Abstract

The service status of rail, fasteners and track slabs is the key determinant of whether the ballastless track is ready for traffic after a fire. The track slab rail support bolt anchoring performance and the shoulder service performance damaged by fire were tested. Experiments of ballastless track slab concrete burned at different high temperatures were carried out to compare macro- and microstructural properties of the concrete under high-temperature burning to study the microstructure of hydration products after high-temperature burning and reveal the damage mechanism of the track slab concrete after a fire. The results show that the fire damage to the rail and fastener is mainly deformations, fractures and strength reduction. The degree of the fire damage of the mortar layer and base slab is much lower than that of the track slab. The main fire damage to the concrete is track and base slab cracks, spalling and gaps. The degree of the fire damage to the mortar layer and base slab is much lower than that of the track slab. The fire damage of the track slab concrete is mainly bursts, and the concrete cracks, spalling and deterioration occur layer by layer from the outside to inside. The shoulder injury is the most serious, the shear resistance is greatly reduced, the rail support is protected by the rail and fastener, the impact of the fire damage is small and the bolt anchoring performance was not decreased. The position of the track slab’s inside damage corresponds to the surface damage position. The steel bar inside the track slab is in good condition, and there is no obvious damage. The bulk expansion of the ballastless track concrete was caused by the expansion of aggregates under fire. When the expansion of aggregates is constrained by the shrinkage of hydration products, greater internal stress is generated, which is the main reason for the cracking or bursting of the ballastless track slab concrete under high temperatures.

1. Introduction

Fire is a sudden disaster that directly impacts a ballastless track structure. Although it occurs infrequently, the consequences can be extremely severe. The high-temperature burning from a fire can cause serious damage to key components of the ballastless track that are exposed externally, such as rails, fasteners, track slabs and wide joints. The service status of these critical components is a key determinant of whether the ballastless track can be operated after a fire [1,2].

In 2018, a fire on an ICE train caused severe damage to the Rheda-type ballastless track on the Cologne–Frankfurt HSR line in Germany, resulting in rail deformation, the failure of the fastening system and cracks in the track slab. In the same year, a vehicle fire on a certain HSR line caused damage to the ballastless track bed due to high temperatures, leading to severe damage to the track slab, with 11 rail supports broken, a 40 mm/10 m track alignment deformation, the failure of the W300-1 type fastening system and varying degrees of deformation in 14 gauge baffles on adjacent upstream track slabs. In 2022, a section of a certain HSR line was severely damaged by a sudden fire in a local natural gas pipeline, with the ballastless track structure and catenary system on the bridge suffering significant damage.

Ballastless track slab concrete belongs to high-strength concrete. Systematic studies on the performance of high-strength concrete after fires have been carried out, including on the compressive strength, shear strength, elastic modulus, damage and fire spalling behavior of high-strength concrete after an exposure to high temperatures [3,4,5]. Du et al. [6] studied the fire spalling behavior of steel fiber-reinforced UHSC with PP fibers of a cubic strength of 115–135 MPa to determine the optimum PP fiber dosage to prevent explosive fire spalling. Five RHSC wall specimens with various concrete strengths, axial load levels, thicknesses and reinforcement configurations were tested under a one-sided bottom-up standard fire by Chen et al. [7], and the time-dependent thermal and deformation evolutions and the spalling characteristics were measured and analyzed. Khaled et al. [8] prepared concrete beam specimens with different strengths and studied the fire resistance of corroded high-strength structural concrete, and all specimens were tested for their residual flexural strength. Eva Lubloy et al. [9] found that the higher strength of concrete and the concomitant change in the test strength will lead to spalling, which will have a major impact on the stability of structures under fire. Neuenschwander et al. [10] investigated the uniaxial performance of concrete at elevated temperatures under cyclic compressive loading and confirmed the suitability of the damage–plasticity modeling concept for concrete under uniaxial compressive stress at elevated temperatures. Nuaklong et al. [11] studied the confounding effect of multi-walled carbon nanotubes and polypropylene fibers on the mechanical and fire resistance of Portland cement mortar, and the strength of the mortar was measured at different temperatures below 1000 °C. Sukontasukkul et al. [12] studied the effect of fire on the flexural properties and residual strength of ordinary concrete and fiber-reinforced concrete and tested the bending load of the sintered sample to determine its toughness and residual strength. Choe et al. [13] found that undried specimens with a water content of 4.16% would experience spalling and also suggested that a higher heating rate would increase the internal vapor pressure of the concrete. Kanéma et al. [14] discovered that larger-sized concrete specimens were more prone to spalling, as the increase in the specimen size lengthened the path for water vapor evaporation, leading to an increased vapor pressure within the matrix. Bastami et al. [15] found that the silica fume content had a significant effect on the high-temperature spalling of high-strength concrete. The silica fume made the concrete matrix structure denser, and as the amount of the silica fume increased, the probability of spalling also increased. Mróz et al. [16] proposed a method using acoustic signals of concrete under fire to identify spalling patterns and intensity. The study analyzed the amplitude and frequency spectrum of acoustic signals to distinguish different spalling patterns of concrete at high temperatures. Xiong et al. [17] investigated the effect of steel fibers on the spalling of ultra-high-performance concrete (UHPC) and found that adding only 1% of steel fibers could not prevent spalling but could reduce the degree of spalling. Shen et al. [18] found that the combination of steel fibers and polypropylene fibers had a positive effect on the spalling resistance of UHPC and recorded the appearance changes, first spalling temperature and first spalling time of the specimens after high temperatures to evaluate the spalling performance of the UHPC.

These studies have greatly deepened the understanding of the damage and mechanical properties of concrete after exposure to high temperatures. However, there is still a lack of targeted research on the temperature field distribution of the ballastless track and the damage and mechanical properties of the concrete track bed after a fire. Based on a full-scale model test on the widespread high-speed railway foundation conducted under sequentially elevated water tables, Liu et al. [19] studied the long-term responses of a high-speed railway subjected to extreme precipitation events. Li et al. [20] provide a comprehensive review of the service life prediction of concrete under the coupling effect of fatigue loads and environmental actions. However, the research on the fire resistance of ballastless tracks has been rarely mentioned. Ma [21] explored the damage and mechanical properties of the ballastless track after a fire; the uniaxial compressive strength, shear strength, peak strain and elastic modulus changes due to temperature were obtained through uniaxial compressive and shear tests of the concrete after an exposure to high temperatures. Then, a vehicle–track coupling system model of a double-block ballastless track was established. The compressive stress and tensile stress of the track slab, as well as the acceleration and vertical displacement of the vehicle body, track slab and rail at the most unfavorable position under a train load after fire damage, were analyzed. The operational stability and safety of the ballastless track vehicle after the fire was evaluated [22]. Xu et al. [23] evaluated the evacuation capacity of complex railway stations under post-earthquake fires, built a BIM-FDS-based evacuation assessment method for complex rail transit stations under post-earthquake fires for sustainable buildings and provided sustainable recommendations for building designs.

In summary, there is currently limited research on the fire resistance of ballastless tracks. In view of this, this paper conducts tests on the apparent quality, concrete surface rebound strength and carbonation depth of six fire-damaged track slabs. A circular saw was used to cut the track slabs along each shoulder in the transverse direction to observe the internal damage of the track slabs, and the concrete rebound strength at different depths was tested. The rail support bolt anchoring and shoulder service performance of the fire-damaged track slabs were also examined. Experiments were conducted on concrete track slabs subjected to different high-temperature burning conditions to compare the macrostructure and microstructure variation rules of the concrete under the high-temperature burning and reveal the damage mechanism of concrete in ballastless track slabs after a fire. The research results can provide a theoretical basis for the service performance of HSR ballastless tracks after a fire.

2. Fire Damage Characteristics Analysis of Ballastless Track Slabs

2.1. Fire Damage Characteristics of Ballastless Track Slab’s Surface

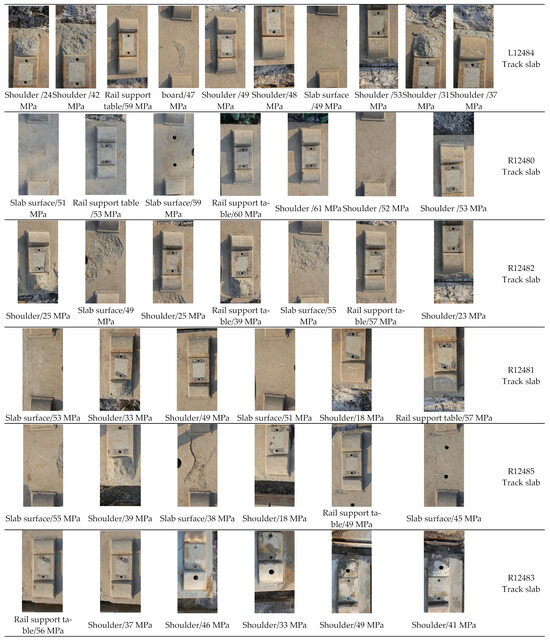

To clarify the surface damage characteristics of ballastless track slabs under fire conditions, tests were conducted on the apparent quality, surface rebound strength and carbonation depth of the concrete of six track slabs damaged in a fire. The six track slabs damaged in the fire are shown in Figure 1.

Figure 1.

Six track slabs damaged in a fire.

- (1)

- Apparent Damage

As shown in Figure 2, a field investigation was conducted on the damaged track slabs due to the fire. It was found that the main forms of fire-induced damage to the track slabs were cracks and spalling. The damaged positions were mostly located at the edges of the track slabs and the shoulders and the middle part of the track slab surfaces on the side close to the fire source. The main fire-induced damage to the metal components, such as rails and fasteners, was deformation, cracking and reduced strength. The main fire-induced damage to the concrete components, such as track slabs and base plates, was cracks, spalling and separation.

Figure 2.

Typical damage characteristics of the ballastless track slab surface after a fire. (a) Shoulder transverse cracking. (b) Shoulder edge cracking. (c) Shoulder oblique cracking. (d) Shoulder through oblique crack. (e) Shoulder and track slab edge spalling. (f) Board surface middle spalling.

- (2)

- Apparent Strength

For the six damaged track slabs after a fire, 62 measuring points were selected in the overheated area. The concrete rebound strength on the slab surface, the rail support, the shoulder and other key parts was tested by using the rebound tester. The positions for detecting the surface concrete rebound strength, the surface conditions and the rebound strength results of damaged track slabs’ concrete due to fire are shown in Figure 3.

Figure 3.

Surface conditions and the rebound strength results of the damaged track slabs’ concrete after a fire.

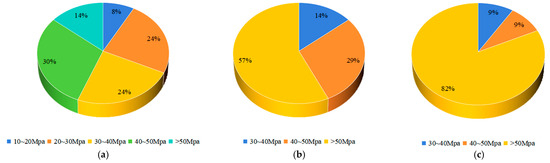

As shown in Figure 3, the discreteness of the test results is relatively large, and there are significant differences in the test results of different parts. The designed strength of the track slab concrete is generally C60. Considering the influence of on-site construction and the operating environment, the concrete surface rebound strength in normal circumstances is generally 50–60 MPa. The distribution statistics of the rebound strength test values of the concrete in different parts are shown in Figure 4 and Table 1.

Figure 4.

Distribution of rebound strength test results of in different parts of track slab concrete. (a) Shoulder. (b) Slab surface. (c) Rail support table.

Table 1.

Statistical results of concrete rebound strength in different parts of track slab concrete.

From Figure 4 and Table 1, it can be seen that the concrete average rebound strength in the rail support table area is the highest, reaching 53.30 MPa. The concrete average rebound strength in the slab surface area is the second, at 51.00 MPa. This indicates that the surface concrete strength of the rail support table and slab surface is less affected by the fire. The shoulder area surface concrete strength is the most severely affected by the fire, with the minimum concrete rebound strength being only 18 MPa and the average value being 36.89 MPa, which is far below the design value. At the same time, the test values of the concrete rebound strength at each measuring point in the shoulder area have a large dispersion. Among them, the measuring points with test values of 20 MPa account for about 8%; those with values between 20 and 30 MPa account for about 24%; those with values between 30 and 40 Mpa account for about 24%; those with values between 40 and 50 MPa account for about 30%; and those with values above 50 MPa account for only 14%. It was found that the shoulders with lower rebound values could all be found to have obvious cracks or spalling. The cracks were mostly inclined cracks. While the shoulders with relatively intact appearances had average rebound values generally above 40 MPa.

Compared with the shoulders, the test values of the concrete rebound strength in the area of the rail support table and the slab surface have a smaller degree of dispersion. The minimum value of the rebound strength in the rail support table area is 39 MPa, and 9% of the measuring points are lower than 40 MPa. The minimum value of the rebound strength in the slab area is 38 MPa, and 14% of the measuring points are lower than 40 MPa. This indicates that although the slab surface suffered obvious damage, such as spalling and cracks, during the fire, the rebound strength of the concrete surface at the damaged locations did not show significant attenuation; the rail support table is located below the rail and does not come into direct contact with open flames. Even when adjacent shoulders suffered severe damage, the surface rebound strength of the rail support table itself was also less affected by the high temperature of the fire.

- (3)

- Carbonization Depth

The carbonation depth of the concrete of the damaged track slab was tested by using a phenolphthalein alcohol solution, as shown in Figure 5. It can be found that the average carbonation depth of the track slab with a good surface condition is 1.5 mm. This test result is relatively small, indicating that the carbonation degree is not serious, and the concrete still has good durability.

Figure 5.

Test results of carbonization depth of fire-affected damaged track slabs.

2.2. Fire Damage Characteristics Inside Ballastless Track Slabs

Based on the investigation results of the appearance of the track slab damaged by the fire in Section 2.1, it can be preliminarily determined that the main failure mode of the track slab in the fire is the concrete cracking caused by high temperatures, which subsequently leads to cracks at the shoulder and the slab surface at the fire-affected positions and ultimately causes the spalling of the surface concrete. Based on the test data, it is inferred that the appearance of cracks in the track slab is the main reason for the reduction in the surface rebound strength. In order to further analyze the damaged condition of the concrete inside the track slab, a circular saw was used to cut the R12483 track slab along the lateral direction at each rail sleeper spacing, as shown in Figure 6. The damage condition inside the track slab was observed, and the concrete rebound strength at different depth positions was tested.

Figure 6.

Cutting the damaged track slab after a fire.

- (1)

- Apparent Damage

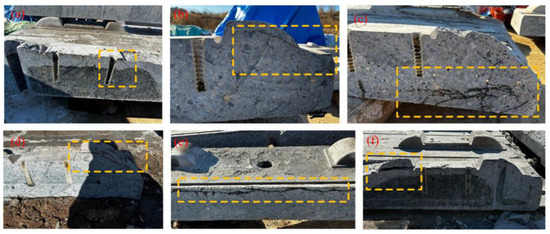

The apparent damage condition inside the track slab after a fire is shown in Figure 7.

Figure 7.

The internal damage condition of the track slab after a fire.

As shown in Figure 7a the oblique crack under the shoulder, about 5 cm in length, extends towards the bolt service sleeve. Figure 7b Oblique cracks appear 3 cm below the shoulder surface, extending to the track slab edge, with a total length of 25 cm. Figure 7c Mesh cracks appear on the track slab edge, extending laterally beneath the bolt sleeve. Figure 7d There is a penetrating oblique crack 2 cm below the shoulder surface. Figure 7e There are transverse cracks 4 cm below the track slab’s middle surface as well as Figure 7f a transverse break along the shoulder. In conclusion, multiple cracks have formed inside the track slab after a fire. The cracks mainly occur at the track slab edges, beneath the shoulder and below the track slab middle part, corresponding to the locations where the surface of the track slab suffered damage in Section 2.1. This indicates that the surface damage caused by the fire has penetrated the track slab.

- (2)

- Apparent Strength

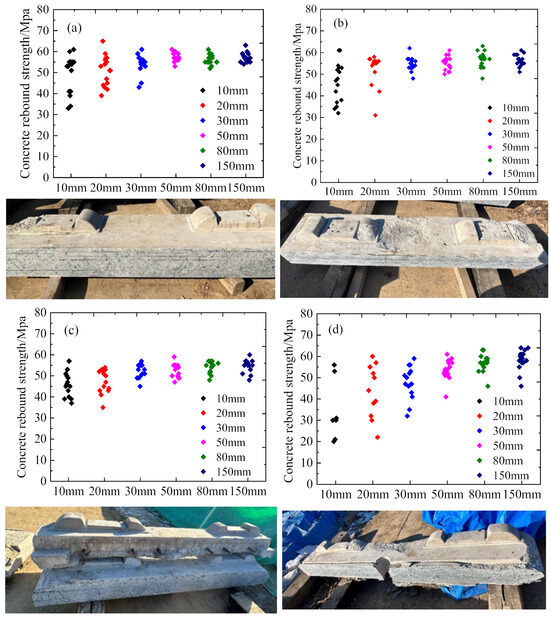

Figure 8.

The distribution of the rebound strength of the concrete at different depths inside the track slab. (a) A diagram of the 1-1 section. (b) A diagram of the 2-2 section. (c) A diagram of the 3-3 section. (d) A diagram of the 4-4 section.

Table 2.

Statistics on the rebound strength of the concrete at different depths inside the track slab.

As can be seen from Figure 8 and Table 2, with the increase in the concrete depth, the rebound strength gradually increases, and the degree of dispersion of the strength gradually decreases; that is, the strength becomes more uniform. Under the high-temperature effect of the fire, the shallow concrete undergoes damage, resulting in a decrease in local strength and a significant drop in the test data at some positions. Therefore, the test results of the shallow concrete rebound strength are rather discrepant. However, when the depth exceeds 50 mm below the slab surface, the concrete strength hardly changes and becomes more uniform.

- (3)

- Core Sample Compressive Strength

To further verify the influence of the fire on the strength and durability of the concrete, core samples of φ50 mm concrete cylindrical specimens will be drilled from the shoulder, the rail support table from the R12480 to R12485 track slabs, and then be cut into several φ50 mm × h50 mm specimens. The compressive strength of the concrete at different depths will be tested, as shown in Table 3; core samples of φ100 mm concrete cylindrical specimens will be drilled from the interplate position from the R12480 to R12485 track slabs and then cut into φ100 mm × h50 mm specimens. The electrical conductivity of the concrete at different depths will be tested, as shown in Table 4.

Table 3.

Test results of compressive strength of core samples of track slabs.

Table 4.

Detection data of core sample electrical flux of track slabs.

From Table 3 and Table 4, it can be seen that the differences in compressive strength may be affected by factors such as the material quality, construction techniques, curing conditions and sampling positions. The test data fluctuate within a certain range, and no significant attenuation has occurred overall. The electric flux value of concrete usually ranges from 0.1 to 1000 mA/m. The test results of the electric flux of the damaged track slabs after a fire all meet the specification requirements, indicating that the durability of the internal concrete has not undergone significant changes. It can be preliminarily judged that the main form of the damage caused by the high temperature of the fire to the track slab concrete is mainly high-temperature cracking, and it has not yet involved the decomposition of the concrete phase or the attenuation of the overall strength of the structure.

3. Mechanical Properties of the Rail Support Bolt Anchoring and the Shoulder Service Performance After a Fire

The rail support bolt anchoring and shoulder service performance after a fire were inspected.

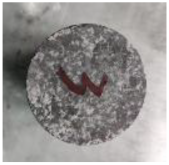

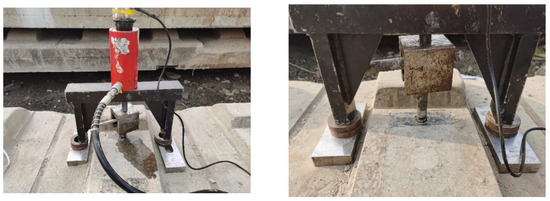

3.1. Pull-Out Bearing Capacity of Service Sleeve

Three service sleeves were tested for the pull-out bearing capacity [24]. The test site photos and test results are shown in Figure 9 and Table 5. According to the test results, the fire had no significant impact on the pull-out bearing capacity of the service sleeves, and all met the requirements of the TB/T3395.5-2015 specification [25]. Moreover, the ultimate pull-out bearing capacity was relatively high.

Figure 9.

The pull-out bearing capacity test of the service sleeve.

Table 5.

The test on the pull-out bearing capacity of the service sleeve.

3.2. Bearing Capacity of Shoulder

Three shoulders of fire-damaged track slabs without cracking were selected for bearing capacity testing. The photographs of the test are shown in Figure 9. The photographs before and after testing for each shoulder, along with the test results, are presented in Figure 10 and Table 6.

Figure 10.

Bearing capacity test of shoulders. (a) Shoulder 1 (before test and after test). (b) Shoulder 2 (before test and after test). (c) Shoulder 3 (before test and after test).

Table 6.

Test results of bearing capacity of shoulders.

According to the test results, it can be seen that the bearing capacity of the shoulders has significantly decreased. The bearing capacity of the intact shoulders is approximately 80 kN, while even if the surface of the shoulders after the fire is intact, their ultimate bearing capacity has dropped to less than 10 kN.

4. Fire Damage Mechanism Analysis of Ballastless Track

The fire test performance of the ballastless track slab concrete was studied.

- (1)

- Specimen Preparation

The ballastless track concrete is made of a C60 concrete mix proportion, as shown in Table 7; the cement is P.O42.5; the ultrafine mineral powder is an average particle size of 2000 mesh; the sand is made of river sand in Zone II with a fineness modulus of 2.65; the gravel is made of secondary gravel; the water reducer is a polycarboxylate-based water reducer; and the solid content is 20%.

Table 7.

Concrete mix ratio of ballastless track slab/kg.

The ballastless track concrete is formed with a steel mold with a size of 100 mm×100 mm × 100 mm. After forming, it stops for 4 h and then is put into a steam curing chamber for maintenance. The temperature is raised for 2 h, the heating rate is 15 °C/h, the temperature is raised to 50 °C for 8 h and then the cooling time is 2 h. After the steam curing, it was transferred to a standard curing room with a temperature of 20 °C ± 2 °C and a humidity of 95% or more for curing, and the test was carried out after 90 d of curing. Cement paste specimens with the same water-to-binder ratio as the ballastless track concrete are the same as those of the ballastless track concrete without a water reducer. The rock column specimens were drilled from the parent rock of the same lithology as the aggregate, and the 50 mm diameter drill was used to drill the core, and the 50 mm growth of the cylinder specimens was cut. The high-temperature furnace is used for the burning test, and the temperature in the high-temperature furnace is adjusted by the temperature controller. Before each burning test, the high-temperature furnace is adjusted to the set temperature, and when the temperature rises to the set temperature, the samples are put into the high-temperature furnace chamber for the burning test. The high-temperature burning time is 2 h, and the test is carried out after the burning is reduced to room temperature. The burning temperature is set at 400 °C, 600 °C, 800 °C and 1000 °C.

- (2)

- Detection method

① Compressive strength, three pieces of each specimen were tested at each temperature, and the loading rate was 50 N/s ± 10 N/s. The test block after the flexural strength test was used for the compressive strength test, and the loading rate was 2400 N/s ± 200 N/s.

② Mass loss rate: The sample mass after burning is the difference between the mass of the specimen after burning and the mass of the specimen without burning, divided by the mass of the specimen without burning.

③ Size change rate: Measure the length of the specimen with vernier calipers before burning, and mark the measurement position; measure the length L1 of the position again after burning; and the length after burning minus the length before burning divided by the length before burning is the size change rate.

④ Pore structure: The cement paste specimens were broken into 2~3 mm specimens, and after hydration was terminated with isopropyl alcohol, the samples were dried to a constant weight in a vacuum drying oven at 45 °C, and the pore structure was analyzed by the Micromeritics AutoPore IV Series Mercury Porosimeter.

⑤ Microstructure morphology: The cement paste specimens were broken into 2~3 mm samples, and after hydration was terminated with isopropyl alcohol, the samples were dried to a constant weight in a vacuum drying oven at 45 °C, and the microstructure morphology was observed with a scanning electron microscope.

4.1. Influence of Burning Temperature on Macro-Performance of Ballastless Track Concrete

- (1)

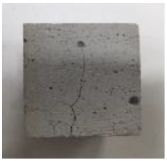

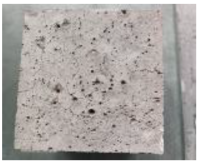

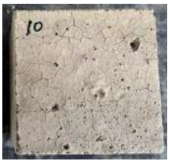

- Appearance of Ballastless Track Concrete

In order to analyze the change characteristics of the ballastless track concrete under different burning temperatures and compare the performance of the ballastless track concrete and its component materials after burning, the appearance of the concrete specimen, paste specimens and rock column specimens of the ballastless track is shown in Table 8 when the burning temperatures are 400 °C, 600 °C, 800 °C and 1000 °C, respectively.

Table 8.

The influence of the burning temperature on the appearance of the track slab concrete and its component materials.

As can be seen from Table 8, the color and surface cracking of the ballastless track concrete and its component materials change significantly under different burning temperatures. When the temperature is above 600 °C, the color changes from gray to earth yellow, cracks appear on the surface of the concrete and paste specimens in different degrees and the surface of paste specimens appears to fall off when the temperature exceeds 800 °C. When the burning temperature is 400 °C~600 °C, the color of the ballastless track concrete is gray, surface cracks appear, the cracks of the paste specimen are more obvious, the color is lighter than that of the concrete and the color of the rock column does not change significantly. When the burning temperature is 800 °C~1000 °C, the color of the ballastless track concrete changes significantly, from gray to earthen yellow, the network cracks increase significantly, the width of the cracks increases significantly, the cracks of the paste specimens increase more significantly, the phenomenon of falling blocks appears in the corners, the color of the rock column specimens changes and there are no cracks on the surface.

The color change under the high-temperature burning is mainly caused by the decomposition of cement hydration products. In addition, the shape of the concrete specimen under the high-temperature burning remained good, and no explosion occurred, which may be related to the burning method. When the specimen was burning, all sides were uniformly heated, and a whole expansion occurred, but no explosion occurred.

- (2)

- Mechanical Properties of Ballastless Track Concrete

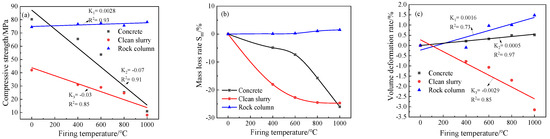

When the burning temperature is 400 °C, 600 °C, 800 °C and 1000 °C, respectively, the compressive strength, mass loss rate and volume deformation rate of the concrete, clean pulp and rock column specimens are shown in Figure 11, Figure 12 and Figure 13.

Figure 11.

Influence of different burning temperatures on mechanical properties of ballastless track concrete. (a) Compressive strength. (b) Mass loss rate. (c) Volume deformation rate.

Figure 12.

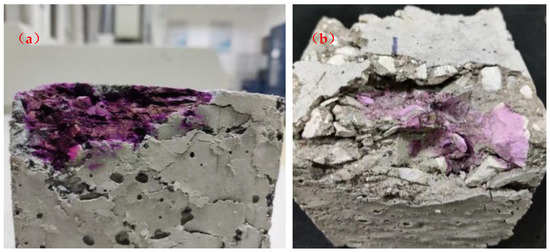

The color development of the phenolphthalein test solution sprayed on the concrete before and after burning. (a) Unburned. (b) After burning at 800 °C.

As can be seen from Figure 11a, the compressive strength of the ballastless track slab concrete specimen and the paste specimen decreased linearly with the increase in the burning temperature, and the linear correlation was significant. Compared with the concrete and cement paste, the compressive strength of rock column specimens has little change, which indicates that the aggregate is relatively stable and is not affected by the burning temperature. The compressive strength of the unburned concrete is 80 MPa, the compressive strength of the paste specimen with the same water–glue ratio is 42 MPa, the compressive strength of the concrete after burning at 600 °C is 53 MPa, the compressive strength of the paste specimen is 29 MPa, the compressive strength of the concrete after burning at 800 °C is 28 MPa and the compressive strength of the paste specimen is 24 MPa. After burning at 1000 °C, the compressive strength of the concrete is 10 MPa, the compressive strength of the paste specimen is 8.1 MPa and the compressive strength of the rock column is between 74 MPa and 78 MPa. When the burning temperature is 600 °C, the compressive strength retention rate of the ballastless track slab concrete is 66%, which is higher than that of ordinary cured concrete. This is mainly because more Ca(OH)2 crystals are generated in the ballastless track concrete under steam curing, and the grains are coarse. The decomposition temperature of Ca(OH)2 is 580 °C, and the decomposition of Ca(OH)2 induces C-S-H gel decomposition. The higher content of Ca(OH)2 indicates that the steam-cured concrete is more resistant to high temperatures. However, after the high temperature of 600 °C, the strength of the track slab concrete is lower than the design grade requirements, which will affect the normal use of the ballastless track slab.

It can be seen from Figure 11b that with the increase in the burning temperature, the mass loss of both the concrete and cement paste gradually increases, while the mass of the rock column has little change. In addition, when the burning temperature is lower than 600 °C, the mass loss rate of the net paste is significantly higher than that of the concrete, and the mass loss rate of the concrete is low. When the burning temperature is higher than 600 °C, the mass loss rate of the concrete rapidly increases, and the mass loss rate of the net paste specimen is slightly changed. When the burning temperature is 600 °C, the mass loss rate of the concrete is 7.5% and the mass loss rate of the paste specimen is 22.7%; when the burning temperature is 800 °C, the mass loss rate of the concrete is 15% and the mass loss rate of the paste specimen is 24.5%; and when the burning temperature is 1000 °C, the mass loss rate of the concrete is 26.1%. The mass loss rate of the clean pulp sample was 24.7%. This shows that compared with the cement paste, the mass loss of the concrete is more moderate, and the burning temperature is significantly reduced when the temperature is higher than 600 °C. When the temperature is lower than 600 °C, the mass loss in the concrete is mainly due to the evaporation of water, and the hydration products are not decomposed in large quantities, and the strength is also maintained within 60% to 70%. However, when the temperature exceeds 600 °C, the mass loss of the concrete is mainly caused by the decomposition of hydration products, resulting in the rapid decay of the compressive strength.

As can be seen from Figure 11c, the volume of the concrete, paste specimens and rock columns changes linearly with the increase in the burning temperature, and the linear correlation is good. However, the change in the law of different materials is different, and the paste specimens shrink with the increase in the burning temperature, while the rock column and concrete specimens expand. When the burning temperature is 600 °C, the size expansion rate of the concrete is 0.33%, the size shrinkage rate of the paste specimen is −1.07% and the size expansion rate of the rock column is 0.96%. When the burning temperature is 800 °C, the size expansion rate of the concrete is 0.49%, the size shrinkage rate of the paste specimen is −1.7% and the size expansion rate of the rock column is 1.005%. This shows that the volume expansion of the concrete under high-temperature burning is mainly caused by the thermal expansion of the aggregate, which generates large internal stress in the interfacial transition zone where the aggregate and slurry make contact. However, the interfacial transition zone in the concrete is generally weak, the volume deformation of each component in the concrete under heat is inconsistent and the expansion deformation exceeds the ultimate tensile strain that the concrete can withstand. This is the main reason for the cracking or bursting of the concrete caused by the high-temperature burning.

The ballastless track slab is a reinforced concrete structure, and the change in the alkali content in the concrete after the high-temperature burning is very important to prevent the corrosion of steel bars. In order to compare the changes in the internal alkalinity of the concrete before and after burning, a phenolphthalein indicator solution was sprayed for observation, and the results are shown in Figure 12.

4.2. Influence of Burning Temperature on Microstructure of Ballastless Track Concrete

- (1)

- Pore Structure of Ballastless Track Concrete

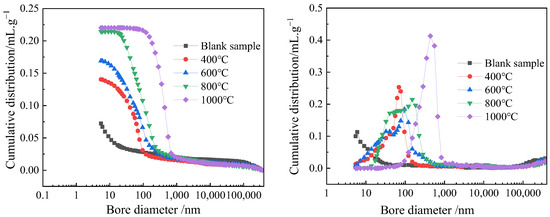

The pore size distribution of hydration products of the ballastless track concrete at different burning temperatures is shown in Figure 13.

Figure 13.

The influence of the burning temperature on the pore structure of concrete hydration products.

As shown in Figure 13, with the increase in the burning temperature, the porosity and the most probable pore diameter in the hydration products of the concrete increase significantly. When the burning temperature is 0, 400 °C, 600 °C and 800 °C, the cumulative pore content in the hydration products is 0.07 mL/g, 0.14 mL/g, 0.17 mL/g and 0.21 mL/g, respectively; the most probable pore diameter and the corresponding pore volume content are 6 nm, 0.11 mL/g, 69 nm, 0.25 mL/g, 151 nm, 0.21 mL/g, 434 nm and 0.41 mL/g, respectively. This indicates that burning at high temperatures destroys the pore structure of the hydration products of the concrete. The increase in porosity suggests that the compactness of the hydration products of the concrete decreases, and the impermeability of the concrete reduces; the increase in the pore diameter indicates that the content of large pores in the hydration products of the concrete increases, the number of large pores significantly increases and the pores become coarse. The high temperature destroys the pore structure of the concrete.

- (2)

- Microstructure Morphologies of Ballastless Track Concrete

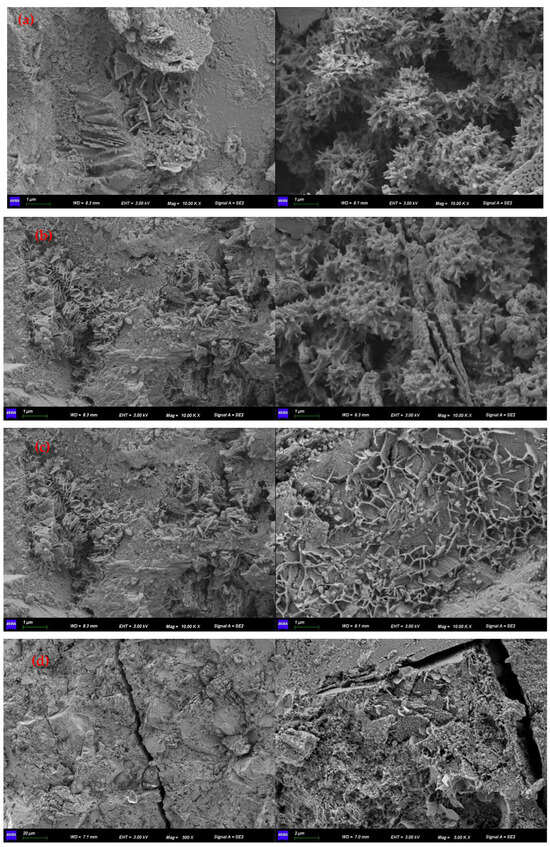

The microstructure morphologies of hydration products in the concrete at different calcination temperatures are shown in Figure 14.

Figure 14.

The influence of the burning temperature on the microstructure morphology of concrete hydration products. (a) Blank sample. (b) Burning at 400 °C. (c) Burning at 600 °C. (d) Burning at 800 °C.

As shown in Figure 14, high-temperature burning has a significant impact on the microstructure morphology of the hydration products of the concrete. After burning, the hydration products undergo significant changes in their C-S-H gel, internal micro-cracks and density. In uncalcined concrete, the hydration products are relatively dense, with the C-S-H gel distributed in clusters, and the ends of the clusters are long, rod-like fibers and closely interlock into a whole. Hexagonal plate-like Ca(OH)2 is clearly visible. There are relatively few cracks in the hydration products. When the burning temperature is 400 °C, the density of the hydration products slightly decreases, while the C-S-H gel still distributes in clusters, the rod-like gel significantly decreases and the hydration products become more loosely interlocked. There are more cracks in the hydration products when the burning temperature is 600 °C, and the hydration products undergo significant changes. The C-S-H gel decomposes, and the C-S-H decomposition residue body becomes one. Cracks are numerous in the hydration products, and the density of the hydration products decreases. When the burning temperature rises to 800 °C, the C-S-H gel basically disappears, and the cracks in the hydration products further develop. The microstructure of the hydration products is completely destroyed. Due to the fact that the C-S-H gel is the main source of the concrete strength, the changes in the cracks and porosity reflect the density of the concrete. When the burning temperature is below 600 °C, the hydration product skeleton still exists, and the concrete can continue to be used after repair. When the temperature rises above 600 °C, the C-S-H gel skeleton collapses, the microstructure is severely damaged and the strength of the ballastless track concrete is lost. This is the main reason for the deterioration of the ballastless track concrete under high-temperature burning.

5. Conclusions

- (1)

- The main fire-induced damage of rails and fasteners is mainly deformation, cracking and strength reduction. The main fire-induced damage of track slabs and base plates is mainly cracks, spalling and separation. The fire-induced damage of mortar layers and base plates is much lower than those of the track slabs. The shoulder was the most severely damaged, and the rail bolt anchoring performance basically did not decline. The internal damage position of the track slab corresponded to the damaged position of the surface layer.

- (2)

- After being exposed to the fire, the track slab surface layer strength with severe damage shows a significant decline. The surface layer of the concrete is without obvious damage, and the internal concrete has basically no significant changes in strength and electrical conductivity, maintaining a relatively high strength. The internal steel bars of the track slab are in good condition, and no obvious damage has occurred.

- (3)

- Under the high temperature of the fire, the aggregates are heated and expanded, causing the volume expansion of the track slab concrete. When the expansion of the aggregates is constrained by the shrinkage of the hydration products, large internal stress is generated. This is the main reason for the cracking or spalling of the track slab concrete under the high temperatures of the fire.

- (4)

- When the temperature of the fire rises above 600 °C, the C-S-H gel framework collapses, the microstructure is severely damaged and the strength of the ballastless track concrete is lost. This is the main cause of the deterioration of the ballastless track concrete under the high-temperature burning of a fire.

Author Contributions

Conceptualization, H.J.; methodology, Y.Y.; software, X.Z. and Y.Y.; data curation, H.J., Y.Y., X.Z., S.L. and Y.P.; validation, J.C., Y.F. and S.X.; formal analysis, J.C.; writing—original draft preparation, H.J.; writing—review and editing, X.Z. and Y.P.; visualization, S.X. and S.L.; supervision, X.Z. and Y.F.; project administration, H.J.; funding acquisition, H.J. and X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Research and Development Program of the China National Railway Group Corporation (P2023G009) and the China Railway Research Institute Group Corporation (2023YJ204).

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

Author Hao Jin, Yike Yang, Xinxin Zhao, Yongjian Pan, Jinhui Chu, Shuming Li, was employed by the company China Academy of Railway Sciences Corporation Limited, National Key Laboratory of High speed Railway Track System, Rail Engineering Research Institute, China Academy of Railway Sciences Corporation Limited. Author Hao Jin, Yike Yang, Yongjian Pan was employed by the company Beijing Tieke Special Engineering Technology Corporation Limited. Author Shenglin Xu, Yulin Feng was employed by the company East China Jiaotong University. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yoo, M.; Park, J.; Jeong, J.; Ahn, S. Analysis of Influence of Seismic Impact on Evacuability in Subway Stations. Dev. Built Environ. 2025, 21, 100637. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, I.; Oh, Y.; Park, J.; Ahn, S. Assessment of Impact of Bottlenecks on Evacuation in Subway Stations Using Network Analysis. Dev. Built Environ. 2025, 21, 100632. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.S.; Onaizi, A.M.; Murali, G.; Abdelgader, H.S. Fire Spalling Behavior of High-Strength Concrete: A Critical Review. Constr. Build. Mater. 2022, 341, 127902. [Google Scholar] [CrossRef]

- Abid, S.R.; Abbass, A.A.; Murali, G.; Al-Sarray, M.L.; Nader, I.A.; Ali, S.H. Repeated Impact Response of Normal- and High-Strength Concrete Subjected to Temperatures up to 600 °C. Materials 2022, 15, 5283. [Google Scholar] [CrossRef]

- Shabanlou, M.; Mofid, M.; Tavakoli, A. Experimental and Numerical Study on the Behavior of Reinforced Concrete Deep Beams with Normal-Strength and High-Strength Concrete After Being Exposed to Fire. Arab. J. Sci. Eng. 2024, 49, 13457–13476. [Google Scholar] [CrossRef]

- Du, Y.; Qi, H.H.; Huang, S.S.; Liew, J.R. Experimental Study on the Spalling Behaviour of Ultra-High Strength Concrete in Fire. Constr. Build. Mater. 2020, 258, 120334. [Google Scholar] [CrossRef]

- Chen, J.; Ji, Y.; Xu, Y.; Wang, G.; Hu, K. Experimental Investigation of Behavior of Reinforced High-Strength Concrete Walls Under Standard Fire. J. Build. Eng. 2024, 87, 109052. [Google Scholar] [CrossRef]

- Sobhan, K.; Reddy, D.V.; Martinez, F. Fire Resistance of Corroded High-Strength Structural Concrete. J. Struct. Fire Eng. 2021, 12, 17–34. [Google Scholar] [CrossRef]

- Lubloy, E. The Relationship Between Concrete Composition and Structural Stability in Case of Fire. Constr. Build. Mater. 2024, 431, 136545. [Google Scholar] [CrossRef]

- Neuenschwander, M.; Knobloch, M.; Fontana, M. Suitability of the Damage-Plasticity Modelling Concept for Concrete at Elevated Temperatures: Experimental Validation with Uniaxial Cyclic Compression Tests. Cem. Concr. Res. 2016, 79, 57–75. [Google Scholar] [CrossRef]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T.; Sukontasukkul, P. Hybrid Effect of Carbon Nanotubes and Polypropylene Fibers on Mechanical Properties and Fire Resistance of Cement Mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Sappakittipakorn, M.; Fujikake, K.; Chindaprasirt, P. Residual Flexural Behavior of Fiber Reinforced Concrete After Heating. Mater. Struct. 2018, 51, 98. [Google Scholar] [CrossRef]

- Choe, G.; Kim, G.; Yoon, M.; Hwang, E.; Nam, J.; Guncunski, N. Effect of Moisture Migration and Water Vapor Pressure Build-Up with the Heating Rate on Concrete Spalling Type. Cem. Concr. Res. 2019, 116, 1–10. [Google Scholar] [CrossRef]

- Kanema, M.; Pliya, P.; Noumowé, A.; Gallias, J.L. Spalling, Thermal, and Hydrous Behavior of Ordinary and High-Strength Concrete Subjected to Elevated Temperature. J. Mater. Civ. Eng. 2011, 23, 921–930. [Google Scholar] [CrossRef]

- Bastami, M.; Chaboki-Khiabani, A.; Baghbadrani, M.; Kordi, M. Performance of High Strength Concretes at Elevated Temperatures. Sci. Iran. 2011, 18, 1028–1036. [Google Scholar] [CrossRef]

- Mróz, K.; Hager, I. Evaluation of Nature and Intensity of Fire Concrete Spalling by Frequency Analysis of Sound Records. Cem. Concr. Res. 2021, 148, 106539. [Google Scholar] [CrossRef]

- Xiong, M.X.; Liew, J.R. Spalling Behavior and Residual Resistance of Fibre Reinforced Ultra-High Performance Concrete After Exposure to High Temperatures. Mater. Constr. 2015, 65, e071. [Google Scholar] [CrossRef]

- Shen, Y.; Dai, M.; Pu, W.; Xiang, Z. Effects of Content and Length/Diameter Ratio of PP Fiber on Explosive Spalling Resistance of Hybrid Fiber-Reinforced Ultra-High-Performance Concrete. J. Build. Eng. 2022, 58, 105071. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, H.; Zhao, C.; Bian, X. Long-Term Responses of High-Speed Railway Subjected to Extreme Precipitation Events. Transp. Geotech. 2022, 37, 100852. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.; Wen, J.; Huang, F.; Wang, Z.; Yi, Z.; Xie, Y. Service Life Prediction of Ballastless Track Concrete Under the Coupling Effect of Fatigue Loads and Environmental Actions: A Review. J. Sustain. Cem.-Based Mater. 2023, 12, 672–686. [Google Scholar] [CrossRef]

- Ma, H.; Chen, W.; Li, X.; Xu, Q.; Lou, P.; Tong, C. Analysis on Damage and Mechanical Properties of Ballastless Track in a Tunnel After a Fire. Materials 2022, 15, 6712. [Google Scholar] [CrossRef]

- Ma, H. Mechanical Properties and Damage Analysis of Ballast Track Structure in Tunnel After Fire. Master’s Thesis, Central South University, Changsha, China, 2023. (In Chinese). [Google Scholar]

- Xu, H.; Wei, Y.; Tan, Y.; Zhou, Q. A BIM-FDS Based Evacuation Assessment of Complex Rail Transit Stations Under Post-Earthquake Fires for Sustainable Buildings. Buildings 2024, 14, 429. [Google Scholar] [CrossRef]

- TB 3396.7-2015; Test Methods for Fastening Systems of High-Speed Railway. Part 7: Vertical Load Test for Cast-In Fastening Components. National Railway Administration: Beijing, China, 2015. (In Chinese)

- TB/T 3395.5-2015; Fastening Systems for High-Speed Railway. Part 5: WJ-8 Fastening System. National Railway Administration: Beijing, China, 2015. (In Chinese)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).