Shear Strength and Ultimate Bearing Capacity of Silt-Based Foamed Concrete Under Local Vertical Loading

Abstract

1. Introduction

2. Experimental Program and Materials

2.1. Materials

2.2. Sample Preparation

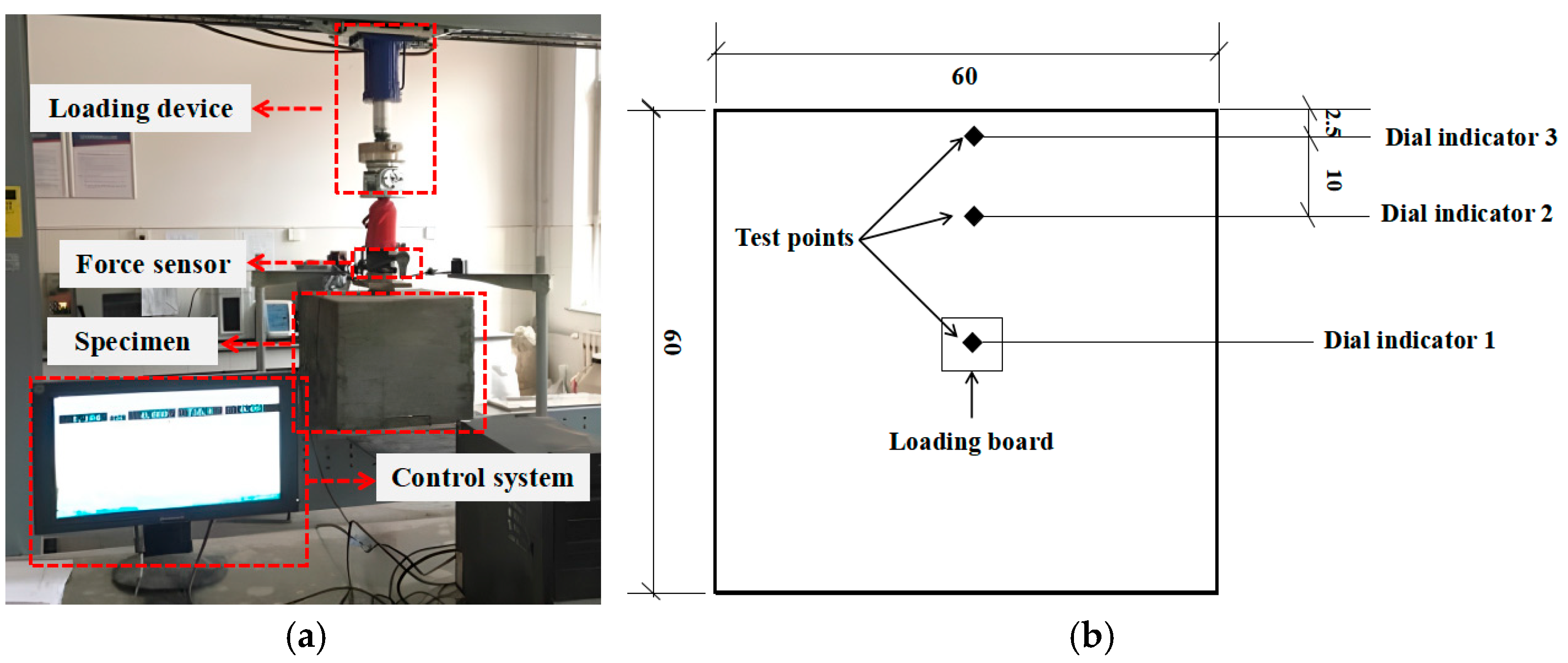

2.3. Static Triaxial Test

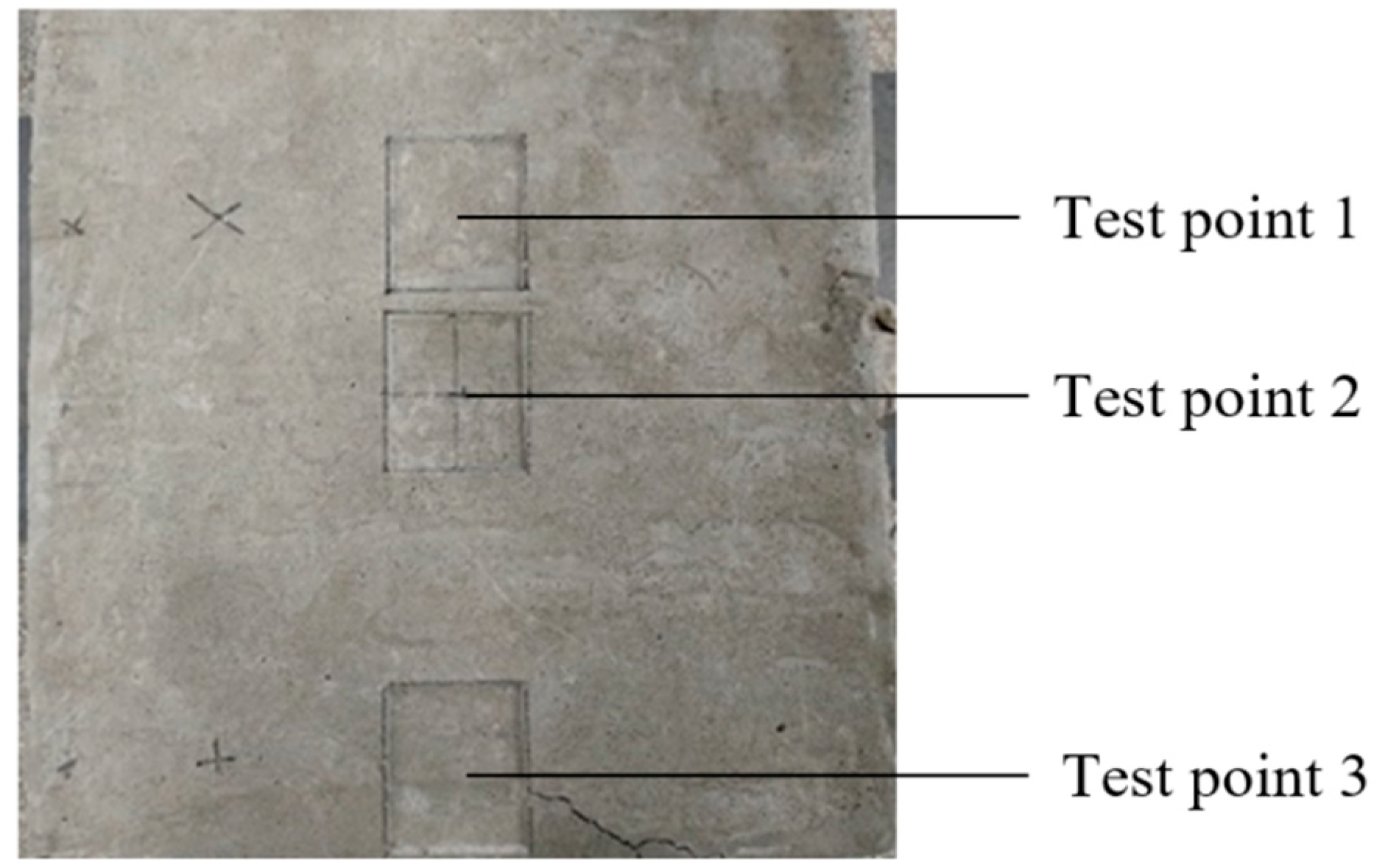

2.4. Local Loading on Foamed Concrete Foundation

3. Test Results and Discussion

3.1. Triaxial Compression of Silt-Based Foamed Concrete

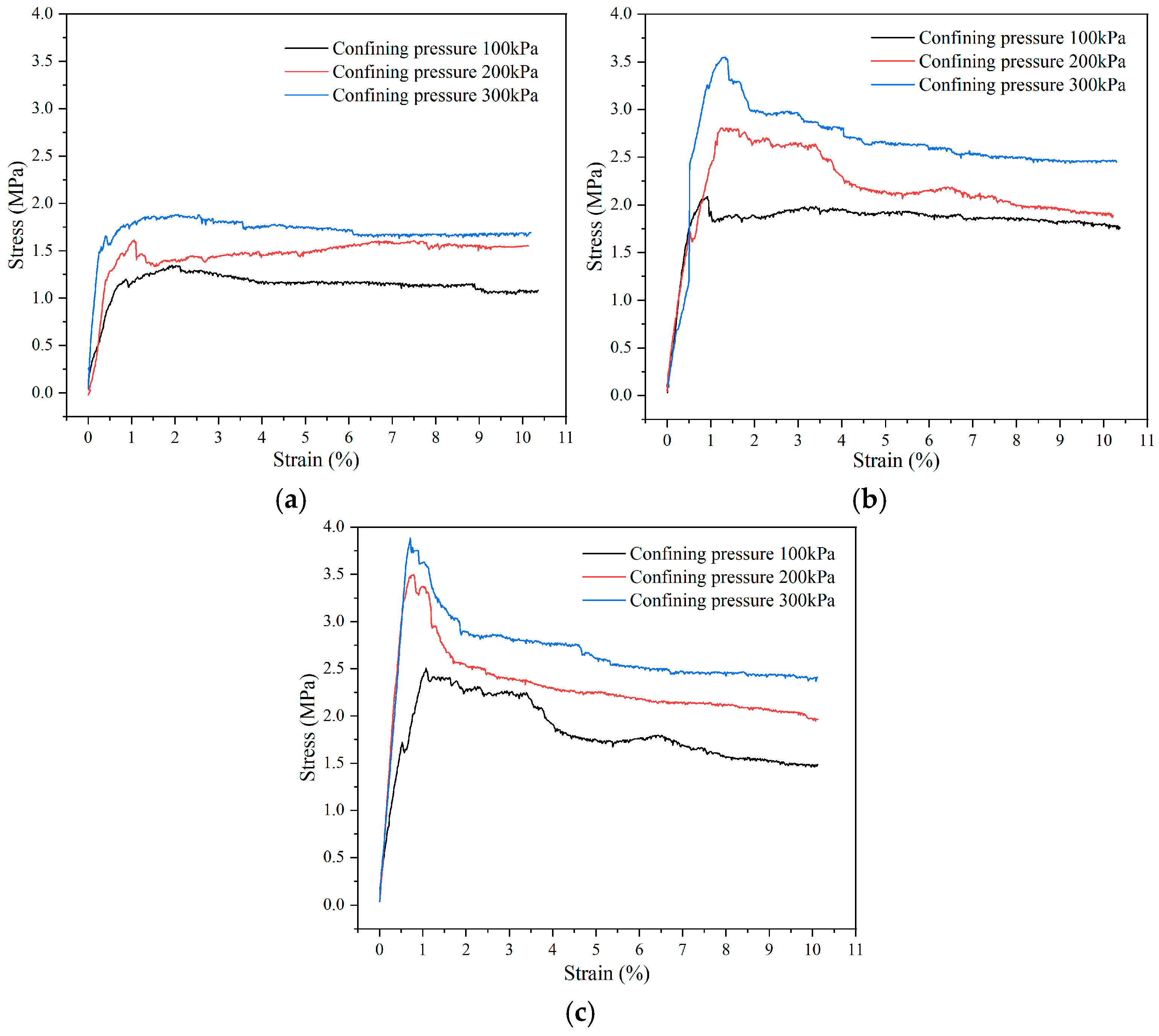

3.1.1. Stress–Strain Curves

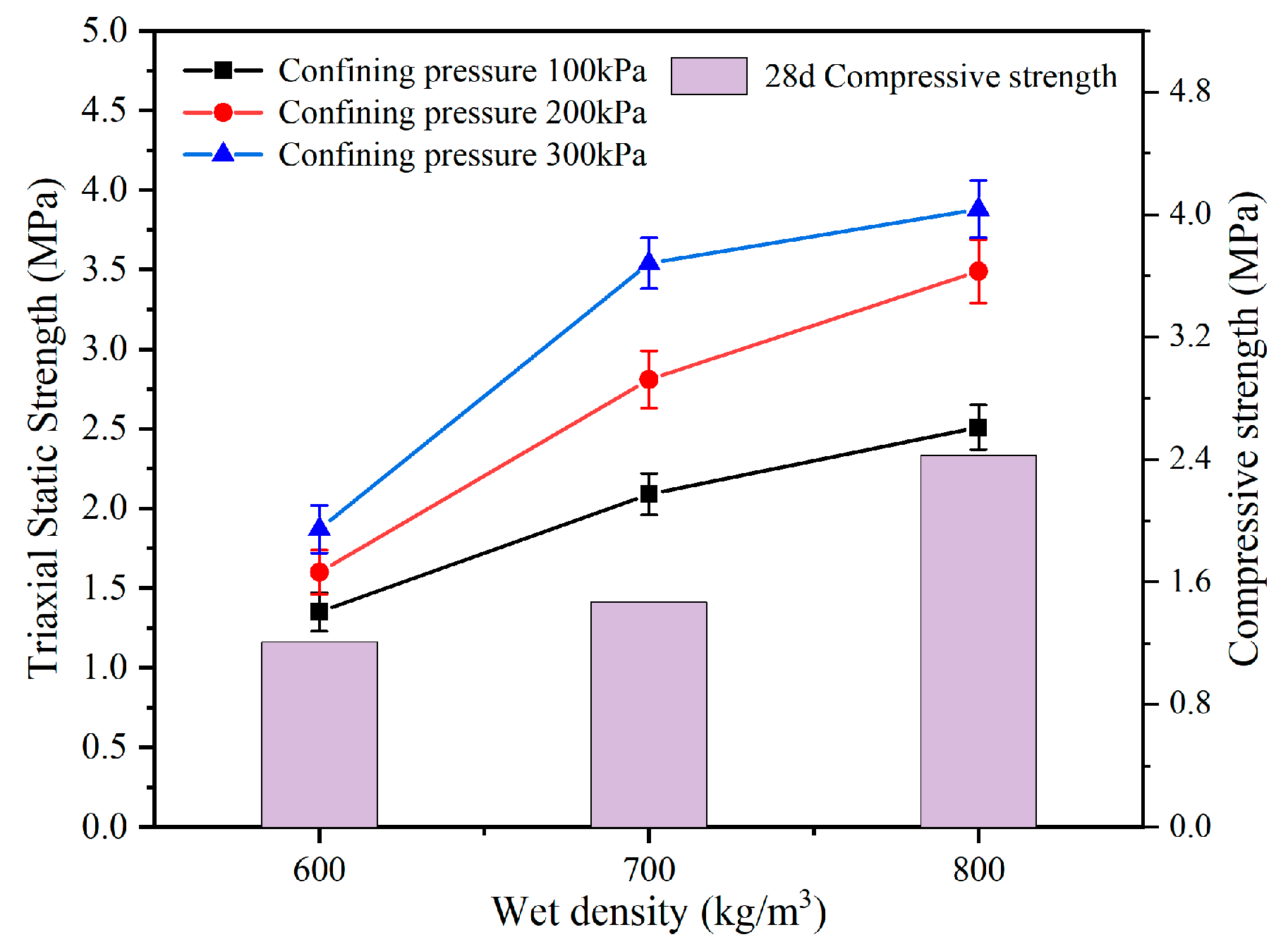

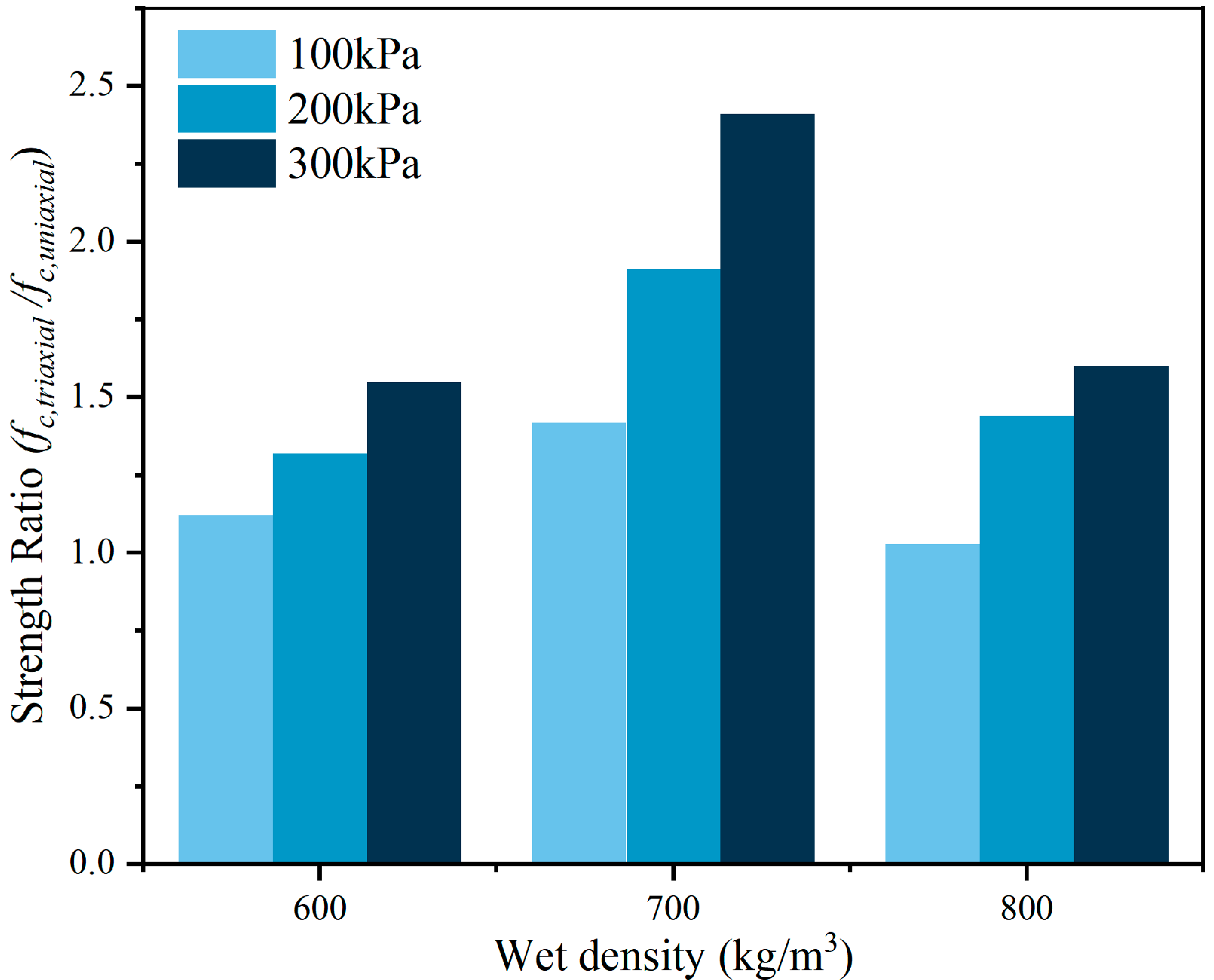

3.1.2. Compression Strength and Strength Ratio

3.1.3. Shear Strength

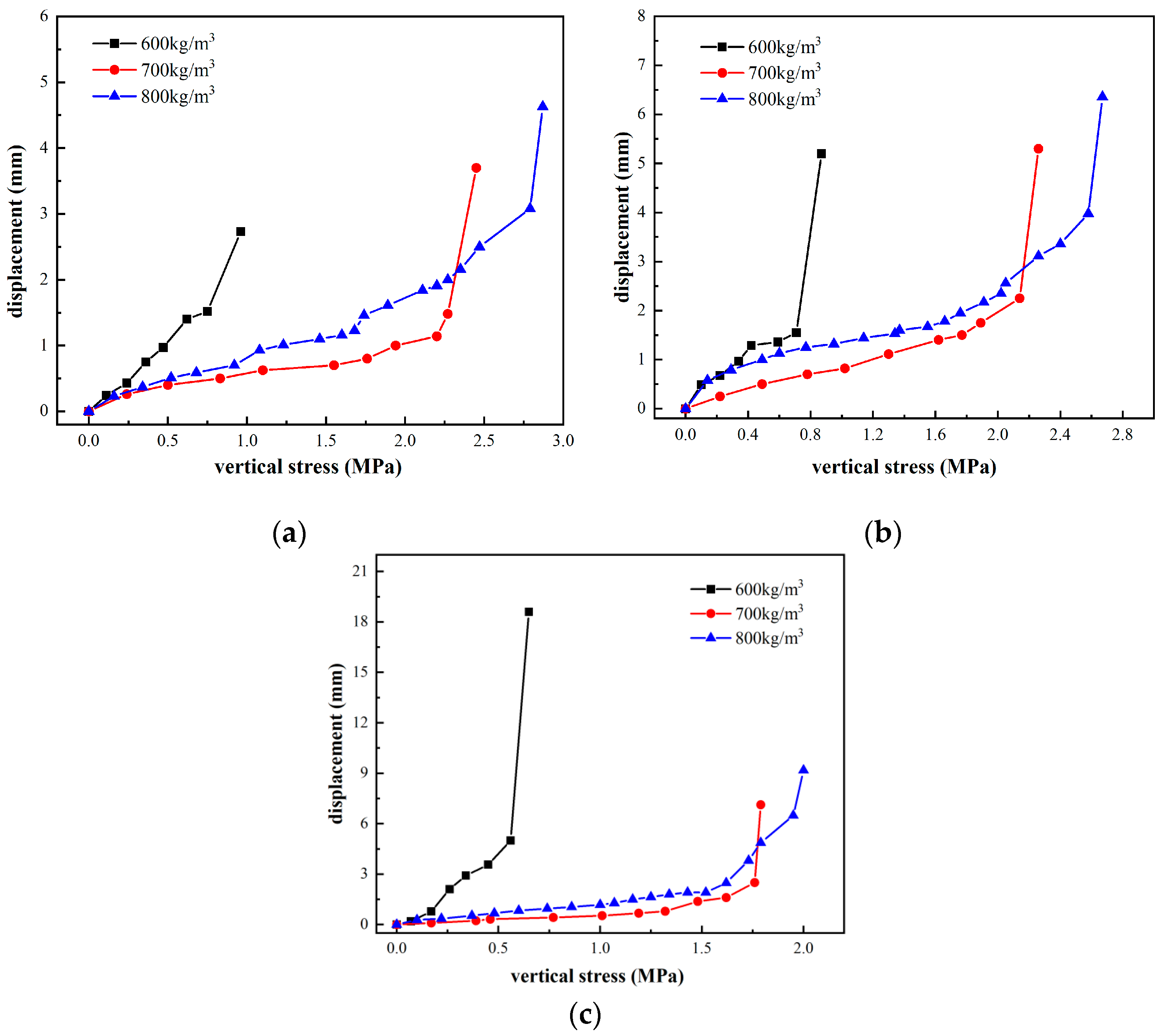

3.2. Deformation and Bearing Capacity Under Different Loading Conditions

3.2.1. The Effect of the Wet Density

3.2.2. The Effect of Different Loading Points

4. Theoretical Analysis of Bearing Capacity

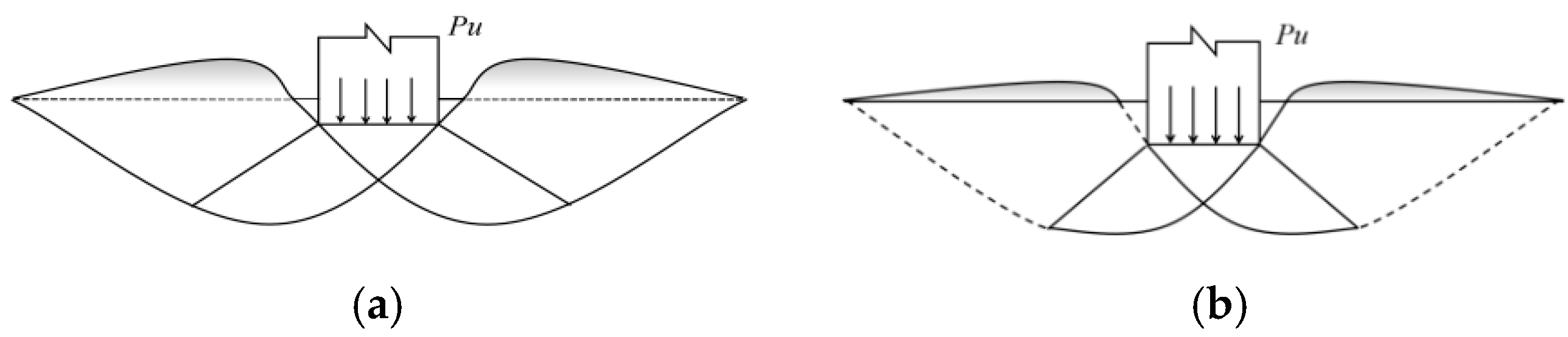

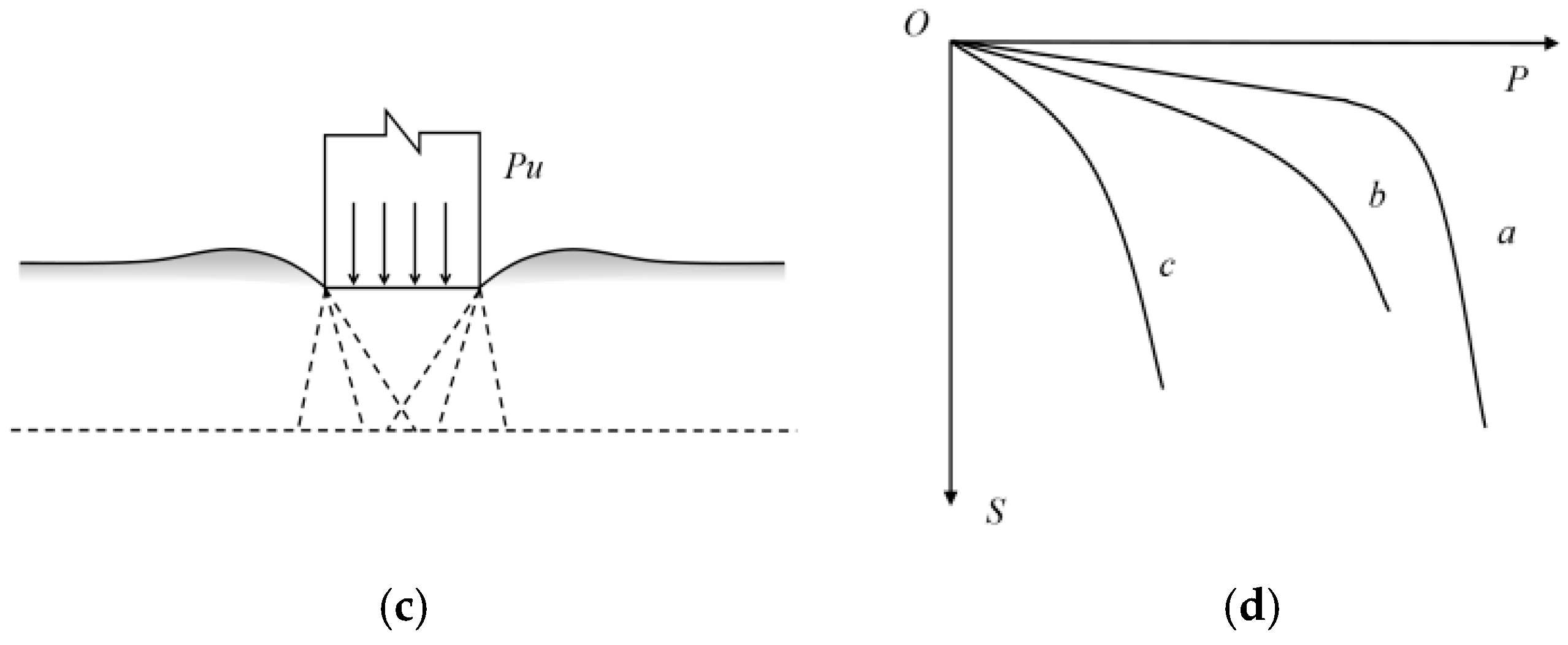

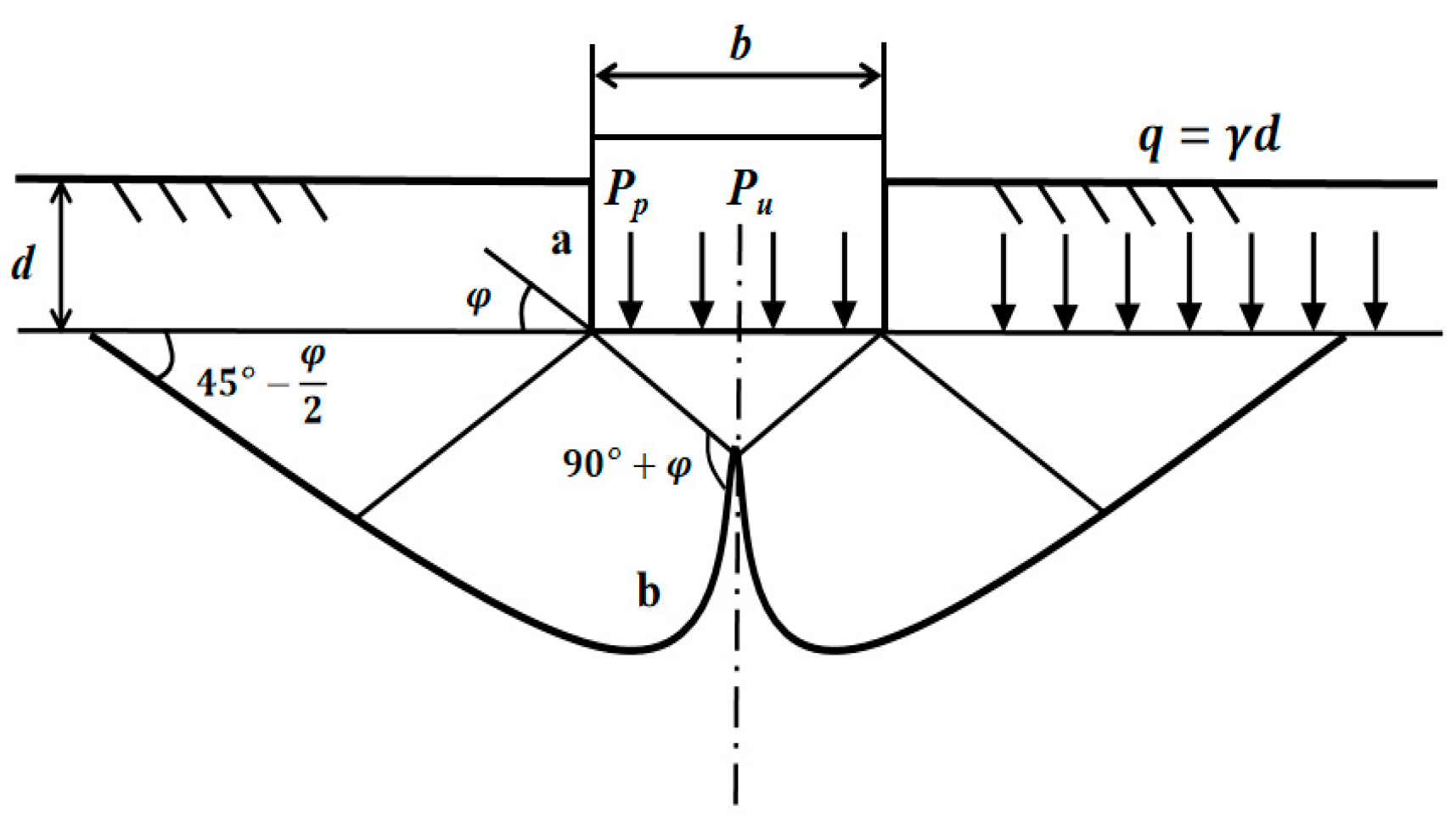

4.1. Typical Damage Models for Foundation Bearing Capacity

4.2. Theoretical Formulation of Silt-Based Foamed Concrete Ultimate Bearing Capacity

5. Conclusions

- As the wet density increased from 600 kg/m3 to 800 kg/m3, the 28-day compressive strength rose from 1.21 MPa to 2.43 MPa, and the triaxial shear strength under 300 kPa confinement increased from 1.87 MPa to 3.88 MPa. This improvement is mainly attributed to reduced porosity and enhanced particle bonding, which increased the material’s load-bearing capacity and deformation resistance.

- The compression of the pore structure improved the particle contact and the load transfer, leading to a significant increase in the strength ratio under confinement. Notably, although the 800 kg/m3 specimen exhibited higher compressive strength, the 700 kg/m3 group showed a maximum strength ratio of 2.41, exceeding that of the 800 kg/m3 group (1.6), due to its better deformability and confinement response.

- When subjected to vertical loads, silt-based foamed concrete exhibits a basin-shaped deformation pattern similar to that of a foundation, and the higher the density of the silt-based foamed concrete, the stronger its deformation resistance.

- Under non-edge loading conditions, the failure mode is closer to local shear failure; under edge loading conditions, the failure mode of silt-based foamed concrete more closely resembles direct shear failure.

- Based on the results of model tests and building upon Terzaghi’s bearing capacity theory formula, this study developed a calculation formula for the ultimate bearing capacity applicable to silt-based foamed concrete with a 30% content. The formula showed good agreement with measured values, with the relative errors within 3%, confirming the formula’s reliability.

- For engineering applications, a wet density of around 700 kg/m3 is recommended to balance strength and lightweight requirements. Engineers should also consider loading position effects, as edge loading may lead to more severe failure. These findings provide practical guidance for the use of silt-based foamed concrete in shallow foundations and embankments.

- This study investigated the triaxial mechanical behavior, deformation characteristics, and bearing capacity of silt-based foamed concrete under vertical loading. Based on experimental data and Terzaghi’s theory, a calculation formula for ultimate bearing capacity was developed, showing good agreement with measured results (relative errors within 3%). The observed shear failure modes and load–deformation behavior provide insights for shallow foundation design and failure prediction. The proposed formula is applicable to silt-based foamed concrete with a 30% silt content and wet densities of 600–800 kg/m3 under short-term loading. However, its accuracy may be limited under extreme environmental conditions, long-term loads, or outside the tested density range. Future work should investigate durability-related performance and explore microstructural evolution using techniques such as micro-CT and digital imaging.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and applications of foamed concrete: A review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Wang, C.; Liu, M.; Wu, J. Using Foamed Concrete Layer to Optimize the Design of Pavement and Subgrade Structures: From the Perspectives Economy and Durability. Arab. J. Sci. Eng. 2023, 48, 12859–12874. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Liu, Z.; Ma, C.; Song, Z.; Cui, F.; Wu, J.; Song, X. Strength characteristics of foamed concrete under coupling effect of constant compressive loading and freeze-thaw cycles. Constr. Build. Mater. 2024, 411, 134565. [Google Scholar] [CrossRef]

- Jusi, U.; Dhamrodji, P.; Maizir, H. Foam Mortar Layer in Soft Subgrade Embankment: A Review. IOP Conf. Ser. Earth Environ. Sci. 2024, 1321, 012040. [Google Scholar] [CrossRef]

- Gencel, O.; Kazmi, S.M.S.; Munir, M.J.; Kaplan, G.; Bayraktar, O.Y.; Yarar, D.O.; Karimipour, A.; Ahmad, M.R. Influence of bottom ash and polypropylene fibers on the physico-mechanical, durability and thermal performance of foam concrete: An experimental investigation. Constr. Build. Mater. 2021, 306, 124887. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Liu, M.; Zhuang, P.; Zhang, H.; Song, X. Dynamic Properties of Silt-Based Foamed Concrete as Filler in Subgrade. J. Mater. Civ. Eng. 2022, 34, 04022241. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, M.; Yu, J.; Sun, Y.; Zhou, P.; Song, J.; Song, X. Mechanical and Physical Properties of Silt-Based Foamed Concrete with Different Silt Types. Arab. J. Sci. Eng. 2022, 47, 12803–12815. [Google Scholar] [CrossRef]

- Zhao, W.; Su, Q.; Wang, W.; Niu, L.; Liu, T. Experimental Study on the Effect of Water on the Properties of Cast In Situ Foamed Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 7130465. [Google Scholar] [CrossRef]

- Zhou, S.E.; Lu, Z.Y.; Jiao, L.; Li, S.X. Compression property and compression strength model of foamed concrete. J. Wuhan Univ. Technol. 2010, 32, 9–13. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, L.; Feng, K. Compound modified experiment of protein-concrete foaming agent. Gongneng Cailiao/J. Funct. Mater. 2015, 46, 09056–09061. [Google Scholar]

- Harith, I.K. Study on polyurethane foamed concrete for use in structural applications. Case Stud. Constr. Mater. 2018, 8, 79–86. [Google Scholar] [CrossRef]

- Bin, R.; Li, J.; Gan, Y.; Huang, J. Mesoscopic simulation of the mechanical behaviour of foam concrete subjected to large compressive deformation. Constr. Build. Mater. 2024, 418, 135367. [Google Scholar] [CrossRef]

- Liu, M.; Wang, J.; Wang, C.; Liu, Z.; Zhang, H.; He, F. Stress-Solid Materials-Voids interaction of foamed concrete in isotropic compression. Constr. Build. Mater. 2022, 358, 129468. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.; Liu, H.; Chan, A.H.C. Stress-Strain Characteristics of Foamed Concrete Subjected to Large Deformation under Uniaxial and Triaxial Compressive Loading. J. Mater. Civ. Eng. 2018, 30, 04018095. [Google Scholar] [CrossRef]

- Su, B.; Zhou, Z.; Li, Z.; Wang, Z.; Shu, X. Experimental investigation on the mechanical behavior of foamed concrete under uniaxial and triaxial loading. Constr. Build. Mater. 2019, 209, 41–51. [Google Scholar] [CrossRef]

- Shi, X.; Huang, J.; Su, Q. Experimental and numerical analyses of lightweight foamed concrete as filler for widening embankment. Constr. Build. Mater. 2020, 250, 118897. [Google Scholar] [CrossRef]

- Luo, X.; Xu, J.-Y.; Liu, Y. The static constitutive model of fiber reinforced cellular materials. Constr. Build. Mater. 2018, 187, 903–906. [Google Scholar] [CrossRef]

- Guo, H.; Guo, W.; Shi, Y. Computational modeling of the mechanical response of lightweight foamed concrete over a wide range of temperatures and strain rates. Constr. Build. Mater. 2015, 96, 622–631. [Google Scholar] [CrossRef]

- Liu, M.P.; Zhang, H.B.; Lv, B.; Du, C.; Wang, J. Investigation on the yield and failure criterion of foamed concrete. J. Build. Eng. 2024, 84, 108604. [Google Scholar] [CrossRef]

- He, Y.; Gao, M.; Zhao, H.; Zhao, Y. Behaviour of Foam Concrete under Impact Loading Based on SHPB Experiments. Shock. Vib. 2019, 2019, 2065845. [Google Scholar] [CrossRef]

- Ni, F.M.-W.; Oyeyi, A.G.; Tighe, S. Structural capacity evaluation of lightweight cellular concrete for flexible pavement subbase. Road Mater. Pavement Des. 2021, 23, 2781–2797. [Google Scholar] [CrossRef]

- Chun, B.S.; Lim, H.S.; Shin, Y.W. Application of constitutive model to predict the behavior of EPS-geofoam. Geetechnical Eng. 2001, 5, 175–183. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. Standard Press of China: Beijing, China, 2007.

- GBT 50123-2019; Standard for Soil Test Methods. China Architecture & Building Press: Beijing, China, 2019.

- Zhang, H.B.; Liu, M.P.; Shuo, Z.; Zhao, Z.; Sun, Y.; Song, X.; Wang, H.; Zhang, X.; Wu, J. An experimental investigation of the triaxial shear behaviors of silt-based foamed concrete. Case Stud. Constr. Mater. 2021, 15, e00713. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, M.P.; Wang, C.A.; Zhang, H.; Zhao, Z.; Wu, J. Compression, Unloading-reloading, and tension mechanical behaviors of Silt-based foamed concrete under uniaxial loading. Constr. Build. Mater. 2022, 347, 128558. [Google Scholar] [CrossRef]

- GB/T 11969-2020; Test Methods of Autoclaved Aerated Concrete. Ministry of Industry and Information Technology: Beijing, China, 2013.

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. China Communications Press: Beijing, China, 2020.

- Huang, J.; Cai, D.; Su, Q.; Yao, H.; Fan, R.; Pei, Y.; Zhang, Z.; Yao, Y.; Luo, J.; Ou, X. Comparative study on static and dynamic characteristics of foamed concrete interlayer-type and traditional layered ballastless track subgrades. Constr. Build. Mater. 2025, 470, 140651. [Google Scholar] [CrossRef]

- Liu, M.P.; Liu, Z.K.; Wang, K.; Ma, C.; Zhang, H.; Zhuang, P. Strength and deformation performances of silt-based foamed concrete under triaxial shear loading. J. Build. Eng. 2022, 60, 105237. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, W.Z.; Tan, X.J.; Huang, S. High-performance foam concrete for seismic-isolation materials of tunnels. Chin. J. Geotech. Eng. 2013, 35, 1544–1552. [Google Scholar]

- Chen, W.; Tian, H.; Yang, F.; Geng, Y. Study of effects of foam concrete preset deformation layer on long-term stability of deep soft rock tunnel. Rock Soil Mech. 2011, 32, 2577–2583. [Google Scholar]

- Kozłowski, M.; Kadela, M.; Kukiełka, A. Fracture Energy of Foamed Concrete Based on Three-Point Bending Test on Notched Beams. Procedia Eng. 2015, 108, 349–354. [Google Scholar] [CrossRef]

- Hansen, J.B. A General Formula for Bearing Capacity; Danish Geotechnical Institute: Copenhagen, Denmark, 1961. [Google Scholar]

- Fan, W.; Bai, X.Y.; Yu, M.H. Formula of ultimate bearing capacity of shallow foundation based on unified strength theory. Rock Soil Mech. 2005, 26, 1616–1621. [Google Scholar]

- Bowles, J.E. Foundation Analysis and Design, 3rd ed.; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

| Specific Surface Area (m2/kg) | Standard Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3 d | 28 d | 3 d | 28 d | ||

| 35.8 | 28.2 | 192 | 231 | 28.1 | 50.7 | 6.5 | 9.6 |

| Foam Expansion Ratio | 1 h Settlement Distance (mm) | 1 h Bleeding Rate (%) | Sedimentation Rate of Slurry (%) | Solid Content (%) | pH | Density (kg/m3) |

|---|---|---|---|---|---|---|

| 24 | 5 | 20 | 2 | 23.4 | 7.2 | 1000 |

| Wet Density (kg/m3) | Silt Content (%) | Mixture Composition (per m3) | |||

|---|---|---|---|---|---|

| Water (kg) | Cement (kg) | Silt (kg) | Foam (kg) | ||

| 600 | 30 | 157.98 | 287.24 | 123.10 | 31.678 |

| 700 | 186.70 | 339.46 | 145.48 | 28.347 | |

| 800 | 215.43 | 391.69 | 167.87 | 25.016 | |

| Wet Density (kg/m3) | (kPa) | (kPa) | (kPa) | Shear Strength Index | |

|---|---|---|---|---|---|

| c (kPa) | (°) | ||||

| 600 | 1350 | 100 | 1250 | 198.6 | 43.2 |

| 1600 | 200 | 1400 | |||

| 1870 | 300 | 1570 | |||

| 700 | 2090 | 100 | 1990 | 347.6 | 50.7 |

| 2810 | 200 | 2610 | |||

| 3540 | 300 | 3240 | |||

| 800 | 2510 | 100 | 2410 | 413.7 | 56.9 |

| 3490 | 200 | 3290 | |||

| 3880 | 300 | 3580 | |||

| Parameter | Density (kg/m3) | |||

|---|---|---|---|---|

| 600 | 700 | 800 | ||

| Internal cohesion c (kPa) | 199 | 348 | 417 | |

| Internal friction angle (°) | 43.2 | 50.7 | 56.9 | |

| Unit weight (kN/m3) | 5.89 | 6.87 | 7.85 | |

| Foundation bearing capacity factor | 72.45 | 45.14 | 27.11 | |

| 69.04 | 56.15 | 42.59 | ||

| 115.0 | 121.28 | 114.84 | ||

| Measured ultimate bearing capacity (kPa) | 1120 | 1580 | 2040 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Wang, J.; Zhang, N.; Wang, C.; Zhang, S.; Tao, Y.; Lou, S.; Sun, Q.; Ren, X.; Zhang, H. Shear Strength and Ultimate Bearing Capacity of Silt-Based Foamed Concrete Under Local Vertical Loading. Buildings 2025, 15, 1914. https://doi.org/10.3390/buildings15111914

Ma C, Wang J, Zhang N, Wang C, Zhang S, Tao Y, Lou S, Sun Q, Ren X, Zhang H. Shear Strength and Ultimate Bearing Capacity of Silt-Based Foamed Concrete Under Local Vertical Loading. Buildings. 2025; 15(11):1914. https://doi.org/10.3390/buildings15111914

Chicago/Turabian StyleMa, Chuanyi, Jun Wang, Ning Zhang, Chuyi Wang, Shengtao Zhang, Yuchen Tao, Shurong Lou, Qingshuo Sun, Xianfu Ren, and Hongbo Zhang. 2025. "Shear Strength and Ultimate Bearing Capacity of Silt-Based Foamed Concrete Under Local Vertical Loading" Buildings 15, no. 11: 1914. https://doi.org/10.3390/buildings15111914

APA StyleMa, C., Wang, J., Zhang, N., Wang, C., Zhang, S., Tao, Y., Lou, S., Sun, Q., Ren, X., & Zhang, H. (2025). Shear Strength and Ultimate Bearing Capacity of Silt-Based Foamed Concrete Under Local Vertical Loading. Buildings, 15(11), 1914. https://doi.org/10.3390/buildings15111914