A Study on Improving the Shape Error of the Lower Mold of Free-Form Concrete Panels Using Magnetic Force

Abstract

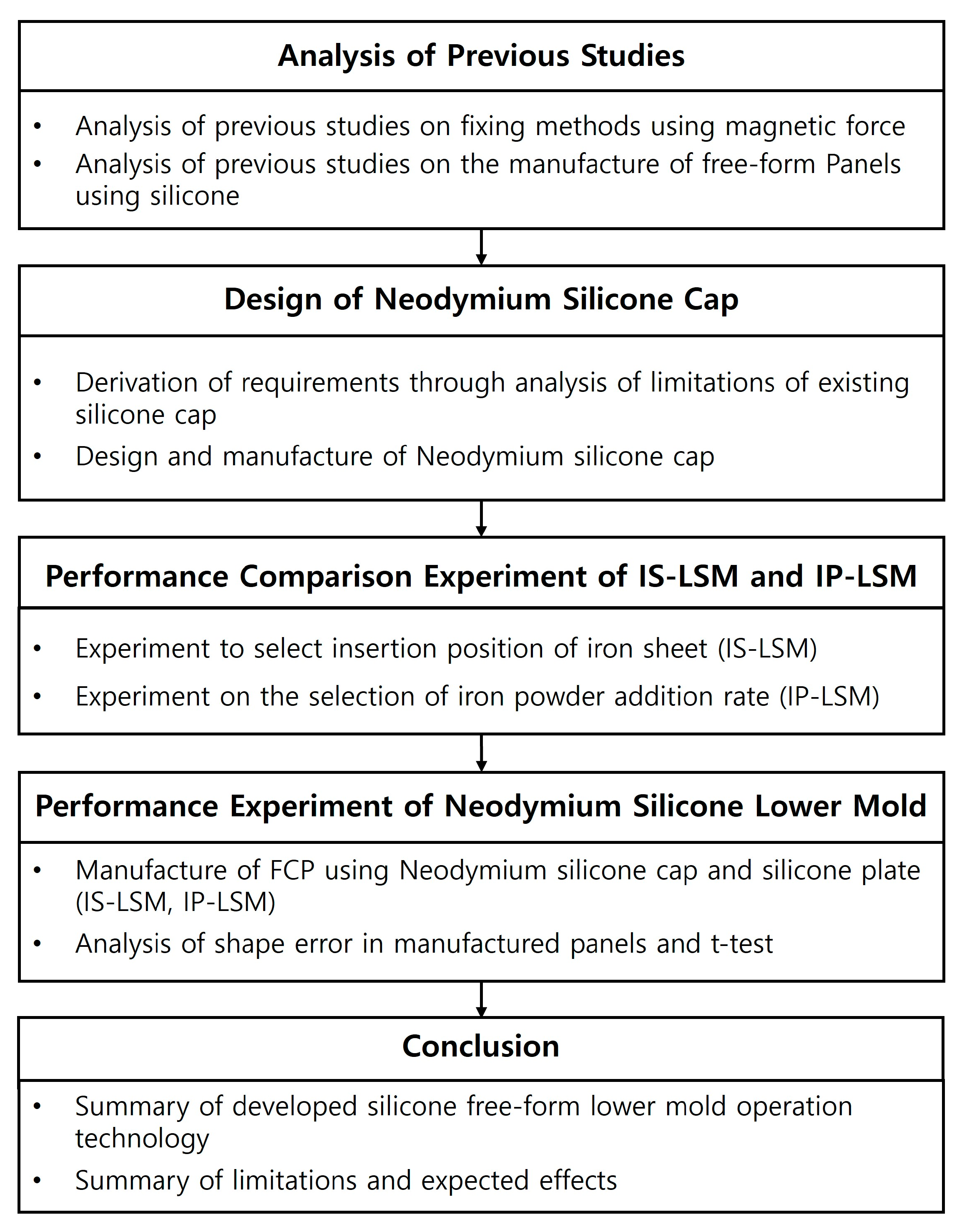

1. Introduction

2. Literature Review

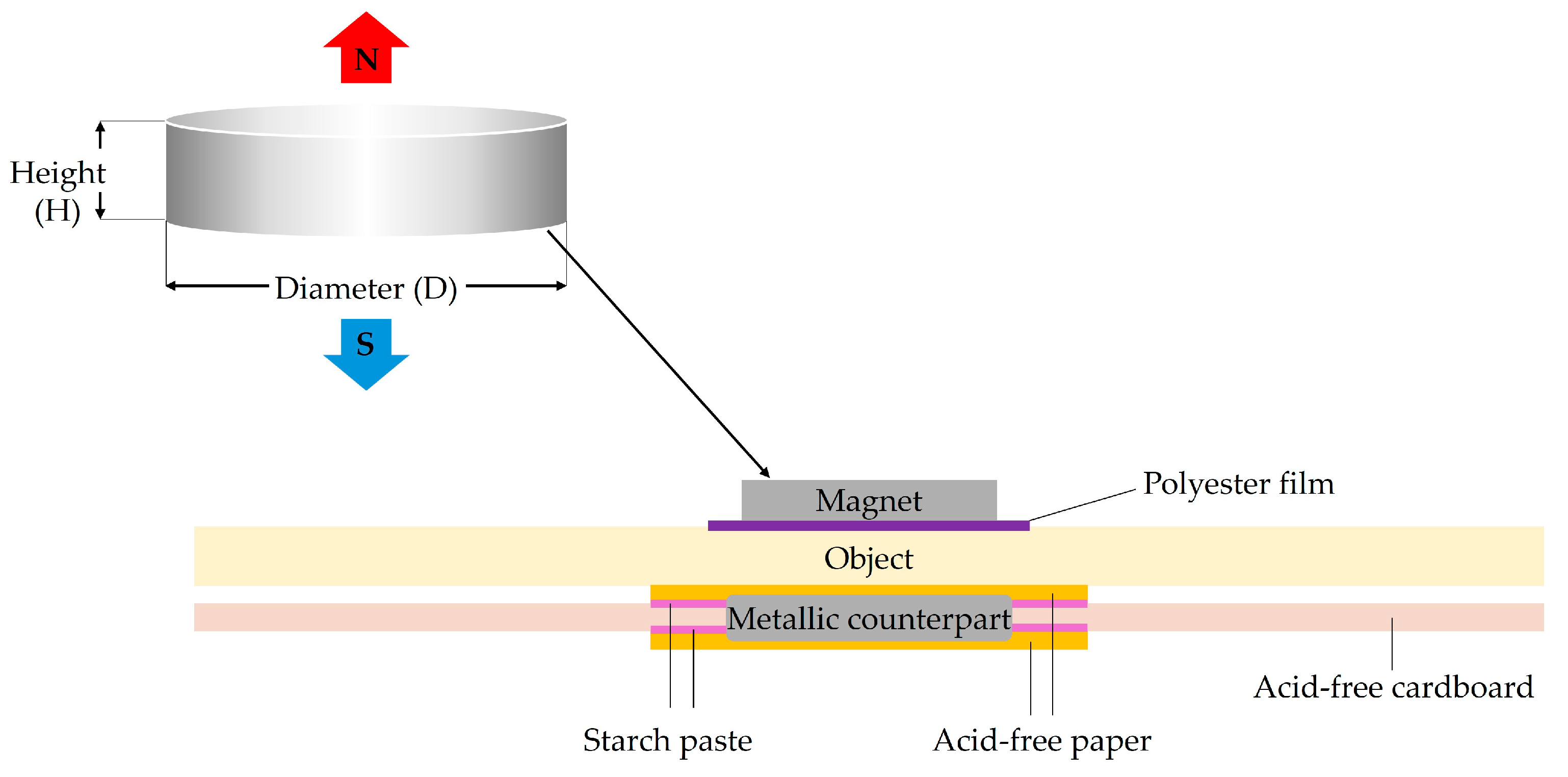

2.1. Analysis of Previous Studies on Fixing Methods Using Magnetic Force

2.2. Analysis of Previous Studies on the Manufacture of Free-Form Panels Using Silicone

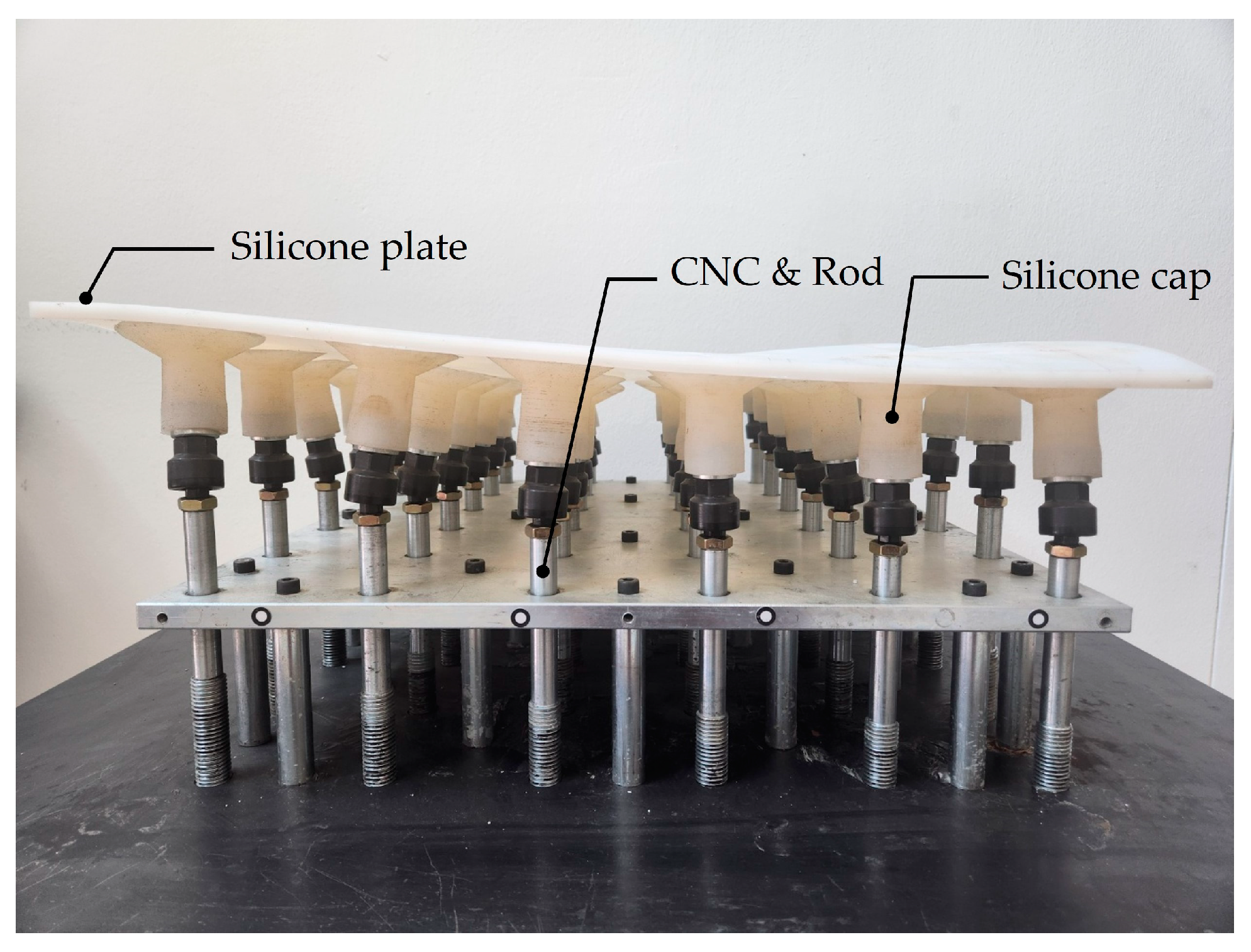

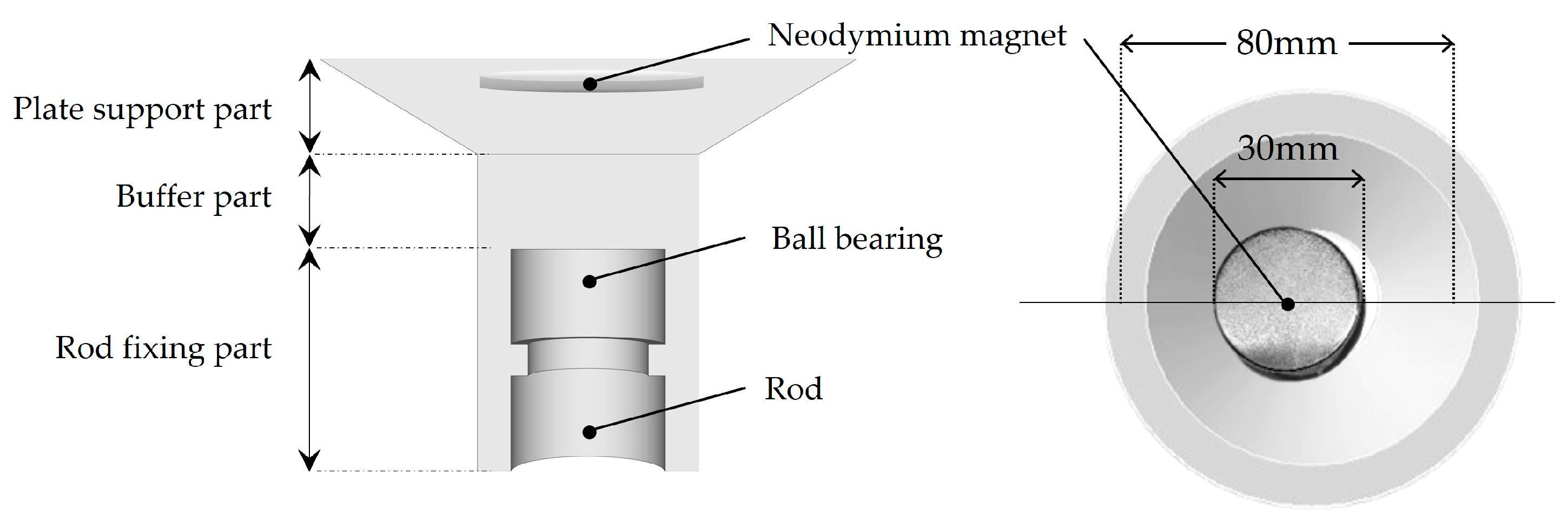

3. Design of Neodymium Silicone Cap

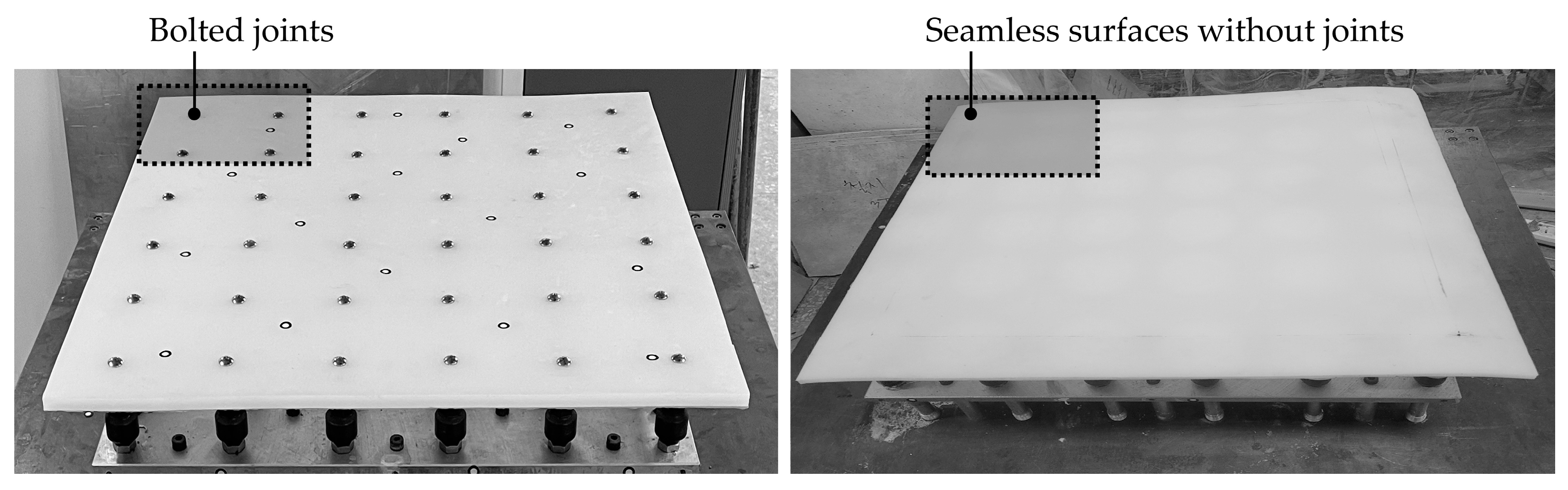

3.1. Analysis of Limitations of Existing Methods

3.2. Neodymium Silicone Cap Design

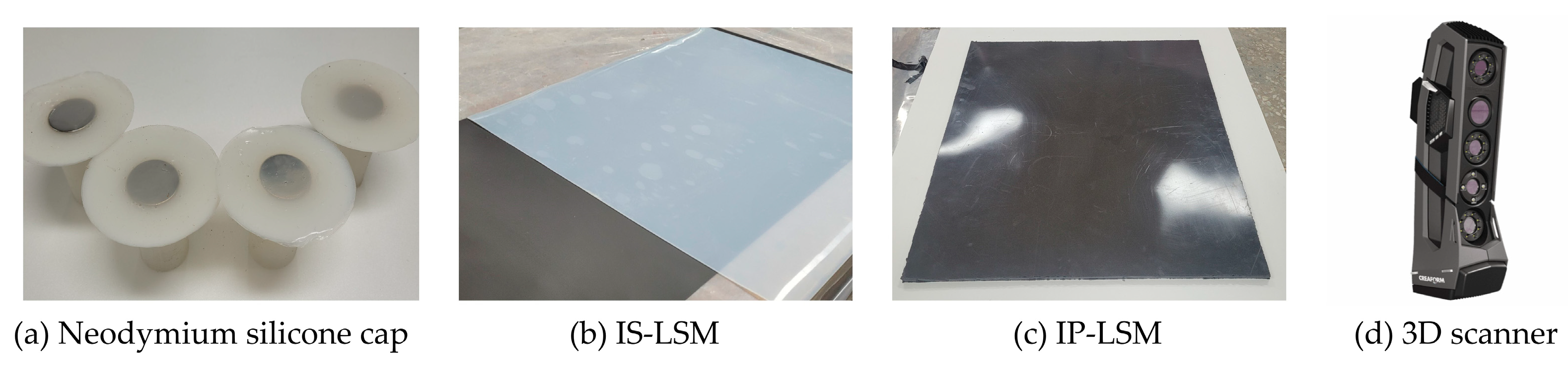

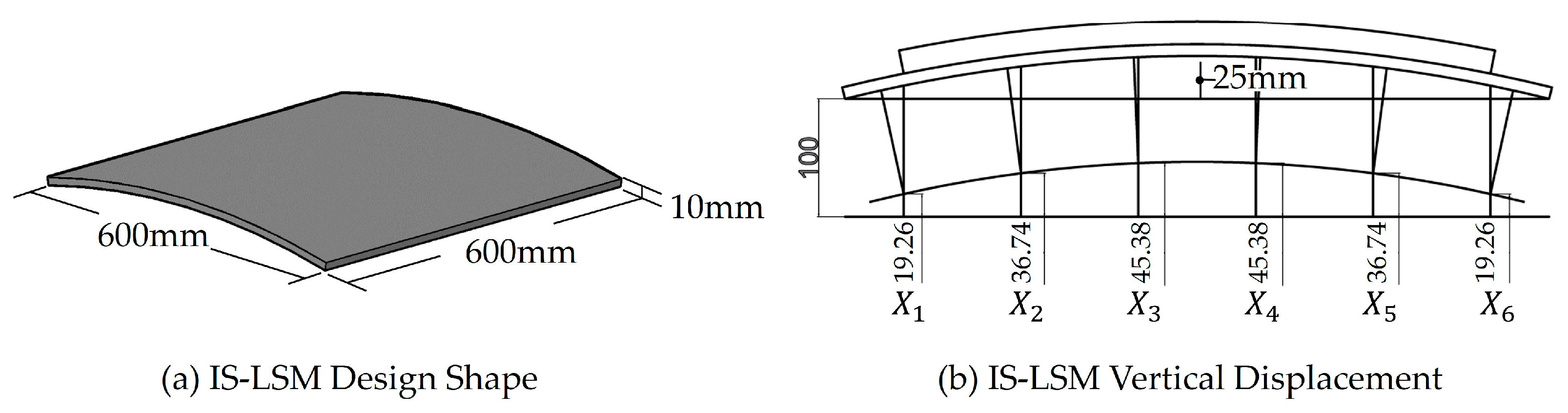

4. Manufacturing and Performance Comparison Experiment of IS-LSM and IP-LSM

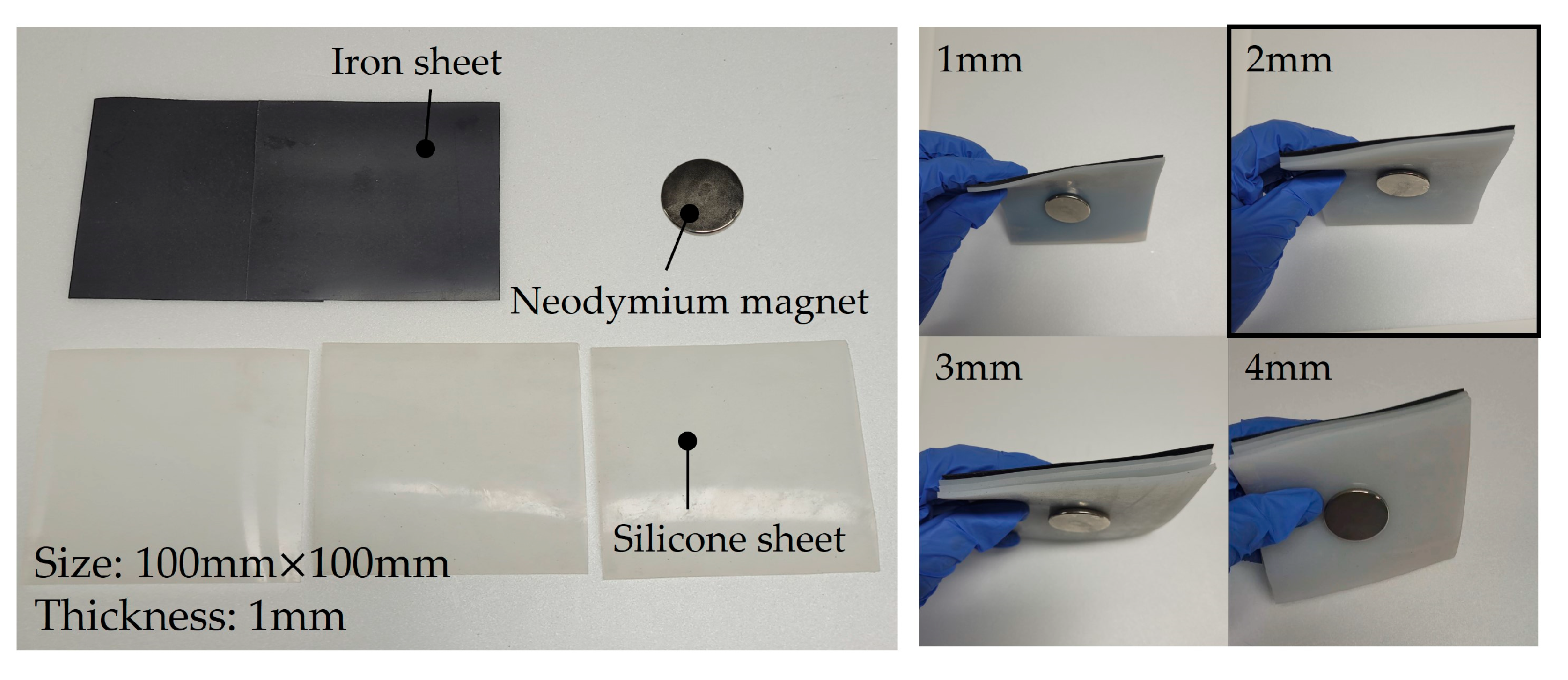

4.1. Performance Experiment for Manufacturing IS-LSM

4.2. Performance Test for IP-LSM Fabrication

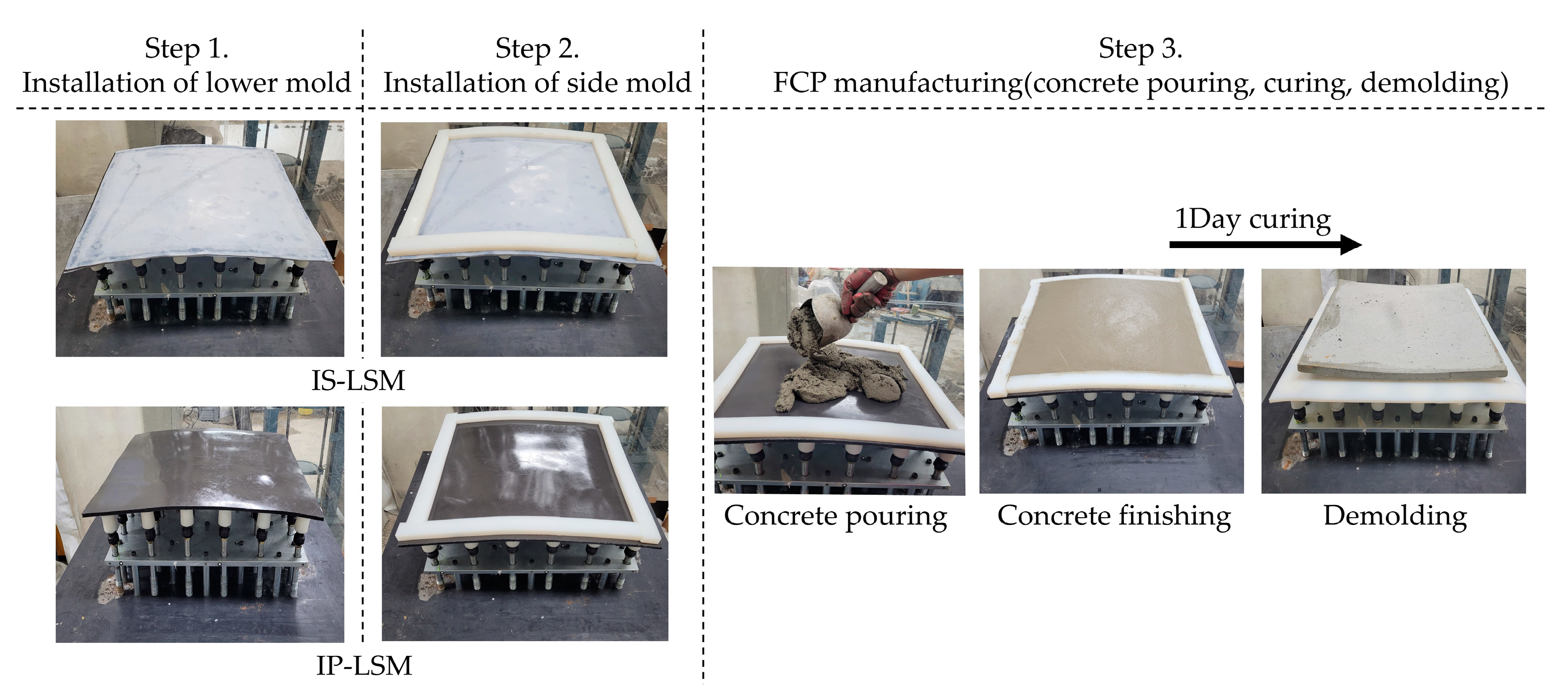

4.3. Experiment on the Manufacturing of Free-Form Concrete Panels

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yun, J.; Youn, J.; Kim, J.; Lee, D. Development of Connection Technology between Multi-Point Press and Flexible Mold for Manufacturing Free-Form Concrete Panel. Buildings 2022, 12, 767. [Google Scholar] [CrossRef]

- Hawkins, W.J.; Herrmann, M.; Ibell, T.J.; Kromoser, B.; Michaelski, A.; Orr, J.J.; Pedreschi, R.; Pronk, A.; Schipper, H.R.; Shepherd, P.; et al. Flexible formwork technologies—A state of the art review. Struct. Concr. 2016, 17, 911–935. [Google Scholar] [CrossRef]

- Lim, J.; Kim, D.Y.; Kim, S. An experimental study for quality assurance of free-form concrete panels produced by CNC machine. J. Civ. Eng. Manag. 2018, 24, 145–154. [Google Scholar] [CrossRef]

- Jeong, K. Development of Two-Sided CNC and Side Mould Control Equipment for Automatic Manufacture of Free-Form Concrete Panel. Master’s Thesis, Hanbat National University, Daejeon, Republic of Korea, 2021. [Google Scholar]

- Pottmann, H.; Schiftner, A.; Bo, P.; Schmiedhofer, H.; Wang, B.; Wallner, J. Freeform surfaces from single curved panels. ACM Trans. Graph. (TOG) 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Park, Y.; Jo, S.; Kim, S. Development of the free-formed concrete structure construction technologies using 3D digital design. In Proceedings of the Korean Institute of Building Construction Conference 2012, Jeonju, Republic of Korea, 18 May 2012; pp. 205–208. Available online: https://koreascience.kr/article/CFKO201228167666625.page (accessed on 16 September 2024).

- Ryu, H.; Kim, S. Case study of concrete surface design and construction method for freeform building based on BIM-focused on tri-bowl. J. Korea Inst. Build. Constr. 2012, 12, 347–357. [Google Scholar] [CrossRef][Green Version]

- Lee, G.; Kim, S. Case study of mass customization of double-curved metal façade panels using a new hybrid sheet metal processing technique. J. Constr. Eng. Manag. 2012, 138, 1322–1330. [Google Scholar] [CrossRef]

- Park, J.; Kim, K. Architectural Product and Formwork Manufacture using 3D Printing—Applicability Verification Through Manufacturing Factor Prediction and Experimentation. Korean J. Constr. Eng. Manag. 2022, 23, 113–117. [Google Scholar] [CrossRef]

- Ryu, J.W. The Transition of Digital Technologies for Irregular Shaped Buildings. J. Korea Acad.-Ind. Coop. Soc. 2011, 12, 4210–4215. [Google Scholar] [CrossRef]

- Youn, J.; Jeong, K.; Kim, J.; Kim, H.; Lee, D. Development of concrete extrusion nozzle for producing free-form concrete panels and extrusion test. Buildings 2023, 13, 784. [Google Scholar] [CrossRef]

- Youn, J.; Yun, J.; Kim, S.; Han, B.; Do, S.; Lee, D. An Analytical Study of the Latest Trends of Free-Form Molds. Sustainability 2022, 14, 3084. [Google Scholar] [CrossRef]

- Kim, S.; Son, S.; Lee, D. Development of Sustainable Production Technology of Free-Form Concrete Panels Using a Multi-Point Press CNC Machine. Sustainability 2021, 13, 1990. [Google Scholar] [CrossRef]

- Shewane, P.G.; Gite, M.; Singh, A.; Narkhede, A.J. An overview of neodymium magnets over normal magnets for the generation of energy. Int. J. Recent Innov. Trends Comput. Commun. 2014, 2, 4056–4059. [Google Scholar]

- Rivadulla, C.; Foffani, G.; Oliviero, A. Magnetic field strength and reproducibility of neodymium magnets useful for transcranial static magnetic field stimulation of the human cortex. Neuromodul. Technol. Neural Interface 2014, 17, 438–442. [Google Scholar] [CrossRef] [PubMed]

- Sterp Moga, E.; Sánchez Ortiz, A. Neodymium Magnets as a Minimal Intervention Alternative to Traditional Treatments for Fixing Paint on Contemporary Paintings. J. Am. Inst. Conserv. 2022, 61, 275–283. [Google Scholar] [CrossRef]

- Noehles, M.; Niehus, L. Mounting Works on Paper with Neodymium Magnets. Restaur. Int. J. Preserv. Libr. Arch. Mater. 2014, 35, 231–248. [Google Scholar] [CrossRef]

- Nical, A.; Foremny, A.; Kaczorek, K.; Kluczuk, P. Selected innovative solutions and overview of molds for precast concrete. In Proceedings of the Creative Construction Conference 2015, Krakow, Poland, 21–24 June 2015. [Google Scholar]

- Kuo, C.; Chen, G.; Huang, S. Study and Analysis of Process Parameters for Silicone Rubber Mold. Mater. Sci. 2018, 24, 399–402. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Alderighi, T.; Malomo, L.; Giorgi, D.; Pietroni, N.; Bickel, B.; Cignoni, P. Metamolds: Computational design of silicone molds. ACM Trans. Graph. 2018, 37, 1–13. [Google Scholar] [CrossRef]

- Gard, F. Flexible Mold: An Innovative Production Method to Produce Precast Double Curved Concrete Panels. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2013. [Google Scholar]

- Jeong, K.; Yun, J.; Kim, K.; Lee, D. Development of Operation Technology and Two-Sided Multi-Point Press Equipment for Improving Accuracy of FCP. Test Eng. Manag. 2020, 83, 4222–4233. [Google Scholar]

- Yun, J. Development of Connection Technology and Operational Technology for the Lower Mold of Free-form Concrete Panels. Master’s Thesis, Hanbat National University, Daejeon, Republic of Korea, 2022. [Google Scholar]

- Youn, J.; Yun, J.; Kim, J.; Lee, D. Development of Variable Side Mold for Free-Form Concrete Panel Production. Buildings 2022, 12, 728. [Google Scholar] [CrossRef]

- Youn, J.; Cho, M.; Chae, H.; Jeong, K.; Kim, S.; Do, S.; Lee, D. Development of Free-Form Assembly-Type Mold Production Technology Using 3D Printing Technology. Buildings 2023, 13, 2197. [Google Scholar] [CrossRef]

| Hardware | |

| Size | 89 × 114 × 346 mm3 |

| Weight | 1.25 kg |

| Scan range | 390 × 390 mm2 |

| Software | |

| Program used | VXelements |

| Support file | STL/TXT/WRL/X3D/X3DZ |

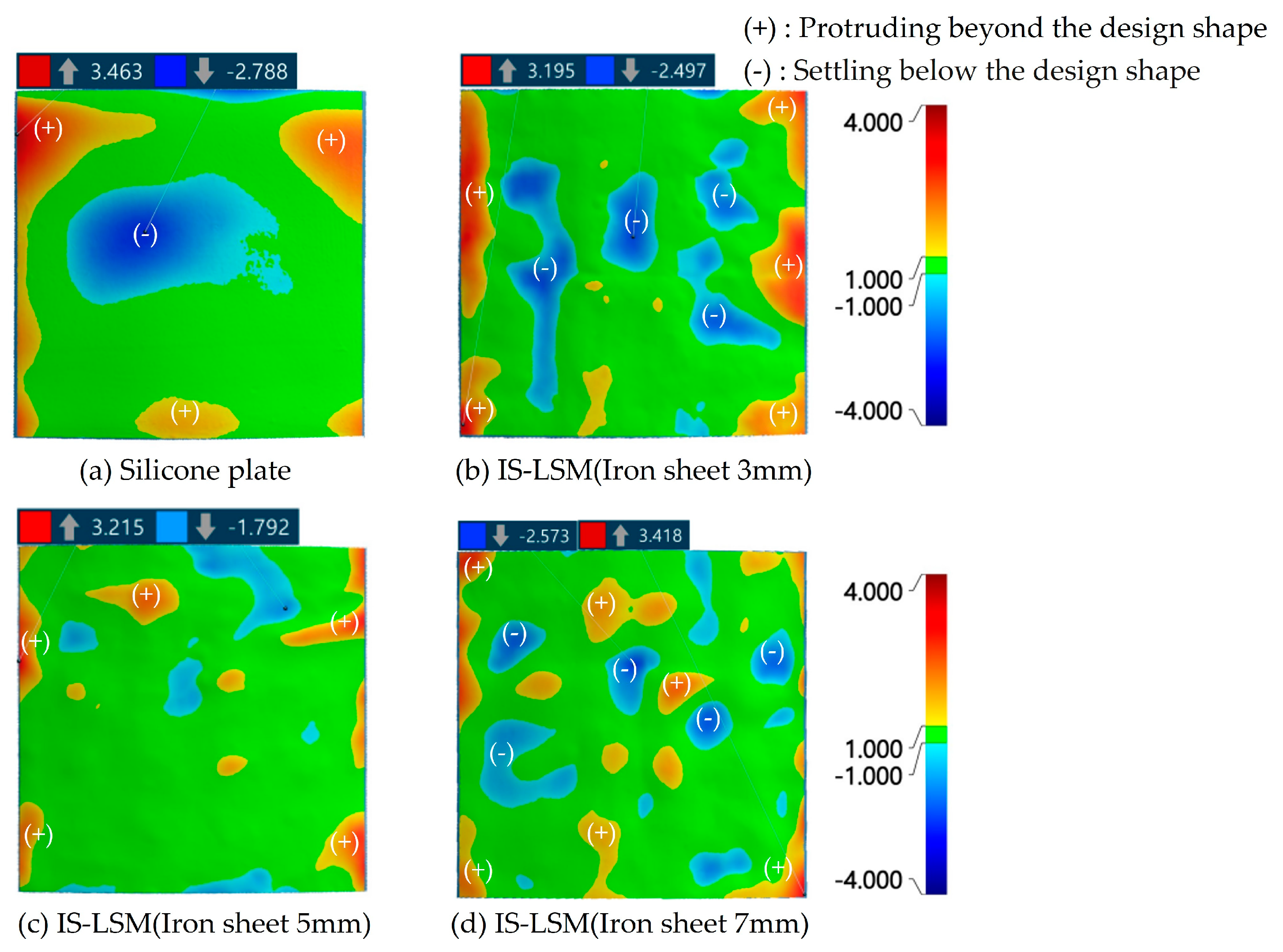

| Min | Max | Std. Deviation | Error Range | Inc/Dec | |

|---|---|---|---|---|---|

| Silicone plate | −2.788 mm | 3.463 mm | 1.120 mm | 6.251 mm | - |

| IS-LSM 3 mm | −2.497 mm | 3.195 mm | 1.114 mm | 5.592 mm | ▼10.54% |

| IS-LSM 5 mm | −1.792 mm | 3.251 mm | 0.787 mm | 5.007 mm | ▼19.90% |

| IS-LSM 7 mm | −2.573 mm | 3.148 mm | 0.920 mm | 5.991 mm | ▼4.16% |

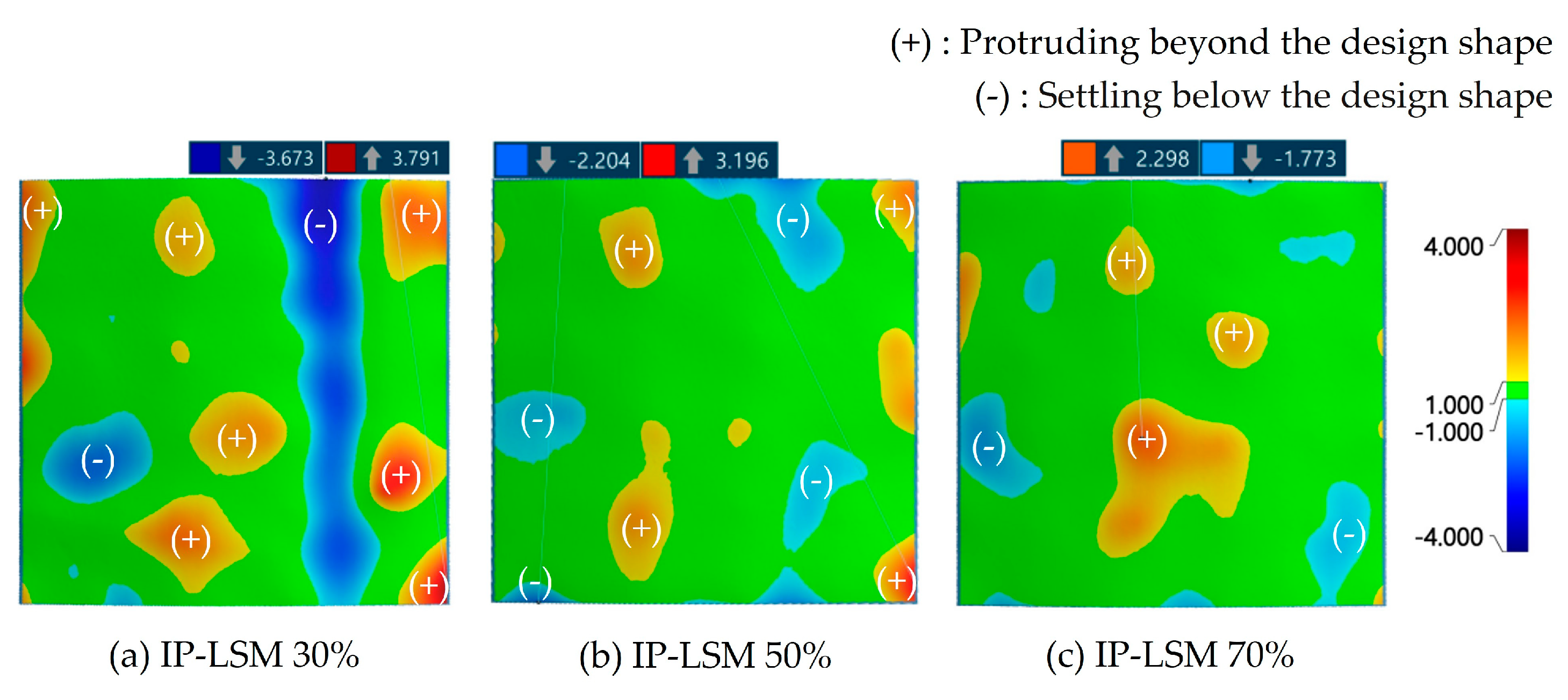

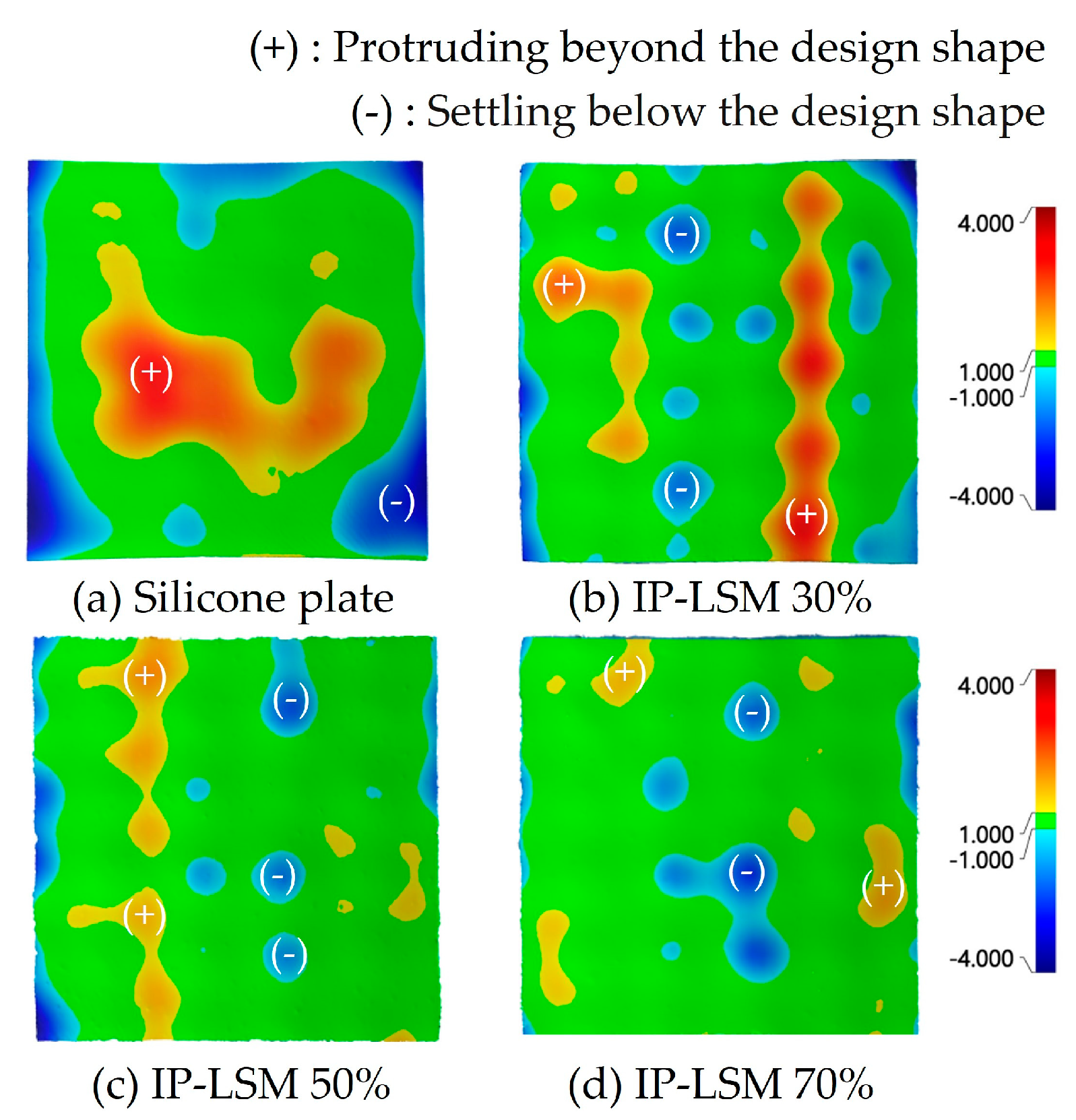

| Min | Max | Std. Deviation | Error Range | Inc/Dec | |

|---|---|---|---|---|---|

| Silicone plate | −2.788 mm | 3.463 mm | 1.120 mm | 6.251 mm | - |

| IP-LSM 30% | −3.673 mm | 3.791 mm | 1.242 mm | 7.464 mm | ▲19.40% |

| IP-LSM 50% | −2.204 mm | 3.196 mm | 0.796 mm | 5.400 mm | ▼13.61% |

| IP-LSM 70% | −1.773 mm | 2.298 mm | 0.783 mm | 4.071 mm | ▼34.87% |

| Size (mm3) | W/C (%) | Cement (g) | Sand (g) | Water (g) |

|---|---|---|---|---|

| 500 × 500 × 20 | 40 | 6500 | 6500 | 2600 |

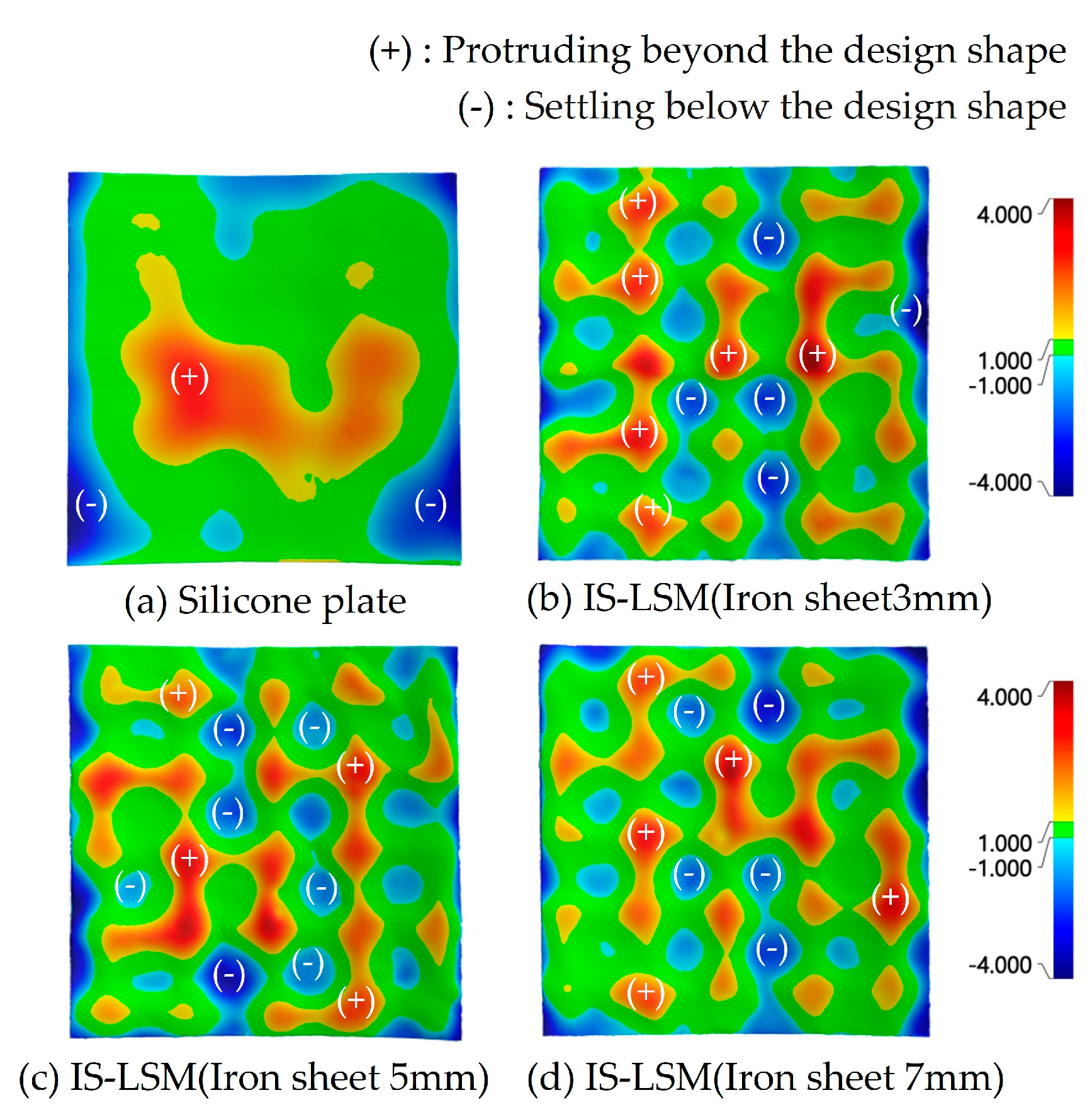

| Min | Max | Std. Deviation | Error Range | Inc/Dec | |

|---|---|---|---|---|---|

| Silicone plate | −4.514 mm | 3.052 mm | 1.400 mm | 7.566 mm | - |

| IS-LSM 3 mm | −4.476 mm | 3.944 mm | 1.425 mm | 8.420 mm | ▲11.29% |

| IS-LSM 5 mm | −4.975 mm | 3.517 mm | 1.439 mm | 8.493 mm | ▲12.25% |

| IS-LSM 7 mm | −4.937 mm | 3.657 mm | 1.419 mm | 8.594 mm | ▲13.59% |

| Min | Max | Std. Deviation | Error Range | Inc/Dec | |

|---|---|---|---|---|---|

| Silicone plate | −4.514 mm | 3.052 mm | 1.400 mm | 7.566 mm | - |

| IS-LSM 3 mm | −4.987 mm | 3.146 mm | 1.123 mm | 8.133 mm | ▲7.49% |

| IS-LSM 5 mm | −4.489 mm | 2.070 mm | 0.902 mm | 6.559 mm | ▼13.31% |

| IS-LSM 7 mm | −2.926 mm | 1.639 mm | 0.792 mm | 4.565 mm | ▼39.66% |

| N | Mean | Std. Deviation | Std. Error | |

|---|---|---|---|---|

| Silicone plate | 640 | 1.134 mm | 0.807 mm | 0.032 mm |

| IP-LSM 30% | 640 | 0.952 mm | 1.065 mm | 0.042 mm |

| IP-LSM 50% | 640 | 0.727 mm | 0.559 mm | 0.022 mm |

| IP-LSM 70% | 640 | 0.654 mm | 0.467 mm | 0.019 mm |

| t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | ||

|---|---|---|---|---|---|---|---|

| Lower | Upper | ||||||

| IP-LSM 50% | −10.477 | 1278 | 0.00 | −0.407 | 0.039 | −0.483 | −0.330 |

| IP-LSM 70% | −12.952 | 1278 | 0.00 | −0.480 | 0.037 | −0.552 | −0.407 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Youn, J.; Jo, M.; Jeong, K.; Lee, J.; Lee, D. A Study on Improving the Shape Error of the Lower Mold of Free-Form Concrete Panels Using Magnetic Force. Buildings 2024, 14, 2979. https://doi.org/10.3390/buildings14092979

Kim J, Youn J, Jo M, Jeong K, Lee J, Lee D. A Study on Improving the Shape Error of the Lower Mold of Free-Form Concrete Panels Using Magnetic Force. Buildings. 2024; 14(9):2979. https://doi.org/10.3390/buildings14092979

Chicago/Turabian StyleKim, Jihye, Jongyoung Youn, Minje Jo, Kyeongtae Jeong, Jaesung Lee, and Donghoon Lee. 2024. "A Study on Improving the Shape Error of the Lower Mold of Free-Form Concrete Panels Using Magnetic Force" Buildings 14, no. 9: 2979. https://doi.org/10.3390/buildings14092979

APA StyleKim, J., Youn, J., Jo, M., Jeong, K., Lee, J., & Lee, D. (2024). A Study on Improving the Shape Error of the Lower Mold of Free-Form Concrete Panels Using Magnetic Force. Buildings, 14(9), 2979. https://doi.org/10.3390/buildings14092979