Analysis Method for the Pouring Stage of Concrete-Filled Steel Tube (CFST) Arch Bridges Considering Time-Varying Heat of Hydration and Elastic Modulus

Abstract

1. Introduction

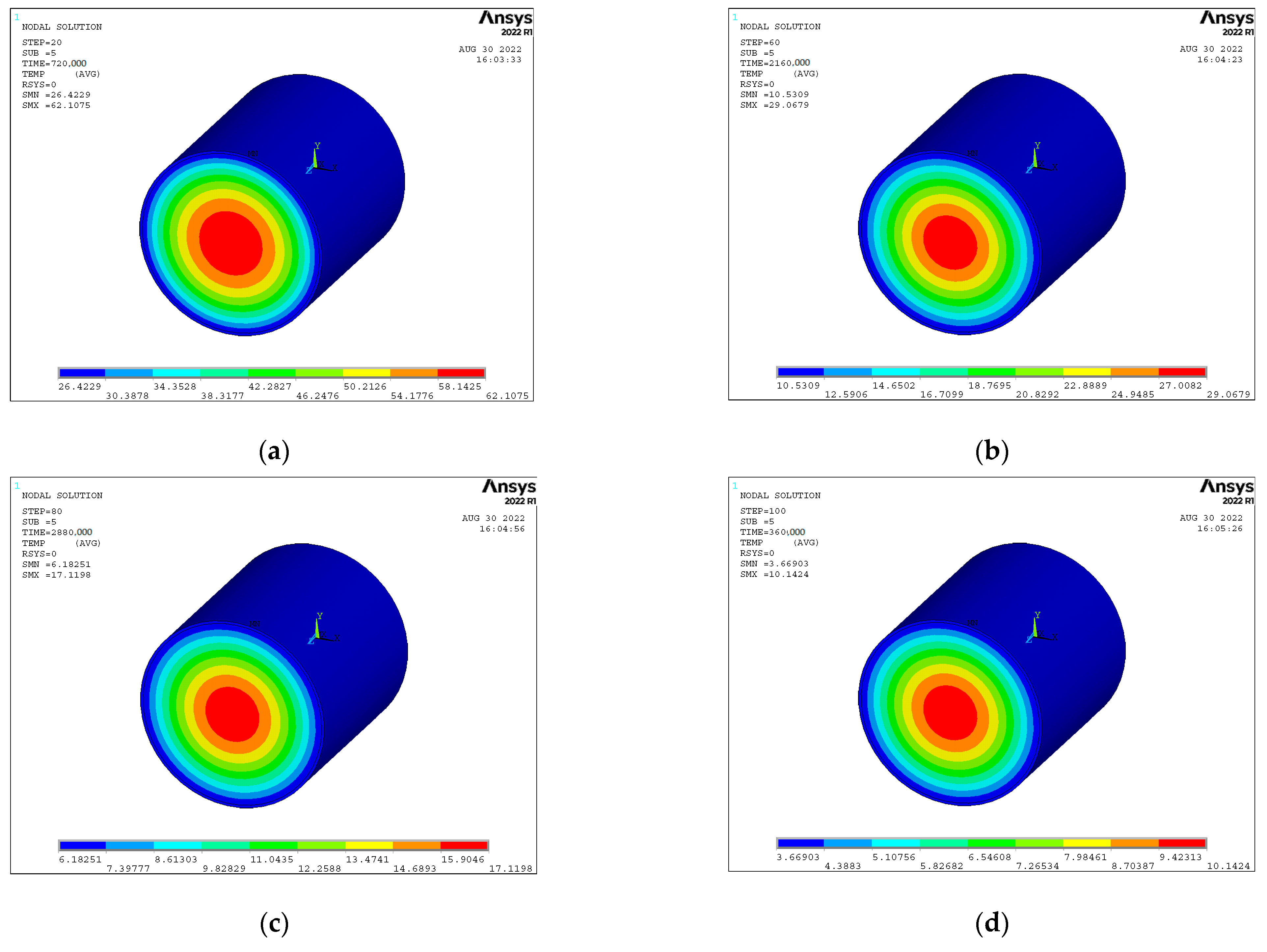

2. Time-Varying Law of the Hydration Heat of CFST Arch Ribs

2.1. Hydration Heat Source Function for CFST Arch Ribs

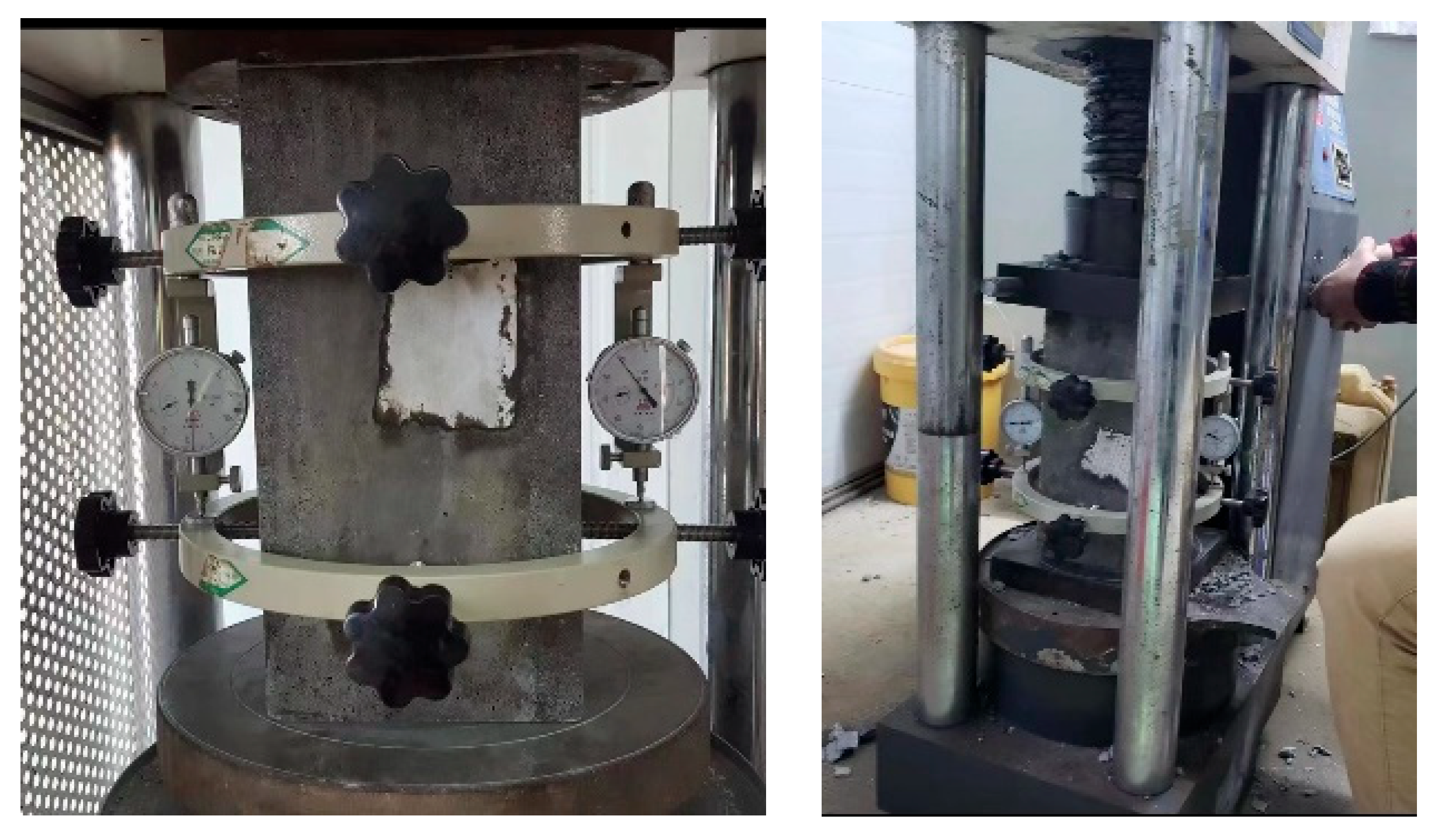

2.2. Experimental Validation of the Hydration Heat Source Function

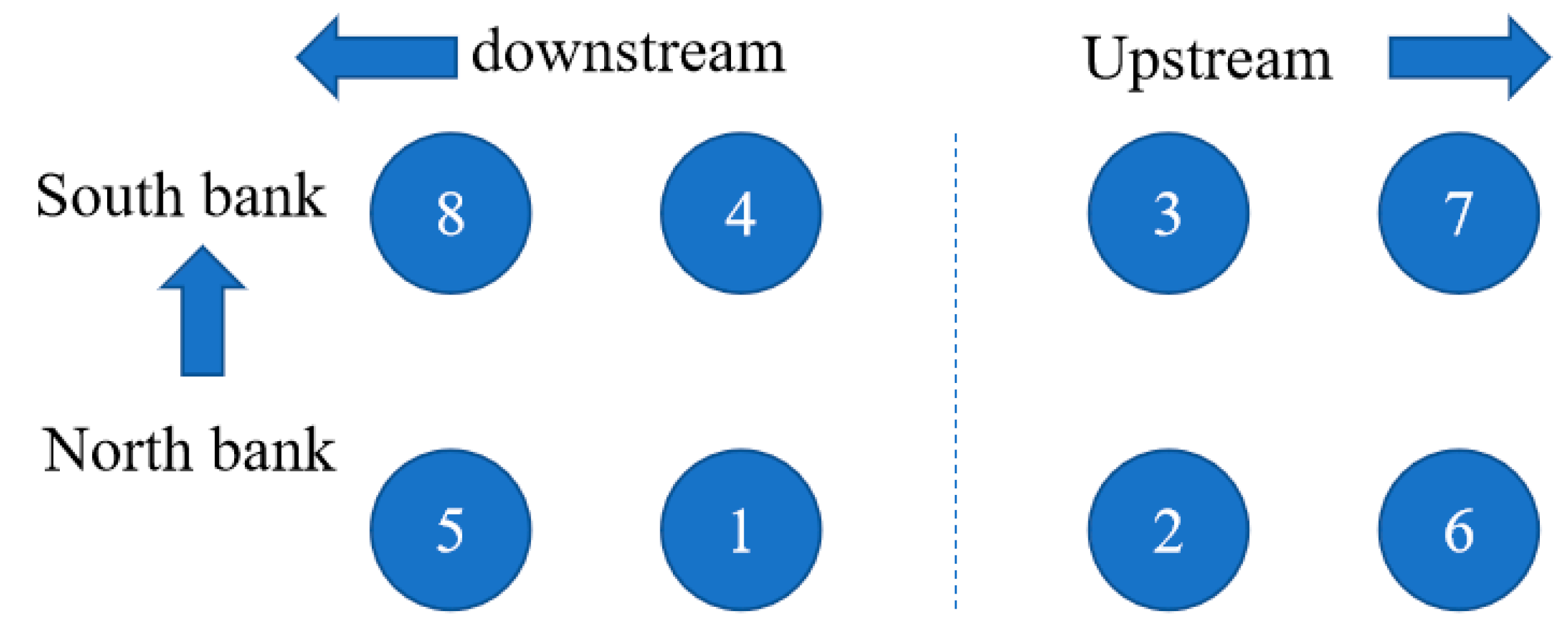

2.2.1. Experimental Design

2.2.2. Test Results and Analyses

2.2.3. Equivalent Loading Method for the Heat of Hydration During the Filling Phase of Arch Ribs

3. Analysis of the Effects of Considering the Time-Varying Heat of Hydration and Elastic Modulus

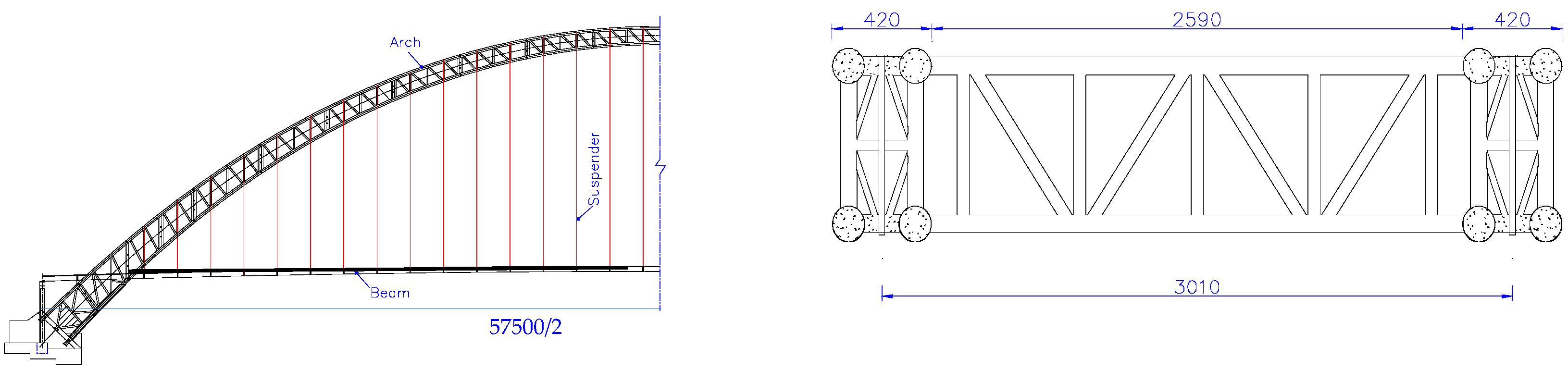

3.1. Engineering Background

3.2. Modeling and Pouring Stage Classification

3.3. Time-Varying Law of the Modulus of Elasticity Based on Initial Age

3.4. Analytical Framework

3.5. Analysis and Discussion

4. Conclusions and Recommendations

- (1)

- Based on the spatiotemporal equivalence assumption (R2 ≥ 0.95) and material homogeneity assumption (thermal conductivity variation ≤5%), studies demonstrate that the hydration heat release peak of core concrete in steel tubes occurs at approximately 20 h in a 0 °C constant-temperature environment but advances to 17 h under 26 °C ambient conditions. Validation via the exponential sensor placement method confirms near-complete hydration heat dissipation within 100 h, with surface sensor displacement causing peak time prediction errors of ±1.2 h.

- (2)

- The proposed hydration heat source function, validated through tests on two CFST members, achieves a reduction in the accuracy error from 8.3% to 3.7% by adopting an intensive 15 min sampling strategy during the acceleration phase. It exhibits strong applicability for thermo-mechanical coupling analysis in CFST arch rib pouring stages, with the correlation coefficient for asymmetric heat source distribution improving to 0.91.

- (3)

- Considering the quasi-steady boundary assumption (neglecting formwork thermal resistance variations within 24 h), the time-varying hydration heat and elastic modulus during concrete pouring induce irreversible residual deflection in the arch ribs. Calculations reveal 18 mm of the total 154 mm residual deflection directly originates from hydration heat effects, while transverse displacements remain low and recoverable due to spatial resolution limitations of the sensors (gradient capture error <1.5 °C/m).

- (4)

- By establishing a hydration heat equivalent loading method incorporating 3D contact thermal resistance correction terms and integrating a time-varying elastic modulus model, this study develops an analytical framework for CFST arch bridges during pouring. Compared to conventional methods, the computational accuracy improves by 44.19%, with the solar radiation azimuth correction factor (0.6–1.4) effectively supporting construction control for bridges exceeding 200 m spans.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tao, Z.; Hasan, M.M.; Han, D.; Qin, Q.; Abdul Ghafar, W. Study of the Axial Compressive Behaviour of Cross-Shaped CFST and ST Columns with Inner Changes. Buildings 2023, 13, 423. [Google Scholar] [CrossRef]

- Yang, J.; Huang, L.; Tong, K.; Tang, Q.; Li, H.; Cai, H.; Xin, J. A Review on Damage Monitoring and Identification Methods for Arch Bridges. Buildings 2023, 13, 1975. [Google Scholar] [CrossRef]

- Han, D.; Tao, Z.; Abdul Ghafar, W.; Hasan, M.M.; Xiao, W.; Wang, T.; Zhou, K.; Dai, H. Experimental Study on the Seismic Performance of L-Shaped CFST Columns in Different Combinations. Buildings 2023, 13, 2320. [Google Scholar] [CrossRef]

- Zheng, J.L.; Du, H.L.; Mu, T.M.; Liu, J.P.; Qin, D.Y.; Mei, G.X.; Tu, B. Innovations in design, construction, and management of pingnan third bridge-the largest-span arch bridge in the world. Struct. Eng. Int. 2022, 32, 134–141. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Zhou, J.T.; Huang, Z.H.; Zhang, X.S.; Xiang, Z.F. Calculation and control method for arch formation of 500m-level steel tube arch bridge. China J. Highway Transp. 2022, 35, 60–72. (In Chinese) [Google Scholar]

- Li, Y.; Li, Y.; Li, J. Optimization calculation method of cable force in the whole process of long-span CFST arch bridge constructed by cable-stayed fastening method. Prog. Build. Steel Struct. 2019, 21, 33–39. (In Chinese) [Google Scholar]

- Zhou, J.T.; Liu, J.; Zhou, W.; Yan, R.Z.; Yan, T. Analysis of the influence of temperature variation on ore-lift value of cable-stayed fastening and main arch ring alignment of CFST arch bridge. J. China Foreign Highw. 2017, 37, 62–66. (In Chinese) [Google Scholar]

- Zhou, Q.; Zhou, J.T.; Zhang, J.C.; Zhang, L. Self-adjusting load pouring method for concrete in long-span CFST arch bridge. J. Harbin Inst. Technol. 2020, 52, 82–89. (In Chinese) [Google Scholar]

- Xie, K.Z.; Wang, H.W.; Guo, X.; Zhou, J.X. Study on the safety of the concrete pouring process for the main truss arch structure in a long-span concrete-filled steel tube arch bridge. Mech. Adv. Mat. Struct. 2021, 28, 731–740. [Google Scholar] [CrossRef]

- Zheng, J.L.; Wang, J.J.; Feng, Z.; Han, Y.; Qin, D.Y. Experiment on vacuum-assisted pouring process of concrete-filled steel tube arch segment. China J. Highw. Transp. 2014, 27, 44–50. (In Chinese) [Google Scholar]

- Han, Y. Experiment and Practical Application of Vacuum-Assisted Concrete Pouring in Steel Tube Arch Bridge. Bridge Constr. 2015, 45, 19–25. (In Chinese) [Google Scholar]

- Zhou, D.W.; Deng, N.C.; Shi, T. Experimental and numerical simulation analysis of large hydration temperature field in CFST arch bridge. J. Guangxi Univ. 2021, 46, 51–59. (In Chinese) [Google Scholar]

- Sun, J.Y.; Xie, J.B. Simulation analysis of the hydration heat of large diameter CFST arch and its effects on loading age. Appl. Therm. Eng. 2019, 150, 482–491. [Google Scholar] [CrossRef]

- Shi, T.; Zheng, J.L.; Deng, N.C.; Chen, Z.; Guo, X.; Wang, S. Temperature load parameters and thermal effects of a long-span concrete-filled steel tube arch bridge in tibet. Adv. Mater. Sci. Eng. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Sun, J.Y.; Xie, J.B.; Zhang, Z.S. Simulation analysis of thermal stress of CFST arch bridge during exothermic hydration process. In Computational and Experimental Simulations in Engineering: Proceedings of ICCES2019; Okada, H., Atluri, S.N., Eds.; Springer International Publishing: New York, NY, USA; Nature Switzerland AG: Cham, Switzerland, 2020; pp. 1015–1021. [Google Scholar]

- Du, Q. Parametric analysis of hydration heat effect on concrete-filled steel tube arch rib. Eng. Constr. 2021, 53, 7–11. (In Chinese) [Google Scholar]

- Wen, H.Q. Research on the Influence of Hydration Heat of Concrete in Long-Span CFST Arch Bridge. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2021. (In Chinese). [Google Scholar]

- Xin, J.; Tang, Q.; Zhou, J.; Zhou, Y.; Luo, C.; Jiang, Y. A novel method for calculating the ultimate bearing capacity of in-service RC arch bridges using sectional constitutive relation. Appl. Math. Model. 2025, 138, 115829. [Google Scholar] [CrossRef]

- Li, Z. Analysis of hydration heat temperature field in CFST arch rib of Xixi river super large bridge. Railw. Eng. 2016, 36–38. (In Chinese) [Google Scholar]

- Shi, T.; Deng, N.; Guo, X.; Xu, W. Experimental Study on Deformation Behavior and Compressive Strength of Concrete Cast in Steel Tube Arches under Low-Temperature Conditions. Adv. Mater. Sci. Eng. 2020, 1, 8016282. [Google Scholar] [CrossRef]

- Chen, B.C.; Liu, Z.Y. Review on temperature issues of concrete-filled steel tube arch bridges. J. Fuzhou Univ. 2009, 37, 412–418. (In Chinese) [Google Scholar]

- Jing, X. Study on Hydration Heat and Pouring Scheme of Concrete in Concrete-Filled Steel Tube Arch. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2012. (In Chinese). [Google Scholar]

- Zhou, D.W.; Deng, N.C.; Guo, X. Experimental study on hydration thermal stress of concrete-filled steel tube under low-temperature pouring conditions. J. Railw. Sci. Eng. 2020, 17, 2807–2815. (In Chinese) [Google Scholar]

- Cai, Z. Properties of Concrete; China Architecture & Building Press: Beijing, China, 1979; pp. 94–101. (In Chinese) [Google Scholar]

- Qin, C.; Gong, J.W.; Xie, G.C.; Jiang, C.M.; Luan, S.Y. Study on hydration heat calculation of portland cement-based cementitious material system. Water Power 2021, 47, 56–62. (In Chinese) [Google Scholar]

- Wang, Y.B. Analysis of Temperature Field and Thermal Effects in Long-Span CFST Arch Bridge. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2013. (In Chinese). [Google Scholar]

- Zhang, F. Study on Pouring Sequence of Long-Span CFST arch Rib and Hydration Heat of Concrete in Tube. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2020. [Google Scholar]

- Yang, Y.; Zhang, R.L.; Qi, Q.; Yang, H.P. Experimental study on temperature field distribution of large-diameter circular concrete-filled steel tube section. Build. Struct. 2020, 50, 99–103. (In Chinese) [Google Scholar]

- Han, Y.; Yang, Z.F.; Qin, D.Y.; Zheng, J. Key construction technologies and innovations of Matan Hongshui river super large bridge. Highway 2019, 64, 125–129. (In Chinese) [Google Scholar]

- Zheng, J.L. Innovative Technologies for Construction of 500-Meter-Level Concrete-Filled Steel Tube Arch Bridges; Shanghai Scientific & Technical Publishers: Shanghai, China, 2019. (In Chinese) [Google Scholar]

- Zhang, W.F. Key installation technologies of Qianwei Minjiang CFST arch bridge. Highway 2021, 66, 142–146. (In Chinese) [Google Scholar]

- Xie, G.Y.; Liu, J.; Yuan, C.C.; Shao, H.Y. Key construction technologies of Zhijing river CFST arch bridge. Bridge Constr. 2009, 57–59, 73. (In Chinese) [Google Scholar]

- Dong, X.Q.; Zhang, F.; Xu, X.F.; Liu, J.Q. Fatigue damage assessment of short hangers in tied-arch bridge. Highway 2018, 63, 74–78. (In Chinese) [Google Scholar]

- Han, Y. Research on Key Calculation Theory and Control for Construction of Super-Long-Span CFST Arch Bridge. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2019. (In Chinese). [Google Scholar]

- Wang, H.W.; Xie, K.Z.; Guo, X.; Zhou, J.X. Stability study on concrete pouring process of arch Rib in long-span CFST arch bridge. World Bridges 2019, 47, 49–53. (In Chinese) [Google Scholar]

| Model | RMSE (°C) | R2 | Parameter Count | Physical Interpretability |

|---|---|---|---|---|

| Exponential [19] | 4.2 | 0.87 | 2 | Low (no peak capture) |

| Hyperbolic [20] | 3.8 | 0.89 | 3 | Moderate |

| Composite Exponential (Proposed) | 1.7 | 0.96 | 4 | High (explicit τ, β) |

| Cement Type | Kernel Type | Kernel Expression |

|---|---|---|

| Grade 42.5 Ordinary Portland Cement | 0.69 | 0.56 |

| Grade 52.5 Ordinary Portland Cement | 0.36 | 0.74 |

| Grade 52.5 Ordinary Portland Cement for Dams | 0.79 | 0.70 |

| Grade 42.5 Portland Slag Cement for Dams | 0.29 | 0.76 |

| Parameter | Reference [25] | Reference [26] | Reference [27] | Reference [28] | Reference [29] |

|---|---|---|---|---|---|

| C | 400 | 360 | 430 | 400 | 480 |

| Fa | 50 | 82 | 70 | 45 | 80 |

| C+Fa | 450 | 442 | 500 | 445 | 560 |

| Fa% | 11.1% | 18.6% | 14.0% | 10.1% | 14.3% |

| C | 392 | 387 | 440 | 465 | 433 |

| Fa | 53 | 90 | 75 | 58 | 42 |

| C+Fa | 445 | 477 | 515 | 523 | 475 |

| Fa% | 11.9% | 18.9% | 14.6% | 11.1% | 8.8% |

| Materials | Cement | Water | Fly Ash | Expansion Agent | Mineral Powder/Microbeads | Silicon Powder | Sand | Stone | Water Reducing Agent |

|---|---|---|---|---|---|---|---|---|---|

| Specimen 1 | 400 | 157 | 45 | 50 | 25 | 10 | 711 | 1052 | 10.6 |

| Specimen 2 | 413 | 144 | 48 | 60 | 42 | 36 | 759 | 1048 | 14.4 |

| Parameter | Variation | Stress Error | Deflection Error |

|---|---|---|---|

| Steel Yield Strength | ±10% | 6.7% | 4.2% |

| Concrete Poisson’s Ratio | ±15% | 3.9% | 2.8% |

| Thermal Conductivity | ±20% | 11.4% | 8.6% |

| Type Age/d | Modulus of Elasticity/GPa |

|---|---|

| 3 | 32.3 |

| 5 | 36.9 |

| 7 | 39.1 |

| 14 | 42.6 |

| 28 | 46.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.; Yao, X.; Xie, K.; Hao, T.; Wang, X. Analysis Method for the Pouring Stage of Concrete-Filled Steel Tube (CFST) Arch Bridges Considering Time-Varying Heat of Hydration and Elastic Modulus. Buildings 2025, 15, 1711. https://doi.org/10.3390/buildings15101711

Yu M, Yao X, Xie K, Hao T, Wang X. Analysis Method for the Pouring Stage of Concrete-Filled Steel Tube (CFST) Arch Bridges Considering Time-Varying Heat of Hydration and Elastic Modulus. Buildings. 2025; 15(10):1711. https://doi.org/10.3390/buildings15101711

Chicago/Turabian StyleYu, Mengsheng, Xinyu Yao, Kaizhong Xie, Tianzhi Hao, and Xirui Wang. 2025. "Analysis Method for the Pouring Stage of Concrete-Filled Steel Tube (CFST) Arch Bridges Considering Time-Varying Heat of Hydration and Elastic Modulus" Buildings 15, no. 10: 1711. https://doi.org/10.3390/buildings15101711

APA StyleYu, M., Yao, X., Xie, K., Hao, T., & Wang, X. (2025). Analysis Method for the Pouring Stage of Concrete-Filled Steel Tube (CFST) Arch Bridges Considering Time-Varying Heat of Hydration and Elastic Modulus. Buildings, 15(10), 1711. https://doi.org/10.3390/buildings15101711