and ANN. Buildings 2025, 15, 992. [Google Scholar] [CrossRef]

- J 1072-2010; Technical Code for Spatial Grid Structures. The Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2010.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).