Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings

Abstract

1. Introduction

1.1. Background and Purpose of the Study

1.2. Research Problem, Objectives, Scope, and Method

2. Literature Review

2.1. Policy Trends in Green Renovation in Korea and the World

2.1.1. Korea

- Private Building Green Remodeling Loan Interest Support Project;

- Support for public buildings owned by public institutions more than 10 years after the completion of construction;

- Pre-investigation and consulting support for institutions willing to participate;

- More than 1000 square meters of private buildings to be completed after 2025, complying with ZEB grade 5.

2.1.2. The EU

- EU Member States comply with NZEB requirements for new buildings defined at the regional level;

- After renovation, the building’s primary energy consumption decreased by 75% compared to its previous state;

- Global Buildings Performance Network (GBPN) energy consumption for ventilation energy consumption of heating/cooling, hot water, and building aids is less than 50–60 kWh/m2 per year;

- Do not release less than 3 kg CO2/m2/year [17].

2.1.3. The USA

- Green remodeling of 4 million existing buildings over four years, reinforcing the insulation performance of 2 million houses;

- Subsidies for upgrading high-efficiency home appliances and installing high-performance windows;

- Legislation of net zero carbon emissions for new commercial buildings by 2030;

- Improve indoor air quality of national and public school facilities, strengthen energy efficiency, and build climate resilience;

- Supply 1.5 million public housing units with guaranteed high-efficiency energy performance [19].

2.1.4. Japan

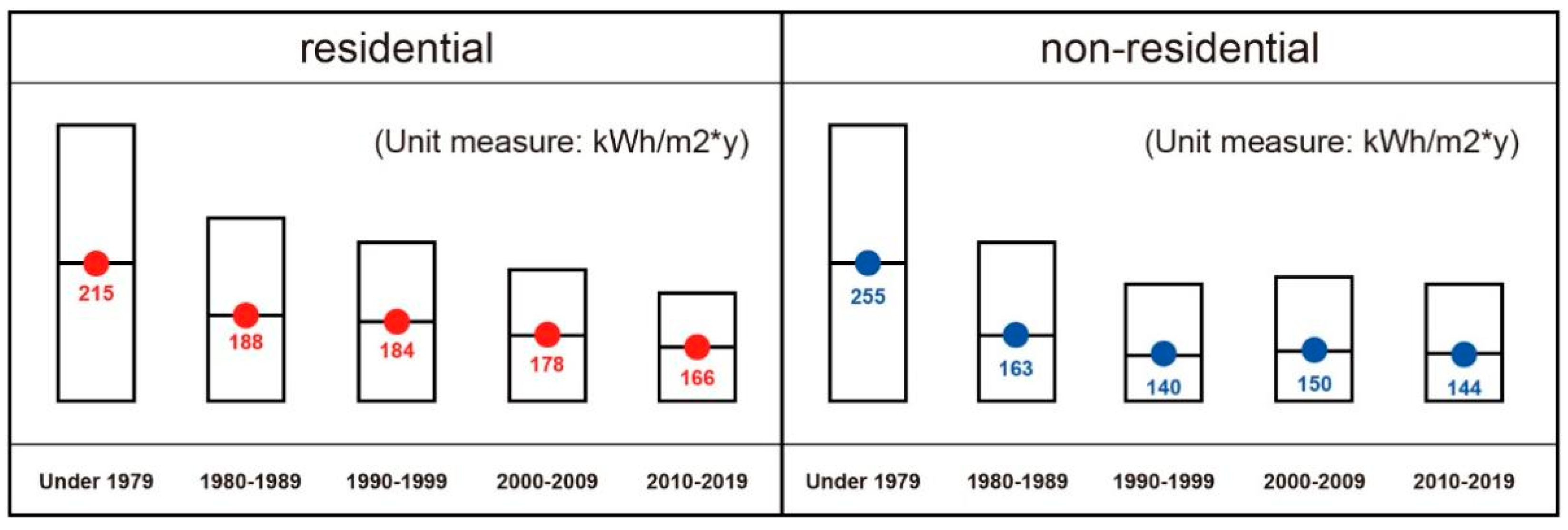

2.2. Challenges Facing Aging Residential Buildings in Korea

2.3. Utilization of CIGS Thin-Film Solar Cells

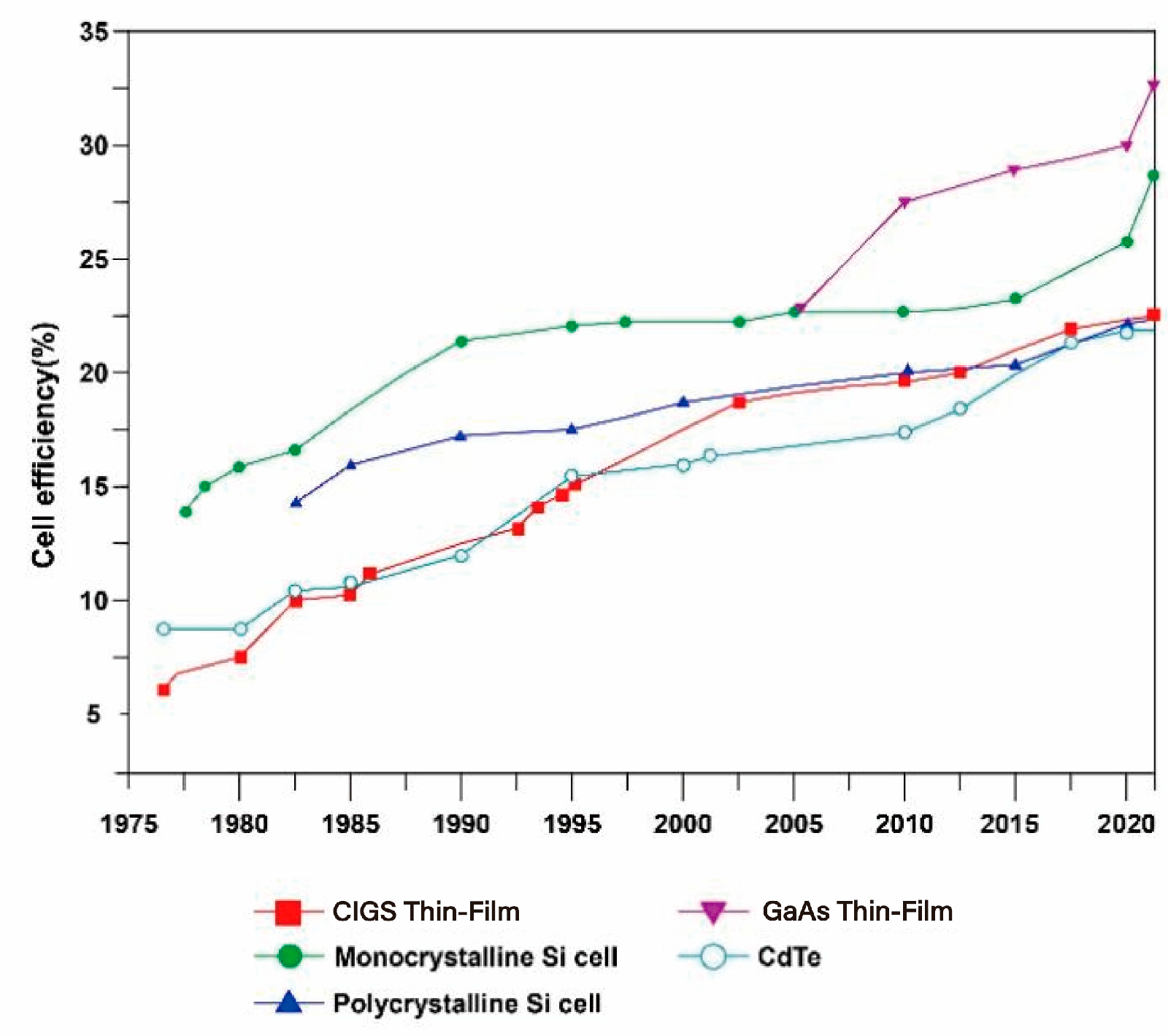

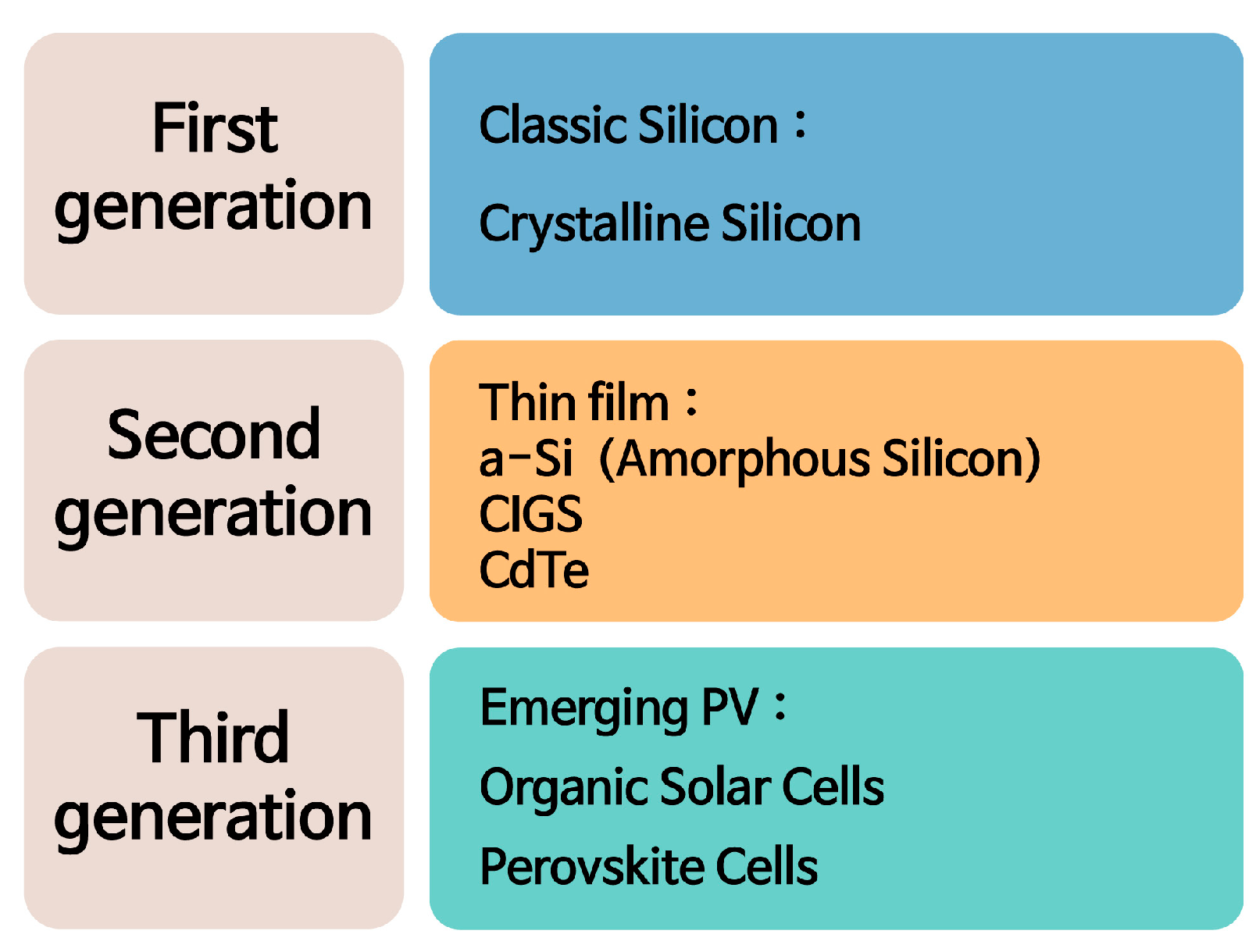

2.3.1. The Stability of the Different Generations of Solar Cells

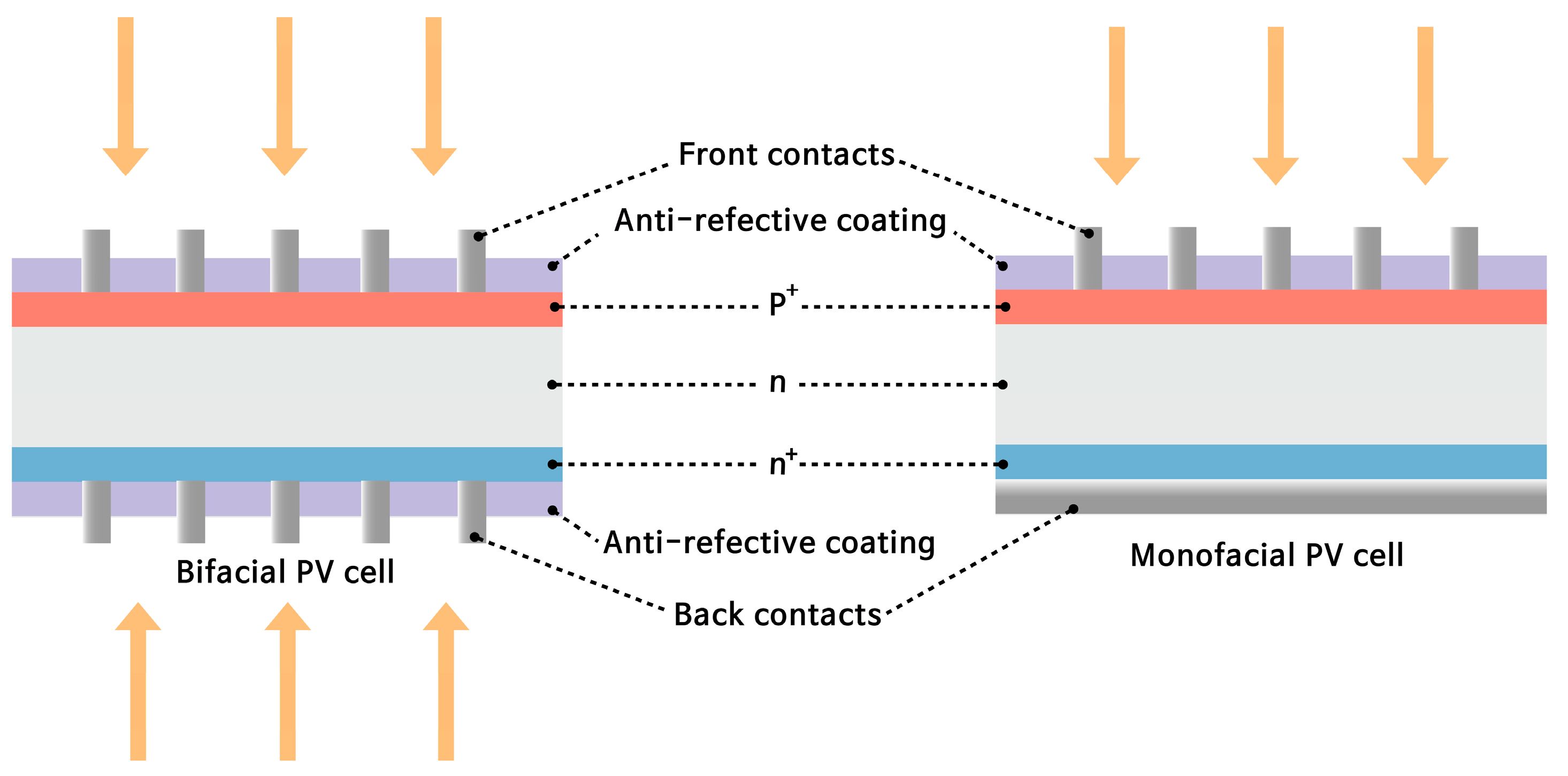

2.3.2. Principle of Power Generation of Bifacial CIGS Thin-Film Solar Cells

2.4. The Application Technology of Green Remodeling in Korea

2.5. Application of Solar Cells in Korea

3. Materials and Methods

3.1. Research Design and Framework

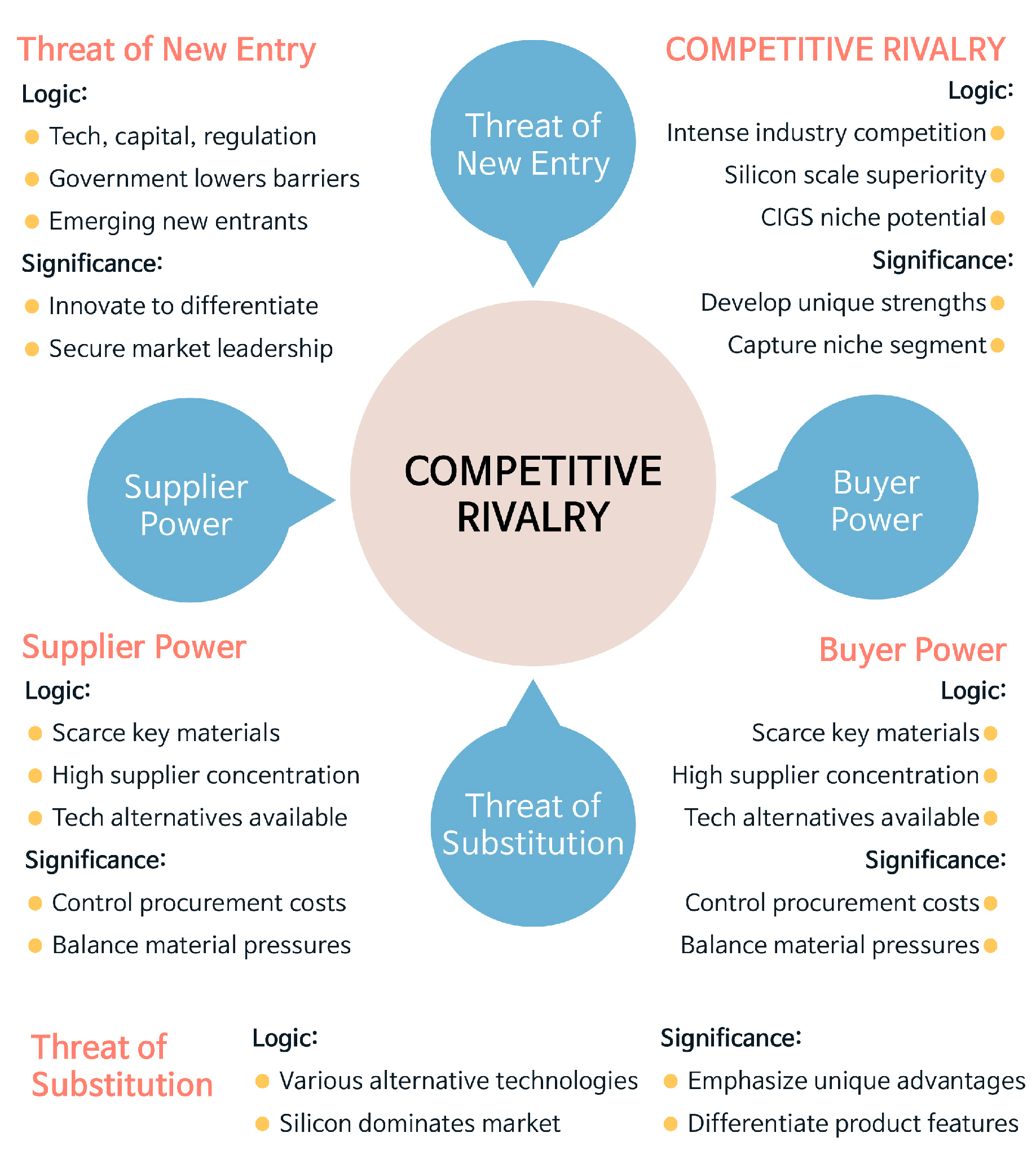

3.2. Porter’s Five Forces Framework

3.2.1. Construction of a CIGS Performance Index System Based on Porter’s Five Forces Framework

- Threat of new entrants → innovation index: The threat of new entrants depends on the level of barriers to entry. These barriers encompass technology patents, capital requirements, and regulatory approvals for integrated building products. As governments worldwide have introduced incentives for green buildings, the barriers to entry have gradually decreased. Consequently, CIGS manufacturers must persist in fortifying their competitive edge through technological innovation and distinctive market positioning.

- Supplier influence → safety index: The bargaining power of suppliers has a direct impact on the market competitiveness of CIGS solar technology. The number of companies in South Korea that can provide the core technology of CIGS thin-film solar cells is extremely limited, resulting in a heavy reliance on foreign imports for raw material supplies and vulnerability to fluctuations in the international market [58].

- Buyer power → economic index: The impact of buyer power on the market penetration of CIGS thin-film solar cells is significant. Given the nascent stage of CIGS technology, the lifecycle and long-term benefits remain to be elucidated. The high installation cost has led to the primary purchasing groups being governments, state-owned enterprises, and private enterprises, while households and individual users tend to opt for more economical alternatives.

- Threat of substitutes → energy saving index: The threat of substitutes primarily originates from technologies and solutions that can meet similar needs. CIGS thin-film solar cells, for instance, have a variety of alternatives. These alternatives may include silicon-based CdTe, GaAs, and other technologies, as well as applications in fields such as windows and exterior wall materials. If these alternatives prove to be more cost-effective, possess superior quality, and result in lower user costs, competition is expected to intensify. To this end, CIGS products must possess substantial energy-saving advantages, including but not limited to annual power generation energy savings, carbon emission reductions, and energy independence.

- The intensity of competition among existing companies in this field is a primary factor. The most salient factor influencing the competitiveness of CIGS cells is the rivalry with preexisting competitors, encompassing silicon solar cells, other thin-film solar cells, windows, and exterior materials. The global CIGS market is dominated by a few mainstream manufacturers such as Solar Frontier (Tokyo, Japan), Avancis (Torgau, Germany) and MiaSolé (Santa Clara, CA, USA). And the South Korean domestic solar cell market has undergone a significant transformation due to the influx of inexpensive Chinese solar cells, resulting in intensified competition within the market. Competition is also influenced by the stage of technological development. The application of CIGS in buildings is still in the introductory stage, while silicon photovoltaics has reached a mature stage. This dynamic suggests that CIGS exhibits greater flexibility and aesthetic adaptability compared to crystalline silicon technology, indicating its strategic potential for integration into building facade applications. The strategic positioning of CIGS companies hinges on their ability to establish unique advantages in specific application domains, such as distinct aesthetic differentiation and seamless design integration. The successful establishment of these competitive market segments is predicated on the ability to leverage these unique strengths.

3.2.2. Applicability of Porter’s Five Forces Framework

3.3. Identifying Performance Indicators from the Literature

3.4. Focus Group Discussions

3.5. Merge and Rename

- (1)

- The presence of superimposed indicator data gives rise to the possibility of double counting during the assessment process;

- (2)

- Most indicators are highly technical (e.g., “U-value”, “LCOE”, “Digital Twin Monitoring”), making them difficult for non-technical personnel (e.g., architects, developers, and investors involved in discussions about safety indicators) to understand and participate in;

- (3)

- Excessive indicators will significantly increase the actual assessment manpower costs and data collection burden, reducing the efficiency of rapid scheme selection;

- (4)

- Too many sub-indicators result in a complex scoring system, increasing the difficulty of weight allocation and affecting model balance.

4. A Porter’s Five Forces Model Analysis of CIGS Thin-Film Solar Cells

4.1. Index Modeling for the Competency of CIGS Thin-Film Solar Cell

- (1)

- Positive Qualitative:

- (2)

- Mutual Inversion:

- (3)

- Identity:

4.1.1. Aesthetic Index

4.1.2. Economic Index

4.1.3. Safety Index

4.1.4. Energy Saving Index

4.1.5. Innovation Index

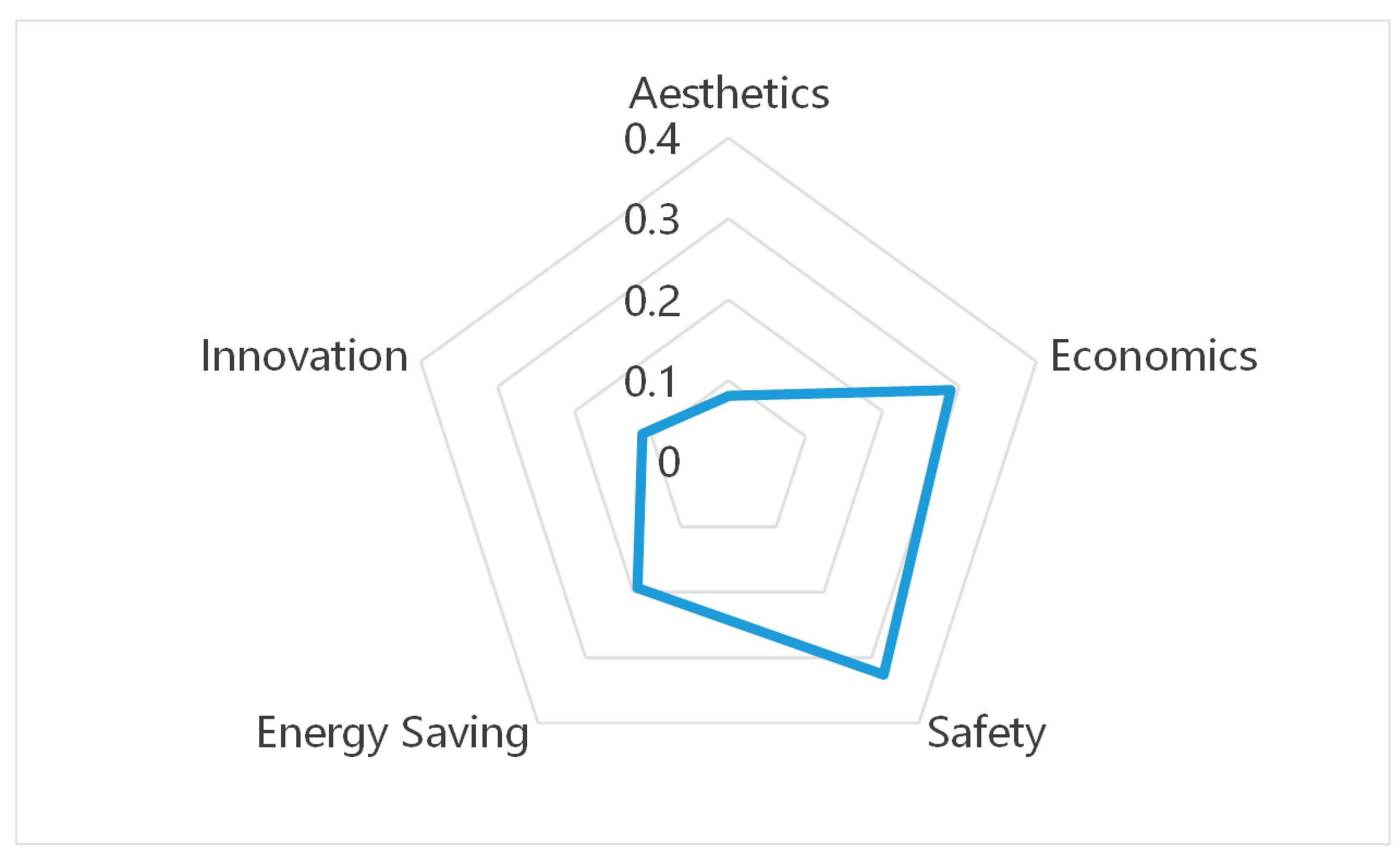

5. Weights of the Competency Model

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- KDI. Reviewing the Global Response to the New Climate System; Korea Economic Information Center: Sejong, Republic of Korea, 2021. [Google Scholar]

- Ministry of Environment. The Revised Roadmap for Achieving the National Greenhouse Gas Reduction Target; Ministry of Environment: Sejong, Republic of Korea, 2018.

- Ministry of Land, Infrastructure and Transport. Architectural Administration System Building Status Statistics (2012–2020); Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2020.

- Gohardani, N.; Björk, F. Sustainable refurbishment in building technology. Smart Sustain. Built Environ. 2012, 1, 241–252. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Guo, R.; Min, Y.; Gao, Y.; Chen, X.; Shi, H.; Liu, C.; Zhuang, C. Unlocking energy and economic benefits of integrated green envelopes in office building retrofits. Build. Environ. 2024, 261, 111747. [Google Scholar] [CrossRef]

- Fan, Y.; Xia, X. Energy-efficiency building retrofit planning for green building compliance. Build. Environ. 2018, 136, 312–321. [Google Scholar] [CrossRef]

- De Oliveira, C.C.; Vaz, I.C.M.; Ghisi, E. Retrofit strategies to improve energy efficiency in buildings: An integrative review. Energy Build. 2024, 321, 114624. [Google Scholar] [CrossRef]

- Habibi, S. Improving building envelope performance with respect to thermal, sound insulation, and lighting: A case study. Build. Acoust. 2019, 26, 243–262. [Google Scholar] [CrossRef]

- Ranđelović, D.; Jovanović, V.; Ignjatović, M.; Marchwiński, J.; Kopyłow, O.; Milošević, V. Improving energy efficiency of school buildings: A case study of thermal insulation and window replacement using Cost-Benefit analysis and energy simulations. Energies 2024, 17, 6176. [Google Scholar] [CrossRef]

- Eriksson, L.S.; Lidelöw, S. Maintaining or replacing a building’s windows: A comparative life cycle study. Int. J. Build. Pathol. Adapt. 2024; ahead-of-print. [Google Scholar]

- Zhou, Z.; Zhang, S.; Wang, C.; Zuo, J.; He, Q.; Rameezdeen, R. Achieving energy efficient buildings via retrofitting of existing buildings: A case study. J. Clean. Prod. 2015, 112, 3605–3615. [Google Scholar] [CrossRef]

- Frilingou, N.; Koasidis, K.; Spyridaki, N.; Nikas, A.; Marinakis, V.; Doukas, H. Is it feasible to implement minimum energy performance standards (MEPS) for existing buildings in Greece? A cost-benefit evaluation. Energy Policy 2024, 188, 114112. [Google Scholar] [CrossRef]

- Jia, L.; Han, J.; Chen, X.; Li, Q.; Lee, C.; Fung, Y. Interaction between Thermal Comfort, Indoor Air Quality and Ventilation Energy Consumption of Educational Buildings: A Comprehensive Review. Buildings 2021, 11, 591. [Google Scholar] [CrossRef]

- Korea Authority of Land & Infrastructure Safety. Available online: https://www.greenremodeling.or.kr/ (accessed on 21 November 2023).

- D’Agostino, D.; Zangheri, P. Development of the NZEBs Concept in Member States Towards Nearly Zero Energy Buildings in Europe Title: Development of the NZEBs Concept in Member States. 2016. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC104344/development%20of%20the%20nzebs%20concept%20in%20member%20states_final.pdf (accessed on 2 December 2021).

- Sáez-De-Guinoa, A.; Zambrana-Vasquez, D.; Fernández, V.; Bartolomé, C. Circular Economy in the European Construction Sector: A Review of Strategies for implementation in Building Renovation. Energies 2022, 15, 4747. [Google Scholar] [CrossRef]

- US Department of Energy. Building Technologies Office Multi-Year Program Plan, Fiscal Years 2016–2020; US Department of Energy: Washington, DC, USA, 2016.

- AURI. The Prospects and Implications of the Green New Deal in the Architecture and Urban Sector in the Biden Era; AURI: Sejong, Republic of Korea, 2021. [Google Scholar]

- KOTRA. Catch the Japanese Remodeling Market; KOTRA: Seoul, Republic of Korea, 2017. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. A Study on the Development of the Core Technology of Plus Energy Residential Complex for Efficient Energy Operation; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2017.

- LHI. A Study on the Green Remodeling Green Architecture Certification for Existing Buildings; LHI: Dajeon, Republic of Korea, 2018. [Google Scholar]

- Kim, C. A review of the deployment programs, impact and barriers of renewable energy policies in Korea. Renew. Sustain. Energy Rev. 2021, 144, 110870. [Google Scholar] [CrossRef]

- Seo, R.J. Design Elements in Apartments for adapting to Climate: A Comparison between Korea and Singapore. Sustainability 2020, 12, 3244. [Google Scholar] [CrossRef]

- Korea Meteorological Administration. Available online: https://data.kma.go.kr/resources/normals/pdf_data/korea_pdf_0106_v2.pdf (accessed on 20 November 2023).

- KMA. Weather Data Open Portal; KMA: Dajeon, Republic of Korea, 2022. [Google Scholar]

- Levermore, G.J. A review of the IPCC Assessment Report Four, Part 1: The IPCC process and greenhouse gas emission trends from buildings worldwide. SAGE J. 2008, 29, 349–361. [Google Scholar] [CrossRef]

- Living Environment Research Office, Seoul Institute of Technology. To Create A Comfortable Settlement Environment Green Remodeling of Deteriorated Buildings; Living Environment Research Office, Seoul Institute of Technology: Seoul, Republic of Korea, 2017. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. The First Basic Plan for Green Buildings; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2014.

- Ministry of Land, Infrastructure and Transport. The Second Basic Plan for Green Buildings; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2019.

- Ministry of Land, Infrastructure and Transport. Available online: https://www.hub.go.kr/portal/opn/tyb/idx-bdrg-totldr.do (accessed on 20 November 2023).

- Halawa, E.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Trombley, J.; Hassan, N.; Baig, M.; Yusoff, S.Y.; Ismail, M.A. A review on energy conscious design of building facades in hot and humid climates: Lessons for (and from) Kuala Lumpur and Darwin. Renew. Sustain. Energy Rev. 2018, 82, 2147–2161. [Google Scholar] [CrossRef]

- Zemella, G.; Faraguna, A. Evolutionary Optimization of Façade Design; Springer: London, UK, 2014. [Google Scholar]

- Al-saggaf, A.; Taha, M.; Hegazy, T.; Ahmed, H. Toward Sustainable Building Design: The impact of Architectural Design Features on Cooling Energy Consumption and Cost in Saudi Arabia. Procedia Manuf. 2020, 44, 140–147. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport. Effect of Energy Efficiency Improvement due to Continuous Green Building Policies Such As Green Remodeling; Ministry of Land, Infrastructure and Transport: Sejong, Republic of Korea, 2022.

- Visa, I.; Burduhos, B.; Neagoe, M.; Moldovan, M.; Duta, A. Comparative analysis of the infield response of five types of photovoltaic modules. Renew. Energy 2016, 95, 178–190. [Google Scholar] [CrossRef]

- Jackson, P.; Hariskos, D.; Wuerz, R. Properties of Cu(In,Ga)Se2 solar cells with new record efficiencies up to 21.7%. Phys. Status Solidi-Rapid Res. Lett. 2015, 9, 28–31. [Google Scholar] [CrossRef]

- Photovoltaic Research. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 20 November 2023).

- Wu, L.; Haotian, L.; Bo, Q.; Suling, Z.; Zheng, U.; Dandan, S. Highly efficient CIGS solar cells based on a new CIGS bandgap gradient design characterized by numerical simulation. Sol. Energy 2022, 233, 337–344. [Google Scholar]

- Kong, H.; Yu, Z.; Zhang, J.; Han, Y.; Wu, L.; Wang, H.; Wang, J. Perspective of CIGS-BIPV’s Product Competitiveness in China. Int. J. Photoenergy 2020, 2020, 5392594. [Google Scholar] [CrossRef]

- Crystalline Silicon Photovoltaics Research. Available online: https://www.energy.gov/eere/solar/crystalline-silicon-photovoltaics-research#:~:text=and%20installed%20for%20a%20given,a%20year (accessed on 14 April 2025).

- Analysis of Performance Degradation of PV Modules. Available online: https://www.powermag.com/analysis-of-performance-degradation-of-pv-modules/ (accessed on 14 April 2025).

- Green, M.A. Commercial progress and challenges for photovoltaics. Nat. Energy 2016, 1, 15015. [Google Scholar] [CrossRef]

- Boulhidja, S.; Mellit, A.; Voswinckel, S.; Lughi, V.; Ciocia, A.; Spertino, F.; Pavan, A.M. Experimental evidence of PID effect on CIGS photovoltaic modules. Energies 2020, 13, 537. [Google Scholar] [CrossRef]

- Kettle, J.; Aghaei, M.; Ahmad, S.; Fairbrother, A.; Irvine, S.; Jacobsson, J.J.; Kazim, S.; Kazukauskas, V.; Lamb, D.; Lobato, K.; et al. Review of technology specific degradation in crystalline silicon, cadmium telluride, copper indium gallium selenide, dye sensitised, organic and perovskite solar cells in photovoltaic modules: Understanding how reliability improvements in mature technologies can enhance emerging technologies. Prog. Photovolt. Res. Appl. 2022, 30, 1365–1392. [Google Scholar]

- Piliougine, M.; Sánchez-Friera, P.; Petrone, G.; Sánchez-Pacheco, F.J.; Spagnuolo, G.; Sidrach-de-Cardona, M. Analysis of the degradation of amorphous silicon-based modules after 11 years of exposure by means of IEC60891:2021 procedure 3. Prog. Photovolt. Res. Appl. 2022, 30, 1176–1187. [Google Scholar] [CrossRef]

- Khenkin, M.V.; Katz, E.A.; Abate, A.; Bardizza, G.; Berry, J.J.; Brabec, C.; Brunetti, F.; Bulović, V.; Burlingame, Q.; Di Carlo, A.; et al. Consensus statement for stability assessment and reporting for perovskite photovoltaics based on ISOS procedures. Nat. Energy 2020, 5, 35–49. [Google Scholar] [CrossRef]

- Graniero, P.; Khenkin, M.; Köbler, H.; Hartono, N.T.P.; Schlatmann, R.; Abate, A.; Unger, E.; Jacobsson, T.J.; Ulbrich, C. The challenge of studying perovskite solar cells’ stability with machine learning. Front. Energy Res. 2023, 11, 1118654. [Google Scholar] [CrossRef]

- Ding, Z.; Kettle, J.; Horie, M.; Chang, S.W.; Smith, G.C.; Shames, A.I.; Katz, E.A. Efficient solar cells are more stable: The impact of polymer molecular weight on performance of organic photovoltaics. J. Mater. Chem. A 2016, 4, 7274–7280. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Ding, K.; Sheriff, H.K.M.; Ye, L.; Liu, H.; Li, C.-Z.; Ade, H.; Forrest, S.R. Non-fullerene acceptor organic photovoltaics with intrinsic operational lifetimes over 30 years. Nat. Commun. 2021, 12, 5419. [Google Scholar] [CrossRef]

- Gu, W.; Ma, T.; Song, A.; Li, M.; Shen, L. Mathematical modelling and performance evaluation of a hybrid photovoltaic-thermoelectric system. Energy Convers. Manag. 2019, 198, 111800. [Google Scholar] [CrossRef]

- Gu, W.; Ma, T.; Ahmed, S.; Zhang, Y.; Peng, J. A comprehensive review and outlook of bifacial photovoltaic (bPV) technology. Energy Convers. Manag. 2020, 223, 113283. [Google Scholar] [CrossRef]

- Ko, H.; Kim, Y.; Lee, N. A Study on the Analysis of the Exterior Shape of an Apartment Using Solar Panels. Korea Inst. Patial Des. J. 2021, 16, 99–112. [Google Scholar]

- Park, J.H.; Nam, W.S.; Jang, J.S. Urban Design cases study analysis using solar cell: Focusing on the use CIGS Thin Film Solar cell. Korea Converg. Soc. 2020, 11, 163–170. [Google Scholar]

- Kim, D.S.; Shin, U.; Yoon, J. Annual Energy Yield Prediction of Building Added PV System Depending on the Installation Angle and the Location in Korea. KIEAE J. 2014, 14, 67–74. [Google Scholar] [CrossRef][Green Version]

- The World of Work Project. Available online: https://worldofwork.io/2019/07/porters-five-forces/#:~:text=Porter%27s%20Five%20Forces%3A%20A%20Simple,market%20and%20existing%20industry%20rivals (accessed on 10 April 2025).

- Harvard Business School. Available online: https://www.isc.hbs.edu/strategy/business-strategy/Pages/the-five-forces.aspx#:~:text=The%20Five%20Forces%20,is%20divided%20among%20industry (accessed on 10 April 2025).

- Beiderbeck, D.; Frevel, N.; Von Der Gracht, H.A.; Schmidt, S.L.; Schweitzer, V.M. Preparing, conducting, and analyzing Delphi surveys: Cross-disciplinary practices, new directions, and advancements. MethodsX 2021, 8, 101401. [Google Scholar] [CrossRef]

- Al-Harbi, K.M.A.-S. Application of the AHP in project management. Int. J. Proj. Manag. 2001, 19, 19–27. [Google Scholar] [CrossRef]

- Armacost, R.L.; Componation, P.J.; Mullens, M.A.; Swart, W.W. An AHP framework for prioritizing customer requirements in QFD: An industrialized housing application. IIE Trans. 1994, 26, 72–79. [Google Scholar] [CrossRef]

- Misran, M.F.R.; Roslin, E.N.; Nur, N.M. AHP-Consensus Judgement on Transitional Decision-Making: With a Discussion on the Relation Towards Open Innovation. J. Open Innov. Technol. Mark. Complex. 2020, 6, 63. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, R.J.; Liu, C.; Sun, C. Solar building envelope potential in urban environments: A state-of-the-art review of assessment methods and framework. Build. Environ. 2023, 244, 110831. [Google Scholar] [CrossRef]

- Alassaf, Y. Comprehensive review of the advancements, benefits, challenges, and design integration of Energy-Efficient materials for sustainable buildings. Buildings 2024, 14, 2994. [Google Scholar] [CrossRef]

- Azami, A.; Sevinç, H. The energy performance of building integrated photovoltaics (BIPV) by determination of optimal building envelope. Build. Environ. 2021, 199, 107856. [Google Scholar] [CrossRef]

- Basher, M.K.; Nur-E-Alam, M.; Rahman, M.M.; Alameh, K.; Hinckley, S. Aesthetically appealing building Integrated photovoltaic Systems for Net-Zero energy buildings. Current Status, Challenges, and Future Developments—A Review. Buildings 2023, 13, 863. [Google Scholar] [CrossRef]

- Callegari, G.; Merolla, E.; Simeone, P. Photovoltaic Breakthrough in architecture: Integration and Innovation Best practice. In The Urban Book Series; Springer: Cham, Switzerland, 2023; pp. 321–333. [Google Scholar]

- Lai, C.; Hokoi, S. Solar façades: A review. Build. Environ. 2015, 91, 152–165. [Google Scholar] [CrossRef]

- Ye, Y.; Zhu, R.; Yan, J.; Lu, L.; Wong, M.S.; Luo, W.; Chen, M.; Zhang, F.; You, L.; Wang, Y.; et al. Planning the installation of building-integrated photovoltaic shading devices: A GIS-based spatiotemporal analysis and optimization approach. Renew. Energy 2023, 216, 119084. [Google Scholar] [CrossRef]

- Xiang, C.; Matusiak, B.S. Façade Integrated Photovoltaics design for high-rise buildings with balconies, balancing daylight, aesthetic and energy productivity performance. J. Build. Eng. 2022, 57, 104950. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Perovskite Solar Cells for BIPV Application: A review. Buildings 2020, 10, 129. [Google Scholar] [CrossRef]

- Block, A.B.; Palou, J.E.; Courtant, M.; Virtuani, A.; Cattaneo, G.; Roten, M.; Li, H.; Despeisse, M.; Hessler-Wyser, A.; Desai, U.; et al. Colouring solutions for building integrated photovoltaic modules: A review. Energy Build. 2024, 314, 114253. [Google Scholar] [CrossRef]

- Fagiolari, L.; Varaia, E.; Mariotti, N.; Bonomo, M.; Barolo, C.; Bella, F. Poly(3,4-ethylenedioxythiophene) in Dye-Sensitized solar cells: Toward Solid-State and Platinum-Free photovoltaics. Adv. Sustain. Syst. 2021, 5, 2100025. [Google Scholar] [CrossRef]

- Mohammad, A.K.; Garrod, A.; Ghosh, A. Do Building Integrated Photovoltaic (BIPV) windows propose a promising solution for the transition toward zero energy buildings? A review. J. Build. Eng. 2023, 79, 107950. [Google Scholar] [CrossRef]

- Mirabi, E.; Abarghuie, F.A.; Arazi, R. Integration of buildings with third-generation photovoltaic solar cells: A review. Clean Energy 2021, 5, 505–526. [Google Scholar] [CrossRef]

- Schoden, F.; Schnatmann, A.K.; Blachowicz, T.; Manz-Schumacher, H.; Schwenzfeier-Hellkamp, E. Circular design principles applied on Dye-Sensitized solar cells. Sustainability 2022, 14, 15280. [Google Scholar] [CrossRef]

- Radwan, A.; Katsura, T.; Memon, S.; Serageldin, A.A.; Nakamura, M.; Nagano, K. Thermal and electrical performances of semi-transparent photovoltaic glazing integrated with translucent vacuum insulation panel and vacuum glazing. Energy Convers. Manag. 2020, 215, 112920. [Google Scholar] [CrossRef]

- Rehman, S.U.; Butt, F.K.; Tariq, Z.; Haq, B.U.; Lin, G.; Li, C. Cubic Germanium monochalcogenides (π-GeS and π-GeSe): Emerging materials for optoelectronic and energy harvesting devices. Sol. Energy 2019, 185, 211–221. [Google Scholar] [CrossRef]

- Sánchez-Pantoja, N.; Vidal, R.; Pastor, M.C. Aesthetic perception of photovoltaic integration within new proposals for ecological architecture. Sustain. Cities Soc. 2018, 39, 203–214. [Google Scholar] [CrossRef]

- Sen, A.; Khamaj, A.; Karmakar, S. Design intervention for addressing the safety and health risks of discomfort glare and UV radiation associated with BIPV installation and maintenance. Energy Build. 2024, 318, 114479. [Google Scholar] [CrossRef]

- Chen, T.; An, Y.; Heng, C.K. A review of Building-Integrated Photovoltaics in Singapore: Status, barriers, and Prospects. Sustainability 2022, 14, 10160. [Google Scholar] [CrossRef]

- Rosa, F. Building-Integrated Photovoltaics (BIPV) in Historical buildings: Opportunities and constraints. Energies 2020, 13, 3628. [Google Scholar] [CrossRef]

- Attoye, D.E.; Aoul, K.A.T. A Review of the Significance and Challenges of Building Integrated Photovoltaics. In Energy Efficient Building Design; Dabija, A.M., Ed.; Springer: Cham, Switzerland, 2020; pp. 3–20. [Google Scholar]

- Saretta, E.; Caputo, P.; Frontini, F. A review study about energy renovation of building facades with BIPV in urban environment. Sustain. Cities Soc. 2018, 44, 343–355. [Google Scholar] [CrossRef]

- Karamanis, D.; Liu, H.; Skandalos, N.; Makis, A.; Kapsalis, V.; D’Agostino, D.; Maduta, C.; Tolis, A.; Trandafir, S.; Parker, D. Transitioning to building integration of photovoltaics and greenery (BIPVGREEN): Case studies up-scaling from cities informal settlements. Environ. Res. Infrastruct. Sustain. 2024, 4, 042001. [Google Scholar] [CrossRef]

- Mariotti, N.; Bonomo, M.; Fagiolari, L.; Barbero, N.; Gerbaldi, C.; Bella, F.; Barolo, C. Recent advances in eco-friendly and cost-effective materials towards sustainable dye-sensitized solar cells. Green Chem. 2020, 22, 7168–7218. [Google Scholar] [CrossRef]

- Weerasinghe, R.; Yang, R.; Wakefield, R.; Too, E.; Le, T.; Corkish, R.; Chen, S.; Wang, C. Economic viability of building integrated photovoltaics: A review of forty-five (45) non-domestic buildings in twelve (12) western countries. Renew. Sustain. Energy Rev. 2020, 137, 110622. [Google Scholar] [CrossRef]

- Debbarma, M.; Sudhakar, K.; Baredar, P. Comparison of BIPV and BIPVT: A review. Resour.-Effic. Technol. 2016, 3, 263–271. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Røstvik, H.N. Photovoltaics and zero energy buildings: A new opportunity and challenge for design. Prog. Photovolt. Res. Appl. 2012, 21, 1319–1336. [Google Scholar] [CrossRef]

- Jayathissa, P.; Jansen, M.; Heeren, N.; Nagy, Z.; Schlueter, A. Life cycle assessment of dynamic building integrated photovoltaics. Sol. Energy Mater. Sol. Cells 2016, 156, 75–82. [Google Scholar] [CrossRef]

- Osseweijer, F.J.; Van Den Hurk, L.B.; Teunissen, E.J.; Van Sark, W.G. A comparative review of building integrated photovoltaics ecosystems in selected European countries. Renew. Sustain. Energy Rev. 2018, 90, 1027–1040. [Google Scholar] [CrossRef]

- Boumaiza, A.; Sanfilippo, A.; Mohandes, N. Modeling multi-criteria decision analysis in residential PV adoption. Energy Strategy Rev. 2021, 39, 100789. [Google Scholar] [CrossRef]

- Li, Y.; Mao, Y.; Wang, W.; Wu, N. Net-Zero Energy Consumption Building in China: An Overview of Building-Integrated Photovoltaic Case and Initiative toward Sustainable Future Development. Buildings 2024, 13, 2024. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Residential net-zero energy buildings: Review and perspective. Renew. Sustain. Energy Rev. 2021, 142, 110859. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2015, 16, 39–53. [Google Scholar] [CrossRef]

- Shakeel, S.R.; Yousaf, H.; Irfan, M.; Rajala, A. Solar PV adoption at household level: Insights based on a systematic literature review. Energy Strategy Rev. 2023, 50, 101178. [Google Scholar] [CrossRef]

- Keller, J.; Kiselman, K.; Donzel-Gargand, O.; Martin, N.M.; Babucci, M.; Lundberg, O.; Wallin, E.; Stolt, L.; Edoff, M. High-concentration silver alloying and steep back-contact gallium grading enabling copper indium gallium selenide solar cell with 23.6% efficiency. Nat. Energy 2024, 9, 467–478. [Google Scholar] [CrossRef]

- Wang, W.; Yang, H.; Xiang, C. Green roofs and facades with integrated photovoltaic system for zero energy eco-friendly building–A review. Sustain. Energy Technol. Assess. 2023, 60, 103426. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Deng, W.; Zhu, D.; Hong, L. Building Integrated Photovoltaic (BIPV) Development Knowledge Map: A review of visual analysis using CIteSpace. Buildings 2023, 13, 389. [Google Scholar] [CrossRef]

- Foley, A.; Smyth, B.M.; Pukšec, T.; Markovska, N.; Duić, N. A review of developments in technologies and research that have had a direct measurable impact on sustainability considering the Paris agreement on climate change. Renew. Sustain. Energy Rev. 2016, 68, 835–839. [Google Scholar] [CrossRef]

- Gholami, H.; Røstvik, H.N.; Müller-Eie, D. Holistic economic analysis of building integrated photovoltaics (BIPV) system: Case studies evaluation. Energy Build. 2019, 203, 109461. [Google Scholar] [CrossRef]

- Al-Shatnawi, Z.; Hachem-Vermette, C.; Lacasse, M.; Ziaeemehr, B. Advances in Cold-Climate-Responsive Building Envelope Design: A Comprehensive Review. Buildings 2024, 14, 3486. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Abdelkareem, M.A.; Al-Alami, A.H.; Ramadan, M.; Mushtaha, E.; Wilberforce, T.; Olabi, A.G. State-of-the-Art technologies for Building-Integrated photovoltaic Systems. Buildings 2021, 11, 383. [Google Scholar] [CrossRef]

- Hamzah, A.H.; Go, Y.I. Design and assessment of building integrated PV (BIPV) system towards net zero energy building for tropical climate. E-Prime-Adv. Electr. Eng. Electron. Energy 2023, 3, 100105. [Google Scholar] [CrossRef]

- Yang, R.; Zang, Y.; Yang, J.; Wakefield, R.; Nguyen, K.; Shi, L.; Trigunarsyah, B.; Parolini, F.; Bonomo, P.; Frontini, F.; et al. Fire safety requirements for building integrated photovoltaics (BIPV): A cross-country comparison. Renew. Sustain. Energy Rev. 2022, 173, 113112. [Google Scholar] [CrossRef]

- Ko, Y.; Aram, M.; Zhang, X.; Qi, D. Fire safety of building integrated photovoltaic systems: Critical review for codes and standards. Indoor Built Environ. 2022, 32, 25–43. [Google Scholar] [CrossRef]

- Wang, W.; Xu, K.; Song, S.; Bao, Y.; Xiang, C. From BIM to digital twin in BIPV: A review of current knowledge. Sustain. Energy Technol. Assess. 2024, 67, 103855. [Google Scholar] [CrossRef]

- Del Pero, C.; Aste, N.; Leonforte, F.; Sfolcini, F. Long-term reliability of photovoltaic c-Si modules–A detailed assessment based on the first Italian BIPV project. Sol. Energy 2023, 264, 112074. [Google Scholar] [CrossRef]

- Elhabodi, T.S.; Yang, S.; Parker, J.; Khattak, S.; He, B.; Attia, S. A review on BIPV-induced temperature effects on urban heat islands. Urban Clim. 2023, 50, 101592. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M. A general approach toward building integrated photovoltaic systems and its implementation barriers: A review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H.; Cornaro, C.; Shahverdian, M.H.; Pierro, M.; Moser, D.; Karimi, N.; Doranehgard, M.H.; Li, L.K. Using machine learning in photovoltaics to create smarter and cleaner energy generation systems: A comprehensive review. J. Clean. Prod. 2022, 364, 132701. [Google Scholar] [CrossRef]

- Masood, F.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Saidur, R.; Alam, M.A.; Akhter, J.; Yusuf, M.; Mehmood, M.; Ali, M. A review of recent developments and applications of Compound Parabolic Concentrator-Based Hybrid Solar Photovoltaic/Thermal Collectors. Sustainability 2022, 14, 5529. [Google Scholar] [CrossRef]

- Samykano, M. Hybrid Photovoltaic thermal systems: Present and future feasibilities for industrial and building applications. Buildings 2023, 13, 1950. [Google Scholar] [CrossRef]

- Deo, R.C.; Şahin, M. Forecasting long-term global solar radiation with an ANN algorithm coupled with satellite-derived (MODIS) land surface temperature (LST) for regional locations in Queensland. Renew. Sustain. Energy Rev. 2017, 72, 828–848. [Google Scholar] [CrossRef]

- Sampaio, P.G.V.; González, M.O.A. Photovoltaic solar energy: Conceptual framework. Renew. Sustain. Energy Rev. 2017, 74, 590–601. [Google Scholar] [CrossRef]

- Yin, Q.; Li, A.; Han, C. The Role of Solar Photovoltaic Roofs in Energy-Saving Buildings: Research progress and future development Trends. Buildings 2024, 14, 3091. [Google Scholar] [CrossRef]

- Ding, X.; Cui, Y.; Chen, Z.; Zhang, H. Energy Efficiency in Biophilic Architecture: A systematic literature review and visual analysis using CiteSpace and VOSViewer. Buildings 2024, 14, 3800. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, X.; Yang, J.; Yoon, J.H. Impact of BIPV windows on building energy consumption in street canyons: Model development and validation. Energy Build. 2021, 249, 111207. [Google Scholar] [CrossRef]

- Gassar, A.A.A.; Koo, C.; Kim, T.W.; Cha, S.H. Performance Optimization Studies on Heating, Cooling and Lighting Energy Systems of Buildings during the Design Stage: A Review. Sustainability 2021, 13, 9815. [Google Scholar] [CrossRef]

- Badiei, A.; Akhlaghi, Y.G.; Zhao, X.; Shittu, S.; Xiao, X.; Li, J.; Fan, Y.; Li, G. A chronological review of advances in solar assisted heat pump technology in 21st century. Renew. Sustain. Energy Rev. 2021, 132, 110132. [Google Scholar] [CrossRef]

- Ma, Z.; Lin, W.; Sohel, M.I. Nano-enhanced phase change materials for improved building performance. Renew. Sustain. Energy Rev. 2016, 58, 1256–1268. [Google Scholar] [CrossRef]

- Wong, I.L. A review of daylighting design and implementation in buildings. Renew. Sustain. Energy Rev. 2017, 74, 959–968. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2015, 54, 299–308. [Google Scholar] [CrossRef]

- Toosi, H.A.; Lavagna, M.; Leonforte, F.; Del Pero, C.; Aste, N. Building decarbonization: Assessing the potential of building-integrated photovoltaics and thermal energy storage systems. Energy Rep. 2022, 8, 574–581. [Google Scholar] [CrossRef]

- Beco, R.C. Study of Innovative Building Integrated Photovoltaic (BIPV) Products and Solutions Based on thin Film and C-Si Technologies. Master’s Thesis, Universidade do Porto, Porto, Portugal, 2019. Available online: https://repositorio-aberto.up.pt/handle/10216/119721 (accessed on 10 April 2025).

- Syafiq, A.; Balakrishnan, V.; Ali, M.S.; Dhoble, S.J.; Rahim, N.A.; Omar, A.; Bakar, A.H.A. Application of transparent self-cleaning coating for photovoltaic panel: A review. Curr. Opin. Chem. Eng. 2022, 36, 100801. [Google Scholar] [CrossRef]

- Dainty, A.R.J.; Cheng, M.; Moore, D.R. Competency-Based model for predicting construction project managers’ performance. J. Manag. Eng. 2004, 21, 2–9. [Google Scholar] [CrossRef]

- Chan, I.Y.S.; Leung, M.; Yu, S.S.W. Managing the stress of Hong Kong Expatriate construction professionals in mainland China: Focus group study exploring individual coping strategies and organizational support. J. Constr. Eng. Manag. 2012, 138, 1150–1160. [Google Scholar] [CrossRef]

- Dainty, A.R.J.; Cheng, M.; Moore, D.R. Redefining performance measures for construction project managers: An empirical evaluation. Constr. Manag. Econ. 2003, 21, 209–218. [Google Scholar] [CrossRef]

- Langford, B.E.; Schoenfeld, G.; Izzo, G. Nominal grouping sessions vs focus groups. Qual. Mark. Res. Int. J. 2002, 5, 58–70. [Google Scholar] [CrossRef]

- Pippin, A.M. Survey of Local Government Green Building Incentive Programs for Private Development. Available online: http://digitalcommons.law.uga.edu/cgi/viewcontent.cgi?article=1010&context=landuse (accessed on 10 April 2025).

- KS Individual Standard Details. Available online: https://www.kssn.net/search/stddetail.do?itemNo=K001010100636 (accessed on 10 April 2025).

- Ahn, S.H.; Park, C.M.; Lee, M.S.; Lee, Y.J.; Lee, J.S. Silicon Solar Cell High Efficiency Materials, Technology Trends and Future Forecasts. Bull. Korea Photovolt. Soc. 2015, 1, 15–23. [Google Scholar]

- Export-Import Bank of Korea Overseas Economic Research Institute. Solar Industry Trends in the First Half of 2023; Export-Import Bank of Korea Overseas Economic Research Institute: Seoul, Republic of Korea, 2023. [Google Scholar]

- Ministry of Land Infrastructure and Transport. Apartment Housing Management Act; Ministry of Land Infrastructure and Transport: Sejong, Republic of Korea, 2023.

- Korea Electric Power Corporation. Electricity Bill Unit Price; Korea Electric Power Corporation: Naju, Republic of Korea, 2023. [Google Scholar]

- KMA. Weather Weather Nuri; KMA: Dajeon, Republic of Korea, 2018. [Google Scholar]

- Chantana, J.; Hirai, S.; Inoue, M.; Masuda, T.; Minemoto, T. Flexible CU(IN,GA)SE2 solar cell with superstrate-type configuration fabricated by a lift-off process. Thin Solid Film. 2018, 662, 110–115. [Google Scholar] [CrossRef]

- Park, J.H.; Kwon, M.J.; Lu, F.; Jang, J.S. A Study on the Sustainable Convergence Design Using Idle Area in Apartment - Focusing on the use of Solar Cell-. Korean Soc. Sci. Art 2023, 41, 97–108. [Google Scholar] [CrossRef]

- Andrea, C.; Ralph, M.; Stefan, W.T.; Nico, T.; Patric, S.; Oliver, H.; Benedikt, B.; Albert, P. Nanopatterned Back-Reflector with Engineered Near-Field/Far-Field Light Scattering for Enhanced Light Trapping in Silicon-Based Multijunction Solar Cells. ACS Photonics 2023, 10, 4061–4070. [Google Scholar]

- Leqi, L.; Nuggehalli, M.R. CIGS and Perovskite Solar Cells—An Overview. Emerg. Mater. Res. 2020, 9, 1–19. [Google Scholar]

- Nam, S.; Kim, J.; Lee, D. Current Status of Aged Public Buildings and Effect Analysis Prediction of Green Remodeling in South Korea. Sustainability 2021, 13, 6649. [Google Scholar] [CrossRef]

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sept | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average temperature (°C) | −1.9 | 0.7 | 6.1 | 12.6 | 18.2 | 22.7 | 25.3 | 26.1 | 22.6 | 15 | 7.5 | 0.2 |

| Daylight hours (h) | 169.6 | 170.8 | 198.2 | 206.3 | 223.0 | 189.1 | 123.6 | 156.1 | 179.7 | 206.5 | 157.3 | 162.9 |

| Precipitation (days) | 6.1 | 5.8 | 7 | 8.4 | 8.6 | 9.9 | 16.3 | 14.7 | 9.1 | 6.1 | 8.8 | 7.8 |

| Humidity (%) | 56.2 | 54.6 | 54.6 | 54.8 | 59.7 | 65.7 | 76.2 | 73.5 | 66.4 | 61.8 | 60.4 | 57.8 |

| Amount of snow (days) | 7.1 | 5.1 | 2.8 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 2.3 | 6.4 |

| Heat wave (days) | 0 | 0 | 0 | 0 | 0.1 | 0.7 | 4.1 | 5.9 | 0.2 | 0 | 0 | 0 |

| Fog (days) | 0.7 | 0.9 | 0.9 | 0.9 | 1 | 1.2 | 2 | 0.3 | 0.3 | 0.2 | 1.2 | 0.7 |

| Wind velocity (m/s) | 2.3 | 2.5 | 2.7 | 2.7 | 2.5 | 2.2 | 2.2 | 2.1 | 1.9 | 2.2 | 2.2 | 2.3 |

| Cold wave (days) | 12.8 | 11.6 | 5.9 | 0.7 | 0 | 0 | 0 | 0 | 0 | 1.5 | 8.7 | 13 |

| Old Age of Buildings | Type of House | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|---|

| 20 to less than 30 years | Sum | 799,927 | 803,062 | 825,790 | 794,865 | 791,237 | 835,901 |

| detached house | 146,537 | 148,713 | 147,480 | 137,760 | 123,743 | 107,657 | |

| Apartment | 418,161 | 428,085 | 451,450 | 433,254 | 455,777 | 520,612 | |

| Townhouse | 45,636 | 48,638 | 52,022 | 54,722 | 50,961 | 49,594 | |

| Multiplex housing | 176,350 | 165,121 | 162,107 | 157,406 | 150,483 | 149,293 | |

| Non-residential house | 13,243 | 12,505 | 12,731 | 11,723 | 10,273 | 8745 | |

| More than 30 years | Sum | 373,416 | 416,145 | 428,331 | 508,928 | 551,001 | 588,320 |

| detached house | 155,798 | 152,684 | 147,542 | 150,326 | 157,280 | 165,735 | |

| Apartment | 163,553 | 185,417 | 196,539 | 265,298 | 290,335 | 307,366 | |

| Townhouse | 29,448 | 32,423 | 33,439 | 34,577 | 37,808 | 39,725 | |

| Multiplex housing | 16,119 | 36,789 | 40,897 | 47,785 | 53,508 | 62,198 | |

| Non-residential house | 8498 | 8832 | 9914 | 10,942 | 12,070 | 13,296 |

| Generation | PV Technology | Power Loss After 1 Year | After 5 Years | After 10 Years | (Time to 80% of Initial) |

|---|---|---|---|---|---|

| First | Crystalline silicon | ~2–3% initial light-induced loss, then ~0.5%/year (~3% total) [42] | ~5% (can be <5% with high quality) [42] | ~8–10% (warranted max ~10%) [47] | ~25–30 years (≈200,000 h) to 80% output [47] |

| Second | a-Si | Significant initial LID: ~2–5% in first year [46] | ~7–8% (initial + ~1%/year) [46] | ~12–15% (after 10 years) [46] | ~10–15 years (unassisted) (Can reach 20+ years with multi-junction designs and light-soaking) [46] |

| CIGS | ~0% loss (some light-soaking gain initially) to at most ~1% in first year [45] | ~2–3% (at ~0.5%/year typical) [45] | ~5% (at ~0.5%/year) [45] (many modules ≥95% even at 10 y) | ~25+ years (often >80% even at 25 y) [45] | |

| CdTe | ~1–5% loss in first 1–2 years (e.g., Cu back-contact diffusion causes ~4–7% over 2 years) [45] | ~5–7% (after initial stabilization, ~0.5–0.7%/year) [45] | ~10–12% (median case) [45] (can be lower with improved design) | ~20–25 years (field data shows ≥80% at 20 years) [45] | |

| Third | Perovskite | Rapid decay: often >20% loss in weeks to months (unencapsulated) typically within hundreds of hours [47] | Device usually fails before 5 years (encapsulated lab cells might last ~1–2 years max) | N/A (no sustained performance at 10 y without replacement) | ~0.1–1 year (≈103–104 h in best reports) [36]—far below the >20-year goal [48] |

| Organic (OPV) | Unprotected: >20% loss in <1 year (rapid photo-oxidation) [49] Encapsulated: can achieve <5% loss in 1000 h (~6 weeks) [50] | Unprotected: cell often non-functional by ~2–3 years [49] Encapsulated: projected ~10% or less by 5 years (per extrapolated 30-year data) [50] | Encapsulated prototypes maintain ~80–90% up to 10 years (estimated) [50] | highly variable: a few months for older OPVs, now ~6–8 years (~50,000–70,000 h) extrapolated with state-of-the-art stabilizations [50] |

| Primary Indicator | Secondary Indicator | Meaning | Reference |

|---|---|---|---|

| Aesthetics | A1 Visible Light Transmittance | Transparency and potential for natural lighting are reflected by the percentage of visible light. | [62,63,64,65,66,67,68,69] |

| A2 Color Rendering Index | The degree to which colors are reproduced (relative to a standard light source). | [64,65,69,70,71,72] | |

| A3 Unified Glare Rating | The degree of discomfort caused by direct or reflected sunlight. | [73,74,75,76] | |

| A4 Architectural Aesthetic Integration | The degree to which colors, patterns, and forms harmonize with the architectural design style and meet architectural aesthetic requirements. | [77,78,79] | |

| A5 Color Customizability | The ability to provide a variety of color or hue options without significantly reducing performance. | [80,81] | |

| A6 Visible Defect Rate | The frequency of visible defects (bubbles, cell grid lines, etc.) | [66,78,82] | |

| Economic | E1 Initial Installation Cost | Initial investment cost per unit area (including materials and construction). | [72,83,84,85,86,87] |

| E2 Energy Savings Costs | The annual reduction in building energy costs due to photovoltaic power generation and enhanced thermal insulation. | [86] | |

| E3 Payback Period | The length of time it takes to recoup the initial investment in energy savings. | [62,87,88] | |

| E4 Return on Investment | The percentage of net income generated by an investment relative to its cost over a specific period. | [72,89] | |

| E5 Lifecycle Cost | The total cost over the entire lifecycle minus the revenue from its power generation. | [90,91] | |

| E6 Levelized Cost of Energy | Average cost per kWh of electricity generated, considering lifecycle and total cost. | [81,88,91,92,93,94,95] | |

| E7 Property Value Appreciation | The installation of solar energy brings additional value to the building. | [63,82,90,95,96,97,98,99,100] | |

| Safety | S1 Fire Resistance | Fire resistance and flame retardancy. | [101,102,103] |

| S2 Impact Resistance | Ability to withstand impacts (e.g., hail, debris). | [102,104,105] | |

| S3 Wind Pressure Resistance | Maximum wind pressure that can be safely withstood without structural damage or excessive deflection. | [106] | |

| S4 Electrical Safety | Ability to protect against electrical hazards (e.g., insulation, grounding, arc protection measures). | [71,72,107] | |

| S5 Expected Service Life | Expected service life (in years) while maintaining performance and safety standards. | [79] | |

| S6 Thermal Safety (Prevent Overheating) | Ability to prevent excessive heat build-up within the system (e.g., through ventilation or temperature-controlled circuit breakers) to reduce the risk of fire or overheating. | [63,80,81,82,83,90,96,102,104,105] | |

| Energy Saving | ES1 Photoelectric Conversion Efficiency | The proportion of solar energy converted to electricity under standard conditions. | [64,67,68,70,71,72,83,106,108,109,110,111,112,113,114] |

| ES2 Annual Energy Output | The total amount of electricity generated per year (kilowatt-hours per square meter per year, depending on the local climate). | [63,74,82,84,86,87,88,90,92,93,96,97,100,115,116,117] | |

| ES3 Solar Heat Gain Coefficient | The lower the proportion of incident solar radiation that is used as heat inside the room, the lower the air conditioning load in summer. | [62,73,74,76,101,102,103,117,118,119,120] | |

| ES4 U Value (heat transfer coefficient) | The lower the heat transfer rate (W/m2·K), the better the insulation properties. | [77,79,118,121] | |

| ES5 Anti-glare | The ability to introduce sufficient light while reducing glare, usually achieved by embedding patterns or coloring. | [89,96,99,108,122,123] | |

| Innovation | I1 Intelligent Dimming Control | Integrate intelligent dimming technologies, such as electrochromism and liquid crystal dimming, to adjust transparency as needed. | [70,74,124] |

| I2 Digital Twin Monitoring | Use digital twin technology to monitor the operation of the photovoltaic facade in real time, diagnose faults, and manage optimization. | [72,75,85,124] | |

| I3 Building Energy Pipe System Integration | Integrate with the building energy management system (BEMS) to achieve optimal linkage control of lighting and air conditioning. | [106,125] | |

| I4 Adaptive Ventilation Design | Introduce innovative ventilation structures (ventilated double-skin photovoltaic windows) into the design to enhance heat dissipation and performance. | [110,113] | |

| I5 Lightweight Flexible Components | Lightweight and flexible CIGS modules are used to facilitate installation and reduce structural loads. | [84,97,100] | |

| I6 Perovskite/CIGS Stacking Technology | Cutting-edge tandem cell technology (perovskite on CIGS) is used to improve efficiency and transparency. | [65,66,69,75,78] | |

| I7 Self-cleaning Coating | Hydrophobic/photocatalytic self-cleaning coatings are applied to reduce dust accumulation and maintenance frequency. | [94,125] | |

| I8 Bioaffinity Design Fusion | Biophilic design combining photovoltaic elements with greenery (e.g., photovoltaic-powered vertical green facades) to enhance well-being and innovation. | [68,88,91,92,95,100,103] | |

| I9 Module Customized Design | Flexible customization of photovoltaic module shape/size to suit various window designs (e.g., curved, triangular). | [62,63,64,65,67,69,70,71,72,73,74,77,80,81,82,83,84,90,92,93,96,97,98,99,101,102,106,107,108,109,110,111,114,115,116,118,119,120,121,122,123,124] | |

| I10 Energy Storage Integration | Combination with local battery or supercapacitor energy storage to achieve energy balance and improve energy resilience. | [112] |

| Primary Indicator | Secondary Indicator |

|---|---|

| Aesthetics | A1 Color |

| A2 Brightness | |

| A3 Harmony | |

| Economic | E1 Initial Cost |

| E2 Maintenance Cost | |

| E3 Expected Revenue | |

| Safety | S1 Strength |

| S2 Pressure Resistance | |

| S3 Cracking | |

| Energy Saving | ES1 Energy Saving |

| ES2 Carbon Emissions | |

| ES3 Energy Independence | |

| Innovation | I1 Technological Progress |

| I2 Learning for Progress |

| Index | Color | Brightness | Harmony |

|---|---|---|---|

| Color | 1 | 0.636 | 0.5 |

| Brightness | 1.571 | 1 | 0.5 |

| Harmony | 2 | 2 | 1 |

| Index | Eigenvector | Weight (%) | Maximum Eigenroot | CI Value |

|---|---|---|---|---|

| Color | 0.683 | 21.382 | 3.023 | 0.011 |

| Brightness | 0.923 | 28.901 | ||

| Harmony | 1.587 | 49.717 |

| Maximum Eigenvalue | CI Value | RI Value | CR Value | Consistency Test Results |

|---|---|---|---|---|

| 3.023 | 0.011 | 0.525 | 0.022 | PASS |

| Aesthetic Index | Score Index | Color | Brightness | Harmony |

|---|---|---|---|---|

| Weight Factor (1) | 0.21382 | 0.28901 | 0.49717 | |

| CIGS Solar Cell | Score | 95 | 90 | 92 |

| Weighted Value | 20.3129 | 26.0109 | 45.73964 | |

| Silicon Solar Cell | Score | 88 | 85 | 82 |

| Weighted Value | 18.81616 | 24.56585 | 40.76794 | |

| Window | Score | 93 | 95 | 95 |

| Weighted Value | 19.88526 | 27.45595 | 47.23115 | |

| Exterior | Score | 90 | 90 | 90 |

| Weighted Value | 19.2438 | 26.0109 | 44.7453 |

| Index | Initial Cost | Maintenance Costs | Projected Income |

|---|---|---|---|

| Initial Cost | 1 | 1 | 0.5 |

| Maintenance Costs | 1 | 1 | 0.357 |

| Projected Income | 2 | 2.8 | 1 |

| Index | Eigenvector | Weight (%) | Maximum Eigenroot | CI Value |

|---|---|---|---|---|

| Initial Cost | 0.794 | 24.206 | 3.013 | 0.006 |

| Maintenance Costs | 0.709 | 21.637 | ||

| Projected Income | 1.776 | 54.157 |

| Maximum Eigenvalue | CI Value | RI Value | CR Value | Consistency Test Results |

|---|---|---|---|---|

| 3.013 | 0.006 | 0.525 | 0.012 | PASS |

| Index | Strength | Pressure Resistance | Crack |

|---|---|---|---|

| Strength | 1 | 1.6 | 1.125 |

| Pressure Resistance | 0.625 | 1 | 0.417 |

| Crack | 0.889 | 2.4 | 1 |

| Index | Power Saving | Carbon Emissions | Energy Independence |

|---|---|---|---|

| Power Saving | 1 | 1.4 | 1.5 |

| Carbon Emissions | 0.714 | 1 | 1.286 |

| Energy independence | 0.667 | 0.778 | 1 |

| Index | Eigenvector | Weight (%) | Maximum Eigenroot | CI Value |

|---|---|---|---|---|

| Power Saving | 1.281 | 41.904 | 3.004 | 0.002 |

| Carbon Emissions | 0.972 | 31.807 | ||

| Energy independence | 0.803 | 26.289 |

| Maximum Eigenvalue | CI Value | RI Value | CR Value | Consistency Test Results |

|---|---|---|---|---|

| 3.004 | 0.002 | 0.525 | 0.004 | PASS |

| Energy Saving Index | Score Index | Power Saving | Carbon Emissions | Energy Independence |

|---|---|---|---|---|

| Weight Factor (1) | 0.41904 | 0.31807 | 0.26289 | |

| CIGS Solar Cell | Score | 95 | 95 | 85 |

| Weighted Value | 39.8088 | 30.21665 | 22.34565 | |

| Silicon Solar Cell | Score | 95 | 93 | 80 |

| Weighted Value | 39.8088 | 29.58051 | 21.0312 | |

| Window | Score | 85 | 85 | 80 |

| Weighted Value | 35.6184 | 27.03595 | 21.0312 | |

| Exterior | Score | 70 | 80 | 70 |

| Weighted Value | 29.3328 | 25.4456 | 18.4023 |

| Index | Advancement of Technology | Study for Progress |

|---|---|---|

| Advancement of Technology | 1 | 1.125 |

| Study for Progress | 0.889 | 1 |

| Index | Eigenvector | Weight (%) | Maximum Eigenroot | CI Value |

|---|---|---|---|---|

| Advancement of Technology | 0.4705 | 47.05 | 2 | 0 |

| Study for Progress | 0.5295 | 52.95 |

| Maximum Eigenvalue | CI Value | RI Value | CR Value | Consistency Test Results |

|---|---|---|---|---|

| 2 | 0 | 0 | 0 | PASS |

| Innovation Index | Score Index | Advancement of Technology | Study for Progress |

|---|---|---|---|

| Weight Factor (1) | 0.5295 | 0.4705 | |

| CIGS Solar Cell | Score | 95 | 95 |

| Weighted Value | 50.3025 | 44.6975 | |

| Silicon Solar Cell | Score | 95 | 95 |

| Weighted Value | 50.3025 | 44.6975 | |

| Window | Score | 80 | 85 |

| Weighted Value | 42.36 | 39.9925 | |

| Exterior | Score | 75 | 85 |

| Weighted Value | 39.7125 | 39.9925 |

| Economic Index | Score Index | Initial Cost | Maintenance Costs | Projected Income |

|---|---|---|---|---|

| Weight Factor (1) | 0.24206 | 0.21637 | 0.54157 | |

| CIGS Solar Cell | Score | 68 | 85 | 85 |

| Weighted Value | 16.46008 | 18.39145 | 46.03345 | |

| Silicon Solar Cell | Score | 80 | 82 | 85 |

| Weighted Value | 19.3648 | 17.74234 | 46.03345 | |

| Window | Score | 95 | 95 | 73 |

| Weighted Value | 22.9957 | 20.55515 | 39.53461 | |

| Exterior | Score | 95 | 90 | 70 |

| Weighted Value | 22.9957 | 19.4733 | 37.9099 |

| Index | Eigenvector | Weight (%) | Maximum Eigenroot | CI Value |

|---|---|---|---|---|

| Strength | 1.216 | 38.711 | 3.03 | 0.015 |

| Pressure Resistance | 0.639 | 20.322 | ||

| Crack | 1.287 | 40.967 |

| Maximum Eigenvalue | CI Value | RI Value | CR Value | Consistency Test Results |

|---|---|---|---|---|

| 3.03 | 0.015 | 0.525 | 0.029 | PASS |

| Safety Index | Score Index | Strength | Pressure Resistance | Crack |

|---|---|---|---|---|

| Weight Factor (1) | 0.40 | 0.30 | 0.30 | |

| CIGS Solar Cell | Score | 92 | 92 | 95 |

| Weighted Value | 36.8 | 27.6 | 28.5 | |

| Silicon Solar Cell | Score | 90 | 85 | 80 |

| Weighted Value | 36 | 25.5 | 24 | |

| Window | Score | 95 | 95 | 95 |

| Weighted Value | 38 | 28.5 | 28.5 | |

| Exterior | Score | 90 | 88 | 75 |

| Weighted Value | 36 | 26.4 | 22.5 |

| Key Factors | Aesthetic Index | Economic Index | Safety Index | Energy Saving Index | Innovation Index | Sum | |

|---|---|---|---|---|---|---|---|

| Weight Factor (1) | 0.08182 | 0.28786 | 0.32505 | 0.19258 | 0.11269 | 1.00 | |

| CIGS Solar Cell | Score | 92 | 79 | 93 | 92 | 95 | |

| Weighted Value | 7.52744 | 22.74094 | 30.22965 | 17.71736 | 10.70555 | 88.92094 | |

| Silicon Solar Cell | Score | 85 | 82 | 85 | 89 | 95 | |

| Weighted Value | 6.9547 | 23.60452 | 27.62925 | 17.13962 | 10.70555 | 86.03364 | |

| Window | Score | 94 | 87 | 95 | 83 | 82 | |

| Weighted Value | 7.69108 | 25.04382 | 30.87975 | 15.98414 | 9.24058 | 88.83937 | |

| Exterior | Score | 90 | 85 | 84 | 73 | 80 | |

| Weighted Value | 7.3638 | 24.4681 | 27.3042 | 14.05834 | 9.0152 | 82.20964 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, F.; Kwon, M.; Jang, J. Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings. Buildings 2025, 15, 1633. https://doi.org/10.3390/buildings15101633

Lu F, Kwon M, Jang J. Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings. Buildings. 2025; 15(10):1633. https://doi.org/10.3390/buildings15101633

Chicago/Turabian StyleLu, Fan, Mijeong Kwon, and Jungsik Jang. 2025. "Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings" Buildings 15, no. 10: 1633. https://doi.org/10.3390/buildings15101633

APA StyleLu, F., Kwon, M., & Jang, J. (2025). Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings. Buildings, 15(10), 1633. https://doi.org/10.3390/buildings15101633