DYMOS: A New Software for the Dynamic Identification of Structures

Abstract

1. Introduction

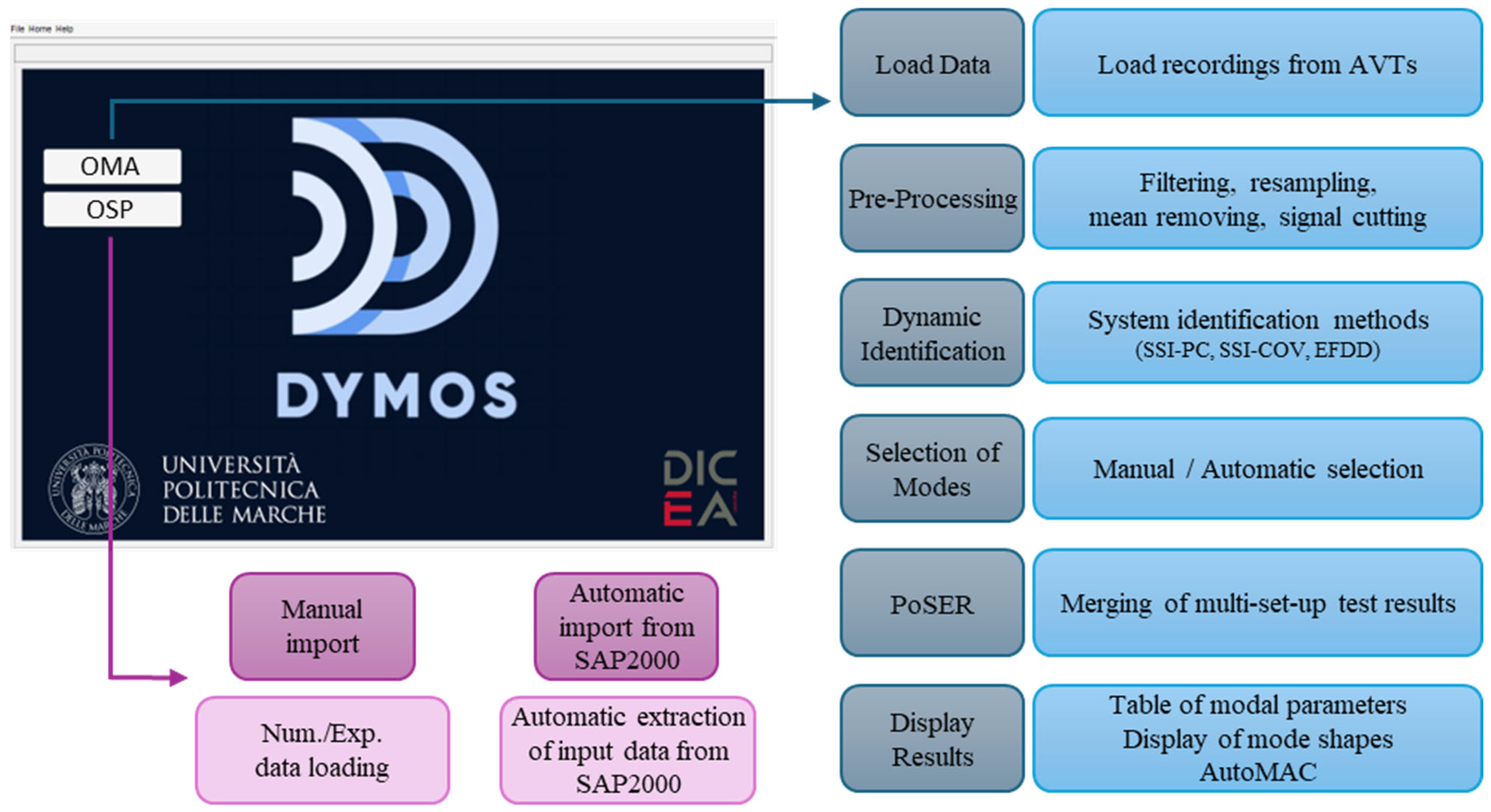

2. Description of the Software Architecture

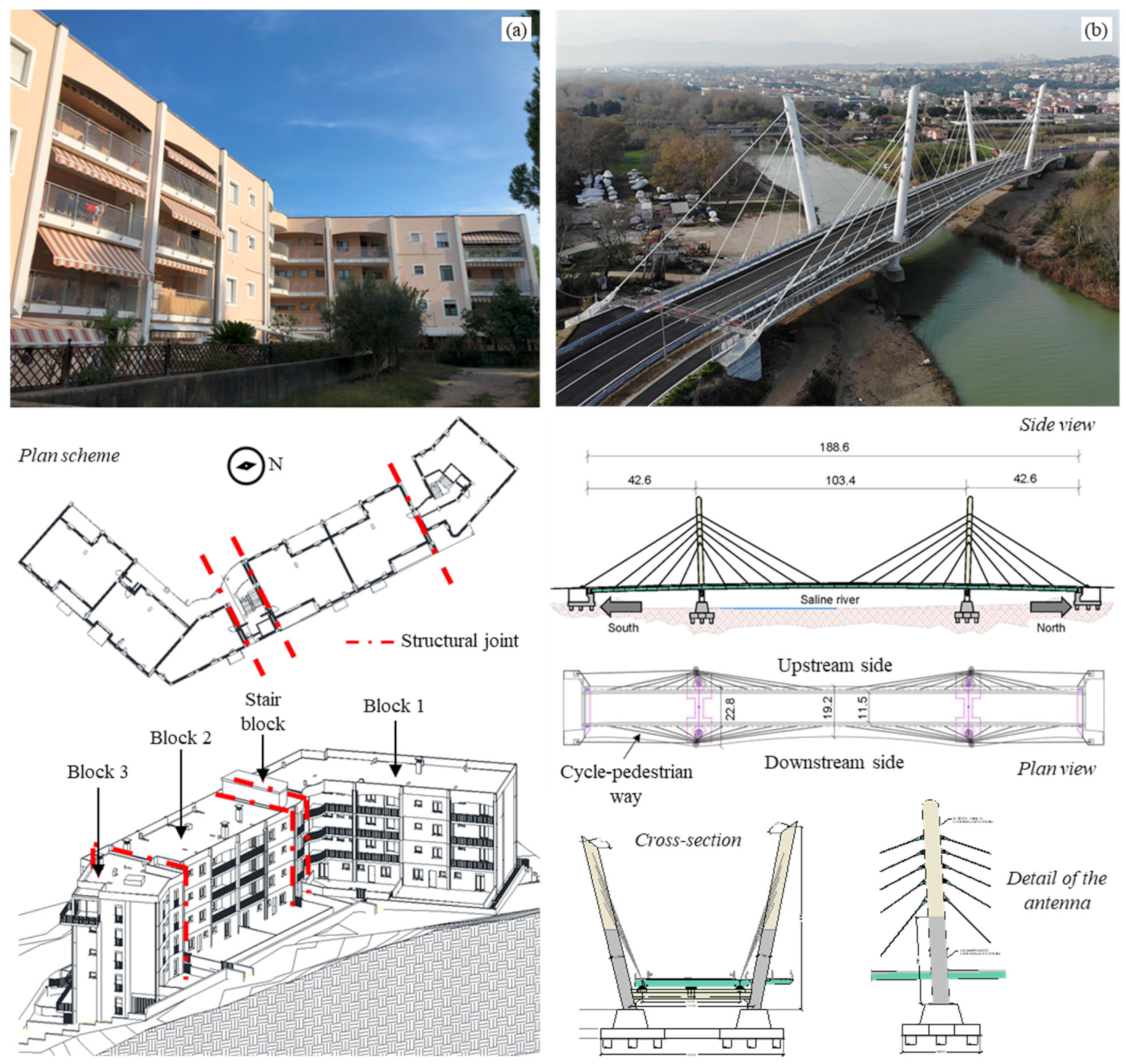

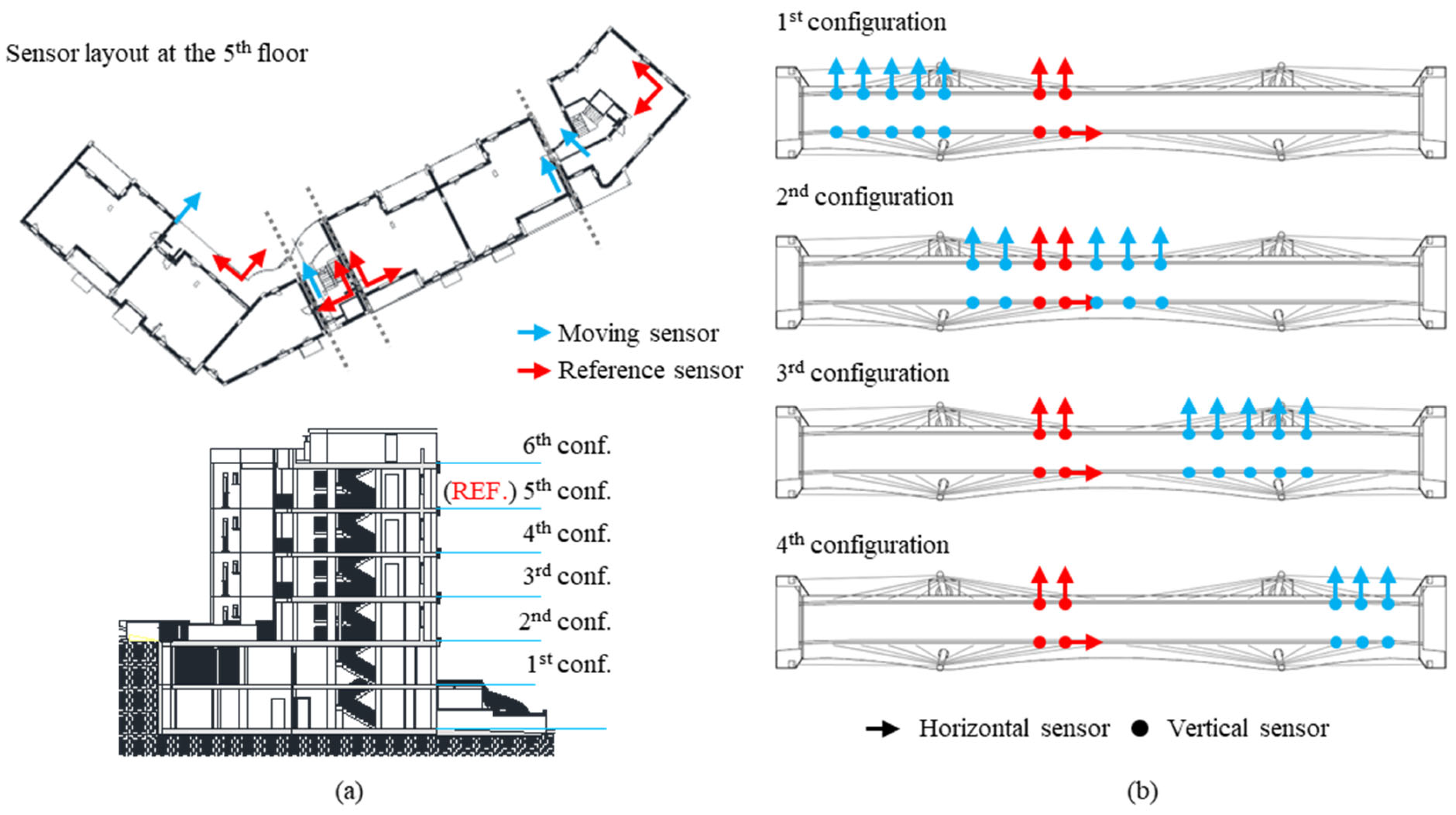

3. Introduction to the Case Studies

4. Signal Pre-Processing

4.1. Module for Loading Signal Recordings

4.2. Signal Pre-Processing Module

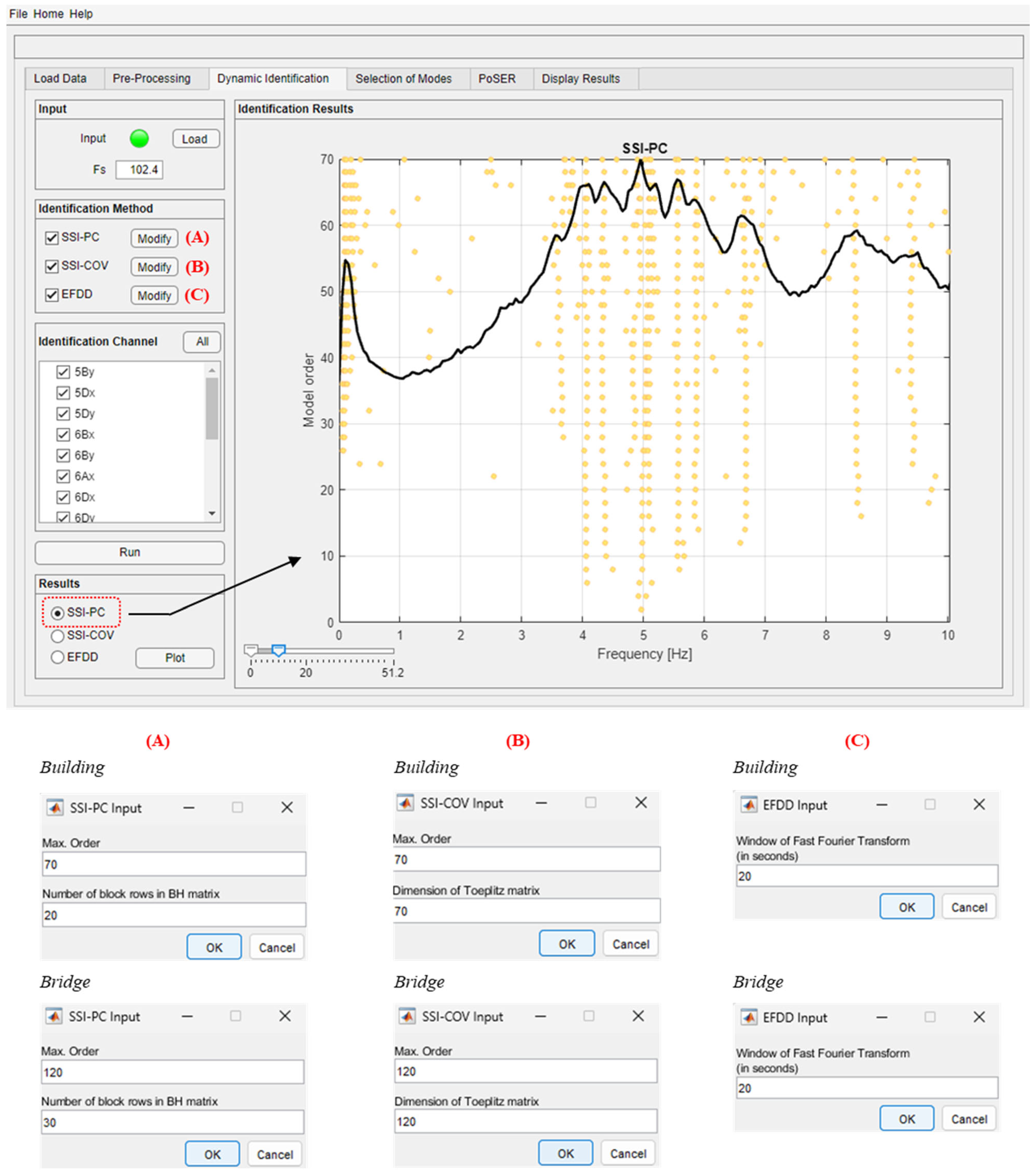

5. System Identification

5.1. Basics on the Identification Methods

5.2. Dynamic Identification Module

5.3. Selection of Modes

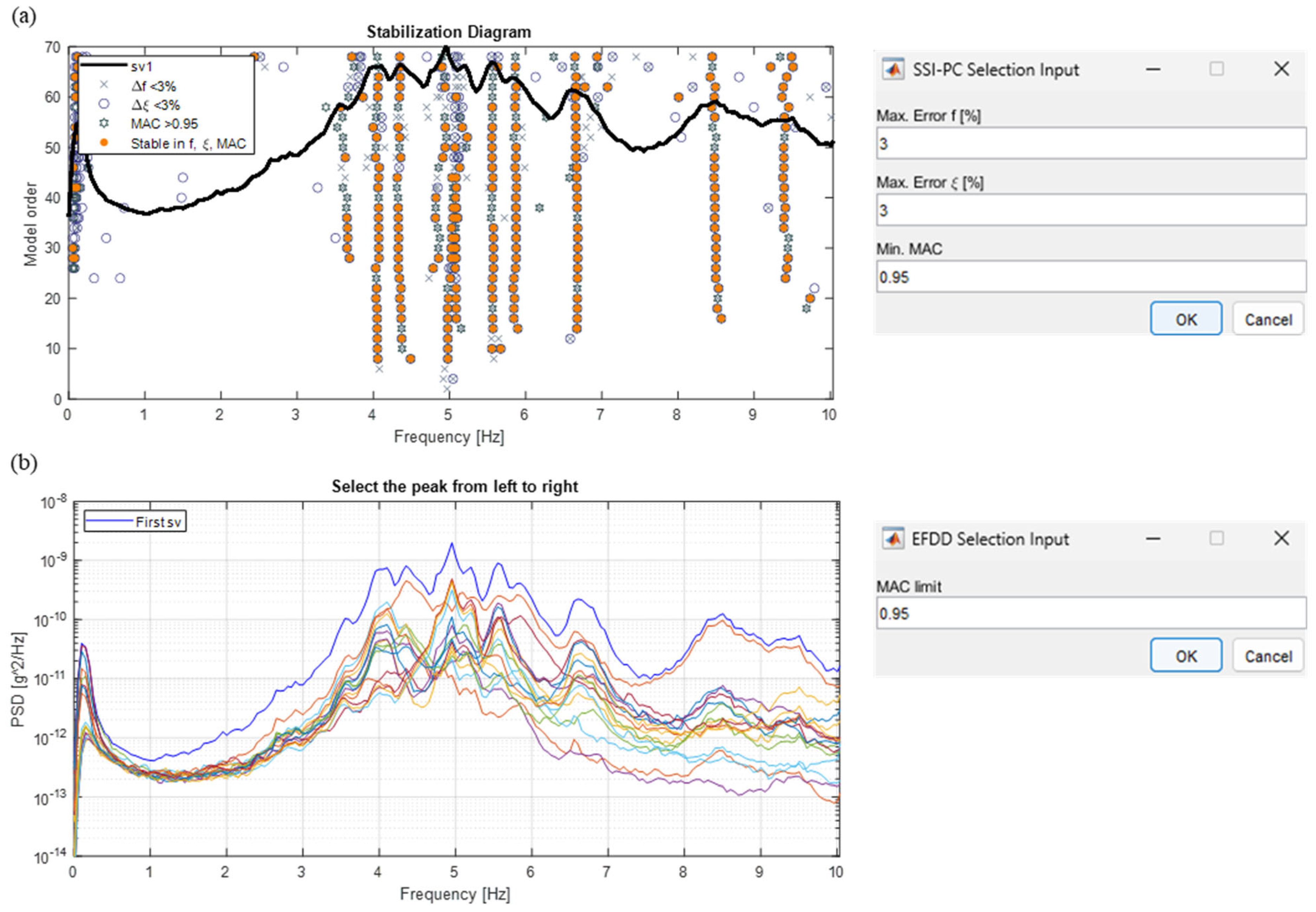

5.3.1. Manual Selection

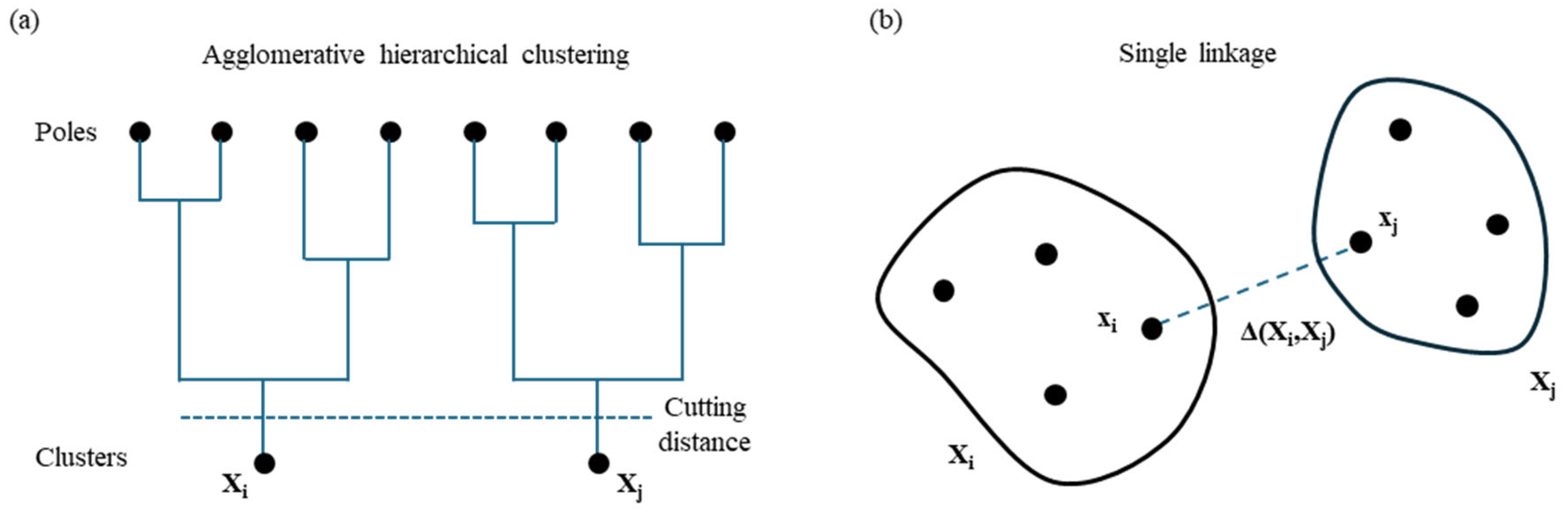

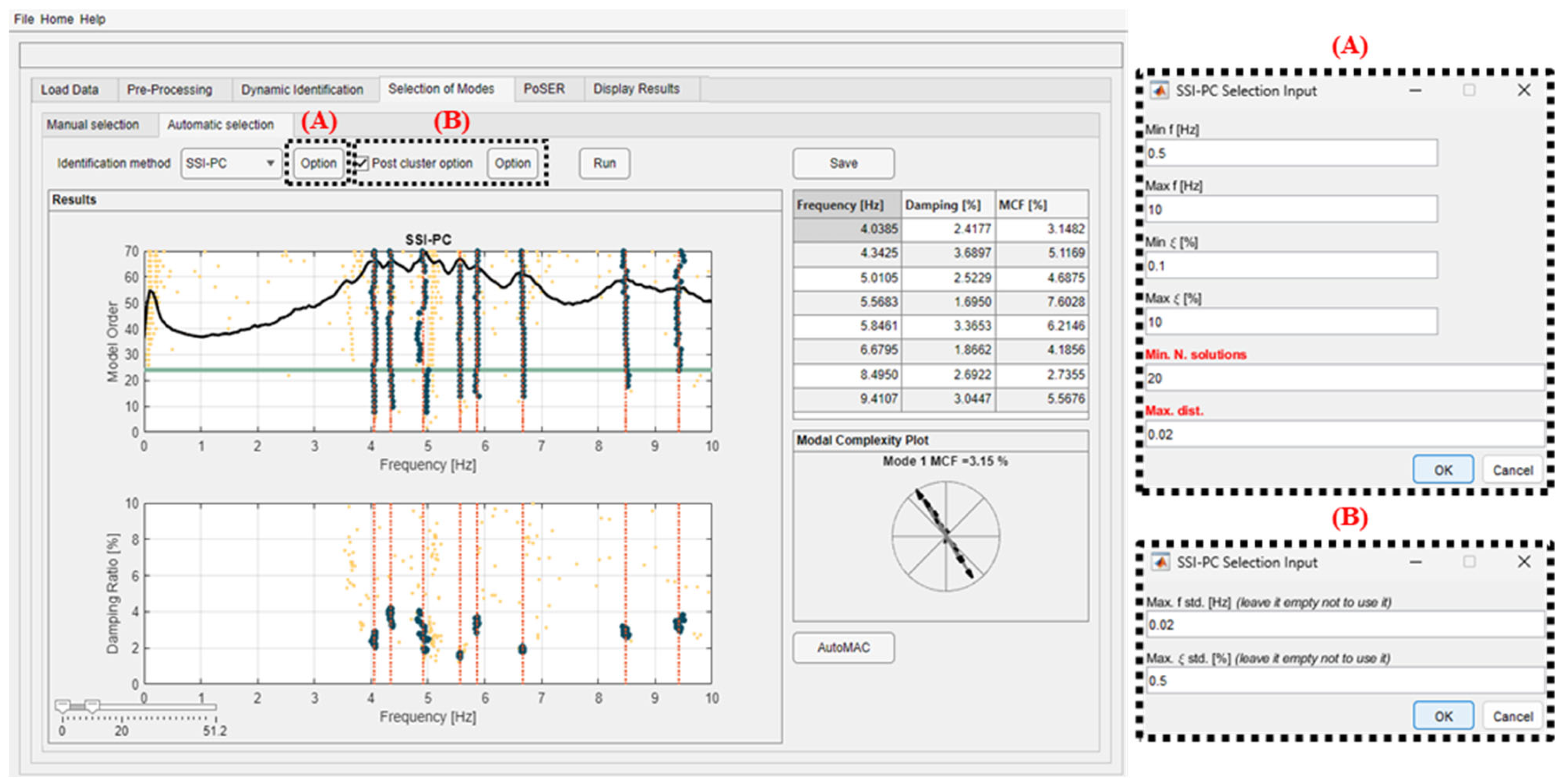

5.3.2. Automatic Selection

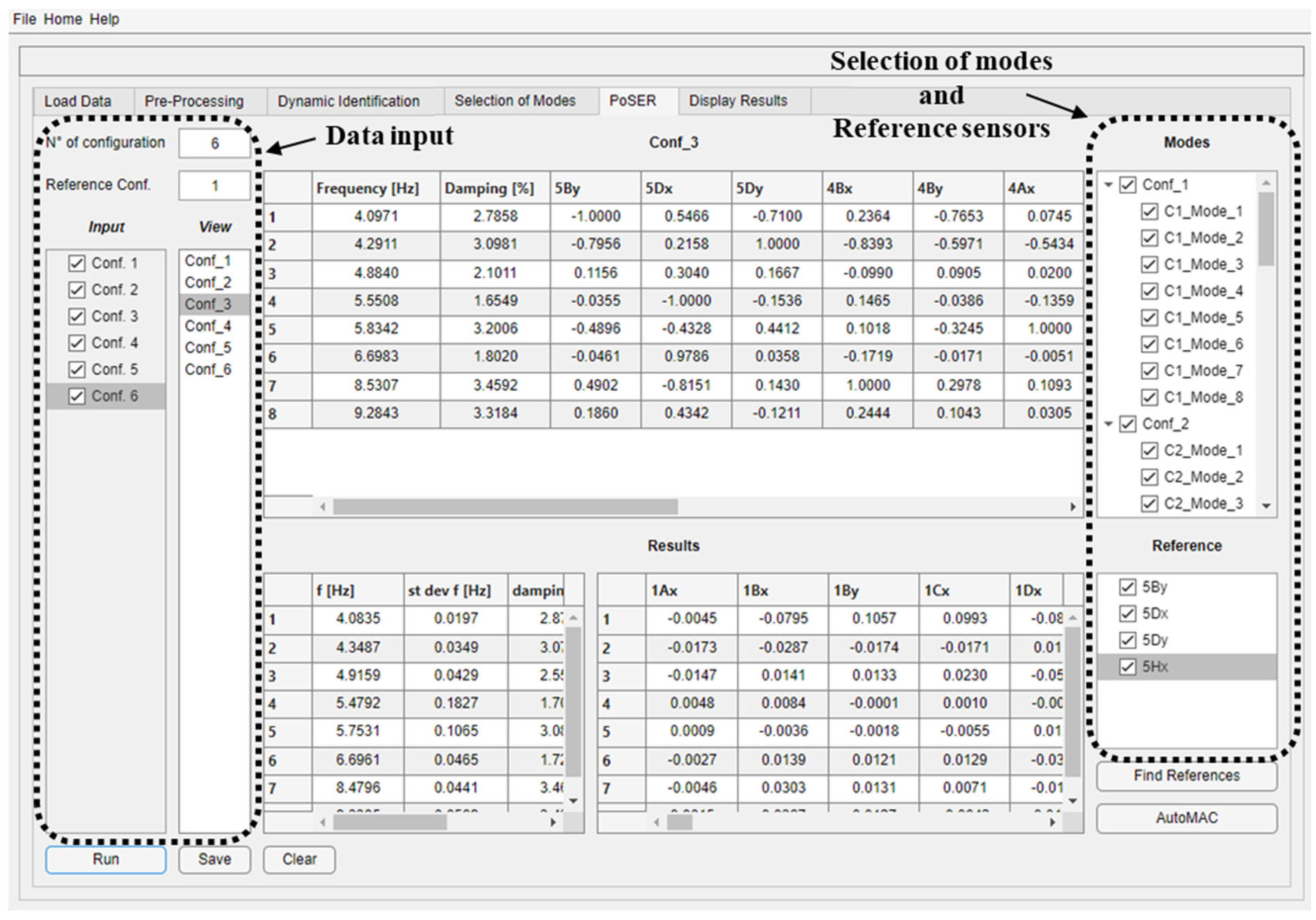

6. Module for Merging Results from Multiple Test Set-Ups

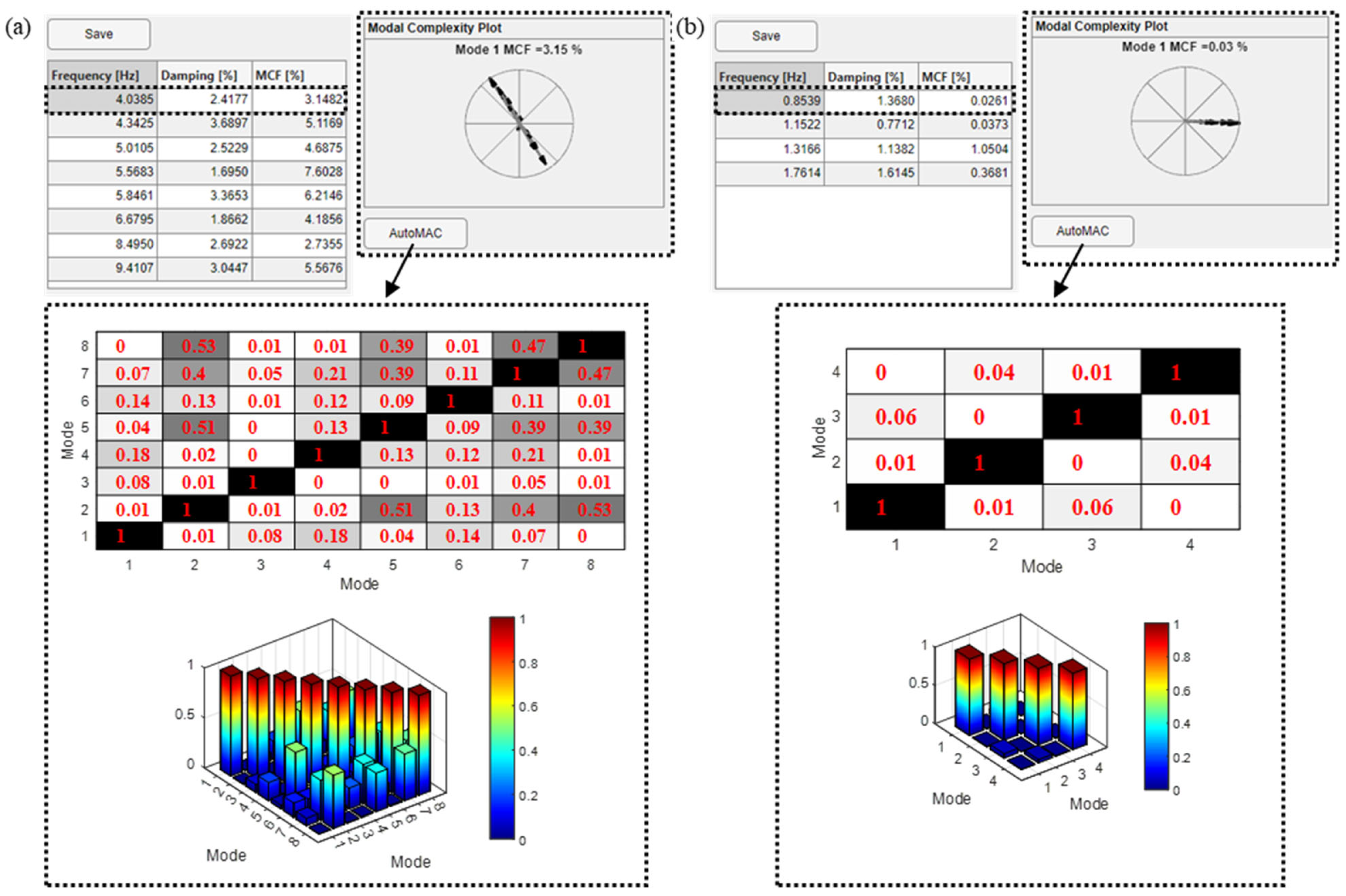

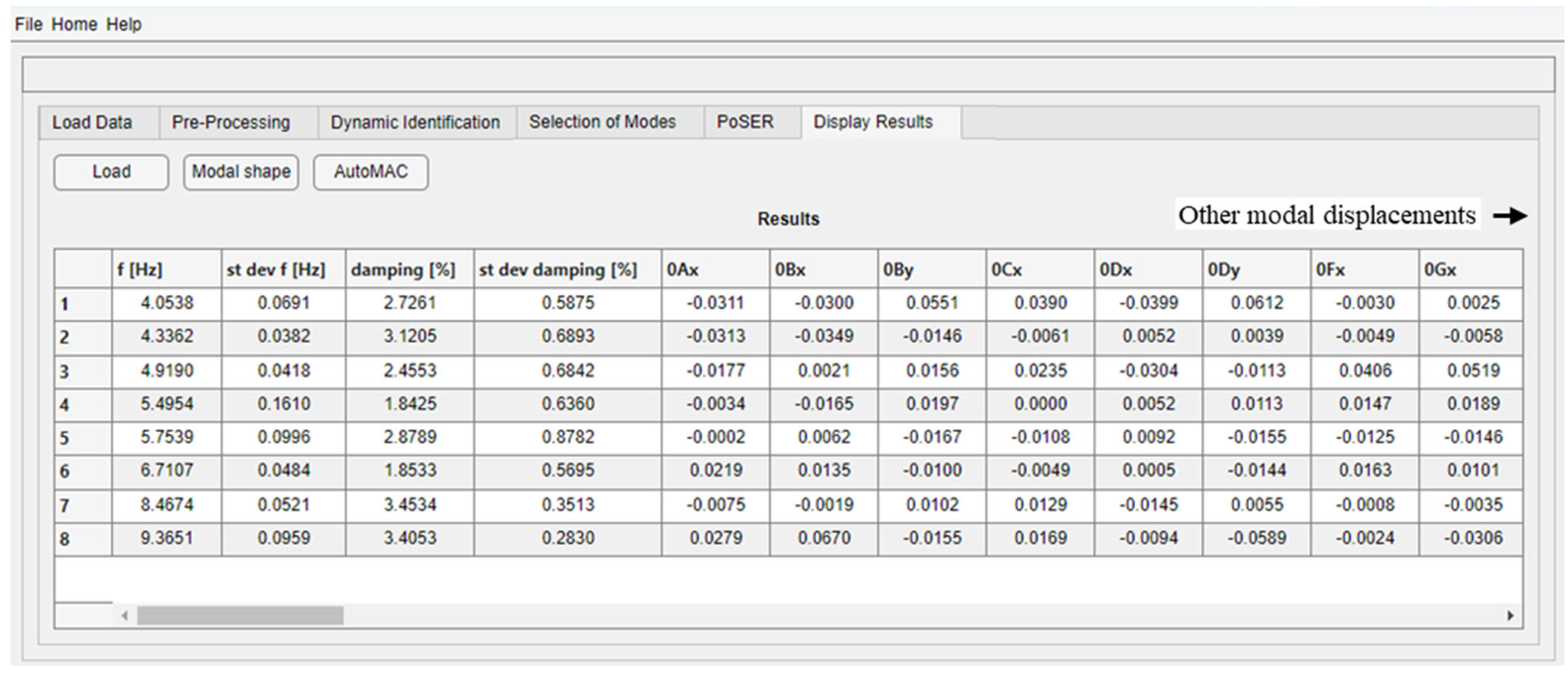

7. Module to Display Results

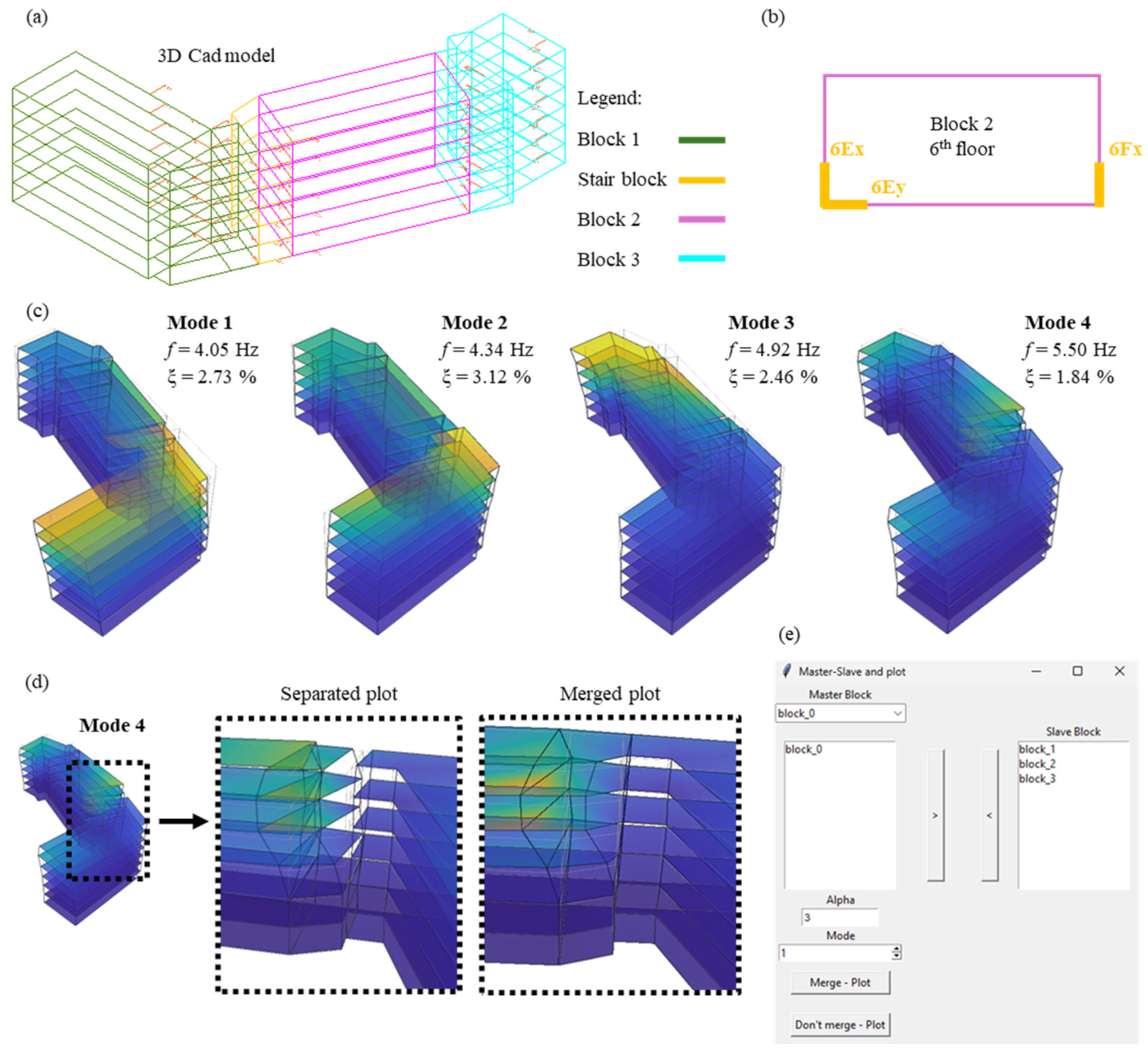

7.1. Tool to Display Mode Shapes for Buildings

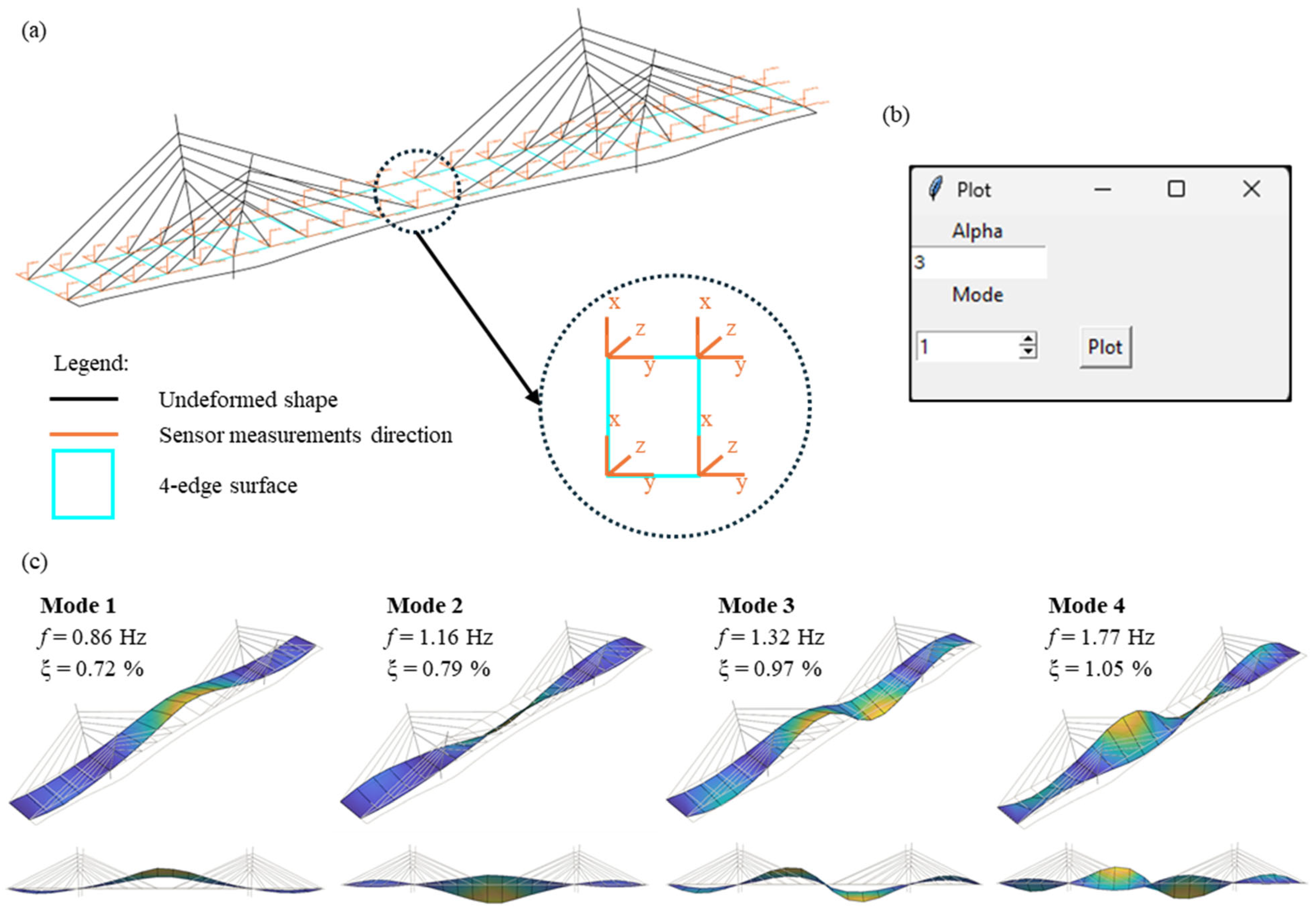

7.2. Tool to Display Mode Shapes for Bridges

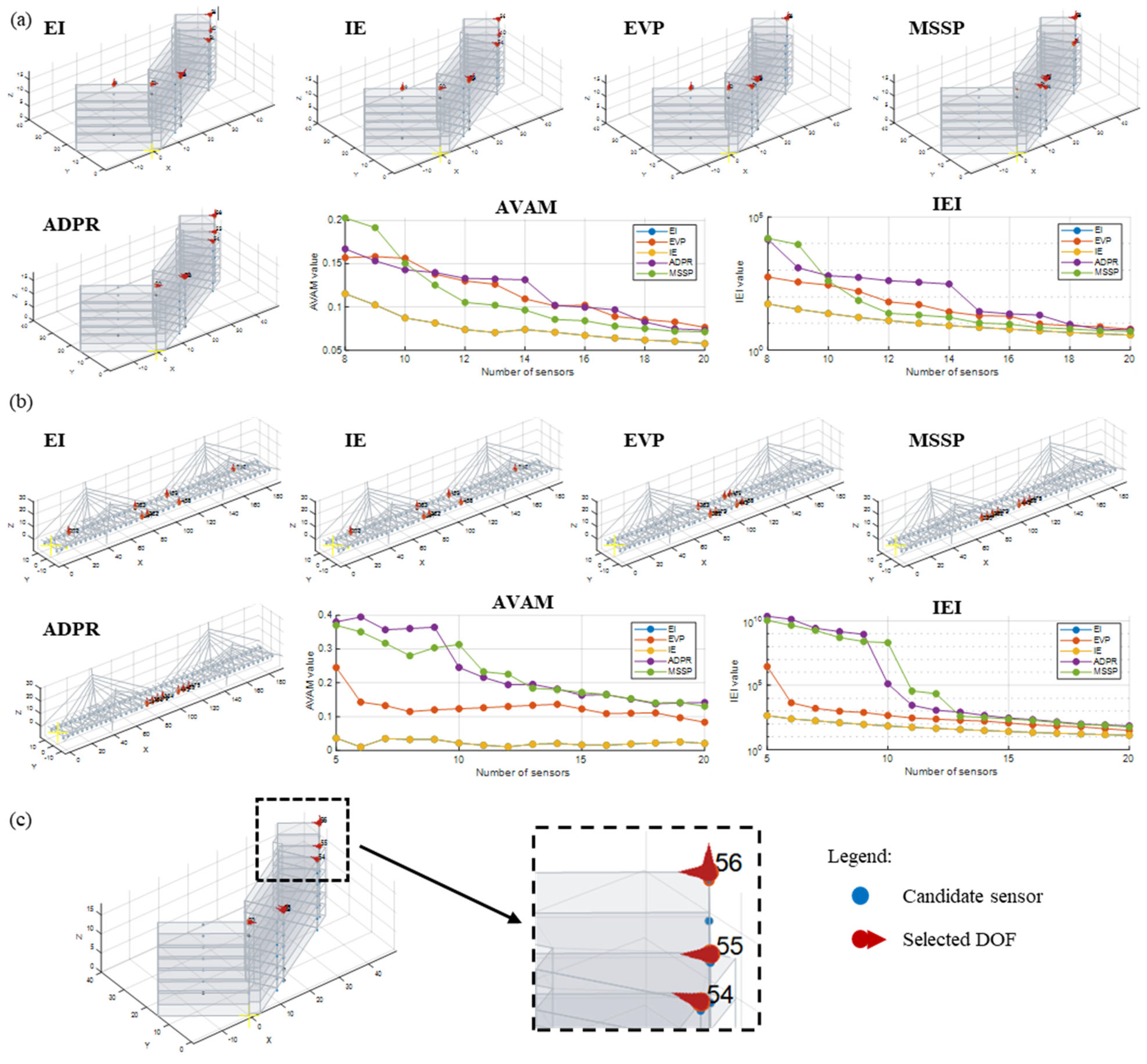

8. Module for the OSP

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rainieri, C.; Fabbrocino, G. Development and validation of an automated operational modal analysis algorithm for vibration-based monitoring and tensile load estimation. Mech. Syst. Signal Process. 2015, 60, 512–534. [Google Scholar] [CrossRef]

- Amador, S.D.R.; Brincker, R. The new Subspace-based poly-reference Complex Frequency (S-pCF) for robust frequency-domain modal parameter estimation. Meas. J. Int. Meas. Confed. 2024, 225, 113995. [Google Scholar] [CrossRef]

- Maes, K.; Van Meerbeeck, L.; Reynders, E.P.B.; Lombaert, G. Validation of vibration-based structural health monitoring on retrofitted railway bridge KW51. Mech. Syst. Signal Process. 2022, 165, 108380. [Google Scholar] [CrossRef]

- Giordano, P.F.; Quqa, S.; Limongelli, M.P. The value of monitoring a structural health monitoring system. Struct. Saf. 2023, 100, 102280. [Google Scholar] [CrossRef]

- Oyarzo-Vera, C.; Ingham, J.; Chouw, N. Vibration-based damage identification of an unreinforced masonry house model. Adv. Struct. Eng. 2017, 20, 331–351. [Google Scholar] [CrossRef]

- Pereira, S.; Magalhães, F.; Gomes, J.P.; Cunha, Á. Modal tracking under large environmental influence. J. Civ. Struct. Health Monit. 2022, 12, 179–190. [Google Scholar] [CrossRef]

- Ventura, C.E.; Schuster, N.D. Structural dynamic properties of a reinforced concrete high-rise building during construction. Can. J. Civ. Eng. 1996, 23, 950–972. [Google Scholar] [CrossRef]

- Anastasopoulos, D.; De Roeck, G.; Reynders, E.P.B. One-year operational modal analysis of a steel bridge from high-resolution macrostrain monitoring: Influence of temperature vs. retrofitting. Mech. Syst. Signal Process. 2021, 161, 107951. [Google Scholar] [CrossRef]

- Pereira, S.; Magalhães, F.; Gomes, J.P.; Cunha, Á.; Lemos, J.V. Vibration-based damage detection of a concrete arch dam. Eng. Struct. 2021, 235, 112032. [Google Scholar] [CrossRef]

- Diord, S.; Magalhães, F.; Cunha, A.; Caetano, E. High spatial resolution modal identification of a stadium suspension roof: Assessment of the estimates uncertainty and of modal contributions. Eng. Struct. 2017, 135, 117–135. [Google Scholar] [CrossRef]

- Borlenghi, P.; Gentile, C.; D’Angelo, M.; Ballio, F. Long-term monitoring of a masonry arch bridge to evaluate scour effects. Constr. Build. Mater. 2024, 411, 134580. [Google Scholar] [CrossRef]

- Arezzo, D.; Quarchioni, S.; Nicoletti, V.; Carbonari, S.; Gara, F.; Leonardo, C.; Leoni, G. SHM of historical buildings: The case study of Santa Maria in Via church in Camerino (Italy). Procedia Struct. Integr. 2023, 44, 2098–2105. [Google Scholar] [CrossRef]

- Diaferio, M.; Foti, D.; Giannoccaro, N.I.; Ivorra, S. Model updating based on the dynamic identification of a baroque bell tower. Int. J. Saf. Secur. Eng. 2017, 7, 519–531. [Google Scholar] [CrossRef]

- Ierimonti, L.; Cavalagli, N.; Venanzi, I.; García-Macías, E.; Ubertini, F. A transfer Bayesian learning methodology for structural health monitoring of monumental structures. Eng. Struct. 2021, 247, 113089. [Google Scholar] [CrossRef]

- Innocenzi, R.D.; Nicoletti, V.; Arezzo, D.; Carbonari, S.; Gara, F.; Dezi, L. A Good Practice for the Proof Testing of Cable-Stayed Bridges. Appl. Sci. 2022, 12, 3547. [Google Scholar] [CrossRef]

- Nicoletti, V.; Arezzo, D.; Carbonari, S.; Gara, F. Dynamic monitoring of buildings as a diagnostic tool during construction phases. J. Build. Eng. 2022, 46, 103764. [Google Scholar] [CrossRef]

- Wah, W.S.L.; Chen, Y.-T.; Roberts, G.W.; Elamin, A. Separating damage from environmental effects affecting civil structures for near real-time damage detection. Struct. Health Monit. 2018, 17, 850–868. [Google Scholar] [CrossRef]

- Ubertini, F.; Cavalagli, N.; Kita, A.; Comanducci, G. Assessment of a monumental masonry bell-tower after 2016 Central Italy seismic sequence by long-term SHM. Bull. Earthq. Eng. 2018, 16, 775–801. [Google Scholar] [CrossRef]

- MOVA/MOSS: Two integrated software solutions for comprehensive Structural Health Monitoring of structures. Mech. Syst. Signal Process. 2020, 143, 106830. [CrossRef]

- Pasca, D.P.; Aloisio, A.; Rosso, M.M.; Sotiropoulos, S. PyOMA and PyOMA_GUI: A Python module and software for Operational Modal Analysis. SoftwareX 2022, 20, 101216. [Google Scholar] [CrossRef]

- Peeters, B. System Identification and Damage Detection in Civil Engineering; KU Leuven: Leuven, Belgium, 2000. [Google Scholar]

- Brincker, R. Some Elements of Operational Modal Analysis. Shock Vib. 2014, 2014, 325839. [Google Scholar] [CrossRef]

- Van Overschee, P.; De Moor, B. Subspace identification for linear systems. In Theory, Implementation, Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996; Volume 14, p. 254. [Google Scholar] [CrossRef]

- Brincker, R.; Ventura, C.; Andersen, P. Damping estimation by Frequency Domain Decomposition. In Proceedings of the International Modal Analysis Conference, Kissimmee, FL, USA, 5–8 February 2001. [Google Scholar]

- Sevim, B.; Bayraktar, A.; Altunişik, A.C.; Adanur, S.; Akköse, M. Modal Parameter Identification of a Prototype Arch Dam Using Enhanced Frequency Domain Decomposition and Stochastic Subspace Identification Techniques. J. Test. Eval. 2010, 38, 588–597. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Pearson: London, UK, 2017. [Google Scholar]

- Magalhães, F.; Cunha, Á.; Caetano, E. Online automatic identification of the modal parameters of a long span arch bridge. Mech. Syst. Signal Process. 2009, 23, 316–329. [Google Scholar] [CrossRef]

- Parloo, E. Application of Frequency-Domain System Identification Techniques in the Field of Operational Modal Analysis. Ph.D. Thesis, Vrije Universiteit Brussel, Ixelles, Belgium, 2003. [Google Scholar]

- SAP2000|STRUCTURAL ANALYSIS AND DESIGN. Available online: https://www.csiamerica.com/products/sap2000 (accessed on 17 June 2024).

- SAP+MATLAB. 2024. Available online: https://it.mathworks.com/matlabcentral/fileexchange/79271-sap-matlab (accessed on 17 June 2025).

- Nicoletti, V.; Quarchioni, S.; Martini, R.; Gara, F.; Gaile, L.; Singh, H. A Novel Software Tool for the Optimal Sensor Placement in Civil Engineering Structures. In Proceedings of the 10th International Operational Modal Analysis Conference (IOMAC 2024), Naples, Italy, 22–24 May 2024; Rainieri, C., Gentile, C., Aenlle López, M., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2024; Volume 514, pp. 448–455. [Google Scholar] [CrossRef]

- Nicoletti, V.; Quarchioni, S.; Amico, L.; Gara, F. Assessment of different optimal sensor placement methods for dynamic monitoring of civil structures and infrastructures. Struct. Infrastruct. Eng. 2024. [Google Scholar] [CrossRef]

- Nicoletti, V.; Amico, L.; Martini, R.; Carbonari, S.; Gara, F.; Dezi, F. The Monitoring System of the New Filomena Delli Castelli Cable-Stayed Bridge. In Experimental Vibration Analysis for Civil Engineering Structures 2023; Limongelli, M.P., Giordano, P.F., Quqa, S., Gentile, C., Cigada, A., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2023; Volume 432, pp. 401–411. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gara, F.; Quarchioni, S.; Nicoletti, V. DYMOS: A New Software for the Dynamic Identification of Structures. Buildings 2025, 15, 2194. https://doi.org/10.3390/buildings15132194

Gara F, Quarchioni S, Nicoletti V. DYMOS: A New Software for the Dynamic Identification of Structures. Buildings. 2025; 15(13):2194. https://doi.org/10.3390/buildings15132194

Chicago/Turabian StyleGara, Fabrizio, Simone Quarchioni, and Vanni Nicoletti. 2025. "DYMOS: A New Software for the Dynamic Identification of Structures" Buildings 15, no. 13: 2194. https://doi.org/10.3390/buildings15132194

APA StyleGara, F., Quarchioni, S., & Nicoletti, V. (2025). DYMOS: A New Software for the Dynamic Identification of Structures. Buildings, 15(13), 2194. https://doi.org/10.3390/buildings15132194