Study on Dynamic Response and Progressive Collapse Resistance of Space Steel Frame Under Impact Load

Abstract

1. Introduction

2. Materials and Methods

2.1. Model Parameters

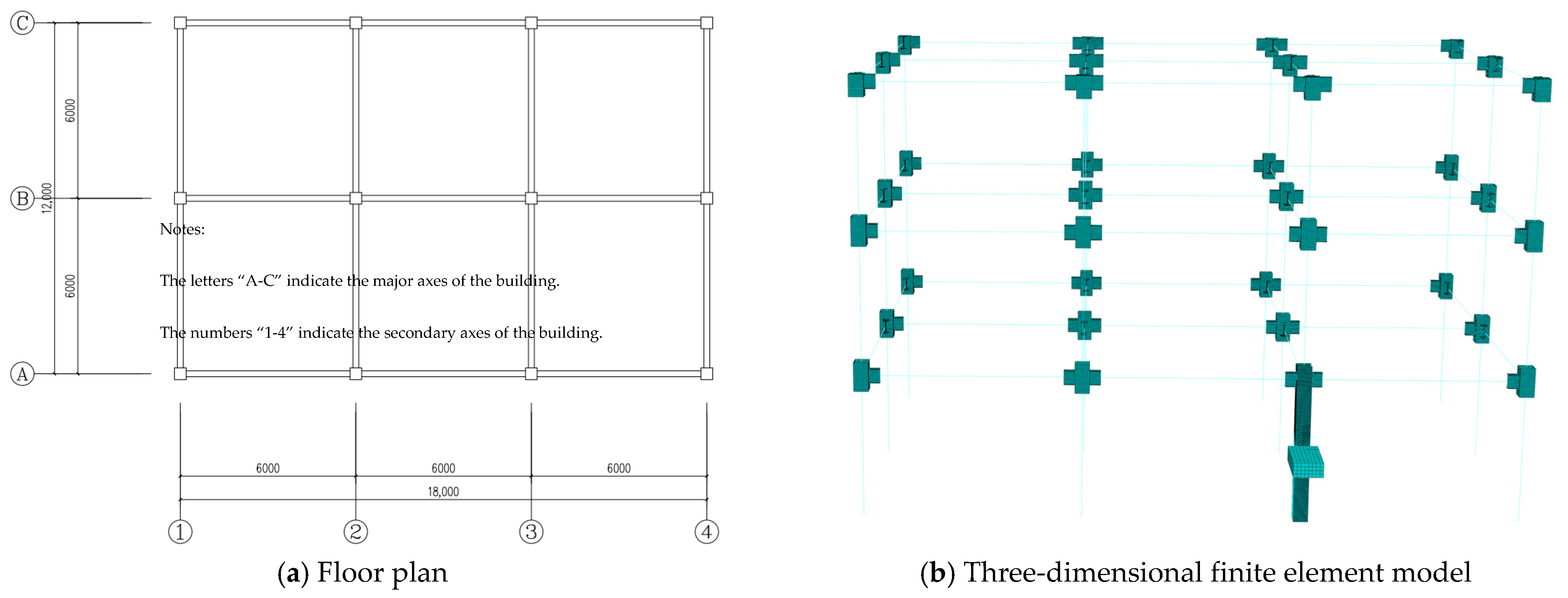

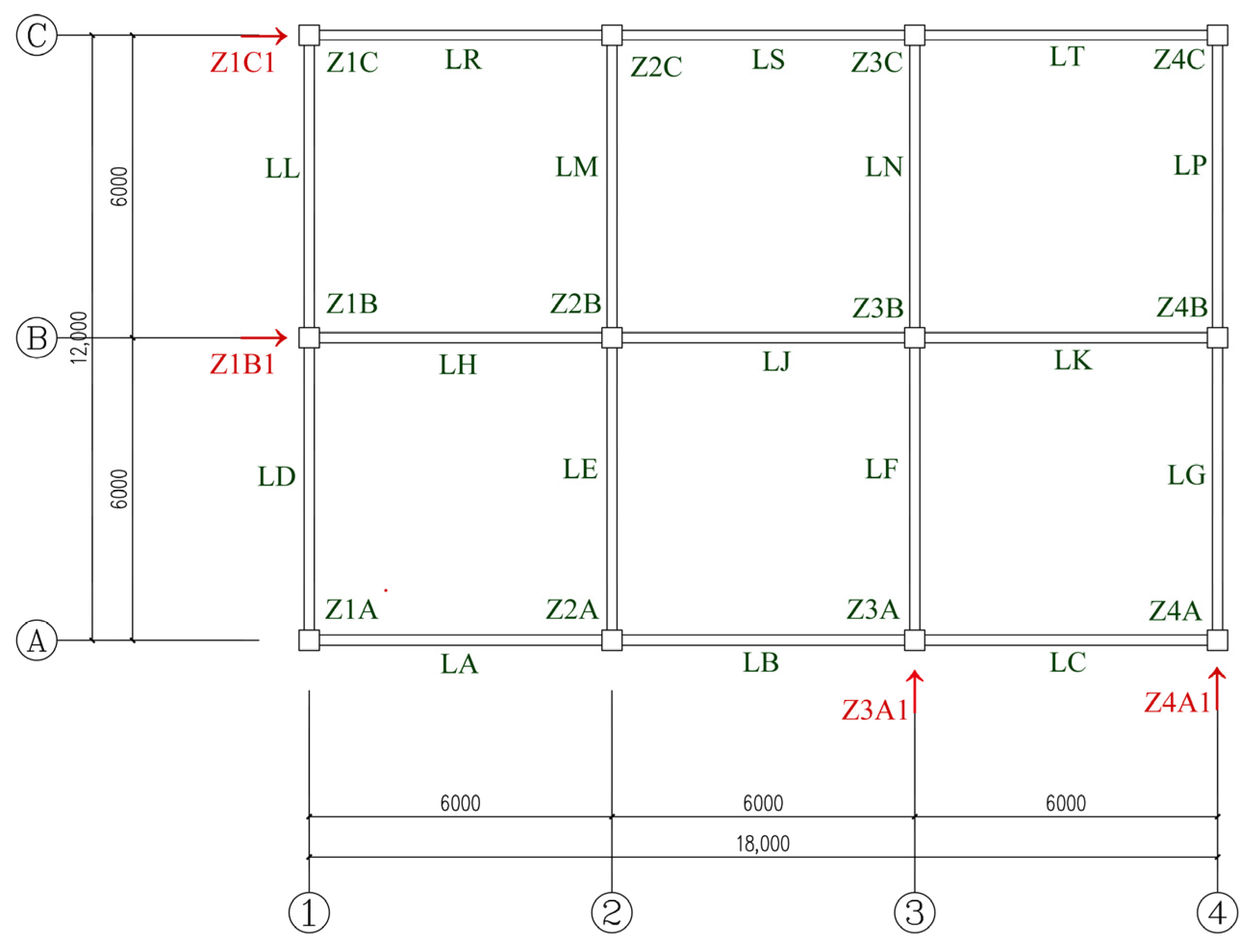

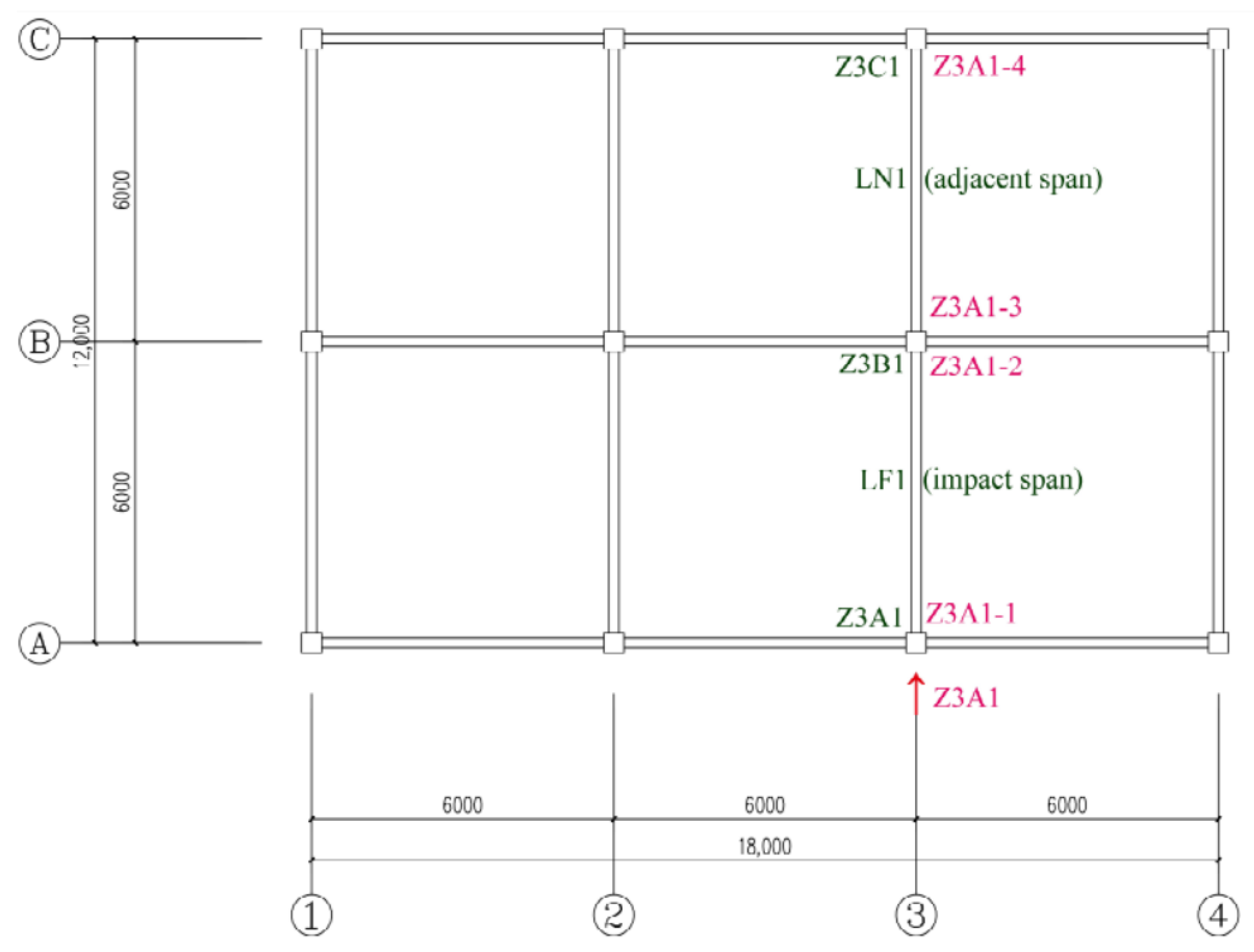

2.1.1. Analytical Models

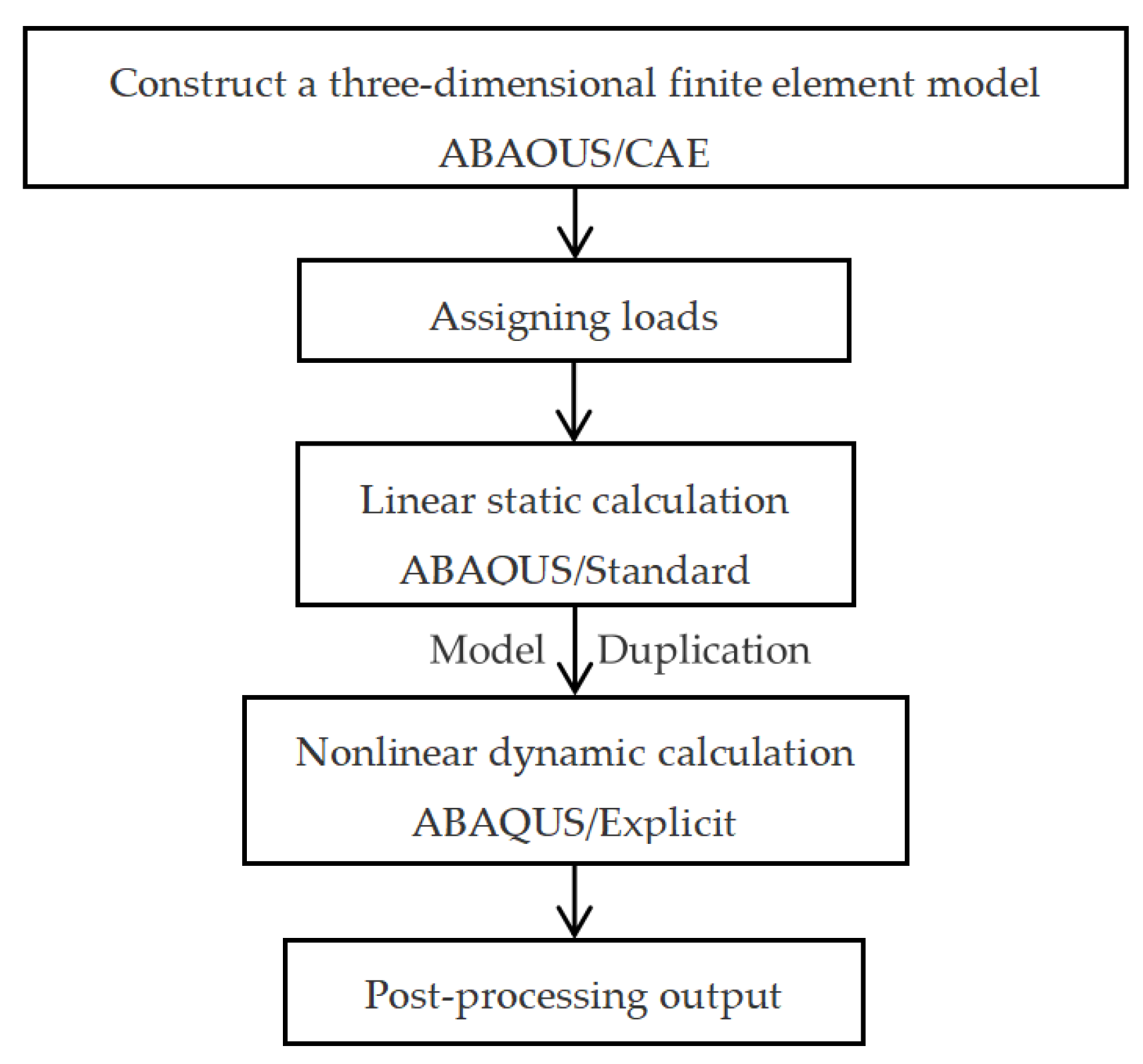

2.1.2. Model Loading Sequence

2.2. Material Parameters

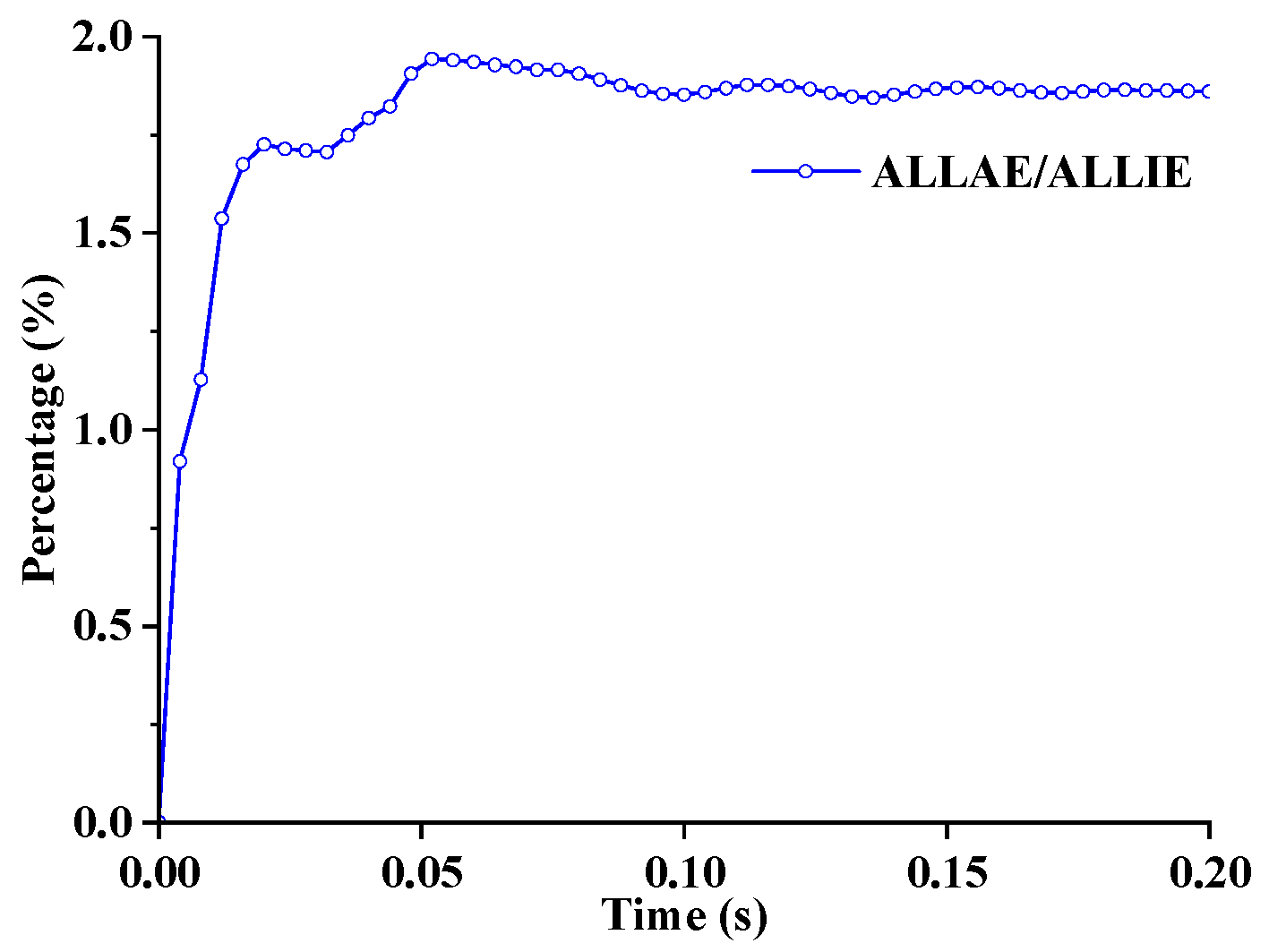

2.3. Contacts, Interactions and Meshing

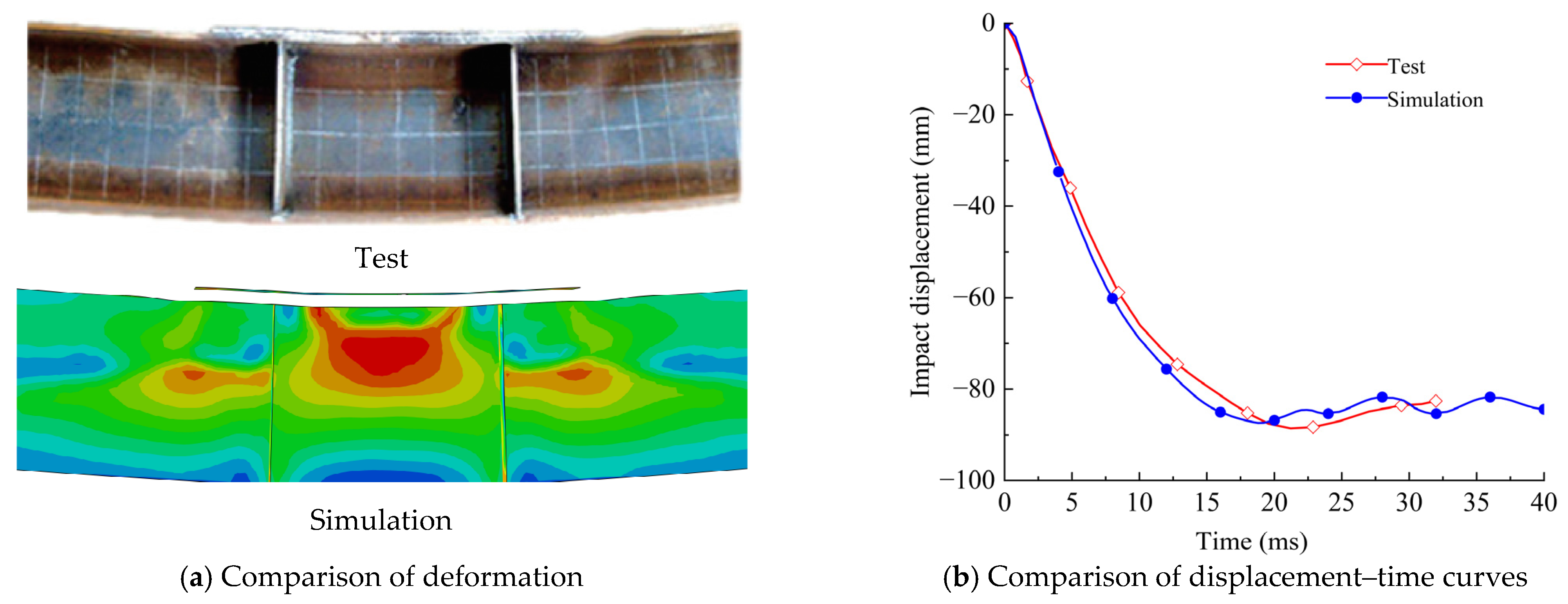

2.4. Modeling Verification

2.5. Impact Parameter Setting

3. Analysis of Dynamic Response

3.1. Displacement Response and Direction of Displacement

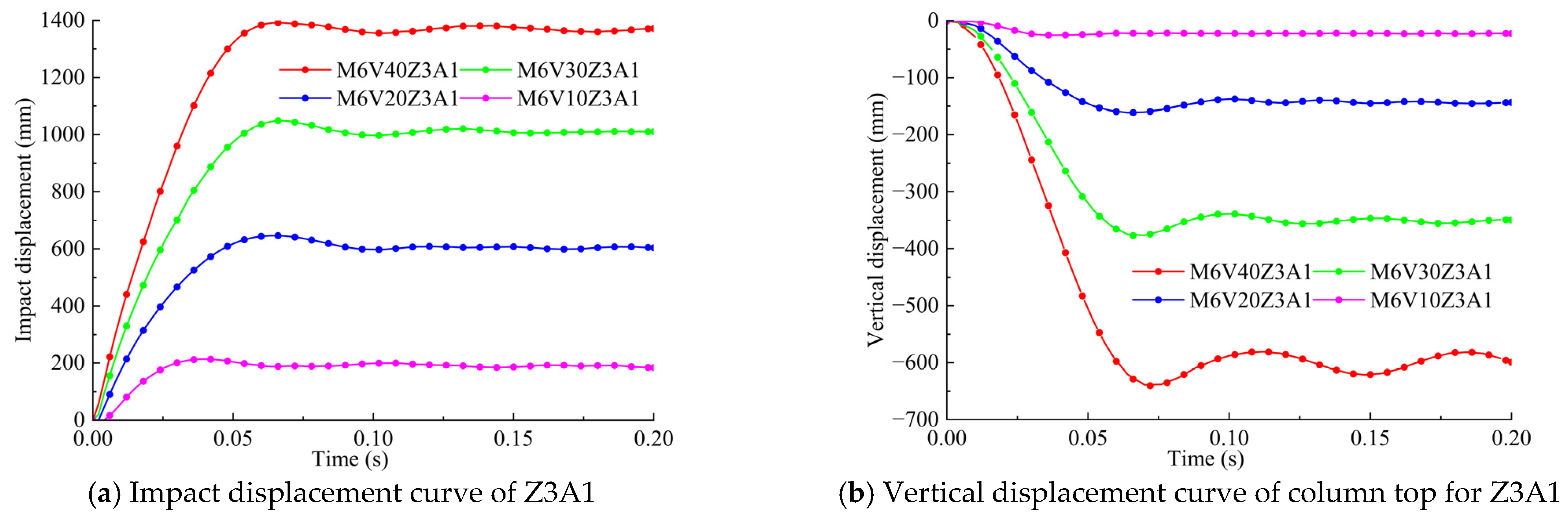

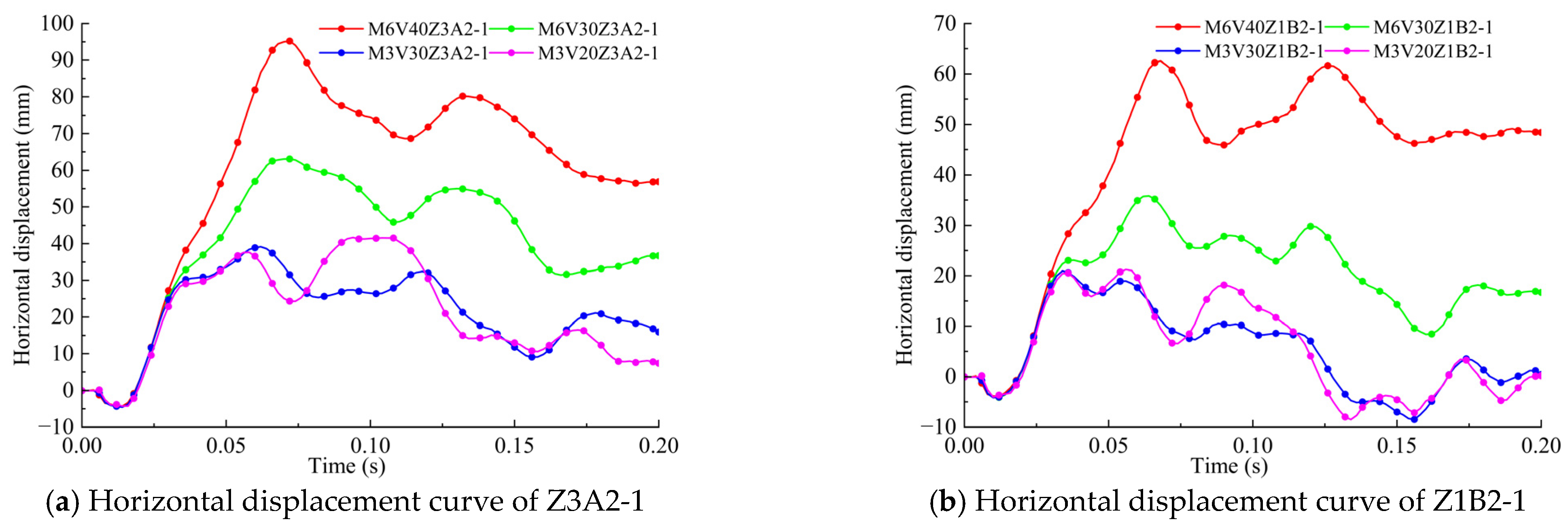

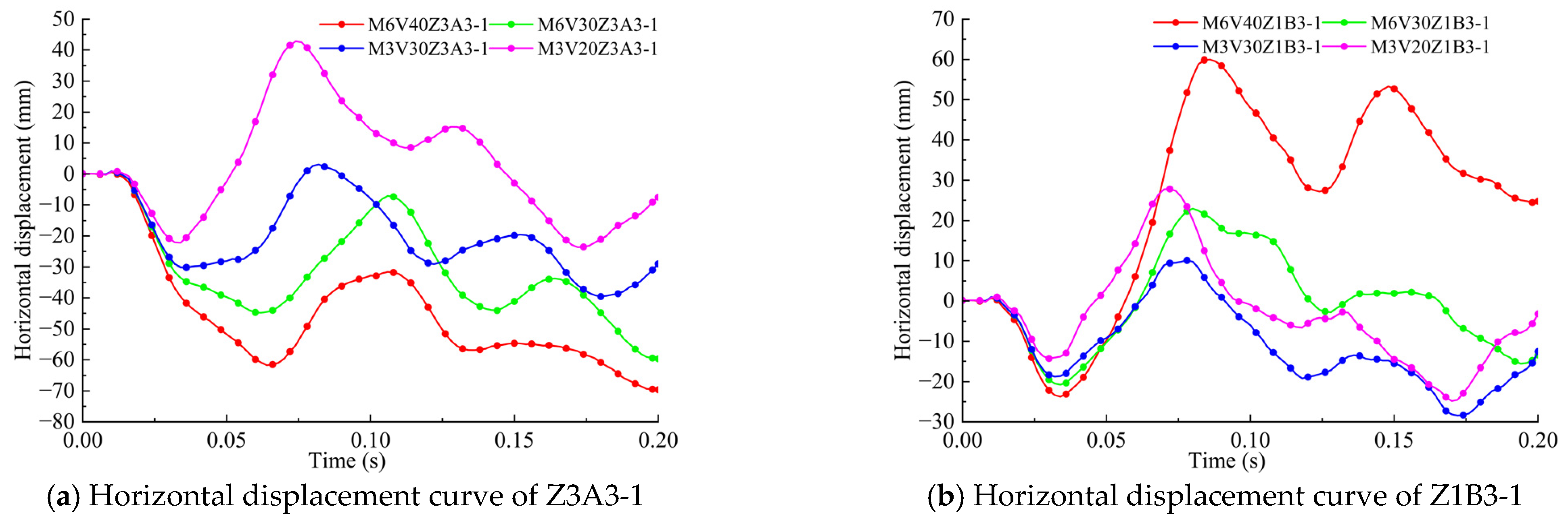

3.2. Impact Velocity and Displacement

3.3. Impact Mass and Displacement

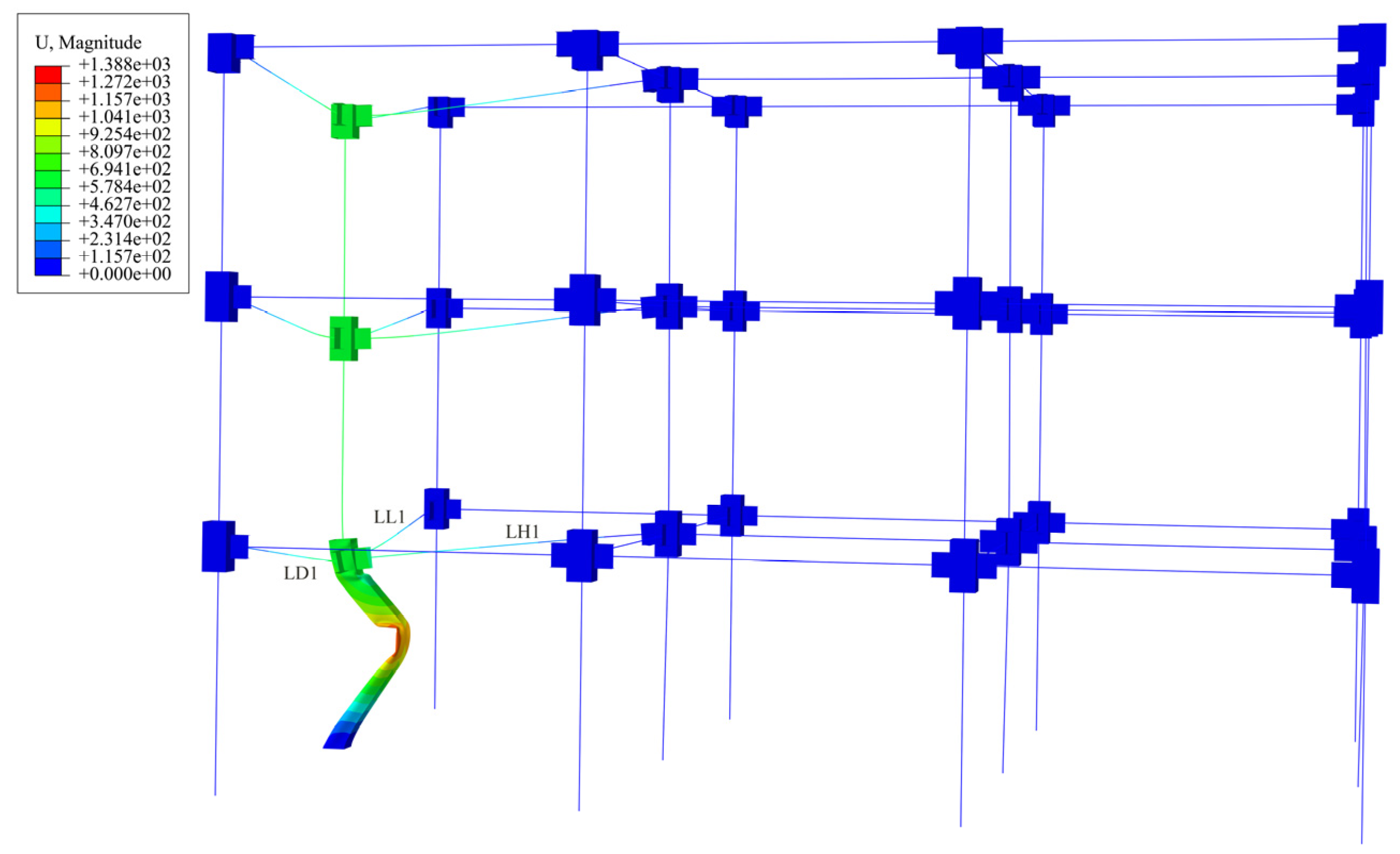

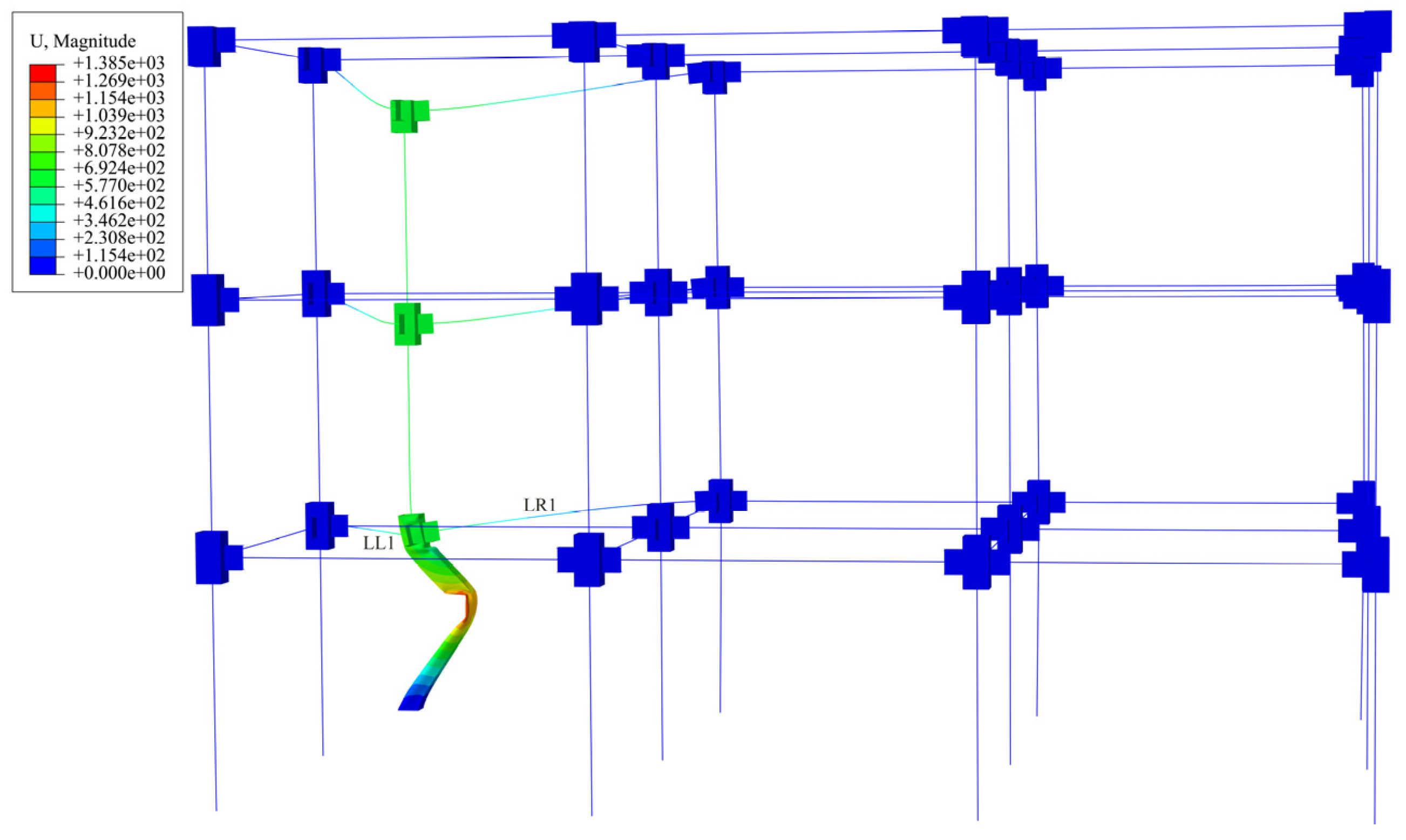

3.4. Different Impacted Columns and Displacement

4. Deformation Damage and Collapse Analysis

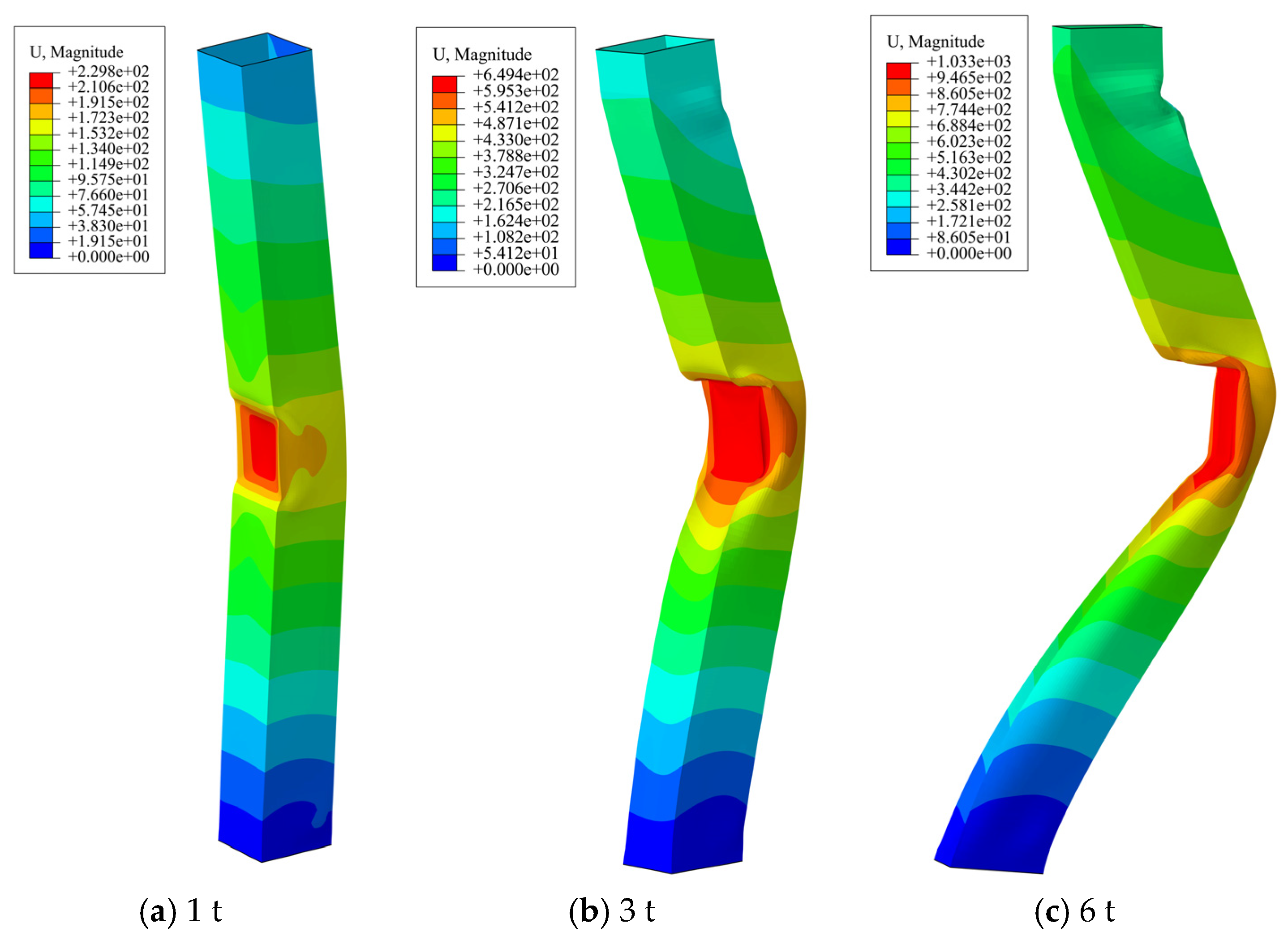

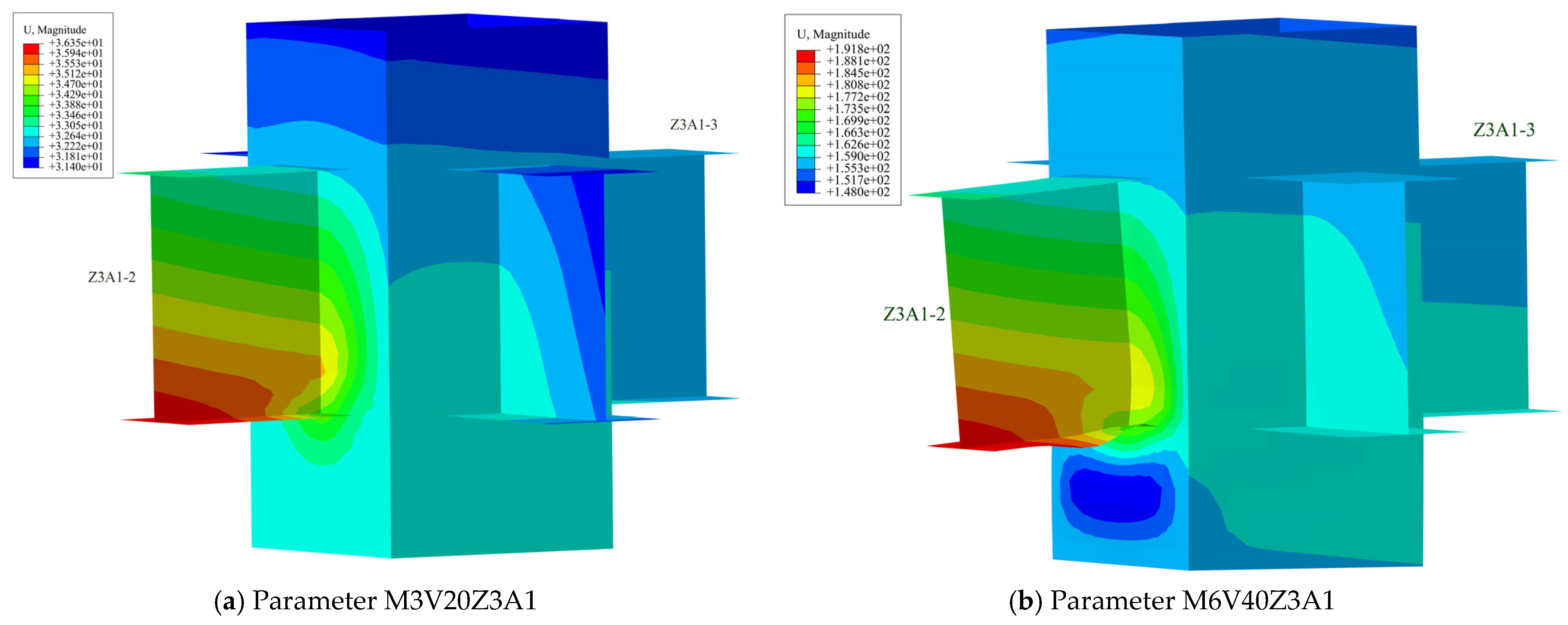

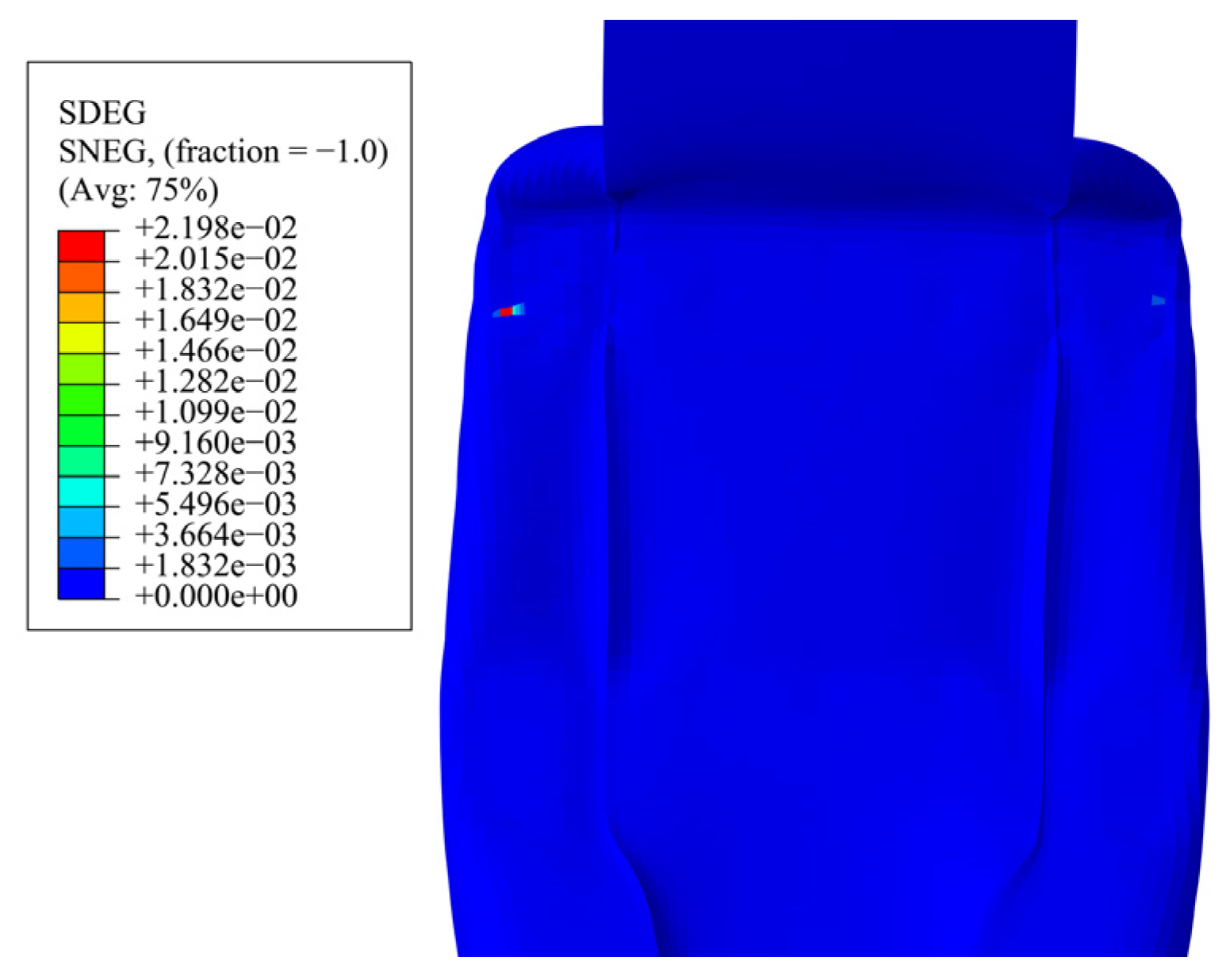

4.1. Deformation Damage Analysis of Steel Frames

4.2. Analysis of Collapse Resistance

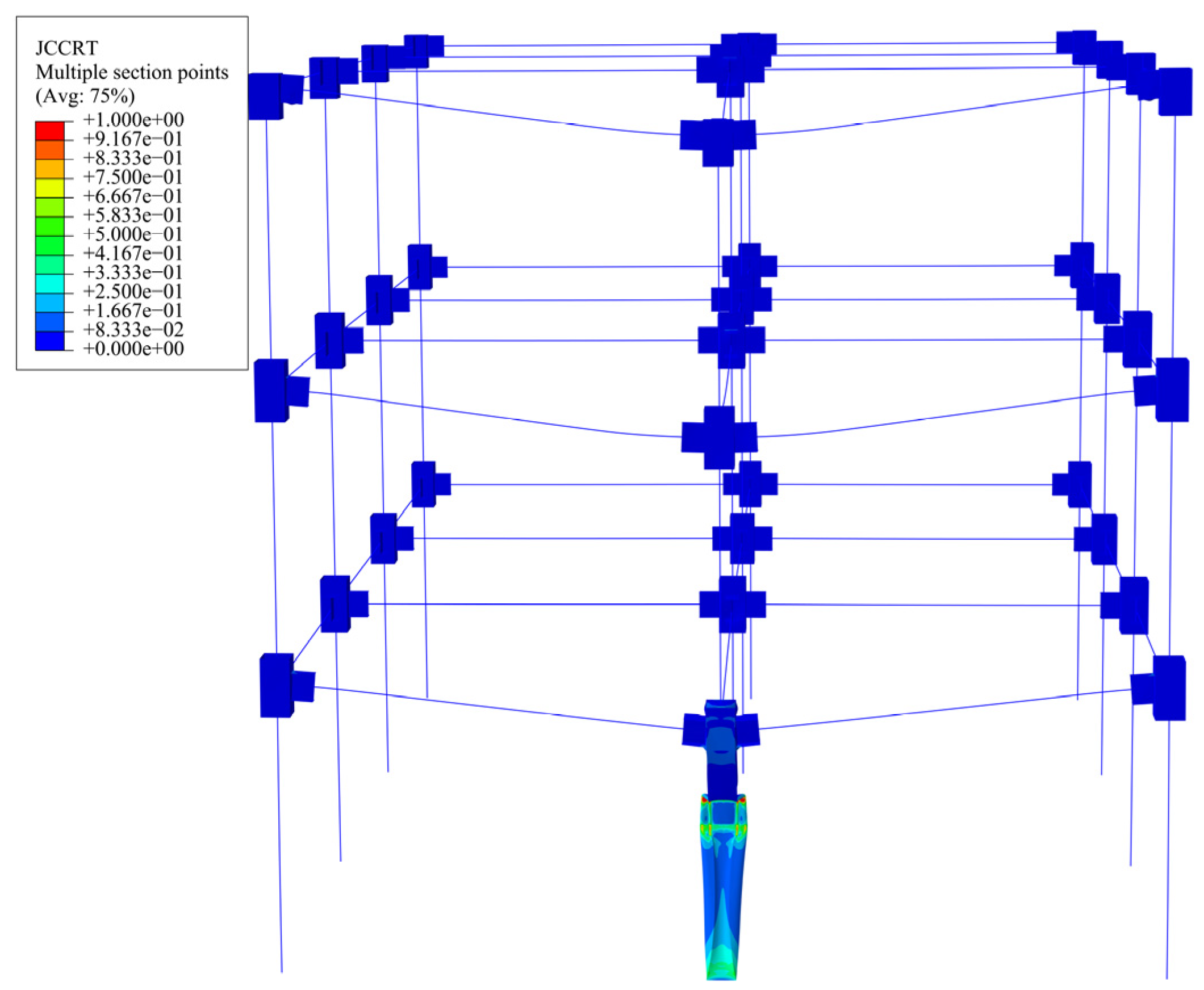

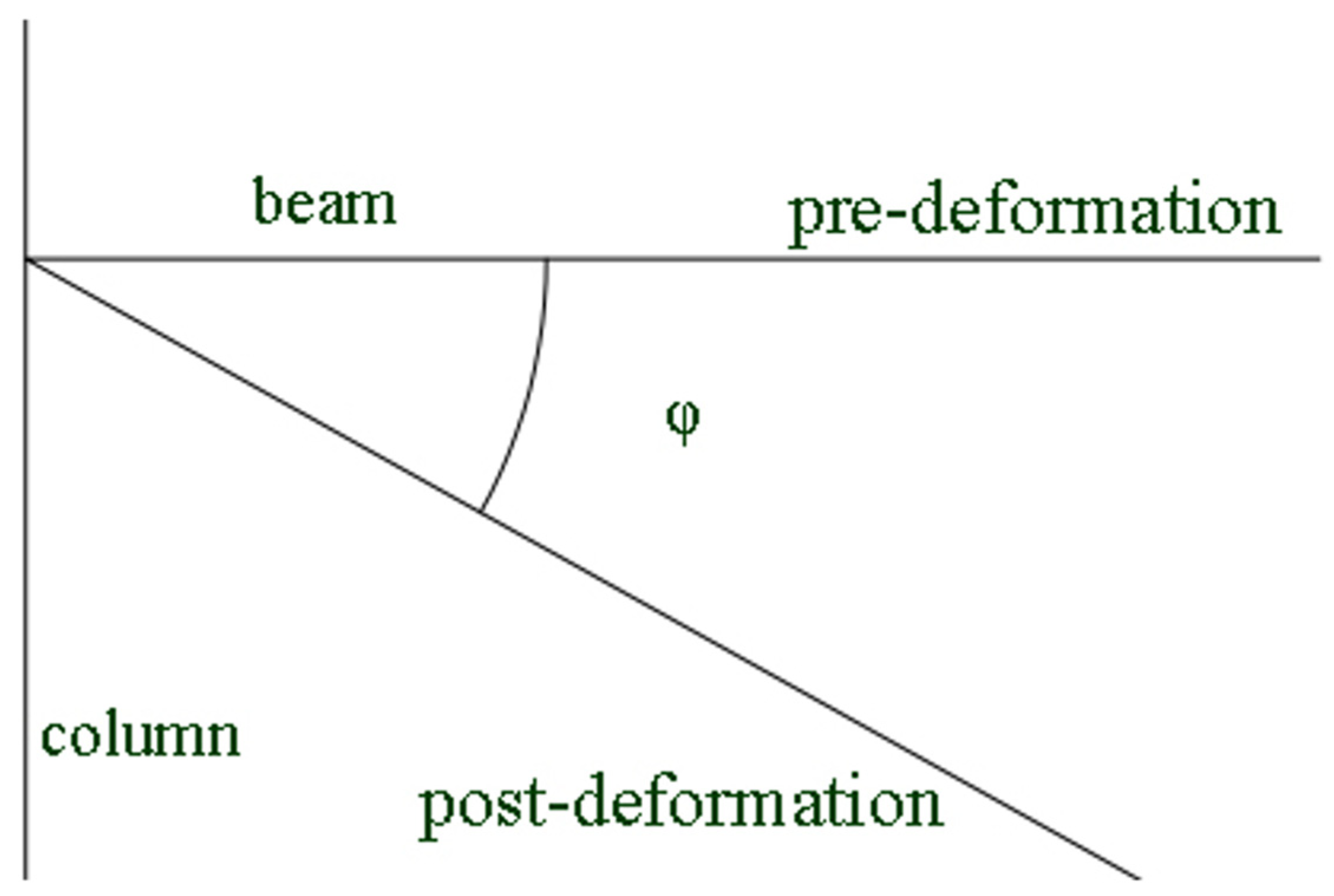

4.2.1. Collapse Determination Criteria

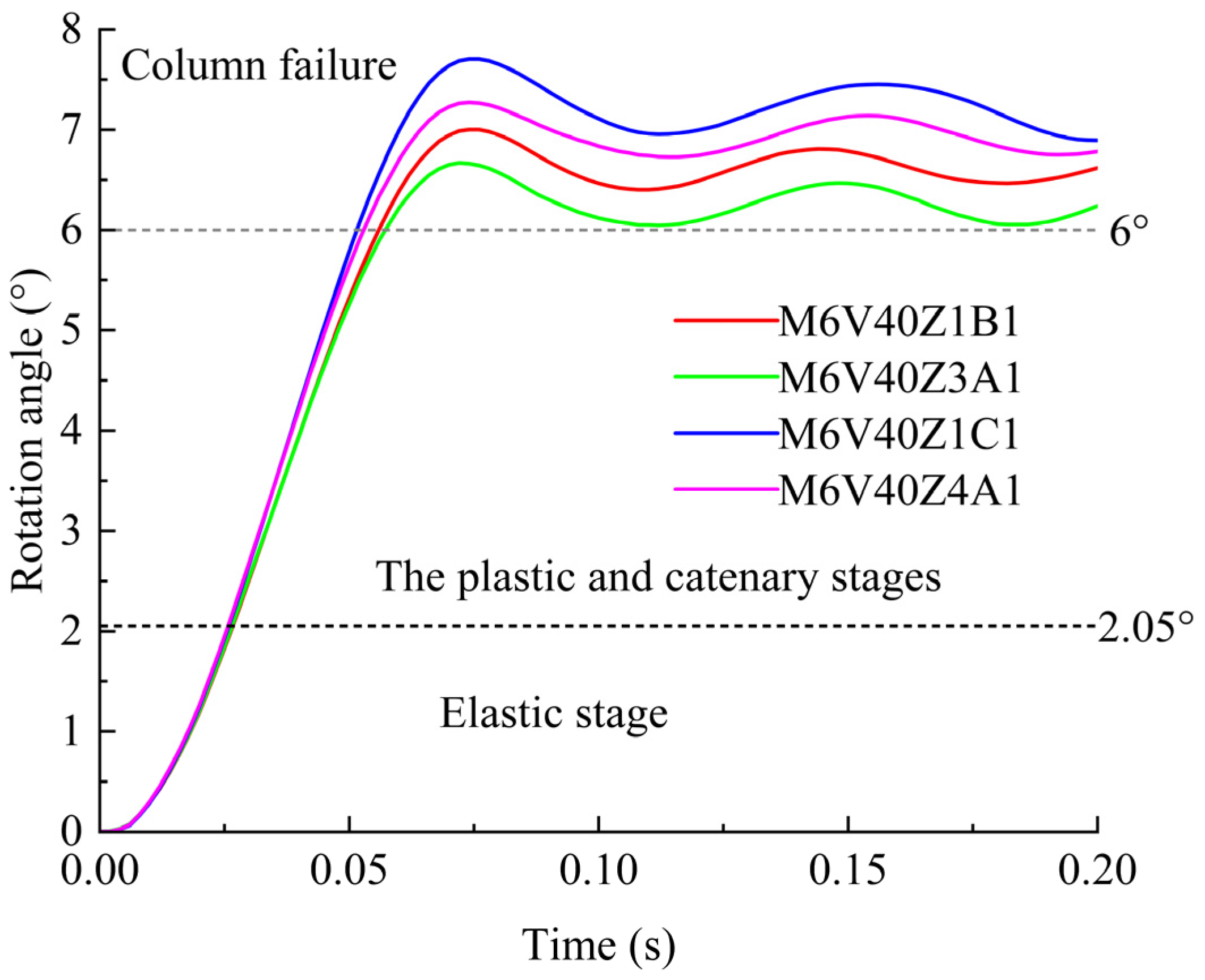

4.2.2. Analysis of the Collapse Process

5. Conclusions and Limitations

- Changing only a single parameter by increasing the mass or velocity, due to the increase in the kinetic energy of the impact, will lead to an increase in the maximum value of the displacement response of the steel frame, causing the steel frame as a whole to produce more significant residual deformation. With the increase in impact kinetic energy, the steel frame develops from the local concave deformation in the impact area to the overall bending deformation, which has a significant impact on the neighboring members and the overall stability is significantly reduced after impact, causing the steel frame as a whole to tilt to the impacted column which may eventually collapse.

- At the same impact kinetic energy, the difference in impact displacements between corner and side center columns is less than 1%, and the difference in vertical displacements ranges from 0% to 17.6%. The displacement of the first-floor joints of the structure with three spans in the impact direction was reduced by about 50% compared to that with two spans. When designing the structure, it is necessary to increase the number of frame spans in the impact direction to improve the overall stability of the structure.

- The main damage to the steel frame occurs at the impact location. The region produces stress concentration in the impact process, the steel column shows local depression deformation and overall bending deformation, the two sides of the steel plate bulge, the inner diaphragm buckles under pressure, and the steel beam shows bending and compression buckling of the beam-end flanges. Within the parameters of this paper, the top and foot of the impacted column are not damaged, and the steel is still in the plastic phase, indicating that Q235B steel has high plasticity and impact resistance.

- The steel frame will collapse when the kinetic energy of the impact is large, and based on the rotation angle of the beams the impact process can be divided into three phases, the elastic phase, the plasticity and catenary phase, and the failure phase of the column members. When impacting the bottom corner columns, the corner columns fail due to the increased deformation under the upper load. The beam members connected with the corner columns fail due to the excessive turning angle, and the steel frame structure undergoes vertical progressive collapse. When the side center columns fail, the overall frame forms a Vierendeel action mechanism to resist the progressive collapse of the structure.

- In order to further extend the existing research results, it is necessary to conduct a parametric study of space steel frames to investigate the impact dynamic response and structural resistance to continuous collapse under different structural arrangements. The contribution of the floor slab is not considered in this paper, and it is necessary to study the effect of the floor slab of the building structure under impact loads for future research on continuous collapse resistance. Meanwhile, this paper verifies the validity of the numerical model by comparing it with the existing scaled-down tests. However, the simplified and scaled-down steel beam impact tests cannot adequately reflect the impact resistance of actual frame structures. Future research should actively carry out full-scale impact tests of frame structures to obtain more accurate data for numerical validation or practical engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kiakojouri, F.; Sheidaii, M.R.; De Biagi, V.; Chiaia, B. Progressive collapse of structures: A discussion on annotated nomenclature. Structures 2021, 29, 1417–1423. [Google Scholar] [CrossRef]

- Pearson, C.; Delatte, N. Lessons from the Progressive Collapse of the Ronan Point Apartment Tower. In Forensic Engineering (2003); Proceedings of the Third Congress, San Diego, CA, USA, 19–21 October 2012; American Society of Civil Engineers: Reston, VI, USA, 2003; pp. 190–200. [Google Scholar]

- Osteraas John, D. Murrah Building Bombing Revisited: A Qualitative Assessment of Blast Damage and Collapse Patterns. J. Perform. Constr. Facil. 2006, 20, 330–335. [Google Scholar] [CrossRef]

- Bažant Zdeněk, P.; Le, J.-L.; Greening Frank, R.; Benson David, B. What Did and Did Not Cause Collapse of World Trade Center Twin Towers in New York? J. Eng. Mech. 2008, 134, 892–906. [Google Scholar] [CrossRef]

- Russell, J.M.; Sagaseta, J.; Cormie, D.; Jones, A.E.K. Historical review of prescriptive design rules for robustness after the collapse of Ronan Point. Structures 2019, 20, 365–373. [Google Scholar] [CrossRef]

- Adam, J.M.; Parisi, F.; Sagaseta, J.; Lu, X. Research and practice on progressive collapse and robustness of building structures in the 21st century. Eng. Struct. 2018, 173, 122–149. [Google Scholar] [CrossRef]

- Kiakojouri, F.; De Biagi, V.; Chiaia, B.; Sheidaii, M.R. Progressive collapse of framed building structures: Current knowledge and future prospects. Eng. Struct. 2020, 206, 110061. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, Q.; Li, L.; Chen, W.; Ye, J.; Li, G.-Q. Review on Quantitative Measures of Robustness for Building Structures Against Disproportionate Collapse. Int. J. High-Rise Build. 2020, 9, 127–154. [Google Scholar] [CrossRef]

- Pei, Q.; Wu, C.; Cheng, Z.; Ding, Y.; Guo, H. The Seismic Performance of New Self-Centering Beam-Column Joints of Conventional Island Main Buildings in Nuclear Power Plants. Materials 2022, 15, 1704. [Google Scholar] [CrossRef]

- Qin, W.; Zhang, Z.; Xi, Z. Towards enhancing the anti-progressive collapse performance of concrete beam-column structures via ECC and BFRP: Experiments and mechanisms. Eng. Struct. 2023, 292, 116558. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Y. Finite element analysis of progressive collapse resistance of precast concrete frame beam-column substructures with UHPC connections. J. Build. Eng. 2024, 82, 108338. [Google Scholar] [CrossRef]

- Qiao, H.; Chen, Y.; Wang, J.; Chen, C. Experimental study on beam-to-column connections with reduced beam section against progressive collapse. J. Constr. Steel Res. 2020, 175, 106358. [Google Scholar] [CrossRef]

- Zhong, W.; Meng, B.; Hao, J. Performance of different stiffness connections against progressive collapse. J. Constr. Steel Res. 2017, 135, 162–175. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, K.; Wang, S.; Tan, L.; Kang, S.-B. Experimental and numerical investigations on progressive collapse resistance of planar reinforced concrete frames with different storeys. Structures 2025, 74, 108489. [Google Scholar] [CrossRef]

- Kiakojouri, F.; De Biagi, V. Catenary mechanism in steel columns under extreme lateral loading: A basis for building progressive collapse analysis. Dev. Built Environ. 2024, 20, 100556. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, X.; Zhang, R.; Du, X. Effect of impact location on the dynamic response of concrete columns reinforced with GFRP bars having various slenderness ratios: A numerical study. Structures 2024, 69, 107571. [Google Scholar] [CrossRef]

- Gao, S.; Yang, J.; Kang, S.B.; Li, F.; Shi, X. Experimental and numerical studies on deformation performance of square concrete-filled steel tubular columns under repeated lateral impacts. Eng. Struct. 2024, 308, 117909. [Google Scholar] [CrossRef]

- Sun, M.J.; Chen, H.; Yi, F.; Ding, Y.B.; Zhou, Y.; He, Q.F.; Zhang, W.-X.; Yi, W.-J. Experimental and numerical study on influence of impact mass and velocity on failure mode of RC columns under lateral impact. Eng. Struct. 2024, 314, 118416. [Google Scholar] [CrossRef]

- Huo, J.; Zhang, J.; Liu, Y.; Fu, F. Dynamic Behaviour and Catenary Action of Axially-restrained Steel Beam Under Impact Loading. Structures 2017, 11, 84–96. [Google Scholar] [CrossRef]

- Pham, T.M.; Hao, H. Plastic hinges and inertia forces in RC beams under impact loads. Int. J. Impact Eng. 2017, 103, 1–11. [Google Scholar] [CrossRef]

- Yin, Z.H.; Jia, P.C.; Li, R.W.; Wu, H. Simplified analytical model for dynamic behaviors of RC member under low-velocity impact. Structures 2025, 77, 109125. [Google Scholar] [CrossRef]

- Chen, Y.; Huo, J.; Chen, W.; Hao, H.; Elghazouli, A.Y. Experimental and numerical assessment of welded steel beam-column connections under impact loading. J. Constr. Steel Res. 2020, 175, 106368. [Google Scholar] [CrossRef]

- Wang, H.; Huo, J.; Elchalakani, M.; Liu, Y.; Zhang, S. Dynamic performance of retrofitted steel beam-column connections subjected to impact loadings. J. Constr. Steel Res. 2021, 183, 106732. [Google Scholar] [CrossRef]

- D’Antimo, M.; Latour, M.; Demonceau, J.F. Drop-weight impact tests on free from damage beam to column connections. J. Constr. Steel Res. 2022, 192, 107215. [Google Scholar] [CrossRef]

- Kukla, D.; Kozlowski, A.; Miller, B.; Ziaja, D.; Wojcik-Grzaba, I.; Gubernat, S. Experimental study of innovative steel beam-to-column joint under impact loading to mitigate progressive collapse. J. Build. Eng. 2025, 102, 112018. [Google Scholar] [CrossRef]

- Kang, H.; Kim, J. Progressive Collapse of Steel Moment Frames Subjected to Vehicle Impact. J. Perform. Constr. Facil. 2015, 29, 04014172. [Google Scholar] [CrossRef]

- Xiang, S.; He, Y.; Zhou, X. Performance assessment of steel parking structure columns subjected to frontal collision based on reduced vehicular models. Eng. Struct. 2022, 265, 114517. [Google Scholar] [CrossRef]

- Liu, H.; Fan, X.; Tian, S.; Deng, X. Dynamic response of buildings under debris flow impact. J. Mt. Sci. 2024, 21, 1581–1597. [Google Scholar] [CrossRef]

- Stephen, D.; Lam, D.; Forth, J.; Ye, J.; Tsavdaridis, K.D. An evaluation of modelling approaches and column removal time on progressive collapse of building. J. Constr. Steel Res. 2019, 153, 243–253. [Google Scholar] [CrossRef]

- Ke, C.; Li, X.; Jiang, J. Dynamic Response Analysis of RC Frame against Progressive Collapse Based on Orthogonal Test. Appl. Sci. Basel 2023, 13, 4317. [Google Scholar] [CrossRef]

- ABAQUS/CAE Computer Software, v 2023; Dassault Systémes, Inc.: Providence, RI, USA, 2022.

- PKPM 2021 Structural Design Software, v 2.1.3.1; China Academy of Building Research: Beijing, China, 2024.

- GB 50017-2017; Code for Design of Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; Architecture & Building Press: Beijing, China, 2017.

- GB 50009-2012; Load Code for the Design of Building Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; Architecture & Building Press: Beijing, China, 2012.

- CECS 392:2021; Code for Anti-Collapse Design of Building Structures. China Engineering Construction Standardization Association: Beijing, China; China Planning Press: Beijing, China, 2021.

- Scholl, N.; Minuth-Hadi, F.; Thiele, K. Modelling the strain rate dependent hardening of constructional steel using semi-empirical models. J. Constr. Steel Res. 2018, 145, 414–424. [Google Scholar] [CrossRef]

- Lin, L.; Zhi, X.; Fan, F.; Meng, S.; Su, J. Determination of Parameters of Johnson-Cook Models of Q235B Steel. J. Vib. Shock 2014, 33, 153–158+172. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, Y. The Difference Between the Built-in Johnson-Cook Fracture Criterion in ABAQUS Finite Element Program and the Original Criterion as well as a Comparative Analysis. J. Nanyang Inst. Technol. 2018, 10, 38–42. [Google Scholar]

- Zhou, T.; Li, W.; Guan, Y.; Bai, L. Damage Analysis of Steel Frames under Cyclic Load Based on Stress Triaxiality. Eng. Mech. 2014, 31, 146–155. [Google Scholar]

- Javidan, M.M.; Kang, H.; Isobe, D.; Kim, J. Computationally efficient framework for probabilistic collapse analysis of structures under extreme actions. Eng. Struct. 2018, 172, 440–452. [Google Scholar] [CrossRef]

- UFC 4—023-03; United States Department of Defense (DoD). Structures to Resist Progressive Collapse. Department of Defense: Washington, DC, USA, 2005.

- Izzuddin, B. A simplified model for axially restrained beams subject to extreme loading. Int. J. Steel Struct. 2005, 5, 421–429. [Google Scholar]

- Qiao, H.; Lu, C.; Wei, J.; Chen, Y. Progressive Collapse Analysis for Steel-Braced Frames Considering Vierendeel Action. J. Perform. Constr. Facil. 2020, 34, 04020069. [Google Scholar] [CrossRef]

| Square Steel Pipe Column Section (mm) | H-Beam Section (mm) |

|---|---|

| F400 × 400 × 12 | H400 × 200 × 8 × 13 |

| A (MPa) | B (MPa) | C | n | m | Tm (K) | Tr (K) | Reference Strain Rate |

|---|---|---|---|---|---|---|---|

| 244.8 | 899.7 | 0.0391 | 0.94 | 0.757 | 1795 | 293 | 0.000833 |

| D1 | D2 | D3 | D4 | D5 |

|---|---|---|---|---|

| −43.408 | 44.608 | 0.016 | 0.0145 | 6.619 |

| Mesh Size (mm) | Impact Displacement (mm) | Vertical Displacement (mm) |

|---|---|---|

| 20 | 1375.4 | 566.3 |

| 30 | 1381.4 | 595.6 |

| 40 | 1381.6 | 595.6 |

| Parameter Combination | Impact Residual Displacement (mm) | Vertical Residual Displacement (mm) | 1-1 (mm) | 1-2 (mm) | 1-3 (mm) | 1-4 (mm) |

|---|---|---|---|---|---|---|

| M6V40Z3A1 | 1384.10 | −595.59 | 206.21 | 171.86 | 158.05 | 157.37 |

| M6V40Z1B1 | 1376.53 | −639.91 | 99.39 | 46.86 | 44.31 | 44.02 |

| M6V40Z4A1 | 1385.93 | −672.78 | 200.74 | 168.58 | 155.20 | 154.89 |

| M6V40Z1C1 | 1380.21 | −700.50 | 100.27 | 45.83 | 43.24 | 42.41 |

| M6V30Z3A1 | 1011.64 | −350.37 | 133.11 | 118.40 | 109.14 | 108.34 |

| M6V30Z1B1 | 1008.31 | −369.55 | 59.49 | 41.64 | 32.06 | 31.07 |

| M6V30Z4A1 | 1015.22 | −381.19 | 132.52 | 112.99 | 105.18 | 104.42 |

| M6V30Z1C1 | 1009.21 | −408.51 | 59.69 | 37.92 | 28.97 | 27.84 |

| M3V30Z3A1 | 642.94 | −160.44 | 71.4 | 65.53 | 61.51 | 60.81 |

| M3V30Z1B1 | 639.54 | −165.45 | 29.04 | 22.56 | 17.95 | 16.90 |

| M3V30Z4A1 | 643.77 | −166.48 | 69.26 | 63.50 | 58.94 | 58.28 |

| M3V30Z1C1 | 638.74 | −176.44 | 27.36 | 19.58 | 15.52 | 14.63 |

| M3V20Z3A1 | 327.29 | −53.51 | 47.85 | 44.86 | 43.14 | 42.42 |

| M3V20Z1B1 | 329.77 | −53.95 | 19.31 | 16.00 | 12.75 | 12.43 |

| M3V20Z4A1 | 329.76 | −53.97 | 50.40 | 46.31 | 44.83 | 44.17 |

| M3V20Z1C1 | 324.52 | −53.71 | 19.50 | 15.05 | 13.25 | 12.19 |

| Member | Ductility | Rotation |

|---|---|---|

| Steel beam | 10 | 6 |

| Plate | 20 | 6 |

| Welded beam flange or cover plate | ___ | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Zhang, Z.; Ke, C. Study on Dynamic Response and Progressive Collapse Resistance of Space Steel Frame Under Impact Load. Buildings 2025, 15, 1888. https://doi.org/10.3390/buildings15111888

Jiang J, Zhang Z, Ke C. Study on Dynamic Response and Progressive Collapse Resistance of Space Steel Frame Under Impact Load. Buildings. 2025; 15(11):1888. https://doi.org/10.3390/buildings15111888

Chicago/Turabian StyleJiang, Junling, Zhishuang Zhang, and Changren Ke. 2025. "Study on Dynamic Response and Progressive Collapse Resistance of Space Steel Frame Under Impact Load" Buildings 15, no. 11: 1888. https://doi.org/10.3390/buildings15111888

APA StyleJiang, J., Zhang, Z., & Ke, C. (2025). Study on Dynamic Response and Progressive Collapse Resistance of Space Steel Frame Under Impact Load. Buildings, 15(11), 1888. https://doi.org/10.3390/buildings15111888