Abstract

In this work, the indoor thermal environment and indoor air quality of rural houses in Northern China were investigated in detail. The current heating situation in rural areas, the causes of indoor air pollution, and the indoor ventilation habits of residents were analyzed. The indoor thermal environment and indoor air quality were improved by upgrading the thermal insulation of the rural housing envelope and installing indoor ventilation systems with heat recovery, leading to an average indoor temperature increase of 6 °C. The Predicted Mean Vote reached approximately 1.0, so the human body heat sensation was more moderate. The air age was greatly reduced, and the indoor air quality was significantly improved. The Predicted Percentage of Dissatisfied dramatically decreased to 15%. Thus, when focusing on heat source renovation in rural areas, priority should be given to improving the energy efficiency of buildings, especially the building envelope insulation performance. Ventilation and air exchange systems with heat recovery are inexpensive and effective, and they are suitable for rural dwellings where the temperatures are not as high as they should be but where the indoor air quality is poor and ventilation is urgently needed.

1. Introduction

Rural dwellings are an important part of China’s residential buildings, and their energy consumption accounts for 24% of the country’s total building energy consumption []. Residential heating energy consumption accounts for more than 45% of total energy consumption and is at the top of the list of rural residential energy consumption. With the development of energy-saving work in rural buildings in Northern China, the thermal performance of building envelopes has greatly improved, the proportion of energy-efficient equipment used has increased, and the energy consumption per unit area of a building has shown a downward trend []. In recent years, some new houses in rural areas have begun to pay attention to the design of wall insulation [,], the airtightness of external windows, and the design of thermal insulation [,]. The indoor thermal environment condition has improved, but it still does not fully meet the requirements of thermal comfort. Most of China’s rural areas are extremely outdated in terms of heating and other forms of domestic energy use, with rudimentary heating equipment and old technology. Solid fuels such as biomass are predominantly burned directly, with low combustion and energy utilization efficiencies, resulting in a considerable waste of energy []. Moreover, there are essentially no effective smoke exhaust measures in rooms, resulting in poor indoor air quality that affects human health []. In rural Northern China, the average outdoor winter temperature typically falls below −10 °C. The thermal insulation performance of rural residential building envelopes is generally poor, resulting in substantial heat loss. Most households rely on solid fuels for heating, which are not only inefficient but also cause severe pollution. Insufficient indoor ventilation leads to the accumulation of pollutants that are difficult to dissipate. Additionally, the combined use of heating and cooking systems increases indoor humidity levels, creating conditions prone to mold contamination.

Ventilation is a well-known effective way to reduce or remove indoor air contaminants that building occupants might otherwise be exposed to. The advantage of natural ventilation is that it can be integrated into the building design and does not consume energy. There are various ways to create natural ventilation in a building. Numerous studies have sought to identify the most effective natural ventilation and shading techniques to reduce overheating problems during hot seasons [,,]. Design focuses and space prototypes for ‘space–airflow’ connections from multiscale spaces were proposed by Yueming Wen []. The following are some highlights of the design: the urban scale, site scale, building scale, and room scale. Natural ventilation can be efficiently improved by carefully planning the design and arrangement of spaces. There are also many innovations in the form of natural ventilation design for residential applications. Unaffected by the wind direction, a unique windcatcher with inlet apertures fitted with flap fins was proposed to provide fresh air []. The authors of [] suggested a passive, horizontally pivoting window with a sash that could be moved to alter the size of the window opening. Wind towers are low-energy ventilation systems that can offer cooling and lower the energy consumption of buildings [,]. Passive ventilation devices called solar chimneys use solar energy to supplement or replace mechanical ventilation [,]. Natural ventilation can also be combined with phase change materials to improve building energy efficiency [,]. However, natural ventilation flow size, velocity size, and air quality requirements are uncontrolled; therefore, they cannot meet high indoor comfort requirements [].

Mechanical ventilation systems have been extensively investigated and employed to remove or reduce indoor air pollution. The majority of mechanical ventilation systems may be able to maintain the indoor air quality of residential buildings at a modest level. Research on residential mechanical ventilation systems can be divided into the performance of ventilation systems, occupants’ ventilation behavior, and heat recovery techniques. Vahur Maask [] suggested techniques for controlling the flexibility of ventilation systems, allowing for the use of ventilation systems with flexible service. The effects of ventilation factors on the energy efficiency of a building were examined by Marco S []. Dayi Lai [] suggested a paradigm for examining ventilation behavior in residential buildings. The utilization of heat recovery over mechanical ventilation systems is one of the primary strategies to minimize heat loss and achieve energy savings when ventilation heat loads increase. Seongjun Park [] measured how the overall particle removal performance of a heat recovery ventilation (HRV) system is impacted by the effectiveness of the HRV filter, airflow rate, and filter bypass factor. The primary categories of heat recovery technology for residential construction applications in cold-temperature regions have been described by H.Y. Bai []. Rotary wheels, flat-plate heat exchangers, and heat pipes are the main types of structural forms. Mechanical ventilation systems are more suitable for buildings with better airtightness, but they are more expensive to use and are currently not applicable to all residential buildings, especially in rural areas with poorer economic conditions. In China, rural residential buildings typically use natural ventilation as their ventilation strategy [].

Low indoor temperatures and poor room airtightness in rural areas during the winter result in an uncomfortable indoor thermal environment. The burning of fuel necessary for indoor heating and cooking causes serious indoor air pollution. In this work, the indoor thermal environment and indoor air quality of rural dwellings in Northern China were investigated and tested in detail, and the current situation of rural heating, causes of indoor air pollution, and indoor ventilation behaviors and habits were analyzed. This study aims to improve the indoor thermal environment and air quality in Northern China’s rural residential buildings by optimizing envelope insulation and introducing heat recovery ventilation systems, providing feasible technical solutions for low-carbon heating and healthy living in rural areas.

2. Materials and Methods

2.1. Research on Ventilation and Air Exchange Technology for Rural Dwellings

A questionnaire survey was conducted to understand the current situation of ventilation and air exchange in rural houses in Northern China and the subjective feelings of residents about indoor air quality to provide basic data for the design of reasonable and effective ventilation and air exchange measures. The survey and testing locations were situated in Northeast China, which falls under the severe cold climate zone according to China’s climatic classification. This region is characterized by an average temperature at or below −10 °C in the coldest month. The relevant questions of the questionnaire are shown in Table 1.

Table 1.

Survey questionnaire content.

On the basis of the questionnaire survey, five houses in a rural area of Jilin Province with typical residential structures and energy forms were selected for field tests. The test instruments and test contents are shown in Table 2. The outdoor air velocity measurement point was located 5 m away from the outer wall. The indoor temperature and humidity measurement points were arranged at heights of 1.1 m and 1.6 m from the floor. This position represents the approximate height when sitting and standing, respectively. Data were recorded every 300 s during the test, and the monitoring was continuous for 24 h. The indoor CO2 concentration measurement points were also arranged at this height, and data were recorded every 10 s. The test period was for 3 consecutive min.

Table 2.

Test equipment parameters.

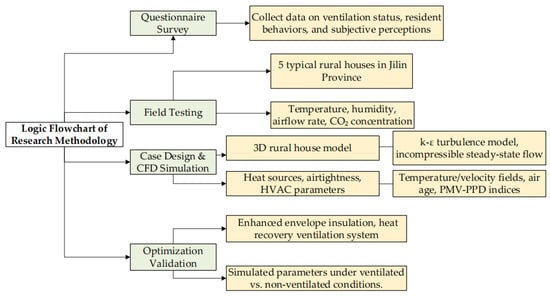

The research methodology is illustrated in the following flowchart (Figure 1).

Figure 1.

Research methodology flowchart.

2.2. Case Design

The supply air input and exhaust air outlet together determine the airflow pattern of a building []. A combination of indoor airflow organization, air age, and indoor thermal comfort needs to be monitored in the case of mechanical ventilation design, and the computational fluid dynamics (CFD) method is adopted. The calculation method used is the k-ε model proposed by Launder and Spalding [].

To simplify the problem of simulating and calculating the impact of ventilation and air exchange technology on the thermal comfort of the indoor environment, the following assumptions are made:

(1) The indoor airflow is an incompressible constant physical Newtonian fluid with steady-state turbulent flow;

(2) Solar radiation and the influence of radiation heat transfer from surfaces in the room are not considered;

(3) Doors, windows, and walls are well sealed, approximating an airtight environment without considering the impact of air leakage, which is very important for simulation studies of ventilation and air exchange conditions.

A three-dimensional model is used to analyze the temperature and flow fields of the rural housing model. Despite its complexity, the airflow and heat transfer system of a chamber meets the momentum, energy, and continuity equations [,,,], and Equations (1)–(3) are used to calculate these factors.

where ρ is the density, kg/m3; xi is the directional component, m; p is the pressure, Pa; μ is the dynamic molecular viscosity, m2/s; μT is the turbulent eddy viscosity, m2/s; gi is the acceleration of gravity, m/s2; cp is the specific heat capacity, J/(kg·K); λ is the thermal molecular conductivity, W/(m·K); λT is the turbulent thermal conductivity, W/(m·K); T is the temperature, K; and ρ0 is the reference temperature.

The default settings for the model constants, which are determined from fundamental turbulence studies, are c1 (1.44), c2 (1.92), cμ (0.09), σκ (1.0), and σε (1.3) [,].

The length, width, and height of the building are 10.8 m, 8.4 m, and 3.3 m, respectively. The size of the air supply outlet is 1 m × 1 m, and the size of the air return outlet is 1 m × 1 m. The layout of the rooms in the building is set up according to the layout of an ordinary farmhouse: kitchen, bathroom, living room, and two bedrooms. To simplify the calculation, the indoor equipment computer is simplified to a square model, the fluorescent lamps are simplified to a square model, and the residents are designed to be in a standing position, which is simplified to a rectangular model. The coordinate origin is the southwest corner of the room of the ground vertex, and the physical model is shown in Figure 2.

Figure 2.

Residential models in Shenyang.

The Shenyang area ventilation calculation parameters are as follows: the winter outdoor calculation temperature is −19 °C, and the summer outdoor calculation temperature is 31.4 °C. Indoor heat sources include humans, computers, lamps, lanterns and geothermal coil heat dissipation. The calculation of the Predicted Mean Vote (PMV) and Predicted Percentage of Dissatisfied (PPD) is based on the situation where the person is sitting still, and the metabolic rate of the human body is 58 W/m2. The work performed by the human body on the outside is not taken into account, the clothing is normal summer clothing, and the thermal resistance of the clothing is 0.08 [m2·K/W(0.5 clo)]. The boundary conditions for the numerical simulation calculations are shown in Table 3.

Table 3.

Boundary conditions.

The heat transfer coefficient of the external envelope is enhanced with reference to the German passive house [] and the Chinese ultralow energy building design standards []. The heat transfer coefficient of the external windows is set at 0.8 W/(m2·K), and that of the external walls is 0.15 W/(m2·K). High-efficiency fresh air systems with heat recovery are designed to replace indoor air, control air humidity, prevent mold and mildew, prevent the buildup of pollutants, and eliminate odors. In Germany, this system is necessary for passive buildings; it reduces heat loss, increases the fresh air temperature, and increases indoor comfort []. Fresh air ventilation systems have become an integral and important part of buildings. German building energy-saving regulations require that buildings be designed with ventilation in mind. Moreover, the heat exchange efficiency needs to be 60% to 80% []. At the preliminary design stage, the architect must communicate with the HVAC engineer to determine the requirements of the new air volume and the installation location of the new air unit, as well as the locations of the inlet and outlet of the new air unit. The parameters of the new air exchanger selected for this program are shown in Table 4.

Table 4.

Fresh air ventilator equipment parameters.

3. Results and Discussion

3.1. Summary of the Research Questionnaire Results

3.1.1. Characteristics of Energy Consumption

Among the rural dwellings studied, the proportion of one-story dwellings was 78%, whereas the proportion of two-story dwellings was 22%. The proportion of building structures that were brick houses was 92%, and the proportion of adobe houses was 8%. This shows that one-story brick houses are the typical form of rural dwelling in Northern China.

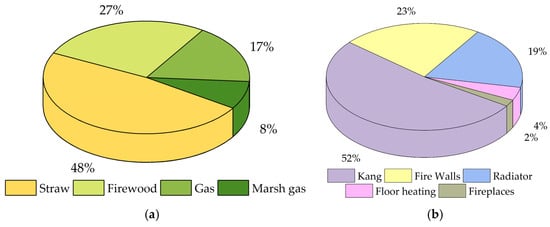

The proportion of daily cooking energy was 48% for straw, 27% for fuel wood, 17% for gas, and 8% for biogas (Figure 3a). The proportion of straw and fuel wood choices was 75%. The burning of large quantities of straw and fuel wood inevitably increases air pollution in dwellings and jeopardizes health. The choice of heating method was varied. The kang is a form of residential heating in rural China with a long history, and in our research study (Figure 3b), 52% of households used this traditional method. The proportion of fire walls associated with the kang was 23%. In addition, the proportion of fireplaces was 2%, the proportion of radiators was 19%, and the proportion of floor heating was 4%. The form of heating in winter in rural areas in Northern China is mainly based on the kang because it can also be used as a stove to fulfill the requirements of cooking and boiling water.

Figure 3.

Rural residential fuel combustion statistics. (a) Selection of heat sources for rural cooking and heating; (b) choice of heating end method.

3.1.2. Indoor Pollution Characteristics

For rural dwellings, in addition to the pollution generated by the burning of straw and firewood, the questionnaire survey revealed that smoking behavior, house decoration, and moldy indoor walls were the main sources of indoor air pollution. Among the residents who completed the questionnaire, as presented in Table 5, 72% were smokers. With the improvement in the rural economic level, the decoration requirements of rural houses increased, and the percentage of those who had not carried out house decoration was 26%. Decoration materials are persistent sources of many environmental pollutants, releasing various volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs) that contribute to indoor air pollution []. In winter, the heating effect of rural dwellings is poor, and the indoor temperature is low, resulting in indoor wall frost and mold, with 31% of households experiencing indoor wall frost and mold.

Table 5.

Indoor pollution questionnaire.

3.1.3. Rural People’s Work and Rest

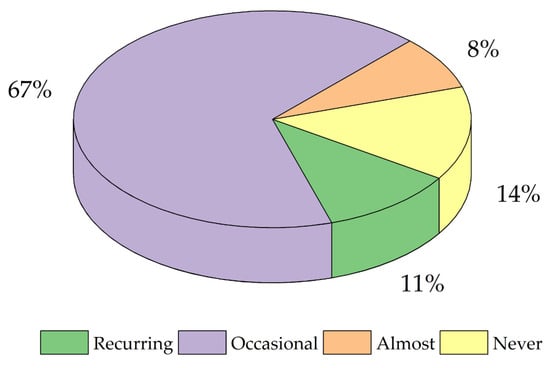

The work and rest habits of villagers are characterized by shorter home stays during busy farming seasons and longer stays during slack farming seasons. According to the results of the questionnaire survey, in the winter, the proportion of people who stayed at home for more than 8 h was 61%, and the proportion of people who stayed at home for less than 8 h was 39%. Winter is a period of agricultural leisure. The percentage of households whose windows were sealed with plastic film in winter was 60%, and the percentage of those without sealing measures was 40%. The use of plastic film seals allows for improved airtightness and insulation in the home but can affect the amount of time windows can be opened. We also interviewed residents about whether they were concerned about indoor air pollution (Figure 4). A total of 72% of the residents were aware of indoor air pollution, with 40% wanting to keep an eye on the situation, while only 28% were not very concerned. The percentage of those who experienced mild discomfort at home, such as sleepiness, dizziness, nausea, and headache, was as high as 67%.

Figure 4.

Research on symptoms of physical discomfort.

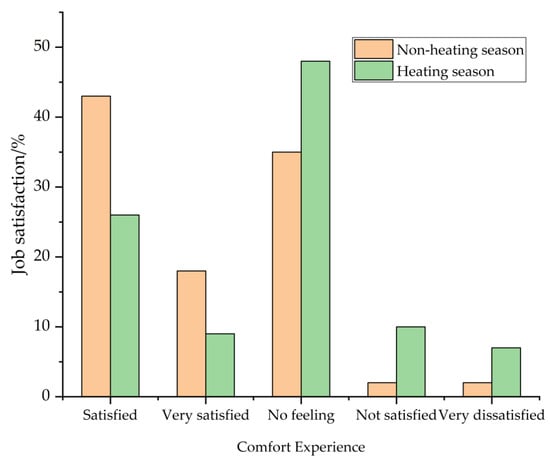

3.1.4. Indoor Air Quality Satisfaction Survey

The results of the survey on residents’ satisfaction with indoor air quality showed that during the heating season, the majority of people (48%) considered their indoor air quality to be poor. The proportion of those who were satisfied was 26%, and the proportion of those who were very satisfied was only 9%. The proportion of those who were dissatisfied and very dissatisfied was 17%. In contrast, during the non-heating season, the majority of people (43%) were satisfied with their indoor air quality, and those that were very satisfied was 18%. Thirty-five percent considered their indoor air quality to be poor, and four percent were dissatisfied and very dissatisfied (Figure 5). People were more satisfied with their indoor air quality in the non-heating season than in the heating season, but 39% of the residents still found their indoor air quality to be unsatisfactory in the non-heating season.

Figure 5.

Indoor air quality satisfaction survey.

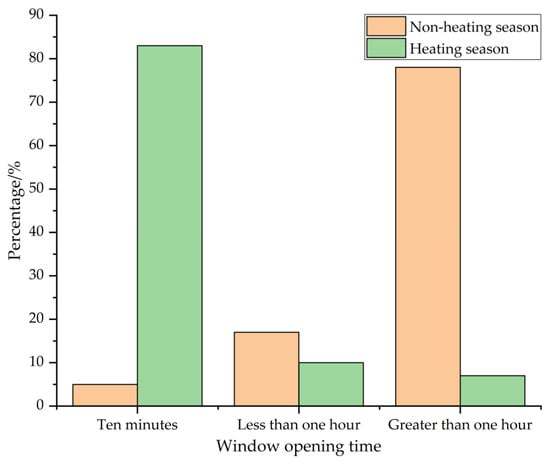

3.1.5. Research on Indoor Ventilation Habits

Opening windows for ventilation is the most common ventilation measure in rural dwellings. According to the results of the questionnaire survey, as illustrated in Figure 6, 74% of residents would choose to open windows for ventilation in the morning in summer, and 66% would open windows for more than one hour. In winter, the proportion of those who open windows frequently was 19%, the proportion of those who occasionally open windows for ventilation because of room odor was 43%, and the proportion of those who never open windows was 38%. A total of 71% of residents chose to open windows for ventilation in the morning when sunny, 47% would open windows for less than ten minutes, and 25% would open windows for more than one hour. In addition to opening windows for ventilation, only 21% of the residences had other measures for ventilation and air exchange, including exhaust fans or skylights. The current situation of ventilation in rural dwellings needs to be improved, not only because there is no good guidance on window opening behavior but also because there are no reasonable ventilation measures.

Figure 6.

Window opening time.

The sources of indoor air pollution in rural homes include three main areas: fuel combustion, mold growth, and interior decoration. The findings in Figure 3 show that the form of heating in winter in rural areas in the North is mainly based on the kang because the kang can also be used as a stove to fulfill the requirements of cooking and boiling water. However, this type of heating has a low combustion efficiency, resulting in incomplete combustion that can produce many harmful gases. Moreover, the thermal insulation performance of rural residential enclosures is poor, the indoor temperature in winter is significantly affected by fluctuations in the outdoor temperature, the overall indoor temperature is low, and the relative humidity is high; these factors make it easy for molds and other microorganisms to grow. Figure 7 shows the smoke produced when a stove is used for heating and cooking combustion, accompanied by the production of a large amount of water vapor in the room. As the standard of living in rural areas has improved, the extensive use of man-made panels, decorative materials, and paint for indoor decoration has brought new sources of pollution to indoor air quality. All these pollutants are prevalent in dwellings in rural areas in Northern China, affecting people’s health and quality of life.

Figure 7.

Current status of rural housing. (a) Smoke from burning stove. (b) Water vapor in a room.

3.2. Field Tests of Ventilation and Air Exchange in Rural Dwellings

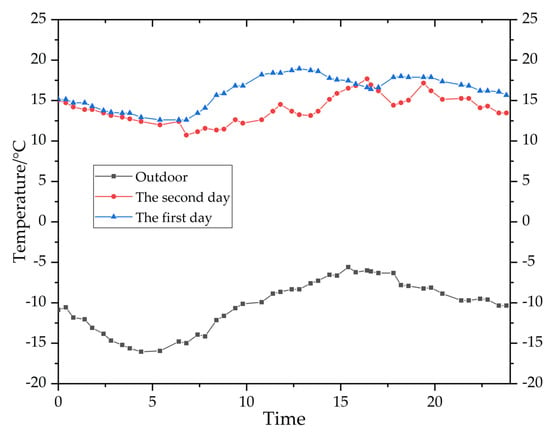

Winter testing of indoor environments in rural homes occurred in December. Typical test conditions were divided into two days. On the first day of testing, the windows of the residence were closed throughout the day. On the second day of testing, the residences followed a normal routine of opening and closing windows. The daily cooking times were 6:00, 12:00, and 17:00. CO2 concentration and air flow rate tests were conducted at 5:00, 9:00, 12:00, 15:00, 17:00, and 19:00 each day.

Figure 8 shows the indoor and outdoor temperature profiles. The lowest average outdoor temperature for both days was −15.0 °C, which occurred at 5:00 p.m. The highest average temperature of −5.6 °C occurred at 15:30 p.m. The indoor temperature trend was the same as the outdoor temperature trend, but there was a delay in time, and the indoor temperature fluctuation was delayed by approximately 1 h compared with the outdoor temperature fluctuation. On the first day, the interior was closed, and the indoor temperature was significantly higher than that on the second day. The minimum indoor temperature was 12.6 °C, and the maximum temperature was 18.9 °C. The trend of the indoor temperature on the first day was closer to the trend of the outdoor temperature. On the second day of testing, the indoor temperature decreased significantly compared with that on the first day because of the intermittent opening of windows in the room. The minimum indoor temperature was 10.7 °C, and the maximum temperature was 17.68 °C. The cooking times were approximately 6:00, 12:00, and 17:00; during this period, the cold outdoor air invaded the room, causing indoor heat loss, and the temperature suddenly decreased at these three time points. Compared with the trend of temperature change on the first day, the whole temperature profile was more volatile.

Figure 8.

Indoor and outdoor temperature curves.

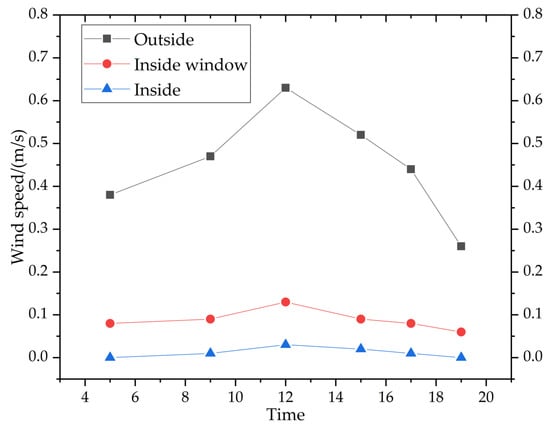

As shown in Figure 9, the indoor and outdoor wind speeds were measured at three locations: outdoors, on the inside of the window, and indoors. The outdoor wind speeds were higher in winter, and the local wind speeds were mostly at breezes of magnitude 2–3. The airtightness of the windows of rural houses is poor, and the wind speed inside the windows was obviously greater than the indoor wind speed. The indoor wind speed was approximately 0. During the cooking of three meals a day, there were significant fluctuations in the indoor wind speed during the cooking period, as there was the act of burning a fire in the kitchen, which was often accompanied by opening windows for ventilation.

Figure 9.

Indoor and outdoor air flow rate curves.

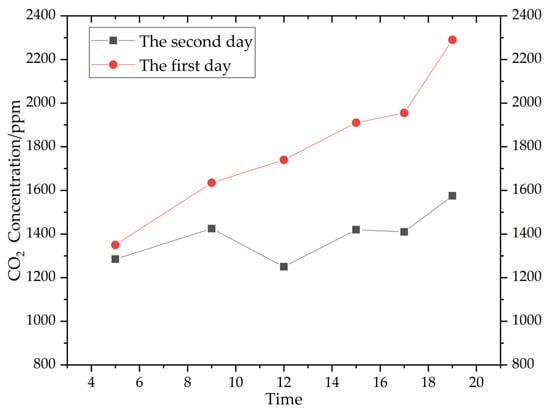

The magnitude of indoor CO2 concentration is an important parameter for measuring indoor air quality. On the first day, the windows were closed tightly and the CO2 produced in the residence could not be vented; thus, the concentration of CO2 gradually increased. The burning of large amounts of wood fuel for heating and cooking in winter resulted in a high overall indoor CO2 concentration in winter. At approximately 17:00, the indoor CO2 concentration reached more than 2000 ppm, exceeding the safety limit in the code to the extent that it jeopardizes the health of the residents []. On the second day of the test, the windows were opened in accordance with the normal living habits of the residents, the natural ventilation allowed CO2, smoke, and other gases to be expelled, and the indoor CO2 concentration was effectively reduced. This phenomenon would be better improved if burning wood was not used for heating in the house.

The indoor temperature in rural dwellings is low, reaching only approximately 20 °C with heating measures, which is 2 to 4 °C lower than the comfortable indoor temperature provided by centralized heating in urban dwellings. Moreover, only the kitchen and bedrooms in the residence are at a more suitable temperature; the coal-burning stove is in the kitchen, and the bedrooms have a kang bed-stove to dissipate heat or are equipped with a heating device. The living room and foyer are colder, mainly because of the poor thermal insulation of the door and window structure, as well as the cold air infiltration and cold air intrusion brought about by the entry and exit of people, which generates a greater heat load.

The high relative humidity of indoor air, caused by the intrusion of cold outdoor air and the production of water vapor during cooking activities, results in a low body temperature for the residents, which increases discomfort. Therefore, the control of humidity should not be neglected in the design of ventilation programs.

As shown in Figure 9, the airtightness of the windows of rural houses is poor, and the wind speed inside the windows is obviously greater than the indoor wind speed. When large quantities of fuel wood are burned for heating and cooking, the overall level of indoor CO2 concentration is high in winter, exceeding the safety limits in the design code and jeopardizing the health of indoor residents. As shown in Figure 10, briefly opening windows can effectively reduce the CO2 concentration but cannot solve its cumulative increase.

Figure 10.

Variation curve of the indoor carbon dioxide concentration.

3.3. Indoor Environment Simulation Under Winter Ventilated Conditions

Airpak 3.0 software was employed to solve the CFD equations and generate distributions of temperature, humidity, wind speed, air age, PMV, and PPD, which were analyzed with specific values 1.5 m above the floor in the room. Due to the good thermal insulation properties of the building envelope, heating is carried out in winter with very low energy consumption. The indoor temperature and relative humidity of the building meet the requirements for indoor comfort.

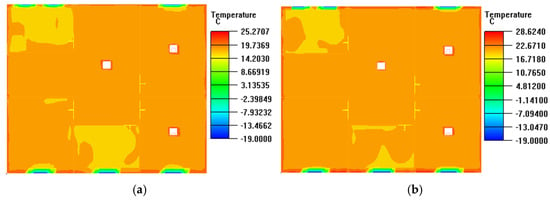

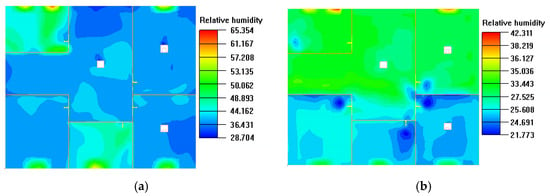

In the simulation process, fresh air relies on only recovered heat preheating without additional heat treatment. There is little difference between the room temperatures under the two simulated conditions. As shown in Figure 11 and Figure 12, compare the changes in temperature and humidity. The average indoor temperature in the room with the fresh air heat recovery system was 22 °C, and the average humidity was 35%. The indoor air was drier with the radiant floor heating system. The relative humidity in the room without a ventilation and air exchange system was approximately 35%. The relative humidity in a room with a ventilation and air exchange system is more suitable.

Figure 11.

Cloud view of indoor temperature changes. (a) Temperature in an unventilated room; (b) temperature in a ventilated room.

Figure 12.

Cloud view of indoor relative humidity changes. (a) Relative humidity in an unventilated room; (b) relative humidity in a ventilated room.

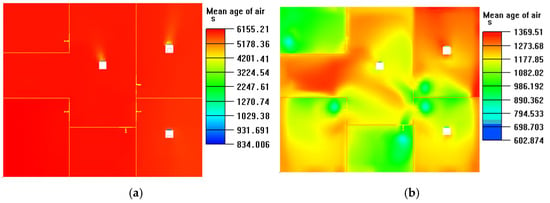

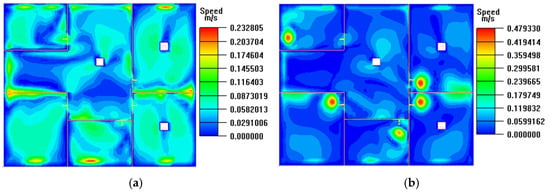

Figure 13 shows the average indoor air velocity, as compared with the air age in Figure 14. under the condition of no ventilation, the average indoor air flow velocity was 0.02 m/s. The air velocity near the center area of the room was nearly 0 m/s. Thus, many areas with stagnant air existed, and the indoor air age was as high as 6055 s. This indoor air quality is very poor and does not meet the fresh air needs of people in the room. The average indoor air velocity of the room with the fresh air system was 0.12 m/s, and the average air age was 1115.8 s, showing significant improvement in indoor air quality.

Figure 13.

Cloud view of the changes in indoor air age. (a) Mean age of air in an unventilated room; (b) mean age of air in a ventilated room.

Figure 14.

Cloud view of the changes in indoor air speed. (a) Air speed in an unventilated room; (b) air speed in a ventilated room.

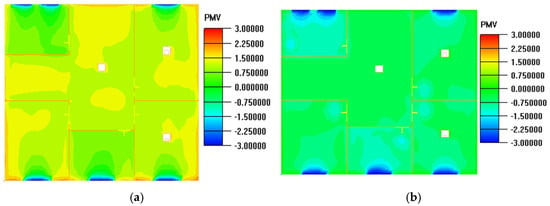

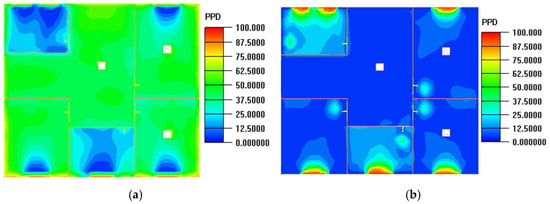

According to the widely accepted ASHRAE standard 55 [] and ISO 7730 standards [] for assessing indoor settings, thermal comfort is a condition of mind that expresses satisfaction with the thermal environment []. PMV-PPD is a typical method for comfort analysis. This study focused on thermal physiology. To analyze this situation, engineers must first ascertain the thermal sensation or thermal balance that occupants of an indoor space may feel in parallel with the thermal dissatisfaction that occupants experience.

As shown in Figure 15, when there was no indoor ventilation, the PMV value of the main activity area of the indoor residents was approximately 1.5; after the system with fresh air heat recovery was set up, the PMV value was approximately 1.0, and the heat feeling was more moderate. However, the thermal sensation on the side of the door and window was obviously cold because the airtightness of the doors and windows of the rural residence is poor; thus, the phenomenon of cold air intrusion and cold air infiltration is more obvious. To improve an indoor thermal environment, the airtightness of doors and windows is an important focus. As shown in Figure 16, when the indoor airtight environment was not ventilated, the indoor resident dissatisfaction rate was approximately 45%. After the system with fresh air heat recovery was set up, the per capita dissatisfaction rate decreased significantly to only 15%.

Figure 15.

Changes in indoor PMV values. (a) PMV in an unventilated room; (b) PMV in a ventilated room.

Figure 16.

Changes in indoor PPD values. (a) PPD in an unventilated room; (b) PPD in a ventilated room.

4. Conclusions

This study investigates the indoor thermal environment and air quality of rural residential buildings in Northern China, highlighting challenges such as poor insulation, inefficient heating, and high indoor pollution. The findings emphasize that, under the premise of energy conservation and carbon reduction, enhancing building insulation performance and installing heat recovery ventilation systems are crucial for ensuring residential thermal comfort and improving overall living conditions.

(1) The main methods of winter indoor heating in rural dwellings in Northern China are the kang, fire wall, and heater, accounting for more than 80% of dwellings. The energy consumed relies mainly on wood fuel and coal, accounting for 75% of the total energy consumed. Under the goals of carbon peaking and carbon neutrality, while the prevention of air pollution and the protection of people’s livelihoods are integrated, the proportion of clean energy heating should be further increased, not only by switching from coal to electricity or natural gas but also by integrating the use of renewable energy sources, such as geothermal, biomass, and solar energy sources, for heating to achieve lower carbon emissions.

(2) Rural residential envelope insulation performance is poor. The winter indoor temperature and humidity are significantly affected by the outdoor environment. The airtightness of doors and windows is poor, the heat loss caused by cold wind intrusion and cold wind infiltration is more serious, and exterior windows and doors produce obvious frost phenomena. While focusing on heat source renovation, priority should be given to the energy efficiency of the building. To make heating affordable for rural residents, it is necessary not only to improve the energy supply structure but also to increase the energy efficiency of rural area buildings. In particular, the thermal insulation performance of the building envelope needs to be improved to fundamentally reduce the energy demand of residents, and thereby, reduce their heating expenditure.

(3) Indoor air pollution in rural dwellings is more serious. One reason is the low efficiency of combustion appliances, which burn incompletely and produce harmful gases. Another reason is that a large amount of water vapor is produced in rooms during heating and cooking activities, leading to an environment that is prone to mold and microbial contamination. In addition, indoor air quality is closely related to building ventilation habits. Unlike urban buildings, winter in the countryside is a period of leisure, with farmers staying at home for long periods of time, and for potentially half of the year. To keep warm in the cold outdoor climate, the ventilation time between indoors and outdoors is shortened, and the proportion of frequently opened windows is only 19%. Mechanical ventilation systems in rural areas can be designed to use heat recovery, which will reduce cost even without considering the preheating of fresh air. These systems are suitable for rural dwellings where the thermal ambient temperature requirements are not high, but the indoor air quality is poor and ventilation is urgently needed.

Subsequent investigations will be dedicated to conducting comprehensive economic evaluations and carbon footprint analyses of retrofit strategies aimed at enhancing indoor environmental quality and thermal comfort in rural dwellings.

Author Contributions

L.Y.: supervision, conceptualization, writing—review and editing. X.H. and S.J.: conceptualization, supervision, writing—review and editing. Y.T.: methodology, writing—review and editing. X.X.: conceptualization, methodology, formal analysis, investigation, validation, writing—original draft. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Shandong Province (Grant number: ZR2021QE197), the Qingdao Agricultural University Doctoral Start-Up Fund (Grant number: 663/1122024) and the industry-academia cooperation project “The research and development of the key technologies for the optimization design of the indoor thermal environment of rural buildings and the improvement of the artistry and durability of decoration materials” (Grant number: 2025370203000711) funded by Linyi Taisheng Decoration Engineering Co., Ltd., Shandong, China.

Data Availability Statement

Raw data supporting the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Author Songyang Ju was employed by the company Shenyang Rundian Heating Power Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- China Building Energy Consumption Research Report. 2020. Available online: https://www.cabee.org/site/content/24021.html (accessed on 19 May 2025).

- Wang, Y.; Guo, L.; Ma, Y.; Han, X.; Xing, J.; Miao, W.; Wang, H. Study on operation optimization of decentralized integrated energy system in northern rural areas based on multi-objective. Energy Rep. 2022, 8, 3063–3084. [Google Scholar] [CrossRef]

- Lin, Y.; Zhao, L.; Yang, W.; Hao, X.; Li, C.-Q. A review on research and development of passive building in China. J. Build. Eng. 2021, 42, 102509. [Google Scholar] [CrossRef]

- Gao, Y.; He, F.; Meng, X.; Wang, Z.; Zhang, M.; Yu, H.; Gao, W. Thermal behavior analysis of hollow bricks filled with phase-change material (PCM). J. Build. Eng. 2020, 31, 101447. [Google Scholar] [CrossRef]

- Zhang, L.; Hou, Y.; Liu, Z.; Du, J.; Xu, L.; Zhang, G.; Shi, L. Trombe wall for a residential building in Sichuan-Tibet alpine valley—A case study. Renew. Energy 2020, 156, 31–46. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, T.; Liu, Z.; Hou, C.; Fukuda, H. A study on influencing factors of optimum insulation thickness of exterior walls for rural traditional dwellings in northeast of Sichuan hills, China. Case Stud. Constr. Mater. 2022, 16, e01033. [Google Scholar] [CrossRef]

- Bai, C.; Zhan, J.; Wang, H.; Yang, Z.; Liu, H.; Liu, W.; Wang, C.; Chu, X.; Teng, Y. Heating choices and residential willingness to pay for clean heating: Evidence from a household survey in rural China. Energy Policy 2023, 178, 113617. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.; Wu, F. Does energy transition improve air quality? Evidence derived from China’s Winter Clean Heating Pilot (WCHP) project. Energy 2020, 206, 118130. [Google Scholar] [CrossRef]

- Figueroa-Lopez, A.; Arias, A.; Oregi, X.; Rodríguez, I. Evaluation of passive strategies, natural ventilation and shading systems, to reduce overheating risk in a passive house tower in the north of Spain during the warm season. J. Build. Eng. 2021, 43, 102607. [Google Scholar] [CrossRef]

- Zoure, A.N.; Genovese, P.V. Implementing natural ventilation and daylighting strategies for thermal comfort and energy efficiency in office buildings in Burkina Faso. Energy Rep. 2023, 9, 3319–3342. [Google Scholar] [CrossRef]

- Guo, W.; Liang, S.; He, Y.; Li, W.; Xiong, B.; Wen, H. Combining EnergyPlus and CFD to predict and optimize the passive ventilation mode of medium-sized gymnasium in subtropical regions. Build. Environ. 2022, r207 Pt A, 108420. [Google Scholar] [CrossRef]

- Wen, Y.; Lau, S.-K.; Leng, J.; Zhou, K.; Cao, S.-J. Passive ventilation for sustainable underground environments from traditional underground buildings and modern multiscale spaces. Tunn. Undergr. Space Technol. 2023, 134, 105002. [Google Scholar] [CrossRef]

- Li, J.; Calautit, J.K.; Jimenez-Bescos, C. Experiment and numerical investigation of a novel flap fin louver windcatcher for multi-directional natural ventilation and passive technology integration. Build. Environ. 2023, 242, 110429. [Google Scholar] [CrossRef]

- Zhang, T.T.; Zhao, Y.; Wang, S.; Wang, J. A passive pivoted window for stabilizing the natural ventilation rate. Energy Build. 2022, 267, 112151. [Google Scholar] [CrossRef]

- Liu, M.; Jimenez-Bescos, C.; Calautit, J.K. Passive heat recovery wind tower: Assessing the overheating risk in summertime and ventilation heat loss reduction in wintertime. Sustain. Energy Technol. Assess. 2023, 58, 103310. [Google Scholar] [CrossRef]

- Liu, M.; Jimenez-Bescos, C.; Calautit, J.K. Performance evaluation of wind tower natural ventilation with passive solid tube heat recovery based on CO2 levels. J. Build. Eng. 2023, 72, 106457. [Google Scholar] [CrossRef]

- Hussein, M.; Maghrabie Abdelkareem, M.A.; Elsaid, K.; Sayed, E.T.; Radwan, A.; Rezk, H.; Wilberforce, T.; Abo-Khalil, A.G.; Olabi, A.G. A review of solar chimney for natural ventilation of residential and non-residential buildings. Sustain. Energy Technol. Assess. 2022, 52 Pt B, 102082. [Google Scholar]

- Fine, J.P.; Zhang, S.; Li, Y.; Touchie, M.F. Analysis of solar chimney ventilation systems in high-rise residential buildings using parallel flow networks. Build. Environ. 2022, 218, 109096. [Google Scholar] [CrossRef]

- Prabhakar, M.; Saffari, M.; de Gracia, A.; Cabeza, L.F. Improving the energy efficiency of passive PCM system using controlled natural ventilation. Energy Build. 2020, 228, 110483. [Google Scholar] [CrossRef]

- Piselli, C.; Prabhakar, M.; de Gracia, A.; Saffari, M.; Pisello, A.L.; Cabeza, L.F. Optimal control of natural ventilation as passive cooling strategy for improving the energy performance of building envelope with PCM integration. Renew. Energy 2020, 162, 171–181. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, J. Operating behavior and corresponding performance of mechanical ventilation systems in Chinese residential buildings. Build. Environ. 2020, 170, 106600. [Google Scholar] [CrossRef]

- Maask, V.; Rosin, A.; Korõtko, T.; Thalfeldt, M.; Syri, S.; Ahmadiahangar, R. Aggregation ready flexibility management methods for mechanical ventilation systems in buildings. Energy Build. 2023, 296, 113369. [Google Scholar] [CrossRef]

- Fernandes, M.S.; Rodrigues, E.; Gaspar, A.R.; Costa, J.J.; Gomes, Á. The contribution of ventilation on the energy performance of small residential buildings in the Mediterranean region. Energy 2020, 191, 116577. [Google Scholar] [CrossRef]

- Lai, D.; Qi, Y.; Liu, J.; Dai, X.; Zhao, L.; Wei, S. Ventilation behavior in residential buildings with mechanical ventilation systems across different climate zones in China. Build. Environ. 2018, 143, 679–690. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Yeo, M.-S.; Rim, D. Performance of a heat recovery ventilation system for controlling human exposure to airborne particles in a residential building. Build. Environ. 2023, 239, 110412. [Google Scholar] [CrossRef]

- Bai, H.Y.; Liu, P.; Alonso, M.J.; Mathisen, H.M. Mathisen. A review of heat recovery technologies and their frost control for residential building ventilation in cold climate regions. Renew. Sustain. Energy Rev. 2022, 162, 112417. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Q. Study of natural ventilation in buildings by large eddy simulation. J. Wind Eng. Ind. Aerodyn. 2001, 89, 1155–1178. [Google Scholar] [CrossRef]

- Ma, H.; Tu, Y.; Yang, X.; Yang, Z.; Liang, C. Influence of tunnel ventilation on the indoor thermal environment of a poultry building in winter. Build. Environ. 2022, 223, 109448. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Ramos, J.C.; Beiza, M.; Gastelurrutia, J.; Rivas, A.; Antón, R.; Larraona, G.S.; de Miguel, I. Numerical modelling of the natural ventilation of underground transformer substations. Appl. Therm. Eng. 2013, 51, 852–863. [Google Scholar] [CrossRef]

- Bidarmaghz, A.; Makasis, N.; Fei, W.; Narsilio, G.A. An efficient and sustainable approach for cooling underground substations. Tunn. Undergr. Space Technol. 2021, 113, 103986. [Google Scholar] [CrossRef]

- Dai, H.; Zhu, C.; Liu, Y. Thermal performance of double-layer porous-microchannel with phase change slurry. Appl. Therm. Eng. 2022, 211, 118457. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Yang, P.; Liu, Y.; Zhu, C.; Wang, L.; Zhong, H. Optimizing air inlet designs for enhanced natural ventilation in indoor substations: A numerical modelling and CFD simulation study. Case Stud. Therm. Eng. 2024, 59, 104408. [Google Scholar] [CrossRef]

- Oosthuizen, P.H.; Oosthuizen, P.H.; Naylor, D. An Introduction to Convective Heat Transfer Analysis; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- Hunt, J.C.R. Mathematical Models of Turbulence. By B. E. LAUNDER and D. B. SPALDING. Academic Press, 1972. 169 pp. £2.50 or $7.50. J. Fluid Mech. 1973, 57, 826–828. [Google Scholar] [CrossRef]

- Zune, M.; Tubelo, R.; Rodrigues, L.; Gillott, M. Improving building thermal performance through an integration of Passivhaus envelope and shading in a tropical climate. Energy Build. 2021, 253, 111521. [Google Scholar] [CrossRef]

- GB/T 51350-2019; Technical Standard for Nearly Zero Energy Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Building Services. Available online: https://passipedia.org/planning/building_services (accessed on 19 May 2025).

- Shen, H.-Y.; Zhang, Y.; Lu, X.-Y.; Chen, L.-B.; Zhu, N.-Z.; Xiao, H.; Yang, G.; Huang, C.; Dai, X.; Ye, J.; et al. How indoor decoration materials contribute to phthalates pollution: Uncovering occurrences, sources, and their implications for environmental burdens in households. J. Hazard. Mater. 2025, 490, 137719. [Google Scholar] [CrossRef]

- Cerri, S.; Maskrey, A.; Peppard, E. Retaining a healthy indoor environment in on-demand mixed-mode classrooms. Dev. Built Environ. 2020, 4, 100031. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 55-2020; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2020.

- ISO 7730:2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Karyono, K.; Abdullah, B.M.; Cotgrave, A.J.; Bras, A. The adaptive thermal comfort review from the 1920s, the present, and the future. Dev. Built Environ. 2020, 4, 100032. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).