1. Introduction

Ultra-high-performance concrete (UHPC) has garnered considerable attention due to its exceptional mechanical properties, including high tensile and compressive strengths and good ductility. This quality comes from including ultrafine granular components, with a maximum diameter of less than 2 mm, along with fibers in its composition. This provides superior performance compared to conventional concrete available on the market [

1]. Its high resistance capacity makes it especially useful in large-scale projects, the production of precast elements, and the recovery of structures, as it is widely used as a material for structural repairs.

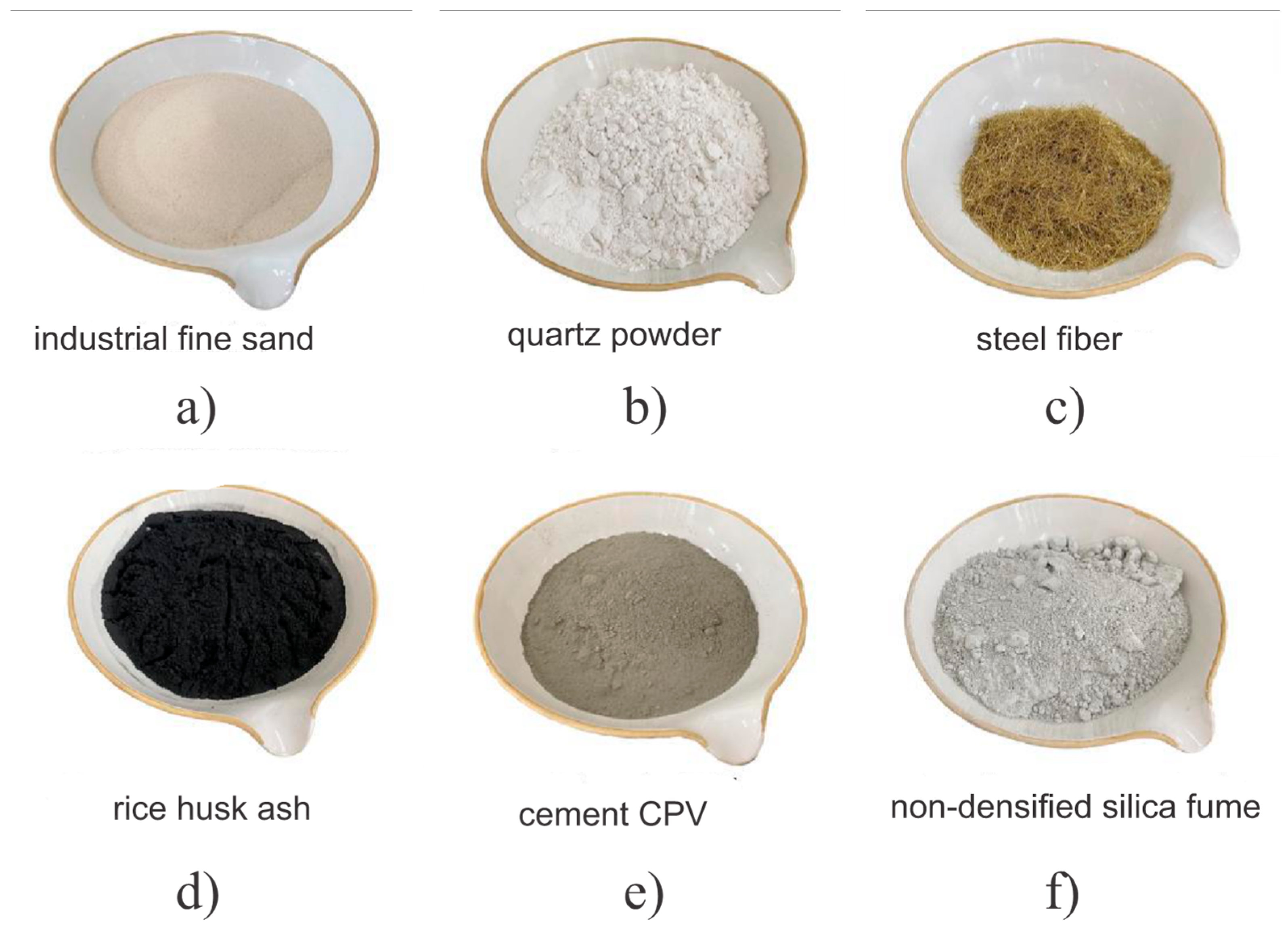

The typical UHPC mix comprises the following materials: cement, non-densified silica fume, quartz powder, fine sand, superplasticizer, water, and fibers, which can be made from various materials, including steel, polypropylene, or glass. However, it is essential to conduct experimental studies to evaluate how local materials affect the mechanical properties of UHPC, including their granulometry and mineralogical composition [

1]. The use of fine aggregates, such as quartz sand or fine sand, reduces weaknesses in the interfacial transition zone (ITZ) between the cementitious matrix and the aggregates while also enabling a more uniform stress distribution. Silica fume, with finer particles and a spherical shape, improves the performance of UHPC by filling the voids between larger particles [

2]. Additionally, the production of UHPC utilizes a low water-to-cement (w/c) ratio, which typically ranges from 0.15 to 0.25 [

3,

4]. This characteristic is essential for achieving high material density; however, it negatively impacts the mix’s workability and homogenization. The fluidity of the mix can be enhanced by incorporating superplasticizer additives, which help to reduce the water-to-binder ratio [

1,

5]. This careful adjustment is aimed at optimizing the mechanical properties of the concrete [

6].

The proper combination of materials in UHPC contributes to a significant increase in compressive strength. However, this behavior results in a lack of deformation capacity, making the material more fragile and compromising its lifespan. To mitigate this limitation, it is essential to incorporate fibers of various materials and dimensions to control microcracks and prevent brittle failures [

7,

8]. Among the options, steel fiber is the most commonly used in the mixture, as it can improve the ductility properties of UHPC [

9,

10]. To reduce production costs, research has explored alternative fibers, such as polypropylene [

11] and glass [

12], which have also demonstrated satisfactory mechanical properties in the material.

UHPC has specific characteristics, such as low permeability and porosity, fewer associated materials, and reduced installation and labor costs [

2,

9,

13]. Additionally, it can be a more sustainable option compared to conventional concrete due to its greater durability, which enables reduced maintenance [

14,

15,

16]. According to this definition, concrete must achieve a minimum compressive strength of 150 MPa to be considered UHPC. However, other standards, such as ASTM C1856 [

17], establish a lower limit of 120 MPa to categorize some concrete as ultra-high performance [

18]. The Canadian Standard Association [

19] specifies that the minimum design characteristic compressive strength for UHPC is 120 MPa, and the minimum design characteristic tensile strength is 5 MPa. Several studies on UHPC corroborate that the compressive strength of concrete has an average value of 130 MPa [

15,

20,

21], the flexural tensile strength is greater than 20 MPa [

15,

22], and the direct tensile strength is greater than 5 MPa [

23,

24].

The mechanical properties of UHPC related to compression behavior are well established in the literature. However, the tensile strength results still show significant variations, both in direct tensile tests and in flexural tensile strength tests. It is known that the flexural tensile test is more common due to the ease of molding concrete prisms. However, variations in the geometry of the prisms can influence the tensile strength results, making this variable relevant for further studies. The flexural strength of the prisms decreases as the sample size increases, evidencing the influence of the specimen dimensions on the properties of the UHPC material. This effect should be taken into account when developing more accurate modeling approaches. The reduction in strength is attributed to the uneven distribution of fibers in thicker elements, while in thinner specimens, the fiber distribution is more uniform, resulting in greater flexural strength [

25,

26].

Even with this information, the use of UHPC remains restricted due to its high cement content, which can reach up to 1100 kg/m

3, resulting in significant environmental impacts, including high carbon dioxide (CO

2) emissions and high energy consumption, primarily associated with the production of Portland cement. In addition, the high initial cost represents a significant barrier [

27]. The cost of high-strength steel fibers accounts for approximately 35% of the total cost of UHPC manufacturing [

20]. However, reducing this percentage is challenging since it is difficult to maintain or improve tensile performance without an adequate amount of these fibers [

27]. Another aspect is the extremely low water-to-cement ratio and the limited extent of hydrated cement, which ranges from 30% to 40% [

28], resulting in a significant amount of non-hydrated cement in the matrix. Part of the non-hydrated cement reacts directly with the superplasticizer additive used in the mixture, and another part of its composition fills the voids. In order to economically optimize the UHPC mixture and minimize environmental impacts, it is recommended to partially replace the cement with mineral additives. Among these, we can mention ground granulated blast-furnace slag, fly ash, metakaolin, and rice husk ash [

27].

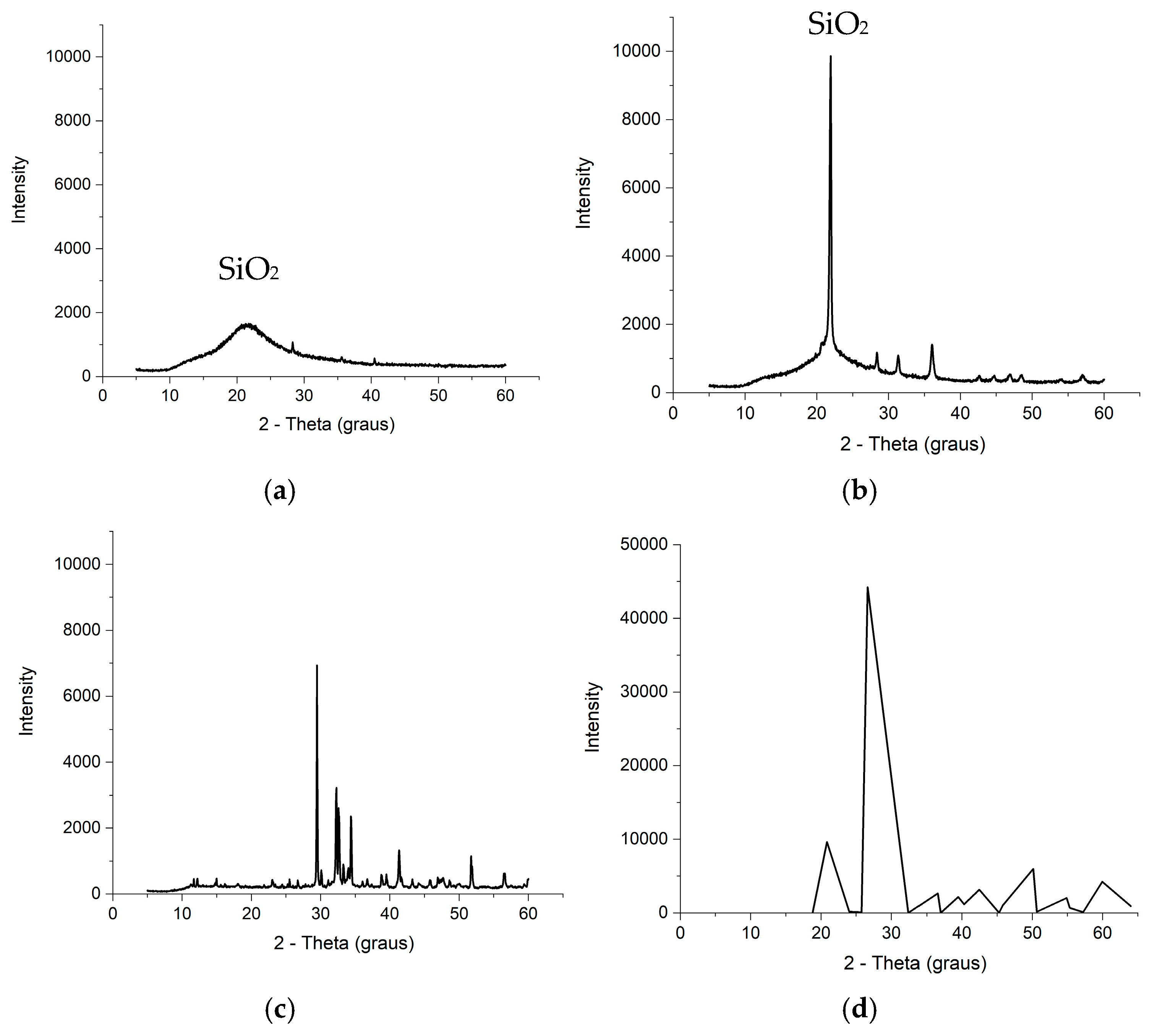

Rice husk ash is produced by burning direct residues from rice production, specifically the rice husks discarded during the production process [

29]. Controlled combustion of rice husks is of fundamental importance for producing RHA with silica concentrations above 90% [

29,

30]. When added to the concrete mix, it helps create hydrated calcium silicate, resulting from the reaction of calcium hydroxide from cement hydration with silica contained in pozzolan, thereby improving the mechanical properties and durability of the concrete [

29,

31]. Furthermore, the use of RHA not only increases compressive strength but also improves the water absorption of concrete by filling pores and voids within the concrete matrix. However, RHA negatively impacts the workability of the paste if the percentage of cement replacement by RHA exceeds 20%, accompanied by an increase in the brittleness of the mixtures [

29,

30,

32].

The use of rice husk ash to produce UHPC was investigated. The results showed that the compressive strength of UHPC using RHA exceeded 150 MPa under normal curing conditions [

33]. Furthermore, the samples with 10% RHA incorporated as a replacement for cement and silica showed better compressive strength than the control mix. The effect on compressive strength when replacing 30% of Portland cement with 15% ground blast furnace slag (GBFS) and 15% rice husk ash (RHA) was analyzed [

2]. The mixture with mineral additions exhibited a compressive strength of 143.5 MPa, whereas the compressive strength of the reference mixture (i.e., without mineral additions) was 159.3 MPa. Furthermore, the mixtures with mineral additions showed a lower embodied CO

2 emission index compared to the reference mixture. In [

29], the authors analyzed the effect of replacing silica with rice husk ash (RHA) on the compressive strength, flexural strength, and permeability of ultra-high-performance concrete (UHPC) at different curing ages. The results obtained by the authors indicated that the addition of RHA to replace SF reduced the fluidity of the fresh UHPC mix, resulting in the trapping of more air bubbles. On the other hand, replacing 2/3 of the silica with rice husk ash increased the compressive strength from 119.3 to 136.6 MPa compared to UHPC without addition, i.e., a gain of 14%. With the addition of RHA, the flexural strength at 3 days was improved, while at 28 and 120 days, there were no significant changes, ranging from 20 to 23 MPa.

Vigneshwari et al. [

34] reported an increase in the splitting tensile strength of approximately 15% to 46% and an increase in flexural strength of about 12% to 44% when using rice husk ash (RHA) compared to controlled concrete under normal curing conditions. Under steam curing conditions, the increases are approximately 10% to 36% for splitting tensile strength and 11% to 38% for flexural strength, depending on different replacement levels.

Based on the aforementioned studies, it is evident that replacing silica with RHA has a significant impact on the mechanical properties of UHPC, including compressive and tensile strengths, as well as the modulus of elasticity. Flexural strength is a critical parameter to study in the UHPC with rice husk ash, because, according to Silva [

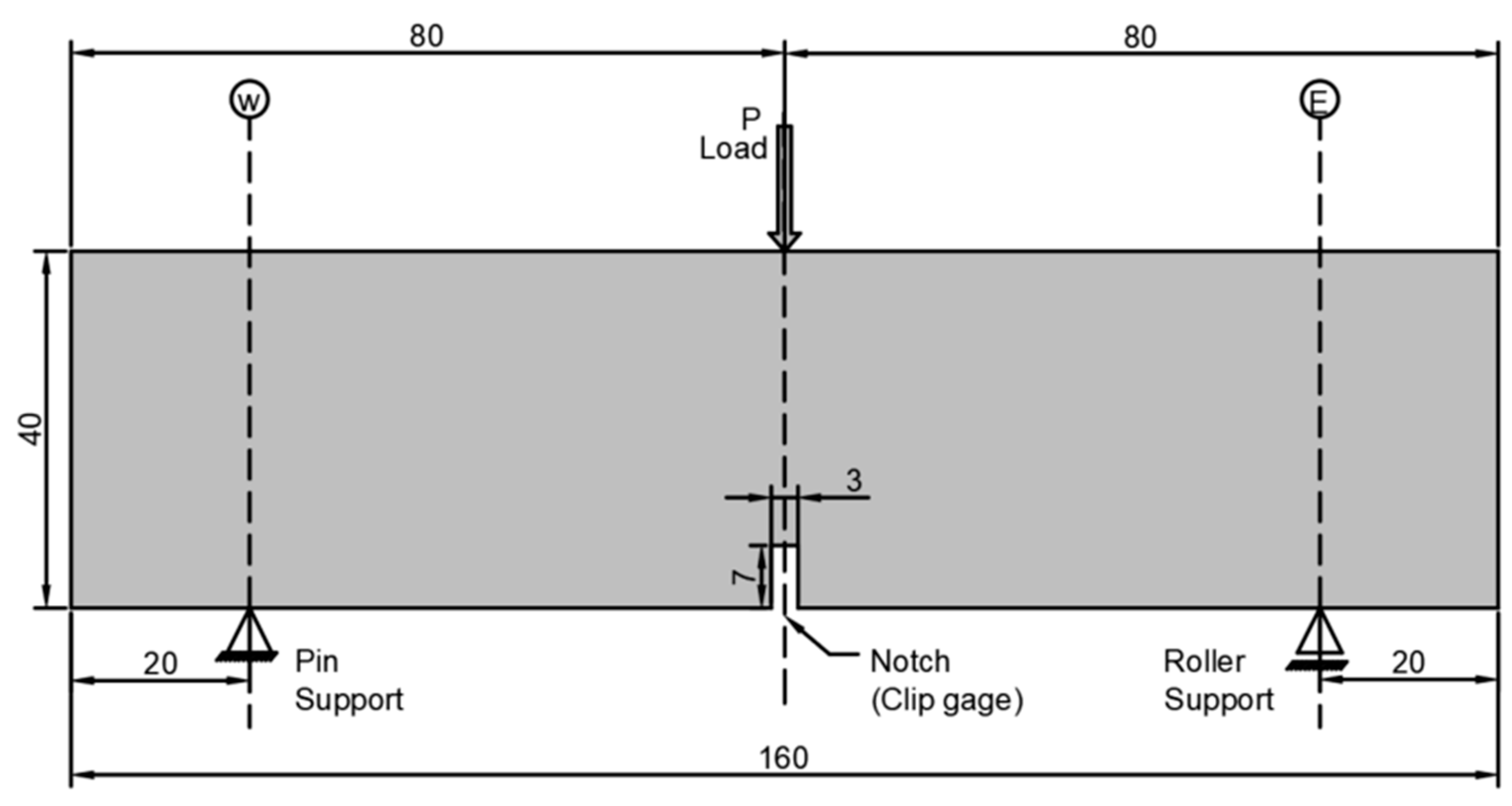

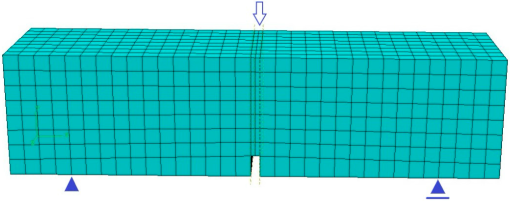

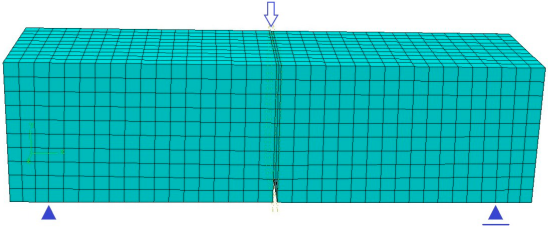

1], mineral additions can significantly influence this property. However, there are few studies in the literature examining the impact of rice husk ash (RHA) on flexural tensile strength. Regarding structural elements subjected to flexural tensile stresses, understanding the tensile strength behavior of UHPC allows for an increase in the load-bearing capacity of these structures. Furthermore, ductility analysis enables structures to operate under cracked conditions without compromising structural integrity. Therefore, this work seeks to fill the knowledge gap on the flexural tensile strength of UHPC with RHA, both experimentally, through tests, and numerically, with the calibration of parameters from flexural tests carried out on 40 × 40 × 160 mm prisms, seeking to obtain parameters of UHPC with RHA to design safer structures, reduce environmental impacts by reducing cement consumption in the UHPC mixture, and also analyze whether variations in the geometry of the prisms influence the flexural tensile strength based on parametric analyses of the numerical models.

3. Results and Discussion

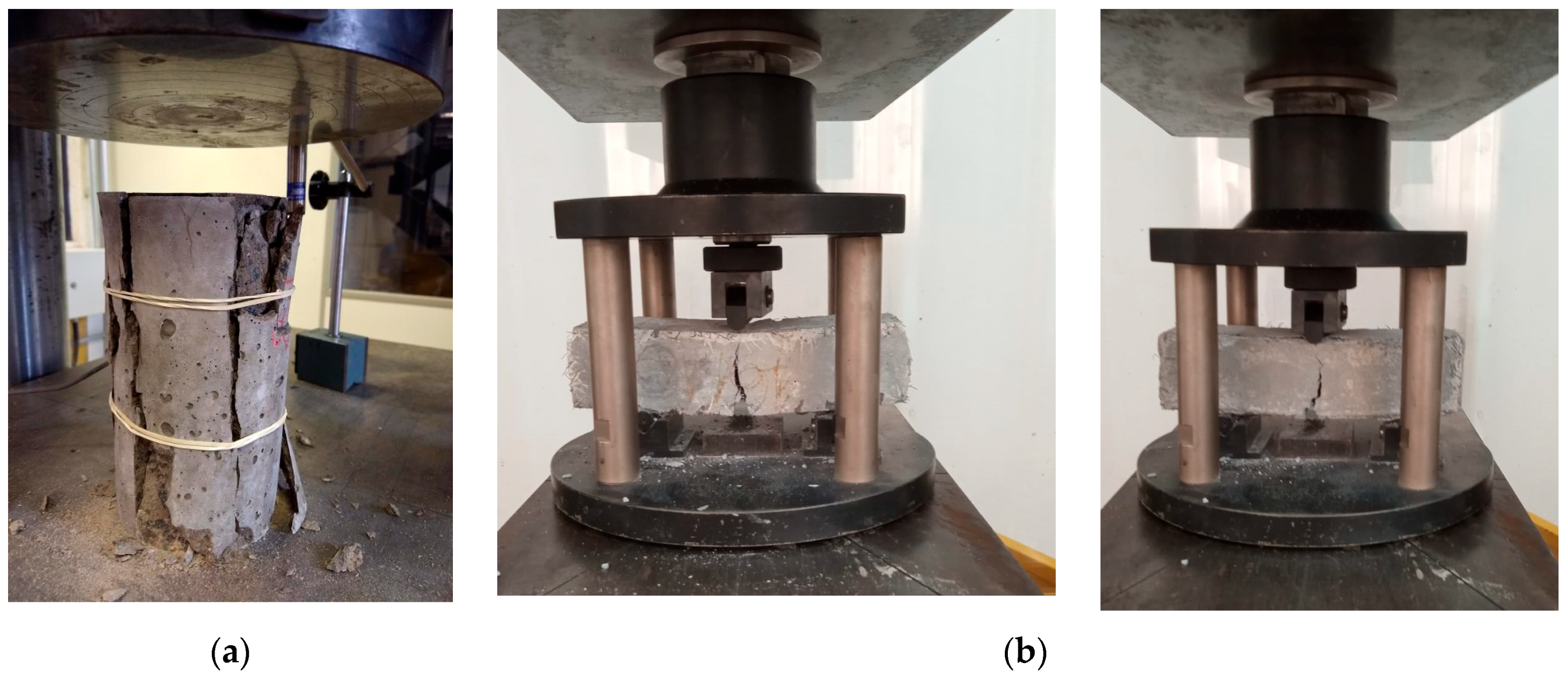

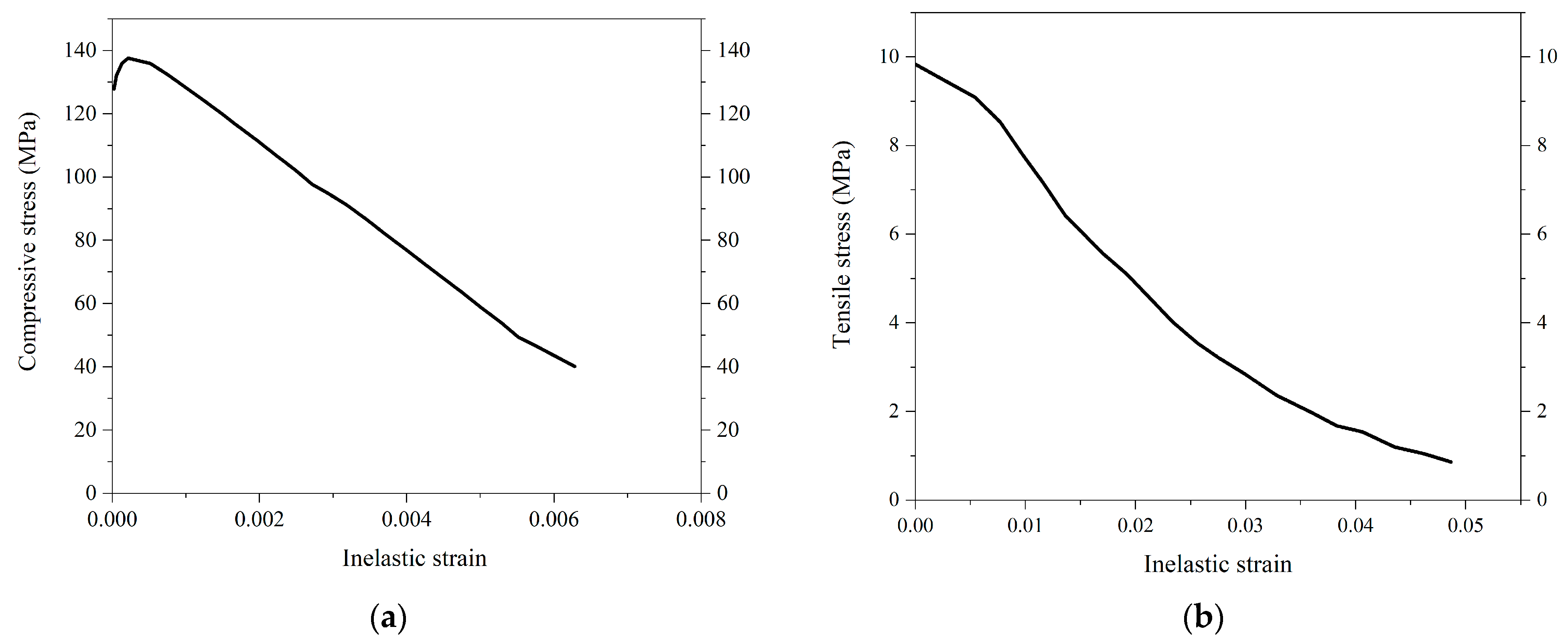

The results of the compressive strength test of the reference UHPC (UHPC_R) and with 20% RHA (UHPC_RHA) (

Figure 4a) at 28 days are presented in

Table 3.

Comparing the results obtained, an increase of approximately 4% in compressive strength is observed, representing a slight improvement for UHPC_RHA with 20% RHA (132.60 MPa) compared to UHPC_R without replacement (127.67 MPa). This result aligns with previous studies, confirming the potential of rice husk ash as a cementitious constituent in the production of UHPC [

33,

38,

39]. Furthermore, this approach promotes the reuse of agricultural waste, such as RHA, thereby contributing to the mitigation of the inappropriate disposal of these materials in the environment.

The results of the flexural tensile strength test for the reference UHPC (UHPC_R) and the UHPC with 20% RHA (UHPC_RHA) are presented in

Table 4 and

Figure 4b.

Comparing the results obtained, an increase in flexural tensile strength was observed with the addition of RHA to UHPC, from 26.05 MPa to 31.57 MPa, representing an approximately 20% increase. This increase was mainly due to the presence of amorphous silica in the RHA composition. The effect of RHA presence on UHPC was more significant on flexural tensile strength than on compressive strength. However, as already mentioned, research on flexural tensile strength in UHPC-RHA mixtures is still quite limited [

29,

34]. Therefore, this work also included a numerical investigation of this property through the numerical simulation of UHPC with RHA. The results of this analysis are presented in the next section to offer a more comprehensive understanding of flexural tensile strength.

To further investigate the environmental impact of incorporating rice husk ash (RHA) into UHPC formulations, a fundamental embodied CO

2 analysis was conducted considering the quantities of materials used in the two mixtures and adopting average emission factors available in the [

40,

41,

42,

43] literature. The emission factors considered were: 0.84 kg CO

2/kg for Portland cement, 0.0031 kg CO

2/kg for silica fume, 0.065 kg CO

2/kg for quartz powder, 0.0026 kg CO

2/kg for fine sand, 2.68 kg CO

2/kg for steel fibers, 0.75 kg CO

2/kg for superplasticizer, 0.00015 kg CO

2/kg for water, and 0.1032 kg CO

2/kg for RHA. The embodied CO

2 emissions were estimated by multiplying the mass of each constituent per cubic meter by its respective emission factor. For the reference UHPC mixture (UHPC_R), the total embodied CO

2 was calculated as 1134.30 kg CO

2/m

3, resulting primarily from the high contributions of Portland cement and steel fibers. For the RHA-modified mixture (UHPC_RHA), incorporating 20% RHA in place of silica fume, the total embodied CO

2 was calculated as 1138.09 kg CO

2/m

3. Thus, contrary to initial expectations, using RHA led to a slight increase of approximately 0.34% in CO

2 emissions compared to the reference mix. This result is attributed to the relatively low emission factor of silica fume compared to the emission associated with the processing of RHA considered in this study. Nevertheless, it is important to highlight that, beyond the carbon footprint analysis, the valorization of agricultural waste and the promotion of a circular economy represent significant environmental benefits associated with using RHA in high-performance concrete mixtures.

5. Conclusions

This study analyzed the effect of adding rice husk ash (RHA) on the flexural tensile strength of fiber-reinforced ultra-high-performance concrete (UHPC) prisms. In addition, the calibration of UHPC parameters with RHA was proposed for numerical simulations based on the CDP model. In the end, parametric analyses were conducted to investigate the impact of prism size on flexural tensile strength for UHPC specimens both with and without RHA addition. The main conclusions obtained in this work are listed below:

Comparing the results obtained, an increase of approximately 4% in compressive strength is observed, representing a small improvement for UHPC with 20% RHA (132.60 MPa) compared to UHPC without replacement (127.67 MPa).

Comparing the results obtained, an increase in flexural tensile strength is observed with the addition of RHA to UHPC (from 26.05 MPa to 31.57 MPa), which represents an increase of approximately 20%.

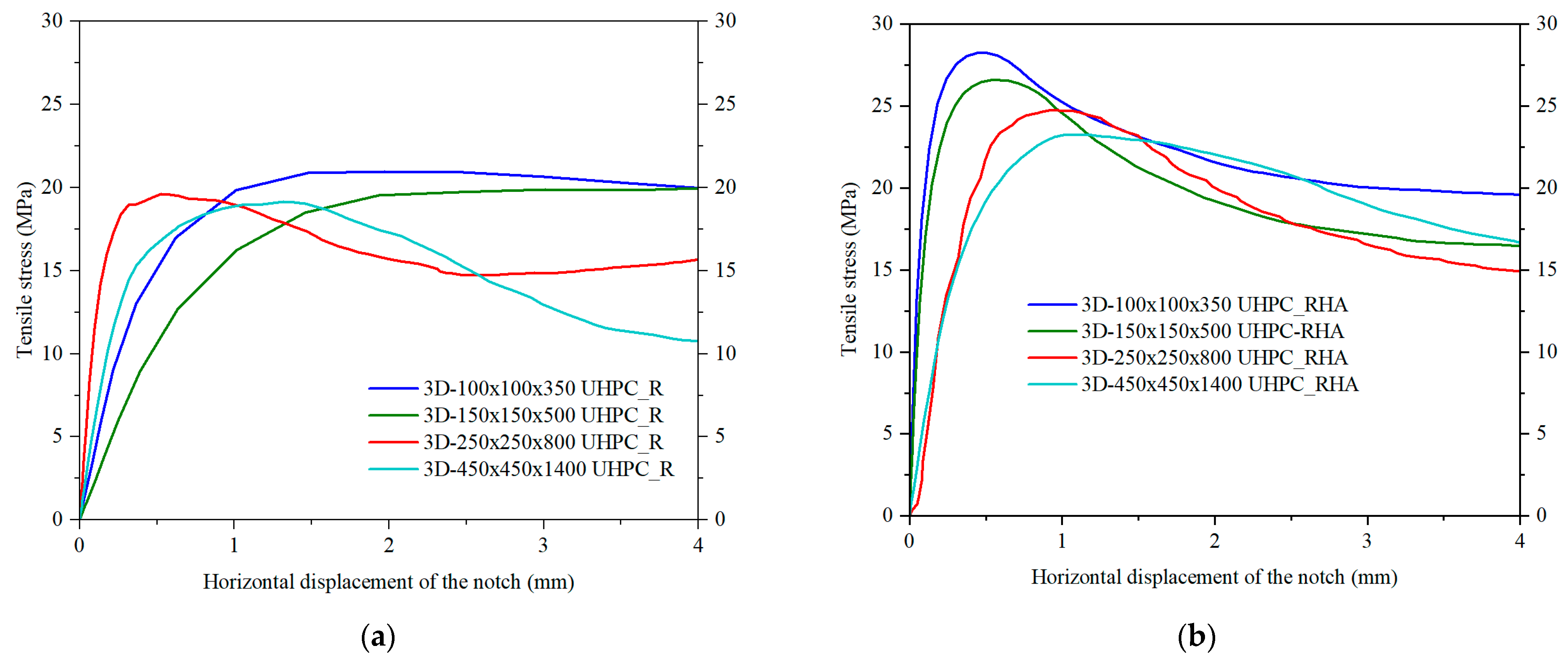

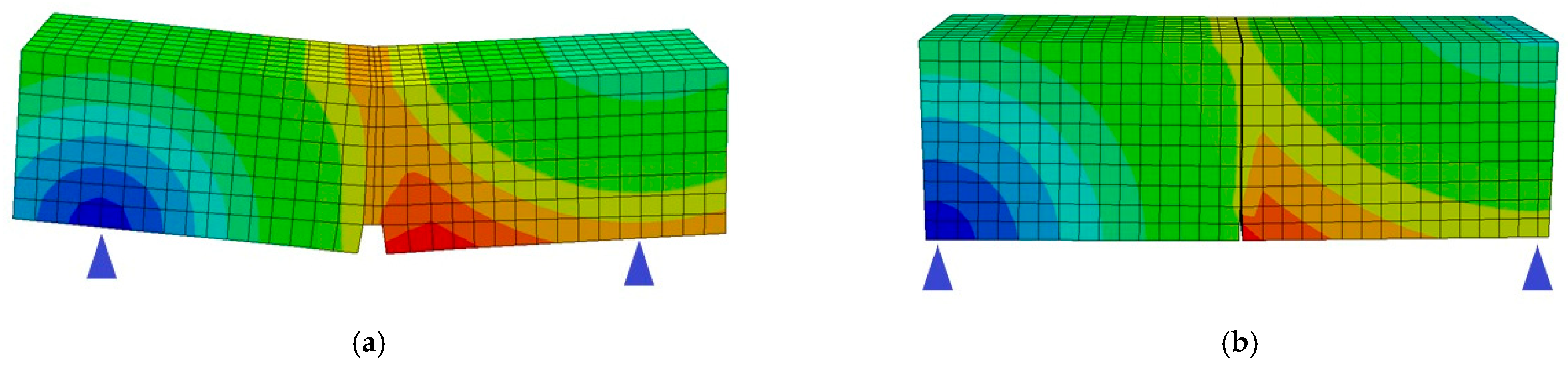

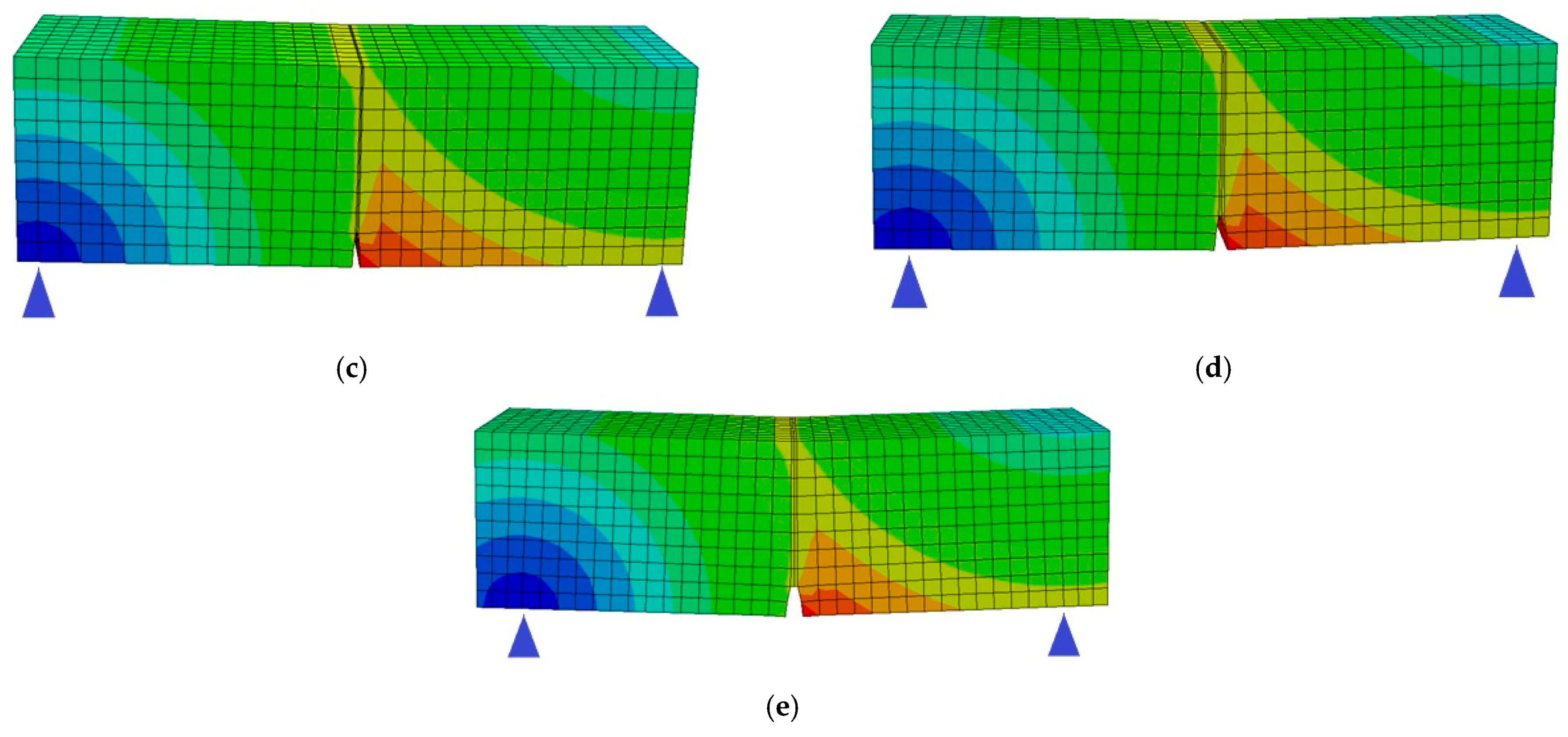

The adjustments of the viscosity and dilatancy angle parameters for the UHPC-RHA in the CDP, considering the UHPC-R input data, showed good representativeness and can be used for numerical simulation.

Numerical extrapolations of the flexural tensile strength test indicate that the size of the concrete prism geometry affects the final results; specifically, as the geometry of the prisms increases, the resistance decreases.

There was a 20% reduction in the tensile strength of UHPC-R from the smallest prismatic model compared to the prism with the largest geometry. While in the UHPC-RHA, this reduction in strength was 30% from the smallest prismatic model to the largest prismatic model.

The tensile strength curves obtained from the numerical model showed that UHPC_RHA exhibited a smaller displacement before reaching rupture compared to UHPC_R, confirming that the presence of RHA enhances the stiffness of UHPC due to its high pozzolanic activity and its filler effect on the microstructure.

The conclusions demonstrate that the inclusion of rice husk ash (RHA) in the UHPC mixture yields satisfactory performance in terms of mechanical strength, particularly in flexural tensile strength. However, this topic has not been fully explored, and further experimental studies are needed to investigate the behavior of RHA in UHPC compositions. In addition, the variation in the geometry of the prisms should be considered in the calculation of the flexural tensile strength, especially in mixtures containing RHA, in which this influence was shown to be more significant. Smaller prisms can be used in the tests; however, the force obtained should be corrected to consider the influence of the smaller geometry of the specimen.

As a suggestion for future work, it is recommended that experimental analyses of the mechanical behavior of UHPC be performed with the addition of rice husk ash (RRA) and different types of fibers, such as polypropylene and glass microfibers. The focus should be on evaluating the tensile strength in bending, considering the variations in the geometries of the prisms used in the tests, to verify whether such variations significantly influence the results.