The Use of Steatite Powder Waste as an Aggregate for the Manufacture of Earth Blocks—An Evaluation of Its Impact on Physical, Mechanical and Thermal Conductivity Properties

Abstract

1. Introduction

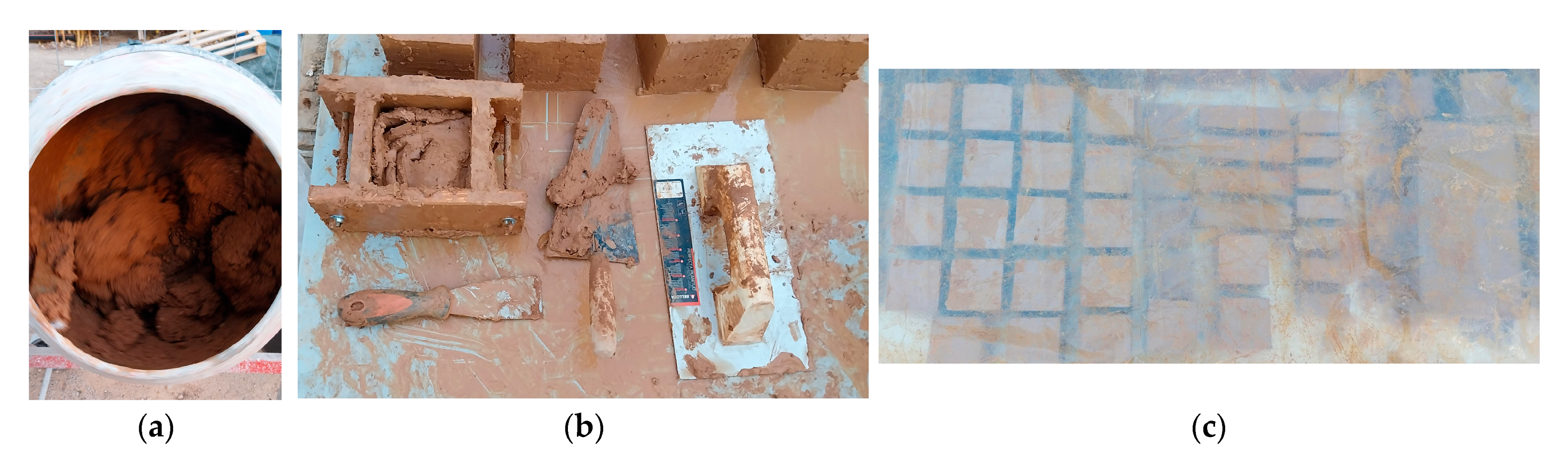

2. Materials and Methods

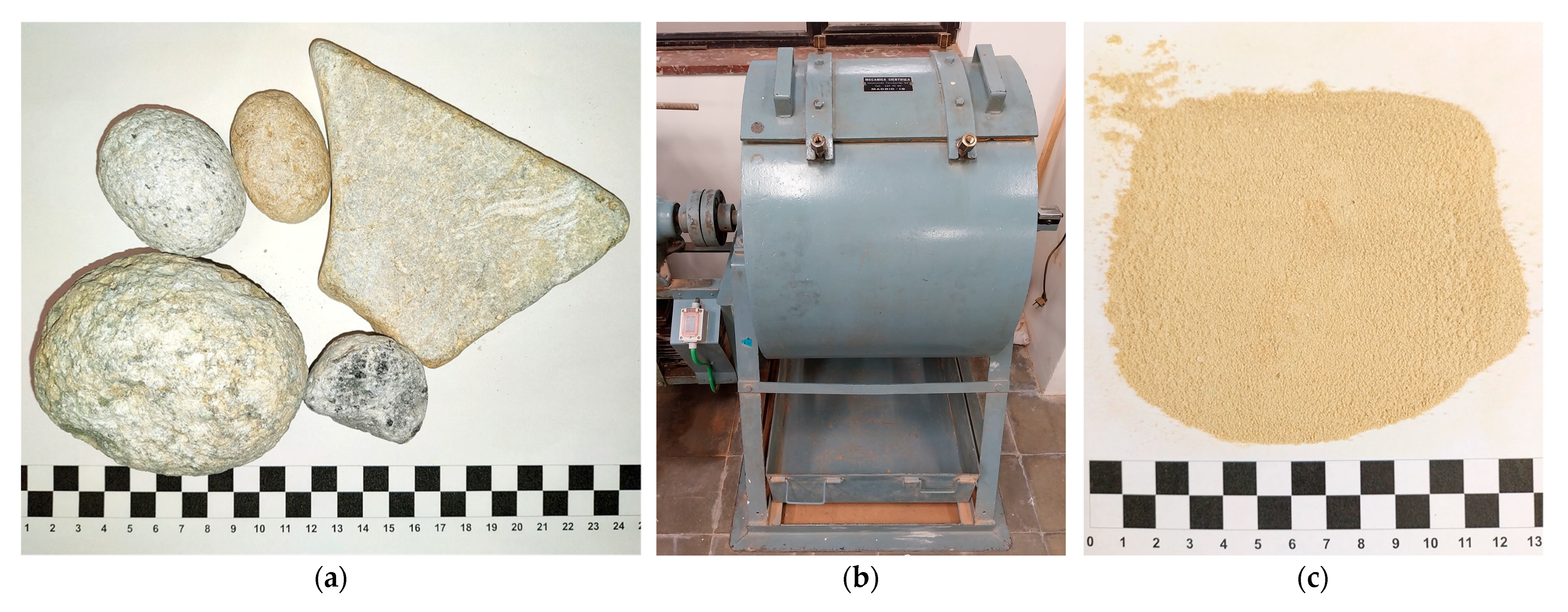

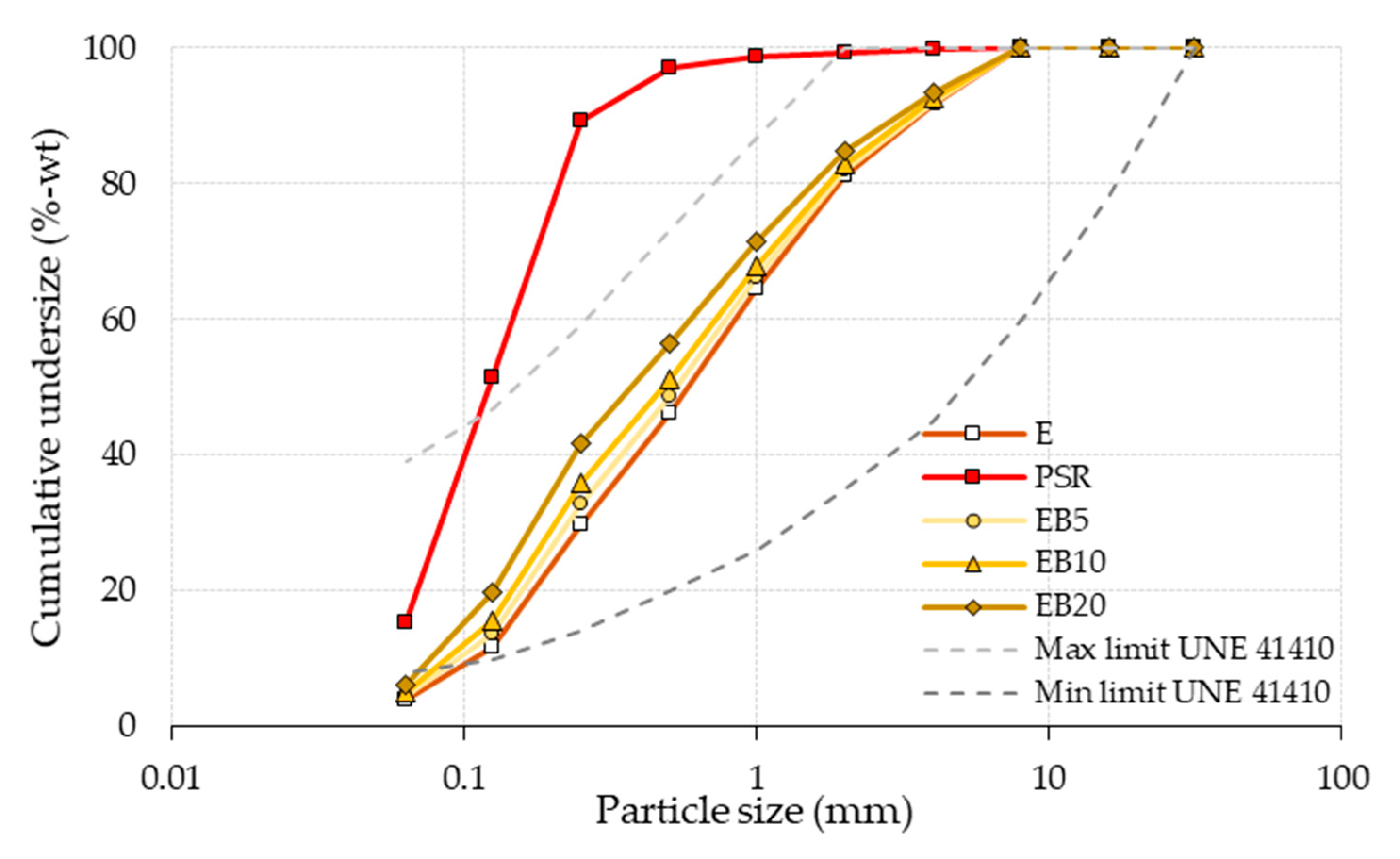

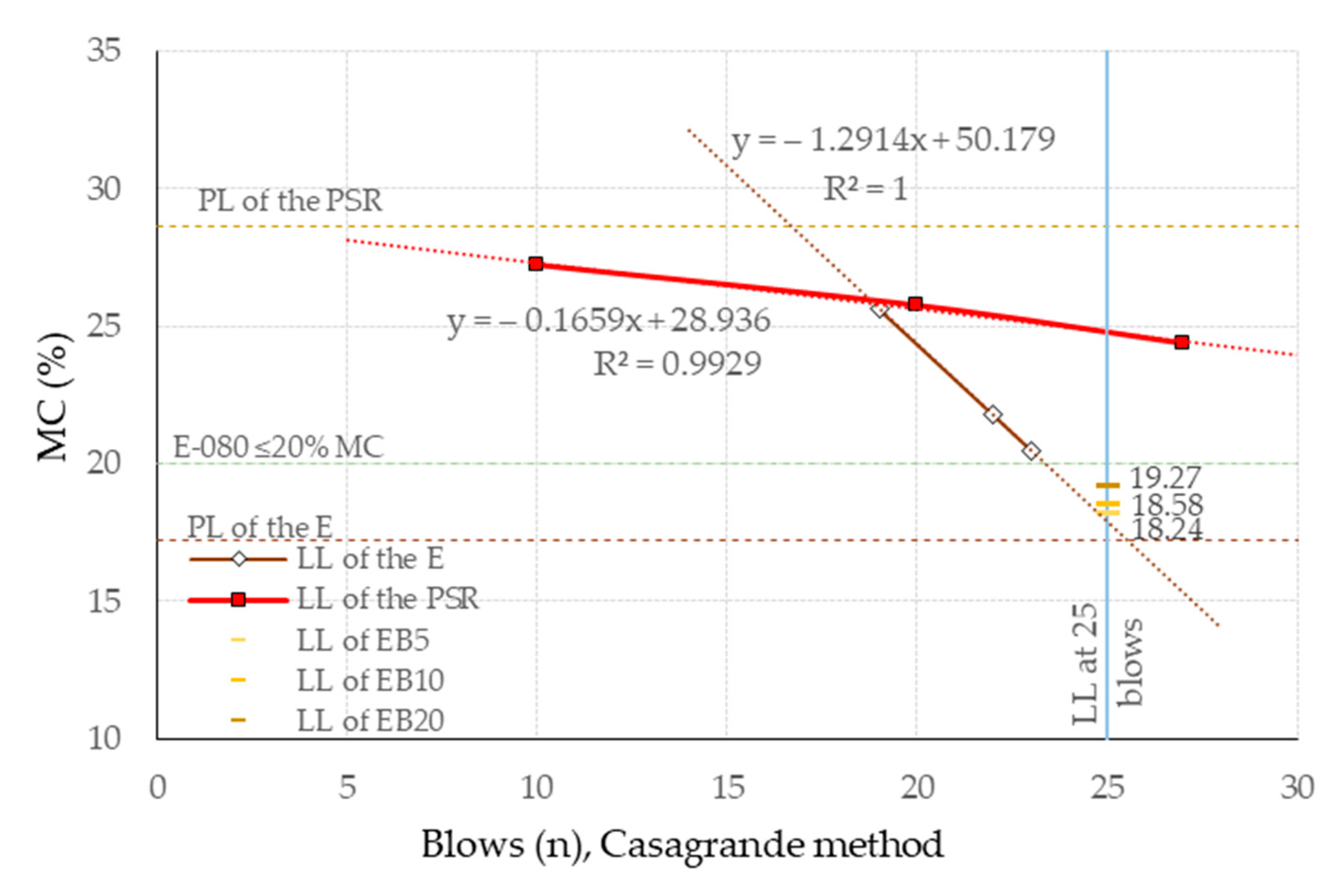

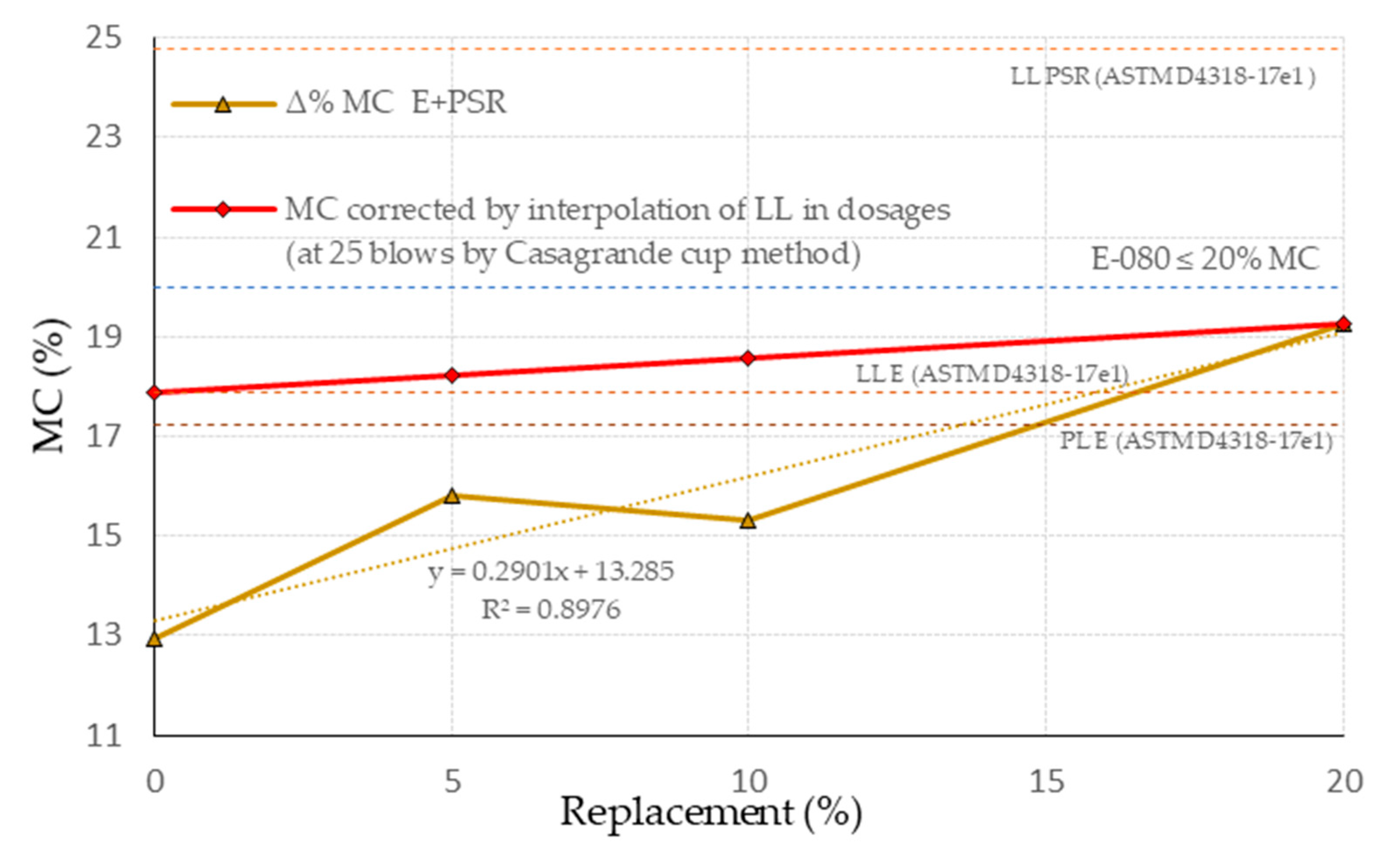

2.1. Materials

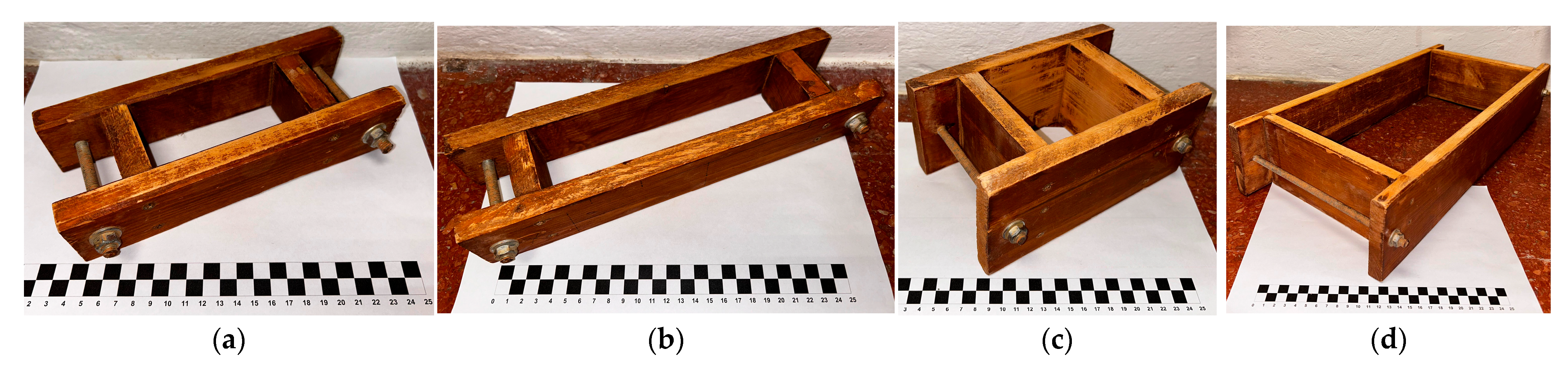

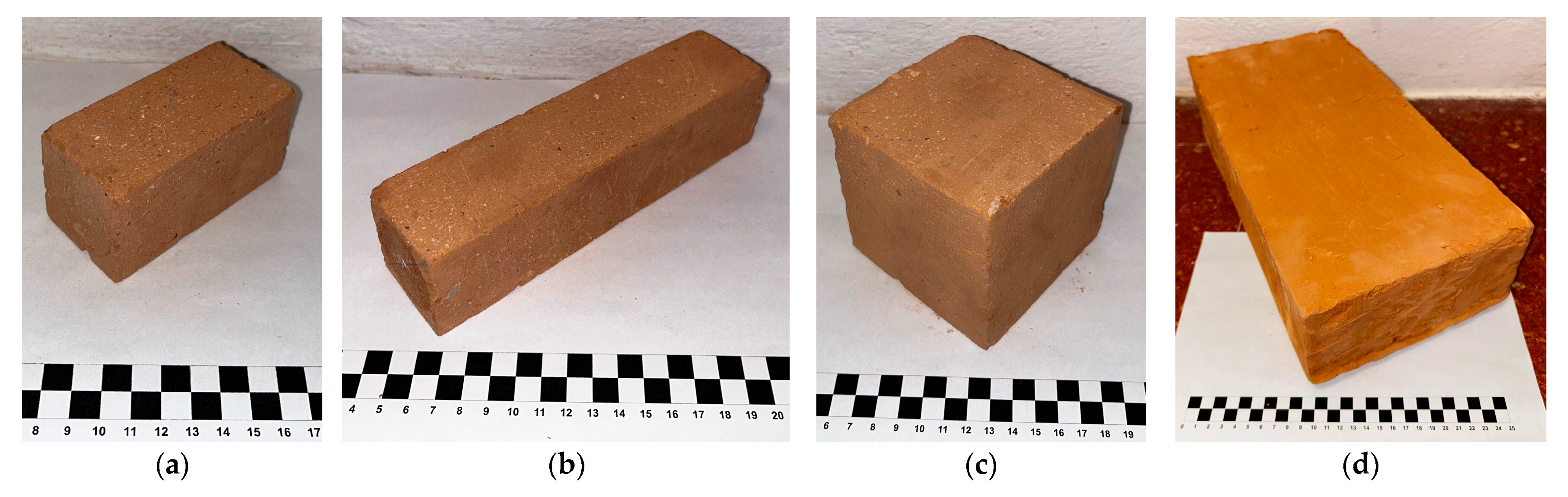

2.2. Methods

- Bulk density, apparent solid density, and porosity, UNE-EN ISO 18754:2022 [73]: With immersion in alcohol, applying to four type (a) specimens and considering their maximum, minimum and average results.

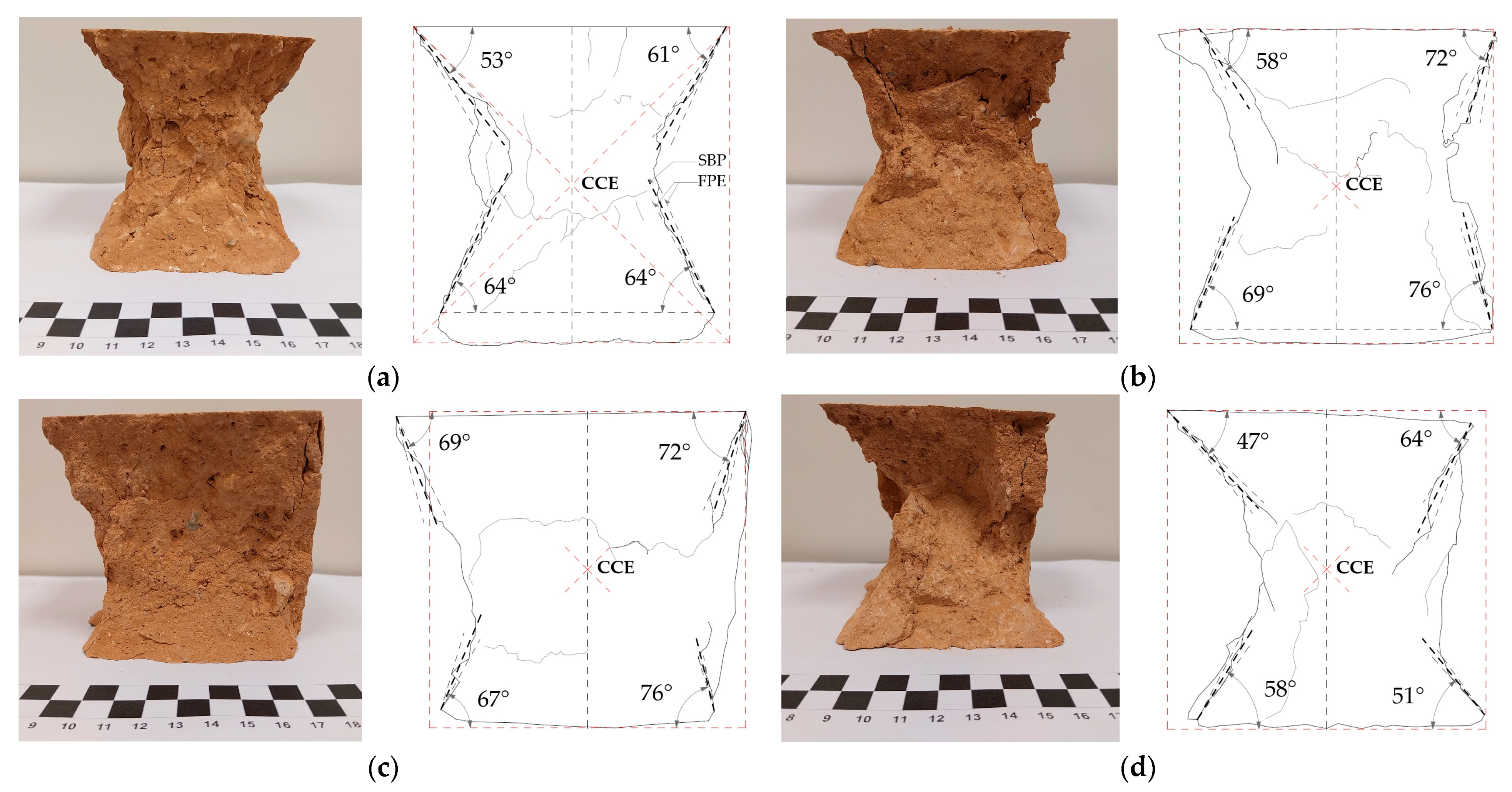

- Compressive strength (fc), using adaptations of the ASTM C39 [78], ASTM C-67 [79], UNE-EN 772-1:2011+A1:2016 [80] and E-080 [68] standards: The use of a 5.4 mm neoprene sheet and a 9 mm metal plate was considered for the test, which would guarantee a load distribution on both sides of the load application, with the charging application speed set at 3 N/min. Six type (c) specimens were tested, considering all the results and obtaining the average of the six. The equipment used was a multi-assay press by Mecánica Científica SA, with a capacity of 300 KN.

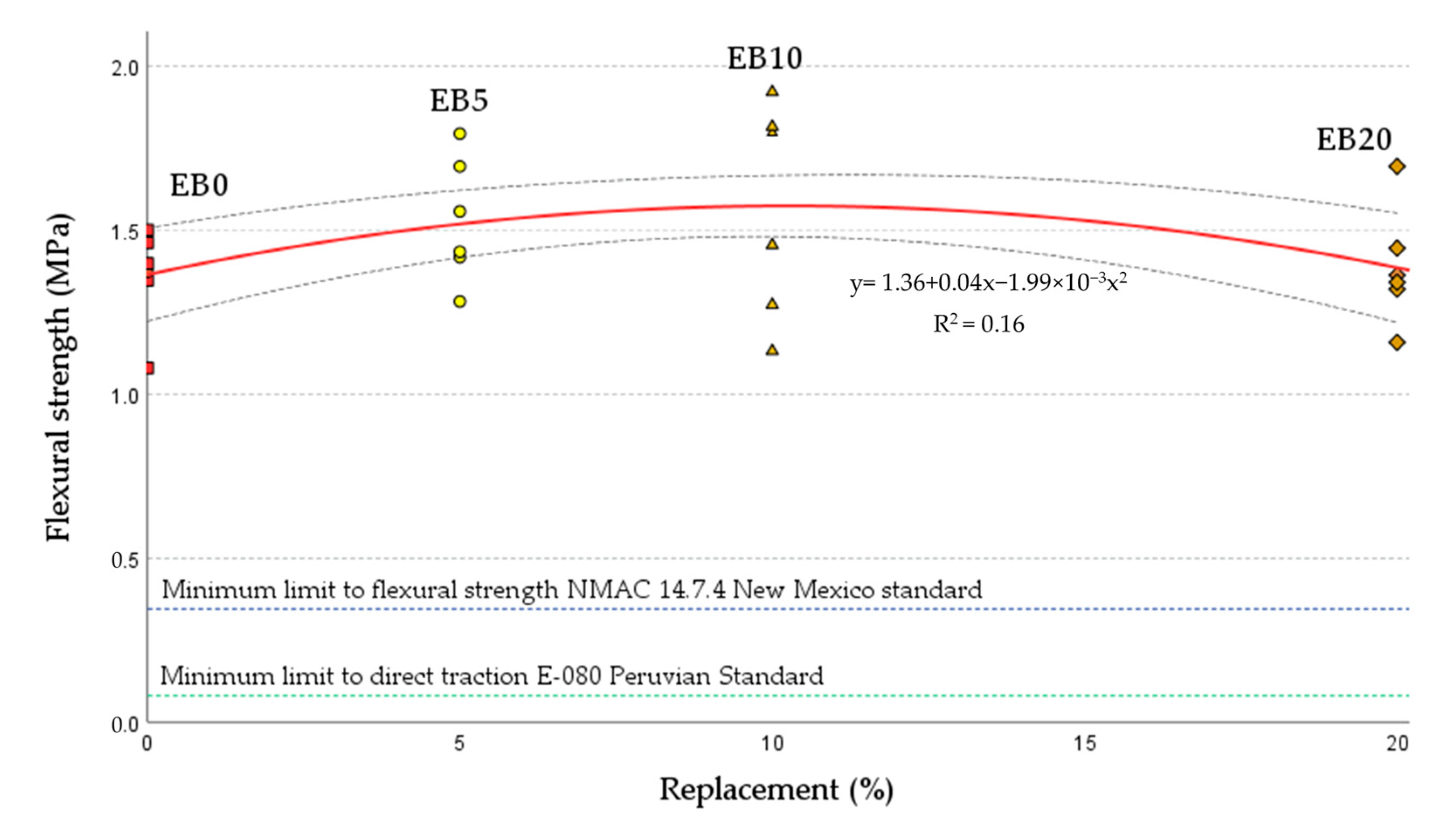

- Three-point flexural strength (fb), ASTM C-67 [79] and ASTM C1161-13 [81] standards were applied, and six type (d) specimens were tested, considering all the results and obtaining the average of the six. The equipment used was the same for the compressive strength test, with the following configuration: two metal cylinders (Φ = 40 mm) as lower support points at an axial distance of 30 cm and centered on the specimen; in the upper part, another support point was also centered on the specimen.

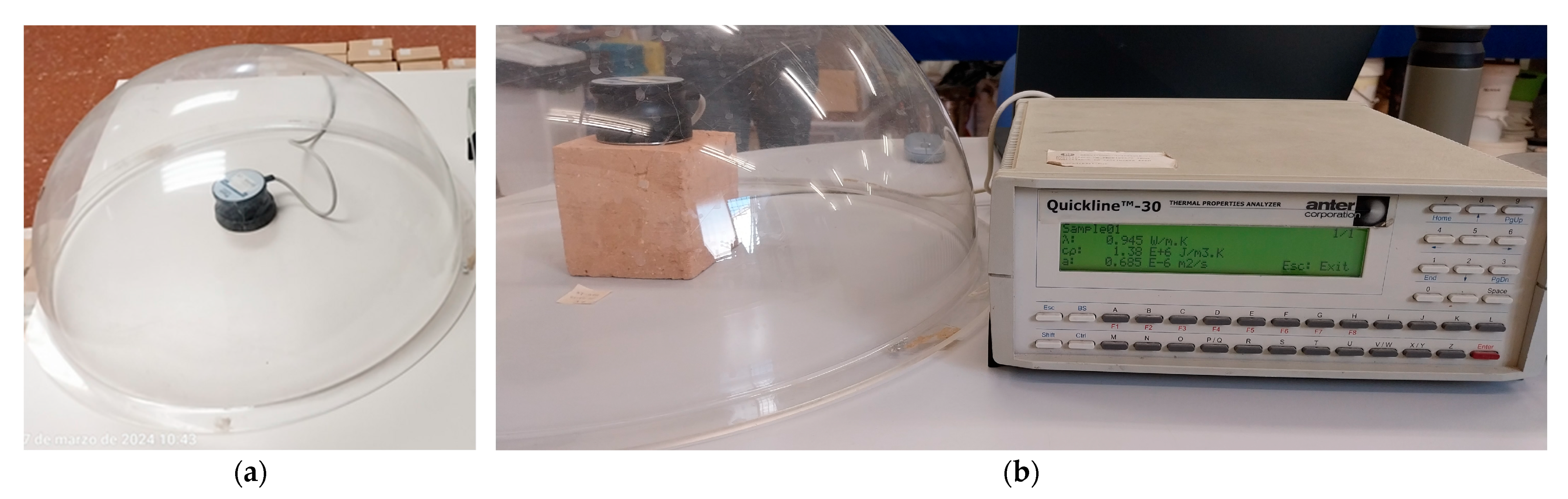

- Thermal conductivity was performed following [84]: Thirteen specimens were used per variable, separately considering the average of the vertical and horizontal faces, as well as that of both together. The probe used had a thermal capture range between 0.3 and 2.0 W/m·K, and the specimens were previously conditioned for 24 h in a climatic chamber at 20 °C with a relative humidity (RH) between 20 and 40%. The test was carried out by introducing each specimen and the probe under a protective acrylic capsule of thickness e = 4.40 mm to avoid errors due to air flows or temperature changes. The determination of the reference value is based on the transient principle of the hot wire by detecting the temperature on the contact surface with the probe. The equipment used was a QuicklineTM-30 conductivity meter, Applied Precision probe and CCI for the climatic chamber. Figure 8 shows the configuration of the test performed.

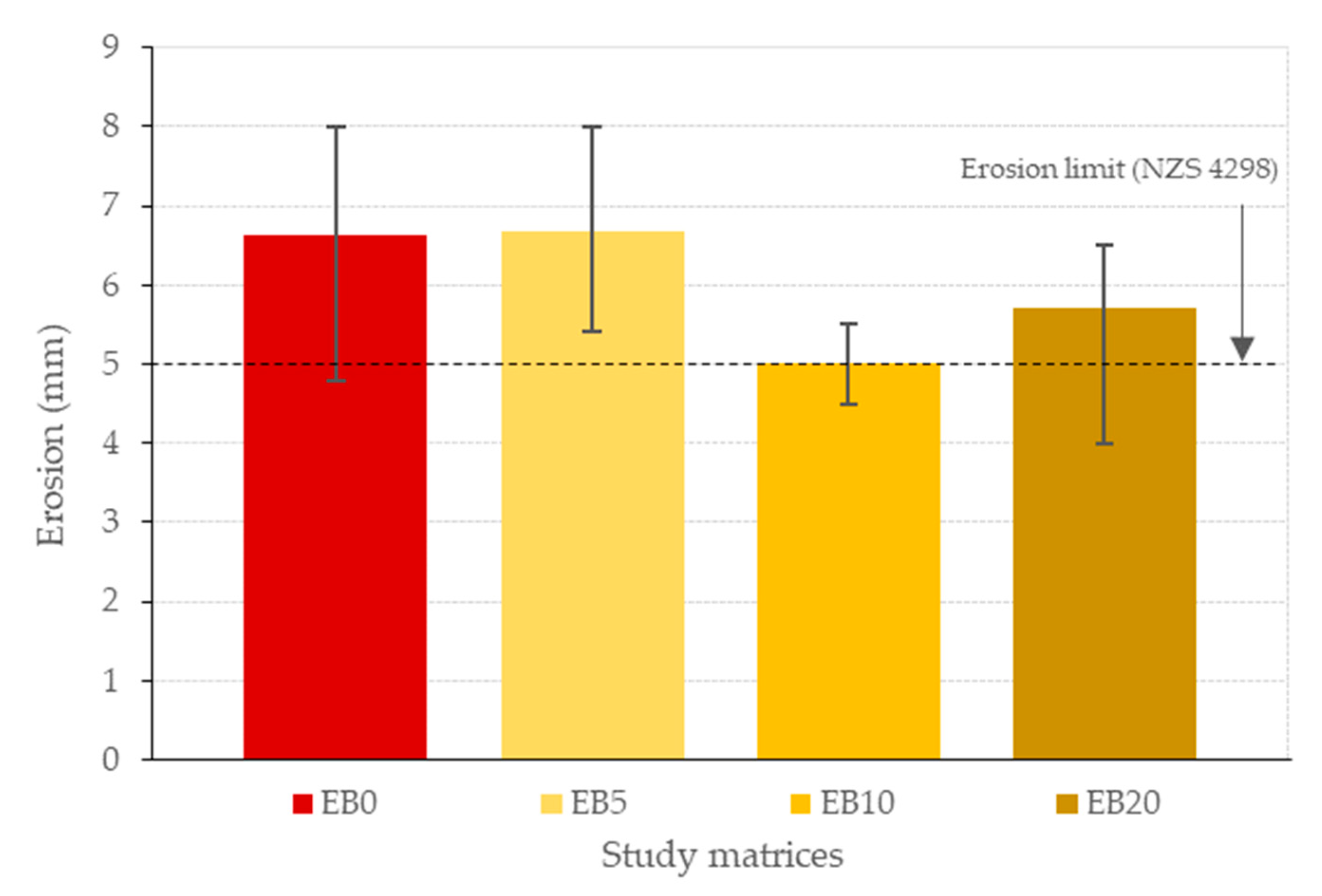

- Drip erosion, applying the NZS 4298:2024 [85] standard and its configurations: 100 mL of water by drip set at a height of 40 cm, impacting the face of a block positioned with a 2:1 inclination and in a test time of no less than 20 min; six type (d) specimens were tested, reporting the minimum, maximum and average values.

- Thermogravimetric analysis (TGA) and chemical composition: This was carried out using a Netzsch thermogravimetric analyzer, model STA 449 F5 Jupiter from Selb, Germany, establishing a range of temperatures (T) from ambient T to T = 1000 °C, with a constant heating rate increase of 10 °C/minute, and subjecting the test to a hydrogen atmosphere. The samples (5 g) for this test were obtained by sectioning representatives of the sizes produced by manually crushing a specimen.

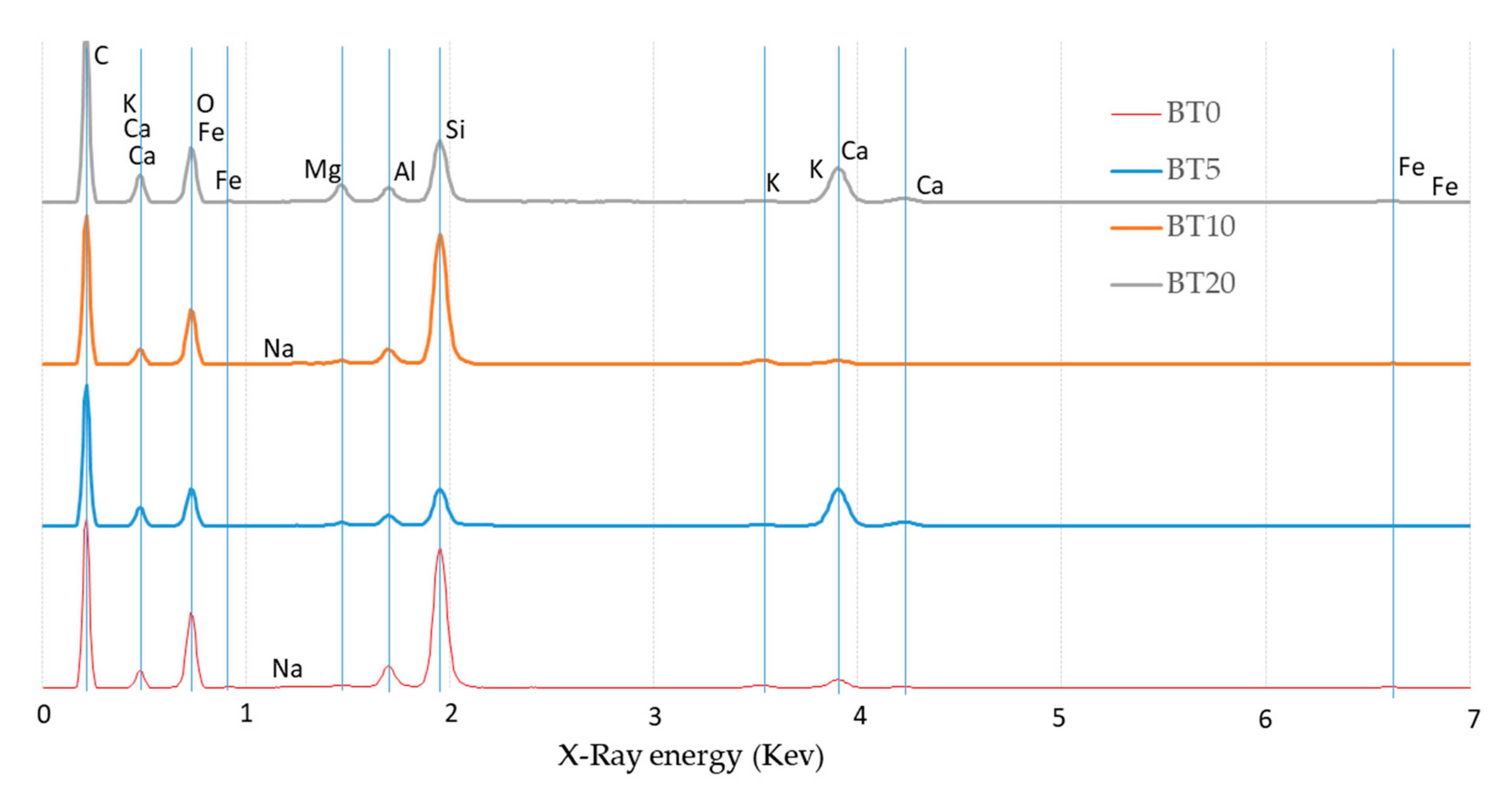

- Chemical identification: Energy-Dispersive Spectroscopy (EDS) analysis coupled with a Scanning Electron Microscope (SEM), JEOL brand, model JSM-6510 (Jeol Ltd., Tokyo, Japan) was used. The SEM used was a JSM-7001F Jeol Field Emission Scanning Electron Microscope, using the Oxford INCA version 4.15 software for the EDS. The samples used were specimens with a size of 2 × 2 × 1 cm cut from EBs using a diamond saw and then embedded in epoxy resin. After hardening, the surface to be studied was subjected to a metallographic polishing process in order to remove scratches and deformations, leaving the surface flat and highly reflective. Finally, the surface was then coated with a thin layer of carbon to improve the sample’s conductivity, prevent charge accumulation on the surface and thus obtain higher-quality images.

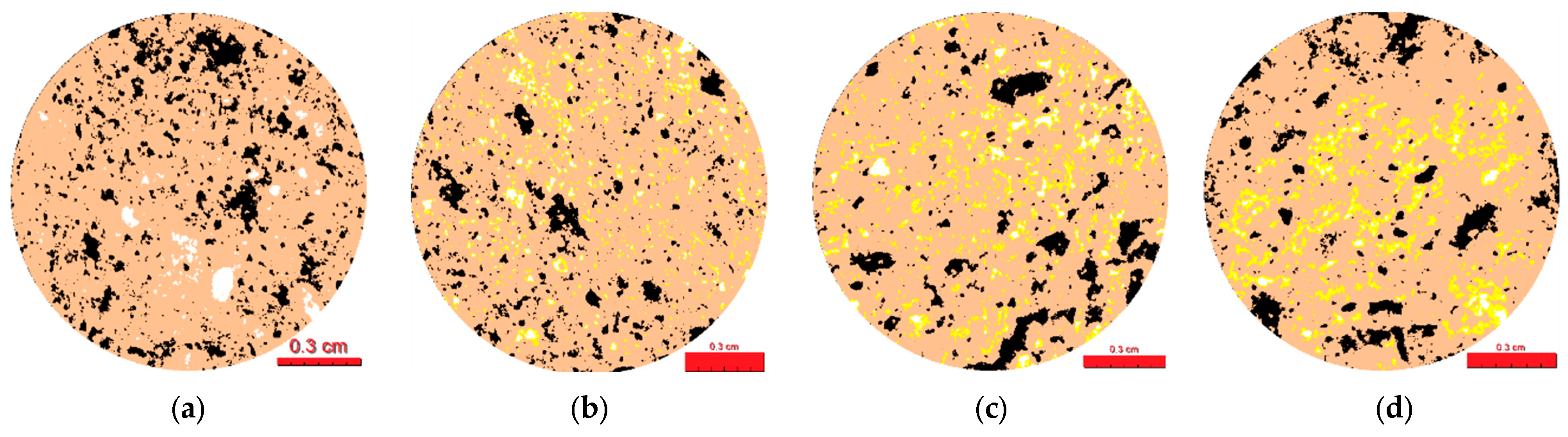

- The optical image analysis (OIA) used the Image-Pro v. 11.0.4 Build 9821 software; the images of the analyzed samples were obtained from those used for SEM before being coated with carbonite.

- Regarding the statistical study of the data obtained, the Statistical Software Package for Social Sciences (SPSS) v. 29.0.0.0 (241) software was used, and the Solver version 2025 Q1 software was used 86 for the numerical regression adjustment study.

3. Results

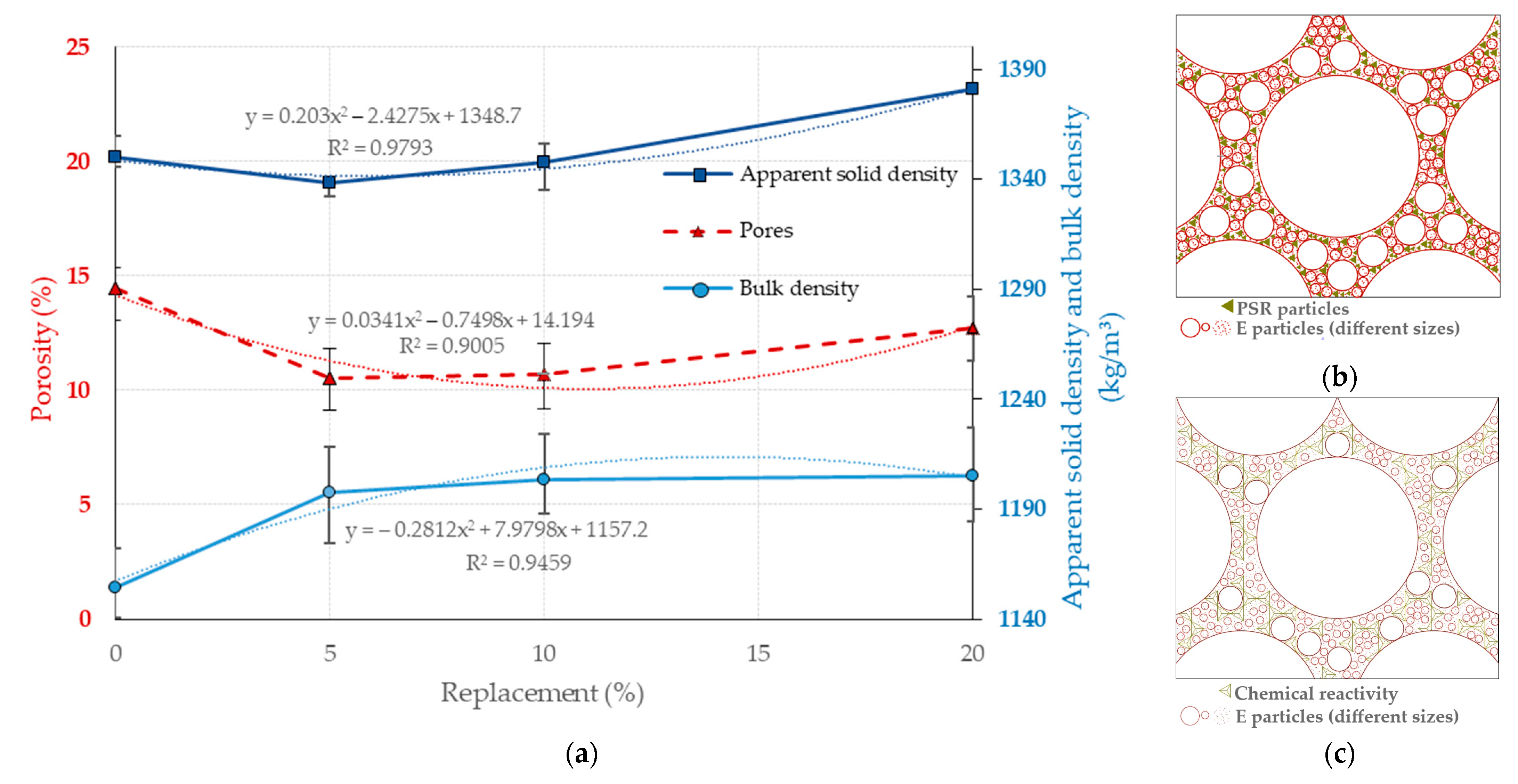

3.1. Bulk Density, Apparent Solid Density and Porosity Test Results

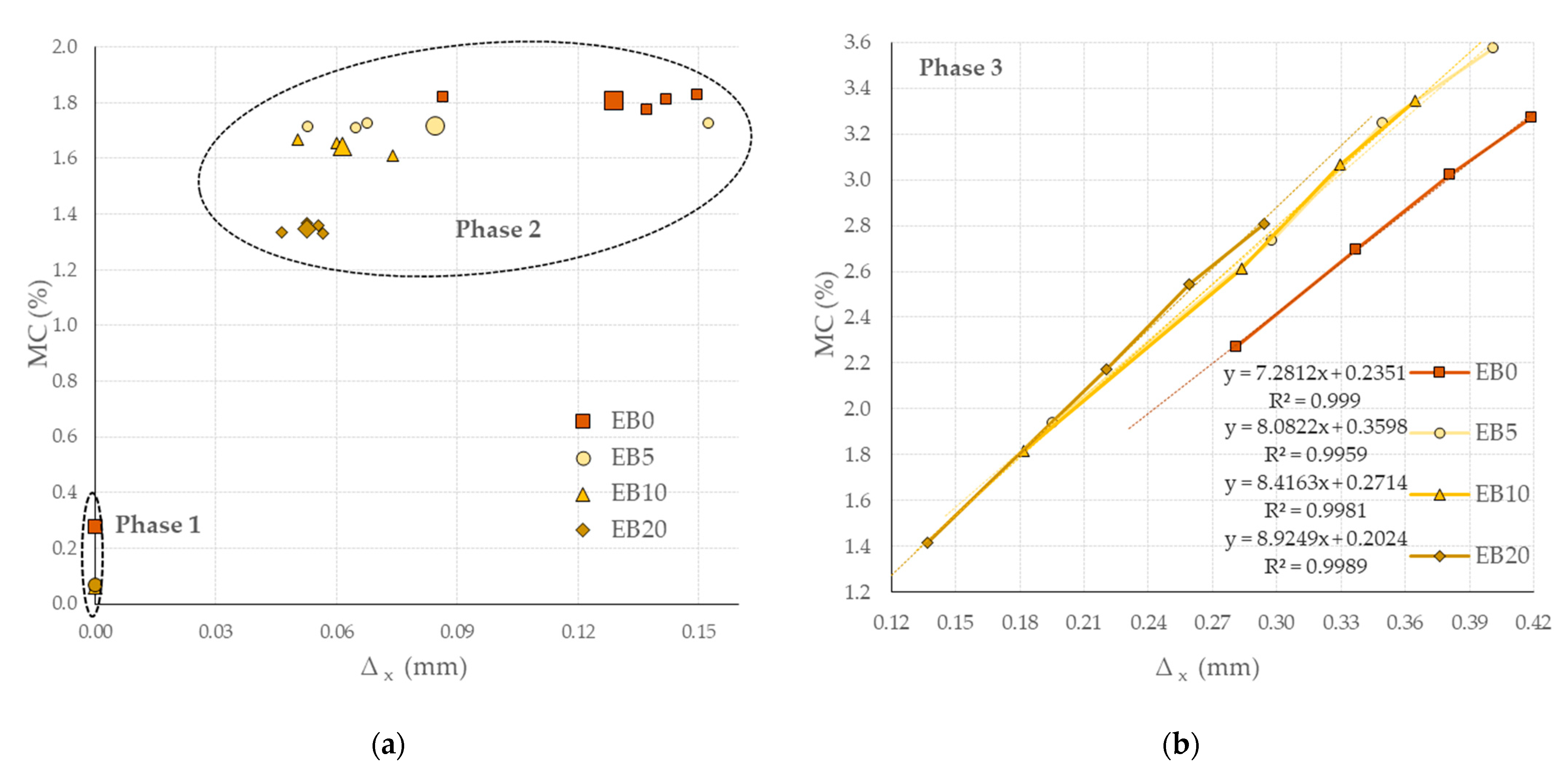

3.2. Results of the Hygroscopicity Dimensional Variation Test

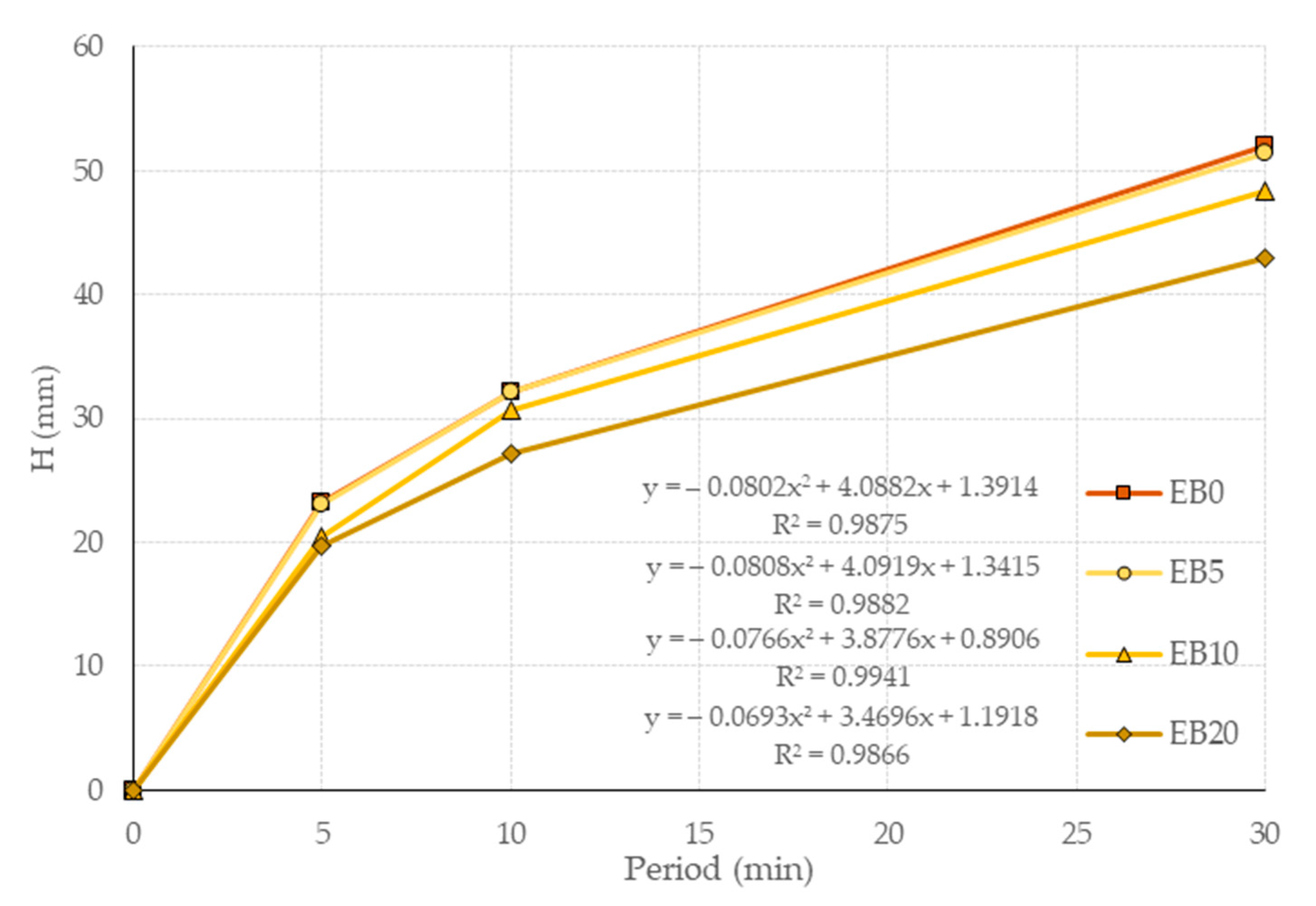

3.3. Capillary Test Results

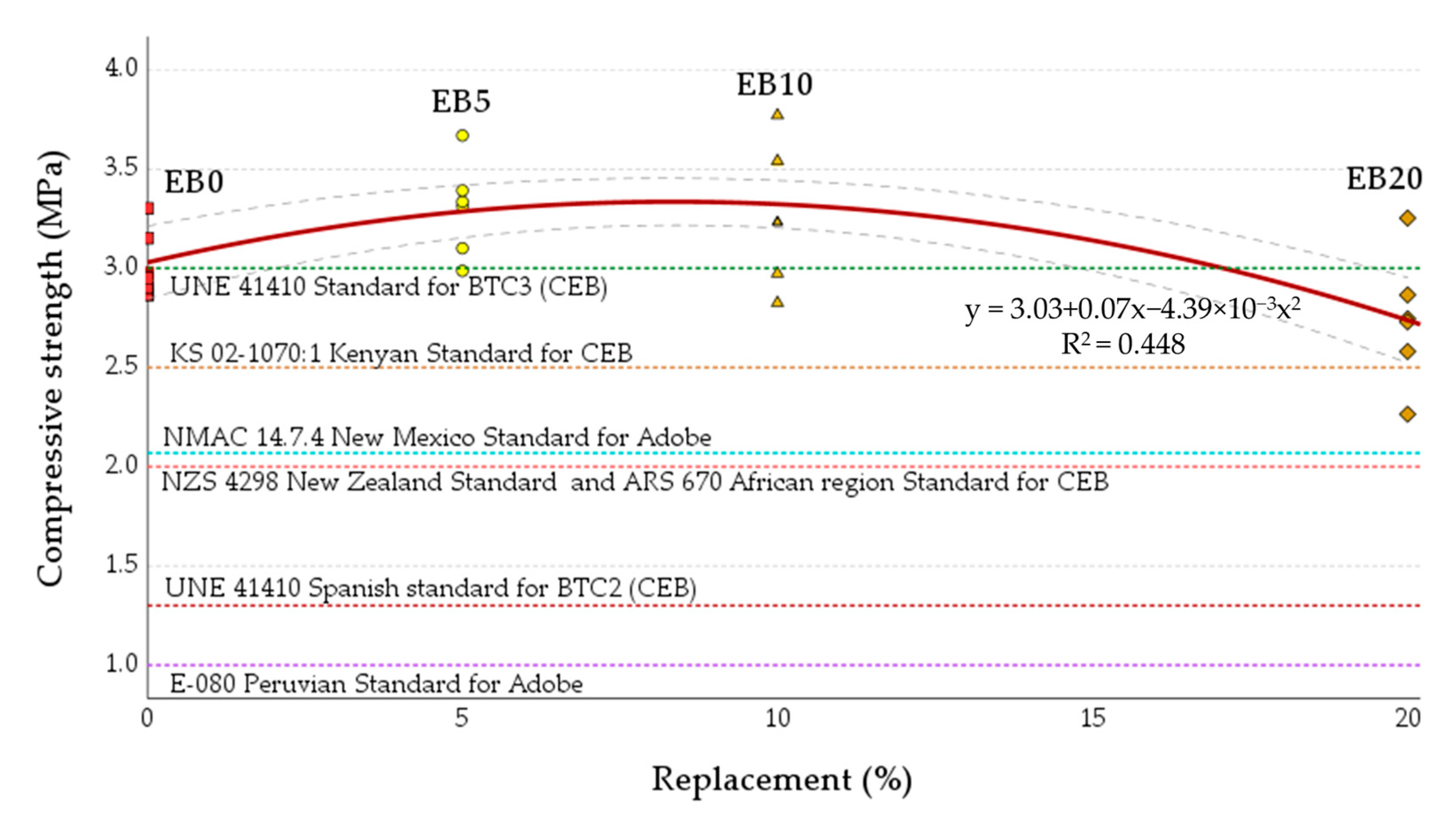

3.4. Compressive Strength Test Results

3.5. Results of the Three-Point Flexural Strength Test

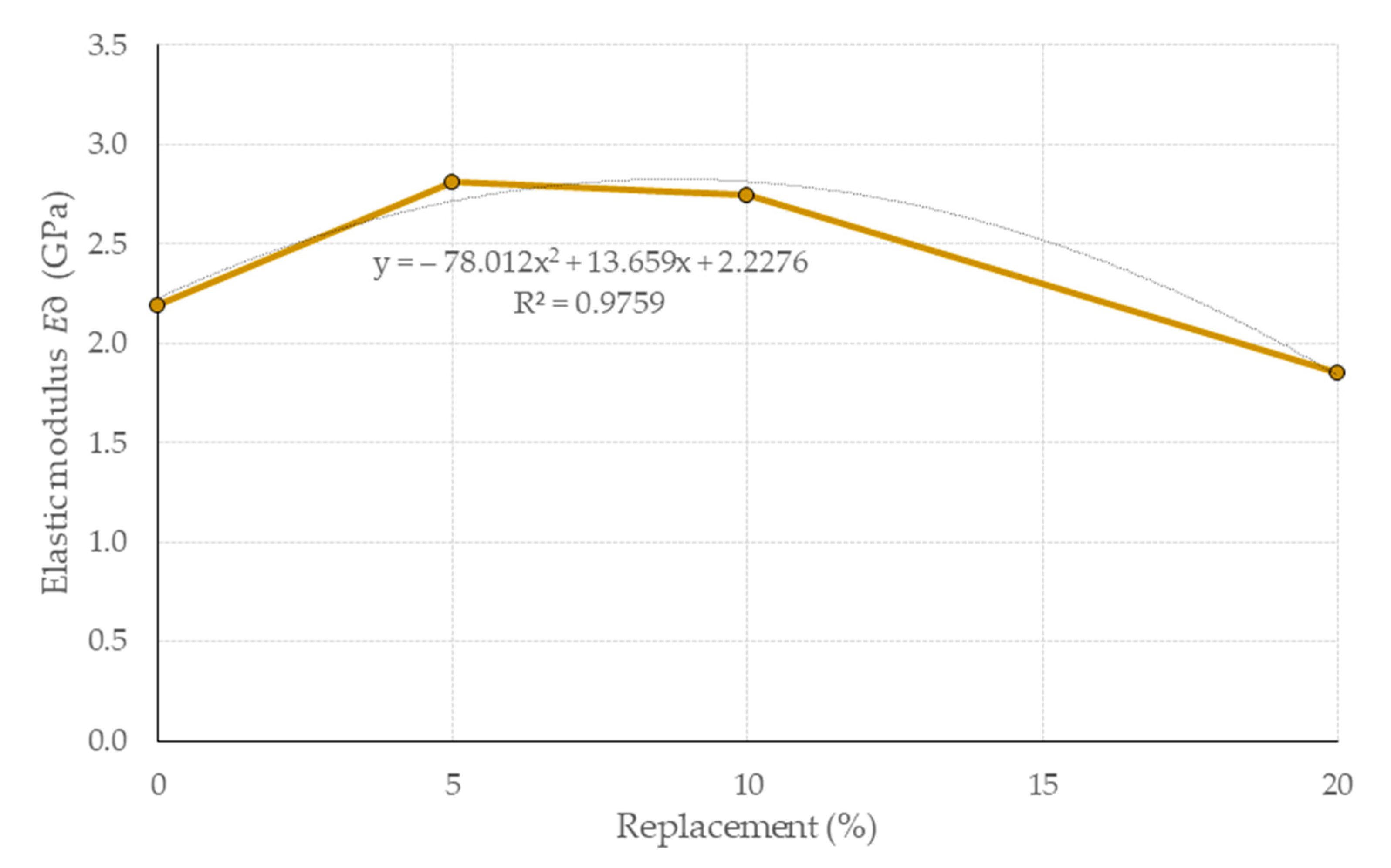

3.6. Ultrasonic Elastic Modulus Evaluation Test Results

3.7. Thermal Conductivity Property Evaluation Results

3.8. Erosion Test Results

3.9. TGA Results

3.10. Chemical Identification Using EDS

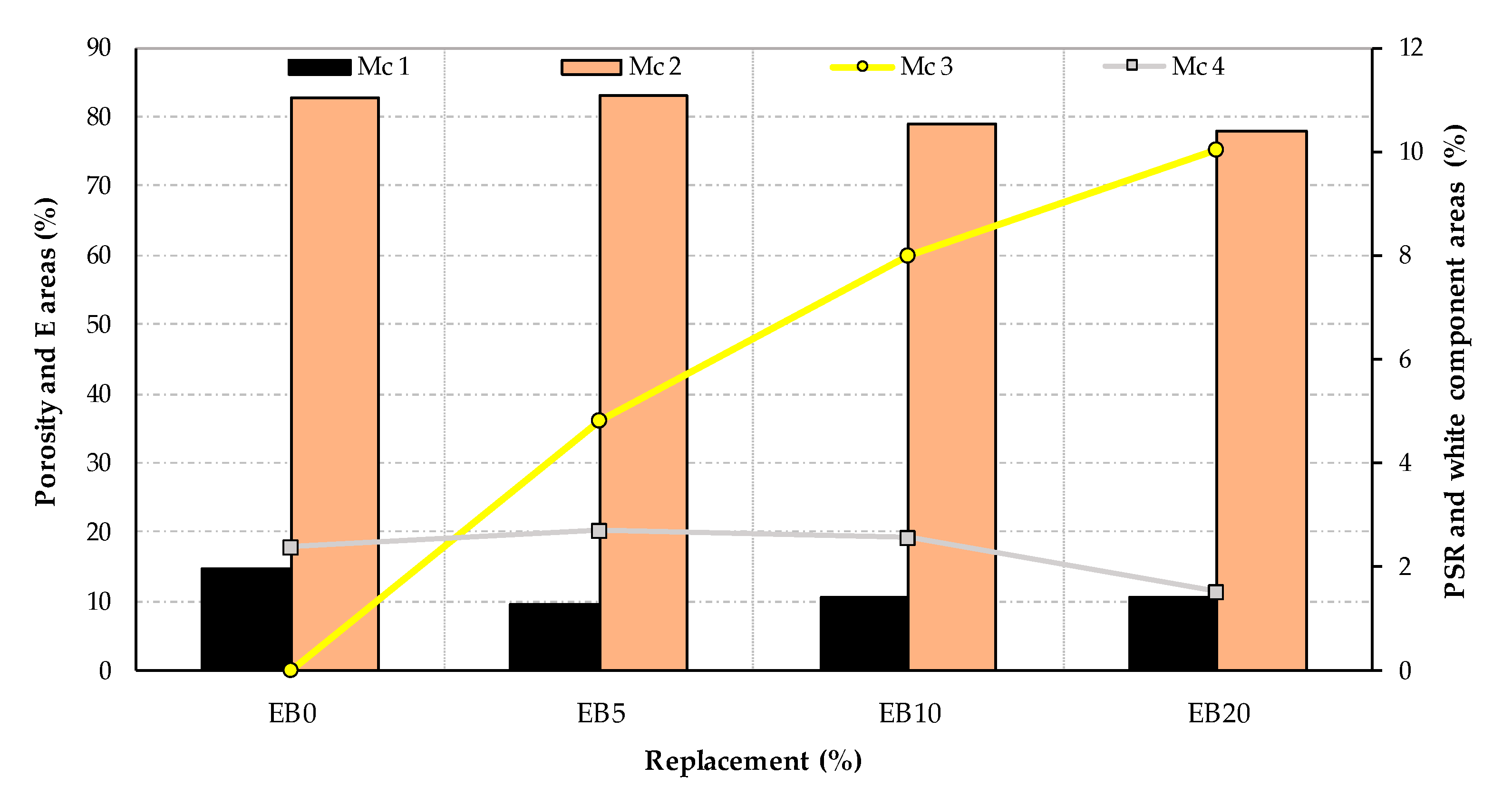

3.11. Microstructural Components of the EB

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaquin, P.A.; Augarde, C.E. Earth Building: History, Science and Conservation; BREPress: Berkeley, CA, USA, 2012; Available online: https://durham-repository.worktribe.com/output/1124958 (accessed on 21 November 2024).

- Pacheco-Torgal, F. 1—Introduction to eco-efficient masonry bricks and blocks. In Eco-Efficient Masonry Bricks and Blocks; Pacheco-Torgal, F., Lourenço, P.B., Labrincha, J.A., Kumar, S., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 1–10. [Google Scholar] [CrossRef]

- Viñuales, G.M. Tecnología y construcción con tierra. Apuntes: Revista de Estudios sobre Patrimonio Cultural. J. Cult. Herit. Stud. 2007, 20, 220–231. [Google Scholar]

- Hernandez, V.; Botero Botero, L.F.; Carvajal Arango, D. Fabricación de bloques de tierra comprimida con adición de residuos de construcción y demolición como reemplazo del agregado pétreo convencional. Ing. Cienc. 2015, 11, 197–220. [Google Scholar] [CrossRef]

- Bestraten, S.; Hormías, E.; Altemir, A. Construcción con tierra en el siglo XXI. Inf. Construcción 2011, 63, 5–20. [Google Scholar] [CrossRef]

- Ouma, J.; Ongwen, N.; Ogam, E.; Auma, M.; Fellah, Z.E.A.; Mageto, M.; Ben Mansour, M.; Oduor, A. Acoustical properties of compressed earth blocks: Effect of compaction pressure, water hyacinth ash and lime. Case Stud. Constr. Mater. 2023, 18, e01828. [Google Scholar] [CrossRef]

- Dormohamadi, M.; Rahimnia, R. Combined effect of compaction and clay content on the mechanical properties of adobe brick. Case Stud. Constr. Mater. 2020, 13, e00402. [Google Scholar] [CrossRef]

- Delgado, M.C.J.; Guerrero, I.C. Earth building in Spain. Constr. Build. Mater. 2006, 20, 679–690. [Google Scholar] [CrossRef]

- El-yahyaoui, A.; Manssouri, I.; Noureddine, O.; Sahbi, H.; Khaldoun, A. Physical and mechanical properties of unfired clay bricks with saw palmetto fibers additive as a construction material. Mater. Today Proc. 2023, 72, 3804–3814. [Google Scholar] [CrossRef]

- Labiad, Y.; Meddah, A.; Beddar, M.; Pantelidis, L. Study on characterization, mechanical, and thermal properties of Alfa fiber–reinforced compressed earth blocks incorporating crushed brick waste. Arab. J. Geosci. 2023, 16, 575. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural additives and biopolymers for raw earth construction stabilization—A review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- Rajurkar, V.; Chitade, A.Z. Study of Natural Fiber over Strength and Density of Cement Stabilized Rammed Earth Blocks. IOP Conf. Ser. Earth Environ. Sci. 2023, 1193, 012025. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A. The mechanical and physical properties of compressed earth block stabilized with lime and filled with untreated and alkali-treated date palm fibers. Constr. Build. Mater. 2016, 104, 52–62. [Google Scholar] [CrossRef]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture, 2nd and rev. ed.; Birkhäuser: Basel, Switzerland; Berlin, Germany; Boston, MA, USA, 2006. [Google Scholar]

- Sujatha, E.R.; Selsia Devi, S. Reinforced soil blocks: Viable option for low cost building units. Constr. Build. Mater. 2018, 189, 1124–1133. [Google Scholar] [CrossRef]

- Van Damme, H.; Houben, H. Earth concrete. Stabilization revisited. Cem. Concr. Res. 2018, 114, 90–102. [Google Scholar] [CrossRef]

- Laguna-Torres, C.A.; González-López, J.R.; Guerra-Cossío, M.Á.; Guerrero-Baca, L.F.; Chávez-Guerrero, L.; Figueroa-Torres, M.Z.; Zaldívar-Cadena, A.A. Effect of physical, chemical, and mineralogical properties for selection of soils stabilized by alkaline activation of a natural pozzolan for earth construction techniques such as compressed earth blocks. Constr. Build. Mater. 2024, 419, 135449. [Google Scholar] [CrossRef]

- Brigatti, M.F.; Galan, E.; Theng, B.K.G. Chapter 2 Structures and Mineralogy of Clay Minerals. In Developments in Clay Science; Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Handbook of Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; Volume 1, pp. 19–86. [Google Scholar] [CrossRef]

- Sanchez-Soto, P.J.; Wiewióra, A.; Avilés, M.A.; Justo, A.; Pérez-Maqueda, L.A.; Pérez-Rodríguez, J.L.; Bylina, P. Talc from Puebla de Lillo, Spain. II. Effect of dry grinding on particle size and shape. Appl. Clay Sci. 1997, 12, 297–312. [Google Scholar] [CrossRef]

- Konta, J. Clay and man: Clay raw materials in the service of man. Appl. Clay Sci. 1995, 10, 275–335. [Google Scholar] [CrossRef]

- Kuzvart, M. Industrial minerals and rocks; Elsevier: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Storemyr, P. Weathering of soapstone in a historical perspective. Mater. Charact. 2004, 53, 191–207. [Google Scholar] [CrossRef]

- Grammatikakis, I.; Demadis, K.D.; Kyriakidis, E.; Cabeza, A.; Leon-Reina, L. New evidence about the use of serpentinite in the Minoan architecture. A μ-Raman based study of the “House of the High Priest” drain in Knossos. J. Archaeol. Sci. Rep. 2017, 16, 316–321. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Mastali, M.; Kinnunen, P.; Illikainen, M. Alkali-activated soapstone waste—Mechanical properties, durability, and economic prospects. Sustain. Mater. Technol. 2019, 22, e00118. [Google Scholar] [CrossRef]

- Cota, F.P.; Alves, R.A.A.; Panzera, T.H.; Strecker, K.; Christoforo, A.L.; Borges, P.H.R. Physical properties and microstructure of ceramic–polymer composites for restoration works. Mater. Sci. Eng. A 2012, 531, 28–34. [Google Scholar] [CrossRef]

- Torres, H.S.S.; Varajão, A.F.D.C.; Sabioni, A.C.S. Technological properties of ceramic produced from steatite (soapstone) residues-kaolinite clay ceramic composites. Appl. Clay Sci. 2015, 112–113, 53–61. [Google Scholar] [CrossRef]

- Baron, A.; Burke, A.L.; Gratuze, B.; Chapdelaine, C. Characterization and origin of steatite beads made by Northern Iroquoians in the St. Lawrence Valley during the 15th and 16th centuries. J. Archaeol. Sci. Rep. 2016, 8, 323–334. [Google Scholar] [CrossRef]

- El Alami, K.; Asbik, M.; Agalit, H. Identification of natural rocks as storage materials in thermal energy storage (TES) system of concentrated solar power (CSP) plants—A review. Sol. Energy Mater. Sol. Cells 2020, 217, 110599. [Google Scholar] [CrossRef]

- Hänchen, M.; Brückner, S.; Steinfeld, A. High-temperature thermal storage using a packed bed of rocks—Heat transfer analysis and experimental validation. Appl. Therm. Eng. 2011, 31, 1798–1806. [Google Scholar] [CrossRef]

- Gökçe, H.; Ağaoğulları, D.; Öveçoğlu, M.L.; Duman, İ.; Boyraz, T. Characterization of microstructural and thermal properties of steatite/cordierite ceramics prepared by using natural raw materials. J. Eur. Ceram. Soc. 2011, 31, 2741–2747. [Google Scholar] [CrossRef]

- Mielcarek, W.; Nowak-Woźny, D.; Prociów, K. Correlación entre las fases de MgSiO3 y la durabilidad mecánica de la cerámica de esteatita. J. Eur. Ceram. Soc. 2004, 24, 3817–3821. [Google Scholar] [CrossRef]

- Soykan, H.Ş. Low-temperature fabrication of steatite ceramics with boron oxide addition. Ceram. Int. 2007, 33, 911–914. [Google Scholar] [CrossRef]

- Kharitonov, F.Y.; Shapiro, L.E. A steatite material having a wide sintering range. Glass Ceram. 1989, 46, 162–165. [Google Scholar] [CrossRef]

- Terzić, A.; Obradović, N.; Stojanović, J.; Pavlović, V.; Andrić, L.; Olćan, D.; Đorđević, A. Influence of different bonding and fluxing agents on the sintering behavior and dielectric properties of steatite ceramic materials. Ceram. Int. 2017, 43, 13264–13275. [Google Scholar] [CrossRef]

- Vakalova, T.V.; Sergeev, N.P.; Maksimova, V.E.; Rusinov, P.G.; Balamygin, D.I. Improvement of sinterability and mechanical properties of magnesia-silicate ceramics with enstatite phase from mixtures of serpentinite with silica additives. J. Ind. Eng. Chem. 2022, 106, 86–102. [Google Scholar] [CrossRef]

- Cota, T.G.; Reis, E.L.; Lima, R.M.F.; Cipriano, R.A.S. Incorporation of waste from ferromanganese alloy manufacture and soapstone powder in red ceramic production. Appl. Clay Sci. 2018, 161, 274–281. [Google Scholar] [CrossRef]

- Mymrin, V.; Alekseev, K.; Fortini, O.M.; Catai, R.E.; Nagalli, A.; Rissardi, J.L.; Molinetti, A.; Pedroso, D.E.; Izzo, R.L.S. Water cleaning sludge as principal component of composites to enhance mechanical properties of ecologically clean red ceramics. J. Clean. Prod. 2017, 145, 367–373. [Google Scholar] [CrossRef]

- Strecker, K.; Panzera, T.H.; Sabariz, A.L.R.; Miranda, J.S. The effect of incorporation of steatite wastes on the mechanical properties of cementitious composites. Mater. Struct. 2010, 43, 923–932. [Google Scholar] [CrossRef]

- Panzera, T.H.; Strecker, K.; Miranda, J.d.S.; Christoforo, A.L.; Borges, P.H.R. Cement-Steatite composites reinforced with carbon fibres: An alternative for restoration of brazilian historical buildings. Mat. Res. 2011, 14, 118–123. [Google Scholar] [CrossRef]

- Panzera, T.H.; Strecker, K.; de Oliveira, L.G.; Vasconcelos, W.L.; Schiavon, M.A. Effect of steatite waste additions on the physical and mechanical properties of clay composites. Mater. Res. 2010, 13, 535–540. [Google Scholar] [CrossRef]

- Venkatesh, V.; Shanmugasundaram, M. Enhancement of mechanical and microstructural characteristics of magnesium oxychloride cement with metasteatite. Case Stud. Constr. Mater. 2024, 21, e03683. [Google Scholar] [CrossRef]

- Vu, V.-A.; Cloutier, A.; Bissonnette, B.; Blanchet, P.; Dagenais, C. Steatite Powder Additives in Wood-Cement Drywall Particleboards. Materials 2020, 13, 4813. [Google Scholar] [CrossRef]

- Influence of ultra-fine steatite powder on the properties of alkali-activated concrete. Proc. Inst. Civ. Eng. Eng. Sustain. 2022, 176, 17–27. [CrossRef]

- Gnanaraj, S.C.; Chokkalingam, R.B.; Thankam, G.L.; Pothinathan, S.K.M. Durability properties of self-compacting concrete developed with fly ash and ultra fine natural steatite powder. J. Mater. Res. Technol. 2021, 13, 431–439. [Google Scholar] [CrossRef]

- Rodrigues, M.L.M.; Lima, R.M.F. Cleaner production of soapstone in the Ouro Preto region of Brazil: A case study. J. Clean. Prod. 2012, 32, 149–156. [Google Scholar] [CrossRef]

- Minisy, I.M.; Salahuddin, N.A.; Ayad, M.M. Adsorption of methylene blue onto chitosan–montmorillonite/polyaniline nanocomposite. Appl. Clay Sci. 2021, 203, 105993. [Google Scholar] [CrossRef]

- Igwe Idumah, C.; Okonkwo, U.C.; Obele, C.M. Recently emerging advancements in montmorillonite polymeric nanoarchitectures and applications. Clean. Mater. 2022, 4, 100071. [Google Scholar] [CrossRef]

- Barbeta Solà, G. Mejora de la Tierra Estabilizada en el Desarrollo de una Arquitectura Sostenible Hacia el Siglo XXI. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2002. [Google Scholar] [CrossRef]

- Frink, L.; Glazer, D.; Harry, K. Canadian Arctic soapstone cooking technology. N. Am. Archaeol. 2012, 33, 429–449. [Google Scholar] [CrossRef]

- Casapino-Espinoza, C.A.; Gómez-Soberón, J.M.; Gómez-Soberón, M.C. The Effect of Recycled Crushed Brick Aggregate on the Physical–Mechanical Properties of Earth Blocks. Buildings 2025, 15, 145. [Google Scholar] [CrossRef]

- UNE 41410:2023; Bloques de Tierra Comprimida (BTC) Para Muros y Tabiques. UNE Asociación Española de Normalización: Madrid, Spain, 2023. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0072146 (accessed on 4 July 2024).

- Standard Specification for Aggregate for Masonry Mortar. Available online: https://www.astm.org/c0144-18.html (accessed on 5 July 2024).

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Publications: London, UK, 1994; ISBN 978-1-85339-193-4. [Google Scholar]

- Noureddine, O.; Manssouri, I.; Sahbi, H.; Limami, H.; Khaldoun, A. Rheological and physico-mechanical investigations on the destabilization of unfired clay bricks with almond husk additive by salt. Constr. Build. Mater. 2023, 375, 130971. [Google Scholar] [CrossRef]

- Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. Available online: https://www.astm.org/c0128-22.html (accessed on 4 July 2024).

- UNE 7050-2:1997; Tamices y Tamizado de Ensayo. Parte 2: Telas Metálicas, Chapas Perforadas y Láminas Electrosoldadas. Medidas Nominales de las Aberturas. UNE Asociación Española de Normalización: Madrid, Spain, 1997. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0000151 (accessed on 4 July 2024).

- UNE-EN ISO 17892-12:2019; Investigación y Ensayos Geotécnicos. Ensayos de Laboratorio de Suelos. Parte 12: Determinación del Límite Líquido y del Límite Plástico. UNE Asociación Española de Normalización: Madrid, Spain, 2019. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=norma-une-en-iso-17892-12-2019-n0062183 (accessed on 13 November 2024).

- AS 1289.3.4.1-2008; Methods of Testing Soils for Engineering Purposes, Method 3.4.1: Soil Classification Tests—Determination of the Linear Shrinkage of a Soil—Standard Method. Standards Australia Store: Sydney, Australia, 2008. Available online: https://store.standards.org.au/product/as-1289-3-4-1-2008 (accessed on 4 July 2024).

- Skempton, A.W. The colloidal activity of clays. Sel. Pap. Soil Mech. 1953, 1, 57–61. [Google Scholar]

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Prediction of Swelling Potential for Compacted Clays. J. Soil Mech. Found. Div. 1962, 88, 53–87. [Google Scholar] [CrossRef]

- Van der Merwe, D.H. The prediction of heave from the plasticity index and percentage clay fraction of soils. Civ. Eng. Siviele Ingenieurswese 1964, 1964, 103–107. [Google Scholar]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, S.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

- Lahdili, M.; El Abbassi, F.-E.; Sakami, S.; Aamouche, A. Mechanical and Thermal Behavior of Compressed Earth Bricks Reinforced with Lime and Coal Aggregates. Buildings 2022, 12, 1730. [Google Scholar] [CrossRef]

- Giroudon, M.; Laborel-Préneron, A.; Aubert, J.-E.; Magniont, C. Comparison of barley and lavender straws as bioaggregates in earth bricks. Constr. Build. Mater. 2019, 202, 254–265. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.-E.; Magniont, C.; Maillard, P.; Poirier, C. Effect of Plant Aggregates on Mechanical Properties of Earth Bricks. J. Mater. Civ. Eng. 2017, 29, 04017244. [Google Scholar] [CrossRef]

- Afnor EDITIONS. XP P13-901. Available online: https://www.boutique.afnor.org/fr-fr/norme/xp-p13901/blocs-de-terre-comprimee-pour-murs-et-cloisons-definitions-specifications-m/fa120503/487 (accessed on 13 December 2024).

- BOE-A-2023-628 Real Decreto 3/2023, de 10 de enero, por el que se establecen los criterios técnico-sanitarios de la calidad del agua de consumo, su control y suministro. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-2023-628 (accessed on 4 July 2024).

- Normas del Reglamento Nacional de Edificaciones (RNE). Available online: https://www.gob.pe/institucion/sencico/informes-publicaciones/887225-normas-del-reglamento-nacional-de-edificaciones-rne (accessed on 16 December 2022).

- UNE-EN ISO 17892-4:2019; Investigación y Ensayos Geotécnicos. Ensayos de Laboratorio de Suelos. Parte 4: Determinación de la Distribución Granulo-métrica. UNE Asociación Española de Normalización: Madrid, Spain, 2019. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0062597 (accessed on 4 July 2024).

- Normas AENOR. ISO 3310-1:2016. Available online: https://tienda.aenor.com/norma-iso-3310-1-2016-062410 (accessed on 10 July 2024).

- Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. Available online: https://www.astm.org/d4318-17e01.html (accessed on 15 June 2023).

- UNE-EN ISO 12570:2000; Prestaciones Higrotérmicas de los Productos y Materiales Para Edificios. Determinación del Contenido de Humedad Mediante Secado a Elevadas Temperaturas. UNE Asociación Española de Normalización: Madrid, Spain, 2000. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0023664 (accessed on 4 July 2024).

- UNE-EN ISO 18754:2022; (Ratificada) Cerámicas Técnicas (Cerámicas Avanzadas, Cerámicas Técnicas Avanzadas). Determinación de la Densidad y de la Porosidad Aparente. UNE Asociación Española de Normalización: Madrid, Spain, 2022. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=norma-une-en-iso-18754-2022-n0069596 (accessed on 5 July 2024).

- Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units. Available online: https://www.astm.org/c0426-22.html (accessed on 16 June 2023).

- UNE-EN 1367-4:2009; Ensayos Para Determinar las Propiedades Térmicas y de Alteración de los Áridos. Parte 4: Determinación de la Retracción por Secado. UNE Asociación Española de Normalización: Madrid, Spain, 2009. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0043307 (accessed on 5 July 2024).

- UNE-EN 771-4:2011+A1:2016; Especificaciones de Piezas Para Fábrica de Albañilería. Parte 4: Bloques de Hormigón Celular Curado en Autoclave. UNE Asociación Española de Normalización: Madrid, Spain, 2016. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0056390 (accessed on 18 February 2025).

- UNE-EN 771-5:2011+A1:2016; Especificaciones de Piezas Para Fábrica de Albañilería. Parte 5: Piezas de Piedra Artificial. UNE Asociación Española de Normalización: Madrid, Spain, 2016. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0056812 (accessed on 18 February 2025).

- Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Available online: https://www.astm.org/c0039_c0039m-21.html (accessed on 4 July 2024).

- Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. Available online: https://www.astm.org/c0067_c0067m-23.html (accessed on 16 June 2023).

- UNE-EN 772-1:2011+A1:2016; Métodos de Ensayo de Piezas Para Fábrica de Albañilería. Parte 1: Determinación de la Resistencia a Compresión. UNE Asociación Española de Normalización: Madrid, Spain, 2016. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0047873 (accessed on 4 July 2024).

- Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature. Available online: https://www.astm.org/c1161-13.html (accessed on 5 July 2024).

- E1876 Método de Prueba Estándar Para el Módulo de Young Dinámico, el Módulo de Corte y el Coeficiente de Poisson mediante Excitación de Impulso de Vibración. Available online: https://www.astm.org/e1876-22.html (accessed on 4 July 2024).

- UNE-EN 14146:2004; Métodos de Ensayo Para Piedra Natural. Determinación del Módulo de Elasticidad Dinámico (con la Medida de Frecuencia de Resonancia Fundamental). UNE Asociación Española de Normalización: Madrid, Spain, 2004. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0032544 (accessed on 4 July 2024).

- Real, S.; Bogas, J.A.; Cruz, R.; Gomes, M.G.; Nabais, M. Thermal performance of compressed earth blocks stabilised with thermoactivated recycled cement. Energy Build. 2024, 314, 114288. [Google Scholar] [CrossRef]

- NZS 4298:2024; Materials and construction for earth buildings. Standards New Zealand: Wellington, New Zealand, 2024. Available online: https://www.standards.govt.nz/shop/NZS-42982024 (accessed on 18 February 2025).

- Solver. Available online: https://www.solver.com/ (accessed on 19 March 2025).

- Augusta Cirvini, S.; Gómez Voltan, J.A. Ensayo y dispositivo para evaluar la absorción capilar en probetas de adobe y tapia. Revista Técnica de la Facultad de Ingeniería Universidad del Zulia 2014, 37, 3–10. [Google Scholar]

- Kenya Bureau of Standards Testing Services Department. UNIDO Knowledge Hub. Available online: https://hub.unido.org/es/node/3003 (accessed on 4 March 2025).

- 14.7.4 NMAC. Available online: https://www.srca.nm.gov/parts/title14/14.007.0004.html (accessed on 4 March 2025).

- KS ARS 670-1:2018; Compressed Earth Blocks—Part 1: Definitions, Classification, Specifications and Conformity Criteria. Kenya Bureau of Standards: Nairobi, Kenya, 2018. Available online: https://webstore.kebs.org/index.php?route=product/product&product_id=18324 (accessed on 4 March 2025).

- Ma, J.; Abdelaal, A.; Zhang, H.; Zhou, A.; Fu, Y.; Xie, Y.M. Ultra-compressed earth block stabilized by bio-binder for sustainable building construction. Case Stud. Constr. Mater. 2024, 21, e03523. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Fontana, P. Mechanical behaviour of earthen materials: A comparison between earth block masonry, rammed earth and cob. Constr. Build. Mater. 2014, 61, 327–339. [Google Scholar] [CrossRef]

- Miccoli, L.; Garofano, A.; Fontana, P.; Müller, U. Experimental testing and finite element modelling of earth block masonry. Eng. Struct. 2015, 104, 80–94. [Google Scholar] [CrossRef]

- Wiehle, P.; Brinkmann, M. Material behaviour of unstabilised earth block masonry and its components under compression at varying relative humidity. Case Stud. Constr. Mater. 2022, 17, e01663. [Google Scholar] [CrossRef]

- Haddad, K.; Lannon, S.; Latif, E. Investigation of Cob construction: Review of mix designs, structural characteristics, and hygrothermal behaviour. J. Build. Eng. 2024, 87, 108959. [Google Scholar] [CrossRef]

- Wiehle, P.; Simon, S.; Baier, J.; Dennin, L. Influence of relative humidity on the strength and stiffness of unstabilised earth blocks and earth masonry mortar. Constr. Build. Mater. 2022, 342, 128026. [Google Scholar] [CrossRef]

- Pefferkorn, E. Structure and stability of natural organic matter/soil complexes and related synthetic and mixed analogues. Adv. Colloid Interface Sci. 1997, 73, 127–200. [Google Scholar] [CrossRef]

- Lawrence, C.D. 9—The Production of Low-Energy Cements. In Lea’s Chemistry of Cement and Concrete (Fourth Edition); Hewlett, P.C., Ed.; Butterworth-Heinemann: Oxford, UK, 1998; pp. 421–470. [Google Scholar] [CrossRef]

- Tadonbou, J.; Pliya, P.; Beaucour, A.-L.; Faria, P.; Noumowe, A. Behavior of earth mortars at high temperature. Constr. Build. Mater. 2024, 425, 136093. [Google Scholar] [CrossRef]

- El hammouti, A.; Charai, M.; Channouf, S.; Horma, O.; Nasri, H.; Mezrhab, A.; Karkri, M.; Tankari, M.A. Laboratory-testing and industrial scale performance of different clays from eastern Morocco for brick manufacturing. Constr. Build. Mater. 2023, 370, 130624. [Google Scholar] [CrossRef]

- Földvári, M. Handbook of Thermogravimetric System of Minerals and Its Use in Geological Practice; Geological Institute of Hungary (=Magyar Állami Földtani Intézet): Budapest, Hungary, 2011; ISBN 978-963-671-288-4. [Google Scholar]

- Santha Kumar, G.; Saini, P.K.; Deoliya, R.; Mishra, A.K.; Negi, S.K. Characterization of laterite soil and its use in construction applications: A review. Resour. Conserv. Recycl. Adv. 2022, 16, 200120. [Google Scholar] [CrossRef]

- Ozturk, S. Optimization of thermal conductivity and lightweight properties of clay bricks. Eng. Sci. Technol. Int. J. 2023, 48, 101566. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Baxter, D.; Wang, X.; Mackinnon, I.D.R.; Xi, Y. Thermal behaviours of clay mixtures during brick firing: A combined study of in-situ XRD, TGA and thermal dilatometry. Constr. Build. Mater. 2021, 299, 124319. [Google Scholar] [CrossRef]

- Terzić, A.; Obradović, N.; Kosanović, D.; Stojanović, J.; Đorđević, A.; Andrić, L.; Pavlović, V.B. Effects of mechanical-activation and TiO2 addition on the behavior of two-step sintered steatite ceramics. Ceram. Int. 2019, 45, 3013–3022. [Google Scholar] [CrossRef]

- Li, M.-T.; Li, Y.-T.; Sun, L.; Xu, Z.-B.; Zhao, Y.; Meng, Z.-H.; Wu, Q.-P. Mejora considerable de la eficiencia de almacenamiento de calor para el sistema termoquímico Mg(OH)2-MgO-H2O con la adición de Ce(NO3)3 y LiOH. Nano Energy 2021, 81, 105603. [Google Scholar] [CrossRef]

- Mastronardo, E.; Bonaccorsi, L.; Kato, Y.; Piperopoulos, E.; Lanza, M.; Milone, C. Strategies for the enhancement of heat storage materials performances for MgO/H2O/Mg(OH)2 thermochemical storage system. Appl. Therm. Eng. 2017, 120, 626–634. [Google Scholar] [CrossRef]

- Yan, J.; Pan, Z.H.; Zhao, C.Y. Experimental study of MgO/Mg(OH)2 thermochemical heat storage with direct heat transfer mode. Appl. Energy 2020, 275, 115356. [Google Scholar] [CrossRef]

- Akbarzadeh, A.; Ahmadlouydarab, M.; Niaei, A. Capabilities of α-Al2O3, γ-Al2O3, and bentonite dry powders used in flat plate solar collector for thermal energy storage. Renew. Energy 2021, 173, 704–720. [Google Scholar] [CrossRef]

- Raja Sekhar, Y.; Sharma, K.V.; Thundil Karupparaj, R.; Chiranjeevi, C. Heat Transfer Enhancement with Al2O3 Nanofluids and Twisted Tapes in a Pipe for Solar Thermal Applications. Procedia Eng. 2013, 64, 1474–1484. [Google Scholar] [CrossRef]

- Aluminium, Gallium, Indium and Thallium. In Chemistry of the Elements (Second Edition); Greenwood, N.N., Earnshaw, A., Eds.; Butterworth-Heinemann: Oxford, UK, 1997; pp. 216–267. ISBN 978-0-7506-3365-9. [Google Scholar]

- Zhang, L.-L.; Zheng, Y.-Y.; Wei, P.-C.; Diao, Q.-F.; Yin, Z.-Y. Nanoscale mechanical behavior of kaolinite under uniaxial strain conditions. Appl. Clay Sci. 2021, 201, 105961. [Google Scholar] [CrossRef]

- Zhao, Y.; Kong, L.; Xu, R.; Liu, J.; Sang, S. Mechanical properties of remolded hydrate-bearing clayey-silty sediments. J. Nat. Gas Sci. Eng. 2022, 100, 104473. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Study of the suitability of unfired clay bricks with polymeric HDPE & PET wastes additives as a construction material. J. Build. Eng. 2020, 27, 100956. [Google Scholar] [CrossRef]

- Cabrera-Covarrubias, F.G.; Gómez-Soberón, J.M.; Almaral-Sánchez, J.L.; Arredondo-Rea, S.P.; Gómez-Soberón, M.C.; Corral-Higuera, R. An Experimental Study of Mortars with Recycled Ceramic Aggregates: Deduction and Prediction of the Stress-Strain. Materials 2016, 9, 1029. [Google Scholar] [CrossRef]

| Designation | E * | PSR * |

|---|---|---|

| EB0 | 100 | - |

| EB5 | 95 | 5 |

| EB10 | 90 | 10 |

| EB20 | 80 | 20 |

| Property | Regulation | Consideration |

|---|---|---|

| Granulometry | UNE-EN ISO 17892-4:2019 [69] | Using ISO 3310 sieve series [70] |

| Specific weight | ASTM C128-22 [55] | - |

| Atterberg limits | ASTM D4318-17e1 [71] and UNE-EN ISO 17892-12:2019 [57] | - |

| MC | ASTM D4318-17e1 [71] and UNE-EN ISO 12570:2000 [72] | - |

| Shrinkage in aggregates | AS 1289.3.4.1-2008 [58] | - |

| Dosage | ASTM C144-18 [52], UNE 41410 [51] and E-080 [68] | [40,41,43,66] |

| Matrix | C | O | Na | Mg | Al | Si | K | Ca | Fe | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| %W | %A | %W | %A | %W | %A | %W | %A | %W | %A | %W | %A | %W | %A | %W | %A | %W | %A | |

| EB0 | 28.40 | 38.45 | 47.18 | 47.95 | 0.15 | 0.10 | 0.25 | 0.17 | 2.48 | 1.49 | 18.32 | 10.61 | 0.57 | 0.24 | 1.93 | 0.78 | 0.74 | 0.22 |

| EB5 | 29.18 | 40.17 | 46.47 | 48.01 | 0.64 | 0.44 | 1.94 | 1.19 | 7.47 | 4.40 | 0.51 | 0.21 | 12.96 | 5.34 | 0.84 | 0.25 | ||

| EB10 | 30.69 | 41.45 | 43.60 | 44.20 | 0.11 | 0.08 | 0.49 | 0.33 | 1.96 | 1.18 | 20.10 | 11.61 | 1.09 | 0.45 | 1.16 | 0.47 | 0.79 | 0.23 |

| EB20 | 32.47 | 43.60 | 44.25 | 44.60 | 2.69 | 1.78 | 1.88 | 1.13 | 8.70 | 5.00 | 0.31 | 0.13 | 8.54 | 3.44 | 1.16 | 0.34 | ||

| RCPSR Coefficients for the EB Properties | ||||

|---|---|---|---|---|

| EB Matrix | fc | fb | E∂ | λ |

| EB0 | 1.082 | 0.962 | 0.871 | 0.811 |

| EB5 | 1.156 | 1.083 | 1.116 | 1.062 |

| EB10 | 1.168 | 1.108 | 1.089 | 1.116 |

| EB20 | 0.966 | 0.981 | 0.735 | 1.079 |

| Compressive Strength (MPa) | Flexural Strength (MPa) | Elastic Modulus (GPa) | Thermal Conductivity (W/m·K) | ||||

|---|---|---|---|---|---|---|---|

| fc Ex. | fc Pr. | fb Ex. | fb Pr. | E∂ Ex. | E∂ Pr | λ Ex. | λ Pr. |

| 3.02 | 3.00 | 1.36 | 1.37 | 2.19 | 2.02 | 0.96 | 0.77 |

| 3.23 | 3.46 | 1.53 | 1.55 | 2.81 | 3.03 | 1.26 | 1.32 |

| 3.26 | 3.50 | 1.56 | 1.51 | 2.74 | 2.53 | 1.32 | 1.44 |

| 2.70 | 2.39 | 1.39 | 1.40 | 1.85 | 1.53 | 1.28 | 1.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casapino-Espinoza, C.A.; Gómez-Soberón, J.M.; Gómez-Soberón, M.C. The Use of Steatite Powder Waste as an Aggregate for the Manufacture of Earth Blocks—An Evaluation of Its Impact on Physical, Mechanical and Thermal Conductivity Properties. Buildings 2025, 15, 1605. https://doi.org/10.3390/buildings15101605

Casapino-Espinoza CA, Gómez-Soberón JM, Gómez-Soberón MC. The Use of Steatite Powder Waste as an Aggregate for the Manufacture of Earth Blocks—An Evaluation of Its Impact on Physical, Mechanical and Thermal Conductivity Properties. Buildings. 2025; 15(10):1605. https://doi.org/10.3390/buildings15101605

Chicago/Turabian StyleCasapino-Espinoza, Carlos Alberto, José Manuel Gómez-Soberón, and María Consolación Gómez-Soberón. 2025. "The Use of Steatite Powder Waste as an Aggregate for the Manufacture of Earth Blocks—An Evaluation of Its Impact on Physical, Mechanical and Thermal Conductivity Properties" Buildings 15, no. 10: 1605. https://doi.org/10.3390/buildings15101605

APA StyleCasapino-Espinoza, C. A., Gómez-Soberón, J. M., & Gómez-Soberón, M. C. (2025). The Use of Steatite Powder Waste as an Aggregate for the Manufacture of Earth Blocks—An Evaluation of Its Impact on Physical, Mechanical and Thermal Conductivity Properties. Buildings, 15(10), 1605. https://doi.org/10.3390/buildings15101605