From Fragmentation to Collective Action: A System Dynamics–Based Approach to Addressing Stakeholder Engagement in the Building Sector’s Circular Economy Transition †

Abstract

1. Introduction

2. State of the Art

Complex System Science Simulation Methodological Tools

3. Methodology

4. Results and Discussion

4.1. Problem Identification

- Owners and users/consumers were primarily concerned with well-being and comfort, and economic feasibility.

- Project managers, designers, architects, and engineers shared a focus on the creative and effective application of technologies, as well as cost efficiency.

- Facility managers were concerned with the creative and effective application of technologies, cost efficiency, and economic feasibility.

- Contractors, subcontractors, construction companies, suppliers, and manufacturers highlighted concerns about natural resource supply, economic feasibility, cost efficiency, and workforce.

- Real estate agencies prioritised economic feasibility.

- Demolition and deconstruction companies, and waste treatment companies focused on economic feasibility, cost efficiency, and workforce.

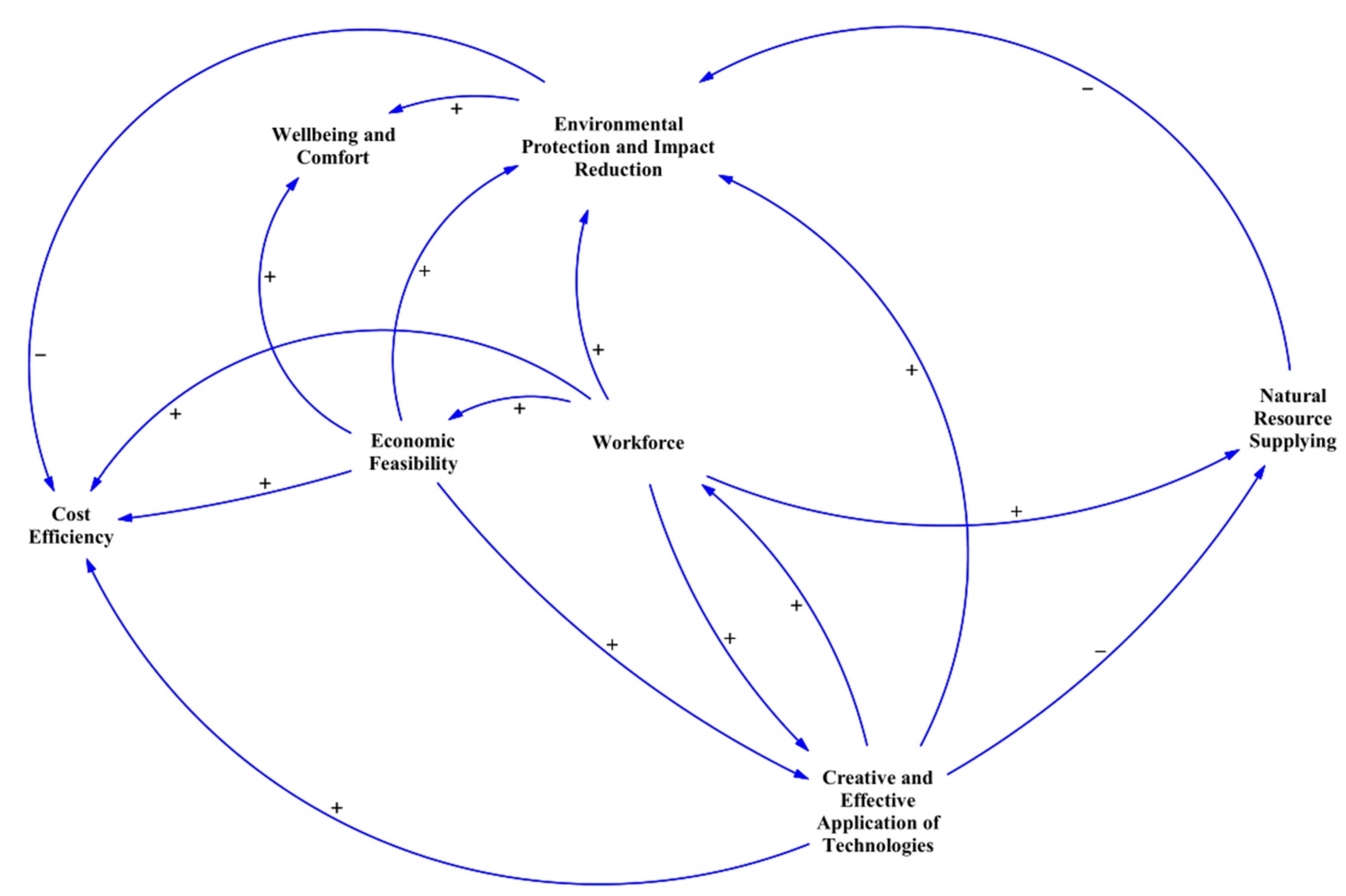

- Social issues included well-being and comfort, referring to stakeholders’ emotional, physical, and psychological state.

- Organisational issues were represented by the workforce, referring to all project professionals directly participating in the building life cycle, including contractors, subcontractors, architects, engineers, project managers, demolition and deconstruction companies, and waste treatment companies.

- Economic issues encompassed economic feasibility, defined as the degree to which benefits outweigh costs and cost efficiency, related to optimising financial performance through improved processes.

- Technical and technological issues included creative and effective application of technologies, referring to the innovative use of technological solutions and natural resource supplying concerning the provision of energy, water, raw materials, and minerals.

- Environmental issues were represented by environmental protection and impact reduction, defined as actions aimed at safeguarding the environment and minimising negative ecological impacts.

4.2. System Conceptualisation

4.2.1. Causal Loop Diagram Construction

4.2.2. Feedback Loop Identification

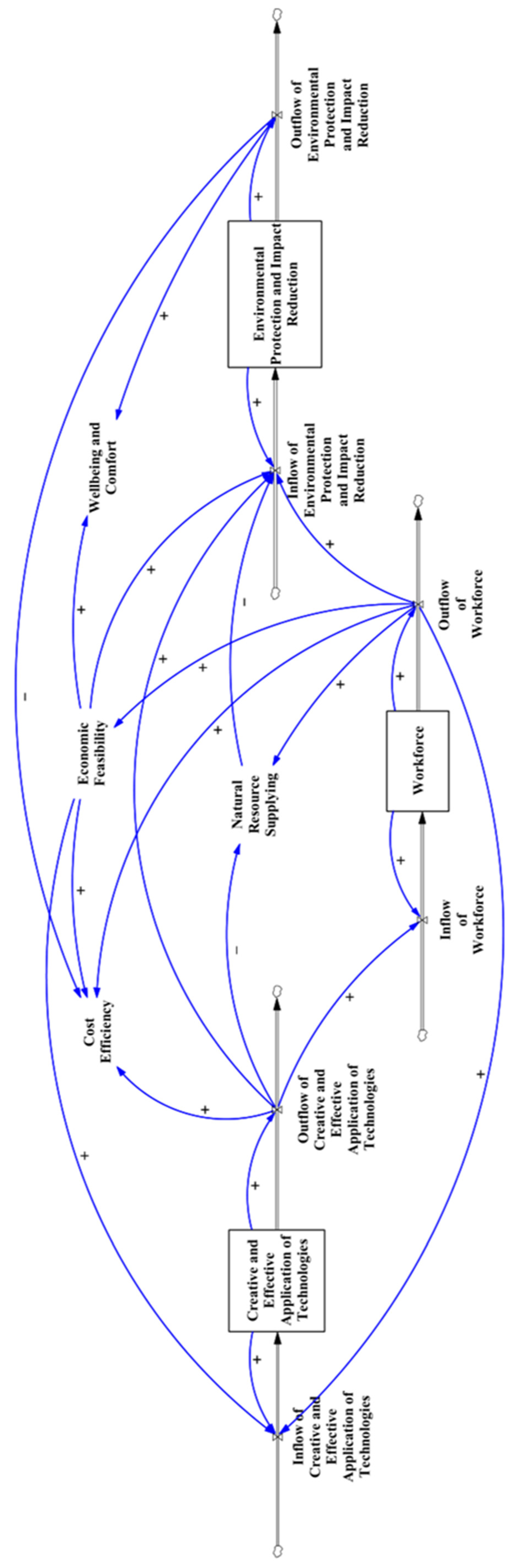

4.2.3. Stock-Flow Diagram Construction

4.2.4. System Dynamics Model Construction

4.3. Model Optimisation

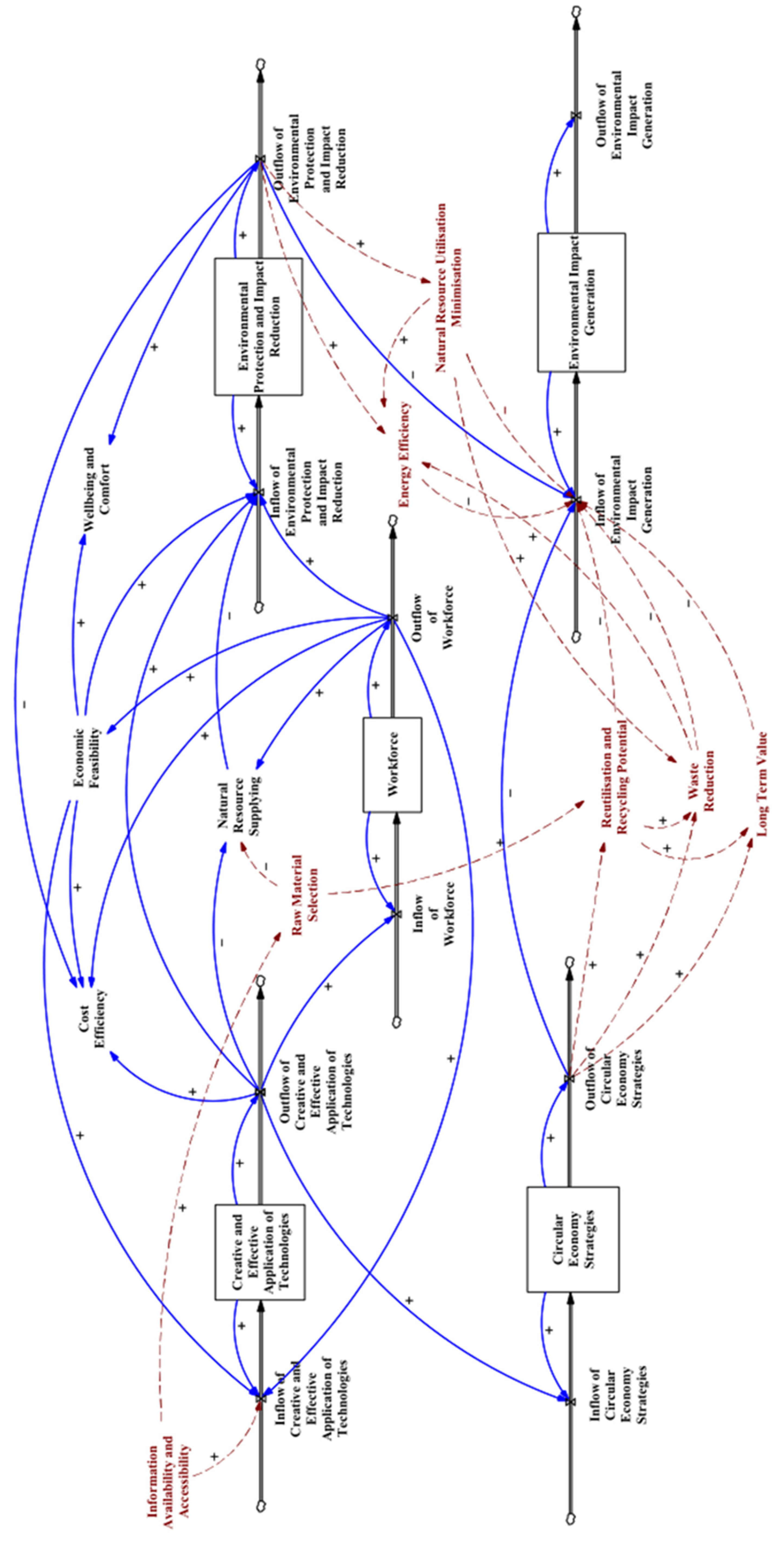

4.3.1. Real Circular Building Scenario Model Construction

- The Green House (The Netherlands);

- The Venlo City Hall (The Netherlands);

- Biological House (Denmark);

- Temporary District Court (The Netherlands);

- The Upcycle House (Denmark);

- The Green Solution House (Denmark);

- The Enterprise Center (UK);

- Rathaus Korbach (Germany);

- The Brummen Town Hall (The Netherlands);

- The Liander Head Office (The Netherlands);

- The Resource Rows (Denmark).

- “Natural Resource Utilisation Minimisation” referred to minimising natural resource utilisation.

- “Raw Material Selection” was attributed to carefully selecting raw materials while considering them as low-impactful as possible to the environment.

- “Energy Efficiency” considered the less energy consumption to perform the same task.

- “Information Availability and Accessibility” meant the easy accessibility and free availability of information through stakeholder collaboration and digital technology utilisation.

- “Waste Reduction” referred to reducing waste production.

- “Reutilisation and Recycling Potential” focused on ensuring the building itself, with its materials and components, a second life through the circular economy principles and strategies such as reuse, recycling, and recovery.

- “Long-term Value” referred to capturing the asset’s long-term value, which can be the functional lifetime, aesthetic, well-being and comfort value, thanks to the circular economy principles and strategies.

4.3.2. Optimised System Dynamics Model Construction

4.4. Discussion

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karmakar, S.; Strezov, V. Impact of Climate Change on Biodiversity and Human Well-Being: A Review. Discov. Sustain. 2022, 3, 73. [Google Scholar] [CrossRef]

- UNFCCC. The Paris Agreement; United Nations Framework Convention on Climate Change: Bonn, Germany, 2015; Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 8 April 2025).

- IPCC. Climate Change 2022: Mitigation of Climate Change; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- International Energy Agency (IEA). Buildings—Energy System. 2022. Available online: https://www.iea.org/energy-system/buildings (accessed on 8 April 2025).

- United Nations Environment Programme (UNEP). 2022 Global Status Report for Buildings and Construction; UNEP: Nairobi, Kenya, 2022; Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 8 April 2025).

- Kaya, F.E.; Scolaro, A.M. Circularity as a Climate Change Mitigation Strategy in the Building Sector: The Stakeholder’s Involvement in the Interconnected Life Cycle Phases. Sustainability 2023, 15, 7554. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change; Ellen MacArthur Foundation: Cowes, UK, 2021; Available online: https://www.ellenmacarthurfoundation.org/completing-the-picture (accessed on 8 April 2025).

- Ellen MacArthur Foundation. Towards the Circular Economy Vol.1: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 8 April 2025).

- Ellen MacArthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015; Available online: https://www.ellenmacarthurfoundation.org/growth-within-a-circular-economy-vision-for-a-competitive-europe (accessed on 8 April 2025).

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Valenzuela, F.; Böhm, S. Against Wasted Politics: A Critique of the Circular Economy. Ephemera 2017, 17, 23–60. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2020, 143, 757–768. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). 2023 Global Status Report for Buildings and Construction; UNEP: Nairobi, Kenya, 2023; Available online: https://www.unep.org/resources/report/global-status-report-buildings-and-construction (accessed on 8 April 2025).

- World Green Building Council (WorldGBC). Circularity Accelerator Playbook: 2023 Edition; WorldGBC: London, UK, 2023; Available online: https://worldgbc.org/wp-content/uploads/2023/05/Circularity-Accelerator-Playbook_2023.pdf (accessed on 8 April 2025).

- European Commission. Circular Economy Action Plan: For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020; Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 8 April 2025).

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building Design and Construction Strategies for a Circular Economy. Archit. Eng. Des. Manag. 2020, 16, 182–195. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Ajayi, A.O. Building Design for Deconstruction: Practice, Needs and Barriers in the UK. Resour. Conserv. Recycl. 2021, 178, 106077. [Google Scholar] [CrossRef]

- Haupt, M.; Hellweg, S. Measuring the Environmental Sustainability of a Circular Economy. Curr. Opin. Environ. Sustain. 2021, 3, 7–16. [Google Scholar] [CrossRef]

- Akanbi, M.O.; Oyedele, L.O.; Ajayi, A.O. Drivers and Barriers to Circular Economy Implementation in the Construction Industry: A Systematic Review. J. Clean. Prod. 2023, 419, 138079. [Google Scholar] [CrossRef]

- Salvioni, D.M.; Almici, A. Transitioning toward a Circular Economy: The Impact of Stakeholder Engagement on Sustainability Culture. Sustainability 2020, 12, 8641. [Google Scholar] [CrossRef]

- Durmisevic, E. Circular Economy in Construction: Design Strategies for Reversible Buildings. Buildings as Material Banks. 2019. Available online: https://www.bamb2020.eu/wp-content/uploads/2019/05/Reversible-Building-Design-Strateges.pdf (accessed on 8 April 2025).

- Kaya, F.E. A Stakeholder-Centric Approach to Advancing building sector’s circular economy transition. Architecture 2025, 5, 6. [Google Scholar] [CrossRef]

- Kaya, F.E.; Scolaro, A.M. Unravelling Complexity Toward Circularity: A System-Dynamics Based Approach. IOP Conf. Ser. Earth Environ. Sci. 2024, 1402, 012022. [Google Scholar] [CrossRef]

- Guzzo, D.; Pigosso, D.C.A.; Videira, N.; Mascarenhas, J. A System Dynamics-Based Framework for Examining Circular Economy Transitions. J. Clean. Prod. 2022, 333, 129933. [Google Scholar] [CrossRef]

- Sterman, J.D. System Dynamics Modeling: Tools for Learning in a Complex World. IEEE Eng. Manag. Rev. 2002, 30, 42. [Google Scholar] [CrossRef]

- Rebs, T.; Brandenburg, M.; Seuring, S. System Dynamics Modeling for Sustainable Supply Chain Management: A Literature Review and Systems Thinking Approach. J. Clean. Prod. 2019, 208, 1265–1280. [Google Scholar] [CrossRef]

- Mashaly, I.; Fernald, J. System Dynamics Modeling as a Decision Support Tool for Simulating Complex Dynamic Systems. Water Resour. Manag. 2020, 34, 1803–1822. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Richardson, G.P. Feedback Thought in Social Science and Systems Theory; University of Pennsylvania Press: Philadelphia, PA, USA, 1991. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012; Available online: https://ellenmacarthurfoundation.org (accessed on 8 April 2025).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualising the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geisendorf, S.; Pietrulla, F. The Circular Economy and Circular Economic Concepts—A Literature Analysis and Redefinition. Thunderbird Int. Bus. Rev. 2018, 60, 771–782. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.N.; Purnell, P. A Systems Thinking Approach to Understanding the Challenges of Achieving the Circular Economy. Environ. Sci. Pollut. Res. 2020, 28, 24785–24806. [Google Scholar] [CrossRef]

- Velte, C.J.; Steinhilper, R. Complexity in a Circular Economy: A Need for Rethinking Complexity Management Strategies. Proc. World Congr. Eng. 2016, 2224, 763–768. [Google Scholar]

- Hopkinson, P.; Zils, M.; Hawkins, P.; Roper, S. Managing a Complex Global Circular Economy Business Model: Opportunities and Challenges. Calif. Manag. Rev. 2018, 60, 71–94. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business Model Innovation for Circular Economy and Sustainability: A Review of Approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Walzberg, J.; Lonca, G.; Hanes, R.J.; Eberle, A.L.; Carpenter, A.; Heath, G.A. Do We Need a New Sustainability Assessment Method for the Circular Economy? A Critical Literature Review. Front. Sustain. 2021, 1, 620047. [Google Scholar] [CrossRef]

- Yazan, D.M.; van Capelleveen, G.; Fraccascia, L. Decision-Support Tools for Smart Transition to Circular Economy. Adv. Ser. Manag. 2022, 28, 151–169. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How Do Scholars Approach the Circular Economy? A Systematic Literature Review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Walzberg, J.; Dandres, T.; Merveille, N.; Cheriet, M.; Samson, R. Should We Fear the Rebound Effect in Smart Homes? Renew. Sustain. Energy Rev. 2020, 125, 109798. [Google Scholar] [CrossRef]

- Franco, S. System Dynamics-Based Simulations to Investigate Firm-Level Effects of the Combination of the Circular Economy Strategies. J. Clean. Prod. 2019, 216, 1012–1026. [Google Scholar]

- Elsawah, S.; Danesh, D.; Ryan, M.A. Strategic Asset Planning Decision Analysis: An Integrated System Dynamics and Multi-Criteria Decision-Making Method. In Proceedings of the INCOSE International Symposium, Orlando, FL, USA, 20–25 July 2019; pp. 788–802. [Google Scholar]

- Sapiri, H.; Huisingh, D.; Reuter, M.A.; Medarac, H. Material Flow Analysis Coupled with System Dynamics for Urban Metabolism and Circular Economy Strategies for Urban Transitions: A Case Study on Phosphorus Flows in the Amsterdam Metropolitan Area. J. Clean. Prod. 2017, 163, S72–S84. [Google Scholar]

- Sapiri, H.; Maas, G.J.; Hogland, W.; Krook, J.; Eklund, M. Applying System Dynamics for Waste Management Research: A Literature Review. Waste Manag. 2014, 34, 2460–2473. [Google Scholar]

- Lieder, M.; Rashid, A.; Rizos, V. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2017, 156, 928–942. [Google Scholar] [CrossRef]

- Gloser-Chahoud, S.; Kleinhans, R.; Teubler, J. Investigating the Effects of Product Lifetimes and Hibernation in European Consumer Electronics Demand. J. Clean. Prod. 2019, 225, 692–701. [Google Scholar]

- Pinto, R.; Diemer, A. Exploring the Effects of Supply Chain Integration Strategies in the European Steel Industry: An Application of System Dynamics Modelling. J. Clean. Prod. 2020, 266, 121780. [Google Scholar]

- Ghufran, M.; Khan, K.I.; Ullah, F.; Nasir, A.R.; Al Alahmadi, A.A.; Alzaed, A.N.; Alwetaishi, M. Circular Economy in the Construction Industry: A Step towards Sustainable Development. Buildings 2022, 12, 1004. [Google Scholar] [CrossRef]

- Kusumowibowo, T.S.; Wahyu Adi, T.J. Circular Economy Model of Indonesian Construction Industry Waste Based on System Dynamics. In Advances in Engineering Research, Proceedings of the Third International Conference on Sustainable Innovation 2019—Technology and Engineering (IcoSITE 2019), Yogyakarta, Indonesia, 30–31 July 2019; Atlantis Press: Dordrecht, The Netherlands, 2019; Volume 187. [Google Scholar]

- Ding, Z.; Yi, G.; Tam, V.W.Y.; Huang, T. A System Dynamics Based Environmental Performance Simulation of Construction Waste Reduction Management in China. Waste Manag. 2016, 51, 130–141. [Google Scholar] [CrossRef]

- Homer, J.B.; Hirsch, G.B. System Dynamics Modeling for Public Health: Background and Opportunities. Am. J. Public Health 2006, 96, 452–458. [Google Scholar] [CrossRef]

- Arup. Circular Buildings Toolkit; Arup: London, UK, 2025; Available online: https://www.arup.com/services/climate-and-sustainability-services/circular-economy-services/circular-buildings-toolkit (accessed on 8 April 2025).

- Dutch Green Building Council; Metabolic; SGS Research; Redevco Foundation. A Framework for Circular Buildings—Indicators for Possible Inclusion in BREEAM. 2018. Available online: https://assets.website-files.com/5d26d80e8836af2d12ed1269/5dea6b3713854714c4a8b755_A-Framework-For-Circular-Buildings-BREEAM-report-20181007-1.pdf (accessed on 8 April 2025).

- De Graaf, D.; Schuitemaker, S. Circular Buildings: Constructing a Sustainable Future; Holland Circular Hotspot: Rotterdam, The Netherlands, 2022; Available online: https://hollandcircularhotspot.nl/news/new-publication-circular-buildings-constructing-a-sustainable-future/ (accessed on 8 April 2025).

- World Business Council for Sustainable Development (WBCSD). Measuring Circular Buildings—Key Considerations. 2022. Available online: https://www.wbcsd.org/wp-content/uploads/2023/10/Measuring-circular-buildings_key-considerations.pdf (accessed on 8 April 2025).

- Lotz, M.T.; Herbst, A. Circular Buildings: Paving the Way to a Net-Zero Industry—Policy Brief. 2023. Available online: https://ieecp.org/publications/circular-buildings-paving-the-way-to-a-net-zero-industry/ (accessed on 8 April 2025).

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strateg. Environ. 2015, 26, 182–196. [Google Scholar] [CrossRef]

- Leuhery, F. The Role of Technology in Employee Training and Development: A Systematic Review of Recent Advances and Future Directions. Manag. Stud. Bus. J. (Product.) 2024, 1, 369–385. [Google Scholar] [CrossRef]

- Nicholas, K.; Deus, T. Technology Adoption and Its Impact on Organisational Productivity: A Case Study of Metropolitan International University. Metrop. J. Bus. Econ. 2024, 3, 515–521. [Google Scholar]

- Cirera, X.; Comin, D.; Cruz, M. Bridging the Technological Divide: Technology Adoption by Firms in Developing Countries; The World Bank: Washington, DC, USA, 2022; Available online: https://openknowledge.worldbank.org/handle/10986/37527 (accessed on 8 April 2025).

- Senaratne, S.; KC, A.; Perera, S.; Almeida, L. Promoting Stakeholder Collaboration in Adopting Circular Economy Principles for Sustainable Construction. In Proceedings of the 9th World Construction Symposium, Virtual, 9–10 July 2021; pp. 473–481. [Google Scholar]

- World Business Council for Sustainable Development. The Business Case for Circular Buildings: Exploring the Economic, Environmental, and Social Value. Available online: https://www.wbcsd.org/wp-content/uploads/2023/10/The-business-case-for-circular-buildings-Exploring-the-economic-environmental-and-social-value-.pdf (accessed on 8 April 2025).

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring Environmental and Economic Costs and Benefits of a Circular Economy Approach to the Construction and Demolition Sector: A Literature Review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Alwaer, H.; Clements-Croome, D.J. Key Performance Indicators (KPIs) and Priority Setting in Using the Multi-Attribute Approach for Assessing Sustainable Intelligent Buildings. Build. Environ. 2010, 45, 799–807. [Google Scholar] [CrossRef]

- Deloitte. Building the Engineering and Construction Workforce. Available online: https://www2.deloitte.com/us/en/insights/industry/engineering-and-construction/ec-workforce-development-strategy.html (accessed on 8 April 2025).

- Siriwardhana, M.; Siriwardhana, P.; Karunasena, G. Enabling Productivity Goals through Construction 4.0 Skills: Theories, Debates, Definitions. J. Clean. Prod. 2023, 425, 139011. [Google Scholar] [CrossRef]

- Baniya, B. Circularity in Facility Management: Conceptualisation and Potential Areas for Circularity-Oriented Actions. Sustainability 2023, 15, 8460. [Google Scholar] [CrossRef]

- International Facility Management Association (IFMA). Integrating Circular Economy in Facility Management for Sustainability. Available online: https://blog.ifma.org/integrating-circular-economy-in-facility-management-for-sustainability (accessed on 8 April 2025).

- Arup. From Principles to Practices: Realising the Value of Circular Economy in Real Estate; Arup Group: London, UK, 2023; Available online: https://www.arup.com/globalassets/downloads/insights/from-principles-to-practices-realising-the-value-of-circular-economy-in-real-estate.pdf (accessed on 8 April 2025).

- Circular Economy Leadership Canada. Advancing Circular Economy in the Real Estate Industry: A Guide for Action; CELC: Ottawa, ON, Canada, 2023; Available online: https://circulareconomyleaders.ca/wp-content/uploads/2024/03/Advancing-Circular-Economy-in-Real-Estate-Industry-Guide-October-2023.pdf (accessed on 8 April 2025).

- Ellen MacArthur Foundation. Supply Chains and the Circular Economy. Available online: https://www.ellenmacarthurfoundation.org/supply-chains/overview (accessed on 8 April 2025).

- Baker Tilly. Redefining Manufacturing through Sustainability and Innovation. Available online: https://www.bakertilly.com/insights/redefining-manufacturing-sustainability-innovation (accessed on 8 April 2025).

- Bassi, F.; Guidolin, M. Resource Efficiency and Circular Economy in European SMEs: Investigating the Role of Green Jobs and Skills. Sustainability 2021, 13, 12136. [Google Scholar] [CrossRef]

- Dräger, P.; Letmathe, P. Who Drives Circularity?—The Role of Construction Company Employees in Achieving High Circular Economy Efficiency. Sustainability 2023, 15, 7110. [Google Scholar] [CrossRef]

- Pero, M.; Moretto, A.; Bottani, E.; Bigliardi, B. Environmental Collaboration for Sustainability in the Construction Industry: An Exploratory Study in Italy. Sustainability 2017, 9, 125. [Google Scholar] [CrossRef]

- World Economic Forum. 4 Promising Digital Technologies for Circular Construction. Available online: https://www.weforum.org/stories/2022/09/4-promising-digital-technologies-for-circular-construction (accessed on 8 April 2025).

- Bellini, A.; Tadayon, A.; Andersen, B.S.; Klungseth, N.J. The Role of Data When Implementing Circular Strategies in the Built Environment: A Literature Review. Clean. Environ. Syst. 2024, 13, 100183. [Google Scholar] [CrossRef]

- McKinsey & Company. Consumers Care About Sustainability—And Back It Up with Their Wallets. Available online: https://www.mckinsey.com/industries/consumer-packaged-goods/our-insights/consumers-care-about-sustainability-and-back-it-up-with-their-wallets (accessed on 8 April 2025).

- Senaratne, S.; Rodrigo, M.N.N.; Almeida, L.A.P.E.; Perera, S.; Jin, X. Systematic Review on Stakeholder Collaboration for a Circular Built Environment: Current Research Trends, Gaps and Future Directions. Resour. Conserv. Recycl. Adv. 2023, 19, 200169. [Google Scholar] [CrossRef]

- European Environment Agency. Building Renovation: Where Circular Economy and Climate Meet. Available online: https://www.eea.europa.eu/publications/building-renovation-where-circular-economy (accessed on 8 April 2025).

- Buyukyazici, D.; Quatraro, F. The Skill Requirements of the Circular Economy. Ecol. Econ. 2025, 232, 108559. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Hon, C.; Teo, M. Artificial Intelligence and Sustainable Development Goals: Systematic Literature Review of the Construction Industry. Sustain. Cities Soc. 2024, 108, 105499. [Google Scholar] [CrossRef]

- Sánchez-García, E.; Martínez-Falcó, J.; Marco-Lajara, B.; Manresa-Marhuenda, E. Revolutionizing the Circular Economy through New Technologies: A New Era of Sustainable Progress. Environ. Technol. Innov. 2024, 33, 103509. [Google Scholar] [CrossRef]

- Schneider Electric. Facility Managers Are the New Sustainability Champions. Available online: https://blog.se.com/buildings/building-management/2024/04/12/facility-managers-are-the-new-sustainability-champions/ (accessed on 8 April 2025).

- Deloitte. Building an Integrated Approach to Real Estate Sustainability. Available online: https://www2.deloitte.com/us/en/insights/industry/financial-services/building-an-integrated-approach-to-sustainable-real-estate.html (accessed on 8 April 2025).

- UNC Institute for the Environment. Sustainability in the Construction and Real Estate Sector. Available online: https://ie.unc.edu/cleantech-story/sustainability-in-the-construction-and-real-estate-sector (accessed on 8 April 2025).

- Forbes Real Estate Council. Achieving a Circular Economy in Real Estate. Forbes, 10 March 2021. Available online: https://www.forbes.com/sites/forbesrealestatecouncil/2021/03/10/achieving-a-circular-economy-in-real-estate (accessed on 8 April 2025).

- Encor Advisors. Supply Chain Sustainability: A Complete Guide. Available online: https://encoradvisors.com/supply-chain-sustainability-a-complete-guide/ (accessed on 8 April 2025).

- GEP. How to Partner with Sustainable Suppliers. Available online: https://www.gep.com/blog/strategy/how-to-partner-with-sustainable-suppliers (accessed on 8 April 2025).

- Ivalua. Creating a Circular Economy: Solutions for a Sustainable Supply Chain. Available online: https://www.ivalua.com/blog/creating-a-circular-economy-solutions-for-a-sustainable-supply-chain/ (accessed on 8 April 2025).

- World Economic Forum. Bridging the Sustainability Skills Gap Across Global Value Chains. Available online: https://www.weforum.org/stories/2024/09/bridge-sustainability-skills-gap-across-global-value-chains (accessed on 8 April 2025).

- European Policy Centre. The Role of Information Transfer in Supporting Circular Economy Transitions. Available online: https://www.epc.eu/content/PDF/2021/DP_the_role_of_information_transfer.pdf (accessed on 8 April 2025).

- Eissa, R.; El-Adaway, I.H. Circular Economy Strategies for Reducing Embodied Carbon in U.S. Commercial Building Stocks: A System Dynamics Modeling Approach. In Computing in Civil Engineering 2023: Resilience, Safety, and Sustainability; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2024; pp. 729–737. [Google Scholar] [CrossRef]

| Tool | Objective | Scale | Strengths | Limitations |

|---|---|---|---|---|

| SD | To explore how system structure shapes the behaviour of complex, evolving systems. | Macro- and Meso-Scale | Captures system-wide feedback loops; Represents market dynamics and social behaviours; Incorporates system parts and the whole; Allows for non-rational decision modelling; Time-dependent (dynamic); Integrates both quantitative and qualitative data; Highlights non-linearities, time delays, and stock accumulations. | May lack detailed representation of processes; Often data-intensive; Results can be hard to generalise; Limited environmental factor consideration; Challenges in capturing heterogeneities within stocks. |

| DES | To analyse the sequence of potentially stochastic events that drive system dynamics. | Micro-Scale | Provides detailed process-level modelling; Effectively captures event randomness; Time-dependent (dynamic); Suitable for analysing process flows and temporal variability. | Data-intensive; Limited to micro-scale; Does not incorporate feedback loops; Less effective for environmental and higher-scale systems. |

| ABM | To explore how interactions among heterogeneous agents influence overall system behaviour. | Micro- and Meso-Scale | Models heterogeneous agents; Captures emergent behaviours and local interactions; Allows for non-rational decision-making; Represents both individual and aggregate behaviours; Includes feedback loops; Time-dependent (dynamic); Avoids assumptions of homogeneity. | Highly data-intensive; Validation is challenging; Difficult to generalise; Model development complexity. |

| OR | To identify the optimal solution for structured decision-making problems. | Micro- and Meso-Scale | Enables optimal decision-making; Suitable for modelling cooperation and conflict scenarios (e.g., game theory); Uses multi-criteria decision-making (MCDM) for trade-offs across multiple criteria. | Computationally demanding; May not yield a solution or may produce infinitely many; Typically static and lacks system dynamics; Complex model development. |

| Stakeholder | General Actions | Phase-Specific Actions |

|---|---|---|

| Owners |

| Design Phase:

|

Construction Phase:

| ||

Use Phase:

| ||

End-of-Life Phase:

| ||

| Users/Consumers |

| Use Phase:

|

| Workforce Members |

| Design Phase:

|

Construction Phase:

| ||

Use Phase:

| ||

End-of-Life Phase:

| ||

| Facility Managers |

| Use Phase:

|

| Real Estate Agencies |

| Use Phase:

|

| Suppliers |

| Production Phase:

|

Construction Phase:

| ||

Use Phase:

| ||

End-of-Life Phase:

| ||

| Manufacturers |

| Production Phase:

|

Construction Phase:

| ||

Use Phase:

| ||

End-of-Life Phase:

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, F.E. From Fragmentation to Collective Action: A System Dynamics–Based Approach to Addressing Stakeholder Engagement in the Building Sector’s Circular Economy Transition. Buildings 2025, 15, 1655. https://doi.org/10.3390/buildings15101655

Kaya FE. From Fragmentation to Collective Action: A System Dynamics–Based Approach to Addressing Stakeholder Engagement in the Building Sector’s Circular Economy Transition. Buildings. 2025; 15(10):1655. https://doi.org/10.3390/buildings15101655

Chicago/Turabian StyleKaya, Fuat Emre. 2025. "From Fragmentation to Collective Action: A System Dynamics–Based Approach to Addressing Stakeholder Engagement in the Building Sector’s Circular Economy Transition" Buildings 15, no. 10: 1655. https://doi.org/10.3390/buildings15101655

APA StyleKaya, F. E. (2025). From Fragmentation to Collective Action: A System Dynamics–Based Approach to Addressing Stakeholder Engagement in the Building Sector’s Circular Economy Transition. Buildings, 15(10), 1655. https://doi.org/10.3390/buildings15101655