Understanding the Causation Mechanism of Construction Workers’ Unsafe Behaviors in Railway Tunnel Engineering Based on 24model and Social Network Analysis

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

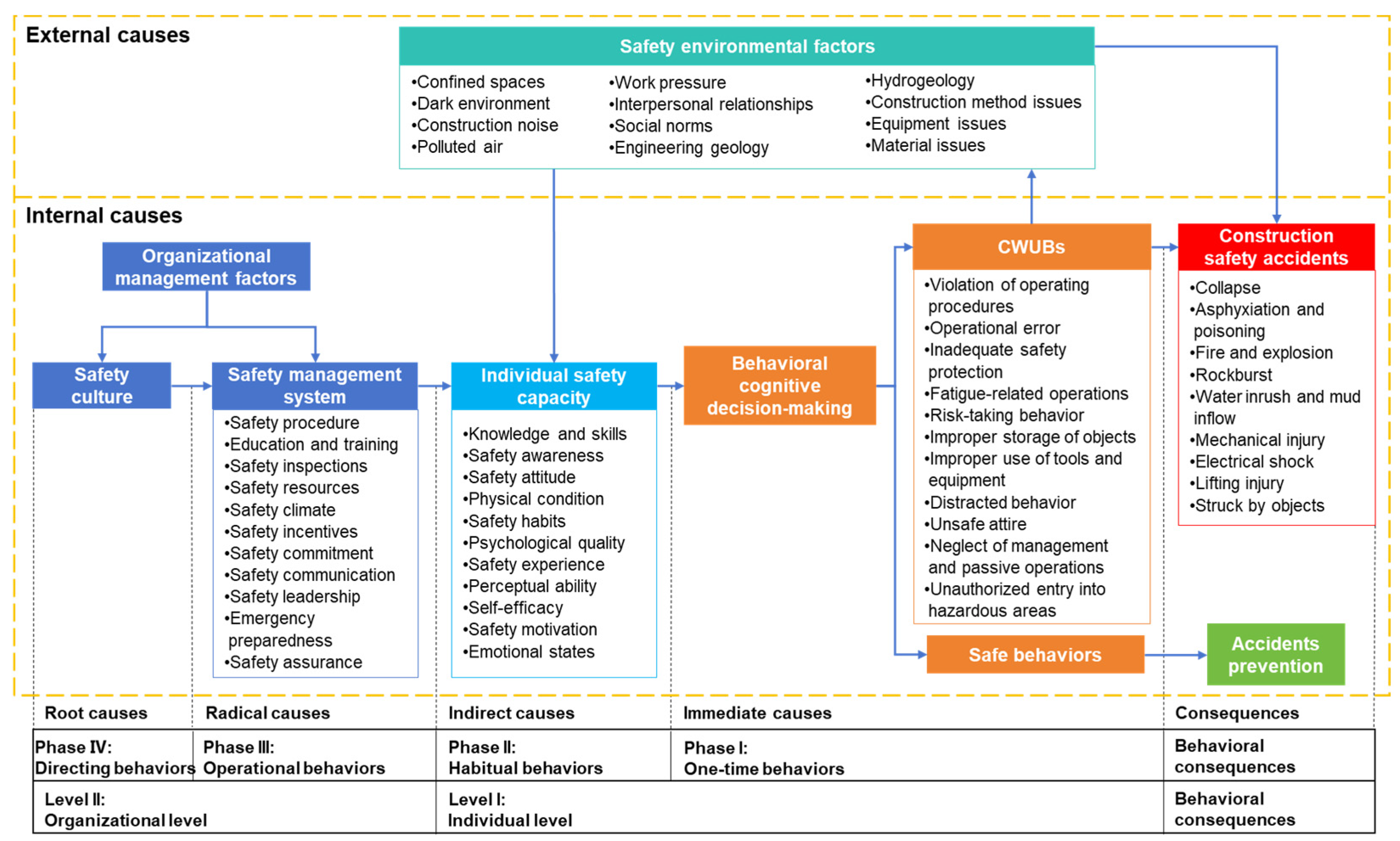

3.1. Framework

3.2. Methods

3.2.1. 24model

3.2.2. Social Network Analysis

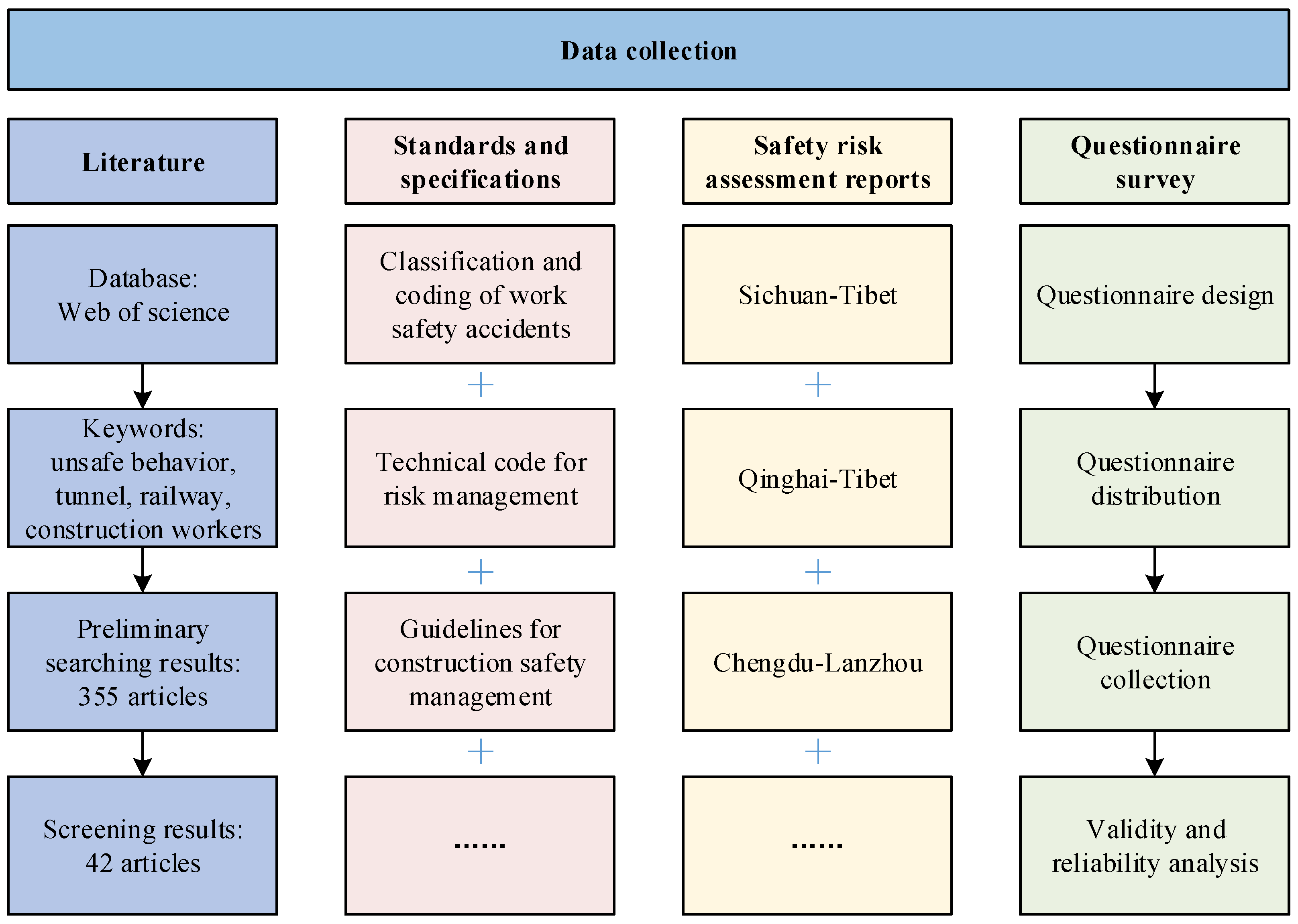

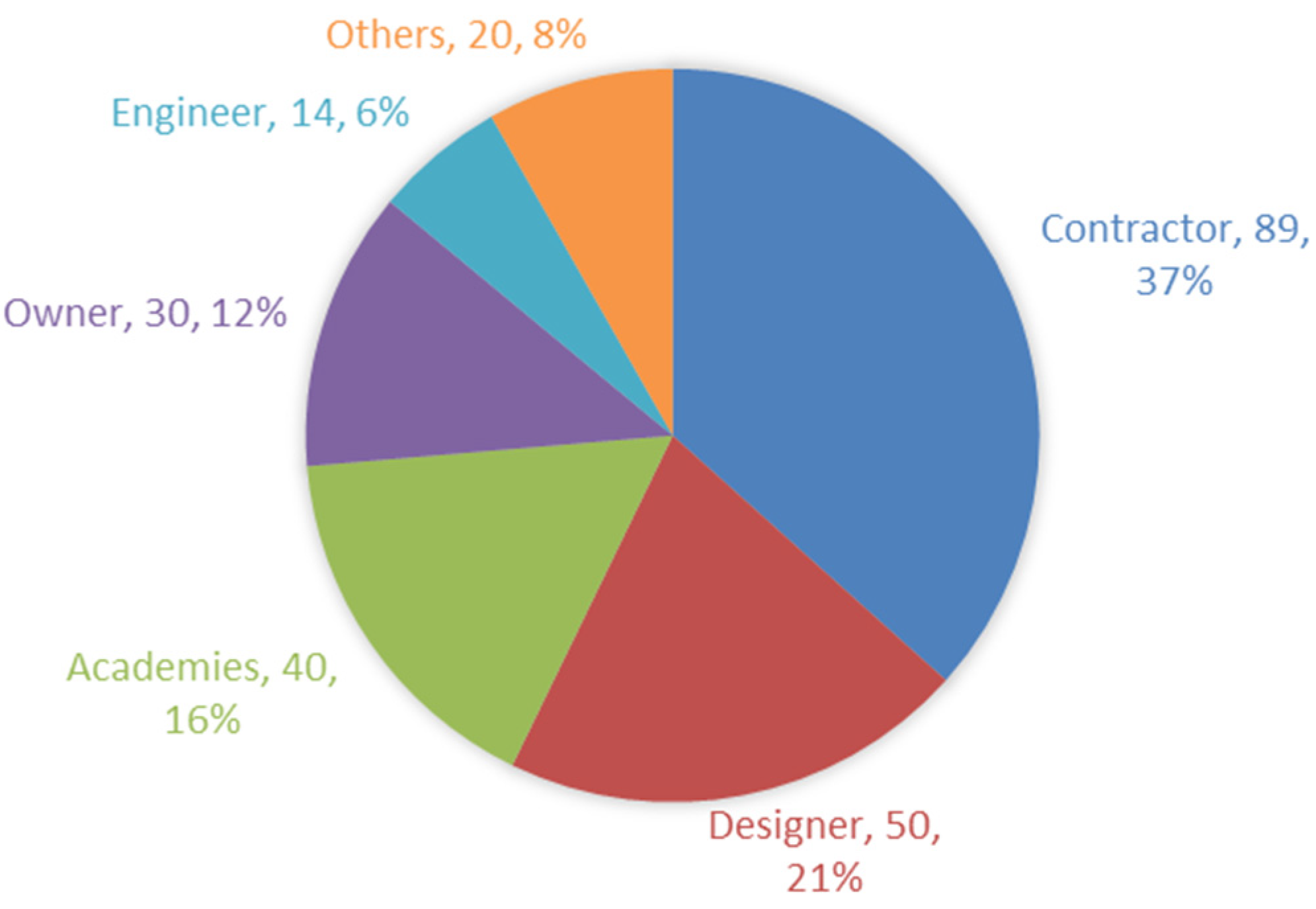

3.3. Data Collection

4. Results

4.1. Identification of Construction Safety Accidents, CWUBs, and Their Influencing Factors in RTE

4.1.1. Construction Safety Accidents in RTE

4.1.2. CWUBs in RTE

4.1.3. Influencing Factors of CWUBs in RTE

4.2. Qualitative Analysis of Causation Mechanism and Causation Relationships’ Extraction for CWUBs in RTE

4.2.1. Construction of 24model for CWUBs in RTE

4.2.2. Determination of Primary and Second Causation Relationships

4.3. Quantitative Analysis of Causation Mechanism for CWUBs in RTE

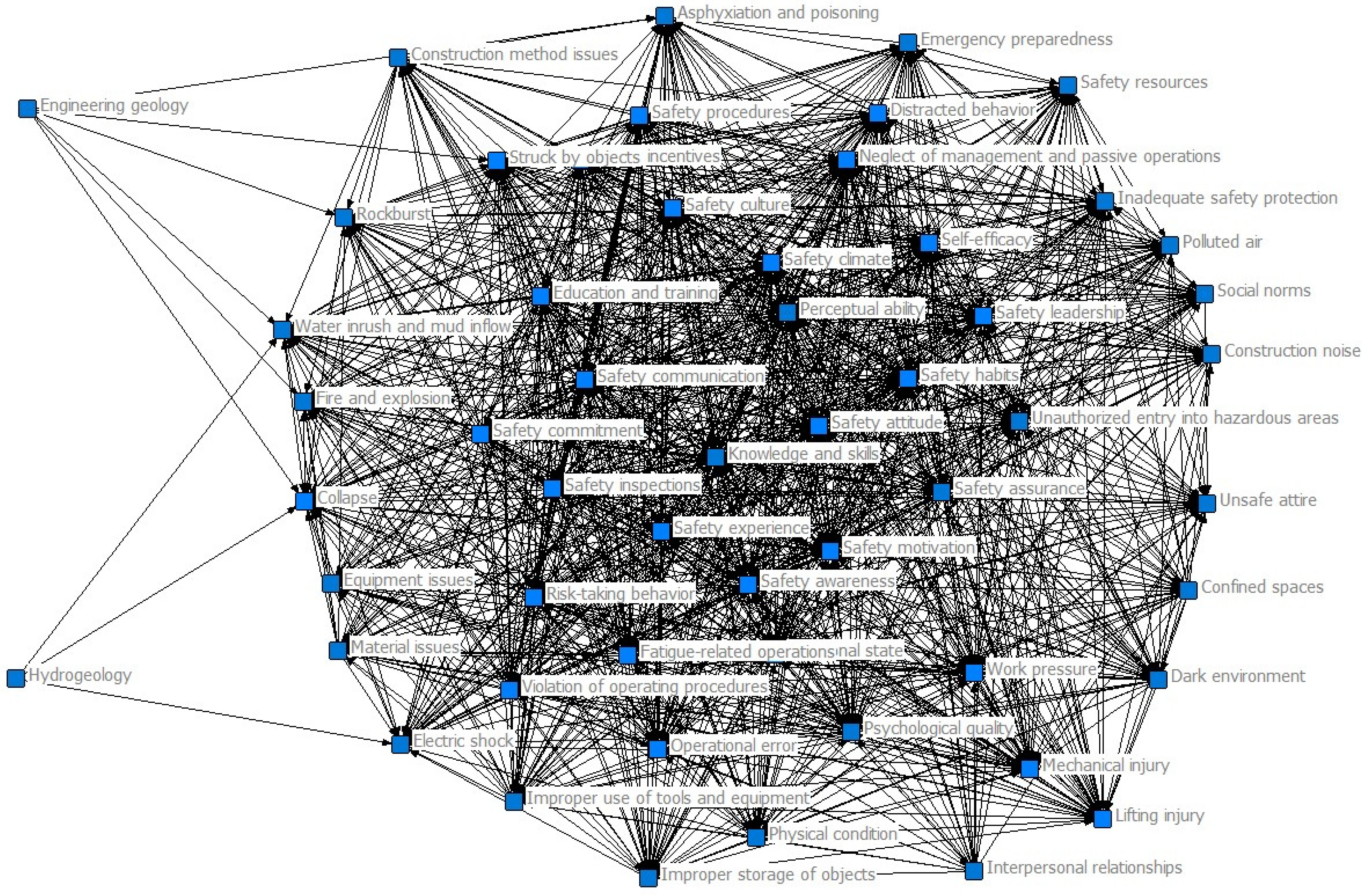

4.3.1. Construction of the Network Model for CWUBs in RTE

4.3.2. Overall, Block, and Individual Network Analysis of CWUBs in RTE

4.3.3. Identification of Key Network Structure and Factors

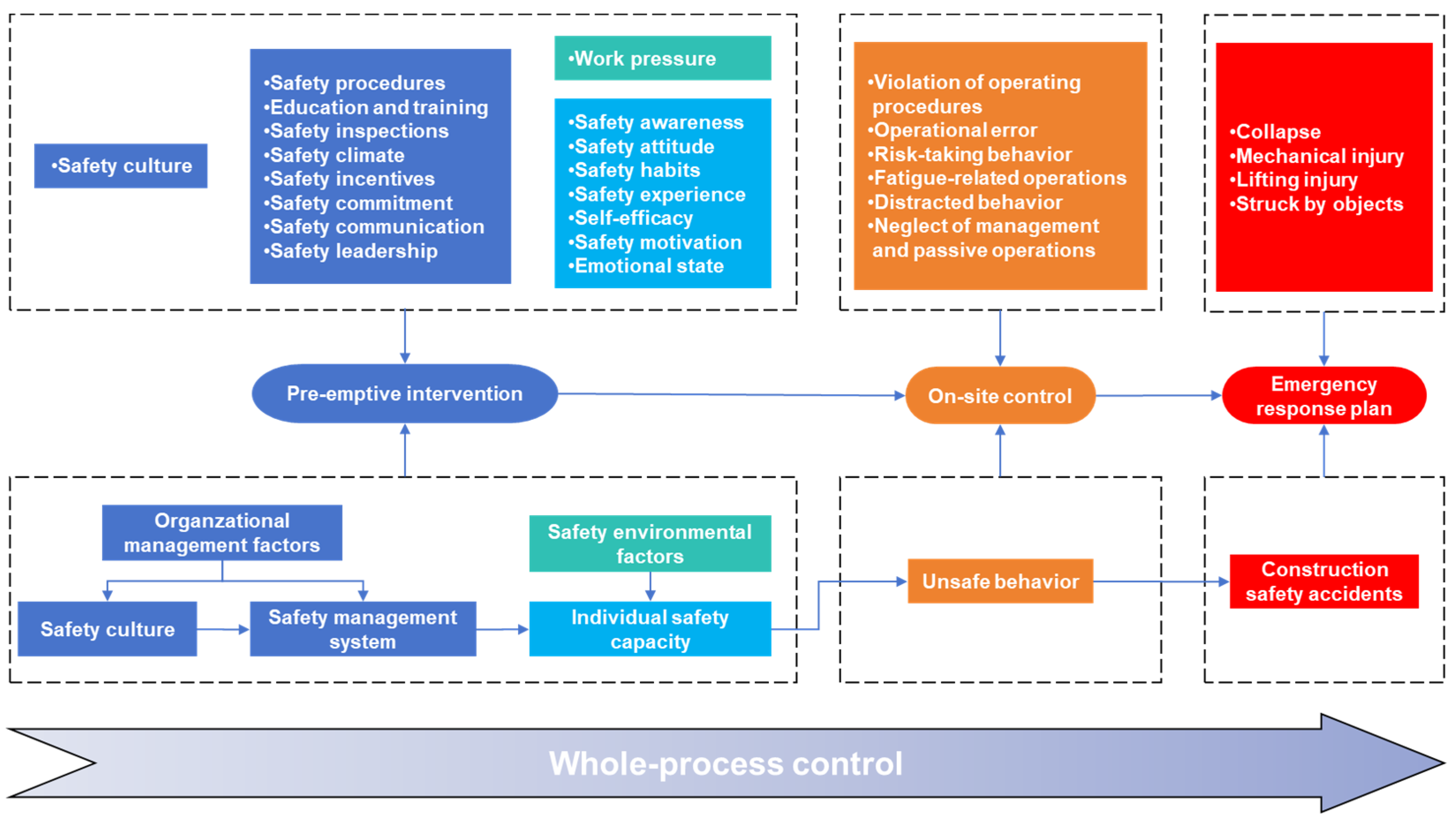

4.4. Intervention Strategies for CWUBs in RTE

4.4.1. Pre-Emptive Intervention of CWUBs’ Influencing Factors

4.4.2. On-Site Control of CWUBs

4.4.3. Emergency Response Plan of Safety Accidents

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CWUBs | Construction workers’ unsafe behaviors |

| RTE | Railway tunnel engineering |

References

- Lin, Y.; Qin, Y.; Wu, J.; Xu, M. Impact of high-speed rail on road traffic and greenhouse gas emissions. Nat. Clim. Change 2021, 11, 952–957. [Google Scholar] [CrossRef]

- High Speed Lines in the World. Available online: https://uic.org/IMG/pdf/20231001_high_speed_lines_in_the_world.pdf (accessed on 29 April 2025).

- Zhang, D.L.; Sun, Z.Y.; Fang, Q. Scientific problems and research proposals for Sichuan-Tibet railway tunnel construction. Undergr. Space 2022, 7, 419–439. [Google Scholar] [CrossRef]

- Zhang, L.M.; Wu, X.G.; Qin, Y.W.; Skibniewski, M.J.; Liu, W.L. Towards a fuzzy bayesian network based approach for safety risk analysis of tunnel-induced pipeline damage. Risk Anal. 2016, 36, 278–301. [Google Scholar] [CrossRef] [PubMed]

- Pooladvand, S.; Hasanzadeh, S. Impacts of stress on workers’ risk-taking behaviors: Cognitive tunneling and impaired selective attention. J. Constr. Eng. Manag. 2023, 149, 04023060. [Google Scholar] [CrossRef]

- Chi, S.; Han, S.; Kim, D.Y. Relationship between unsafe working conditions and workers’ behavior and impact of working conditions on injury severity in us construction industry. J. Constr. Eng. Manag. 2013, 139, 826–838. [Google Scholar] [CrossRef]

- Goh, Y.M.; Sa’adon, N.F.B. Cognitive factors influencing safety behavior at height: A multimethod exploratory study. J. Constr. Eng. Manag. 2015, 141, 04015003. [Google Scholar] [CrossRef]

- Ai Lin Teo, E.; Yean Yng Ling, F.; Sern Yau Ong, D. Fostering safe work behaviour in workers at construction sites. Eng. Constr. Archit. Manag. 2005, 12, 410–422. [Google Scholar] [CrossRef]

- Leung, M.Y.; Chan, Y.S.; Yuen, K.W. Impacts of stressors and stress on the injury incidents of construction workers in Hong Kong. J. Constr. Eng. Manag. 2010, 136, 1093–1103. [Google Scholar] [CrossRef]

- Fang, D.P.; Wu, C.L.; Wu, H.J. Impact of the supervisor on worker safety behavior in construction projects. J. Manag. Eng. 2015, 31, 04015001. [Google Scholar] [CrossRef]

- Prayogo, A.; Teophilea, H.S.; Nugraha, P.; Sunindijo, R.Y.; Maharani, C.F.; Yang, K.J. Noise disturbance increases negative emotions and unsafe behaviour among construction workers. Int. J. Constr. Manag. 2024, 1–8. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, T.S.; Zhou, W.; Tang, J.J. Safety risk factors of metro tunnel construction in China: An integrated study with EFA and SEM. Saf. Sci. 2018, 105, 98–113. [Google Scholar] [CrossRef]

- Shin, M.; Lee, H.-S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Ye, G.; Yue, H.Z.; Yang, J.J.; Li, H.Y.; Xiang, Q.T.; Fu, Y.; Cui, C. Understanding the sociocognitive process of construction workers’ unsafe behaviors: An agent-based modeling approach. Int. J. Environ. Res. Public Health 2020, 17, 1588. [Google Scholar] [CrossRef]

- Zaira, M.M.; Hadikusumo, B.H.W. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Saf. Sci. 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Kong, T.; Fang, W.L.; Love, P.E.D.; Luo, H.B.; Xu, S.J.; Li, H. Computer vision and long short-term memory: Learning to predict unsafe behaviour in construction. Adv. Eng. Inf. 2021, 50, 101400. [Google Scholar] [CrossRef]

- Chen, W.Q.; Deng, J.J.; Niu, L.C. Identification of core risk factors and risk diffusion effect of urban underground engineering in China: A social network analysis. Saf. Sci. 2022, 147, 105591. [Google Scholar] [CrossRef]

- Chen, H.Y.; Shen, G.Q.; Feng, Z.B.; Yang, S. Safety risk assessment of shield tunneling under existing tunnels: A hybrid trapezoidal cloud model and Bayesian network approach. Tunn. Undergr. Space Technol. 2024, 152, 105936. [Google Scholar] [CrossRef]

- Zhou, H.; Gao, B.W.; Zhao, X.B.; Peng, L.Y.; Bai, S.C. Developing a cloud evidence method for dynamic early warning of tunnel construction safety risk in undersea environment. Dev. Built Environ. 2023, 16, 100225. [Google Scholar] [CrossRef]

- Yang, J.J.; Ye, G.; Xiang, Q.T.; Kim, M.; Liu, Q.J.; Yue, H.Z. Insights into the mechanism of construction workers’ unsafe behaviors from an individual perspective. Saf. Sci. 2021, 133, 105004. [Google Scholar] [CrossRef]

- Liang, Q.; Zhou, Z.Y.; Ye, G.; Shen, L.Y. Unveiling the mechanism of construction workers’ unsafe behaviors from an occupational stress perspective: A qualitative and quantitative examination of a stress-cognition-safety model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Hu, Z.; Chan, W.T.; Hu, H.; Xu, F. Cognitive factors underlying unsafe behaviors of construction workers as a tool in safety management: A review. J. Constr. Eng. Manag. 2023, 149, 03123001. [Google Scholar] [CrossRef]

- Xiang, Q.T.; Liu, Y.; Goh, Y.M.; Ye, G.; Safiena, S. Investigating the impact of hazard perception failure on construction workers’ unsafe behavior: An eye-tracking and thinking-aloud approach. J. Constr. Eng. Manag. 2024, 150, 04024066. [Google Scholar] [CrossRef]

- Ni, G.D.; Zhang, Q.; Fang, Y.Q.; Zhang, Z.Y.; Qiao, Y.N.; Wang, W.S.; Deng, Y.L. How resilient safety culture correct unsafe behavior of new generation of construction workers: The mediating effects of job crafting and perceived work meaningfulness. Eng. Constr. Archit. Manag. 2023, 30, 4821–4845. [Google Scholar] [CrossRef]

- Dedobbeleer, N.; Beland, F. A safety climate measure for construction sites. J. Saf. Res. 1991, 22, 97–103. [Google Scholar] [CrossRef]

- Sommovigo, V.; Setti, I.; Maiolo, M.E.; Argentero, P. Tunnel construction workers’ well-being: The role of job control and supervisor support. Int. J. Constr. Manag. 2021, 21, 945–957. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D.P. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Hu, Y.P.; Wang, M.N.; Wang, Q.L.; Liu, D.G.; Tong, J.J. Field test of thermal environment and thermal adaptation of workers in high geothermal tunnel. Build. Environ. 2019, 160, 106174. [Google Scholar] [CrossRef]

- Kim, D.K.; Park, S. Business cycle and occupational accidents in Korea. Saf. Health Work 2020, 11, 314–321. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.Y.; Zhao, Y.J.; Luoren, Y.Q.; Liang, K.Z.; Tang, B. Knowledge discovery of correlations between unsafe behaviors within construction accidents. Eng. Constr. Archit. Manag. 2022, 29, 1797–1816. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention; A Scientific Approach; McGraw-Hill: New York, NY, USA, 1931; p. 366. [Google Scholar]

- Bird, F.E.; Germain, G.L. Damage Control: A New Horizon in Accident Prevention and Cost Improvement; American Management Association: New York, NY, USA, 1966. [Google Scholar]

- Reason, J. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Stewart, J.M. The turnaround in safety at the Kenora pulp & paper mill. Prof. Saf. 2001, 46, 34–44. [Google Scholar]

- Fang, D.P.; Zhao, C.; Zhang, M.C. A cognitive model of construction workers’ unsafe behaviors. J. Constr. Eng. Manag. 2016, 142, 04016039. [Google Scholar] [CrossRef]

- Fu, G.; Zhao, Z.Q.; Hao, C.B.; Wu, Q. The accident path of coal mine gas explosion based on 24model: A case study of the ruizhiyuan gas explosion accident. Processes 2019, 7, 73. [Google Scholar] [CrossRef]

- Wu, Y.L.; Fu, G.; Wu, Z.R.; Wang, Y.X.; Xie, X.C.; Han, M.; Lyu, Q. A popular systemic accident model in China: Theory and applications of 24Model. Saf. Sci. 2023, 159, 106013. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Fang, D.P.; Zhang, M.C. Understanding the causation of construction workers’ unsafe behaviors based on system dynamics modeling. J. Manag. Eng. 2015, 31, 04014099. [Google Scholar] [CrossRef]

- Tang, B.; Guo, S.Y.; Li, J.C.; Lu, W. Exploring the risk transmission characteristics among unsafe behaviors within urban railway construction accidents. J. Civ. Eng. Manag. 2022, 28, 443–456. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Xiang, T.; Guo, H.L.; Ma, L.; Guan, Z.Y.; Fang, Y.H. Impact of physical and mental fatigue on construction workers’ unsafe behavior based on physiological measurement. J. Saf. Res. 2023, 85, 457–468. [Google Scholar] [CrossRef]

- Fang, Q.; Castro-Lacouture, D.; Li, C.Q. Smart safety: Big data-enabled system for analysis and management of unsafe behavior by construction workers. J. Manag. Eng. 2024, 40, 04023053. [Google Scholar] [CrossRef]

- Fang, Q.; Chen, X.C.; Castro-Lacouture, D.; Li, C.Q. Intervention and management of construction workers’ unsafe behavior: A simulation digital twin model. Adv. Eng. Inf. 2023, 58, 102182. [Google Scholar] [CrossRef]

- Wu, H.; Han, Y.; Zhang, M.; Abebe, B.D.; Legesse, M.B.; Jin, R.Y. Identifying unsafe behavior of construction workers: A dynamic approach combining skeleton information and spatiotemporal features. J. Constr. Eng. Manag. 2023, 149, 04023115. [Google Scholar] [CrossRef]

- Ding, C.; Liu, Q.L.; Guo, X.W.; Xue, T.T.; Wang, Z.H. Identifying unsafe behaviors of construction workers through an unsupervised multi-anomaly GAN approach. Autom. Constr. 2024, 165, 105509. [Google Scholar] [CrossRef]

- Mohajeri, M.; Ardeshir, A.; Banki, M.T.; Malekitabar, H. Discovering causality patterns of unsafe behavior leading to fall hazards on construction sites. Int. J. Constr. Manag. 2022, 22, 3034–3044. [Google Scholar] [CrossRef]

- Yu, Y.T.; Guo, H.L.; Ding, Q.H.; Li, H.; Skitmore, M. An experimental study of real-time identification of construction workers’ unsafe behaviors. Autom. Constr. 2017, 82, 193–206. [Google Scholar] [CrossRef]

- Guo, H.L.; Yu, Y.T.; Ding, Q.H.; Skitmore, M. Image-and-skeleton-based parameterized approach to real-time identification of construction workers unsafe behaviors. J. Constr. Eng. Manag. 2018, 144, 04018042. [Google Scholar] [CrossRef]

- Eker, H. Natural language processing risk assessment application developed for marble quarries. Appl. Sci. 2024, 14, 9045. [Google Scholar] [CrossRef]

- Jeelani, I.; Asadi, K.; Ramshankar, H.; Han, K.; Albert, A. Real-time vision-based worker localization & hazard detection for construction. Autom. Constr. 2021, 121, 103448. [Google Scholar] [CrossRef]

- Arslan, M.; Cruz, C.; Ginhac, D. Visualizing intrusions in dynamic building environments for worker safety. Saf. Sci. 2019, 120, 428–446. [Google Scholar] [CrossRef]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; Sage Publications: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Kitzinger, J. Qualitative research: Introducing focus groups. Brit. Med. J. 1995, 311, 299–302. [Google Scholar] [CrossRef]

- Fu, G.; Cao, J.L.; Zhou, L.; Xiang, Y.C. Comparative study of HFACS and the 24Model accident causation models. Pet. Sci. 2017, 14, 570–578. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.C.; Jia, Q.S.; Li, Z.H.; Chen, P.; Ge, Y. The development history of accident causation models in the past 100 years: 24Model, a more modern accident causation model. Process Saf. Environ. Prot. 2020, 134, 47–82. [Google Scholar] [CrossRef]

- Wasserman, S.; Faust, K. Social Network Analysis: Methods and Applications; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Li, C.Z.; Hong, J.K.; Xue, F.; Shen, G.Q.; Xu, X.X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Work Safety Law of the Peoples Republic of China. Available online: https://www.mem.gov.cn/fw/flfgbz/fg/202107/t20210716_416558.shtml (accessed on 29 April 2025).

- Classification and Coding of Work Safety Accidents. Available online: https://www.mem.gov.cn/gk/zfxxgkpt/fdzdgknr/202504/W020250516592549873622.pdf (accessed on 29 April 2025).

- Q/CR 9006-2014; Technical Code for Risk Management of Railway Construction Engineering. China Railway: Beijing, China, 2014.

- Guidelines for Construction Safety Management of Railway Construction Projects; China Railway: Beijing, China, 2023.

- Technical Code for Risk Management of Railway Tunnel Projects; China Railway: Beijing, China, 2016.

- Railway Safety Risk Classification Control and Hidden Danger Investigation and Treatment Management Measures. Available online: https://www.nra.gov.cn/xxgk/gkml/ztjg/gfzd/gfxw/zuti/jgzf/202303/t20230320_340029.shtml (accessed on 29 April 2025).

| Organizational Management Factors | Individual Safety Capacity | Safety Environmental Factors |

|---|---|---|

| Safety culture (M1) | Knowledge and skills (P1) | Confined spaces (E1) |

| Safety procedures (M2) | Safety awareness (P2) | Dark environment (E2) |

| Education and training (M3) | Safety attitude (P3) | Construction noise (E3) |

| Safety inspections (M4) | Physical condition (P4) | Polluted air (E4) |

| Safety resources (M5) | Safety habits (P5) | Work pressure (E5) |

| Safety climate (M6) | Psychological quality (P6) | Interpersonal relationships (E6) |

| Safety incentives (M7) | Safety experience (P7) | Social norms (E7) |

| Safety commitment (M8) | Perceptual ability (P8) | Engineering geology (E8) |

| Safety communication (M9) | Self-efficacy (P9) | Hydrogeology (E9) |

| Safety leadership (M10) | Safety motivation (P10) | Construction method issues (E10) |

| Emergency preparedness (M11) | Emotional state (P11) | Equipment issues (E11) |

| Safety assurance (M12) | Material issues (E12) |

| Number of Nodes | Number of Connections | Density |

|---|---|---|

| 55 | 1314 | 0.442 |

| Network Diameter | Average Shortest Path |

|---|---|

| 3 | 1.218 |

| Network Connectivity | Network Reciprocity |

|---|---|

| 0.600 | 0.165 |

| Number of Blocks | 22 | 23 | 24 |

|---|---|---|---|

| Fit index | 0.493 | 0.612 | 0.788 |

| K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 | K11 | K12 | K13 | K14 | K15 | K16 | Sending | Receiving | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| K1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 | 1 | |||

| K2 | 1 | 1 | 0 | |||||||||||||||

| K3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 | 0 | ||||||||

| K4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7 | 0 | |||||||||

| K5 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 | 1 | |||

| K6 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 10 | 1 | |||||

| K7 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 6 | 1 | |||||||||

| K8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7 | 0 | |||||||||

| K9 | 1 | 1 | 0 | |||||||||||||||

| K10 | 1 | 1 | 2 | 0 | ||||||||||||||

| K11 | 0 | 0 | ||||||||||||||||

| K12 | 0 | 0 | ||||||||||||||||

| K13 | 1 | 1 | 1 | 1 | 1 | 1 | 5 | 1 | ||||||||||

| K14 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 6 | 1 | |||||||||

| K15 | 1 | 1 | 0 | |||||||||||||||

| K16 | 1 | 1 | 1 | 3 | 0 | |||||||||||||

| Sending | 0 | 0 | 1 | 3 | 6 | 6 | 6 | 0 | 4 | 7 | 9 | 10 | 6 | 7 | 9 | 7 | ||

| Receiving | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| Rank | Factors | CD(ni-in) | Factors | CD(ni-out) |

|---|---|---|---|---|

| 1 | Safety attitude | 106 | Safety climate | 114 |

| 2 | Safety habits | 103 | Safety culture | 112 |

| 3 | Safety awareness | 102 | Education and training | 109 |

| 4 | Perceptual ability | 96 | Safety leadership | 109 |

| 5 | Safety motivation | 95 | Safety procedures | 108 |

| 6 | Self-efficacy | 90 | Safety attitude | 107 |

| 7 | Knowledge and skills | 86 | Safety habits | 104 |

| 8 | Struck by objects | 82 | Safety inspections | 103 |

| 9 | Mechanical injury | 79 | Safety awareness | 102 |

| 10 | Lifting injury | 77 | Safety incentives | 101 |

| Rank | Factors | CB(ni) |

|---|---|---|

| 1 | Safety climate | 53.046 |

| 2 | Safety culture | 41.844 |

| 3 | Collapse | 25.833 |

| 4 | Safety awareness | 25.632 |

| 5 | Safety attitude | 25.632 |

| 6 | Emotional state | 25.427 |

| 7 | Safety communication | 24.676 |

| 8 | Safety experience | 22.694 |

| 9 | Safety motivation | 21.32 |

| 10 | Safety habits | 19.174 |

| Rank | Factors | CC(ni-in) | Factors | CC(ni-out) |

|---|---|---|---|---|

| 1 | Lifting injury | 0.720 | Safety climate | 0.871 |

| 2 | Struck by objects | 0.711 | Safety culture | 0.857 |

| 3 | Mechanical injury | 0.692 | Education and training | 0.857 |

| 4 | Electric shock | 0.684 | Safety inspections | 0.844 |

| 5 | Asphyxiation and poisoning | 0.651 | Safety commitment | 0.844 |

| 6 | Collapse | 0.643 | Safety communication | 0.844 |

| 7 | Fire and explosion | 0.614 | Safety incentives | 0.831 |

| 8 | Water inrush and mud inflow | 0.614 | Safety procedures | 0.818 |

| 9 | Rock burst | 0.545 | Safety leadership | 0.818 |

| 10 | Unauthorized entry into hazardous areas | 0.509 | Safety assurance | 0.818 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Xia, B.; Cheng, Q.; Yin, Y.; Chen, H. Understanding the Causation Mechanism of Construction Workers’ Unsafe Behaviors in Railway Tunnel Engineering Based on 24model and Social Network Analysis. Buildings 2025, 15, 1841. https://doi.org/10.3390/buildings15111841

Hu X, Xia B, Cheng Q, Yin Y, Chen H. Understanding the Causation Mechanism of Construction Workers’ Unsafe Behaviors in Railway Tunnel Engineering Based on 24model and Social Network Analysis. Buildings. 2025; 15(11):1841. https://doi.org/10.3390/buildings15111841

Chicago/Turabian StyleHu, Xiaodong, Bo Xia, Qintao Cheng, Yang Yin, and Huihua Chen. 2025. "Understanding the Causation Mechanism of Construction Workers’ Unsafe Behaviors in Railway Tunnel Engineering Based on 24model and Social Network Analysis" Buildings 15, no. 11: 1841. https://doi.org/10.3390/buildings15111841

APA StyleHu, X., Xia, B., Cheng, Q., Yin, Y., & Chen, H. (2025). Understanding the Causation Mechanism of Construction Workers’ Unsafe Behaviors in Railway Tunnel Engineering Based on 24model and Social Network Analysis. Buildings, 15(11), 1841. https://doi.org/10.3390/buildings15111841