Abstract

Prefabricated construction is an effective method for reducing project time and waste and improving quality and safety compared to traditional construction. However, its widespread adoption faces risks and challenges, having detrimental impacts on project performance. This research aims to assess prefabricated construction risks in Iraq using fuzzy synthetic evaluation (FSE). After determining the mean importance score for the likelihood and impact of risks extracted from comprehensive theoretical reviews, significant risks were selected using normalization, followed by FSE. The theoretical review results yielded 79 risks across 11 categories. After normalization, 34 significant risks across 10 categories were identified. The results showed that all risk categories had a medium probability and impact, except for investment and political risks, while experience risks had a high probability and high impact, respectively. FSE results showed that the highest risk importance index was for experience (12.075), followed by political (11.753), capital investment (11.362), safety (11.242), and design risks (10.902). Through its detailed and integrated methodology, the study contributes to formulating an accurate roadmap for FSE of prefabricated construction risks and provides accurate results that add a deeper understanding of risks, helping project managers identify significant risks and formulate the necessary policies to mitigate and control them.

1. Introduction

Construction projects are considered among the largest within industrial sectors due to the invested currency and resources that are used []. Prefabricated construction is an efficient construction method in which prefabricated components can be manufactured in a controlled environment and quickly assembled on-site []. Compared with traditional construction methods in the engineering and construction industry, prefabricated construction has many benefits, including reduced project completion time [,], improved quality and strength [,,], reduced material waste [,], higher seismic load resistance [], enhanced sustainability and cleaner production [,,], reduced environmental impacts [], a safer working environment [], workflow continuity [], reduced carbon emissions [,], reduced number of contractors on-site, and improved worker safety [,].

Some or even all of the components of prefabricated buildings are formed in prefabricated factories and then transported to the construction site for lifting operations, which improves the clutter of traditional construction sites, but also increases the number of lifting operations []. Since most of the work carried out on-site is performed off-site, it can improve the shortcomings of the construction industry and take advantage of the benefits of the off-site construction industry [].

Off-site construction (80–85% of the work) [] can be classified into four types: sub-assembly of components, non-volumetric pre-assembly, volumetric pre-assembly, and modular construction [,]. The remaining tasks such as excavation, foundation laying, and module installation are performed on-site []. The extensive off-site work of modular construction leads to significantly reduced construction time and reduced risks, injuries, and fatalities compared to conventional construction [].

Research has proven that it is an environmentally friendly and cleaner approach []. It is a sustainable construction method that leads to sustainable market growth []. There is also an opportunity to reduce safety incidents because it is not deeply affected by external environmental factors, such as rainfall and wind. Workers can become familiar with the work and workspace as a result of repetitive tasks in manufacturing plants []. Additionally, fewer workers are required with a reduced amount of on-site work []. A study found that the implementation of modular construction resulted in fewer work interruptions and less pollution and other noise-related features compared to conventional construction []. Ref. [] showed that the increased use of modular construction resulted in a significant reduction in construction waste. Traditional construction methods primarily lead to various types of pollution which subsequently lead to negative consequences, one of which is climate change []. Therefore, adopting modular construction can solve the ever-growing issue of environmental sustainability [].

Ref. [] focused on the performance evaluation of modular buildings in Australia and highlighted that a 25% reduction in labor costs and a 40% reduction in construction time is achieved for modular construction compared to conventional construction. Modular construction also promises a pleasant working environment for construction workers [].

Modular construction has recently received increasing attention due to its relative advantages and well-documented benefits compared to conventional construction, leading to its increased adoption in many countries []. Modular construction is widely accepted as an efficient construction method, especially in developed countries, for residential building construction []. Other less developed countries can also use it as a sustainable alternative to conventional construction [].

Despite the advantages of prefabricated construction, some challenges hinder its widespread adoption []. The widespread adoption and implementation of modular construction is a complex process associated with multiple risks and uncertainties []. Developed countries have extensive experience in dealing with modular construction risks, while developing countries lack sufficient expertise in this field. The novelty of modular construction, insufficient skilled workforce, and lack of experience pose a potential risk to its implementation []. For less developed countries, modular construction is an innovative construction method with unique scale, steps, and interfaces []. These unique characteristics are associated with various complexities that lead to potential risks and thus pose new challenges for decision-makers [].

Prefabricated construction risks have detrimental effects on project performance, quality, productivity, schedules and safety. Therefore, assessing its potential risks can mitigate their negative impacts on construction projects [].

The application of general construction risk management to modular construction is limited because the activities involved are different from those in general construction []. Modular construction is a custom-made product, and therefore any shortages cannot be compensated by other manufacturers []. In addition, transporting modular components to the site requires special transportation vehicles and cranes for assembly. Restrictions on the size and weight of modular components impose constraints on the delivery of components to the construction site []. From an economic perspective, uncertainty in demand and the high initial capital cost of implementing modular construction lead to the risk of delays in achieving the return on initial investment [].

1.1. Literature Review

Ref. [] modeled the main risks and identified poor logistics, delays resulting from design changes, inefficient scheduling, contractual risks, and limited labor as the main risks affecting the time and cost of modular construction. Ref. [] identified construction costs, limited storage capacity, and end-user preferences as the main risk factors for implementing modular construction. Ref. [] assessed the significance of potential design risk factors by reviewing international empirical experts from 18 countries. The analysis results showed that the five most significant design risk factors include design inadequacy; late involvement of suppliers, manufacturers, and contractors; inaccurate information, defective design, and change orders; design information gap between the designer and manufacturer; and a lack of dedicated design codes and guidelines. The Fuzzy Analytical Hierarchy Process (AHP) and simulation techniques were used to assess and rank risks by a focused group of experts from the modular construction industry []. Dynamic risk models were created in China, combining safety risks collected from the theoretical literature and through a questionnaire. The model was combined with structural equation modeling (SEM). The results showed that pre-, during-, and post-construction processes significantly impact quality risks []. Ref. [] used an improved Gray-TOPSIS (GRA-TOPSIS) comprehensive risk assessment model. Ref. [] developed an improved IM-Fuzzy Cognitive Map (IM-FCM) model to assess the safety risks of prefabricated construction. Ref. [] identified 25 major safety risks in prefabricated construction and their technical safety specifications across the stages of production, entry, transportation, storage, lifting, and installation of prefabricated components. Data were collected through surveys, and the main risk factors were examined using a structural equation model (SEM). Ref. [] created a safety risk assessment model for prefabricated building lifting based on the structural entropy weight credibility measurement theory. Ref. [] evaluated the incidence of safety-related accidents in modular construction that occurred in the United States from 2000 to 2018 and analyzed the risk factors by developing a causal map and conducting a comparative analysis of the types and causes of accidents occurring in conventional and modular construction. Ref. [] proposed a framework to identify and assess the risks affecting modular construction implementation in Pakistan using Fuzzy Delphi. Critical risk factors were prioritized using the new Full Consistency Computation (FUCOM) method. The results showed that the three most important risks in modular construction implementation in Pakistan were “insufficient experience and skills in modular construction”, “insufficient capacity of modular construction manufacturers”, and “insufficient capacity to make design changes during the construction phase”.

1.2. Research Gaps

Although numerous studies have addressed risks in prefabricated construction, there is still a lack of comprehensive assessment frameworks that comprehensively examine a wide range of risks beyond design and safety aspects. Furthermore, most existing research focuses on developed countries, with limited attention paid to developing countries such as Iraq, where prefabricated construction is still in its infancy. Iraq faces challenges in construction projects, such as persistent cost overruns, delays, and declining quality []. Furthermore, due to the unique nature of prefabricated construction, risk management approaches used in traditional construction are not always applicable. Therefore, there is a need for context-specific, integrated, and data-driven approaches that can monitor and analyze prefabricated construction risks in developing countries.

1.3. Study Objectives

This study aims to fill the identified gaps by pursuing the following objectives:

- Conduct a comprehensive identification and classification of risks associated with prefabricated construction in developing countries, with a focus on Iraq as a case study.

- Assess and classify the significance of these risks using an integrated and objective systematic approach based on fuzzy logic.

- Develop a risk assessment framework adapted to the unique characteristics and challenges of modular construction in resource-constrained environments.

- Support decision-makers and practitioners in designing appropriate risk mitigation and control strategies tailored to the prefabricated construction sector.

2. Materials and Methods

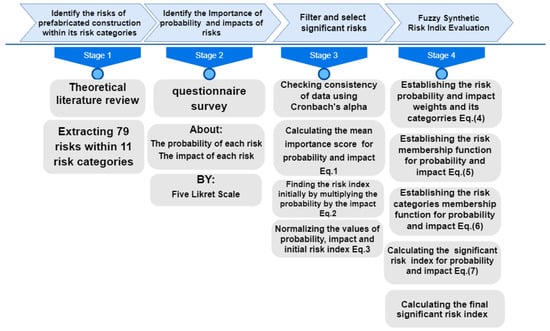

Figure 1 shows the research methodology as follows:

Figure 1.

The research methodology.

2.1. Comprehensive Review of Theoretical Literature

The review included the theoretical literature related to all types of prefabricated building risks.

2.2. Exploratory Survey

An exploratory survey was conducted to assess the probability score and impact score of each risk identified from the theoretical review. A five-point Likert scale was used to collect expert evaluations. The questionnaire was developed after an extensive review of the literature on prefabricated building risks.

Questionnaire Development

The questionnaire includes the following:

- Personal information of respondents: Table 1 shows the personal information of respondents. The questionnaire was distributed in most Iraqi governorates and across various engineering disciplines related to prefabricated building. Due to time constraints, 36 responses were accepted. The sample represents the northern, central, and south regions of Iraq, so the sample can be considered representative of all regions of Iraq based on the similar limited use of prefabricated buildings due to risks.

Table 1. The personal information of the respondents.

Table 1. The personal information of the respondents.

The personal information of respondents includes the following:

- Place of work: Most of the respondents (41.9%) are from the Salah al-Din Governorate, followed by 35.5% from the Nineveh Governorate, 9.7% from Kirkuk, and 3.2% from Dohuk. This means that most of the respondents are from the governorates of northern Iraq, where 6.5% are from Baghdad (central Iraq) and 3.2% are from Diwani (south).

- Academic qualification: In total, 54.8% of respondents hold a bachelor’s degree, 22.6% hold a master’s degree, 19.4% hold a doctorate, and the lowest percentage holds a higher diploma (3.2%).

- The roles of respondents in the prefabricated construction process: Supervising engineers, 29%, and site engineers, 25.8%, represent the highest percentages of respondents, followed by 12.9% for design engineers, 9.7% for both academics and contractors, respectively, and 6.5%, the lowest percentage, for both project managers and consultants.

- Specialization: Most of the respondents, 83.9%, are civil, followed by 9.7% architectural, and 6.5% mechanical.

- Years of experience: Most of the respondents, 41.9%, have 11 or more years of experience, 38.7% have 6–10 years, and 19.4% of the respondents have 1–5, the fewest years of experience.

- Work sector: Most of the respondents, 80.6%, work in the government sector in infrastructure projects and service and on educational buildings, and 19.4% work in private sector projects.

- 2.

- Evaluation of the probability score and impact score of each risk: The questionnaire included an assessment of all prefabricated building risk categories extracted from the theoretical review and grouped them into 11 risk categories.

2.3. Questionnaire Analysis

Questionnaire analysis using the SPSS program included the following:

- Assess the internal consistency of the data by obtaining Cronbach’s alpha coefficient using SPSS version 26.

- Calculate the mean importance scores for both the probability score and the impact score using Equation (1), as referenced in [,]:

MS = (∑SF)/(∑F)

2.4. Calculate the Risk Assessment Index Initially

Find the initial risk assessment (RA) index using Equation (2) [,]:

where P is the probability score, and I is the impact.

RA = P × I

In this study, the term “Probability Score” refers to expert-assigned values on the Likert scale from 1 to 5, representing a qualitative judgment of risk likelihood, rather than mathematical probability.

2.5. Perform Normalization

Perform normalization of the probability, impact, and initial risk index scores using Equation (3) [,,]. The goal of normalization is to extract the important risks according to normalization:

where Xi(k) is the value of Yi(k) after normalization, and max Yi(k) and min Yi(k) are the smallest and largest values of Yi(k).

2.6. Perform the Fuzzy Synthetic Evaluation

Fuzzy synthetic evaluation (FSE), a branch of fuzzy set theory, has been widely developed and applied in various disciplines to measure multiple evaluations. It is an analytical tool that objectively addresses the subjective judgment inherent in human decision-making []. FSE can provide a synthetic evaluation of an object related to many criteria in a fuzzy decision-making environment []. It is worth noting that FSE has been adopted in many fields, such as environmental analysis, human resource management, and risk assessment (RA). FSE has been applied to analyze the risks of sustainable projects in Singapore []. FSE has been used to evaluate the resource management efficiency of contractors in subway projects in China []. According to previous studies, FSE has advantages in dealing with complex evaluations with multiple characteristics and levels [,]. Therefore, this method was chosen to assess the risks of prefabricated construction in Iraq. Fuzzy synthetic evaluation (FSE) has seen a significant increase in its adoption in multi-criteria decision-making (MCDM) contexts due to its ability to handle ambiguity and imprecise linguistic data. Recent studies demonstrate that this method offers several advantages over traditional techniques such as the Analytic Hierarchy Method (AHP) and DEMATEL, particularly in highly uncertain environments. One of the most notable features of FSE is its ability to address the subjectivity and uncertainty associated with individual evaluations. Unlike some other methodologies that rely heavily on pairwise comparisons or expert-based weighting, FSE can assign weights automatically or rely on objective and consistent scoring rules, thus reducing human bias [,]. FSE also effectively addresses ambiguity arising from human perception by using fuzzy logic, which incorporates qualitative values into the scoring process. This is reflected in its ability to convert inaccurate human responses into fuzzy quantitative scoring. This approach is more suitable for situations where accurate or standardized assessments from participants are difficult to obtain [,]. Furthermore, FSE enables the manipulation of correlations between different criteria within the scoring process by using fuzzy fitting coefficients that account for interrelationships between indicators [,]. This distinguishes it from traditional methods that typically require combining multiple methodologies to address these correlations, which can increase computational complexity. In contrast, FSE simplifies the evaluation process by eliminating complex hierarchical structures and relying on direct integration between criteria and assessment scores [].

Based on the above, it can be argued that FSE represents a flexible and effective methodological framework for conducting multi-criteria evaluations in environments characterized by ambiguity and uncertainty, which explains its increasing reliance in applied research and contemporary professional practice.

Fuzzy synthetic evaluation (FSE) was performed to determine the importance levels of both the probability score and impact score for the significant risks identified in the previous step. The objective of this process is to derive the importance index for probability score I prob. and the importance index for impact score Iimp. using the FSE method, as detailed in the following steps [,]:

- Establish weights for risks and risk categories using Equation (4) [,]:

- 2.

- Membership function establishment: (evaluation matrix): Membership function matrices are established for risks and risk categories. The membership matrix is an assessment of the degree of representation (membership) of a risk within a fuzzy set and its values range from zero to 1 [,].

In this research, the membership function for risks and risk categories is calculated based on experts’ assessment of the probability score once and impact another time according to the five-point Likert scale, using Equation (5) [,], noting that the sign + in the equation does not mean addition.

where MFR is the membership function for each risk 0 ≤ MFR ≤ 1; ∑ MFR = 1

Xr: percentage of each risk assessed by the respondent according to the scale used (five-point scale). (g1 = 1, g2 = 2, g3 = 3, g4 = 4, and g5 = 5.)

- 3.

- Establishing the membership function for the risk categories: the membership function for the categories is established using Equation (6):

D = Wi × R

- 4.

- Creating the importance index for risk categories:

The importance index is calculated for each risk category (calculating the importance index for the probability score of the risk Iprob. and the importance index for the impact of the risk Iimp.) using Equation (7).

2.7. Find the Final Risk Index

Find the final risk index by multiplying the probability index by the impact index.

3. Results and Discussion

3.1. The Results of the Theoretical Review

Table 2 represents the risks of prefabricated construction according to their categories and references, which includes capital investment, political, material, equipment, safety, spatial mismanagement, workplace and environment, design, supply chain, administrative, poor scheduling, and experience risks.

Table 2.

The risks of prefabricated construction according to their categories and references.

3.2. Results of Data Consistency

Cronbach’s alpha was used to measure the internal consistency of questionnaire items. It is the most common and widely used test in studies that aims to assess the homogeneity of items in measuring the same dimension or concept. Table 3 shows that the value of the Cronbach coefficient for prefabricated building risks is (0.905) using the SPSS v.26 program analysis, which means that the consistency and reliability of the data are excellent [,]. According to [], the use of alpha is appropriate and sufficient if the scale is designed to measure one or more specific dimensions, without the need for additional reliability tests such as test–retest or inter-rater reliability, which are used in research contexts different from the nature of this study. Therefore, relying solely on Cronbach’s alpha serves the statistical and methodological purpose in this context [].

Table 3.

Cronbach coefficient.

3.3. Results of Mean Importance Scores for Probability, Impact, and Risk Index

Based on the analysis conducted using SPSS version 26, the mean importance scores for the probability score and the impact score of each risk within each category were calculated. Subsequently, the initial risk index mean score was derived using Equation (2). The levels of the mean importance scores for the probability, impact, and risk index were classified according to Table 4. Table 5 presents the detailed mean importance scores for the probability score, impact score, and initial risk index for each identified risk within its corresponding category.

Table 4.

The levels of mean importance scores for probability, impact, and risk index.

Table 5.

The mean importance scores for probability, impact, and risk index for each risk within each category.

- Capital investment risks: The mean probability score of all investment risks is medium except for the risk of economic conditions, which has a high mean probability score. The mean impact score of all risks is medium, and the mean risk index score of all investment risks is low except for the risk of economic conditions, which is medium.

- Political risks: The mean probability score for political risks is generally medium except for P4 (poor government support and regulations), which has a high score. Similarly, the mean impact score is medium overall, except for P4 (poor government support and regulations) and P5 (unsupportive planning and building regulations), which have high impact scores. Therefore, the mean risk index is medium, except for P1 (changing government policies), P2 (changing political support due to change in the political environment), and P3 (labor strike), which have low risk index scores.

- Material and equipment risk: The mean probability score and mean impact score of material and equipment risk are generally medium. However, specific risks such as M6 (crane failure), M9 (technological inefficiency), and M11 (improper use of equipment) show deviations from this trend. Consequently, the mean risk index is low for most of these risks, except for M6, M7 (part obsolescence as a result of long-term operation of equipment), M8 (materials/components, defective structure and crane, and defective equipment), M9, and M10 (improper use of equipment), which have medium risk index scores.

- Safety Risk: The mean probability score for safety risks is generally medium, except for S8 (no occupational training and safety for workers), S13 (no regular security checks and fixes), and S14 (safety measures not applied), which have high mean probability scores. The mean impact score for safety risks is also medium overall, except for S4 (no hazard indicator for the equipment), S6 (no security check at the time of admission), S11 (not wearing personal protective equipment), S12 (defective personal protective equipment), S13, and S14, which are rated with high impact scores. Consequently, the mean risk index for most safety risks is medium, except for S1 (poor fall prevention), S3 (safety device for crane when not in operation), S5 (overloading lifting), and S7 (low security awareness), which have low risk index scores.

- Risks of spatial mismanagement: The mean probability score and mean impact score of spatial mismanagement risks are generally medium, except for the high mean impact of T5 (crowded work areas). Therefore, the mean risk index is low, except for T5.

- Workplace and environment risks: The mean probability score and mean impact score of workplace and environment risks are medium. Therefore, the mean risk index is low except for E2 (lighting and bad ventilation), which has a medium index score.

- Design Risks: The mean probability score and mean impact score of design risks are generally medium, except for D3 (the inability to make changes in the design), which has a high mean probability score. Therefore, the mean risk index is medium, except for D1 (lack of appropriate codes and design standards for prefabricated construction), D2 (complicated design of prefabricated buildings), which have low risk index scores.

- Supply chain risks: The mean probability score and mean impact score of supply chain risks are medium, so the mean risk index is low, except for U2 (complex supply chain), U4 (delays in delivering modular components to the site), and U5 (supply chain information gap and inconsistency), which have low risk index scores.

- Administrative risks: The mean probability score of administrative risks is medium except for R7 (deficiency of professional managers on site), which has a high mean probability score. The mean impact score of administrative risks is also medium, except for R2 (poor cooperation and communication between project participants), R3 (stakeholder fragmentation and management complexity), R4 (lack of best management practices), and R7, which have high impact scores. Therefore, the mean risk index for all administrative risks is medium.

- Poor scheduling risks: The mean probability score and mean impact score of poor scheduling risks are medium, so the initial mean risk index is low.

- Experience risk: The mean probability score for experience risk is medium, except for K2 (contractors’ lack of experience in prefabricated construction), which has a high mean probability score. The mean impact score for experience risk is high, except for K1 (insufficient skills and experience in prefabricated construction), which has a medium impact score. Therefore, the mean risk index for experience risk is medium.

- Summary of mean scores for probability, impact, and risk index:

Table 6 presents a summary of the mean probability, impact, and initial risk index scores for each risk category. It also highlights individual risks whose scores deviate significantly from their respective category means.

Table 6.

Summary of mean scores for probability, impact, and initial risk index.

3.4. Result of Risk Filtering

Risks were filtered according to their importance based on normalization, where risks with a normalization value greater than or equal to 0.5 were taken into consideration [,]. Then, fuzzy synthetic evaluation analyses were conducted on them, and the risks with a normalization of less than 0.5 were considered to be of little importance and were not included in the rest of the analysis. Table 7 shows the normalization results. According to the mean probability score of risks, the filtering included selecting 41 risks, while the normalization of risks according to the mean impact score included filtering the selection of 55 risks, and normalization according to the initial risk index score included filtering 34 risks. Since most of the risks had a medium importance level according to the Likert scale, the important risks were selected according to the risk index to include thirty-four risks (two political risks, three experience risks, seven administrative risks, ten safety risks, six material and equipment risks, three supply chain risks, one design risk, one investment risk, and one spatial mismanagement risk). In order for each category to have at least two risks, the highest risk was added to each of the categories of investment risks, design risks, and spatial mismanagement risks, and the highest two risks were added to the risks of the workplace and environment, so that the number of important risks that were selected became thirty-nine risks. The risks of poor scheduling were neglected because their risk index was low.

Table 7.

The normalization N.

3.5. Results of Fuzzy Synthetic Evaluation

Results of establishing weights for significant risk and risk categories. Table 8 presents the calculation of appropriate weights for the probability scores and impact scores of each risk and each risk category.

Table 8.

The calculation of appropriate weights.

3.5.1. Membership Function Calculation

The membership function for risks was calculated before calculating the membership function for categories based on the respondents’ assessment of the importance of each risk according to the five-point Likert scale. For example, for risk I6, from the questionnaire results, it was shown that 3.2% of respondents rated the probability score of risk I6 (high cost price) as very high, 22.6% rated the weights for the probability scores of its occurrence as high, 51.6% rated the weights for the probability scores of its occurrence as medium, and 22.6% rated the weights for the probability scores of its occurrence as low. The membership function for I6 can be calculated using Equation (3):

The membership function for I6 can be written as (0.00, 0.226, 0.516, 0.226, and 0.032) [], in the same way the membership function for the residual risk is calculated, as shown in Table 9.

Table 9.

The membership matrix for the probability score.

3.5.2. Membership Function (Evaluation Matrix) for Risks Categories

After finding the membership function for the risks under each category, the membership function for the risk category is found using Equation (6). To find the evaluation matrix for the probability score of the capital investment risk category (I), the fuzzy evaluation matrix R for capital investment risks is as follows:

The corresponding weight vector W for the two risk factors the following:

The fuzzy synthetic evaluation vector DI is calculated as follows:

This results in

Table 9 shows the details of the membership matrix calculations for the probability score of the occurrence of risks and risk categories, and Table 10 shows the results of the membership matrix for the impact of the occurrence of risks and risk categories.

Table 10.

Calculation of the importance index for probability score Iprob. and impact score Iimp. for each risk category.

3.5.3. Importance Index for Risk Categories

The risk probability score index Iprob. and risk impact index were calculated for each category as follows:

- Importance index of the probability score and impact score Iimp.:

Table 10 presents a detailed calculation of the importance index of each risk category for the probability score Iprob. and the impact score Iimp. using Equation (7). To calculate the importance index for the probability score of capital investment risks, Equation (7) is applied:

- 2.

- Risk Importance Index: Table 11 shows the risk importance index according to the categories, based on the multiplication of the importance probability score index and the importance impact score index. The importance probability score index and importance impact score are medium for all risks, and the importance index is medium for all risks except for material and equipment risks, administrative risks, and workplace and environment risks. It is clear that the highest risk probability score index is for political risks, followed by safety risks and experience risks, respectively. The highest impact score index is for experience risks, followed by political risks and capital investment risks. Therefore, the highest risk index is for experience risks, followed by political risks and capital risks. Material and equipment risks, administrative risks, and workplace and environment risks share the lowest ranking for each of the probability, impact, and risk index scores, respectively.

Table 11. The risk importance indices according to the categories.

Table 11. The risk importance indices according to the categories.

4. Discussion

This study gives a detailed overview of the risk environment surrounding prefabricated construction in Iraq—a country where this method remains underutilized despite its globally recognized advantages. The findings illustrate the complex and multifaceted nature of risks that hinder the widespread adoption of this construction approach.

4.1. Interpreting the Findings in the Iraqi Context

The results showed that all risk categories have medium importance using FSE, with experience risks leading the way (12.075), followed by political risks (11.753), capital investment risks (11.362), safety risks (11.242), and design risks (10.902).

The results showed that the highest important risks (probability score, impact, and risk index) are P4 (poor government support and regulations), K2 (contractors’ lack of experience in prefabricated construction), R7 (deficiency of professional managers on site), S11 (not wearing personal protective equipment), S14 (safety measures not applied), and I7 (increase in cost price). Experience-related risks (12.075), particularly contractors’ lack of experience in prefabricated construction, emerged as the most significant. This outcome aligns with broader limitations in Iraq’s vocational education and training systems, where hands-on instruction in modern construction practices remains inadequate. Political risks (11.753)—driven by poor government support and regulations —reflect broader institutional fragility and a lack of strategic policymaking, which commonly characterizes Iraq’s public infrastructure development. Capital investment and safety-related risks also ranked highly, emphasizing the difficulty of obtaining financing for technologically advanced solutions like prefabrication, increases in cost price, and workers not wearing personal protective equipment, as well as S14 (safety measures not applied). Additionally, design-related risks—the inability to make changes in the design (stopping the design and wrong specifications) during the construction phase—were identified as impediments to effective implementation.

The results of the current study showed that material and machinery risks (7.84), administrative risks (9.429), and workplace and environment risks (9.913) are of little significance, given that prefabricated construction in Iraq is still in its early stages. This finding likely reflects the relatively early stage of prefabricated construction in Iraq, where widespread adoption has not yet revealed deeper logistical and managerial challenges often seen in more developed markets.

4.2. Practical Recommendations for Managing the Most Serious Risks

In light of the most critical risks identified, the following practical strategies are recommended:

- Enhancing expertise and training: Establish specialized training initiatives targeting contractors, engineers, and construction workers to enhance competencies in prefabrication, collaborate with academic institutions and technical colleges to integrate prefabrication methodologies into engineering curricula, and promote knowledge-sharing platforms to facilitate the dissemination of best practices among industry professionals.

- Strengthening the governmental role: Develop a comprehensive and supportive policy framework that includes updated building codes, simplified approval processes, and dedicated public investment mechanisms to encourage prefabrication adoption.

- Financial facilitation: Establish public–private partnerships offering low-interest loans and tax incentives to reduce the financial burden of adopting prefabricated technologies.

- Safety regulation enforcement: Enforce stringent occupational safety protocols, conduct routine inspections, and provide incentives to firms that demonstrate high compliance with PPE usage and safety training.

- Improving supply chain management: Encourage local manufacturing of prefabricated components to reduce reliance on imported materials, integrate digital supply chain tracking systems to improve logistics and mitigate delivery disruptions, and establish strategic partnerships with logistics service providers to enhance transportation efficiency and reduce supply chain vulnerabilities.

- Promoting knowledge transfer: Create a centralized digital platform to disseminate best practices, case studies, and innovative applications of prefabricated construction from both local and international contexts.

4.3. Comparison with Previous Research in Similar Contexts

The results are broadly consistent with findings from other developing countries facing similar socioeconomic conditions. The results of the study are consistent with [,], which indicated that the lack of professional expertise and specialization is a major obstacle to adopting prefabricated construction in developing nations like Nepal and Pakistan. They also roughly agreed with [] in that the most significant risk is the delay in achieving the return on initial investment. The results of this study differ from those of [], which emphasized the weaknesses of logistics services, delays caused by design changes, and inadequate scheduling. However, both studies agree on the limited number of experienced workers as a significant risk. Additionally, the findings differ significantly from [], where the most critical risks identified were construction costs, storage capacity, and end-user preferences in developed countries (such as England). In Iraq, these risks appear less prominent, likely due to the smaller scale of ongoing modular construction efforts. Overall, while the exact prioritization of risks may differ by region, a consistent trend emerges in developing countries: challenges related to workforce skills, policy development, and capital access remain prevalent. This underlines the necessity for localized risk management frameworks and opportunities for cross-national knowledge exchange.

5. Conclusions

The main conclusions, based on the discussion and analysis conducted during this study, are as follows:

- The main risks to prefabricated construction in Iraq: The research identified a list of major risks hindering prefabricated construction in Iraq, most notably the lack of experienced contractors, weak government support systems, and financial risks associated with initial investment. This demonstrates the failure of developing countries to adopt advanced construction technologies.

- The importance of increasing expertise and training human resources: The skills and experience gap in prefabricated construction is the most significant factor hindering the use of this technology in Iraq.

- Strengthening government support and regulatory frameworks: The Iraqi government plays a crucial role in supporting the adoption of prefabricated construction by establishing clear and supportive regulatory policies. Incentives such as tax exemptions and low-interest loans can encourage investment in this sector. In addition, maintaining a stable political environment will further promote the sustainability and growth of this construction method.

- Enhancing occupational health and safety standards: Occupational safety regulations at prefabricated construction sites should be strengthened, particularly with regard to the mandatory use of protective equipment and strict adherence to preventive safety protocols. Improving safety practices will enhance both worker and investor confidence, while also minimizing accidents during the implementation phase.

- Improving financial risk management: To avoid concerns about initial investment expenditures, the government could prioritize the formulation of flexible and supportive financing arrangements for projects involving prefabricated construction, in the form of subsidized loan programs or grants that help companies overcome financial obstacles in the early implementation phase.

- Supply chain innovation: Although risks in materials and equipment are of minor importance in this research, it is also necessary to strengthen the supply chain for prefabricated components by promoting local production and digital tools to monitor materials and streamline delivery processes.

- Investing in modernizing production plants: Companies should invest in upgrading production plants and adopting automation and robotics technologies to enhance manufacturing accuracy and the quality of prefabricated components. Building Information Modeling (BIM) technology should also be used to enhance stakeholder coordination and project risk management. Based on these findings, it is essential to emphasize the need for Iraq to implement comprehensive approaches to facilitate and encourage prefabricated construction in infrastructure projects. Coordination between the private and public sectors, as well as the design of encouraging policies, will ensure this required technological change.

5.1. Limitations of the Study

Although this study provided comprehensive insights into the risks of prefabricated construction in Iraq, there are some limitations that should be taken into consideration:

- Limited data: Data were collected from a specific group of participants in the Iraqi construction sector, which may affect the generalizability of the results to all sectors or other regions in the country.

- Changing economic and political environment: Since the study relied on current data, the results may be subject to change over time due to political and economic shifts that may affect the sector. Future developments may lead to changes in risk assessment.

5.2. Suggestion for Future Research

There are several suggestions for future research in this area:

- Studying economic and environmental impacts: Studying the impact of prefabricated construction technologies on energy consumption and carbon emissions could provide important insights that support the shift towards greater sustainability in the construction sector.

- Evaluating the impact of government policies: Studies should be conducted on the impact of various government policies on the adoption of prefabricated construction in Iraq. Examining the experiences of other countries can provide valuable lessons for adapting local policies to the Iraqi context.

- Analysis of consumer behavior and end-user preferences: Studying consumer and end-user attitudes toward prefabricated construction projects in Iraq and understanding how these preferences affect the success of these projects can help improve marketing and design strategies.

- Using information technology to improve supply chains: Research on how modern technologies such as artificial intelligence and the Internet of Things (IoT) can be used to improve supply chain operations in prefabricated construction projects can be developed. This technology can contribute to reducing costs and improving efficiency.

- Evaluating the effectiveness of vocational training programs in capacity building: In-depth study should be conducted on the effectiveness of vocational training programs for prefabricated construction in Iraq to determine whether these programs actually contribute to improving skills and reduce the risks associated with a lack of experience.

Author Contributions

Conceptualization, M.A.M.; Methodology, M.A.M.; Software, M.A.M.; Validation, S.S.F.; Formal analysis, M.A.M.; Investigation, M.A.M.; Resources, M.A.M.; Data curation, S.S.F.; Writing—review & editing, S.S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BIM | Building Information Modeling |

| FSE | Fuzzy synthetic evaluation |

References

- Jaber, A.Z. Assessment risk in construction projects in Iraq using COPRAS-SWARA combined method. J. Southwest. Jiaotong Univ. 2019, 54, 1–12. [Google Scholar] [CrossRef]

- Anaç, M.; Gumusburun Ayalp, G.; Erdayandi, K. Prefabricated Construction Risks: A Holistic Exploration through Advanced Bibliometric Tool and Content Analysis. Sustainability 2023, 15, 11916. [Google Scholar] [CrossRef]

- Song, Y.; Wang, J.; Liu, D.; Guo, F. Study of occupational safety risks in prefabricated building hoisting construction based on HFACS-PH and SEM. Int. J. Environ. Res. Public Health 2022, 19, 1550. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Cui, J. Identification of hazard sources in prefabricated building construction by entropy weight method. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Lanzhou, China, 3–5 July 2020; IOP Publishing: Bristol, UK, 2020; Volume 560, p. 012073. [Google Scholar] [CrossRef]

- Wallbaum, H.; Ostermeyer, Y.; Salzer, C.; Escamilla, E.Z. Indicator-based sustainability assessment tool for affordable housing construction technologies. Ecol. Indic. 2012, 18, 353–364. [Google Scholar] [CrossRef]

- Li, X.J. Research on investment risk influence factors of prefabricated building projects. J. Civ. Eng. Manag. 2020, 26, 599–613. [Google Scholar] [CrossRef]

- Chang, Y.F.; Ishii, H. Fuzzy multiple criteria decision-making approach to assessing the project quality management in the project. Procedia Comput. Sci. 2013, 22, 928–936. [Google Scholar] [CrossRef]

- Zhao, W.H. Discussion on the construction safety risk management of prefabricated residential buildings. Constr. Saf. 2017, 5, 13–15. [Google Scholar]

- Du, J.; Jing, H.Q.; Daniel, C.L.; Sugumaran, V. Multi-agent simulation for managing design changes in prefabricated construction projects. Eng. Constr. Archit. Manag. 2020, 27, 270–295. [Google Scholar] [CrossRef]

- Utama, W.P.; Chan, A.P.; Zahoor, H.; Gao, R.; Jumas, D.Y. Making decision toward overseas construction projects. Eng. Constr. Archit. Manag. 2019, 26, 285–302. [Google Scholar] [CrossRef]

- Sun, H.; Sun, J.; Wu, Y.H.; Zhao, K.J. Introduction to large-scale intelligent PC component automatic production line. Concr. Cem. Prod. 2015, 1, 35–38. [Google Scholar]

- Luo, L.Z.; Mao, C.; Shen, L.Y.; Li, Z.D. Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system. Eng. Constr. Archit. Manag. 2015, 22, 622–643. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Meng, Q.; Hu, X. Barriers to the development of prefabricated buildings in china: A news coverage analysis. Eng. Constr. Archit. Manag. 2021, 28, 2884–2903. [Google Scholar] [CrossRef]

- Li, X.; Liao, F.; Wang, C.; Alashwal, A. Managing Safety Hazards in Metro Subway Projects under Complex Environmental Conditions. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2022, 8, 04021079. [Google Scholar] [CrossRef]

- Guan, L.; Abbasi, A.; Ryan, M.J. Analyzing green building project risk interdependencies using interpretive structural modeling. J. Clean. Prod. 2020, 256, 120372. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Yu, Y.; Xu, Y.; Xu, M.; Zhang, R.; De Dieu, G.J.; Yin, D.; Liu, Z. Historical data-driven risk assessment of railway dangerous goods transportation system: Comparisons between entropy weight method and scatter degree method. Reliab. Eng. Syst. Saf. 2021, 205, 107236. [Google Scholar] [CrossRef]

- Xing, X.; Zhong, B.; Luo, H.; Li, H.; Wu, H. Ontology for safety risk identification in metro construction. Comput. Ind. 2019, 109, 14–30. [Google Scholar] [CrossRef]

- Ji, Y.; Li, Y.; Liu, Y. Prefabricated building hoisting safety risk identification and control. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Beijing, China, 20–22 September 2019; IOP Publishing: Bristol, UK, 2019; Volume 371, p. 032004. [Google Scholar] [CrossRef]

- Jeong, G.; Kim, H.; Lee, H.-S.; Park, M.; Hyun, H. Analysis of safety risk factors of modular construction to identify accident trends. J. Asian Archit. Build. Eng. 2022, 21, 1040–1052. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Kassem, M.A.; Alhajlah, H.H.; Bimenyimana, S. Evaluation Method for Quality Risks of Safety in Prefabricated Building Construction Using SEM–SDM Approach. Int. J. Environ. Res. Public Health 2022, 19, 5180. [Google Scholar] [CrossRef]

- Wang, S.; Tang, J.; Zou, Y.; Zhou, Q. Research on production process optimization of precast concrete component factory based on value stream mapping. Eng. Constr. Archit. Manag. 2020, 27, 850–871. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Perspectives of UK house builders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Pamucar, D.; Garai-Fodor, M.; Csiszárik-Kocsir, Á. Evaluation of critical risk factors in the implementation of modular construction. PLoS ONE 2022, 17, e0272448. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-H.; Kim, J.-S.; Lee, H.-J.; Lee, Y.-M.; Kim, H.-G. Small-scale Public Rental Housing Development Using Modular construction—Lessons Learned from Case Studies in Seoul, Korea. Sustainability 2019, 11, 1120. [Google Scholar] [CrossRef]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Standardization Strategy for Modular Industrial Plants. J. Constr. Eng. Manag. 2015, 141, 04015026. [Google Scholar] [CrossRef]

- Smith, R. Prefab Architecture: A Guide to Modular Design and Construction, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 217–251. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Parry, M.L.; Canziani, O.; Palutikof, J.; Van der Linden, P.; Hanson, C. Climate Change 2007-Impacts, Adaptation and Vulnerability: Working Group II Contribution to the Fourth Assessment Report of the IPCC; Cambridge University Press: Cambridge, UK, 2007; Volume 4, 976p. [Google Scholar]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef]

- Li, H.X.; Al-Hussein, M.; Lei, Z.; Ajweh, Z. Risk identification and assessment of modular construction utilizing fuzzy analytic hierarchy process (AHP) and simulation. Can. J. Civ. Eng. 2013, 40, 1184–1195. [Google Scholar] [CrossRef]

- Kisi, K.; Mani, N.; Shrestha, K.J.; Shrestha, K.; Kayastha, R. Opportunities and Challenges for Modular Construction in Developing Nations: A Case Study in the Nepalese Construction Industry. In Proceedings of the 7th Canadian Society for Civil Engineers (CSCE) Annual Conference, Montreal, QC, Canada, 12–15 June 2019. [Google Scholar]

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Frosolini, M. A Lean Approach for Real-Time Planning and Monitoring in Engineer-to-Order Construction Projects. Buildings 2018, 8, 38. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings–A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Milani, A.S. Life cycle sustainability performance assessment framework for residential modular buildings: Aggregated sustainability indices. Build. Environ. 2018, 138, 21–41. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Understanding the Key Risks Affecting Cost and Schedule Performance of Modular Construction Projects. J. Manag. Eng. 2021, 37, 04021023. [Google Scholar] [CrossRef]

- Agapiou, A. Barriers to Offsite Construction Adoption: A Quantitative Study among Housing Associations in England. Buildings 2022, 12, 283. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Antwi-Afari, M.F. Exploring the design risk factors for modular integrated construction projects. Constr. Innov. 2023, 23, 213–228. [Google Scholar] [CrossRef]

- Xin, Y.Y.; Yang, D.L.; Fang, Q.C. Application of improved GRA-TOPSIS model in risk assessment of prefabricated building construction. J. Saf. Environ. 2023, 23, 2212–2222. [Google Scholar]

- Wang, Q.K.; Zhu, K.; Guo, P.W. Safety risk assessment of prefabricated building construction based on IM-FCM. J. Saf. Environ. 2023, 23, 2202–2211. [Google Scholar]

- Li, H.R. Research on Control of Prefabricated Building Construction Safety Risk Based on Design Process. Master’s Thesis, Southeast University, Nanjing, China, 2018. [Google Scholar]

- Li, W.L.; Li, H.M.; Pei, X.W. Safety risk assessment of prefabricated building hoisting construction based on structure entropy weight-credibility measure theory. Eng. J. Wuhan Univ. 2020, 53, 410–417. [Google Scholar]

- Ali, N.F.; Mansor, M.A. Specify the priorities of indicators for measuring the performance success of construction projects. Tikrit J. Eng. Sci. 2022, 29, 36–45. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Macchion, L. A comprehensive risk assessment model based on a fuzzy synthetic evaluation approach for green building projects: The case of Vietnam. Eng. Constr. Archit. Manag. 2023, 30, 2837–2861. [Google Scholar] [CrossRef]

- Kumar, M.H.; Ramu, P. Risk Assessment and Hazard Identification in Prefabricated Structures and its Industries. Int. J. Mod. Dev. Eng. Sci. 2023, 2, 16–18. Available online: https://www.ijmdes.com (accessed on 7 May 2025).

- Mansor, M.A.; Mohammed, S.R. Assessment of environmental and governance sustainability of Iraqi Middle provinces. In Proceedings of the 1st International Scientific Conference of Engineering Sciences-3rd Scientific Conference of Engineering Science (ISCES), Diyala, Iraq, 11 January 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 299–304. [Google Scholar] [CrossRef]

- Mansor, M.A. Economic and social sustainability for Iraqi middle provinces. Adv. Sci. Technol. Eng. Syst. 2018, 3, 447–453. [Google Scholar] [CrossRef]

- Adegoriola, M.I.; Lai, J.H.; Yung, E.H.; Chan, E.H. Development of a significant index model for assessing heritage building maintenance management challenges. Eng. Constr. Archit. Manag. 2024, 31, 3398–3428. [Google Scholar] [CrossRef]

- Deng, B.; Zhou, D.; Zhao, J.; Yin, Y.; Li, X. Fuzzy synthetic evaluation of the critical success factors for the sustainability of public private partnership projects in China. Sustainability 2021, 13, 2551. [Google Scholar] [CrossRef]

- Hsu, T.H.; Yang, T.S. The application of fuzzy synthetic decision to the human resource management. Fu Jen Manag. Rev. 1997, 4, 85–100. [Google Scholar]

- Zhao, X.; Hwang, B.-G.G.; Gao, Y. A fuzzy synthetic evaluation approach for risk assessment: A case of Singapore’s green projects. J. Clean. Prod. 2016, 115, 203–213. [Google Scholar] [CrossRef]

- Mu, S.; Cheng, H.; Chohr, M.; Peng, W. Assessing risk management capability of contractors in subway projects in mainland China. Int. J. Proj. Manag. 2014, 32, 452–460. [Google Scholar] [CrossRef]

- Xu, Y.; Chan, A.P.C.; Yeung, J.F.Y. Developing a fuzzy risk allocation model for PPP projects in China. J. Constr. Eng. Manag. 2010, 136, 894–903. [Google Scholar] [CrossRef]

- Akter, M.; Jahan, M.; Kabir, R.; Karim, D.S.; Haque, A.; Rahman, M.; Salehin, M. Risk assessment based on fuzzy synthetic evaluation method. Sci Total Environ. 2019, 658, 818–829. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Negre, E. Fuzzy synthetic method for evaluating explanations in recommender systems. arXiv 2024. [Google Scholar] [CrossRef]

- Guo, R.; Wu, Z. Social sustainable supply chain performance assessment using hybrid fuzzy-AHP-DEMATEL-VIKOR: A case study in manufacturing enterprises. Environ. Dev. Sustain. 2022, 25, 12273–12301. [Google Scholar] [CrossRef]

- Ly, T.H.; Roh, S.; Jang, H. Selection of Functional Logistics Service Providers: AHP and DEMATEL Application. Korean Data Anal. Soc. 2021, 23, 1517–1534. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P.; Ameyaw, E.E. A fuzzy synthetic evaluation analysis of operational management critical success factors for public-private partnership infrastructure projects. Benchmarking An. Int. J. 2017, 24, 2092–2112. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2022, 22, 133–147. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Hwang, B.G. Risks of modular integrated construction: A review and future research direcions. Front. Eng. Manag. 2020, 7, 63–80. [Google Scholar] [CrossRef]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat. Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wang, J.; Wu, J.; Shi, W.; Ji, D.; Wang, X.; Zhao, X. Constraints Hindering the Development of High-Rise Modular Buildings. Appl. Sci. 2020, 10, 7159. [Google Scholar] [CrossRef]

- Blismas, N.; Pasquire, C.; Gibb, A. Benefit evaluation for off-site production in construction. Constr. Manag. Econ. 2006, 24, 121–130. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhong, R.Y.; Xue, F.; Xu, G.; Chen, K.; Huang, G.G.; Shen, G.Q. Integrating RFID and BIM technologies for mitigating risks and im-proving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Wu, P.; Xu, Y.; Jin, R.; Lu, Q.; Madgwick, D.; Hancock, C.M. Perceptions towards risks involved in off-site construction in the integrated design & construction project delivery. J. Clean. Prod. 2019, 213, 899–914. [Google Scholar] [CrossRef]

- Hassim, S.; Jaafar, M.S.; Sazalli, S.A. The contractor perception towers industrialised building system risk in construction projects in Malaysia. Am. J. Appl. Sci. 2009, 6, 937. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Blismas, N.G.; Pendlebury, M.; Gibb, A.; Pasquire, C. Constraints to the Use of Off-site Production on Construction Projects. Arch. Eng. Des. Manag. 2005, 1, 153–156. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, Y.S. Analysis of cost-increasing risk factors in modular construction in Korea using FMEA. KSCE J. Civ. Eng. 2017, 21, 1999–2010. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Risks Identification and Allocation in the Supply Chain of Modular Integrated Construction (MiC). In Proceedings of the Modular and Offsite Construction (MOC) Summit, Banff, AB, Canada, 21–24 May 2019; pp. 189–197. [Google Scholar] [CrossRef]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Hsu, P.Y.; Angeloudis, P.; Aurisicchio, M. Optimal logistics planning for modular construction using two stage stochastic programming. Autom. Constr. 2018, 94, 47–61. Available online: https://api.semanticscholar.org/CorpusID:115370628 (accessed on 7 May 2025). [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Luo, L. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat. Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Li, C.Z.; Xu, X.; Shen, G.Q.; Fan, C.; Li, X.; Hong, J. A model for simulating schedule risks in prefabrication housing production: A case study of six-day cycle assembly activities in Hong Kong. J. Clean. Prod. 2018, 185, 366–381. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Simulation based multiple disturbances evaluation in the precast supply chain for improved disturbance prevention. J. Clean. Prod. 2018, 177, 232–244. [Google Scholar] [CrossRef]

- Durdyev, S.; Ismail, S. Offsite Manufacturing in the Construction Industry for Productivity Improvement. Eng. Manag. J. 2019, 31, 35–46. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Blismas, N.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Arif M, editor. Constr. Innov. 2009, 9, 72–83. [Google Scholar] [CrossRef]

- Luo, L.; Shen, G.Q.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Arch. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Kamar, K.M.; Alshawi, M.; Hamid, Z. Barriers to industrialized building system (IBS): The case of Malaysia. In Proceedings of the BuHu 9th International Postgraduate Research Conference (IPGRC), Salford, UK, 29 January 2009; Volume 30. [Google Scholar]

- Han, Y.; Wang, L. Identifying barriers to off-site construction using grey DEMATEL approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Lovell, H.; Smith, S.J. Agencement in housing markets: The case of the UK construction industry. Geoforum 2010, 41, 457–468. [Google Scholar] [CrossRef]

- Nurhafizah, A.; Fadzilawani, A.A.; Muniroh, H.; Siti, A.M. Reliability Analysis: Application of Cronbach’s Alpha in Research Instruments. Pioneer. Future Delving Into E-Learn. Landsc. 2024, 114–119. Available online: https://appspenang.uitm.edu.my/sigcs/ (accessed on 7 May 2025).

- Mansor, M.A. Multi-Criteria Decision Making for Prioritizing Project Manager Skills according to Construction Project Success Factors. Eng. Technol. Appl. Sci. Res. 2025, 15, 21861–21875. [Google Scholar] [CrossRef]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Nnaji, C.; Gambatese, J.; Karakhan AOsei-Kyei, R. Development and application of safety technology adoption decision-making tool. J. Constr. Eng. Manag. 2020, 146, 04020028. [Google Scholar] [CrossRef]

- Yevu, S.K.; Yu, A.T.W.; Darko, A.; Addy, M.N. Evaluation model for influences of driving forces for electronic procurement systems application in Ghanaian construction projects. J. Constr. Eng. Manag. 2021, 147, 04021076. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).