A Deformation-Based Peridynamic Model: Theory and Application

Abstract

1. Introduction

2. Materials and Methods: Deformation-Based PD Formulation

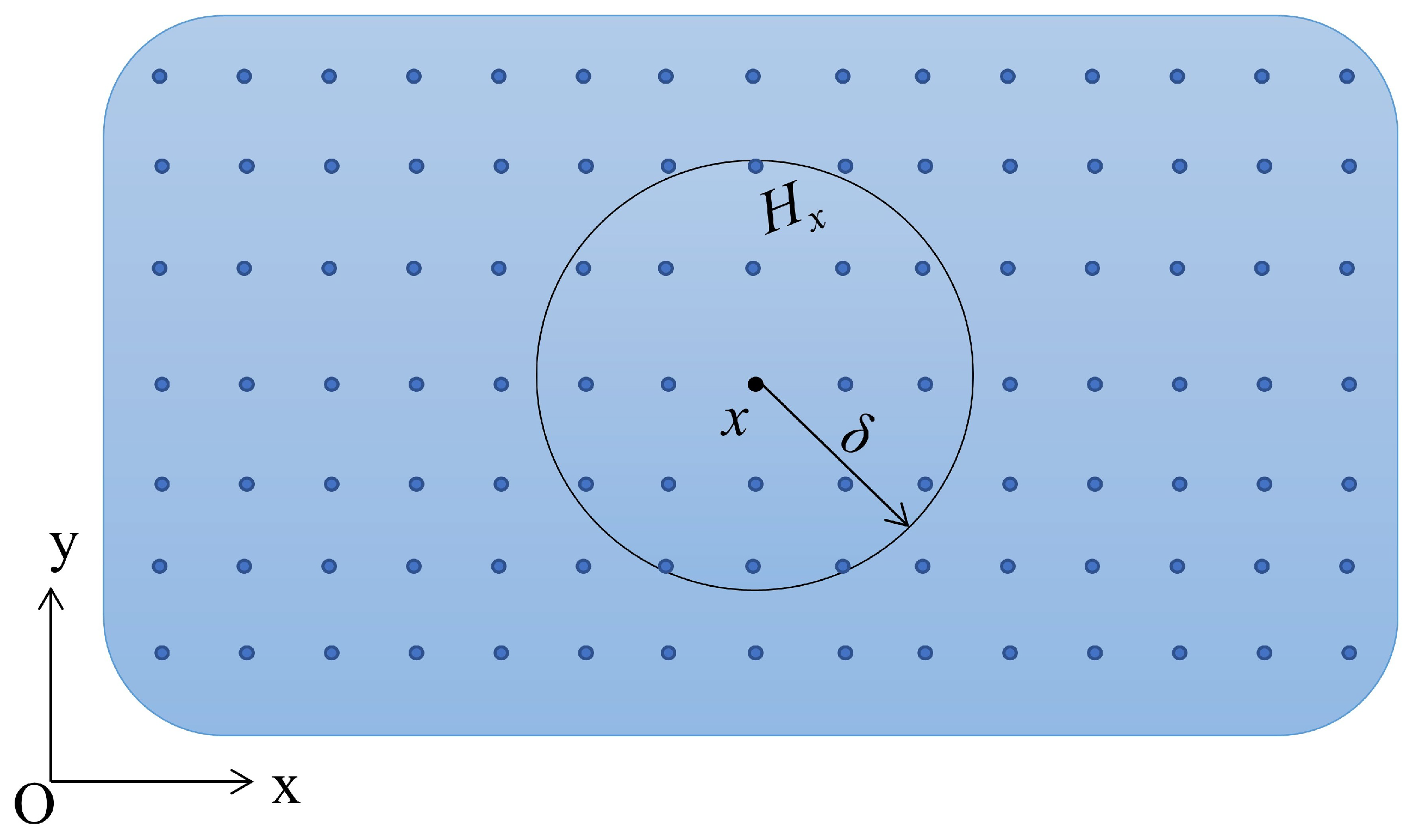

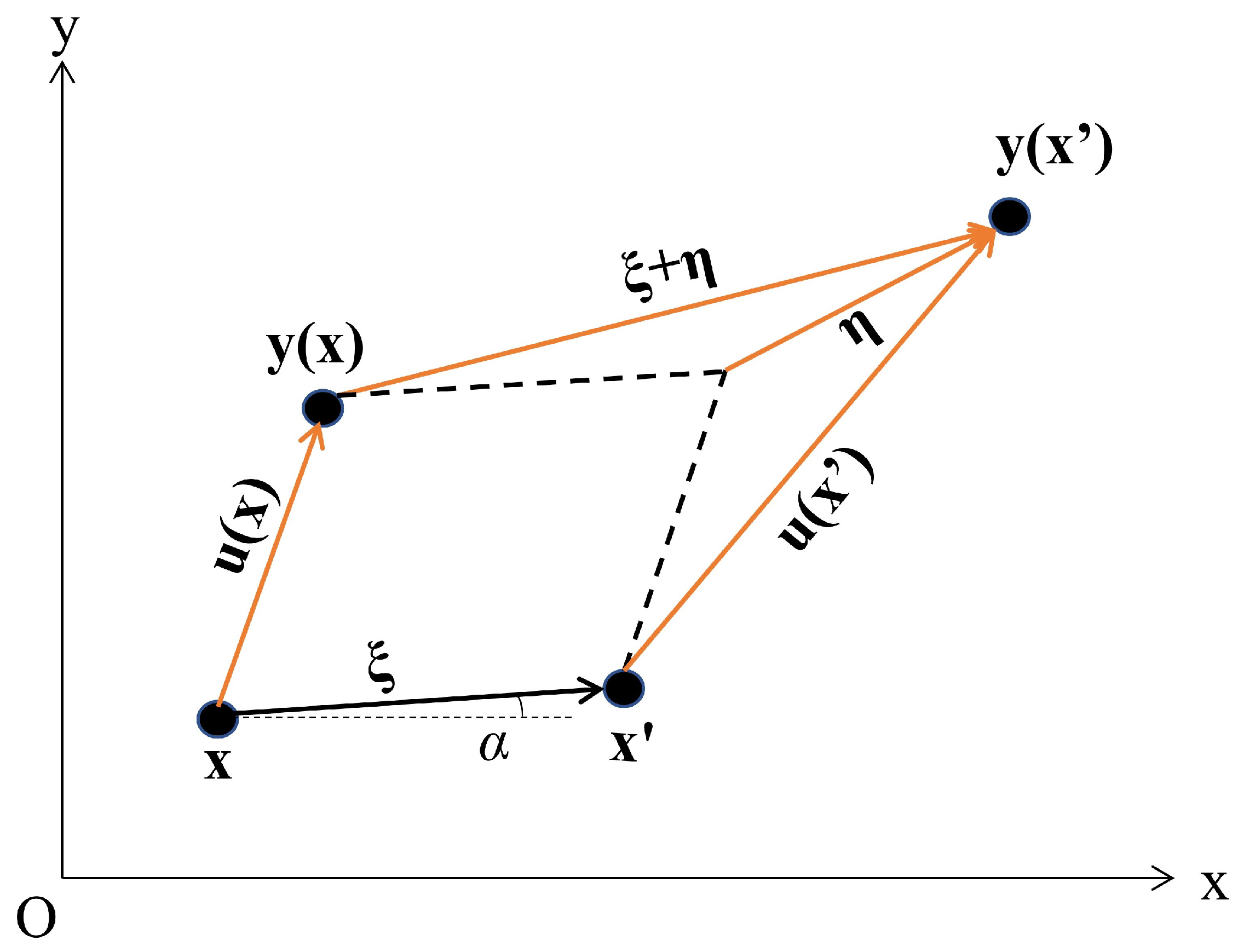

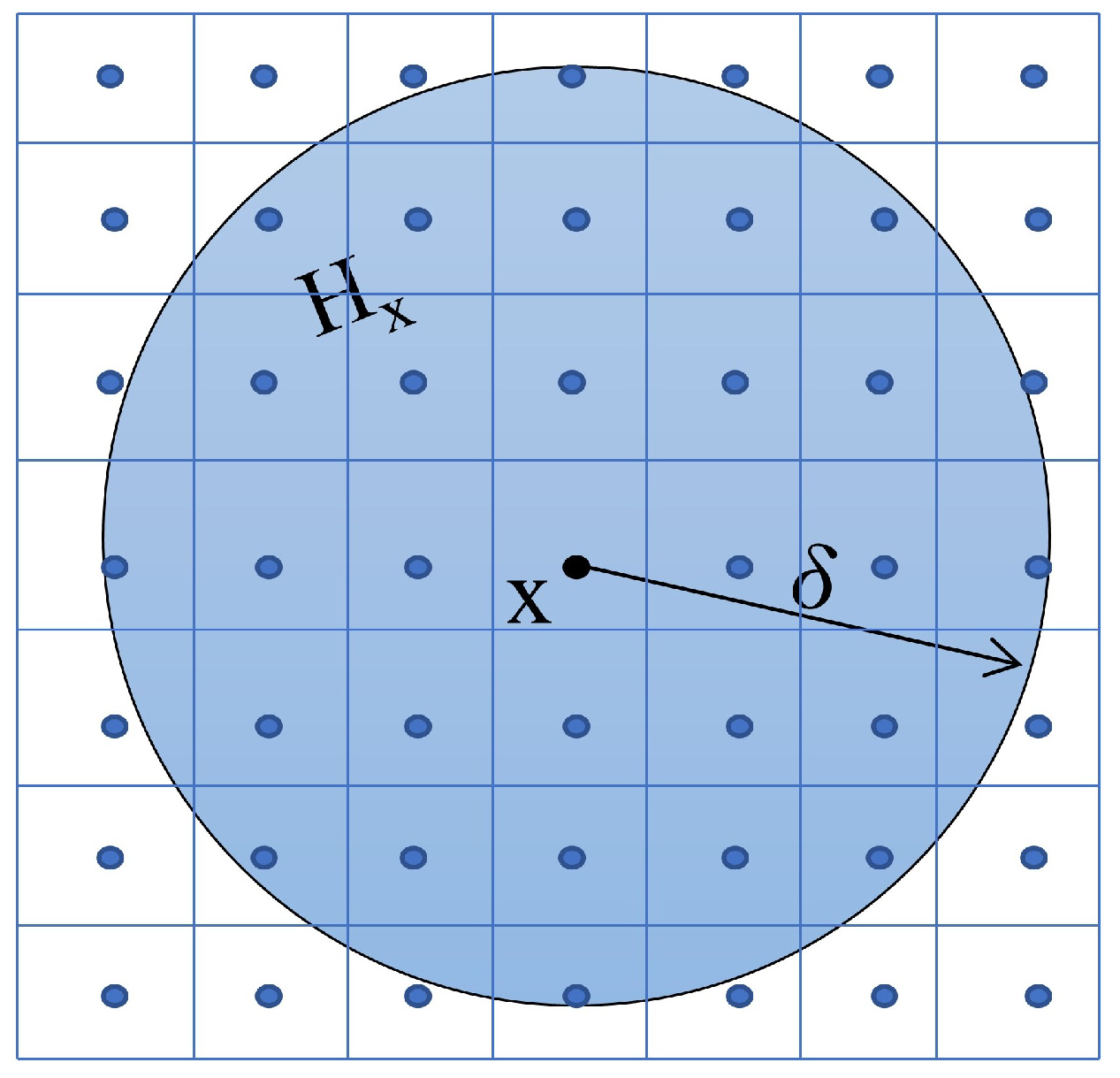

2.1. A Brief Introduction to PD

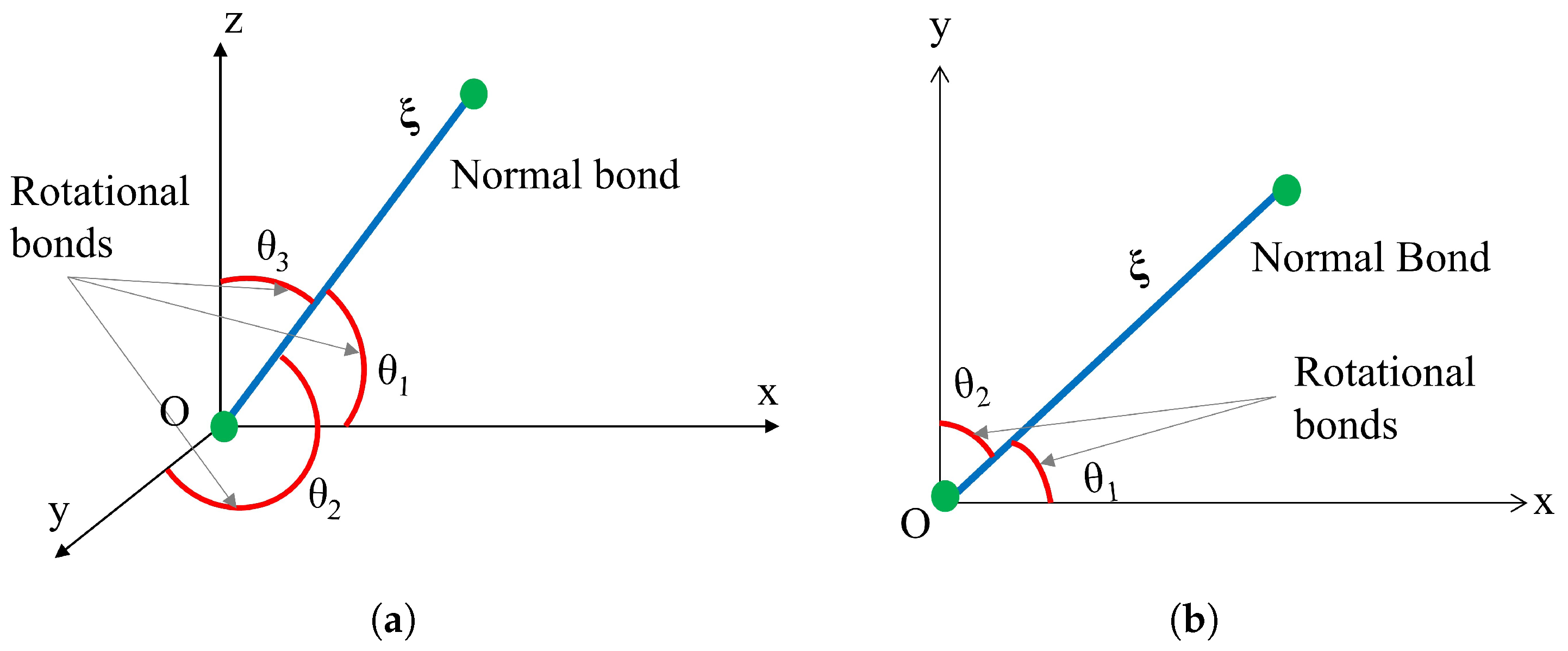

2.2. Virtual Internal Bond Method

2.3. Two Parameter PD

Failure Criteria

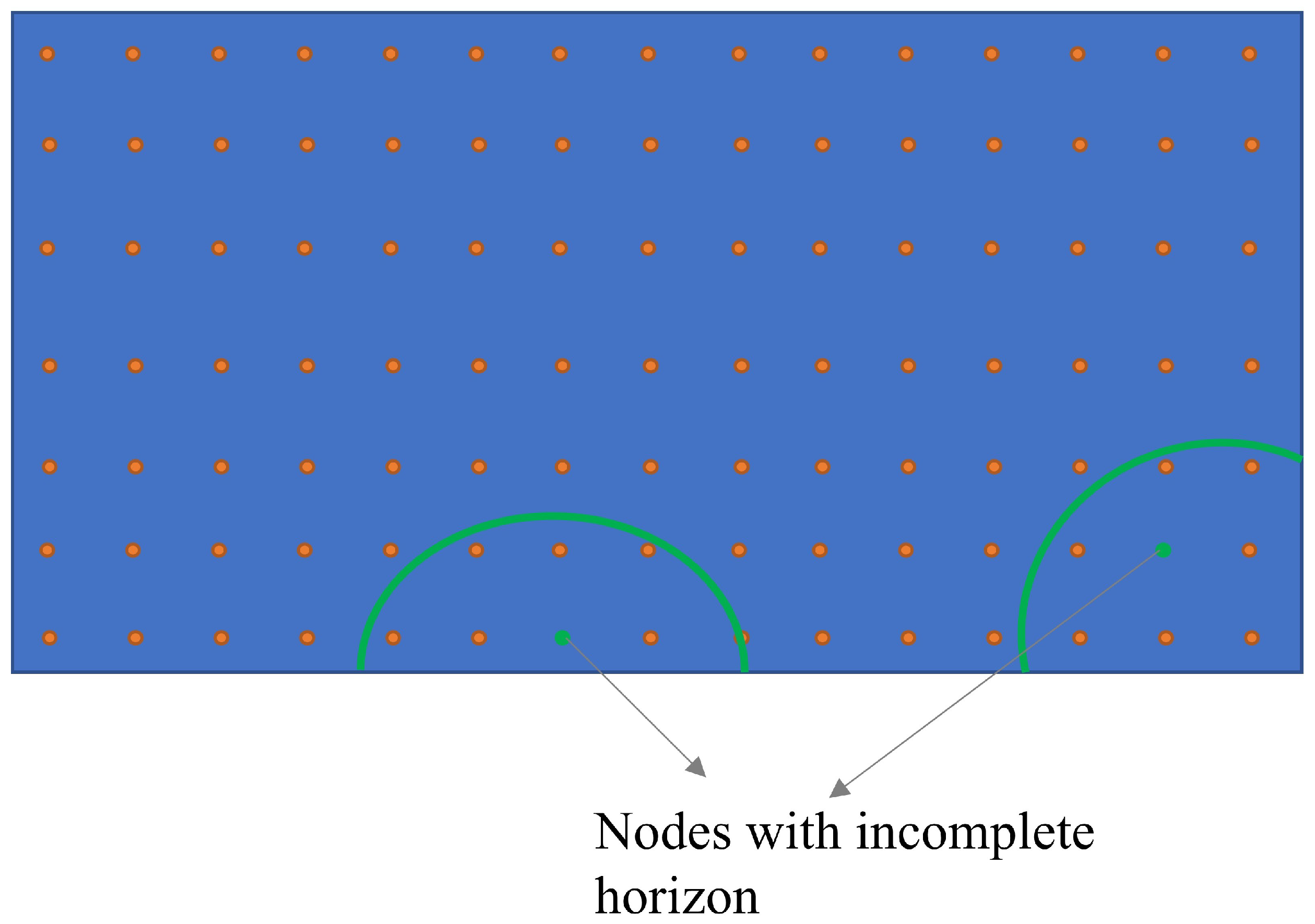

2.4. Stress-Based Correction Factor

3. Numerical Experiment and Results

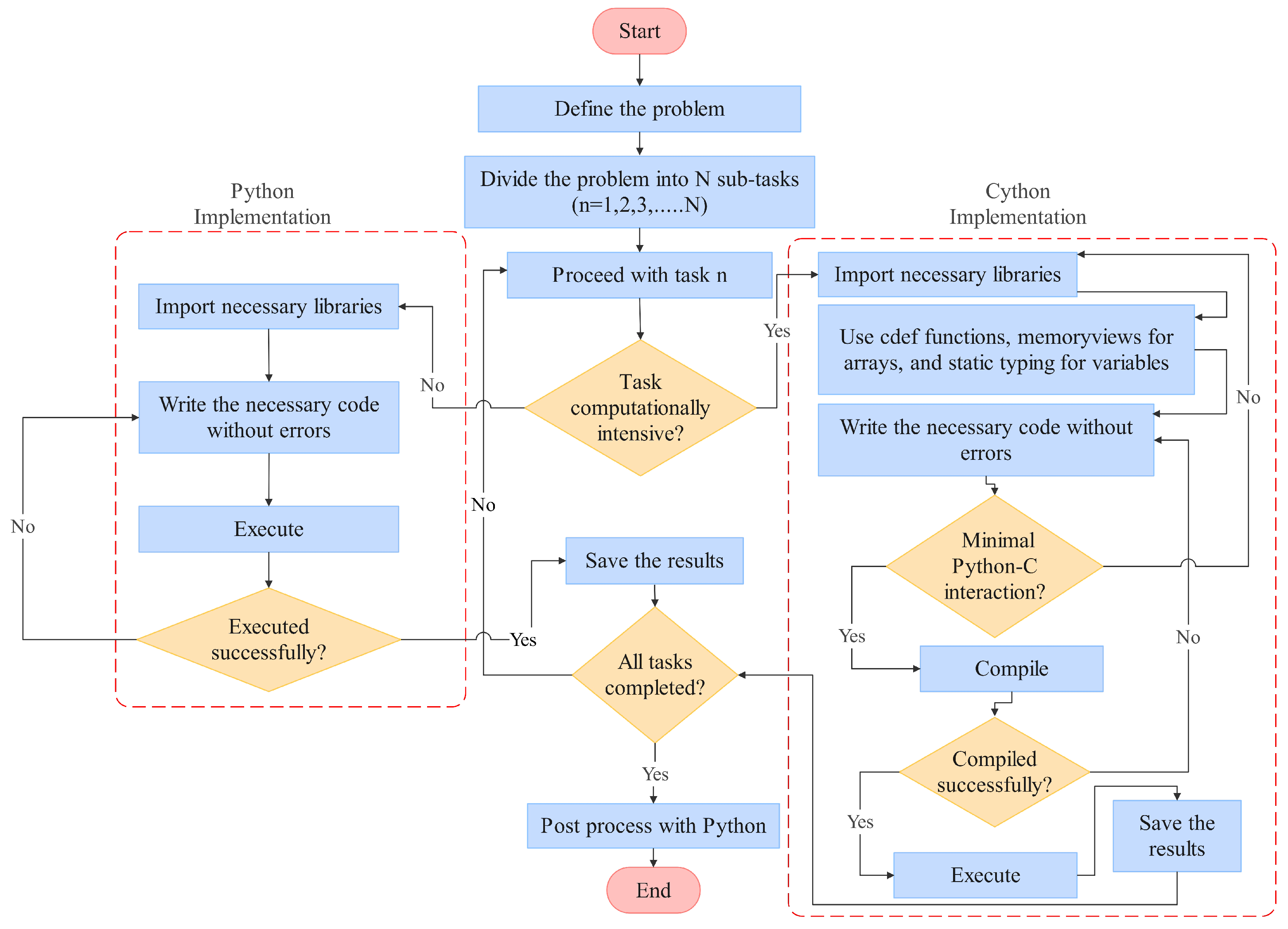

3.1. Implementation of Cython

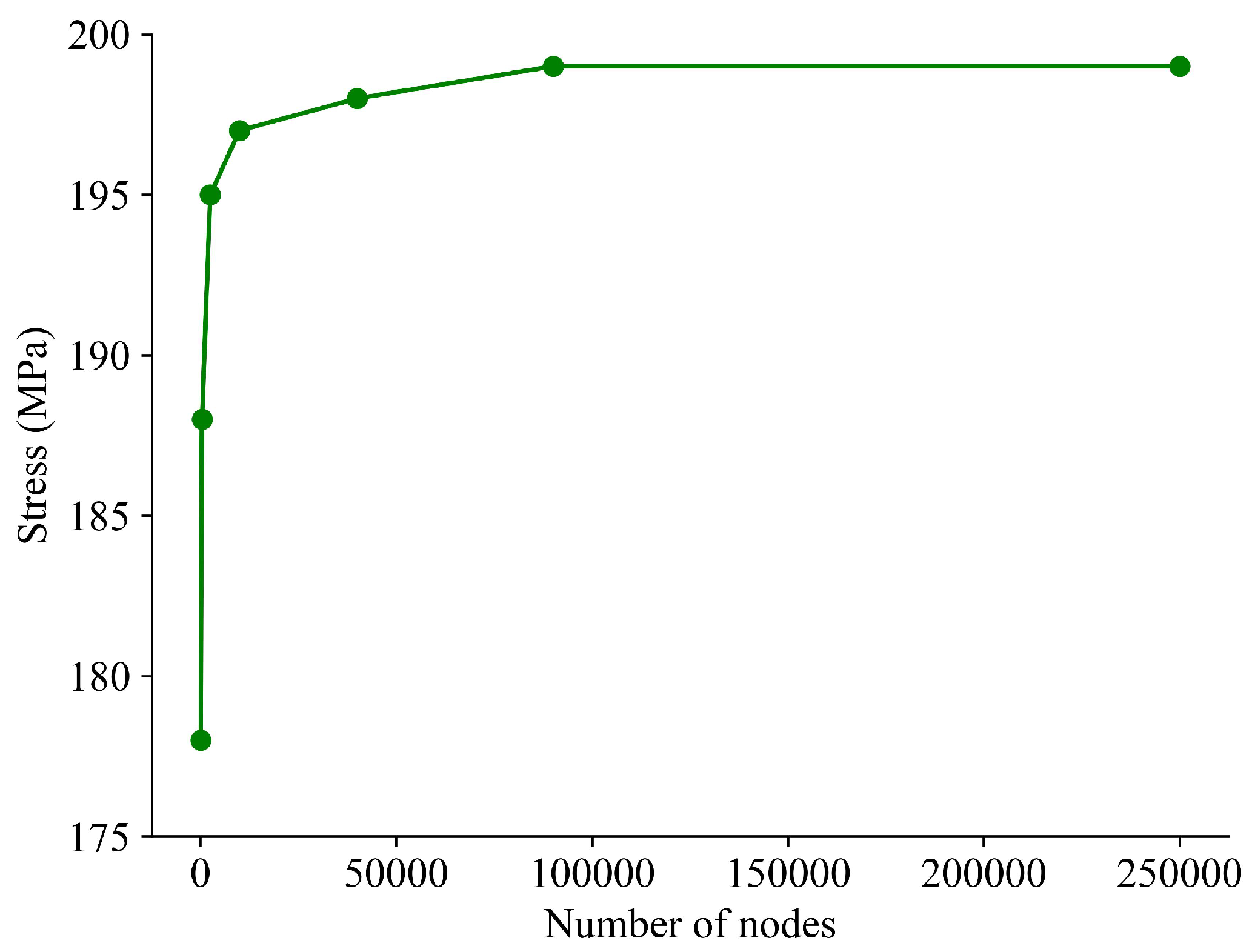

3.2. 2D Plate Under Uniaxial Loading

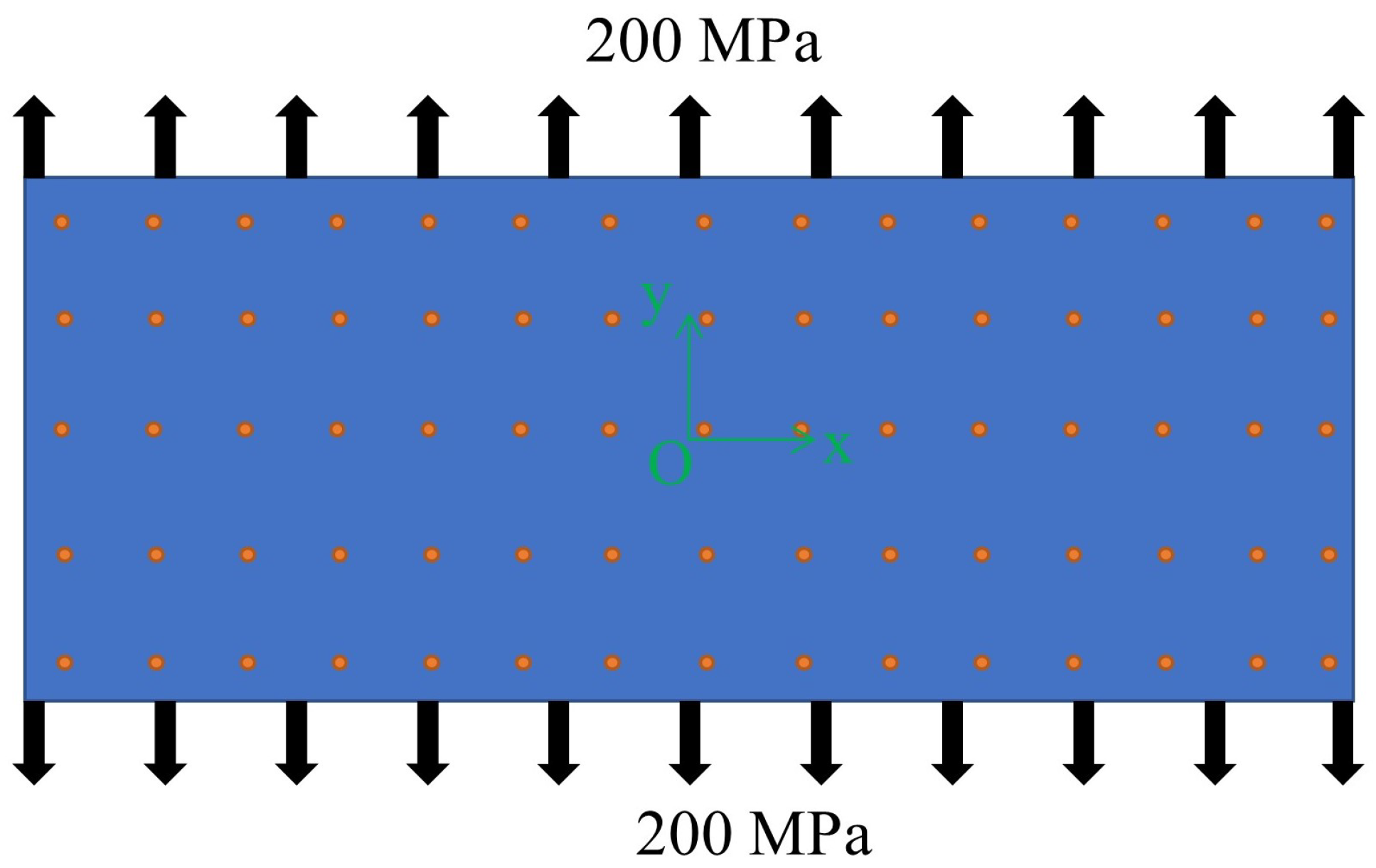

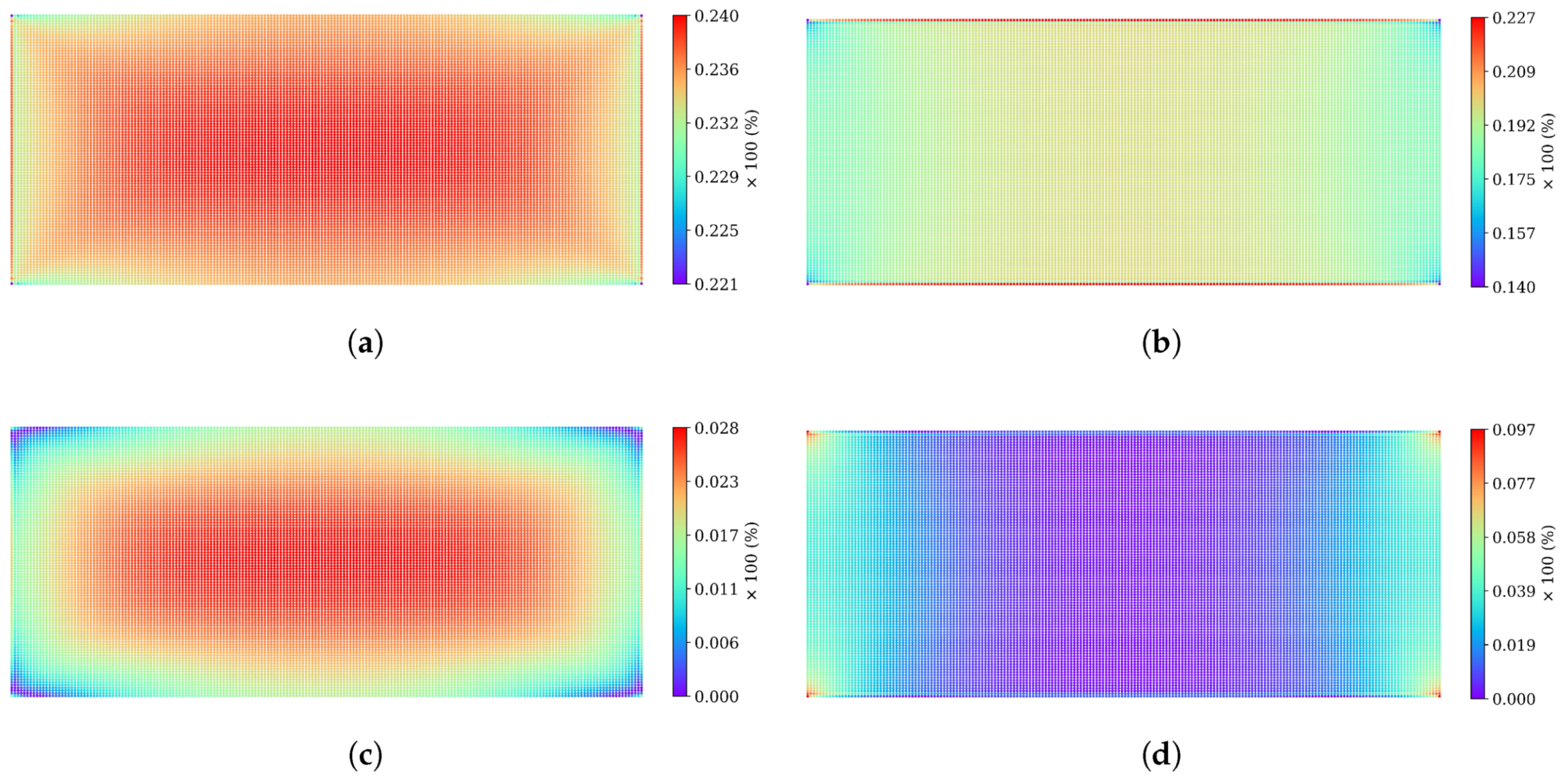

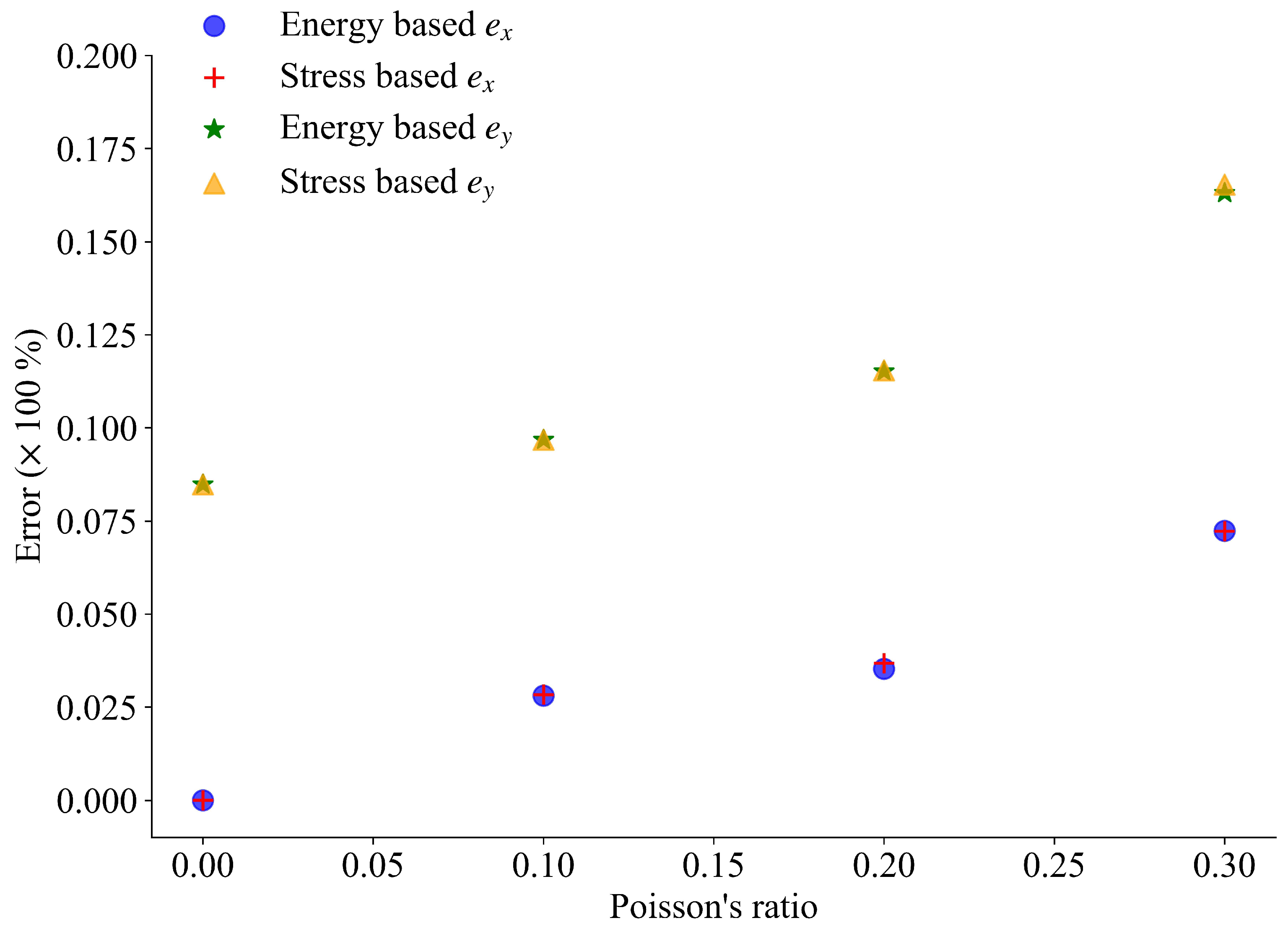

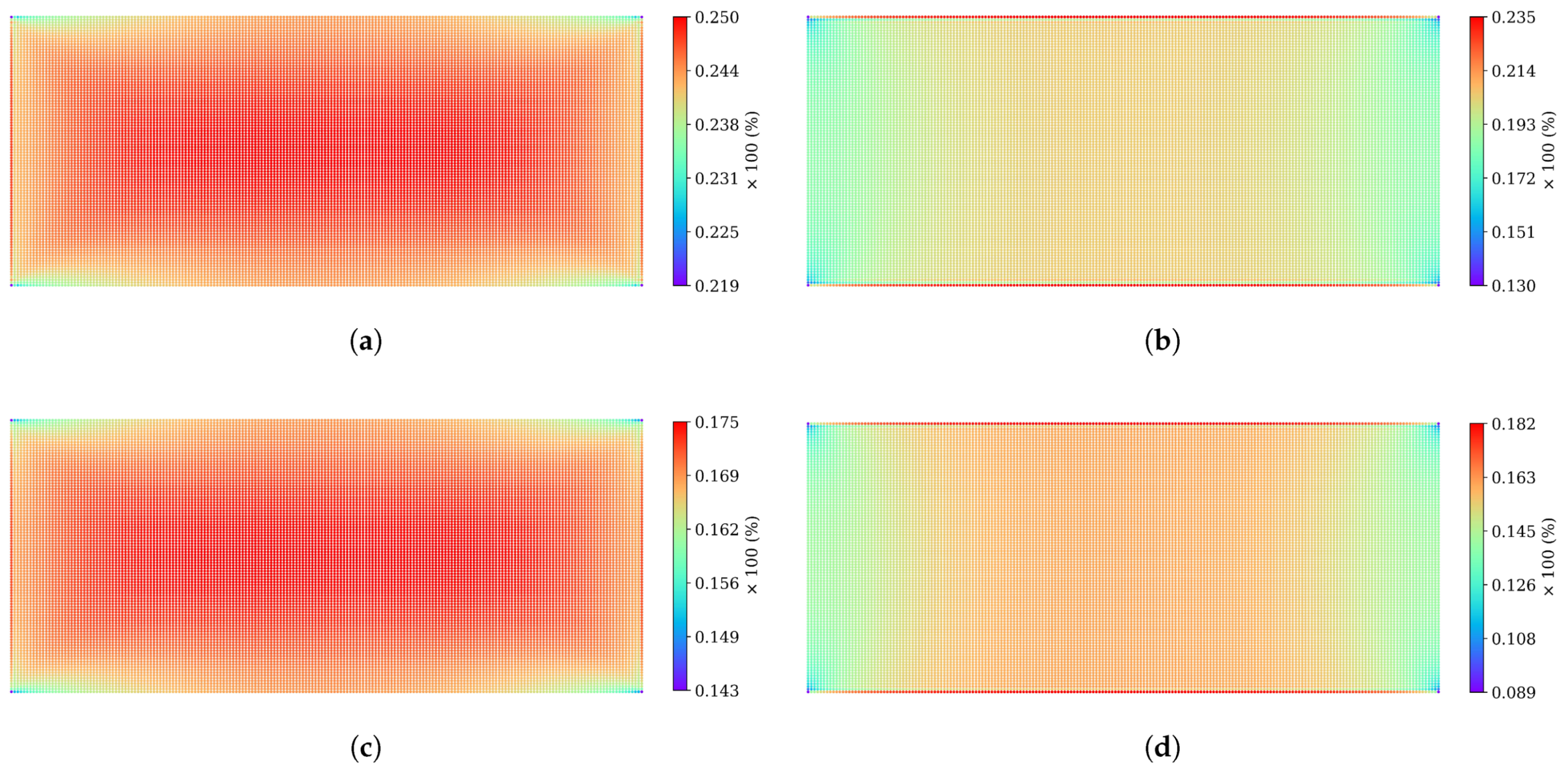

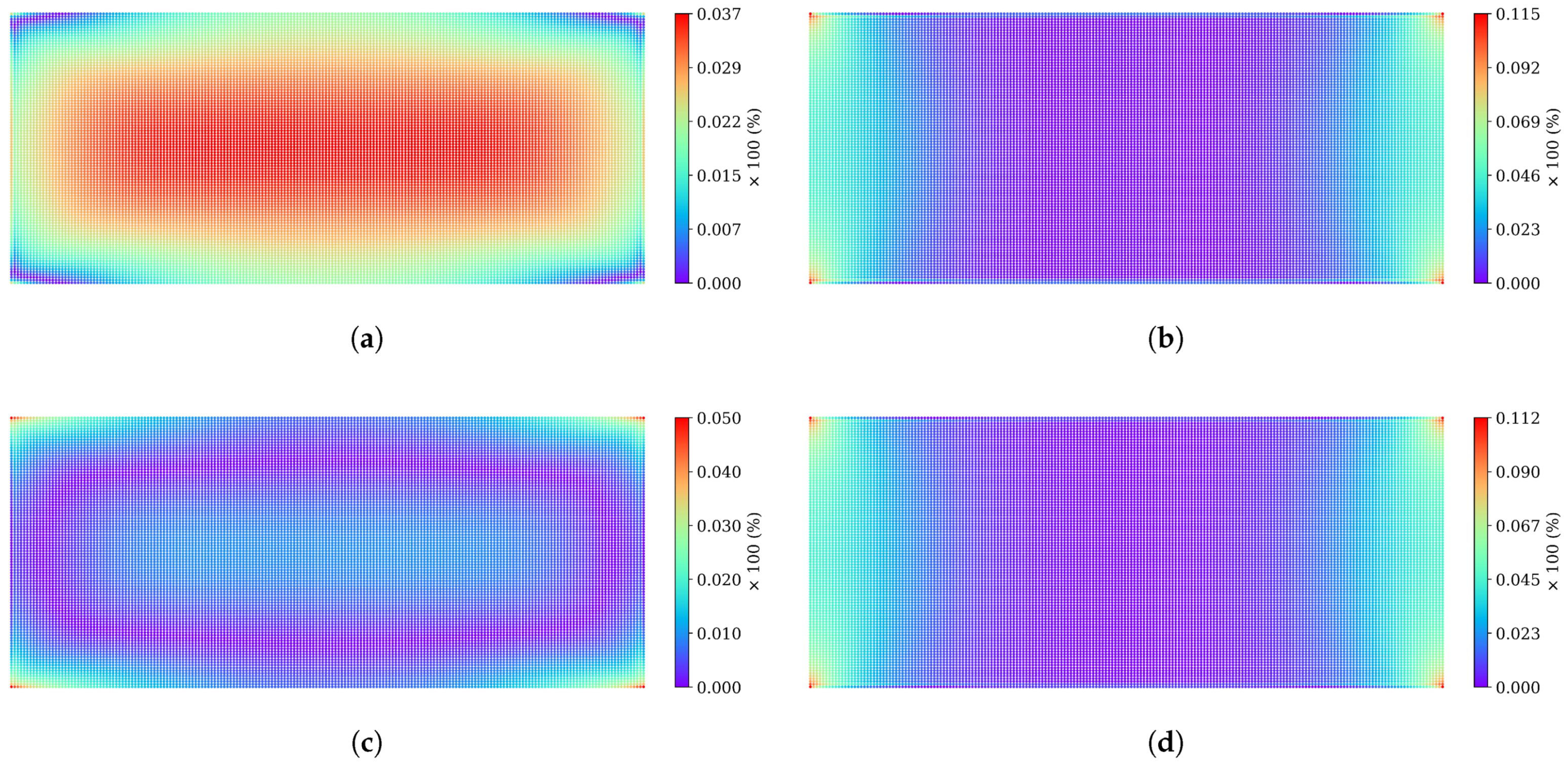

3.3. Rectangular Plate with a Hole

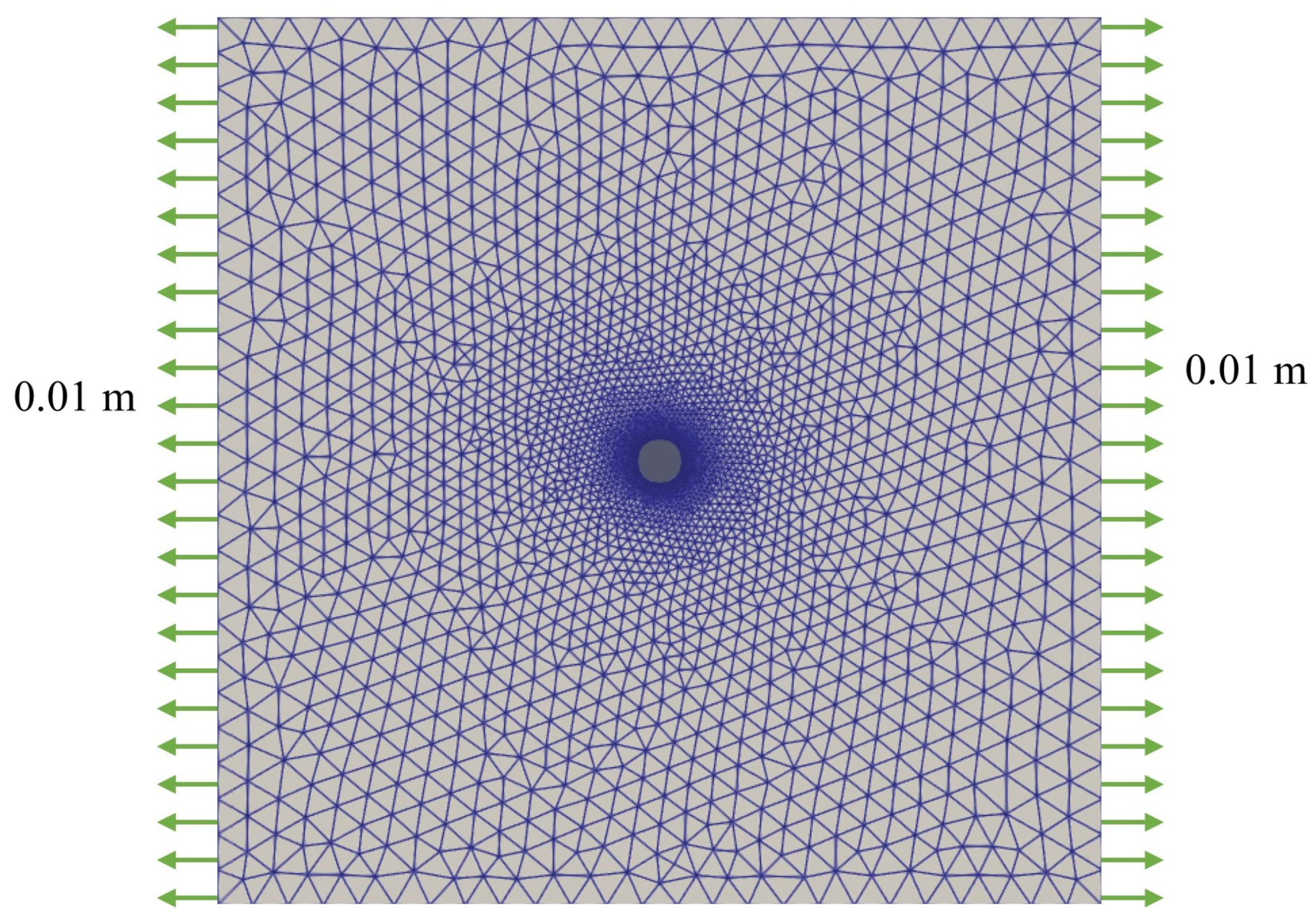

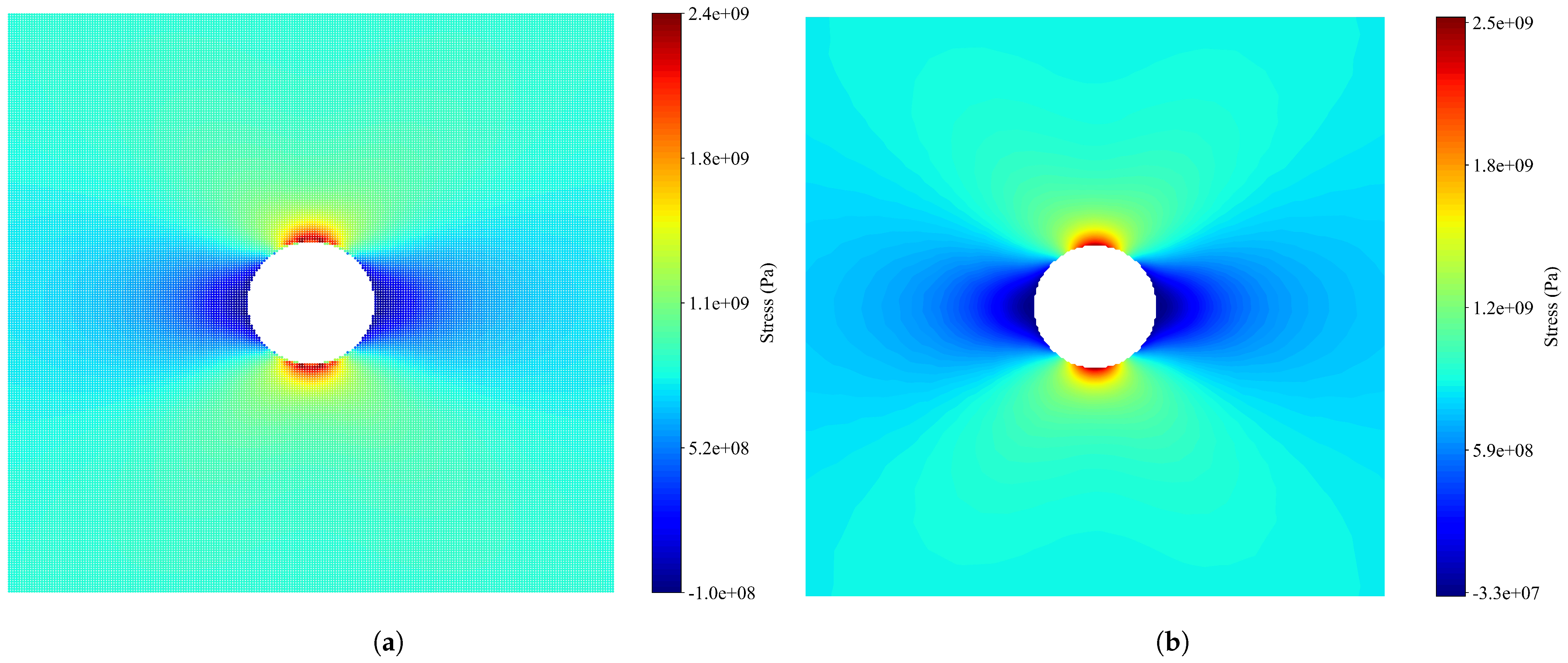

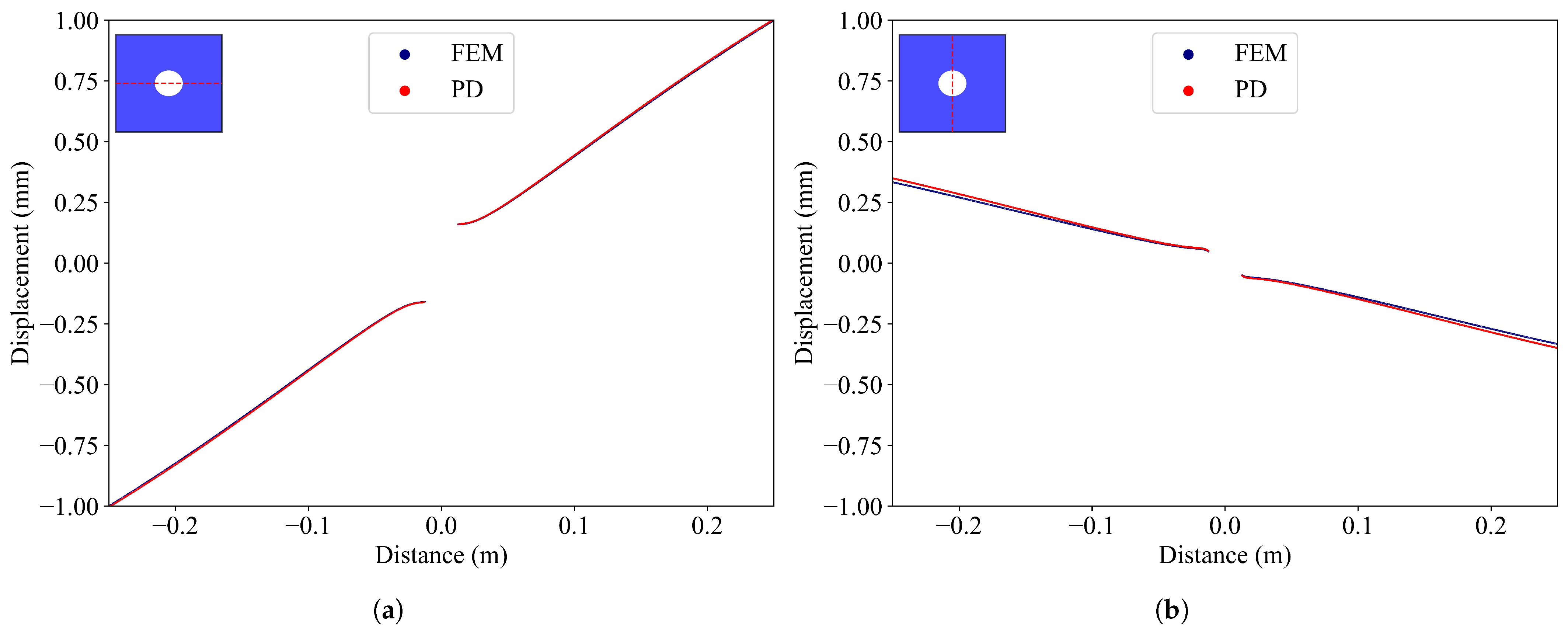

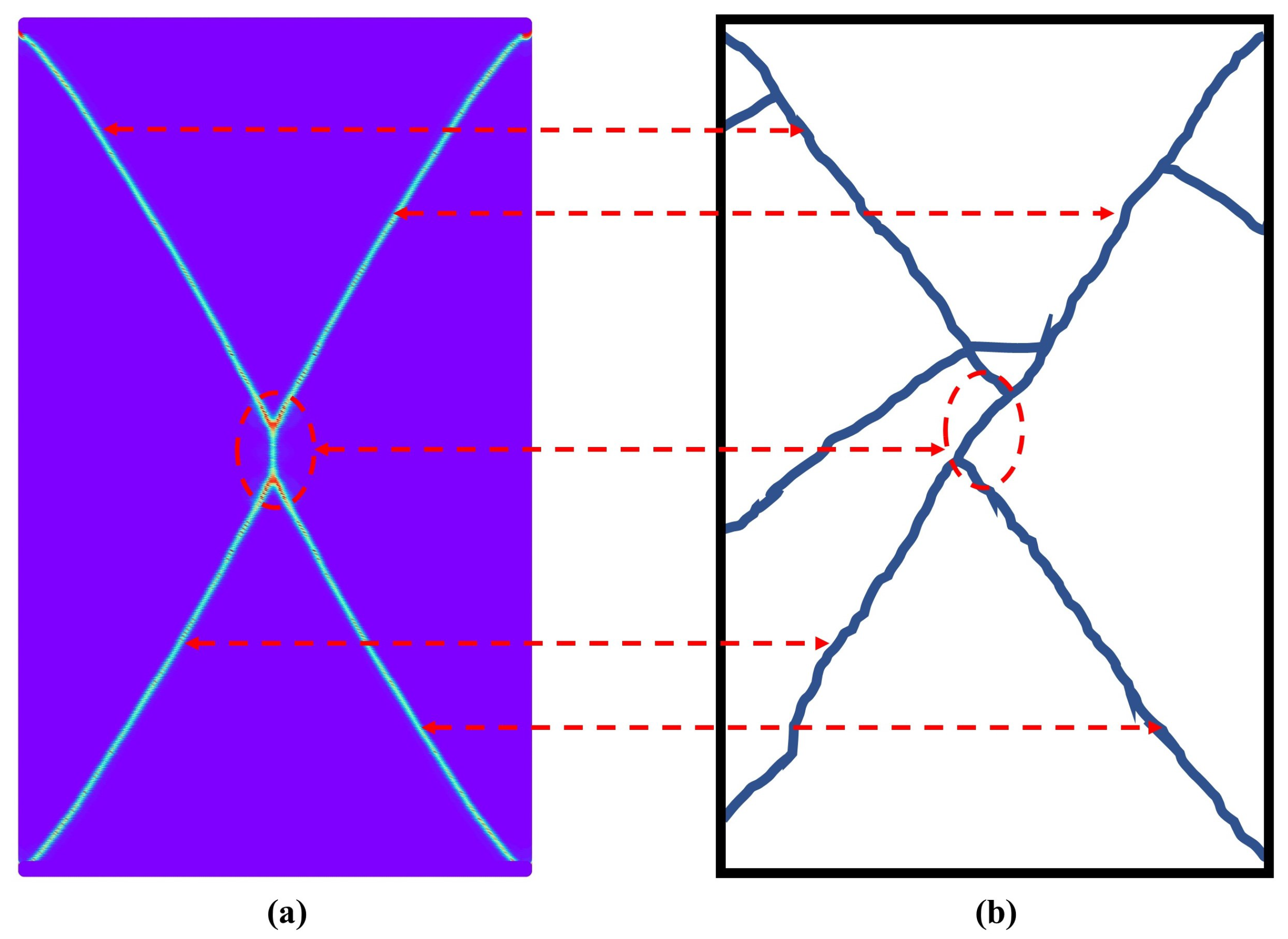

3.4. Uniaxial Compression Test

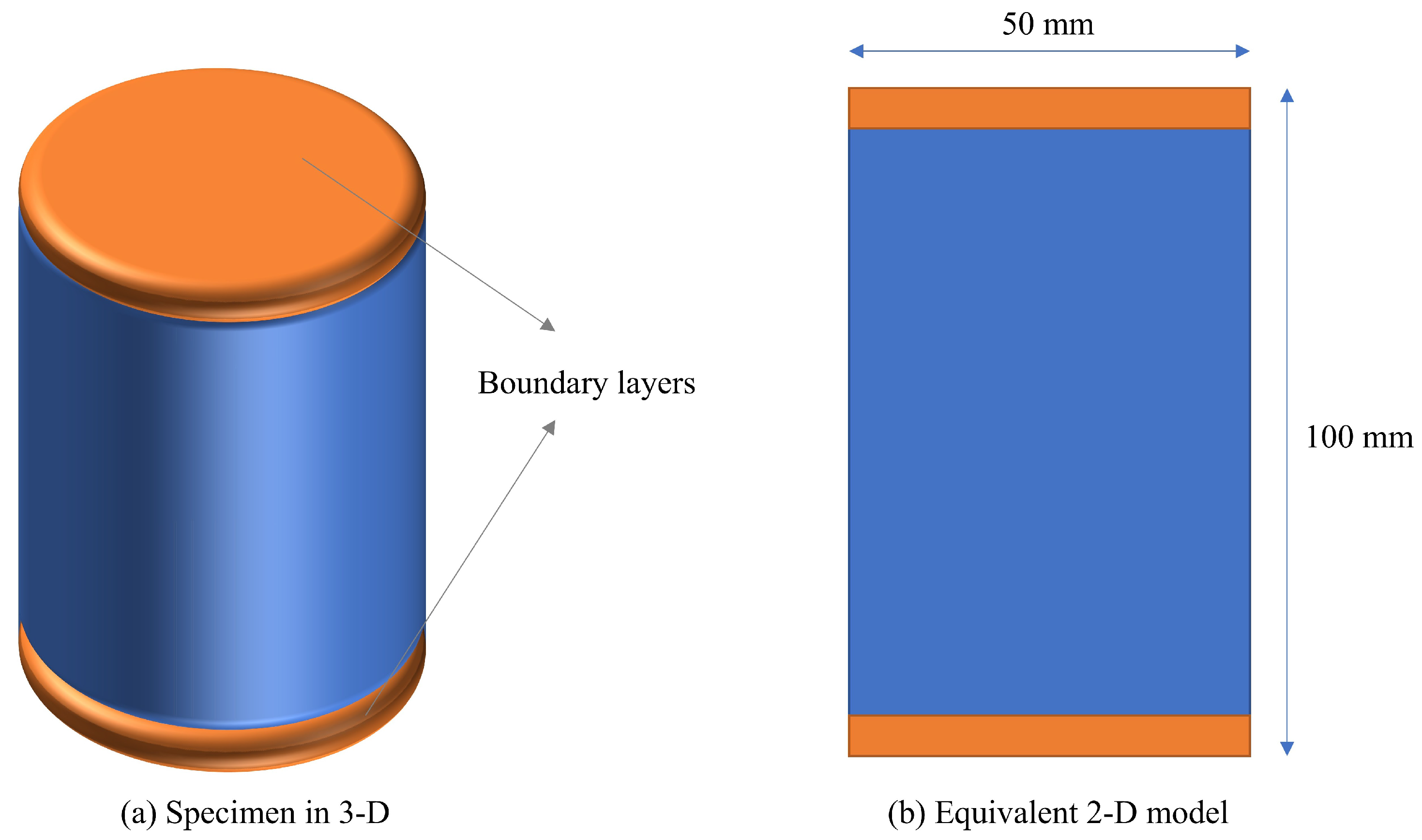

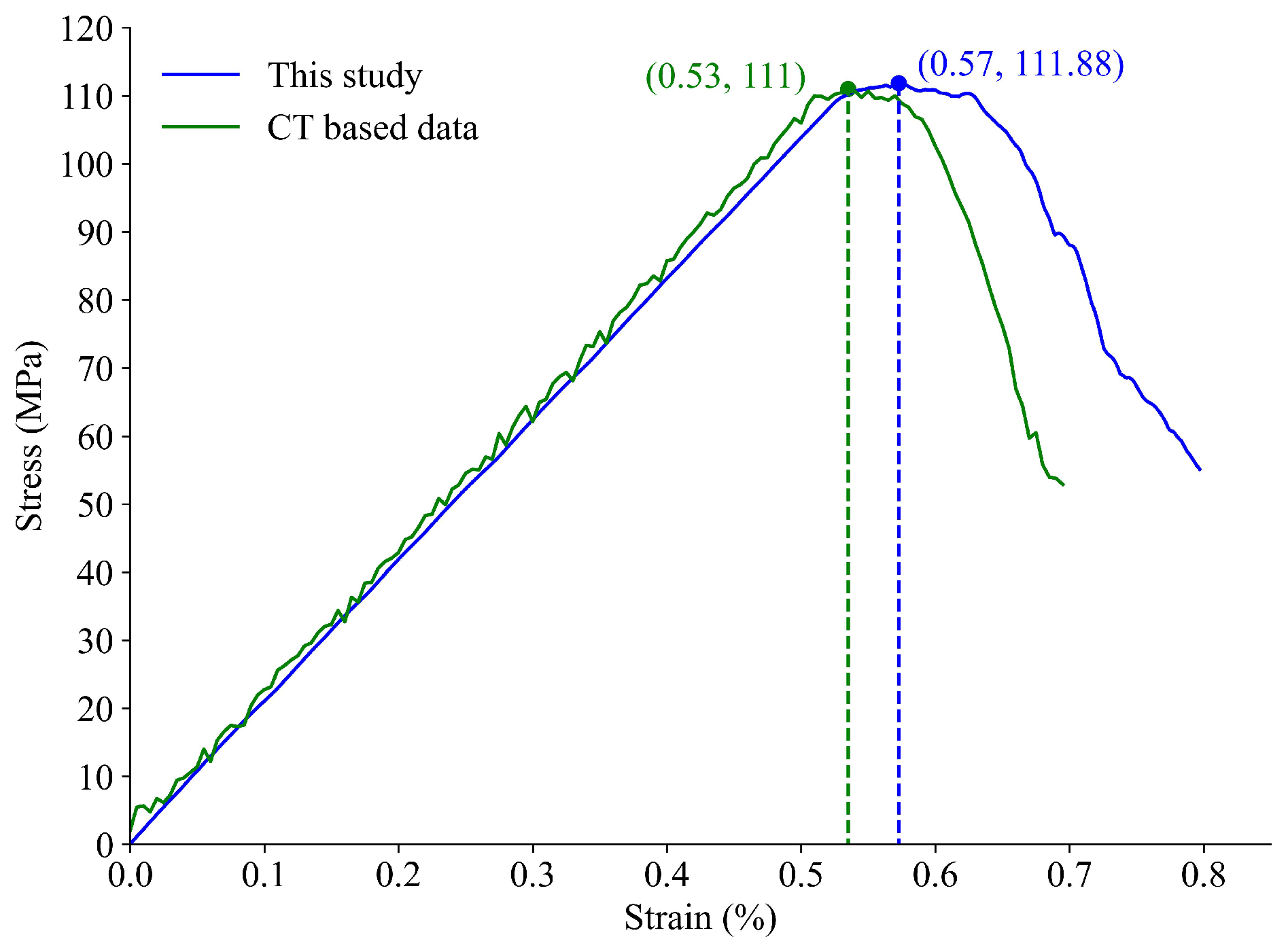

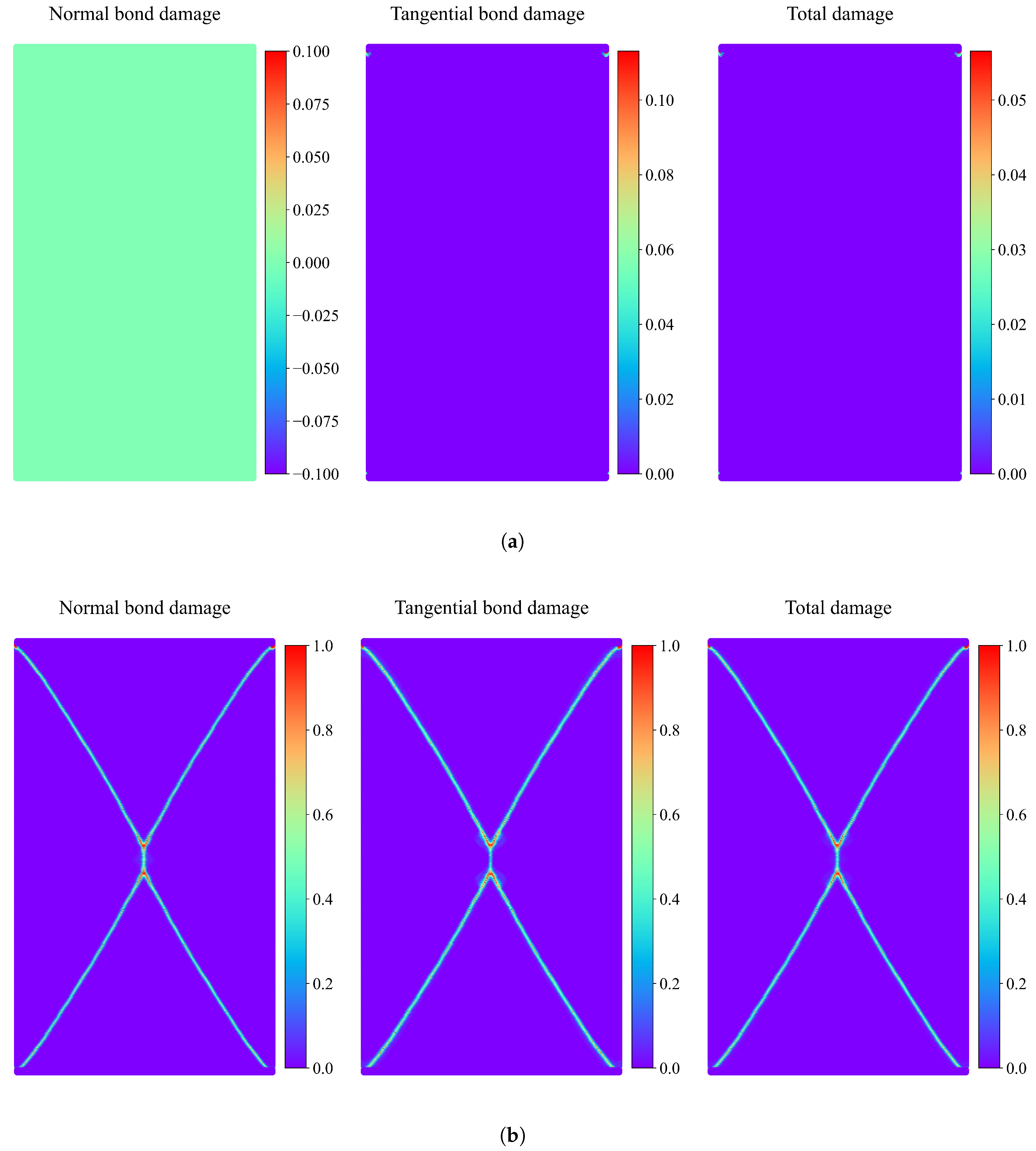

3.5. Comparison with Existing Method

4. Discussion

5. Conclusions

- Individual PD bonds are treated as virtual internal bonds, with equivalent normal and tangential stiffness derived through strain energy equivalence with a classical continuum model. Relationships between these stiffness parameters and traditional elastic constants are established. The resulting PD equations support materials with Poisson’s ratios up to 1/3 for plane-stress conditions and up to 1/4 for plane-strain conditions.

- The proposed stress-based correction method effectively mitigates skin effects. The absolute errors introduced are of the same magnitude as those calculated using the energy-based correction method. The accuracy of node displacement compared to analytical displacements improves as Poisson’s ratio decreases, indicating the correction’s dependence on the sample’s Poisson’s ratio.

- Before correction, PD equations using bond strain conditions yield lower absolute displacement errors along the loading axis compared to those using bond deformation. However, after correction, both methods produce similar errors along this axis. Along the other axis, although the absolute errors are higher before correction for PD equations formulated using bond deformation, they tend to be lower near the boundary after correction compared to those formulated using bond strain conditions. This implies that the PD model developed based on bond deformation could potentially be more effective compared to the model derived from bond strain.

- Deformation-based PD has proven effective in accurately capturing the stress concentration factor, demonstrating its potential for application in modeling complex geometries.

- A mixed-mode failure criterion is derived for deformation-based PD. X-shaped conjugate shear failure is observed in granite specimens, resembling the failure of intact rocks under uniaxial compression testing. Additionally, tangential bond failure occurs before normal bond failure in the uniaxial test.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PD | peridynamics |

| BBPD | bond-based peridynamics |

| FEM | finite element method |

References

- Silling, S.A. Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 2000, 48, 175–209. [Google Scholar] [CrossRef]

- Silling, S.A.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

- Ai, D.; Zhao, Y.; Wang, Q.; Li, C. Crack propagation and dynamic properties of coal under SHPB impact loading: Experimental investigation and numerical simulation. Theor. Appl. Fract. Mech. 2020, 105, 102393. [Google Scholar] [CrossRef]

- Silling, S.A.; Epton, M.; Weckner, O.; Xu, J.; Askari, E. Peridynamic States and Constitutive Modeling. J. Elast. 2007, 88, 151–184. [Google Scholar] [CrossRef]

- Dimola, N.; Coclite, A.; Fanizza, G.; Politi, T. Bond-based peridynamics, a survey prospecting nonlocal theories of fluid-dynamics. Adv. Contin. Discret. Model. 2022, 2022, 60. [Google Scholar] [CrossRef]

- Fallah, A.S.; Giannakeas, I.N.; Mella, R.; Wenman, M.R.; Safa, Y.; Bahai, H. On the Computational Derivation of Bond-Based Peridynamic Stress Tensor. J. Peridyn. Nonlocal Model. 2020, 2, 352–378. [Google Scholar] [CrossRef]

- Battistini, A.; Haynes, T.A.; Jones, L.; Wenman, M.R. Bond-based peridynamics model of 3-point bend tests of ceramic-composite interfaces. J. Am. Ceram. Soc. 2024, 107, 6004–6018. [Google Scholar] [CrossRef]

- Silling, S.A. Introduction to peridynamics. In Handbook of Peridynamic Modeling; Bobaru, F., Foster, J.T., Geubelle, P.H., Silling, S.A., Eds.; Chapman and Hall/CRC: New York, NY, USA, 2016; pp. 63–98. [Google Scholar]

- Gerstle, W.; Sau, N.; Silling, S. Peridynamic modeling of concrete structures. Nucl. Eng. Des. 2007, 237, 1250–1258. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Shou, Y. The modeling of crack propagation and coalescence in rocks under uniaxial compression using the novel conjugated bond-based peridynamics. Int. J. Mech. Sci. 2017, 128–129, 614–643. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Wang, Y.; Shou, Y. A 3-D conjugated bond-pair-based peridynamic formulation for initiation and propagation of cracks in brittle solids. Int. J. Solids Struct. 2018, 134, 89–115. [Google Scholar] [CrossRef]

- Huang, X.; Li, S.; Jin, Y.; Yang, D.; Su, G.; He, X. Analysis on the influence of Poisson’s ratio on brittle fracture by applying uni-bond dual-parameter peridynamic model. Eng. Fract. Mech. 2019, 222, 106685. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, Z.; Li, L.; Li, Z.; Zhang, D.; Cheng, S. Strength reduction model for jointed rock masses and peridynamics simulation of uniaxial compression testing. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Yang, S.Q.; Yang, Z.; Zhang, P.C.; Tian, W.L. Experiment and peridynamic simulation on cracking behavior of red sandstone containing a single non-straight fissure under uniaxial compression. Theor. Appl. Fract. Mech. 2020, 108, 102637. [Google Scholar] [CrossRef]

- Ha, Y.D.; Lee, J.; Hong, J.W. Fracturing patterns of rock-like materials in compression captured with peridynamics. Eng. Fract. Mech. 2015, 144, 176–193. [Google Scholar] [CrossRef]

- Yaghoobi, A.; Chorzepa, M.G. Fracture analysis of fiber reinforced concrete structures in the micropolar peridynamic analysis framework. Eng. Fract. Mech. 2017, 169, 238–250. [Google Scholar] [CrossRef]

- Du, W.; Fu, X.; Sheng, Q.; Chen, J.; Du, Y.; Zhang, Z. Study on the failure process of rocks with closed fractures under compressive loading using improved bond-based peridynamics. Eng. Fract. Mech. 2020, 240, 107315. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Z.; Gao, C.; Zhang, D.; Wang, M.; Wei, C.; Bai, S. Peridynamic micro-elastoplastic constitutive model and its application in the failure analysis of rock masses. Comput. Geotech. 2021, 132, 104037. [Google Scholar] [CrossRef]

- Li, S.; Lu, H.; Jin, Y.; Sun, P.; Huang, X.; Bie, Z. An improved unibond dual-parameter peridynamic model for fracture analysis of quasi-brittle materials. Int. J. Mech. Sci. 2021, 204, 106571. [Google Scholar] [CrossRef]

- Feng, K.; Zhou, X.P. Peridynamic simulation of the mechanical responses and fracturing behaviors of granite subjected to uniaxial compression based on CT heterogeneous data. Eng. Comput. 2023, 39, 1–23. [Google Scholar] [CrossRef]

- Diana, V.; Casolo, S. A bond-based micropolar peridynamic model with shear deformability: Elasticity, failure properties and initial yield domains. Int. J. Solids Struct. 2019, 160, 201–231. [Google Scholar] [CrossRef]

- Madenci, E.; Barut, A.; Phan, N. Bond-based peridynamics with stretch and rotation kinematics for opening and shearing modes of fracture. J. Peridyn. Nonlocal Model. 2021, 3, 211–254. [Google Scholar] [CrossRef]

- Chen, Z.; Ju, J.W.; Su, G.; Huang, X.; Li, S.; Zhai, L. Influence of micro-modulus functions on peridynamics simulation of crack propagation and branching in brittle materials. Eng. Fract. Mech. 2019, 216, 106498. [Google Scholar] [CrossRef]

- Kilic, B.; Madenci, E. Structural stability and failure analysis using peridynamic theory. Int. J. Non-Linear Mech. 2009, 44, 845–854. [Google Scholar] [CrossRef]

- Kilic, B.; Madenci, E. Prediction of crack paths in a quenched glass plate by using peridynamic theory. Int. J. Fract. 2009, 156, 165–177. [Google Scholar] [CrossRef]

- Madenci, E.; Oterkus, E. Peridynamic Theory and Its Applications; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Shen, S.; Yang, Z.; Han, F.; Cui, J.; Zhang, J. Peridynamic modeling with energy-based surface correction for fracture simulation of random porous materials. Theor. Appl. Fract. Mech. 2021, 114, 102987. [Google Scholar] [CrossRef]

- Kilic, B.; Madenci, E. Coupling of peridynamic theory and the finite element method. J. Mech. Mater. Struct. 2010, 5, 707–733. [Google Scholar] [CrossRef]

- Macek, R.W.; Silling, S.A. Peridynamics via finite element analysis. Finite Elem. Anal. Des. 2007, 43, 1169–1178. [Google Scholar] [CrossRef]

- Liu, Y.; Han, F.; Zhang, L. An extended fictitious node method for surface effect correction of bond-based peridynamics. Eng. Anal. Bound. Elem. 2022, 143, 78–94. [Google Scholar] [CrossRef]

- Mitchell, J.; Silling, S.; Littlewood, D. A position-aware linear solid constitutive model for peridynamics. J. Mech. Mater. Struct. 2015, 10, 539–557. [Google Scholar] [CrossRef]

- Le, Q.; Bobaru, F. Surface corrections for peridynamic models in elasticity and fracture. Comput. Mech. 2018, 61, 499–518. [Google Scholar] [CrossRef]

- Gao, H.; Klein, P. Numerical simulation of crack growth in an isotropic solid with randomized internal cohesive bonds. J. Mech. Phys. Solids 1998, 46, 187–218. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, X. Micromechanical consideration of tensile crack behavior based on virtual internal bond in contrast to cohesive stress. Theor. Appl. Fract. Mech. 2005, 43, 342–359. [Google Scholar] [CrossRef]

- Zhennan, Z.; Xiurun, G. Micromechanical modelling of elastic continuum with virtual multi-dimensional internal bonds. Int. J. Numer. Methods Eng. 2006, 65, 135–146. [Google Scholar] [CrossRef]

- Boresi, A.P.; Chong, K.; Lee, J.D. Elasticity in Engineering Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Ha, Y.D.; Bobaru, F. Characteristics of dynamic brittle fracture captured with peridynamics. Eng. Fract. Mech. 2011, 78, 1156–1168. [Google Scholar] [CrossRef]

- Seleson, P.; Parks, M.L.; Gunzburger, M.; Lehoucq, R.B. Peridynamics as an upscaling of molecular dynamics. Multiscale Model. Simul. 2009, 8, 204–227. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Lai, X.; Liu, L. Peridynamic stress is the static first Piola–Kirchhoff Virial stress. Int. J. Solids Struct. 2022, 241, 111478. [Google Scholar] [CrossRef]

- Lutz, M. Programming Python: Powerful Object-Oriented Programming; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2010. [Google Scholar]

- Behnel, S.; Bradshaw, R.; Citro, C.; Dalcin, L.; Seljebotn, D.S.; Smith, K. Cython: The Best of Both Worlds. Comput. Sci. Eng. 2011, 13, 31–39. [Google Scholar] [CrossRef]

- Sauvé, R.; Metzger, D. Advances in dynamic relaxation techniques for nonlinear finite element analysis. J. Press. Vessel Technol.-Trans. 1995, 117, 170–176. [Google Scholar] [CrossRef]

- Ha, Y.D.; Bobaru, F. Studies of dynamic crack propagation and crack branching with peridynamics. Int. J. Fract. 2010, 162, 229–244. [Google Scholar] [CrossRef]

- Zhu, Q.Z.; Ni, T. Peridynamic formulations enriched with bond rotation effects. Int. J. Eng. Sci. 2017, 121, 118–129. [Google Scholar] [CrossRef]

| Poisson’s Ratio | (%) | (%) | Computed Poisson’s Ratio | Remarks |

|---|---|---|---|---|

| 0.0 | - | 22.074 | 0.0 | Uncorrected |

| 0.0 | - | 8.482 | 0.0 | Corrected |

| 0.1 | 23.973 | 22.674 | 0.124 | Uncorrected |

| 0.1 | 5.144 | 7.658 | 0.104 | Corrected |

| 0.2 | 24.983 | 23.468 | 0.249 | Uncorrected |

| 0.2 | 3.680 | 11.545 | 0.205 | Corrected |

| 0.3 | 26.611 | 24.587 | 0.378 | Uncorrected |

| 0.3 | 7.224 | 16.532 | 0.311 | Corrected |

| E (GPa) | (kg/m3) | UCS (MPa) | (Jm2) | (Jm2) | (°) | |

|---|---|---|---|---|---|---|

| 21 | 2800 | 0.23 | 112 | 93 | 170 |

| Parameters | Values |

|---|---|

| material spacing | 0.0002 m |

| horizon | 0.0006 m |

| critical tensile deformation | µm |

| critical compressive deformation | µm |

| critical tangential deformation | µm |

| loading rate | m/s |

| time step | 1 s |

| Before Correction | After Correction | |||||||

|---|---|---|---|---|---|---|---|---|

| Poisson’s Ratio | Deformation | Stretch | Deformation | Stretch | ||||

| 0 | - | 22.074 | - | 17.700 | - | 8.482 | - | 8.251 |

| 0.1 | 23.973 | 22.674 | 17.204 | 17.924 | 2.840 | 9.682 | 3.667 | 9.419 |

| 0.2 | 24.983 | 23.468 | 17.504 | 18.193 | 3.680 | 11.545 | 4.984 | 11.237 |

| 0.3 | 26.611 | 24.587 | 18.254 | 18.568 | 7.224 | 16.532 | 10.111 | 16.072 |

| After Correction | ||||

|---|---|---|---|---|

| Poisson’s Ratio | Deformation | Stretch | ||

| 0.0 | - | 5.550 | - | 5.417 |

| 0.1 | 2.840 | 6.305 | 2.010 | 6.142 |

| 0.2 | 3.680 | 7.421 | 2.505 | 7.219 |

| 0.3 | 5.672 | 10.247 | 4.7971 | 9.908 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adhikari, B.; Li, D.; Han, Z. A Deformation-Based Peridynamic Model: Theory and Application. Buildings 2025, 15, 1931. https://doi.org/10.3390/buildings15111931

Adhikari B, Li D, Han Z. A Deformation-Based Peridynamic Model: Theory and Application. Buildings. 2025; 15(11):1931. https://doi.org/10.3390/buildings15111931

Chicago/Turabian StyleAdhikari, Bipin, Diyuan Li, and Zhenyu Han. 2025. "A Deformation-Based Peridynamic Model: Theory and Application" Buildings 15, no. 11: 1931. https://doi.org/10.3390/buildings15111931

APA StyleAdhikari, B., Li, D., & Han, Z. (2025). A Deformation-Based Peridynamic Model: Theory and Application. Buildings, 15(11), 1931. https://doi.org/10.3390/buildings15111931