A Whole-Life Carbon Assessment of a Single-Family House in North India Using BIM-LCA Integration

Abstract

1. Introduction and Background

- What is the whole-life carbon emission of a typical single-family residential dwelling unit of Northern India?

- How significant is the contribution of embodied carbon compared to operational carbon over the complete lifecycle of a typical single-family residential dwelling unit in northern India?

- Which specific building materials contribute most significantly to the embodied CO2e emissions of single-family residential construction based on their mass and resource type?

- How can BIM-LCA integrated methodology contribute to more effective decision-making in the design and policy-making process towards sustainable residential construction practices?

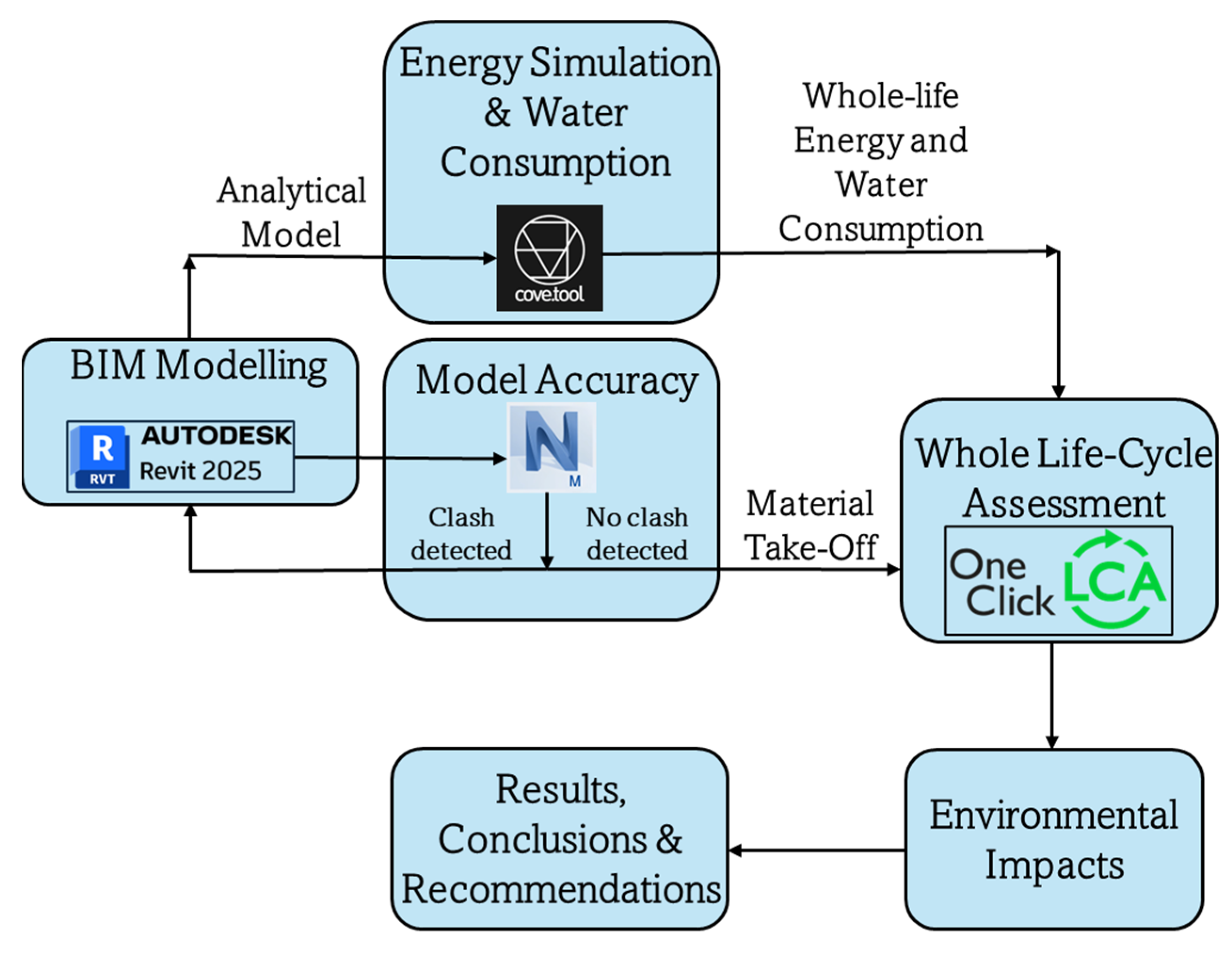

2. Materials and Methods

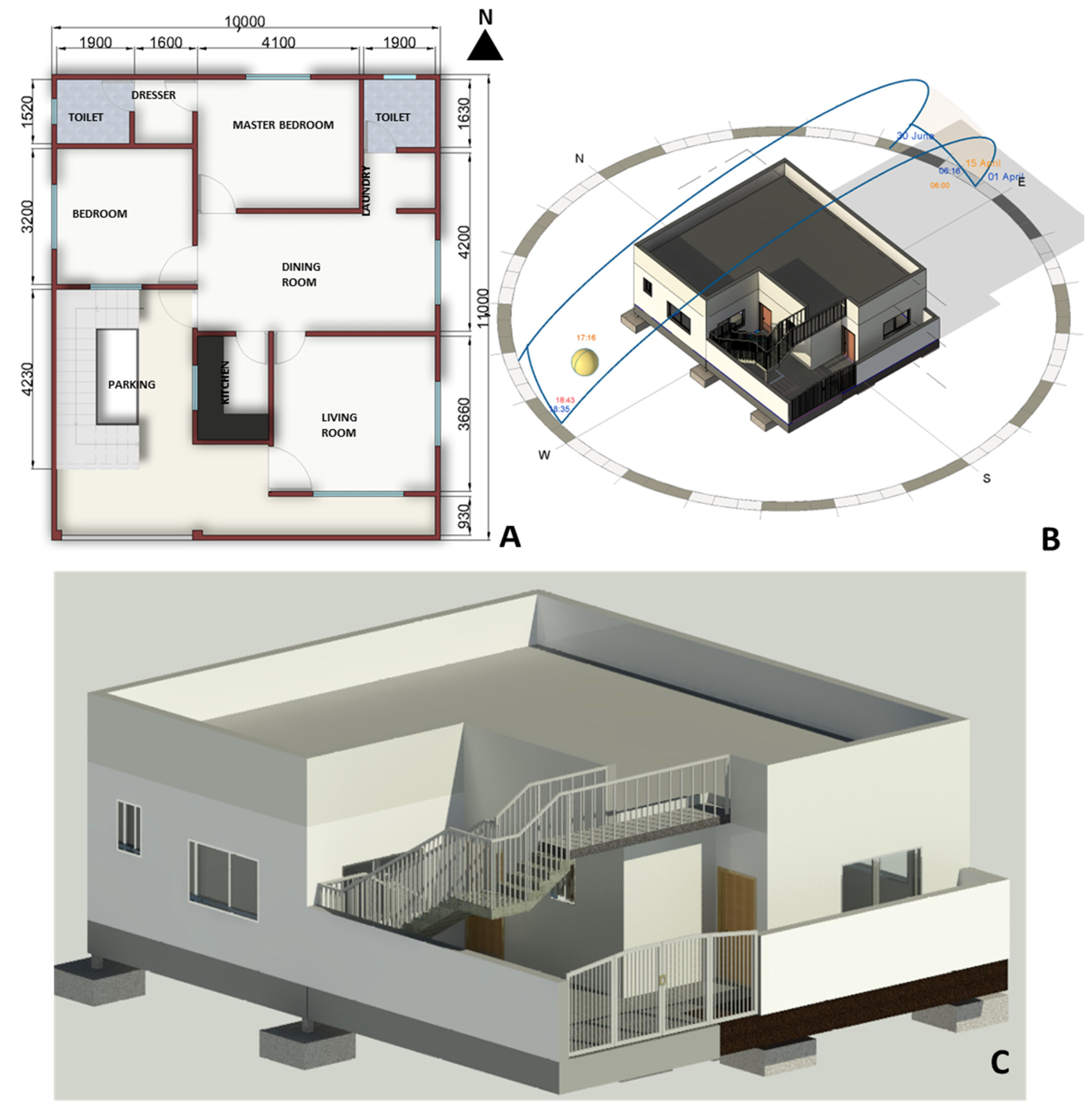

2.1. Case Study Building Description

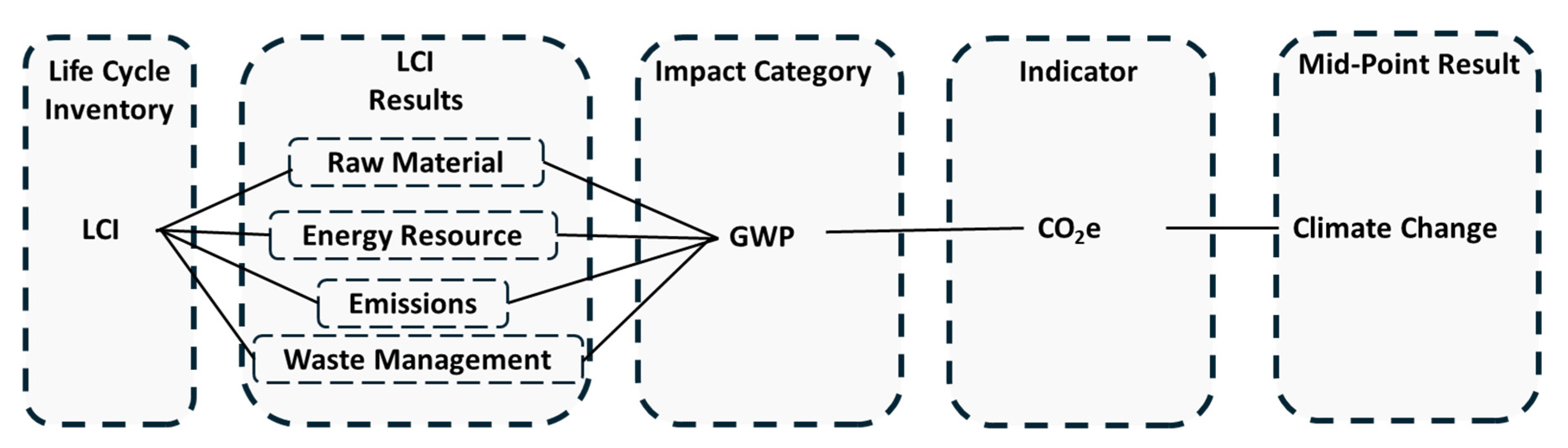

2.2. Lifecycle Assessment of Residential House in Northern India

2.2.1. Goal and Scope Definition

2.2.2. Lifecycle Inventory (LCI) and Assumptions

2.2.3. Lifecycle Impact Assessment

2.2.4. Interpretation

2.3. Model Validation and Quality Assurance

- Solid brick masonry walls that are 230 mm thick with a U-value of approximately 1.8 W/m2K, [115];

- A reinforced concrete roof slab (U-value ≈ 1.5 W/m2K), [116];

- Single-glazed windows with a U-value of approximately 5.3 W/m2K [117].

- A cooling setpoint of 27 °C, with activation when indoor temperatures exceeded 30 °C;

- An average COP (Coefficient of Performance) of 3.2–3.5, representing 3- to 5-star BEE-rated systems available on the Indian market [117].

3. Results

3.1. Energy, Water and Climate Analysis

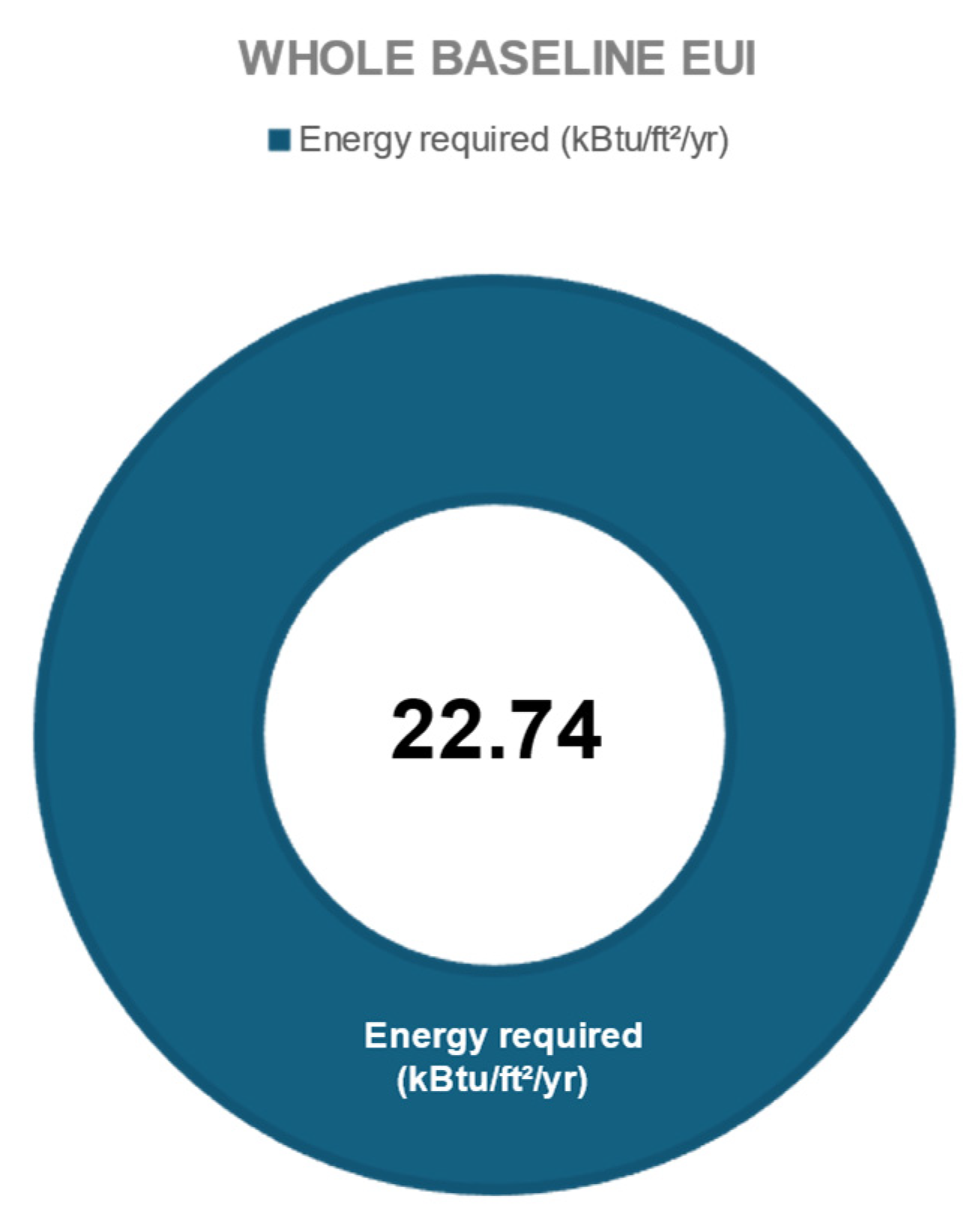

3.1.1. Energy Use Intensity (EUI)

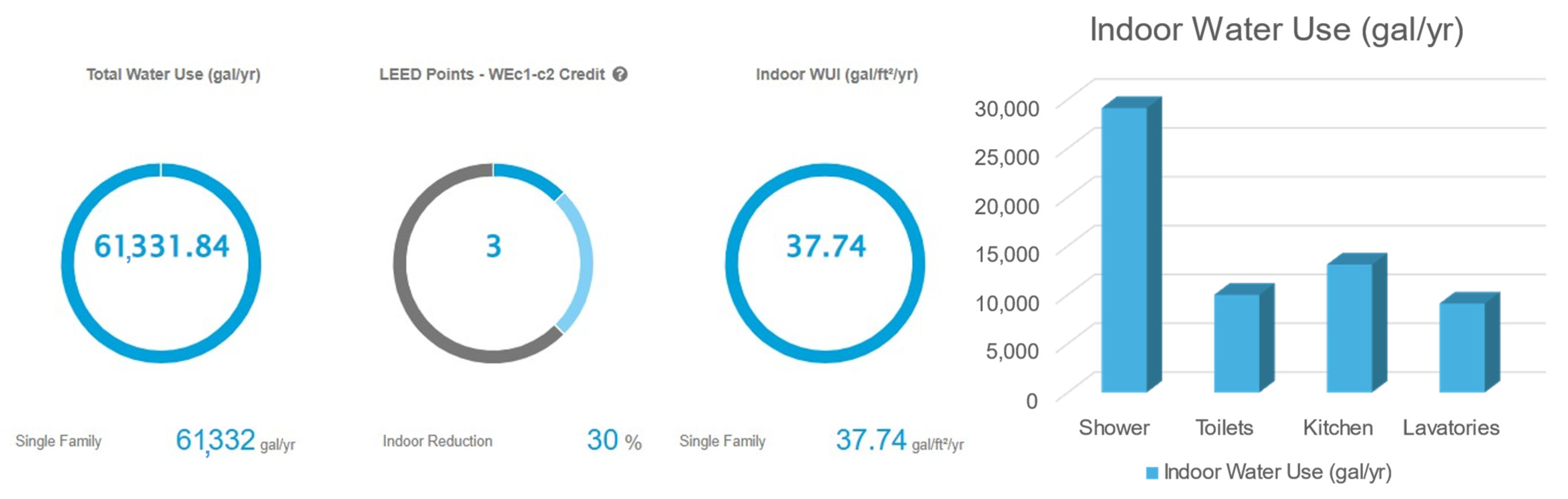

3.1.2. Water Consumption

3.2. Lifecycle Impact Breakdown by Stage

3.2.1. Global Warming Potential (kg CO2e) Across Lifecycle Stages

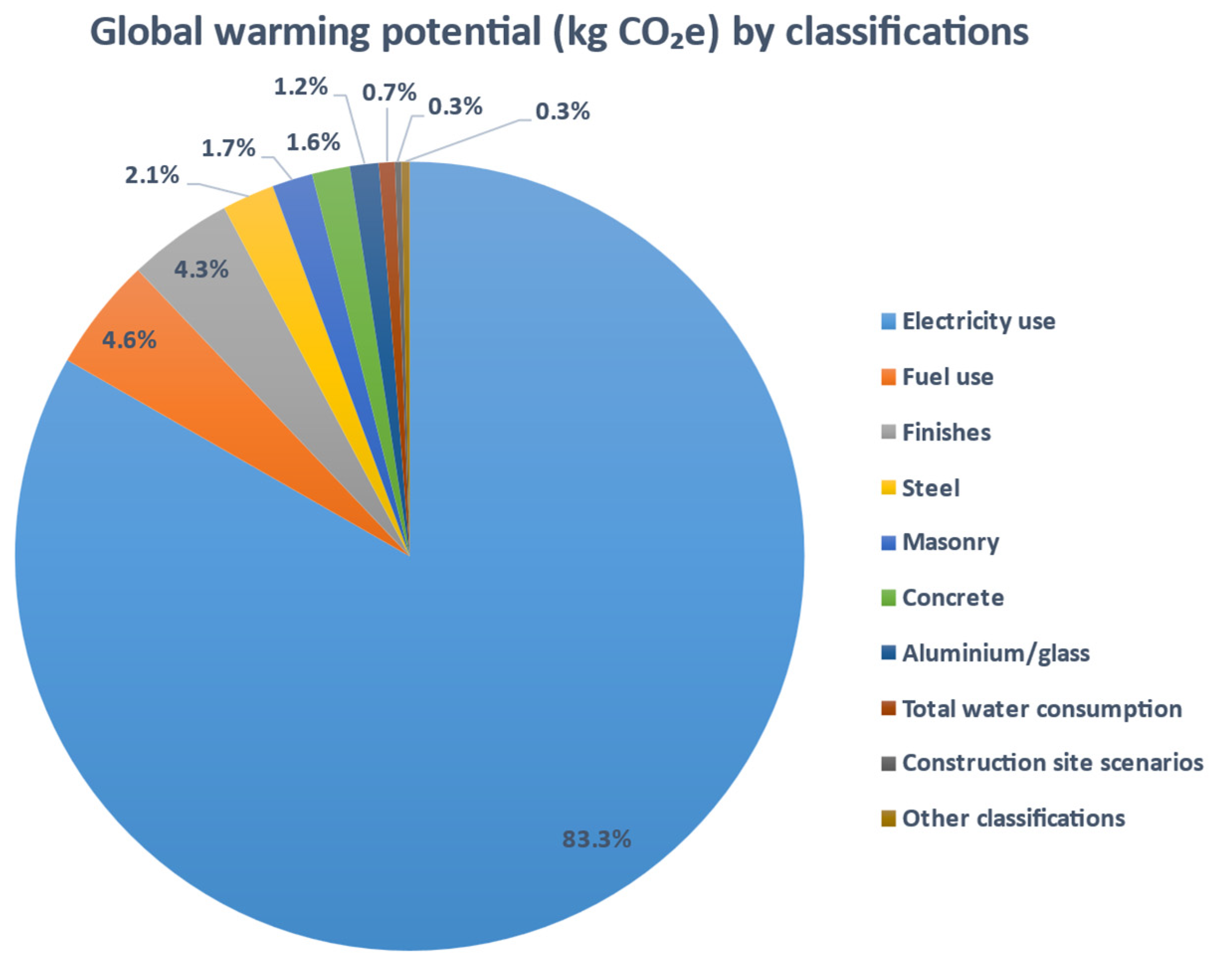

3.2.2. Global Warming Potential (kg CO2e) by Classifications

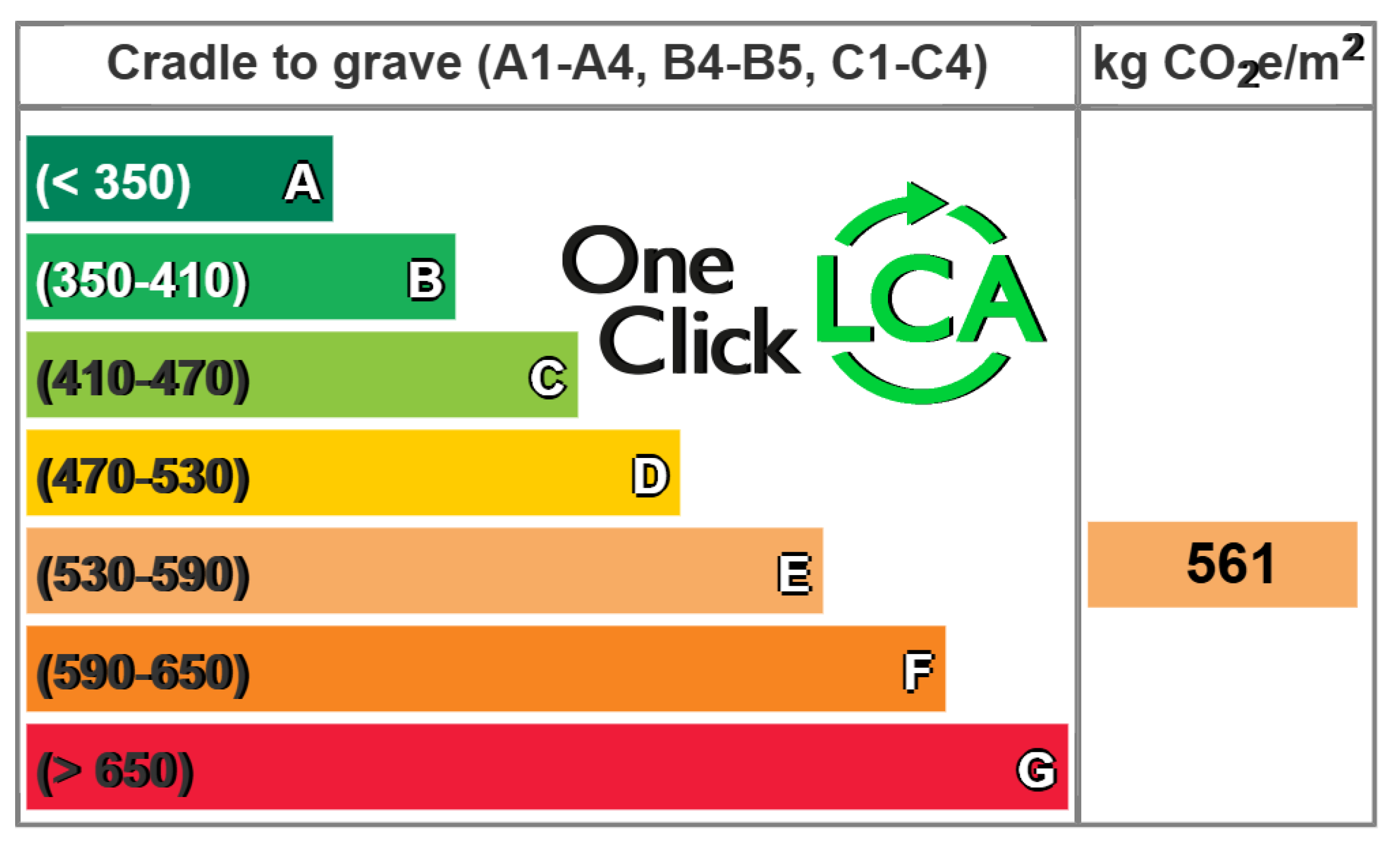

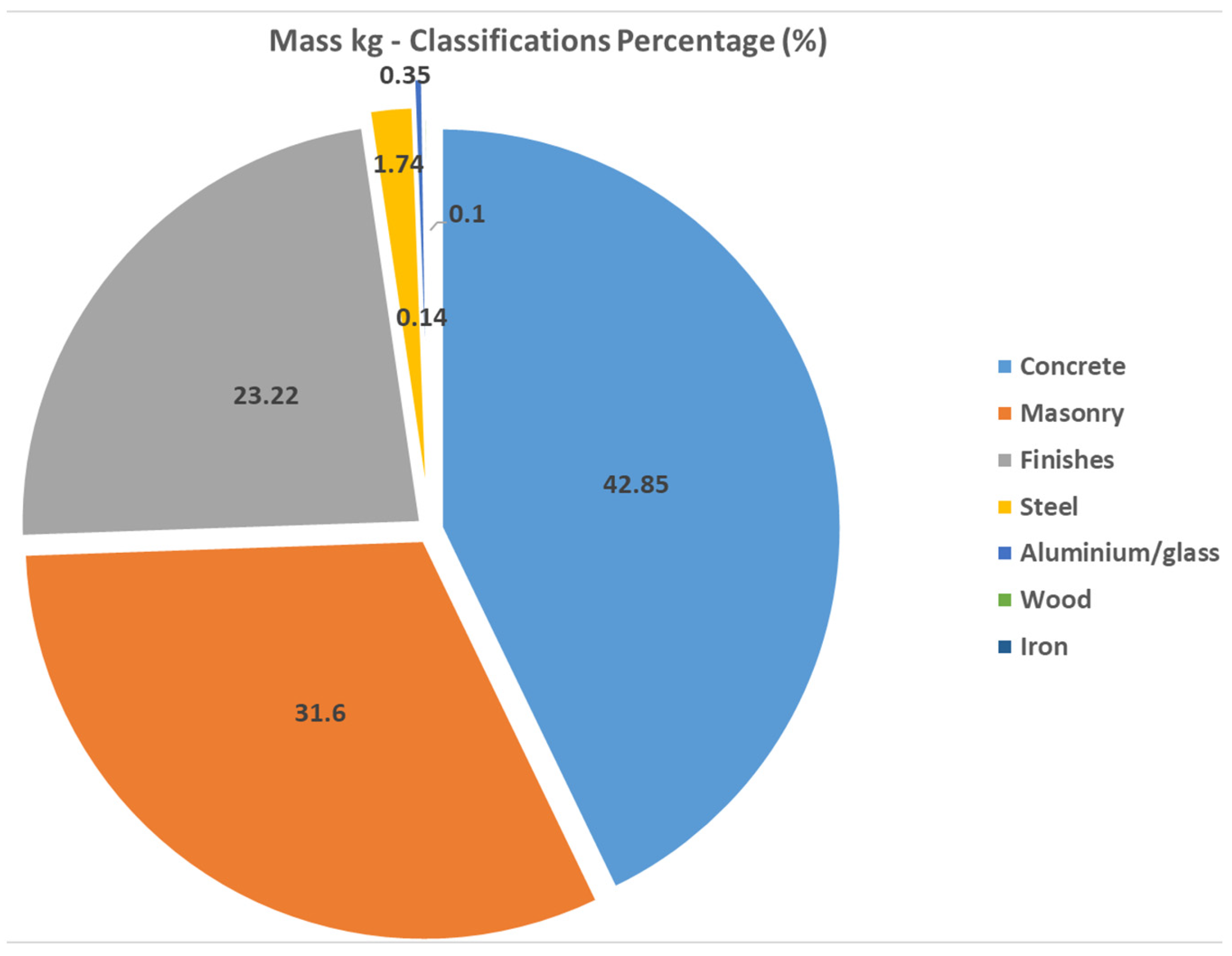

3.2.3. Global Warming Potential (kg CO2e) by Resource Types and Mass Classification (kg)

3.3. Integration of BIM-Based Workflows with LCA

- We ensured data consistency (the same building geometry and specs used for both energy and LCA, avoiding double modeling errors).

- We could visualize impacts via BIM (for example, producing color-coded models showing the carbon intensity of each building element to communicate hotspots to the design team).

- We improved collaboration: multiple stakeholders (architects and sustainability consultants) could use the same BIM model to derive the info they need, which aligns with the benefits of BIM noted in the literature (improved information exchange and decision-making).

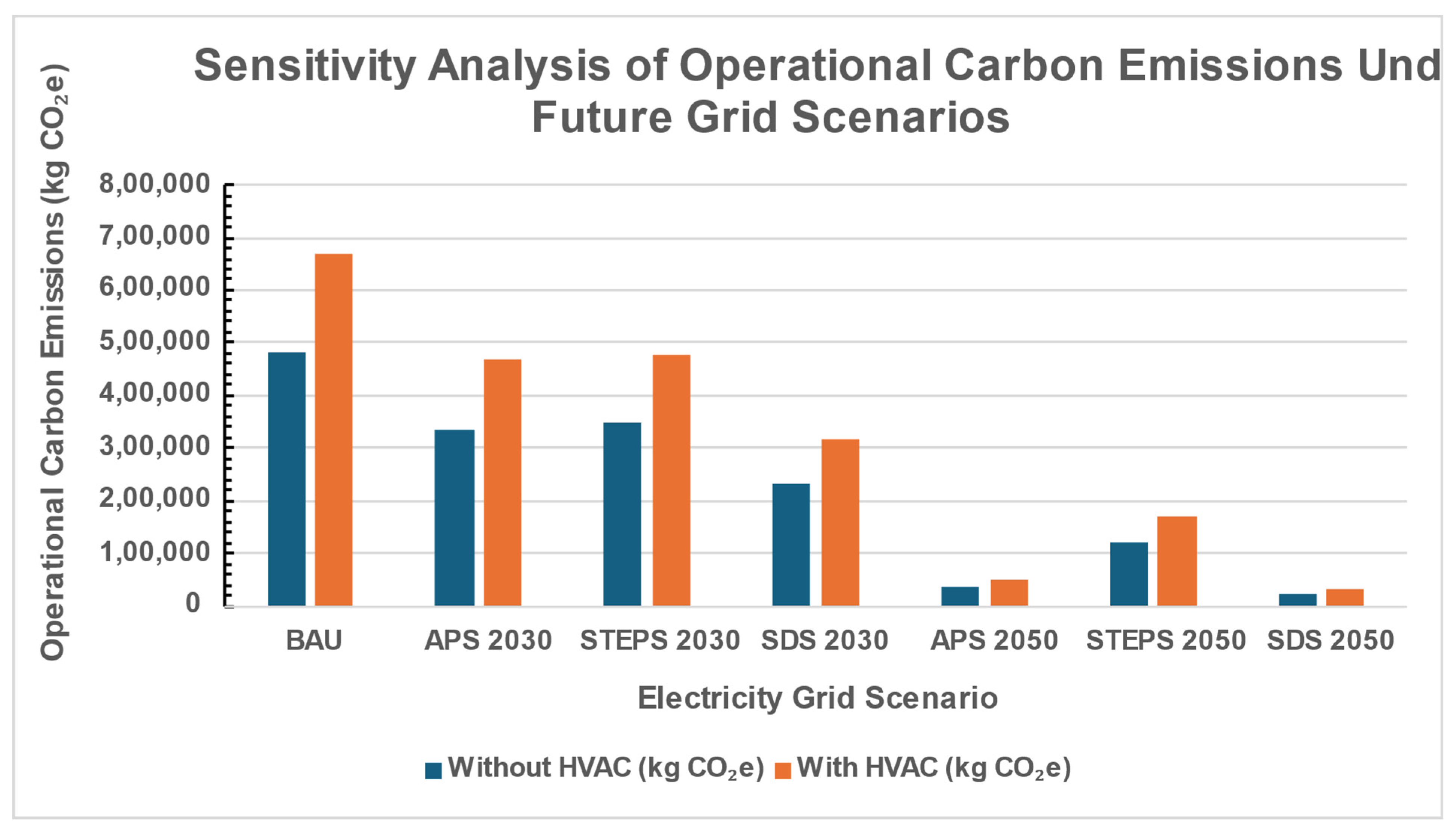

3.4. Sensitivity Analysis of Grid Emission Scenarios

- APS (Announced Pledges Scenario).

- STEPS (Stated Policies Scenario).

- SDS (Sustainable Development Scenario).

4. Discussion

4.1. Embodied vs. Operational Carbon Significance

4.2. Major Building Materials Driving Embodied CO2

4.3. BIM–LCA Integration for Sustainable Design Decisions

4.4. Policy and Regulatory Implications for Low-Carbon Housing in India

- Use low-carbon bricks for masonry: Replacing conventional clay bricks with fly ash bricks—as tested in this study—can reduce wall-related CO2e emissions from 6.7% to 2.3%. The trial mix used bricks with ~37% fly ash content, demonstrating the effectiveness of such substitutions [152].

- Adopt green concrete mixes: Substituting a portion of Portland cement with supplementary cementitious materials (e.g., fly ash, slag) can cut concrete-related emissions by up to 50%, significantly reducing the embodied carbon of structural elements [153].

- Leverage BIM-LCA tools in design decisions: Integrate LCA analysis with BIM during the early-design stage to evaluate the impact of different material and design options on the building’s carbon footprint. Also, integrating LCA within the BIM workflow allows the real-time assessment of design choices on lifecycle emissions, enabling the identification of material and energy hotspots prior to construction [154].

- Support India’s Net Zero by 2070 Target: The findings from this study highlight actionable pathways to reduce carbon intensity in residential buildings. Embedding lifecycle carbon assessments into building codes (e.g., NBC) and mandating low-carbon materials and BIM-LCA integration can significantly reduce emissions in India’s rapidly urbanizing sector. These measures align with international climate commitments, including India’s pledge at COP26 to achieve net-zero emissions by 2070 [138].

4.5. Limitations and Assumptions

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gabric, A.J. The Climate Change Crisis: A Review of Its Causes and Possible Responses. Atmosphere 2023, 14, 1081. [Google Scholar] [CrossRef]

- Halder, N.; Kumar, M.; Deepak, A.; Mandal, S.K.; Azmeer, A.; Mir, B.A.; Nurdiawati, A.; Al-Ghamdi, S.G. The Role of Urban Greenery in Enhancing Thermal Comfort: Systematic Review Insights. Sustainability 2025, 17, 2545. [Google Scholar] [CrossRef]

- Sathaye, J.; Shukla, P.R.; Ravindranath, N.H. Climate Change, Sustainable Development and India: Global and National Concerns. Curr. Sci. 2006, 90, 314–325. [Google Scholar]

- Sun, Q.; Miao, C.; Hanel, M.; Borthwick, A.G.L.; Duan, Q.; Ji, D.; Li, H. Global Heat Stress on Health, Wildfires, and Agricultural Crops under Different Levels of Climate Warming. Environ. Int. 2019, 128, 125–136. [Google Scholar] [CrossRef]

- Azmeer, A.; Tahir, F.; Al-Ghamdi, S.G. Progress on Green Infrastructure for Urban Cooling: Evaluating Techniques, Design Strategies, and Benefits. Urban. Clim. 2024, 56, 102077. [Google Scholar] [CrossRef]

- Mondal, S.K.; Huang, J.; Wang, Y.; Su, B.; Kundzewicz, Z.W.; Jiang, S.; Zhai, J.; Chen, Z.; Jing, C.; Jiang, T. Changes in Extreme Precipitation across South Asia for Each 0.5 °C of Warming from 1.5 °C to 3.0 °C above Pre-Industrial Levels. Atmos. Res. 2022, 266, 105961. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, D.; Lang, X. Climate Change of 4 °C Global Warming above Pre-Industrial Levels. Adv. Atmos. Sci. 2018, 35, 757–770. [Google Scholar] [CrossRef]

- Warren, R.; Price, J.; Forstenhäusler, N.; Andrews, O.; Brown, S.; Ebi, K.; Gernaat, D.; Goodwin, P.; Guan, D.; He, Y.; et al. Risks Associated with Global Warming of 1.5 to 4 °C above Pre-Industrial Levels in Human and Natural Systems in Six Countries. Clim. Change 2024, 177, 48. [Google Scholar] [CrossRef]

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development. In Global Warming of 1.5 °C; Cambridge University Press: Cambridge, UK, 2022; pp. 93–174. [Google Scholar]

- Kanwal, Q.; Tahir, F.; Al-Humaiqani, M.; Al-Qawasmeh, R.; Mir, B.A.; Azmeer, A.; Terán-Cuadrado, G.; Yu, Z.; Nurdiawati, A.; Al-Ghamdi, S.G. Building a National Framework for Life Cycle Assessment: Pathways to Sustainable Development in Saudi Arabia; King Abdullah University of Science and Technology (KAUST): Thuwal, Saudi Arabia, 2025. [Google Scholar] [CrossRef]

- Habib, S.; Tahir, F.; Hussain, F.; Macauley, N.; Al-Ghamdi, S.G. Current and Emerging Technologies for Carbon Accounting in Urban Landscapes: Advantages and Limitations. Ecol. Indic. 2023, 154, 110603. [Google Scholar] [CrossRef]

- Mohajan, H.K. Greenhouse Gas Emissions, Global Warming and Climate Change: Successful Shipping Management of American President Line (APL). In Proceedings of the 15th Chittagong Conference on Mathematical Physics, Jamal Nazrul Islam Research Centre for Mathematical and Physical Sciences (JNIRCMPS), University of Chittagong, Chittagong, Bangladesh, 2017. Available online: https://www.researchgate.net/publication/315668490 (accessed on 18 June 2025).

- Audi, M.; Ali, A.; Kassem, M. Greenhouse Gases: A Review of Losses and Benefits. Int. J. Energy Econ. Policy 2020, 10, 403–418. [Google Scholar] [CrossRef]

- Van Aalst, M.K. The Impacts of Climate Change on the Risk of Natural Disasters. Disasters 2006, 30, 5–18. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.; Ho, K. Implications of Climate Change on Marine Biodiversity. Glob. J. Agric. Soil Sci. 2020, 1, 1–6. [Google Scholar]

- Harley, C.D.G.; Hughes, A.R.; Hultgren, K.M.; Miner, B.G.; Sorte, C.J.B.; Thornber, C.S.; Rodriguez, L.F.; Tomanek, L.; Williams, S.L. The Impacts of Climate Change in Coastal Marine Systems. Ecol. Lett. 2006, 9, 228–241. [Google Scholar] [CrossRef] [PubMed]

- Banholzer, S.; Kossin, J.; Donner, S. The Impact of Climate Change on Natural Disasters. In Reducing Disaster: Early Warning Systems for Climate Change; Springer: Dordrecht, The Netherlands, 2014; Volume 9789401785983, pp. 21–49. ISBN 9789401785983. [Google Scholar]

- Florides, G.A.; Christodoulides, P. Global Warming and Carbon Dioxide through Sciences. Environ. Int. 2009, 35, 390–401. [Google Scholar] [CrossRef]

- Pecl, G.T.; Araújo, M.B.; Bell, J.D.; Blanchard, J.; Bonebrake, T.C.; Chen, I.C.; Clark, T.D.; Colwell, R.K.; Danielsen, F.; Evengård, B.; et al. Biodiversity Redistribution under Climate Change: Impacts on Ecosystems and Human Well-Being. Science 2017, 355, eaai9214. [Google Scholar] [CrossRef]

- Malhi, Y.; Franklin, J.; Seddon, N.; Solan, M.; Turner, M.G.; Field, C.B.; Knowlton, N. Climate Change and Ecosystems: Threats, Opportunities and Solutions. Philos. Trans. R. Soc. B Biol. Sci. 2020, 375, 20190104. [Google Scholar] [CrossRef]

- Bhyan, P.; Shrivastava, B.; Kumar, N. Allocating Weightage to Sustainability Criteria’s for Performance Assessment of Group Housing Developments: Using Fuzzy Analytic Hierarchy Process. J. Build. Eng. 2023, 65, 105684. [Google Scholar] [CrossRef]

- Terán-Cuadrado, G.; Sbahieh, S.; Tahir, F.; Nurdiawati, A.; Almarshoud, M.A.; Al-Ghamdi, S.G. Evaluating the Influence of Functional Unit on Life Cycle Assessment (LCA) Reliability of Concrete. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Yu, Z.; Nurdiawati, A.; Kanwal, Q.; Al-Humaiqani, M.M.; Al-Ghamdi, S.G. Assessing and Mitigating Environmental Impacts of Construction Materials: Insights from Environmental Product Declarations. J. Build. Eng. 2024, 98, 110929. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Cooling, Opportunities for Energy-Efficient Air Conditioning; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2020.

- Global Alliance for Buildings and Construction Global Status Report for Buildings and Construction 2021; UNEP: Nairobi, Kenya, 2021.

- World Green Building Council. Bringing Embodied Carbon Upfront: Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon. Available online: https://worldgbc.org/article/bringing-embodied-carbon-upfront/ (accessed on 18 June 2025).

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied Energy in Residential Buildings-towards the Nearly Zero Energy Building: A Literature Review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Gardezi, S.S.S.; Shafiq, N. Operational Carbon Footprint Prediction Model for Conventional Tropical Housing: A Malaysian Prospective. Int. J. Environ. Sci. Technol. 2019, 16, 7817–7826. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy Use in the Life Cycle of Conventional and Low-Energy Buildings: A Review Article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Zimmermann, R.K.; Kanafani, K.; Rasmussen, F.N.; Andersen, C.; Birgisdóttir, H. LCA-Framework to Evaluate Circular Economy Strategies in Existing Buildings. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042044. [Google Scholar] [CrossRef]

- Kanafani, K.; Zimmermann, R.K.; Rasmussen, F.N.; Birgisdóttir, H. Learnings from Developing a Context-Specific LCA Tool for Buildings—The Case of Lcabyg 4. Sustainability 2021, 13, 1508. [Google Scholar] [CrossRef]

- Napolano, L.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. LCA-Based Study on Structural Retrofit Options for Masonry Buildings. Int. J. Life Cycle Assess. 2015, 20, 23–35. [Google Scholar] [CrossRef]

- Alshamrani, O.S.; Galal, K.; Alkass, S. Integrated LCA-LEED Sustainability Assessment Model for Structure and Envelope Systems of School Buildings. Build. Environ. 2014, 80, 61–70. [Google Scholar] [CrossRef]

- EN 15978:2011; Sustainability of Construction Works. Assessment of Environmental Performance of Buildings: Calculation Method. CEN (European Committee for Standardization): Bruxelles, Belgium, 2011.

- Jafary Nasab, T.; Monavari, S.M.; Jozi, S.A.; Majedi, H. Assessment of Carbon Footprint in the Construction Phase of High-Rise Constructions in Tehran. Int. J. Environ. Sci. Technol. 2020, 17, 3153–3164. [Google Scholar] [CrossRef]

- Escamilla, E.Z.; Habert, G.; Daza, J.F.C.; Archilla, H.F.; Echeverry Fernández, J.S.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Radhi, H. On the Effect of Global Warming and the UAE Built Environment. In Global Warming; Sciyo: Rijeka, Croatia, 2010. [Google Scholar]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life Cycle Assessment of a Danish Office Building Designed for Disassembly. Build. Res. Inf. 2019, 47, 666–680. [Google Scholar] [CrossRef]

- Gustafsson, M.; Dipasquale, C.; Poppi, S.; Bellini, A.; Fedrizzi, R.; Bales, C.; Ochs, F.; Sié, M.; Holmberg, S. Economic and Environmental Analysis of Energy Renovation Packages for European Office Buildings. Energy Build. 2017, 148, 155–165. [Google Scholar] [CrossRef]

- Victoria, M.F.; Perera, S.; Davies, A.; Fernando, N. Carbon and Cost Critical Elements: A Comparative Analysis of Two Office Buildings. Built Environ. Proj. Asset Manag. 2017, 7, 460–470. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-Cycle Assessment of Office Buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Abrahamsen, F.E.; Ruud, S.G.; Gebremedhin, A. Assessing Efficiency and Environmental Performance of a Nearly Zero-Energy University Building’s Energy System in Norway. Buildings 2023, 13, 169. [Google Scholar] [CrossRef]

- Teshnizi, Z.; Pilon, A.; Storey, S.; Lopez, D.; Froese, T.M. Lessons Learned from Life Cycle Assessment and Life Cycle Costing of Two Residential Towers at the University of British Columbia. Procedia CIRP 2018, 69, 172–177. [Google Scholar] [CrossRef]

- Lo-Iacono-Ferreira, V.G.; Torregrosa-López, J.I.; Capuz-Rizo, S.F. Use of Life Cycle Assessment Methodology in the Analysis of Ecological Footprint Assessment Results to Evaluate the Environmental Performance of Universities. J. Clean. Prod. 2016, 133, 43–53. [Google Scholar] [CrossRef]

- Kmet’kovä, J.; Krajčik, M. Energy Efficient Retrofit and Life Cycle Assessment of an Apartment Building. Energy Procedia 2015, 78, 3186–3191. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life Cycle Assessment of an Apartment Building: Comparison of an Attributional and Consequential Approach. Energy Procedia 2014, 62, 132–140. [Google Scholar] [CrossRef]

- Wrålsen, B.; O’Born, R.; Skaar, C. Life Cycle Assessment of an Ambitious Renovation of a Norwegian Apartment Building to NZEB Standard. Energy Build. 2018, 177, 197–206. [Google Scholar] [CrossRef]

- Van Gulck, L.; Van de Putte, S.; Delghust, M.; Van Den Bossche, N.; Steeman, M. Environmental and Financial Assessment of Façade Renovations Designed for Change: Developing Optimal Scenarios for Apartment Buildings in Flanders. Build. Environ. 2020, 183, 107178. [Google Scholar] [CrossRef]

- Simons, A.; Firth, S.K. Life-Cycle Assessment of a 100% Solar Fraction Thermal Supply to a European Apartment Building Using Water-Based Sensible Heat Storage. Energy Build. 2011, 43, 1231–1240. [Google Scholar] [CrossRef]

- Ochoa, L.; Ries, R.; Matthews, H.S.; Hendrickson, C. Life Cycle Assessment of Residential Buildings. In Proceedings of the Construction Research Congress 2005: Broadening Perspectives—Proceedings of the Congress, San Diego, CA, USA, 5–7 April 2005; pp. 173–181. [Google Scholar]

- Hoxha, E.; Habert, G.; Lasvaux, S.; Chevalier, J.; Le Roy, R. Influence of Construction Material Uncertainties on Residential Building LCA Reliability. J. Clean. Prod. 2017, 144, 33–47. [Google Scholar] [CrossRef]

- Papadaki, D.; Nikolaou, D.A.; Assimakopoulos, M.N. Circular Environmental Impact of Recycled Building Materials and Residential Renewable Energy. Sustainability 2022, 14, 4039. [Google Scholar] [CrossRef]

- Rodrigues, C.; Freire, F. Environmental Impacts and Costs of Residential Building Retrofits—What Matters? Sustain. Cities Soc. 2021, 67, 102733. [Google Scholar] [CrossRef]

- Korentz, J.; Nowogońska, B. Assessment of the Life Cycle of Masonry Walls in Residential Buildings. MATEC Web Conf. 2018, 174, 01025. [Google Scholar] [CrossRef]

- Andersson, M.; Barkander, J.; Kono, J.; Ostermeyer, Y. Abatement Cost of Embodied Emissions of a Residential Building in Sweden. Energy Build. 2018, 158, 595–604. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.-S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China-A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Chen, W.; Wu, F.; Geng, W.; Yu, G. Carbon Emissions in China’s Industrial Sectors. Resour. Conserv. Recycl. 2017, 117, 264–273. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Y.; Teng, Y.; Yu, B.; Wang, J.; Zhang, H.; Duan, H. Can Buildings Sector Achieve the Carbon Mitigation Ambitious Goal: Case Study for a Low-Carbon Demonstration City in China? Environ. Impact Assess. Rev. 2021, 90, vp. [Google Scholar] [CrossRef]

- Ma, W.; Hao, J.L.; Zhang, C.; Di Sarno, L.; Mannis, A. Evaluating Carbon Emissions of China’s Waste Management Strategies for Building Refurbishment Projects: Contributing to a Circular Economy. Environ. Sci. Pollut. Res. 2023, 30, 8657–8671. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, L.; Liu, J. Embodied Carbon Emissions of Office Building: A Case Study of China’s 78 Office Buildings. Build. Environ. 2016, 95, 365–371. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, K.; Zhang, Z. Life Cycle Carbon Emissions of Two Residential Buildings in China: Comparison and Uncertainty Analysis of Different Assessment Methods. J. Clean. Prod. 2020, 266, 122037. [Google Scholar] [CrossRef]

- Su, X.; Tian, S.; Shao, X.; Zhao, X. Embodied and Operational Energy and Carbon Emissions of Passive Building in HSCW Zone in China: A Case Study. Energy Build. 2020, 222, 110090. [Google Scholar] [CrossRef]

- Yu, D.; Tan, H.; Ruan, Y. A Future Bamboo-Structure Residential Building Prototype in China: Life Cycle Assessment of Energy Use and Carbon Emissi. Energy Build. 2011, 43, 2638–2646. [Google Scholar] [CrossRef]

- Jiang, P.; Dong, W.; Kung, Y.; Geng, Y. Analysing Co-Benefits of the Energy Conservation and Carbon Reduction in China’s Large Commercial Buildings. J. Clean. Prod. 2013, 58, 112–120. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of Energy Consumption and Carbon Emission from the Building Construction Sector in China, a Process-Based LCA Approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Emami, N.; Marteinsson, B.; Heinonen, J. Environmental Impact Assessment of a School Building in Iceland Using LCA-Including the Effect of Long Distance Transport of Materials. Buildings 2016, 6, 46. [Google Scholar] [CrossRef]

- Lee, K.; Tae, S.; Shin, S. Development of a Life Cycle Assessment Program for Building (SUSB-LCA) in South Korea. Renew. Sustain. Energy Rev. 2009, 13, 1994–2002. [Google Scholar] [CrossRef]

- Mir, B.A.; Nurdiawati, A.; Al-Ghamdi, S.G. Assessing the Environmental Impact of Freshwater Use in LCA: Established Practices and Current Methods. Environ. Sci. Water Res. Technol. 2025, 11, 196–221. [Google Scholar] [CrossRef]

- Reza, B.; Sadiq, R.; Hewage, K. Emergy-Based Life Cycle Assessment (Em-LCA) of Multi-Unit and Single-Family Residential Buildings in Canada. Int. J. Sustain. Built Environ. 2014, 3, 207–224. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative Analysis between a Complete LCA Study and Results from a BIM-LCA Plug-In. Autom. Constr. 2018, 90, 188–200. [Google Scholar] [CrossRef]

- Aktas, C.B.; Bilec, M.M. Impact of Lifetime on US Residential Building LCA Results. Int. J. Life Cycle Assess. 2012, 17, 337–349. [Google Scholar] [CrossRef]

- Kirupakaran, K. Sustainable Construction Technologies. In Civil Engineering Innovations for Sustainable Communities with Net Zero Targets; CRC Press: Boca Raton, FL, USA, 2024; pp. 39–64. [Google Scholar]

- Chaudhary, A.; Akhtar, A. Template for Evaluating Cradle-to-Site Environmental Life Cycle Impacts of Buildings in India. ACS Environ. Au 2023, 3, 94–104. [Google Scholar] [CrossRef] [PubMed]

- Jain, M.; Rawal, R. Emissions from a Net-Zero Building in India: Life Cycle Assessment. Build. Cities 2022, 3, 398. [Google Scholar] [CrossRef]

- Chottemada, P.G.; Kar, A.; Kara De Maeijer, P. Environmental Impact Analysis of Alkali-Activated Concrete with Fiber Reinforcement. Infrastructures 2023, 8, 68. [Google Scholar] [CrossRef]

- Yadav, J.; Singh, V.P.; Kumar, A. Life Cycle Assessment of Sustainable Building Materials. In Sustainable Technologies for Energy Efficient Buildings; CRC Press: Boca Raton, FL, USA, 2024; pp. 64–101. [Google Scholar]

- Sravani, T.; Prasanna Venkatesan, R.; Madhumathi, A. A Comparative LCA Study of Passive Cooling Roof Materials for a Residential Building: An Indian Case Study. Mater. Today Proc. 2022, 64, 1014–1022. [Google Scholar] [CrossRef]

- Choudhary, K.; Sangwa, N.R.; Sangwan, K.S. Comparative Life Cycle Assessment of Flooring Options for Sustainable Buildings. Constr. Innov. 2023, 25, 1108–1126. [Google Scholar] [CrossRef]

- Venkatesh, G. Critique of Selected Peer-Reviewed Publications on Applied Social Life Cycle Assessment: Focus on Cases from Developing Countries. Clean. Technol. Environ. Policy 2019, 21, 413–430. [Google Scholar] [CrossRef]

- Gaurav, G.; Bihari Singh, A.; Mistry, S.; Gupta, S.; Dangayach, G.S.; Meena, M.L. Recent Progress of Scientific Research on Life Cycle Assessment. Mater. Today Proc. 2021, 47, 3161–3170. [Google Scholar] [CrossRef]

- Talpur, B.D.; Liuzzi, S.; Rubino, C.; Cannavale, A.; Martellotta, F. Life Cycle Assessment and Circular Building Design in South Asian Countries: A Review of the Current State of the Art and Research Potentials. Buildings 2023, 13, 3045. [Google Scholar] [CrossRef]

- Basu, M.; Kaja, N.; Rao, P. Study on Life Cycle Assessment and Life Cycle Sustainability Assessment of Buildings: A Review. J. Inst. Eng. (India) Ser. A 2024, 105, 749–766. [Google Scholar] [CrossRef]

- Chadchan, J.; Shankar, R. An Analysis of Urban Growth Trends in the Post-Economic Reforms Period in India. Int. J. Sustain. Built Environ. 2012, 1, 36–49. [Google Scholar] [CrossRef]

- Sharma, R.; Joshi, P.K. Mapping Environmental Impacts of Rapid Urbanization in the National Capital Region of India Using Remote Sensing Inputs. Urban. Clim. 2016, 15, 70–82. [Google Scholar] [CrossRef]

- Moncaster, A.M.; Symons, K.E. A method and tool for ‘cradle to grave’ embodied carbon and energy impacts of UK buildings in compliance with the new TC350 standards. Energy Build. 2013, 66, 514–523. [Google Scholar] [CrossRef]

- Terán-Cuadrado, G.; Tahir, F.; Nurdiawati, A.; Almarshoud, M.A.; Al-Ghamdi, S.G. Current and Potential Materials for the Low-Carbon Cement Production: Life Cycle Assessment Perspective. J. Build. Eng. 2024, 96, 110528. [Google Scholar] [CrossRef]

- Government of Indian Ministry of Power. Eco-Niwas Samhita (ENS) 2024 (Energy Conservation and Sustainable Building Code-Residential). 2023. Available online: https://beeindia.gov.in/sites/default/files/ENS%202024_Buildign%20Code%20for%20Residential%20Buildings.pdf (accessed on 18 June 2025).

- The Energy and Resources Institute (TERI); Ministry of New and Renewable Energy (MNRE). GRIHA (Green Rating for Integrated Habitat Assessment) Rating System. Available online: https://www.grihaindia.org/ (accessed on 15 March 2025).

- Dekkiche, H.; Taileb, A. The Importance of Integrating LCA into the LEED Rating System. Procedia Eng. 2016, 145, 844–851. [Google Scholar] [CrossRef]

- Thilakaratne, R.; Lew, V. Is LEED Leading Asia?: An Analysis of Global Adaptation and Trends. Procedia Eng. 2011, 21, 1136–1144. [Google Scholar] [CrossRef]

- Forouzandeh, N.; Tahsildoost, M.; Zomorodian, Z.S. A Review of Web-Based Building Energy Analysis Applications. J. Clean. Prod. 2021, 306, 127251. [Google Scholar] [CrossRef]

- Le, A.B.D.; Whyte, A.; Biswas, W.K. Carbon Footprint and Embodied Energy Assessment of Roof-Covering Materials. Clean. Technol. Environ. Policy 2019, 21, 1913–1923. [Google Scholar] [CrossRef]

- Bureau of Indian Standards. National Building Code of India 2016 (NBC 2016). Available online: https://www.bis.gov.in/standards/technical-department/national-building-code/ (accessed on 16 March 2025).

- Office of the Registrar General & Census Commissioner, India. Population Census. Table HH-01: Normal Households by Household Size (Total), NCT of Delhi—2011. Available online: https://censusindia.gov.in/nada/index.php/catalog/?page=1&sort_by=popularity&sort_order=desc&ps=15 (accessed on 15 March 2025).

- Bureau of Energy Efficiency (BEE) Energy Efficiency in Indian Households. Ministry of Power. Available online: https://beeindia.gov.in (accessed on 20 May 2025).

- International Energy Agency (IEA). India Energy Outlook 2021; International Energy Agency: Paris, France, 2021; Available online: https://www.iea.org/reports/india-energy-outlook-2021 (accessed on 20 May 2025).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 16 March 2025).

- ISO 21929-1:2011; Sustainability in Building Construction—Sustainability Indicators Part 1: Framework for the Development of Indicators and a Core Set of Indicators for Buildings. Available online: https://www.iso.org/standard/46599.html (accessed on 24 March 2025).

- ISO 21931-1:2022; Sustainability in Buildings and Civil Engineering Works—Framework for Methods of Assessment of the Environmental, Social and Economic Performance of Construction Works as a Basis for Sustainability Assessment. Available online: https://www.iso.org/standard/71183.html (accessed on 24 March 2025).

- EN 15804:2012+A2:2019; Sustainability of Construction Works. Available online: https://cdn.standards.iteh.ai/samples/70014/d1c2e14c078c467d8e2ad35806a52ae2/SIST-EN-15804-2012-A2-2019.pdf (accessed on 24 March 2025).

- Song, X.; Carlsson, C.; Kiilsgaard, R.; Bendz, D.; Kennedy, H. Life Cycle Assessment of Geotechnical Works in Building Construction: A Review and Recommendations. Sustainability 2020, 12, 8442. [Google Scholar] [CrossRef]

- De Toro, P.; Iodice, S. Urban Metabolism Evaluation Methods: Life Cycle Assessment and Territorial Regeneration. Regen. Territ. 2022, 128, 213–230. [Google Scholar]

- Ylmén, P.; Peñaloza, D.; Mjörnell, K. Life Cycle Assessment of an Office Building Based on Site-Specific Data. Energies 2019, 12, 2588. [Google Scholar] [CrossRef]

- Gundabattini, E.; Masselli, C.; Gnanaraj, D.; Tadikonda, S.; Karnati, V.; Vemireddy, V. Improving the Energy Performances of the Refrigeration Systems with Subcooling Using the Eco-Friendly Refrigerant R600a: Initial Experimental Results. Instrum. Mes. Métrologie 2020, 19, 73–81. [Google Scholar] [CrossRef]

- Arpke, A.; Hutzler, N. Operational Life-Cycle Assessment and Life-Cycle Cost Analysis for Water Use in Multioccupant Buildings. J. Archit. Eng. 2005, 11, 99–109. [Google Scholar] [CrossRef]

- Zhang, W.; Tan, S.; Lei, Y.; Wang, S. Life Cycle Assessment of a Single-Family Residential Building in Canada: A Case Study. Build. Simul. 2014, 7, 429–438. [Google Scholar] [CrossRef]

- Bureau of Indian Standards. National Building Code of India 2016, Part 8: Building Services—Section 1: Lighting and Ventilation; BIS: New Delhi, India, 2016. Available online: https://www.bis.gov.in (accessed on 3 April 2025).

- Bureau of Energy Efficiency. Energy Conservation Building Code (ECBC) 2017. Available online: https://ecbc.in/resources/stateref/ECBCchange.pdf (accessed on 18 June 2025).

- Central Electricity Authority (CEA). CO2 Baseline Database for the Indian Power Sector. Available online: https://cea.nic.in/old/index.html (accessed on 20 May 2025).

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories; Volume 2: Energy. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_4_Ch4_Fugitive_Emissions.pdf (accessed on 20 May 2025).

- Bulle, C.; Margni, M.; Patouillard, L.; Boulay, A.-M.; Bourgault, G.; De Bruille, V.; Cao, V.; Hauschild, M.; Henderson, A.; Humbert, S.; et al. IMPACT World+: A Globally Regionalized Life Cycle Impact Assessment Method. Int. J. Life Cycle Assess. 2019, 24, 1653–1674. [Google Scholar] [CrossRef]

- Cavalliere, C.; Hollberg, A.; Dell’Osso, G.R.; Habert, G. Consistent BIM-Led LCA during the Entire Building Design Process. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012099. [Google Scholar] [CrossRef]

- Bansal, N.K.; Hauser, G.; Minke, G. Passive Building Design: A Handbook of Natural Climate Control; Elsevier Science: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Bureau of Energy Efficiency. Eco-Niwas Samhita: Energy Conservation Building Code for Residential Buildings; Ministry of Power, Government of India: New Delhi, India, 2018. [Google Scholar]

- Sahu, T.K.; Patanwar, P.; Bhaskar, M.; Singh, S.; Gautam, B.S.; Gupta, P.; Singroul, S.; Kumar, R.; Rakesh, C.; Kumar, A.; et al. Evaluating Energy Efficiency in LIG Buildings Using Louver Shading Systems. Case Stud. Therm. Eng. 2025, 72, 106272. [Google Scholar] [CrossRef]

- Burak Gunay, H.; Darwazeh, D.; Shillinglaw, S.; Wilton, I. Remote Characterization of Envelope Performance through Inverse Modelling with Building Automation System Data. Energy Build. 2021, 240, 110893. [Google Scholar] [CrossRef]

- U.S. Green Building Council. LEED v4 for Building Design and Construction. Available online: https://www.usgbc.org/resources/leed-v4-building-design-and-construction-current-version (accessed on 3 April 2025).

- Pasanen, P.; Castro, R. Carbon Heroes Benchmark Program—Whole Building Embodied Carbon Profiling. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012028. [Google Scholar] [CrossRef]

- Chou, M.-I.; Chou, S.-F.; Patel, V.; Pickering, M.D.; Stucki, J.W. Manufacturing Fired Bricks with Class F Fly-Ash from Illinois Basin Coals; University of Illinois Urbana-Champaign: Champaign, IL, USA, 2006. [Google Scholar]

- Rahmat, M.N.; Saleh, A.M. Strength and Environmental Evaluation of Building Bricks Using Industrial Waste for Liveable Environments. Constr. Build. Mater. 2023, 403, 132864. [Google Scholar] [CrossRef]

- Fernández-Pereira, C.; de la Casa, J.A.; Gómez-Barea, A.; Arroyo, F.; Leiva, C.; Luna, Y. Application of Biomass Gasification Fly Ash for Brick Manufacturing. Fuel 2011, 90, 220–232. [Google Scholar] [CrossRef]

- Solutions, S. Life Cycle Database—India Electricity Grid Mix Scenarios (APS, STEPS, SDS), 2030 and 2050. Available online: https://sphera.com/solutions/product-stewardship/life-cycle-assessment-software-and-data/ (accessed on 28 May 2025).

- Simpson, K.; Janda, K.B.; Owen, A. Preparing ‘Middle Actors’ to Deliver Zero-Carbon Building Transitions. Build. Cities 2020, 1, 610. [Google Scholar] [CrossRef]

- Central Electricity Authority. CO2 Baseline Database for the Indian Power Sector—Version 20; Central Electricity Authority: New Delhi, India, 2023. [Google Scholar]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG Emissions of Buildings—The Hidden Challenge for Effective Climate Change Mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring Embodied Carbon Dioxide Equivalent of Buildings: A Review and Critique of Current Industry Practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Vintzileou, E.; Panagiotidou, E. An Empirical Model for Predicting the Mechanical Properties of FRP-Confined Concrete. Constr. Build. Mater. 2008, 22, 841–854. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging Energy-Efficiency and CO2 Emission-Reduction Technologies for Cement and Concrete Production: A Technical Review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Alireza, A.F.F.; Rashidi, T.H.; Akbarnezhad, A.; Waller, S.T. BIM-Enabled Sustainability Assessment of Material Supply Decisions. Eng. Constr. Archit. Manag. 2017, 24, 668–695. [Google Scholar] [CrossRef]

- Francisco, A.; Truong, H.; Khosrowpour, A.; Taylor, J.E.; Mohammadi, N. Occupant Perceptions of Building Information Model-Based Energy Visualizations in Eco-Feedback Systems. Appl. Energy 2020, 276, 115410. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC Analysis within a BIM-Based Environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Raouf, A.M.I.; Al-Ghamdi, S.G. Building Information Modelling and Green Buildings: Challenges and Opportunities. Archit. Eng. Des. Manag. 2019, 15, 1–28. [Google Scholar] [CrossRef]

- Saleem, M.; Chhipi-Shrestha, G.; Túlio Barbosa Andrade, M.; Dyck, R.; Ruparathna, R.; Hewage, K.; Sadiq, R. Life Cycle Thinking-Based Selection of Building Facades. J. Archit. Eng. 2018, 24. [Google Scholar] [CrossRef]

- Middlemiss, L.; Stevens, M.; Ambrosio-Albalá, P.; Pellicer-Sifres, V.; van Grieken, A. How Do Interventions for Energy Poverty and Health Work? Energy Policy 2023, 180, 113684. [Google Scholar] [CrossRef]

- Mohan, S.; Vijayalaxmi, J. Embodied Carbon Impacts of Green Building Rating Systems. In Embodied and Operational Carbon in Buildings; Springer: Singapore, 2024; pp. 13–25. [Google Scholar]

- Ghosh, A.; Neogi, S. Energy Efficiency in Buildings and Related Assessment Tools Under Indian Perspective. In Strategic Management, Decision Theory, and Decision Science; Springer: Singapore, 2021; pp. 33–50. [Google Scholar]

- Kumar Kirme, S.; Kapse, V.S. A Comprehensive Review of Residential Building Energy Efficiency Measures in India. Energy Build. 2024, 319, 114537. [Google Scholar] [CrossRef]

- Al-Ghamdi, S.G.; Bilec, M.M. Whole-Building LCA and Green Building Rating Systems: Exploratory Review of the Available Tools Whole-Building LCA and Green Building Rating Systems 2. In Proceedings of the International Symposium on Sustainable Systems and Technologies, Dearborn, MI, USA, 17–19 May 2015. Sustainable Conoscente Network. [Google Scholar]

- Al-Ghamdi, S.G.; Bilec, M.M. Green Building Rating Systems and Whole-Building Life Cycle Assessment: Comparative Study of the Existing Assessment Tools. J. Archit. Eng. 2017, 23, 04016015. [Google Scholar] [CrossRef]

- Nurdiawati, A.; Mir, B.A.; Al-Ghamdi, S.G. Recent Advancements in Prospective Life Cycle Assessment: Current Practices, Trends, and Implications for Future Research. Resour. Environ. Sustain. 2025, 20, 100203. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Lubloy, E. Sustainability and Durability Performance Evaluation of Geopolymer Concrete with Industrial Effluent as Alternative to Conventional River Sand. Dev. Built Environ. 2024, 19, 100517. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Adak, D.; Kapoor, K.; Tabish, M. Low Carbon Concrete: Advancements, Challenges and Future Directions in Sustainable Construction. Discov. Concr. Cem. 2025, 1, 3. [Google Scholar] [CrossRef]

- Basavaraj, A.; Gettu, R. Life cycle assessment as a tool in sustainability assessment of concrete systems: Why and how? Indian Concr. J. 2022, 96, 1–20. [Google Scholar]

- Kiruthika, K.; Ambily, P.S.; Ponmalar, V.; Kaliyavaradhan, S.K. Computation of Embodied Energy and Carbon Dioxide Emissions of Geopolymer Concrete in High-Rise Buildings: A Case Study in Chennai City. Eur. J. Environ. Civ. Eng. 2024, 28, 1517–1543. [Google Scholar] [CrossRef]

- Singh, N.; Sharma, R.L.; Yadav, K. Sustainable Solutions: Exploring Supplementary Cementitious Materials in Construction. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 2191–2224. [Google Scholar] [CrossRef]

- Mahevi, S.A.; Kaliluthin, A.K.; Husain, D.; Ansari, Y.; Ahmad, I. Ecological Footprint and Economic Assessment of Ready-Mix Concrete Production. In Ecological Footprint of Industrial Spaces and Processes; Springer: Cham, Switzerland, 2024; pp. 37–48. [Google Scholar]

- Chandel, R.; Chandel, S.S.; Prasad, D.; Dwivedi, R.P. Sustainable Passive Solar and Photovoltaic Integrated Technology Interventions for Climate Responsive Net Zero Energy Buildings in Western Himalayan Mountainous Terrain of India. Next Sustain. 2024, 3, 100039. [Google Scholar] [CrossRef]

- Vora, S.; Rajgor, M.; Pitroda, J. A critical review of net zero energy efficient design strategies in construction sector. Int. J. Adv. Res. Innov. Ideas Educ. 2017, 3, 1187–1194. [Google Scholar]

- Sengupta, N.; Roy, S.; Guha, H. Assessing Embodied GHG Emission Reduction Potential of Cost-Effective Technologies for Construction of Residential Buildings of Economically Weaker Section in India. Asian J. Civ. Eng. 2018, 19, 139–156. [Google Scholar] [CrossRef]

- Shaik, S.; Roy, A.; Hussain Shaik, A.; Rehaan Chandan, M.; Arıcı, M.; Saxena, K.K.; Alam, T. Innovate, Insulate, Integrate: Embracing Circular Economy in Innovative Insulations for Reduced Air Conditioning Expenses and Carbon Mitigation in Fly Ash Brick Buildings. Energy Build. 2024, 322, 114694. [Google Scholar] [CrossRef]

- Kumar, D.; Maurya, K.K.; Mandal, S.K.; Mir, B.A.; Nurdiawati, A.; Al-Ghamdi, S.G. Life Cycle Assessment in the Early Design Phase of Buildings: Strategies, Tools, and Future Directions. Buildings 2025, 15, 1612. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A Review of the Methodology and Its Application to Sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life Cycle Assessment. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Heo, Y.; Choudhary, R.; Augenbroe, G.A. Calibration of Building Energy Models for Retrofit Analysis under Uncertainty. Energy Build. 2012, 47, 550–560. [Google Scholar] [CrossRef]

- Sokol, J.; Cerezo Davila, C.; Reinhart, C.F. Validation of a Bayesian-Based Method for Defining Residential Archetypes in Urban Building Energy Models. Energy Build. 2017, 134, 11–24. [Google Scholar] [CrossRef]

- Frischknecht, R.; Rebitzer, G. The Ecoinvent Database System: A Comprehensive Web-Based LCA Database. J. Clean. Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, X.; Wang, D.; Song, C.; Liu, J. A Prediction Model of VOC Partition Coefficient in Porous Building Materials Based on Adsorption Potential Theory. Build. Environ. 2015, 93, 221–233. [Google Scholar] [CrossRef]

- Hollberg, A.; Ruth, J. LCA in Architectural Design—A Parametric Approach. Int. J. Life Cycle Assess. 2016, 21, 943–960. [Google Scholar] [CrossRef]

- India’s Role in Global Energy Governance Framework: 2040 and Beyond; Ganeshan, S., Bhattacharjya, S., Eds.; The Energy and Resources Institute (TERI): New Delhi, India, 2022; ISBN 978-93-94657-01-4. [Google Scholar]

| Parameter | Description |

|---|---|

| Location | New Delhi, India (urban context, composite climate zone) |

| House type | Single-family residential dwelling unit (stand-alone, ground-floor construction) |

| Floors/stories | Ground floor |

| Total floor area | 110 m2 (approx. 1184 ft2) |

| Gross floor internal area | 99 m2 |

| Bedrooms/bathrooms | 2 bedrooms, 2 bathrooms, 1 living room, 1 kitchen and 1 dining area |

| Occupancy | 5 persons (normal households’ size by population census 2011) [96] |

| Structural system | Reinforced concrete frame {columns, beams, RCC (reinforced cement concrete), slabs} |

| Wall construction | Brick masonry (burnt clay bricks) with cement plaster |

| Roof construction | Flat RCC slab roof with waterproofing |

| Floor finishes | Ceramic tile with cement screed subfloor |

| Windows/doors | Single-glazed aluminum windows; wood/metal doors |

| HVAC and comfort systems | Natural ventilation, ceiling fans, 1 split AC unit (master bedroom), portable room heater |

| Design lifespan | 60 years (service life considered for LCA) |

| Design standards | Aligned with National Building Code (NBC 2016) standards for mid-income housing; moderate energy efficiency (basic insulation, natural ventilation features) |

| Class | Material | Quantity | Qty_Type |

|---|---|---|---|

| Foundation | Concrete—Cast-in-Place Concrete | 9.84 | M3 |

| Foundation | Reinforcement Steel | 890 | KG |

| Wall | Brick Common | 76.18 | TON |

| Wall | Mortar | 13944 | KG |

| Wall | Acrylic Topcoat Paint for Exterior | 0.02514 | M3 |

| Wall | Emulsion Paint for Interior | 0.05686 | M3 |

| Slab | Concrete—Cast-in-Place Concrete | 14.93 | M3 |

| Slab | Reinforcement Steel | 1350 | KG |

| Slab | Concrete—Screed | 7.08 | M3 |

| Column | Concrete—Cast-in-Place Concrete | 1.08 | M3 |

| Column | Reinforcement steel | 155 | KG |

| Beam | Concrete—Cast-in-Place Concrete | 1.05 | M3 |

| Beam | Reinforcement steel | 180 | KG |

| Roof | Roof_Generic—150 mm | 14.52 | M3 |

| Roof | Reinforcement Steel | 1450 | KG |

| Roof | Plaster | 2420 | KG |

| Stairs | Ready-Mix Concrete C25/30 | 1.62 | M3 |

| Stairs | Reinforcement Steel | 180 | KG |

| Door | Wood | 43 | M2 |

| Door | Metal Door with Steel Core | 250 | KG |

| Window | Window | 33 | M2 |

| Horizontal finish | Stone and Ceramic mix | 1930 | KG |

| Other | Damp-proofing | 0.37 | M3 |

| Result Category | Global Warming Potential (kg CO2e) |

|---|---|

| A1–A3 Materials | 41,947.7 |

| A4 Transport | 3875.8 |

| A5 Construction | 3924.8 |

| B1 Use phase | 0.272 |

| B2 Maintenance | 151.5 |

| B3 Repair | 10,328.4 |

| B4–B5 Replacement | 4261.7 |

| B6 Energy | 508,314.6 |

| B7 Water | 3774.9 |

| C1 Deconstruction/demolition | 601.8 |

| C2 Waste transport | 805.3 |

| C3 Waste processing | 15.9 |

| C4 Waste disposal | 519.2 |

| Total | 578,522 |

| Results per denominator: Gross internal floor area (IPMS/RICS): 99.0 m2 Global warming potential per m2: 5844 kg CO2e/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, D.; Maurya, K.K.; Mandal, S.K.; Halder, N.; Mir, B.A.; Nurdiawati, A.; Al-Ghamdi, S.G. A Whole-Life Carbon Assessment of a Single-Family House in North India Using BIM-LCA Integration. Buildings 2025, 15, 2195. https://doi.org/10.3390/buildings15132195

Kumar D, Maurya KK, Mandal SK, Halder N, Mir BA, Nurdiawati A, Al-Ghamdi SG. A Whole-Life Carbon Assessment of a Single-Family House in North India Using BIM-LCA Integration. Buildings. 2025; 15(13):2195. https://doi.org/10.3390/buildings15132195

Chicago/Turabian StyleKumar, Deepak, Kranti Kumar Maurya, Shailendra K. Mandal, Nandini Halder, Basit Afaq Mir, Anissa Nurdiawati, and Sami G. Al-Ghamdi. 2025. "A Whole-Life Carbon Assessment of a Single-Family House in North India Using BIM-LCA Integration" Buildings 15, no. 13: 2195. https://doi.org/10.3390/buildings15132195

APA StyleKumar, D., Maurya, K. K., Mandal, S. K., Halder, N., Mir, B. A., Nurdiawati, A., & Al-Ghamdi, S. G. (2025). A Whole-Life Carbon Assessment of a Single-Family House in North India Using BIM-LCA Integration. Buildings, 15(13), 2195. https://doi.org/10.3390/buildings15132195