The Effect of Fly Ash Additive on the Thermal Conductivity of Polystyrene Concrete

Abstract

1. Introduction

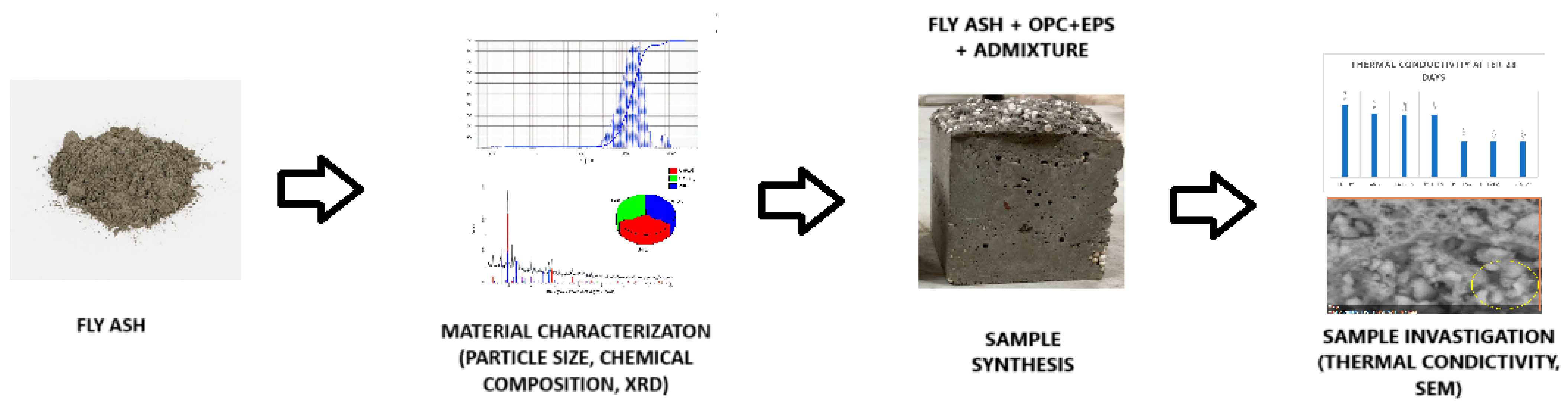

2. Materials and Methods

2.1. Materials

2.2. Preparation of Polystyrene Concrete Mixtures

2.3. Research Methods

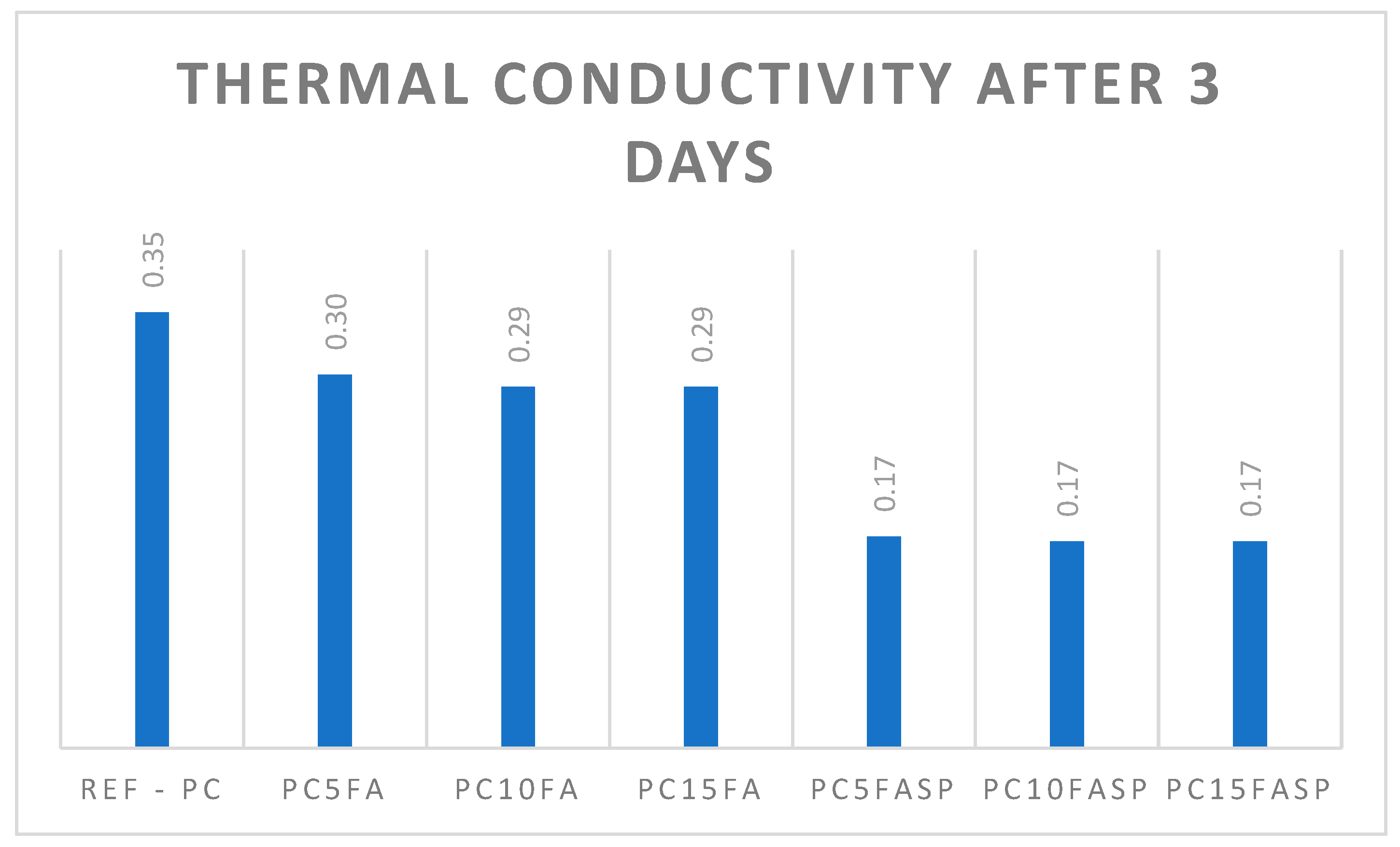

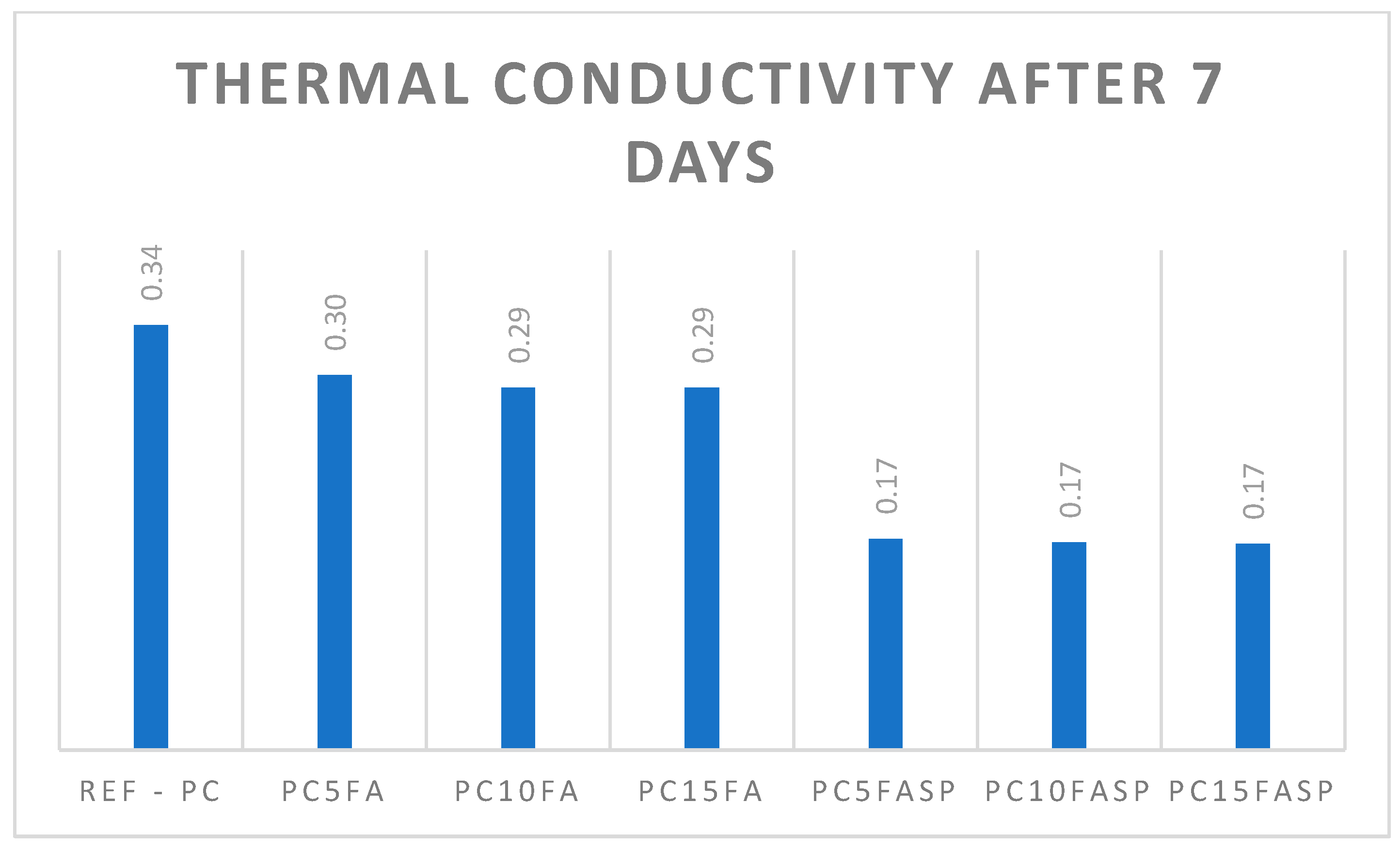

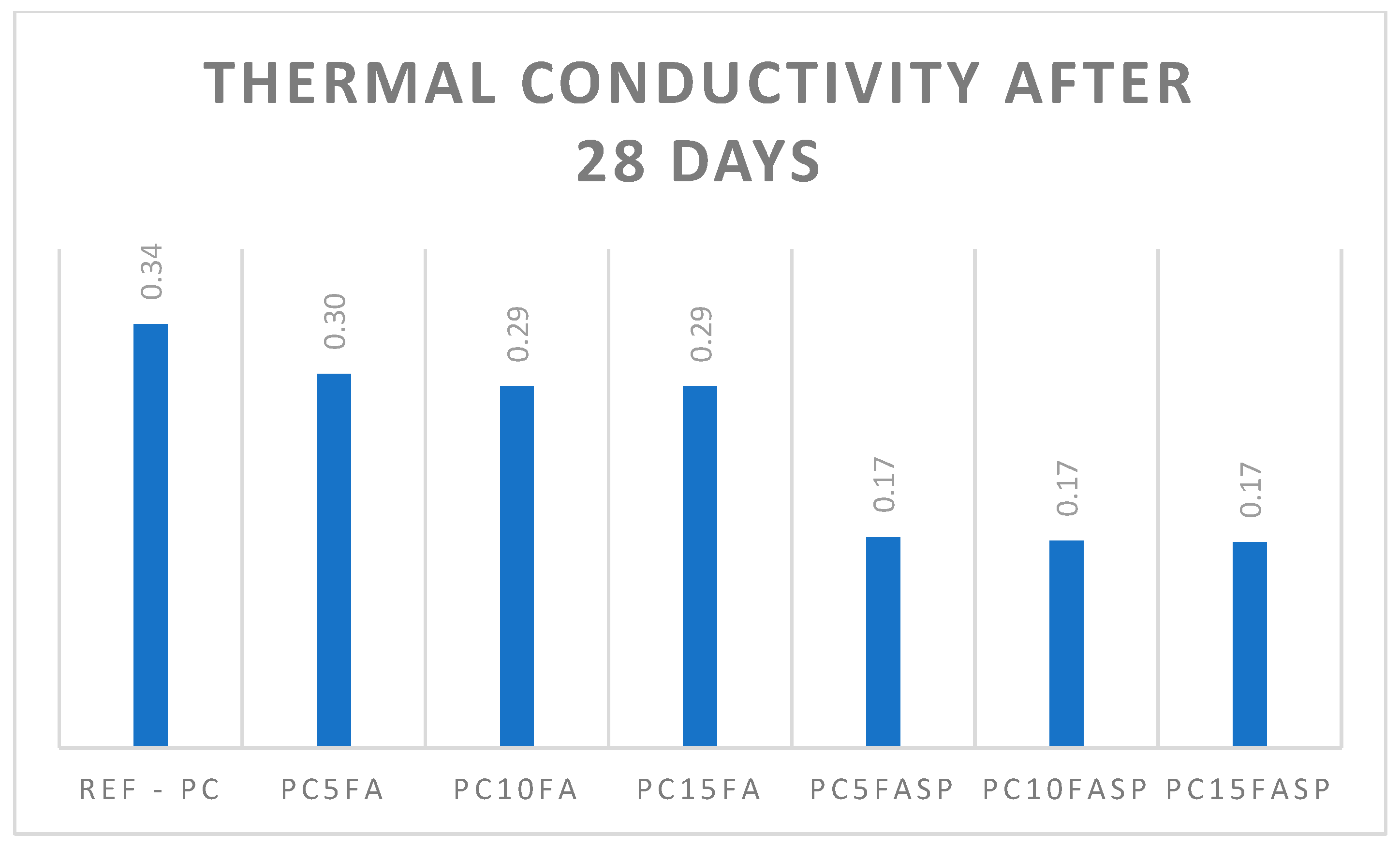

3. Results

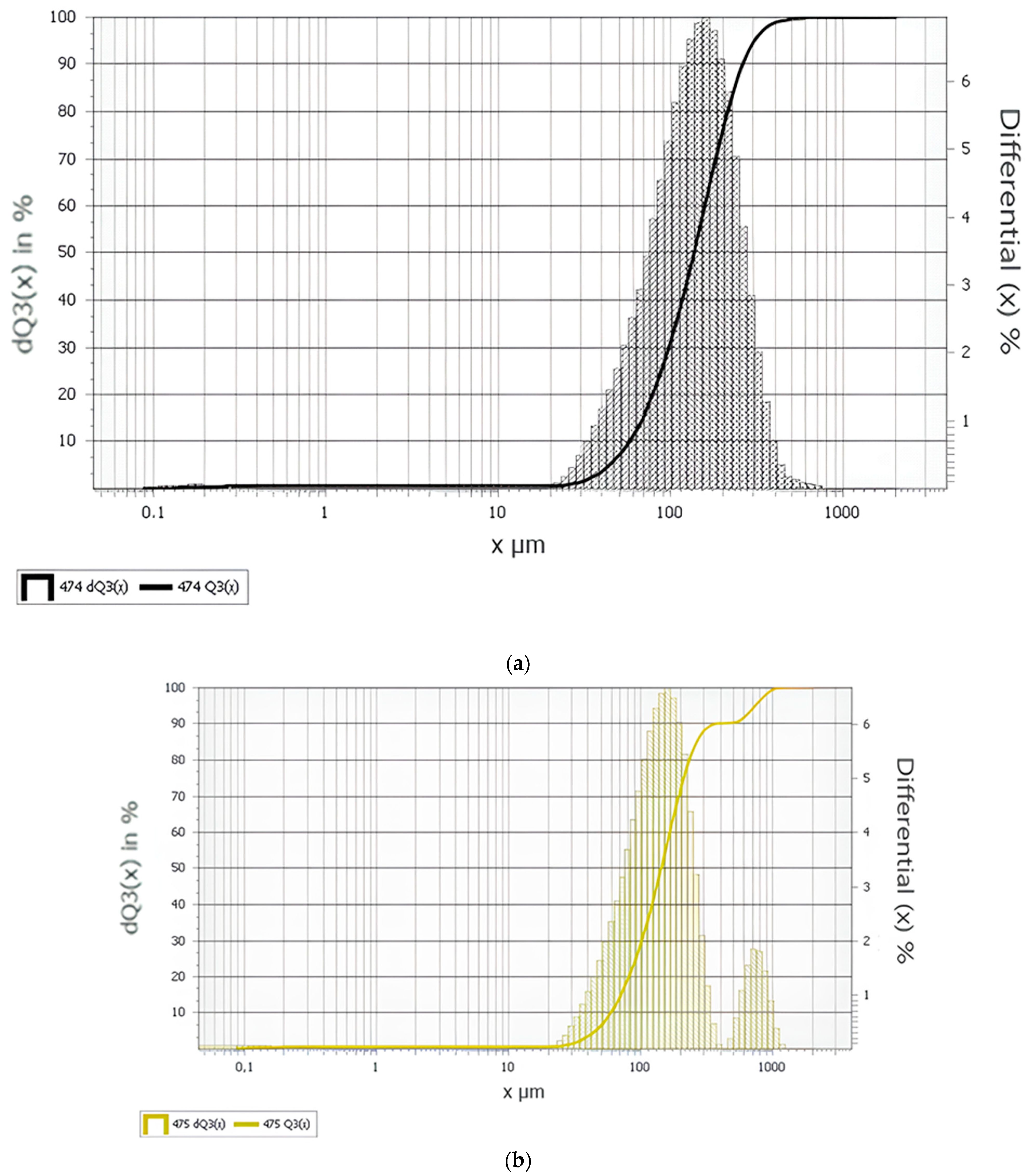

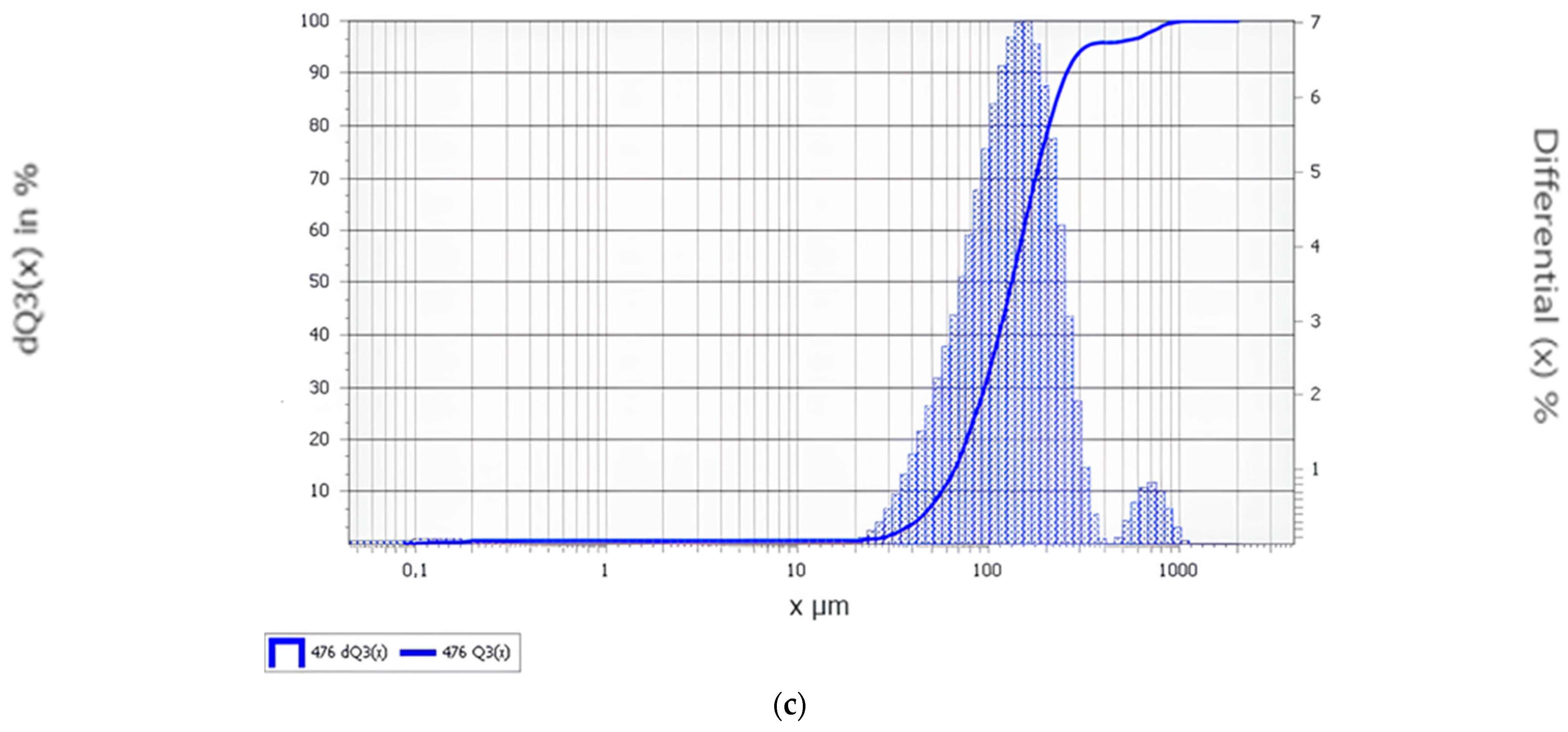

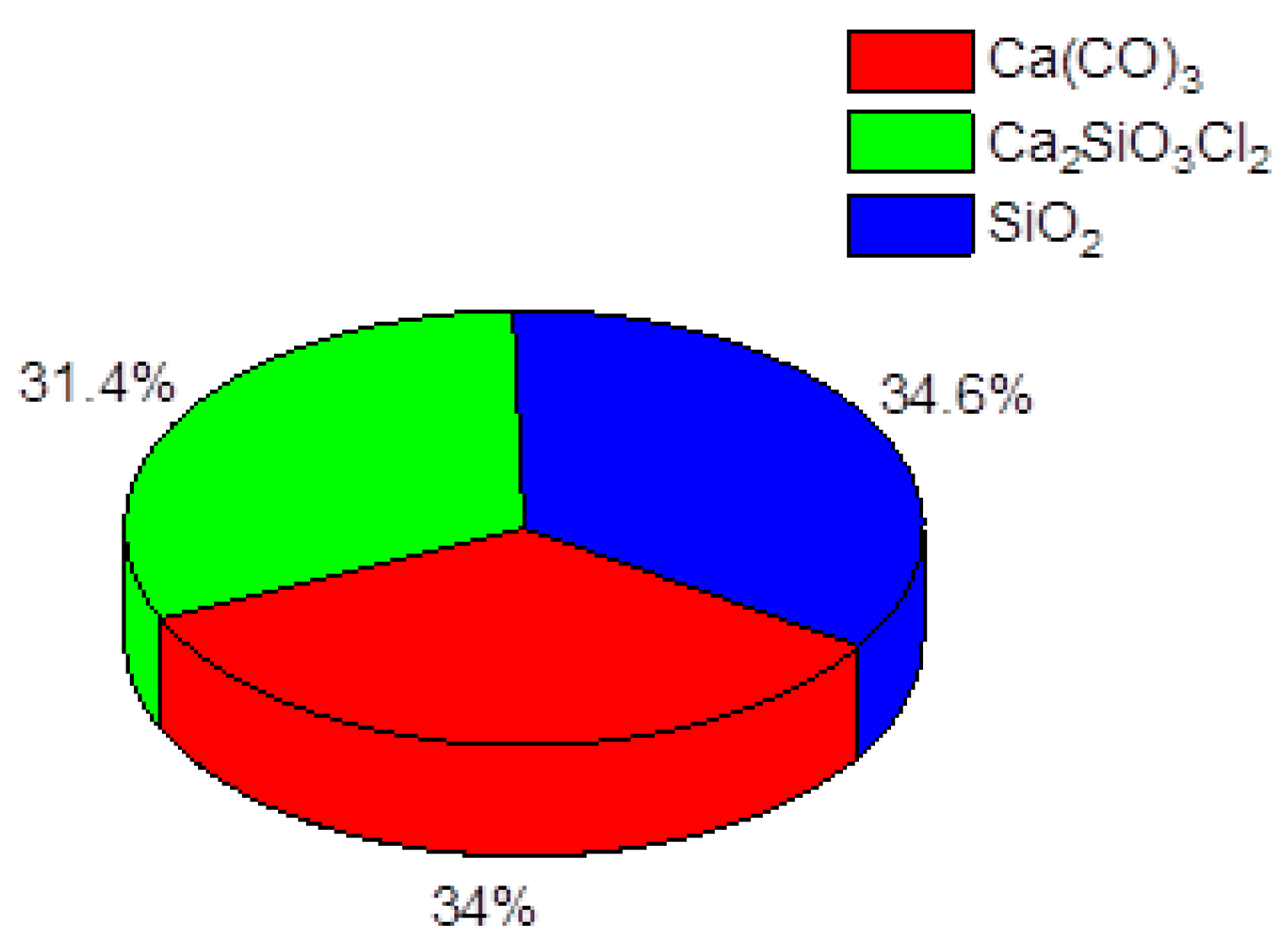

3.1. Characterization of Astana Fly Ash

3.2. Characterization of Polyester–Concrete Mixtures

4. Discussion

5. Conclusions

- Energy efficiency: The reduced thermal conductivity of polystyrene concrete with fly ash from Astana is in line with the global drive for energy-efficient building materials. Reduced thermal conductivity results in lower energy consumption for heating and cooling, which contributes to sustainable buildings.

- Waste management: By using local waste, this study supports sustainable waste management practices and reduces the environmental burden associated with landfill disposal of fly ash.

- Practical implications: The practical implications of this study extend to the construction industry in Astana and beyond.

- Utilization of local resources: The availability of fly ash in Astana as an additive in building materials offers a cost-effective and sustainable solution to improve the thermal performance of buildings in the region. This is in line with regional sustainability and energy efficiency goals.

- Energy savings: When polystyrene concrete modified with Astana fly ash is used in construction projects, builders and developers can benefit from reduced energy costs associated with heating and cooling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mierzwiński, D.; Walter, J.; Wanat, D. Possibilities of Checking Water Content in Porous Geopolymer Materials Using Impedance Spectroscopy Methods. Materials 2023, 16, 5190. [Google Scholar] [CrossRef] [PubMed]

- Niyazbekova, R.; Mukhambetov, G.; Tlegenov, R.; Aldabergenova, S.; Shansharova, L.; Mikhalchenko, V.; Bembenek, M. The Influence of Addition of Fly Ash from Astana Heat and Power Plants on the Properties of the Polystyrene Concrete. Energies 2023, 16, 4092. [Google Scholar] [CrossRef]

- Kurek, I.; Florek, E.; Gozdur, W.; Ziejewska, C.; Marczyk, J.; Łach, M.; Korniejenko, K.; Duży, P.; Choińska, M.; Szechyńska-Hebda, M.; et al. Foamed Eco-Geopolymer Modified by Perlite and Cellulose as a Construction Material for Energy-Efficient Buildings. Energies 2022, 15, 4297. [Google Scholar] [CrossRef]

- Pławecka, K.; Bazan, P.; Lin, W.-T.; Korniejenko, K.; Sitarz, M.; Nykiel, M. Development of Geopolymers Based on Fly Ashes from Different Combustion Processes. Polymers 2022, 14, 1954. [Google Scholar] [CrossRef]

- Islam, M.R.; Siddique, M.A.; Kabir, M.R.; Rahman, M.A. Properties of lightweight polymer concrete containing fly ash and waste glass powder. Constr. Build. Mater. 2019, 238, 117679. [Google Scholar] [CrossRef]

- Malheiro, R.; Camões, A.; Meira, G.; Reis, R.; Nóbrega, A. Impact of Combined Action of Chloride and Carbonation on Cement-Based Materials with Fly Ash. Sci 2024, 6, 13. [Google Scholar] [CrossRef]

- Mierzwiński, D.; Łach, M.; Gądek, S.; Lin, W.-T.; Tran, H.D.; Korniejenko, K. A brief overview of the use of additive manufacturing of concreate materials in construction. Acta Innov. 2023, 48, 22–37. [Google Scholar] [CrossRef]

- Chen, S.C.; Wang, M.T.; Gu, L.S.; Lin, W.T.; Liang, J.F.; Korniejenko, K. Effects of incorporating large quantities of nickel slag with various particle sizes on the strength and pore structure of cement-based materials. Constr. Build. Mater. 2023, 393, 18. [Google Scholar] [CrossRef]

- Ichetaonye, S.I.; Ajekwene, K.K.; Tenebe, O.G.; Yibowei, M.E.; Amoke, A.; Idemudia, O.L.; Momoh, F.P. Eco-concrete hybrid blocks of styrofoam beads/modified palm kernel shell using cement or carbonized rice husk as a binder for construction components. Innov. Infrastruct. Solut. 2023, 8, 162. [Google Scholar] [CrossRef]

- Mahzuz, H.M.A.; Ahmed, I.U.; Singha, K.K.; Sharmin, R. Production of styrofoam bricks using strengthening admixture. Int. J. Mason. Res. Innov. 2020, 6, 81–96. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Zhang, M.H.; Bilodeau, A.; Malhotra, V.M. Effect of the Grinding on the Physical Properties of Fly Ashes. Cem. Concr. Res. 1997, 27, 1861–1874. [Google Scholar] [CrossRef]

- Opoczky, L. Grinding Technical Questions of Producing Composite Cement. Int. J. Miner. Process. 1996, 44–45, 395–404. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Cao, Y.F.; George, L.; Wuhrer, R. High-temperature performance of alkali-activated binders of fly ash and calcium aluminate. Ceram. Int. 2023, 49, 14389–14398. [Google Scholar] [CrossRef]

- Solikin, M.; Zaini, A.N.; Setiawan, B.; Asroni, A. Flexural Strength Analysis of Styrofoam Concrete Hollow Panel Walls Incorporated with High Volume Fly Ash. Civ. Eng. Archit. 2020, 8, 320–325. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, B.; Tian, B.; Lu, X.; Xiong, B. Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition. Buildings 2022, 12, 2113. [Google Scholar] [CrossRef]

- Mohammed, I.I.; Nariman, N.A.; Shakor, P.; Ismail, O.; Rizgar, K. Post-Fire Mechanical Properties of Concrete Incorporating Waste EPS (Styrofoam) as Aggregate Replacement. CivilEng 2023, 4, 359–372. [Google Scholar] [CrossRef]

- Hemmings, R.T.; Berry, E.E. On the Glass in Coal Fly Ashes: Recent Advances. MRS Online Proc. Libr. 1987, 113, 3–38. [Google Scholar] [CrossRef]

- Pala, S.N.; Rasool, M.A.; Bashir, I.A.; Rasool, S. Experimental investigation on effect of replacement of cement with silica fume and styrofoam balls on mortar cubes. Int. J. Civ. Eng. Technol. 2017, 8, 1785–1789. [Google Scholar]

- Ziejewska, C.; Grela, A.; Mierzwiński, D.; Hebda, M. Influence of Waste Glass Addition on the Fire Resistance, Microstructure and Mechanical Properties of Geopolymer Composites. Materials 2023, 16, 6011. [Google Scholar] [CrossRef]

- Kozub, B.; Castro-Gomes, J. An Investigation of the Ground Walnut Shells’ Addition Effect on the Properties of the Fly Ash-Based Geopolymer. Materials 2022, 15, 3936. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Y.; Che, Z.; Zhang, K.; Niu, D. Study on the durability of eco-friendly recycled aggregate concrete with supplementary cementitious materials: The combined action of compound salt solution of MgSO4, Na2SO4, and NaCl and dry-wet cycles. Constr. Build. Mater. 2023, 377, 131149. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, J.; Sun, H.; Xu, F. Effect of Fly Ash Belite Cement on Hydration Performance of Portland Cement. Crystals 2021, 11, 740. [Google Scholar] [CrossRef]

- Tan, Y.; Zhao, B.; Yu, J.; Xiao, H.; Long, X.; Meng, J. Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis. Polymers 2023, 15, 1013. [Google Scholar] [CrossRef] [PubMed]

- Smoleń, W.; Marczyk, J.; Łach, M.; Nguyen, T.; Korniejenko, K. Effect of microsilica addition on properties of geopolymer composites. J. Achiev. Mater. Manuf. Eng. 2023, 121, 46–59. [Google Scholar] [CrossRef]

- AlTawaiha, H.; Alhomaidat, F.; Eljufout, T. A Review of the Effect of Nano-Silica on the Mechanical and Durability Properties of Cementitious Composites. Infrastructures 2023, 8, 132. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Tong, K.T. Mechanical and durability properties of alkali-activated fly ash concrete with increasing slag content. Constr. Build. Mater. 2021, 301, 124330. [Google Scholar] [CrossRef]

- Zygmunt Kowalska, B.; Szajding, A.; Zakrzewska, P.; Kuźnia, M.; Stanik, R.; Gude, M. Disposal of rigid polyurethane foam with fly ash as a method to obtain sustainable thermal insulation material. Constr. Build. Mater. 2024, 417, 135329. [Google Scholar] [CrossRef]

- Bicer, A. Effect of production temperature on thermal and mechanical properties of polystyrene–fly ash composites. Adv. Compos. Lett. 2020, 29. [Google Scholar] [CrossRef]

- ISO 50001:2018; Energy Management System. ISO: Geneva, Switzerland, 2018.

- GOST 27006-2019; Concretes. Rules for Selection of Composition. Available online: https://meganorm.ru/Index2/1/4293729/4293729498.htm (accessed on 4 September 2024).

- GOST 7076-99; Building Materials and Products. Method of Determination of Thermal Conductivity and Thermal Resistance under Stationary Thermal Regime. Available online: https://www.russiangost.com/p-62728-gost-7076-99.aspx (accessed on 4 September 2024).

- Sitarz, M.; Figiela, B.; Łach, M.; Korniejenko, K.; Mróz, K.; Castro-Gomes, J.; Hager, I. Mechanical Response of Geopolymer Foams to Heating—Managing Coal Gangue in Fire-Resistant Materials Technology. Energies 2022, 15, 3363. [Google Scholar] [CrossRef]

- SNiP-RK-5.03-34-2005; Plain and Reinforced Concrete Structures. General Provisions. Available online: https://www.kazakhstanlaws.com/p-21050-snip-rk-503-34-2005.aspx (accessed on 4 September 2024).

- Sayadi, A.A.; Tapia, V.; Neitzert, R.; Clifton, G. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Sales, A.; Rodrigues de Souza, F.; Nunes dos Santos, W.; Zimer, A.M.; Almeida, F.d.C.R. Lightweight composite concrete produced with water treatment sludge and sawdust: Thermal properties and potential application. Constr. Build. Mater. 2010, 24, 2446–2453. [Google Scholar] [CrossRef]

- Buema, G.; Lisa, G.; Kotova, O.; Ciobanu, G.; Ivaniciuc, L.; Favier, L.; Harja, M. Application of thermal analysis to improve the preparation conditions of zeolitic materials from flying ash. Environ. Eng. Manag. J. 2021, 20, 377–388. [Google Scholar]

- Sosoi, G.; Abid, C.; Barbuta, M.; Burlacu, A.; Balan, M.C.; Branoaea, M.; Vizitiu, R.S.; Rigollet, F. Experimental Investigation on Mechanical and Thermal Properties of Concrete Using Waste Materials as an Aggregate Substitution. Materials 2022, 15, 1728. [Google Scholar] [CrossRef]

- Kishor, M.S.V.R.; Behera, A.; Rajak, D.K.; Pradeep, L.M.; Pruncu, I.C. Manufacturing and mechanical characterization of fly-ash-reinforced Materials for furnace lining applications. J. Mater. Eng. Perform. 2020, 29, 6307–6321. [Google Scholar] [CrossRef]

- Lazarova, K.; Boycheva, S.; Vasileva, M.; Zgureva, D.; Georgieva, B.; Babeva, T. Zeolites from fly ash embedded in a thin niobium oxide matrix for optical and sensing applications. J. Phys. Conf. Ser. 2019, 1186, 012024. [Google Scholar] [CrossRef]

- Ongwandee, M.; Namepol, K.; Yongprapat, K.; Homwuttiwong, S.; Pattiya, A.; Morris, J.; Chavalparit, O. Coal bottom ash use in traditional ceramic production: Evaluation of engineering properties and indoor air pollution removal ability. J. Mater. Cycles Waste Manag. 2020, 22, 2118–2129. [Google Scholar] [CrossRef]

- Peng, X.; Tonglin, Z. Comprehensive utilization of high alumina coal fly ash under the recyclable economy model. Ind. Chem. 2018, 4, 128. [Google Scholar] [CrossRef]

- Bąk, A.; Pławecka, K.; Bazan, P.; Łach, M. Influence of the addition of phase change materials on thermal insulation properties of foamed geopolymer structures based on fly ash. Energy 2023, 278, 127624. [Google Scholar] [CrossRef]

- Raza, Y.; Raza, H.; Ahmad, A.; Quazi, M.M.; Abid, M.; Kazmi, M.R.; Rahman, S.M.A.; Zulfattah, Z.M.; Rizwanul Fattah, I.M. Production and investigation of mechanical properties of graphene/polystyrene nano composites. J. Polym. Res. 2021, 28, 217. [Google Scholar] [CrossRef]

- Yu, Z.P.; Yang, W.J. Research on thermal properties of polystyrene granular concrete under the influence of multiple factors. J. Build. Eng. 2024, 86, 108799. [Google Scholar] [CrossRef]

- Nwokediegwu, Z.Q.S.; Ilojianya, V.I.; Ibekwe, K.I.; Adefemi, A.; Etukudoh, E.A.; Umoh, A.A. Advanced Materials for Sustainable Construction: A Review Of Innovations and Environmental Benefits. Eng. Sci. Technol. J. 2024, 5, 201–218. [Google Scholar] [CrossRef]

- Sičáková, A.; Špak, M.; Kozlovská, M.; Kováč, M. Long-Term Properties of Cement-Based Composites Incorporating Natural Zeolite as a Feature of Progressive Building Material. Adv. Mater. Sci. Eng. 2017, 2017, 7139481. [Google Scholar] [CrossRef]

- Stergiou, K.; Ntakolia, C.; Varytis, P.; Koumoulos, E.; Karlsson, P.; Moustakidis, S. Enhancing property prediction and process optimization in building materials through machine learning: A review. Comput. Mater. Sci. 2023, 220, 112031. [Google Scholar] [CrossRef]

- Korniejenko, K.; Halyag, N.P.; Mucsi, G. Fly ash as a raw material for geopolymerisation—Chemical composition and physical properties. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012002. [Google Scholar] [CrossRef]

- Satayeva, A.; Baimenov, A.; Azat, S.; Zhantikeyev, U.; Seisenova, A.; Tauanov, Z. Review on coal fly ash generation and utilization for resolving mercury contamination issues in Central Asia: Kazakhstan. Environ. Rev. 2022, 30, 418–437. [Google Scholar] [CrossRef]

- Darmansyah, D.; You, S.J.; Wang, Y.F. Advancements of coal fly ash and its prospective implications for sustainable materials in Southeast Asian countries: A review. Renew. Sustain. Energy Rev. 2023, 188, 113895. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef]

- Thomas, B.S.; Dimitriadis, P.; Kundu, C.; Varsha Vuppaladadiyam, S.S.; Singh Raman, R.K.; Bhattacharya, S. Extraction and separation of rare earth elements from coal and coal fly ash: A review on fundamental understanding and on-going engineering advancements. J. Environ. Chem. Eng. 2024, 12, 112769. [Google Scholar] [CrossRef]

| Cement | Setting Time, h-min | Bending Strength, MPa, in Days | Ultimate Compressive Strength, MPa, in Days | |||||

|---|---|---|---|---|---|---|---|---|

| Start | End | 3 | 7 | 28 | 3 | 7 | 28 | |

| Portland cement 400 | 1-47 | 4-20 | 2.67 | 3.5 | 4.22 | 20.7 | 30.12 | 41.0 |

| Chemical Composition, wt % | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Other Elements | Loss on Ignition | Sum | |

| Portland cement | 20.49 | 4.80 | 4.40 | 63.42 | 1.47 | 2.25 | 0.86 | 1.55 | 100.00 |

| Samples | Cement (%) | Polystyrene (vol. %) | Ash (%) | Superplasticizer (%) | Water (mL) |

|---|---|---|---|---|---|

| REF-PC | 100 | 60 | - | - | 660 |

| PC5FA | 95 | 60 | 5 | - | 660 |

| PC10FA | 90 | 60 | 10 | - | 660 |

| PC15FA | 85 | 60 | 15 | - | 660 |

| PC5FASP | 95 | 60 | 5 | 0.30 | 660 |

| PC10FASP | 90 | 60 | 10 | 0.30 | 660 |

| PC15FASP | 85 | 60 | 15 | 0.30 | 660 |

| No. | Item | Sample 1 | Sample 2 | Sample 3 | No. | Item | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | A1 | 17.346 | 19.755 | l9.608 | 17 | Rb | 0.012 | 0.014 | 0.015 |

| 2 | Si | 40.919 | 50.989 | 52.327 | 18 | Sr | 0.236 | 0.230 | 0.237 |

| 3 | P | 0.610 | 0.695 | 0.717 | 19 | y | 0.025 | 0.025 | 0.025 |

| 4 | S | 0.199 | 0.091 | 0.079 | 20 | Zr | 0.140 | 0.155 | 0.166 |

| 5 | CI | 0.126 | 0.171 | 0.172 | 21 | Nb | 0.006 | 0.006 | 0.006 |

| 6 | K | 1.629 | 2.094 | 2.207 | 22 | STi | 0.028 | 0.026 | 0.025 |

| 7 | Ca | 9.926 | 4.155 | 3.350 | 23 | Te | 0.018 | 0.021 | 0.017 |

| 8 | Ti | 2.847 | 2.998 | 3.1 70 | 24 | Ba | 0.287 | 0.251 | 0.254 |

| 9 | V | 0.059 | 0.055 | 0.060 | 25 | Eu | 0.162 | 0.120 | 0.1 15 |

| 10 | Ml | 0.405 | 0.321 | 0.303 | 26 | Yb | 0.017 | 0.01 5 | 0.016 |

| 11 | Fe | 24.916 | 17.659 | 16.999 | 27 | Re | 0.000 | 0.000 | 0.000 |

| 12 | Ni | 0.001 | 0.004 | --- | 28 | Os | 0.000 | 0.000 | 0.000 |

| 13 | Si | 0.045 | 0.053 | 0.051 | 29 | Ir | 0.000 | 0.000 | 0.000 |

| 14 | Zn | 0.018 | 0.069 | 0.032 | 30 | Pb | 0.004 | 0.008 | 0.009 |

| 15 | Ga | 0.013 | 0.013 | 0.014 | 31 | Nd | --- | 0.002 | 0.002 |

| 16 | As | 0.004 | 0.004 | 0.004 | 32 | Lu | --- | --- | 0.014 |

| № | Name of Phase | Type of Structure | Crystal Lattice Parameters, Å |

|---|---|---|---|

| 1 | Ca(CO)3—PDF-00-042-1455 | Rhombo.H.axes | a = 5.00366, c = 17.19992, V = 372.93 Å3 |

| 2 | Ca2SiO3Cl2—PDF-00-042-1455 | Orthorhombic | a = 12.63558, b = 15.69570, c = 7.74071, V = 1535.17 Å3 |

| 3 | SiO2—PDF-01-070-7344 | Hexagonal | a = 4.94838, c = 5.40751, V = 114.67 Å3 |

| Buildings and Premises, Coefficients a and b | Degree-Days of the Heating Period, Dd °C-day | Standard Values of Heat Transfer Resistance, Rreq m2·°C/W, of Envelope Structures | ||||

|---|---|---|---|---|---|---|

| Walls | Floors and Slabs over Passages | Attic Ceilings, over Unheated Cellars and Basements | Windows and Balcony Doors, Shop Windows, and Stained Glass Windows | Lanterns with Vertical Glazing | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1. Residential, medical preventive, and child care institutions, schools, boarding schools, hotels, and dormitories | 2000 4000 6000 8000 10,000 12,000 | 2.1 2.8 3.5 4.2 4.9 5.6 | 3.2 4.2 5.2 6.2 7.2 8.2 | 2.8 3.7 4.6 5.5 6.4 7.3 | 0.3 0.45 0.6 0.7 0.75 0.8 | 0.3 0.35 0.4 0.45 0.5 0.55 |

| a | - | 0.00035 | 0.0005 | 0.00045 | - | 0.000025 |

| b | - | 1.4 | 2.2 | 1.9 | - | 0.25 |

| 2. Public, other than those mentioned above, administrative and domestic, industrial, and other buildings and premises with damp or wet conditions | 2000 4000 6000 8000 10,000 12,000 | 1.8 2.4 3.0 3.6 4.2 4.8 | 2.4 3.2 4.0 4.8 5.6 6.4 | 2.0 2.7 3.4 4.1 4.8 5.5 | 0.3 0.4 0.5 0.6 0.7 0.8 | 0.3 0.35 0.4 0.45 0.5 0.55 |

| a | - | 0.0003 | 0.0004 | 0.00035 | 0.00005 | 0.000025 |

| b | - | 1.2 | 1.6 | 1.3 | 0.2 | 0.25 |

| 3. Production facilities with dry and normal conditions | 2000 4000 6000 8000 10,000 12,000 | 1.4 1.8 2.2 2.6 3.0 3.4 | 2.0 2.5 3.0 3.5 4.0 4.5 | 1.4 1.8 2.2 2.6 3.0 3.4 | 0.25 0.3 0.35 0.4 0.45 0.5 | 0.2 0.25 0.3 0.35 0.4 0.45 |

| a | - | 0.0002 | 0.00025 | 0.0002 | 0.000025 | 0.000025 |

| b | - | 1.0 | 1.5 | 1.0 | 0.2 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tlegenov, R.B.; Niyazbekova, R.K.; Jexembayeva, A.E.; Korniejenko, K.; Aruova, L.B.; Aldabergenova, S.S.; Maykonov, A.S. The Effect of Fly Ash Additive on the Thermal Conductivity of Polystyrene Concrete. Buildings 2024, 14, 2850. https://doi.org/10.3390/buildings14092850

Tlegenov RB, Niyazbekova RK, Jexembayeva AE, Korniejenko K, Aruova LB, Aldabergenova SS, Maykonov AS. The Effect of Fly Ash Additive on the Thermal Conductivity of Polystyrene Concrete. Buildings. 2024; 14(9):2850. https://doi.org/10.3390/buildings14092850

Chicago/Turabian StyleTlegenov, Rassul B., Rimma K. Niyazbekova, Assel E. Jexembayeva, Kinga Korniejenko, Lyazat B. Aruova, Saule S. Aldabergenova, and Aslan S. Maykonov. 2024. "The Effect of Fly Ash Additive on the Thermal Conductivity of Polystyrene Concrete" Buildings 14, no. 9: 2850. https://doi.org/10.3390/buildings14092850

APA StyleTlegenov, R. B., Niyazbekova, R. K., Jexembayeva, A. E., Korniejenko, K., Aruova, L. B., Aldabergenova, S. S., & Maykonov, A. S. (2024). The Effect of Fly Ash Additive on the Thermal Conductivity of Polystyrene Concrete. Buildings, 14(9), 2850. https://doi.org/10.3390/buildings14092850