Effect of Vibration Mixing on the Mechanical Properties of Carbon Nanotube-Reinforced Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

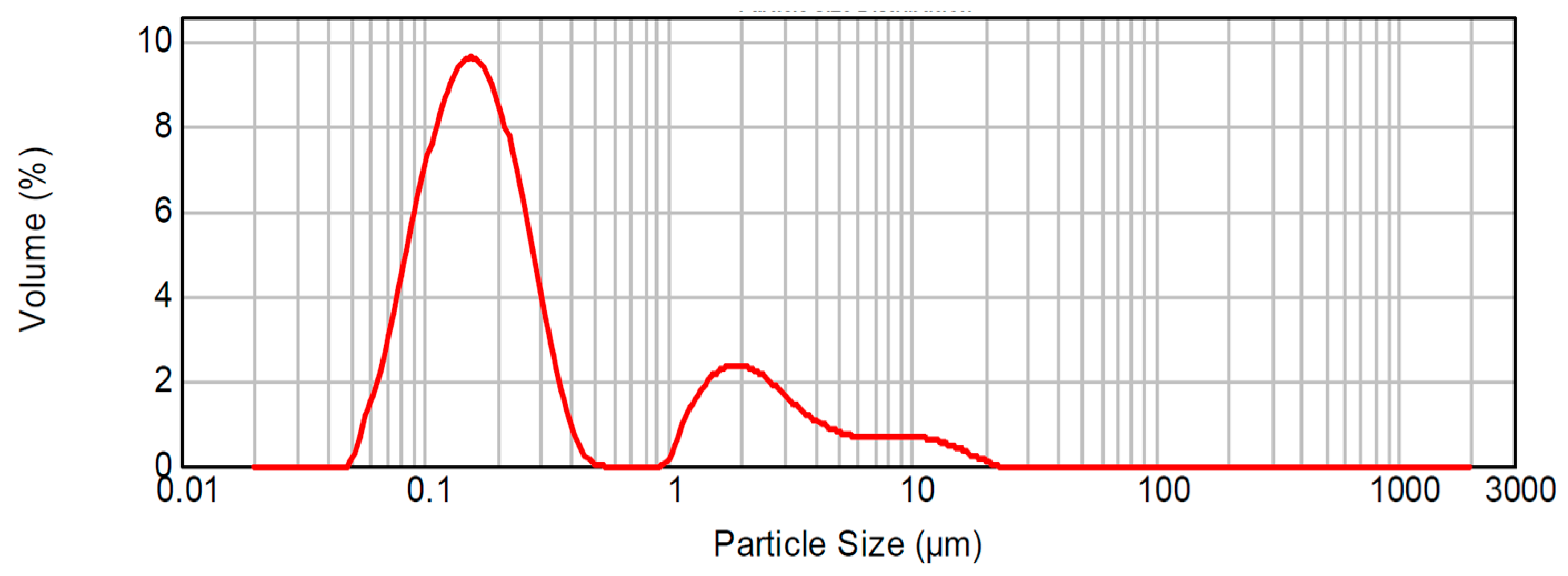

2.1. Materials

2.2. Mix Proportions and Sample Preparation

2.3. Testing Method

2.4. Microscopic Analysis

3. Results and Discussion

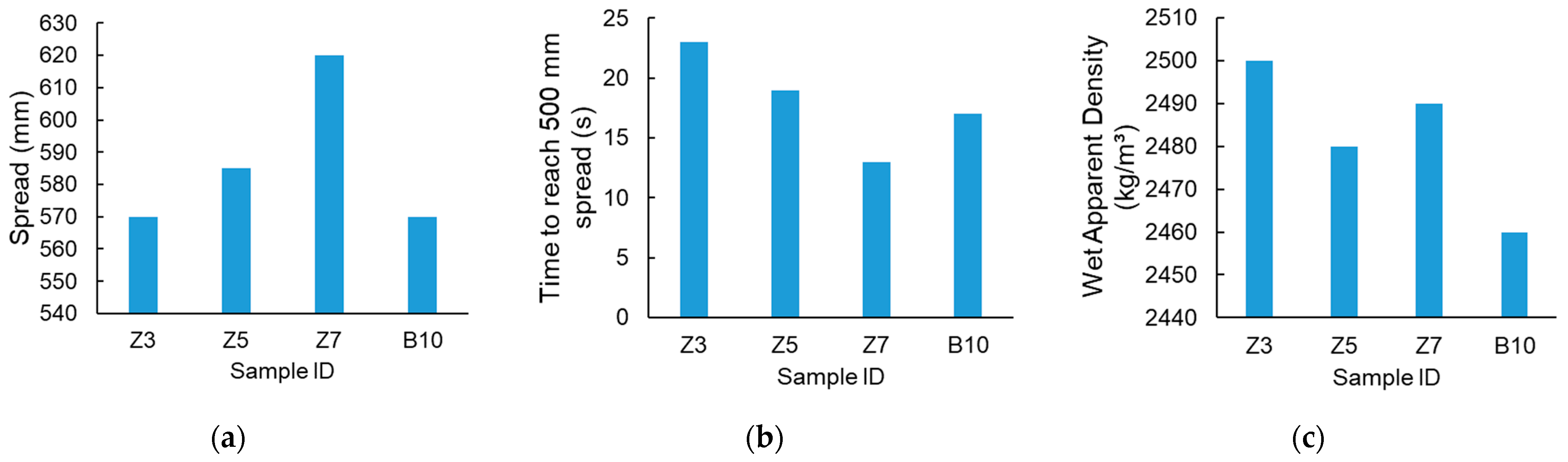

3.1. Ultra-High-Performance Concrete (UHPC) Workability

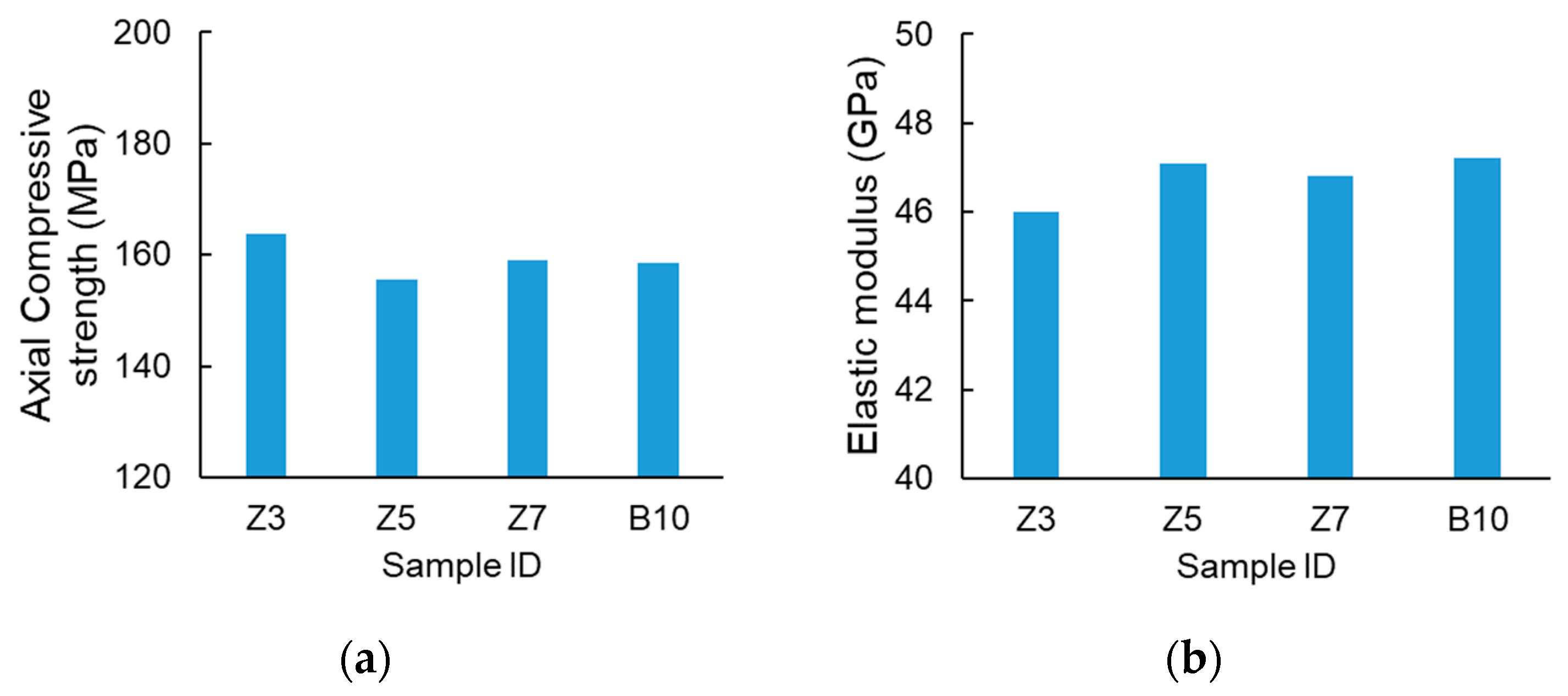

3.2. UHPC Axial Compressive Performances

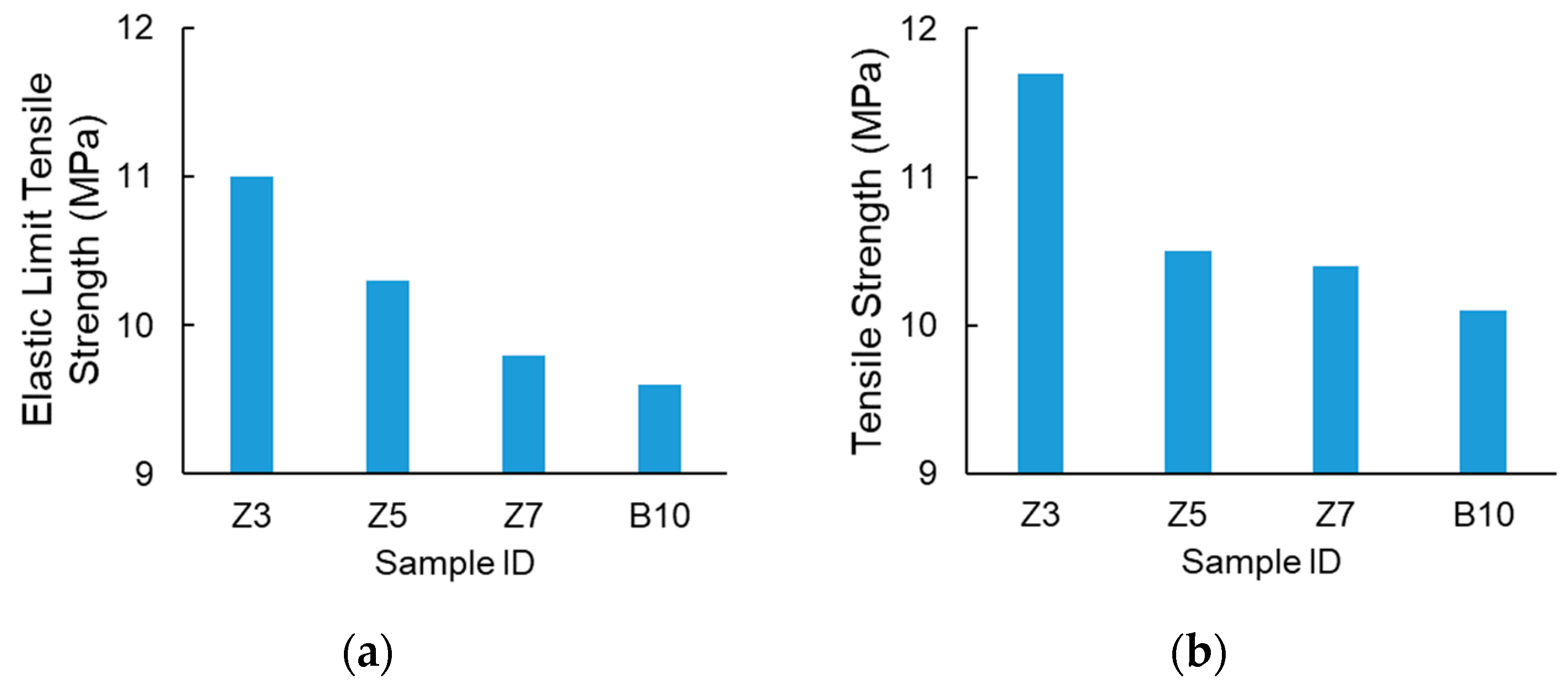

3.3. UHPC Tensile Performances

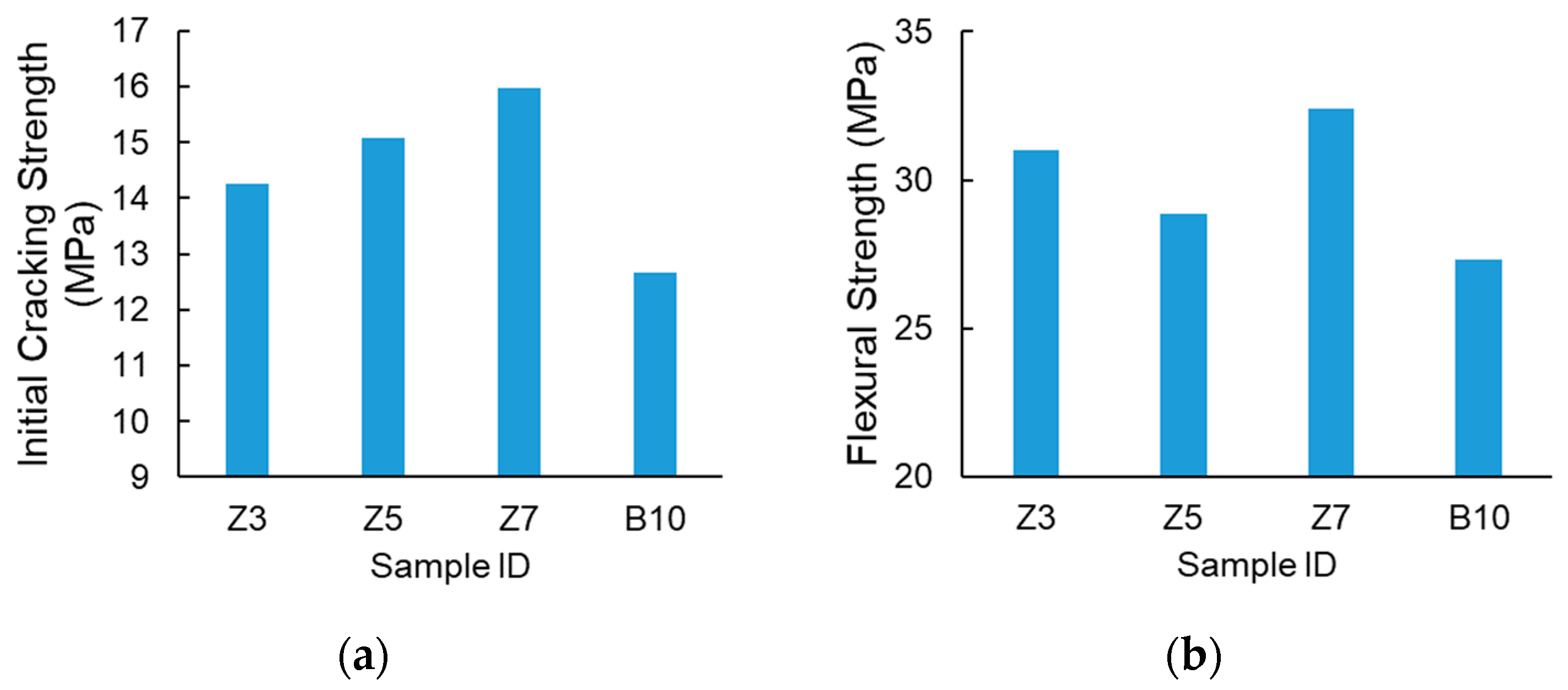

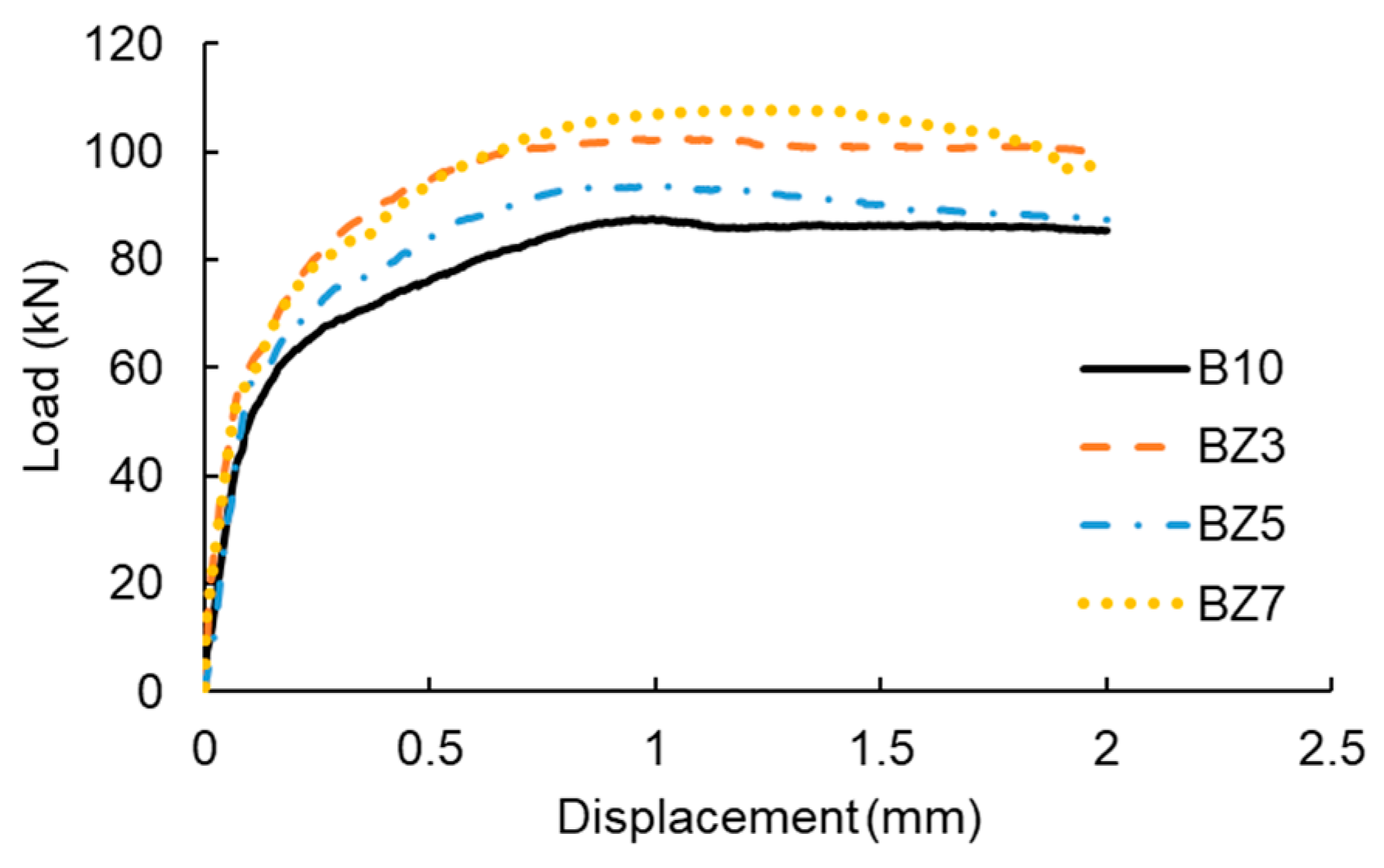

3.4. UHPC Flexural Performances

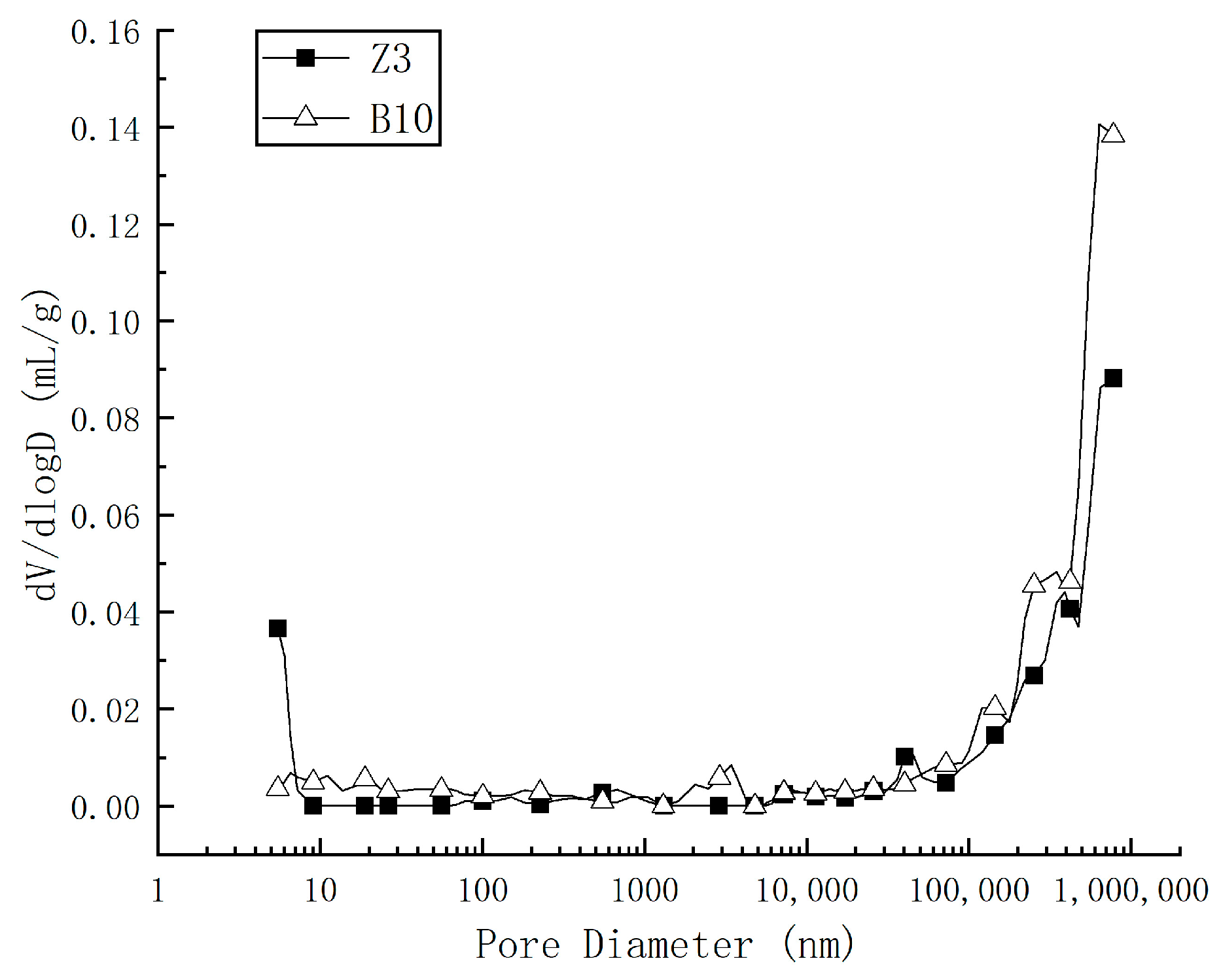

3.5. Mechanism Analysis

- The intense vibrations in vibration mixing help expel trapped air from the UHPC mixture, resulting in an increased wet apparent density and improved mechanical properties.

- Although CNTs are prepared as a well-dispersed slurry before use, their dispersion within UHPC is challenging with twin-shaft mixing due to its lower mixing frequency. Vibration mixing, with its high-frequency vibrations, promotes a more uniform distribution of CNTs within the UHPC matrix than twin-shaft mixing, thereby enhancing its mechanical properties. Zheng et al. [30] also reported a similar benefit of vibration mixing on improving the distribution of steel fibers within UHPC.

- During bending or tensile loading, once the matrix cracks, the tensile stress is transferred to the steel fibers. As the load increases, the fibers are gradually pulled out, eventually leading to specimen failure. Vibration mixing improves the dispersion of CNTs, enhancing the mechanical properties of the paste and the transition zone. This improvement increases the bond strength between the matrix and the steel fibers, making fiber pull-out more difficult and thus improving the tensile and flexural performance of UHPC.

4. Conclusions

- Vibration mixing is shown to be a more effective method for CNT-reinforced UHPC, offering better flowability, higher wet apparent density, and superior mechanical properties compared to twin-shaft mixing, even with shorter mixing times.

- For the best balances of axial compressive strength, tensile strength, and flexural performance, a vibration mixing time of 3 min is optimal, considering the vibration mixing times ranging from 3 to 7 min.

- The significant improvement in the mechanical performance of UHPC with vibration mixing is attributed to two main factors: (a) the intense vibrations help expel air from the UHPC mixture, leading to an increased wet apparent density, reduced porosity, and a lower number of large pores in the hardened UHPC, thereby enhancing its mechanical properties; (b) vibration mixing promotes the uniform dispersion of CNTs, which improves the matrix strength and the transition zone, thereby increasing the bond strength between the matrix and steel fibers and enhancing the overall strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Chen, B.; Xia, Y.; Liu, S.; Xiao, Q.; Guo, W.; Wang, H. Study and data-driven modeling of flexural behaviors of ultra-high-performance concrete reinforced by milling steel fiber. Mech. Adv. Mater. Struct. 2023, 1–14. [Google Scholar] [CrossRef]

- Guo, W.; Chen, B.; Yang, Y.; Xia, Y.; Xiao, Q.; Liu, S.; Wang, H. Effect of curing regimes and fiber contents on flexural behaviors of milling steel fiber-reinforced ultrahigh-performance concrete: Experimental and data-driven studies. J. Mater. Civ. Eng. 2024, 36, 04024152. [Google Scholar] [CrossRef]

- Wang, H.; Chen, B.; Yang, Y.; Xia, Y.; Xiao, Q.; Liu, S.; Guo, W. Abrasion resistance of milling steel fibre-reinforced ultrahigh-performance concrete. Mag. Concr. Res. 2024, 76, 696–706. [Google Scholar] [CrossRef]

- Chen, B.; Ji, T.; Huang, Q.; Wu, H.; Ding, Q.; Chan, Y. Review of research on ultra-high performance concrete. J. Archit. Civ. Eng. 2014, 31, 1–24. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2014&filename=XBJG201403002&uniplatform=OVERSEA&v=yzVq56khXi7sYLXPOTLiGOdCU6FJwiHZcBE-12tUhB223VjF0IgPOWJqZd-G0M74 (accessed on 10 April 2024).

- Shao, X.; Fan, W.; Huang, Z. Application of ultra-high-performance concrete in engineering structures. China Civ. Eng. J. 2021, 54, 1–13. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Zhuang, W. Dispersion of Multi Walled Carbon Nanotubes and Its Modification of Cement Based Materials. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar] [CrossRef]

- Wu, J.; Xu, K.; Liu, X.; Zeng, C.; Wang, J. Damping properties of CNT-reinforced cementitious composites. Concrete 2023, 6, 75–80. (In Chinese). Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2023&filename=HLTF202306015&uniplatform=OVERSEA&v=TncgIr4Hi996a0rPGvlfkRfhbu34OYSBO2hi7luJ0Gy2uKPnJXgz1EoAY2-I3K8u (accessed on 22 April 2024).

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Govind; Chandra, A.; Mathur, R.B.; Dhawan, S.K. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Dai, W.; Wang, D. Cutting methods and perspectives of carbon nanotubes. J. Phys. Chem. C 2021, 125, 9593–9617. [Google Scholar] [CrossRef]

- Volder, M.F.L.D.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Anvari, A. The Influence of CNT structural parameters on the properties of CNT and CNT-reinforced epoxy. Int. J. Aerosp. Eng. 2020, 2020, 4873426. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Li, J.; Jia, X. Study on mechanical properties of cement composites enhanced by carbon nanotubes. Concrete 2022, 8, 97–101. (In Chinese). Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2022&filename=HLTF202208021&uniplatform=OVERSEA&v=V3X7y6mwMKulGcoDKjYwZhKSbO_ruDby35cNKBQXB5lOgj6cPn6Rp3xwklTzCoIk (accessed on 6 April 2024).

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Jung, M.; Lee, Y.; Hong, S.-G.; Moon, J. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 2020, 131, 106017. [Google Scholar] [CrossRef]

- Cheng, F.; Li, X.M.; Huang, Z.Y. Dispersion effect of carbon nanotubes in UHPC and its influence on mechanical properties of UHPC. China Concr. Cem. Prod. 2023, 4, 6–8+29. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.; Liu, P.; Zhang, Y.; Zhang, C.; She, W. Uniaxial tensile and compressive stress-strain behavior of multi-scale fiber-reinforced ultra-high performance concrete. J. Chin. Ceram. Soc. 2020, 48, 1155–1167. [Google Scholar] [CrossRef]

- Song, S.; Qiao, W.; Zhang, L.; Huang, Z. Effect of vibratory stirring on properties of reactive pow der concrete. Concrete 2018, 12, 5–7+10. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2019&filename=HLTF201812002&uniplatform=OVERSEA&v=QHAEoC5qJFhiwdYgBh_VwbOR0wxfA-Ho_u-iAsiQhj6BnLTwUQsFNPxCfvXqt2l4 (accessed on 25 April 2024).

- Zhao, L.J.; Jiang, W.Z.; Hou, J.R.; Feng, Z.; Xue, S. Influence of mixing methods on performance of compressive strength for cement stabilized macadam mixture. China J. Highw. Transp. 2018, 31, 151–158. [Google Scholar] [CrossRef]

- Li, C.; Nie, J.; Feng, Z.; Deng, S.; Lei, Z.; Zhang, Y. Effect of vibratory mixing on the construction and mechanical properties of ultra-high performance concrete. Bull. Chin. Ceram. Soc. 2019, 38, 2586–2594. [Google Scholar] [CrossRef]

- Li, K.; Zhang, F.L.; Wei, B.H.; Li, X.C.; Zhang, H.J.; Zhang, M.D. Mix design and performance analysis of ultra-high performance concrete under different mixing modes. Constr. Technol. 2022, 51, 122–124+130. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2022&filename=SGJS202212025&uniplatform=OVERSEA&v=wv0c209KXRd4uVXij8KFMiBreCGwBtT0gXusVdnfZBMmDs4cG8LO4nhXddMXJ1nq (accessed on 23 April 2024).

- He, Z.Y.; Yang, J.Y.; Zou, L.M. Research on the effect of the double-horizontal-shaft vibrating mixing on the performance of ultra-high performance concrete. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2023, 20, 154–162. [Google Scholar] [CrossRef]

- Luo, W.; Xiong, G.Q.; Xiong, C.C.; Zheng, Y.; Wang, C. Preparation of steel fiber reinforced high strength lightweight concrete using vibration mixing technology. J. Cent. South Univ. (Sci. Technol.) 2020, 51, 14–22. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2020&filename=ZNGD202001003&uniplatform=OVERSEA&v=rbbA6i8h25UxJxskPPK9pFRjWdeGp3FJjBDKQ9aQFyYnRE4v9uJ6RxlHk1iUiogl (accessed on 5 May 2024).

- Zhang, P.; Su, J.; Guo, J.; Hu, S. Influence of carbon nanotube on properties of concrete: A review. Constr. Build. Mater. 2023, 369, 130388. [Google Scholar] [CrossRef]

- GB/T 50080; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Academy of Building Research: Beijing, China, 2016. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT50080-2016 (accessed on 13 March 2024).

- T/CECS 864-2021; Standard for Test Method of Ultra-High Performance Concrete. Shanghai Research Institute of Building Science Co., Ltd.: Shanghai, China, 2021. Available online: https://www.gongbiaoku.com/book/3dt21846axm (accessed on 15 March 2024).

- T/CBMF 37-2018; Fundamental Characteristics and Test Methods of Ultra-High Performance Concrete. China Building Materials Federation: Beijing, China, 2018. Available online: https://www.ccpa.com.cn/site/content/4185.html (accessed on 15 March 2024).

- Zheng, Y.; Zhou, Y.; Huang, X.; Min, Y.; Luo, H.; Chen, Y.; Li, W. Study on performance improvement of ultra-high performance concrete by vibration mixing. Constr. Build. Mater. 2022, 327, 126823. [Google Scholar] [CrossRef]

- Liu, J.; An, M.; Huang, L.; Wang, Y.; Han, S. Influence of vibrating compaction time on the strength and microstructure of ultra-high performance concrete. Constr. Build. Mater. 2023, 409, 133584. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, Y.; Nie, F.; Luo, H.; Huang, X. Effect of a novel vibration mixing on the fiber distribution and mechanical properties of ultra-high performance concrete. Sustainability 2022, 14, 7920. [Google Scholar] [CrossRef]

| ID | Mixing Method | Mixing Time | UHPC Premix (kg/m3) | Water Reducer (kg/m3) | Defoamer (kg/m3) | Water (kg/m3) | CNT Slurry (kg/m3) |

|---|---|---|---|---|---|---|---|

| Z3 | Vibration Mixing | 3 min | 2239.5 | 38 | 0.4 | 118.235 | 17.5 |

| Z5 | Vibration Mixing | 5 min | 2239.5 | 38 | 0.4 | 118.235 | 17.5 |

| Z7 | Vibration Mixing | 7 min | 2239.5 | 38 | 0.4 | 118.235 | 17.5 |

| B10 | Twin-Shaft Mixing | 10 min | 2239.5 | 38 | 0.4 | 118.235 | 17.5 |

| ID | Energy Absorption Capacity (kN·mm) | Energy Absorption at Yield (kN·mm) | Ductility Index |

|---|---|---|---|

| Z3 | 187.85 | 3.59 | 52.33 |

| Z5 | 167.75 | 3.78 | 44.38 |

| Z7 | 191.91 | 3.20 | 59.97 |

| B10 | 157.66 | 3.43 | 45.97 |

| ID | Total Pore Volume (mL/g) | Average Pore Diameter (nm) | Porosity (%) | Pore Size Distribution (%) | |||

|---|---|---|---|---|---|---|---|

| <10 nm | 10–100 nm | 100–1000 nm | >1000 nm | ||||

| Z3 | 0.0417 | 87.96 | 9.14 | 0.60 | 0.05 | 0.35 | 8.14 |

| B10 | 0.0632 | 178.71 | 12.24 | 0.33 | 0.64 | 0.40 | 10.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Yin, J.; Wang, W.; Liu, F.; Xiao, M.; Yang, Y.; Cui, H. Effect of Vibration Mixing on the Mechanical Properties of Carbon Nanotube-Reinforced Ultra-High-Performance Concrete. Buildings 2024, 14, 2545. https://doi.org/10.3390/buildings14082545

Zhou L, Yin J, Wang W, Liu F, Xiao M, Yang Y, Cui H. Effect of Vibration Mixing on the Mechanical Properties of Carbon Nanotube-Reinforced Ultra-High-Performance Concrete. Buildings. 2024; 14(8):2545. https://doi.org/10.3390/buildings14082545

Chicago/Turabian StyleZhou, Li, Jiangang Yin, Wei Wang, Fucai Liu, Min Xiao, Yibo Yang, and Haibo Cui. 2024. "Effect of Vibration Mixing on the Mechanical Properties of Carbon Nanotube-Reinforced Ultra-High-Performance Concrete" Buildings 14, no. 8: 2545. https://doi.org/10.3390/buildings14082545

APA StyleZhou, L., Yin, J., Wang, W., Liu, F., Xiao, M., Yang, Y., & Cui, H. (2024). Effect of Vibration Mixing on the Mechanical Properties of Carbon Nanotube-Reinforced Ultra-High-Performance Concrete. Buildings, 14(8), 2545. https://doi.org/10.3390/buildings14082545