Crack Identification Method for Prefabricated Concrete Pavement Based on Distributed Strain Monitoring

Abstract

1. Introduction

2. Crack Identification Method Based on Distributed Long-Gauge Optic Fiber Sensing

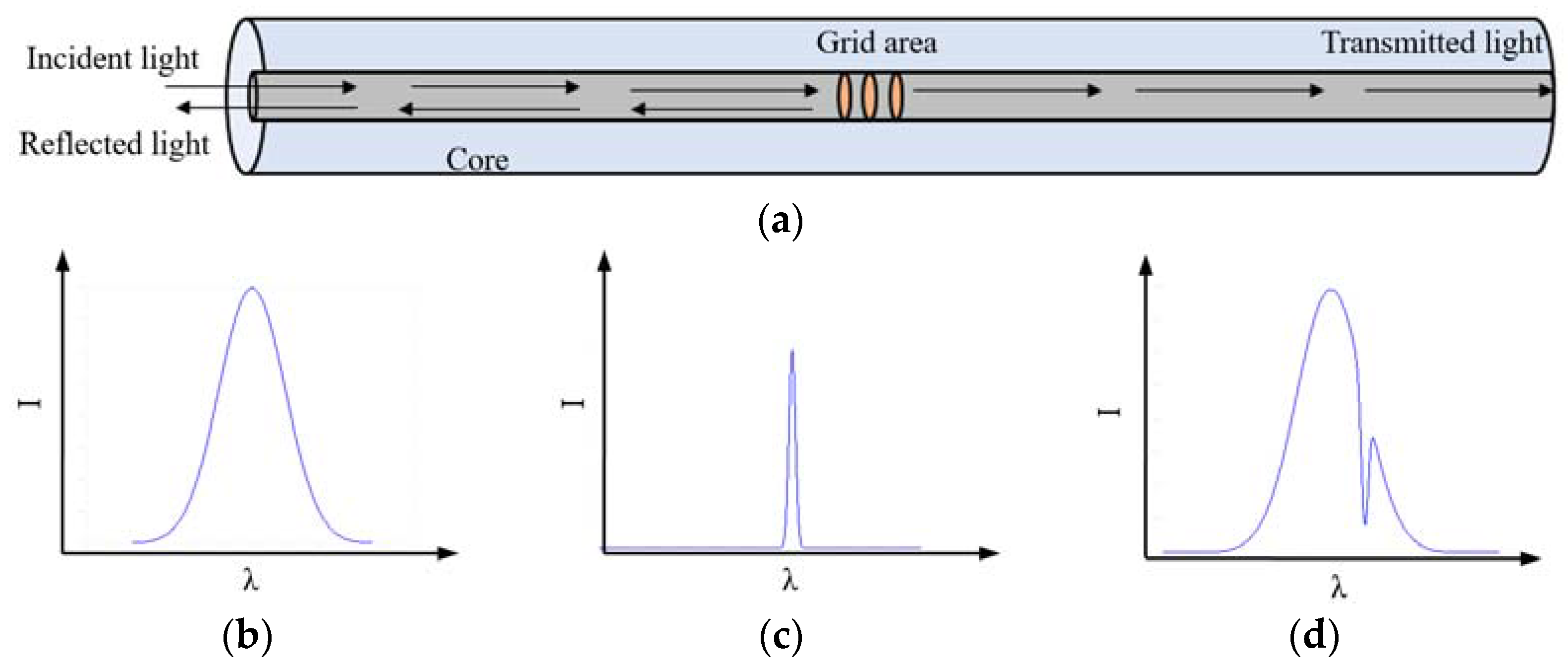

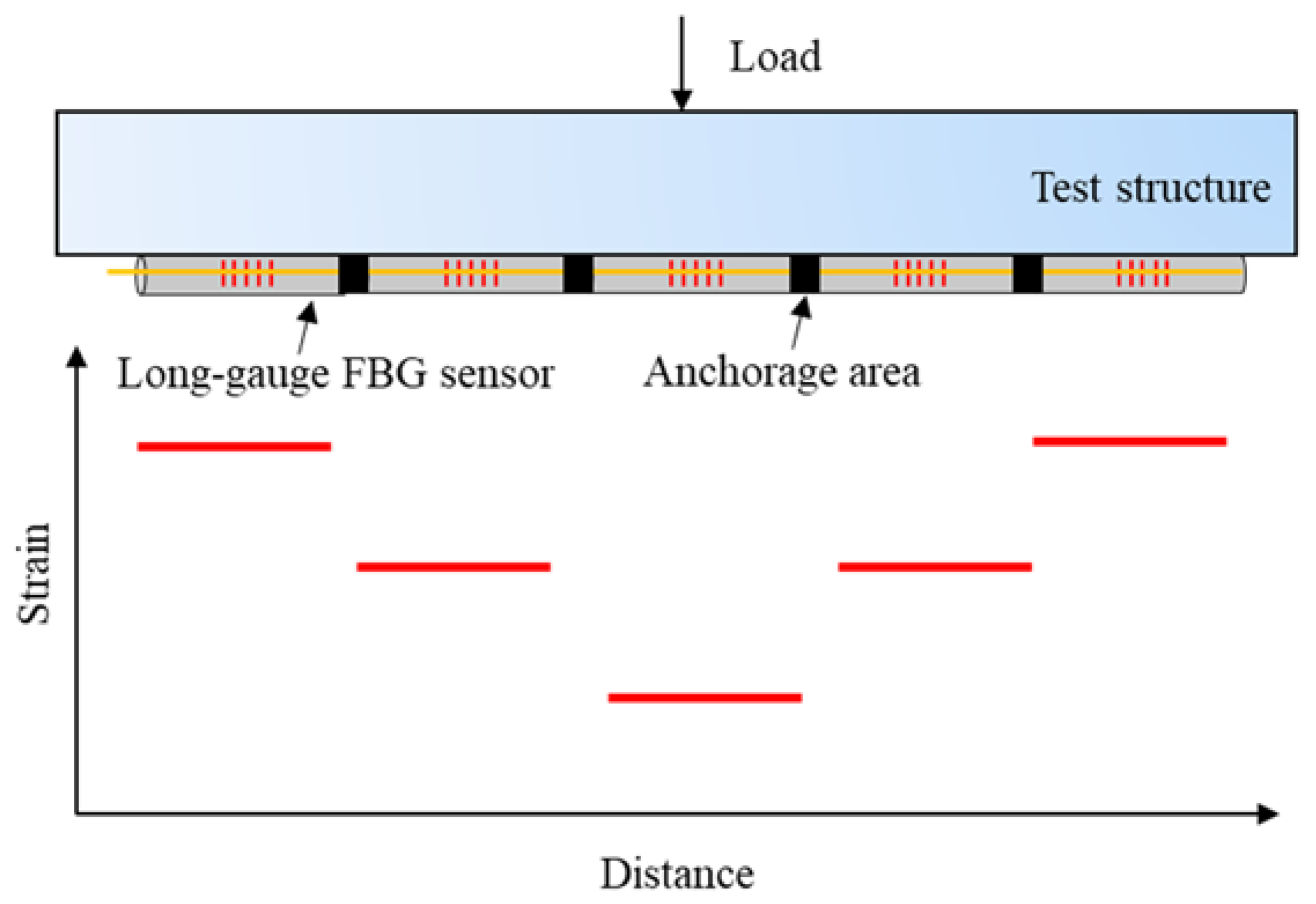

2.1. Distributed Long-Gauge Optic Fiber Sensing

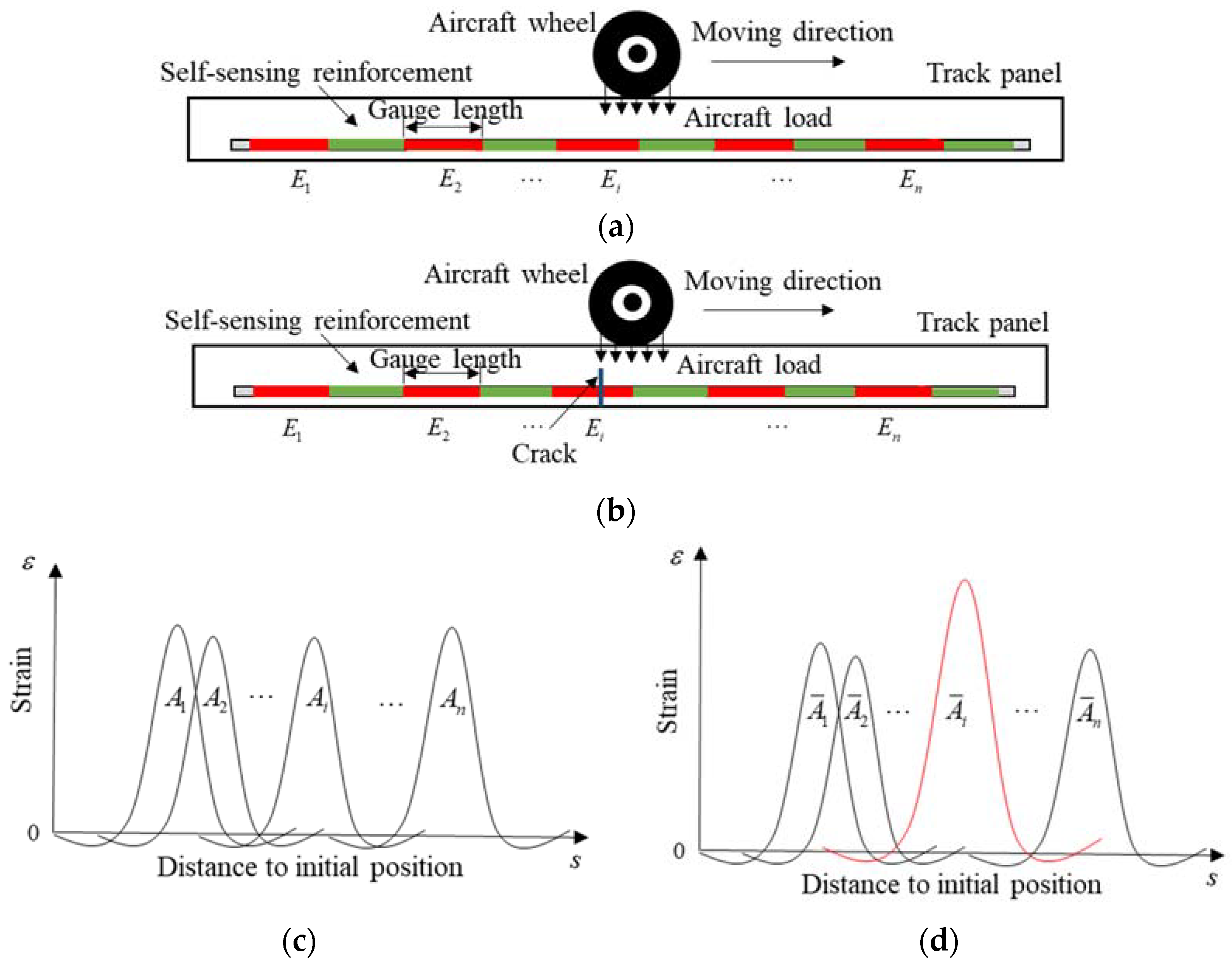

2.2. Crack Identification Method

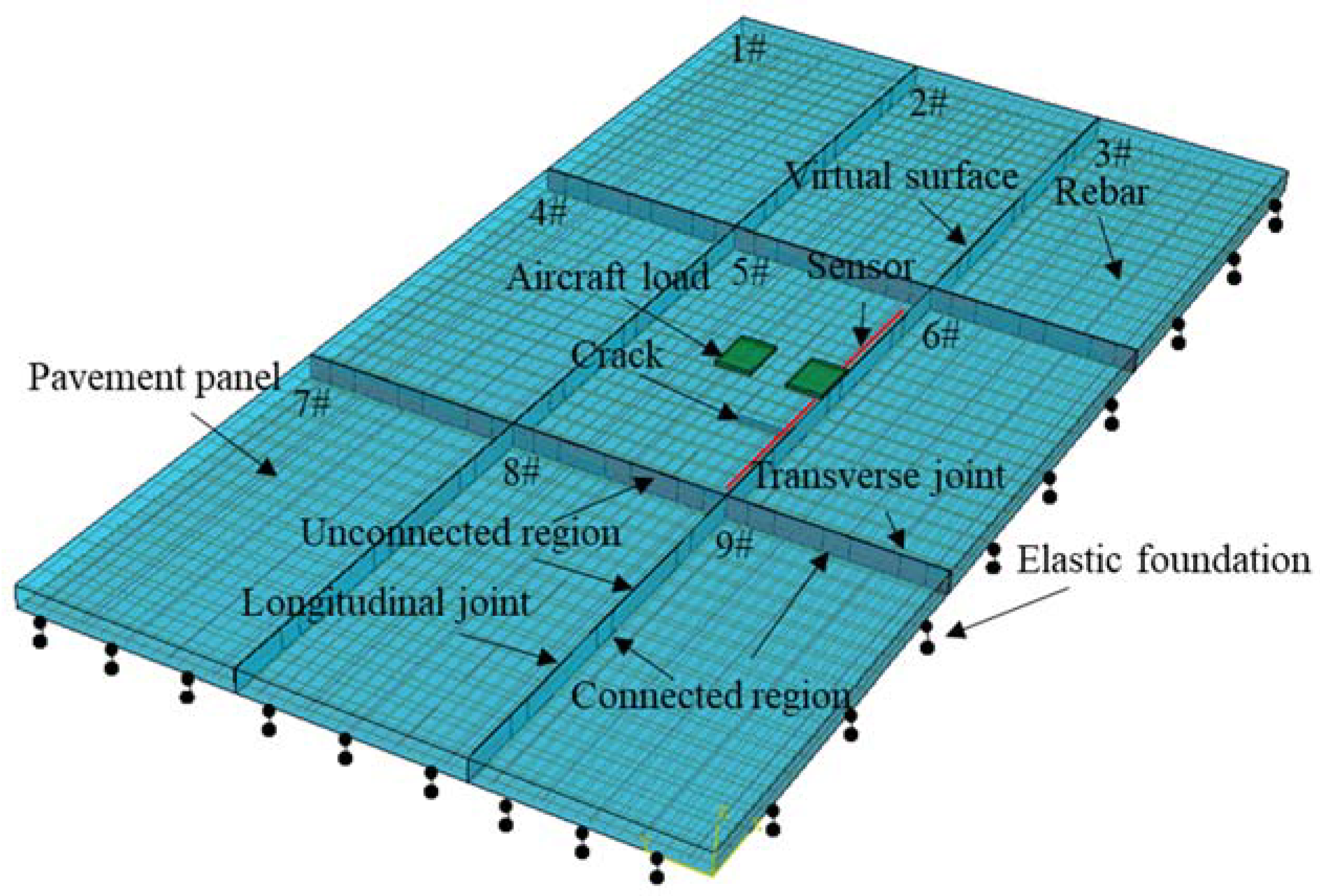

3. Finite Element Modeling of Prefabricated Pavement

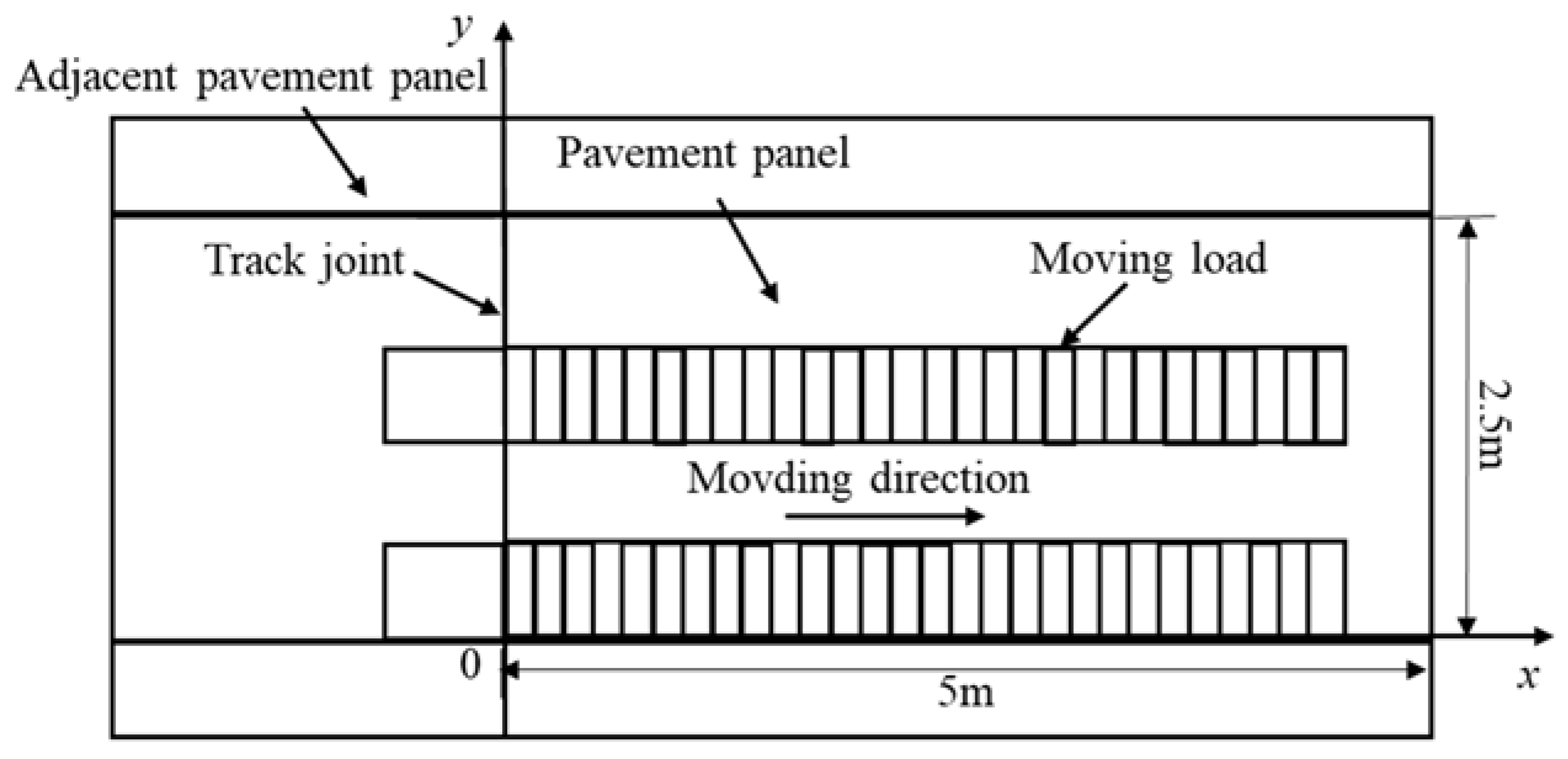

3.1. General Information of Prefabricated Pavement Model

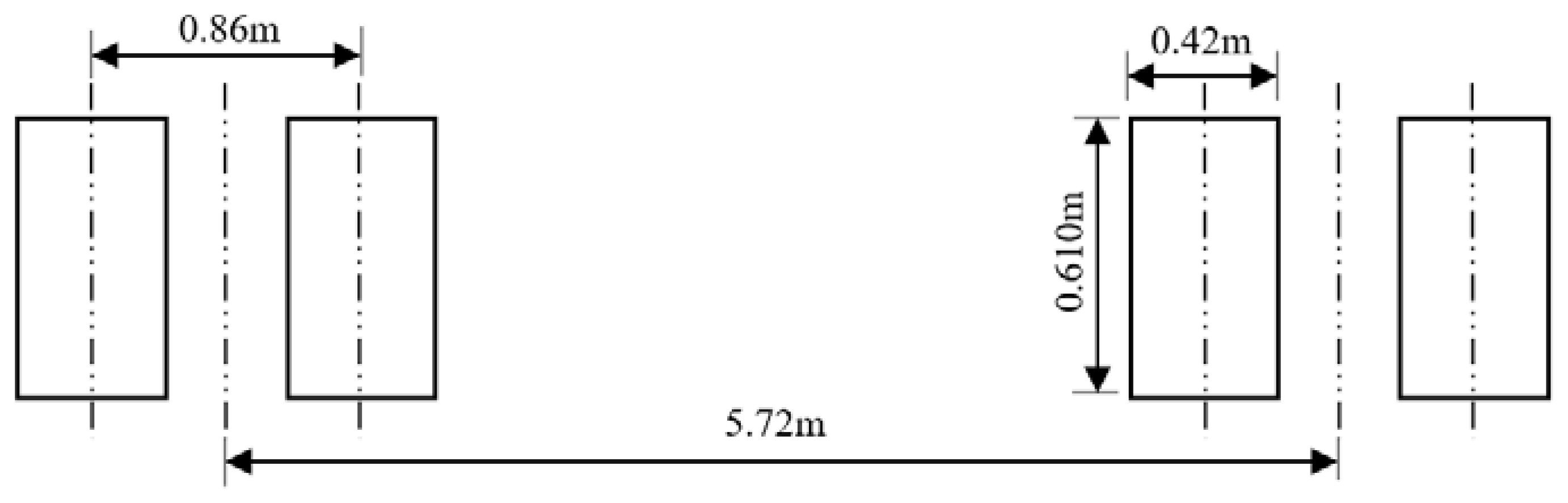

3.1.1. Pavement Model Construction

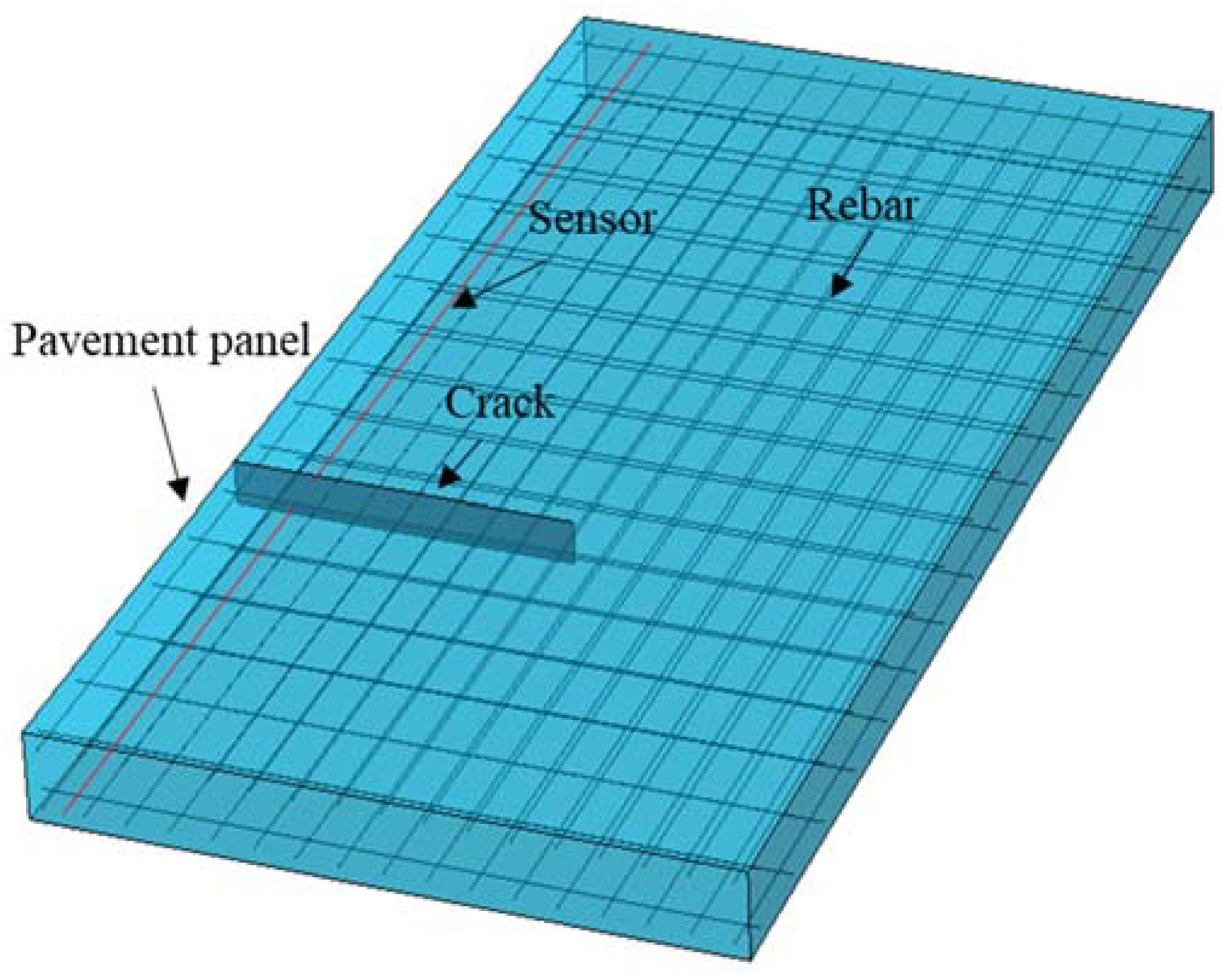

3.1.2. Crack Simulation and Location Selection

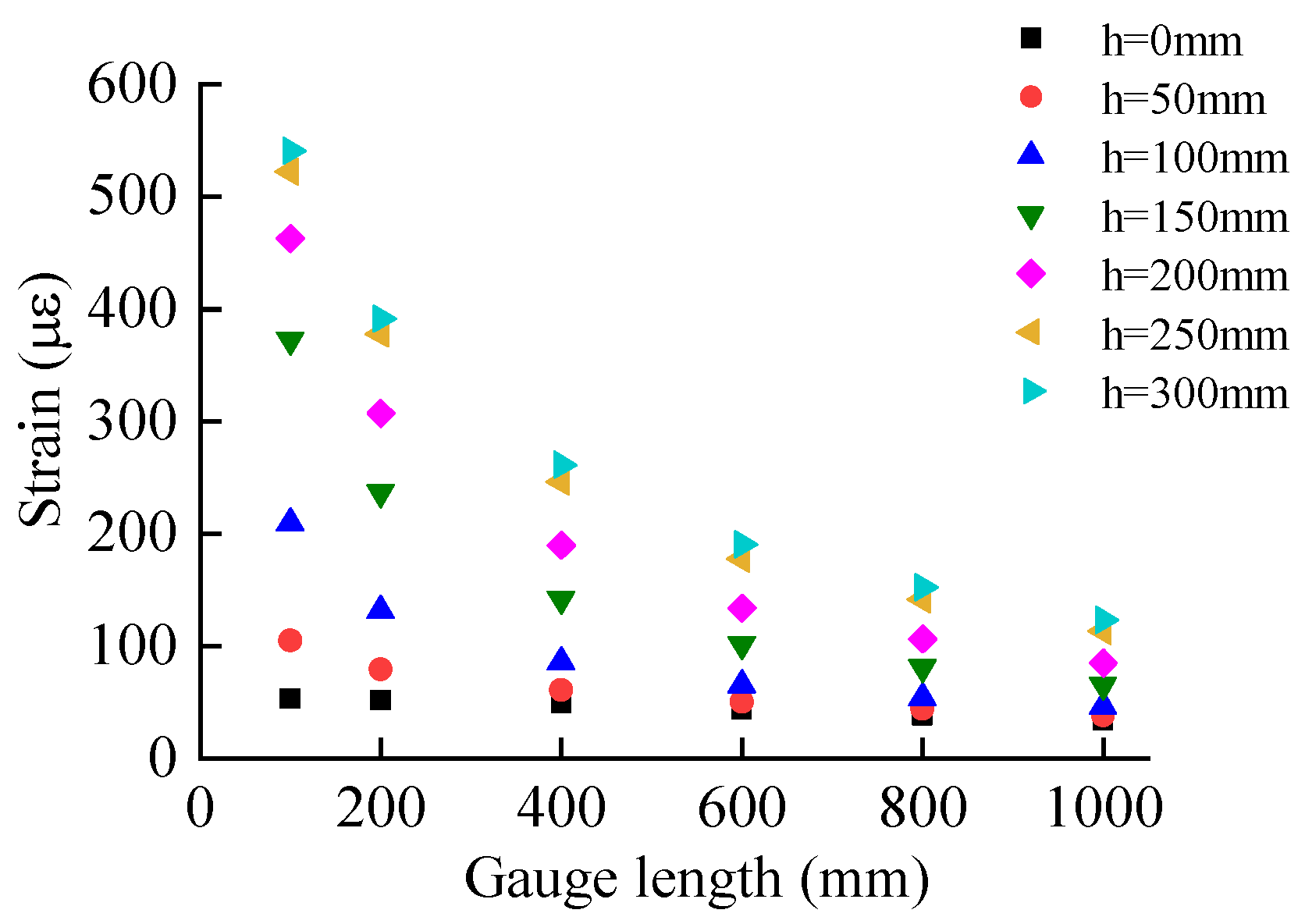

3.1.3. Sensor Position Selection and Scale Distance Optimization

3.2. Results of Crack Identification

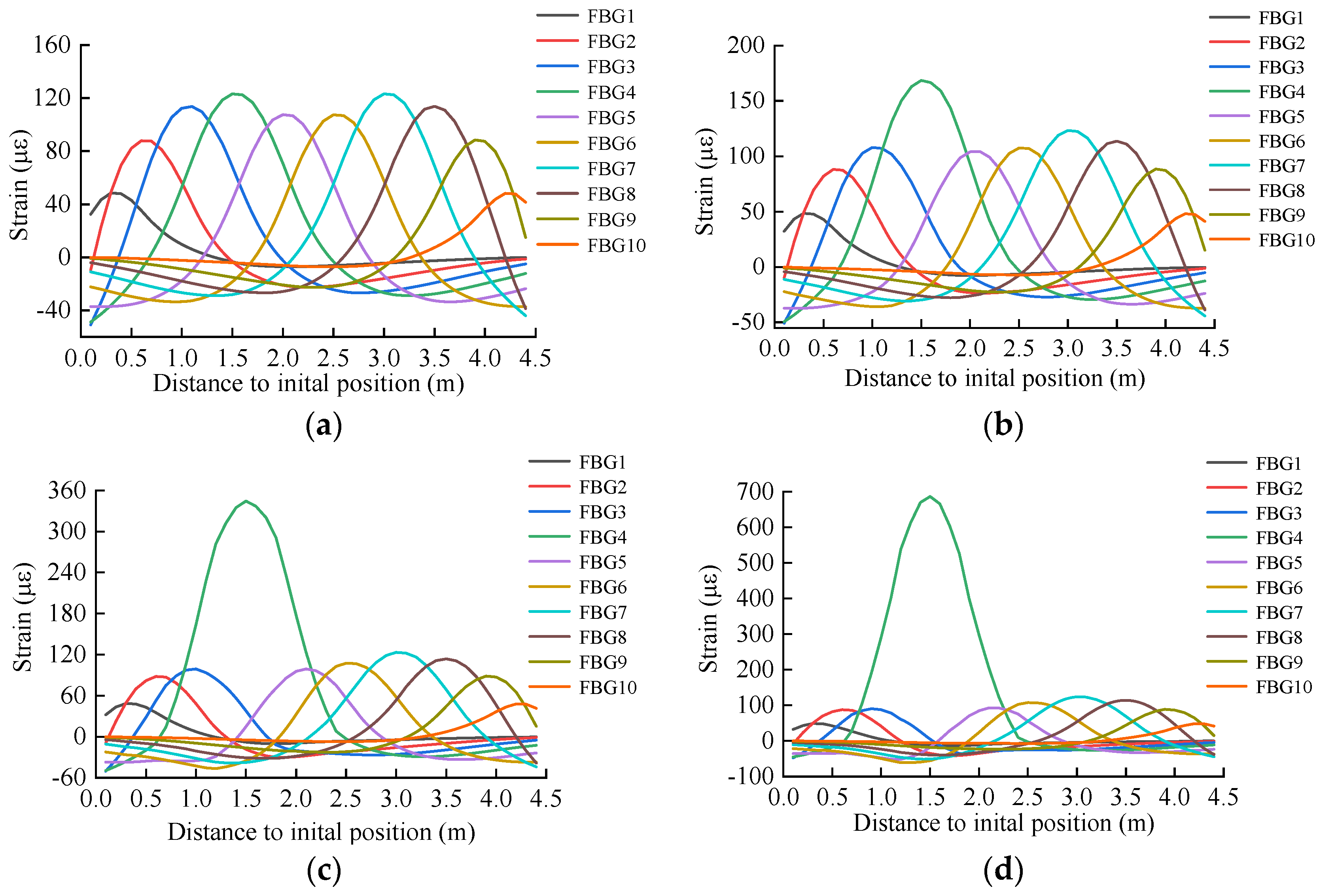

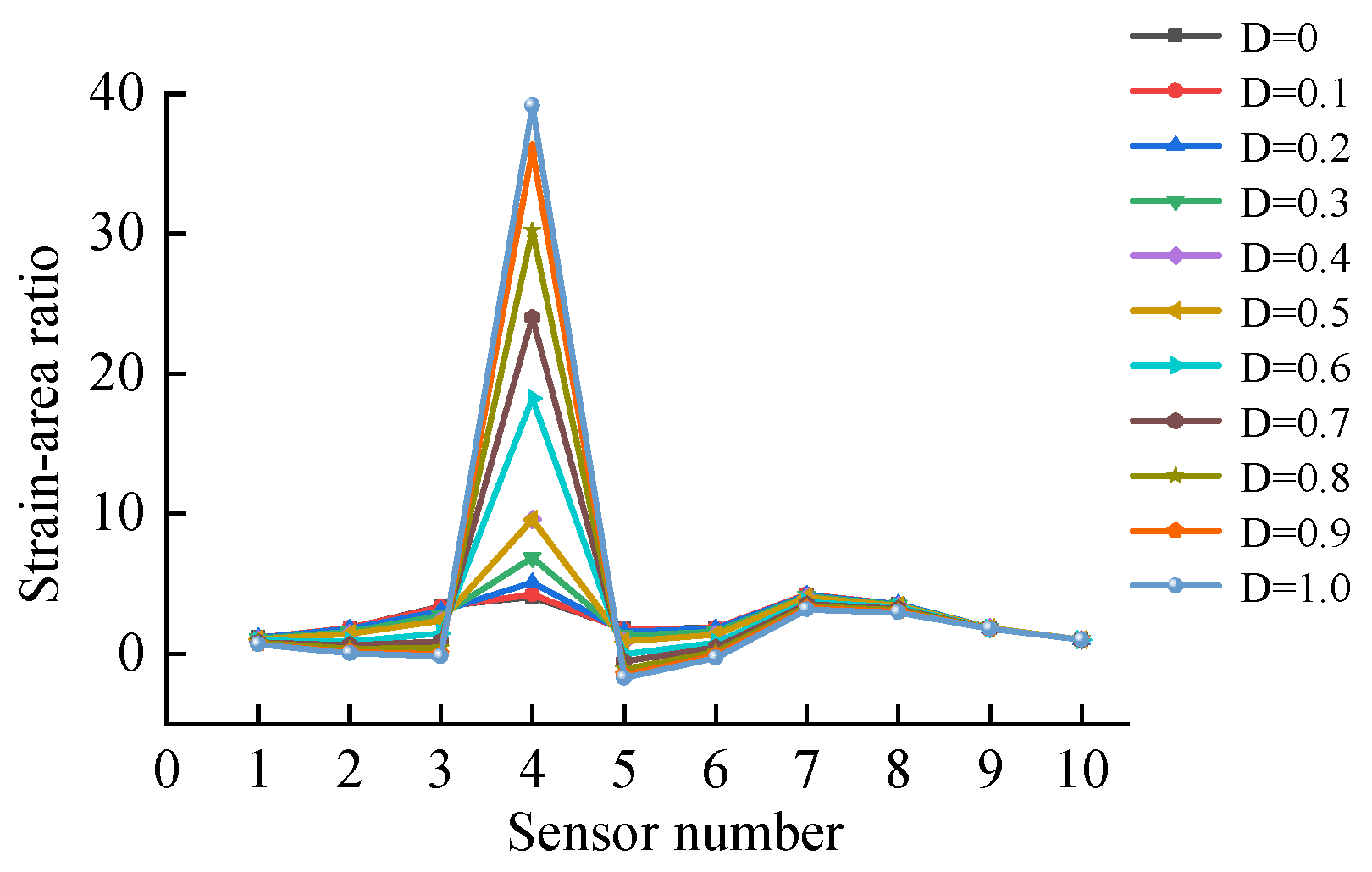

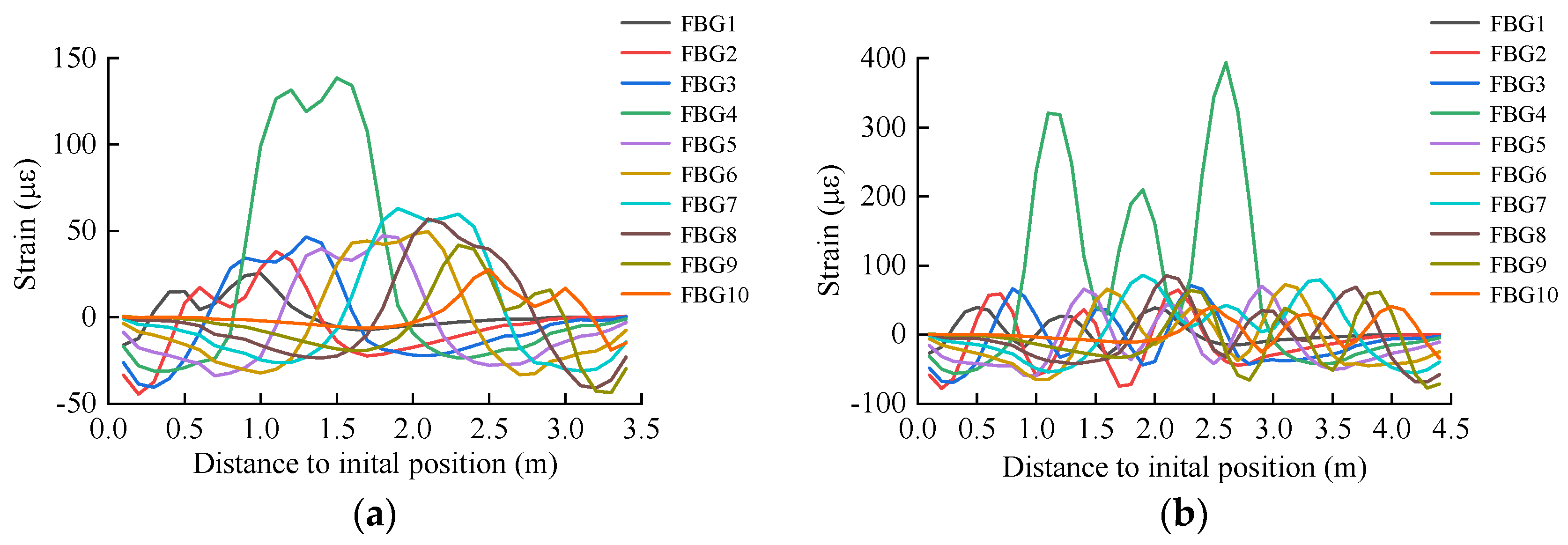

3.2.1. Single Crack

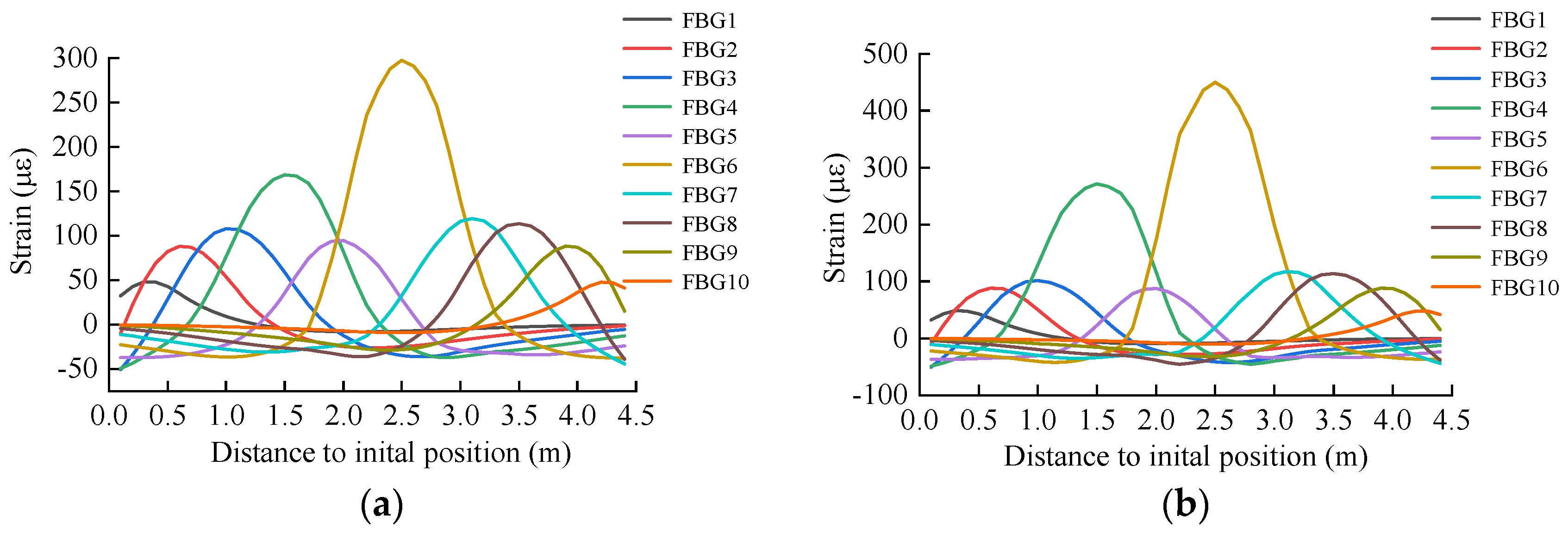

3.2.2. Multiple Cracks

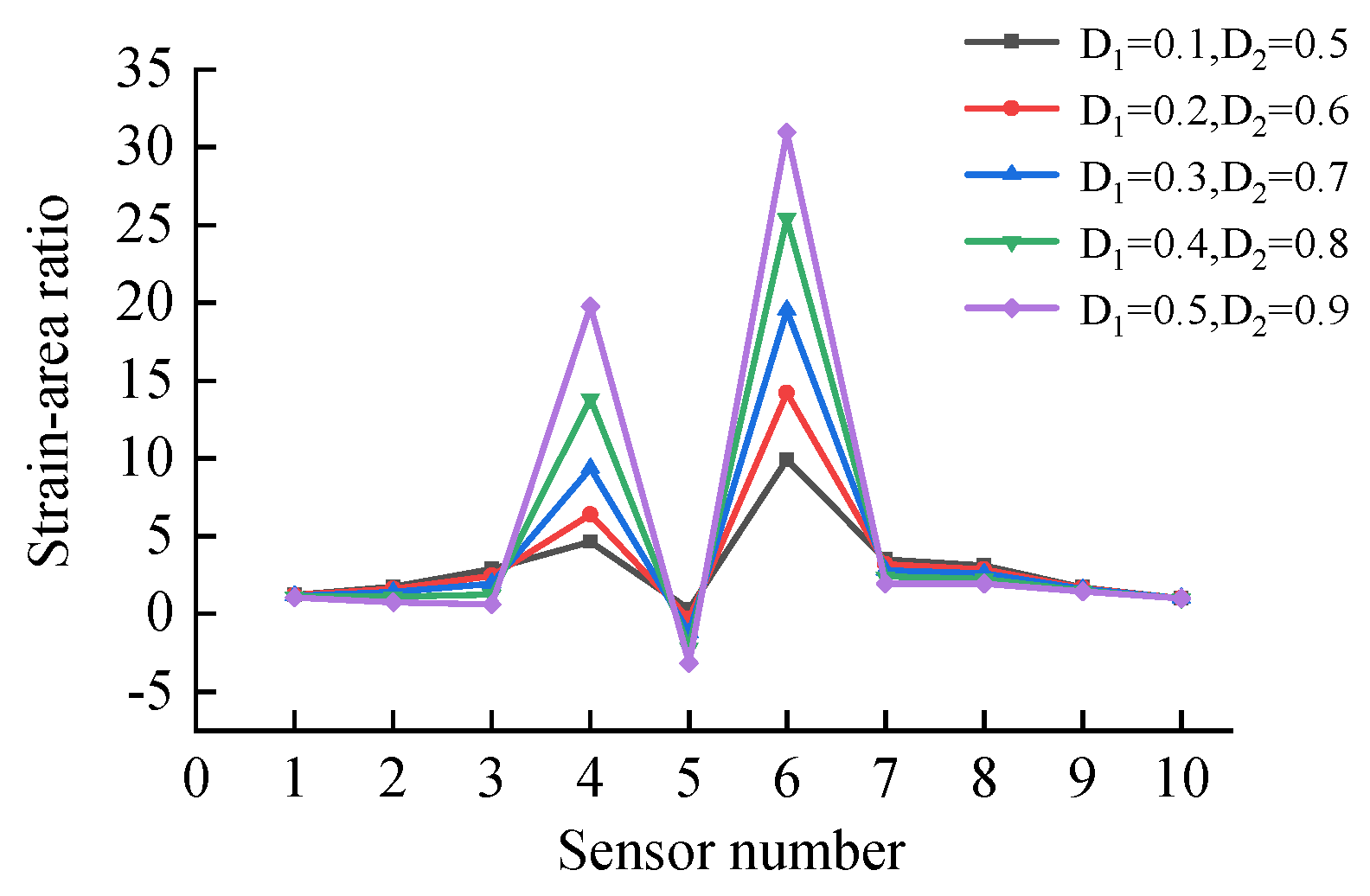

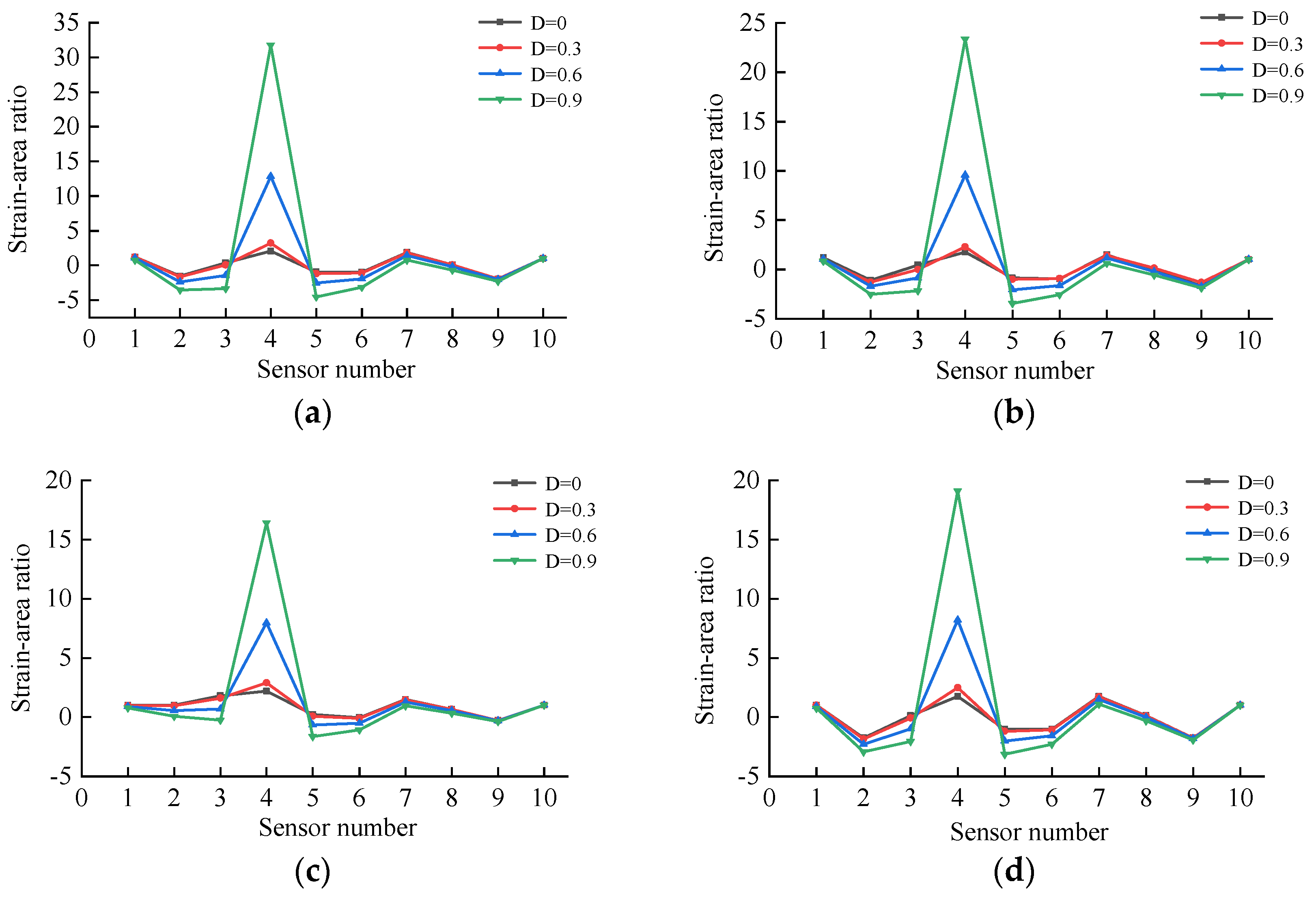

3.3. Analysis of Influencing Factors

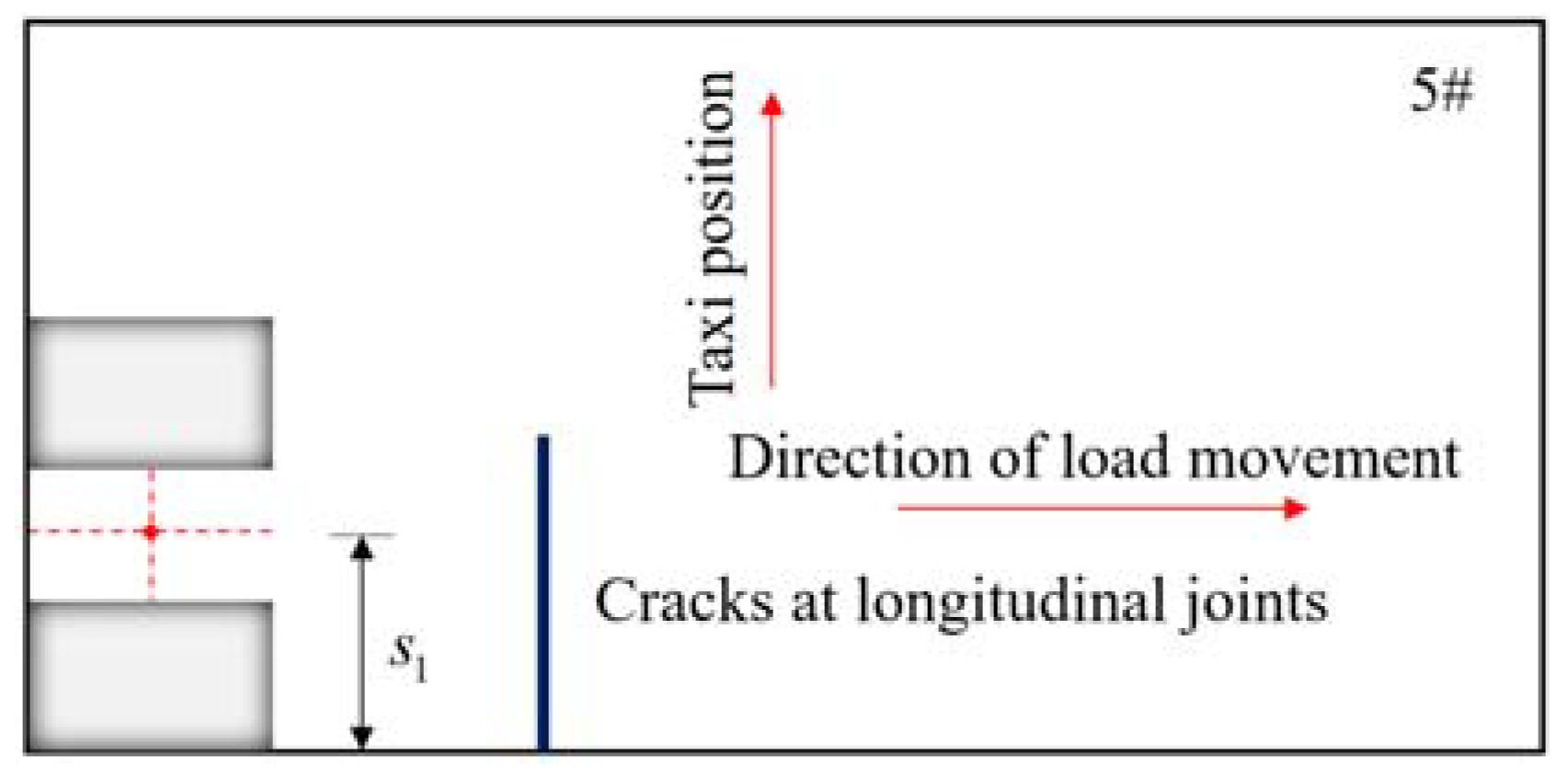

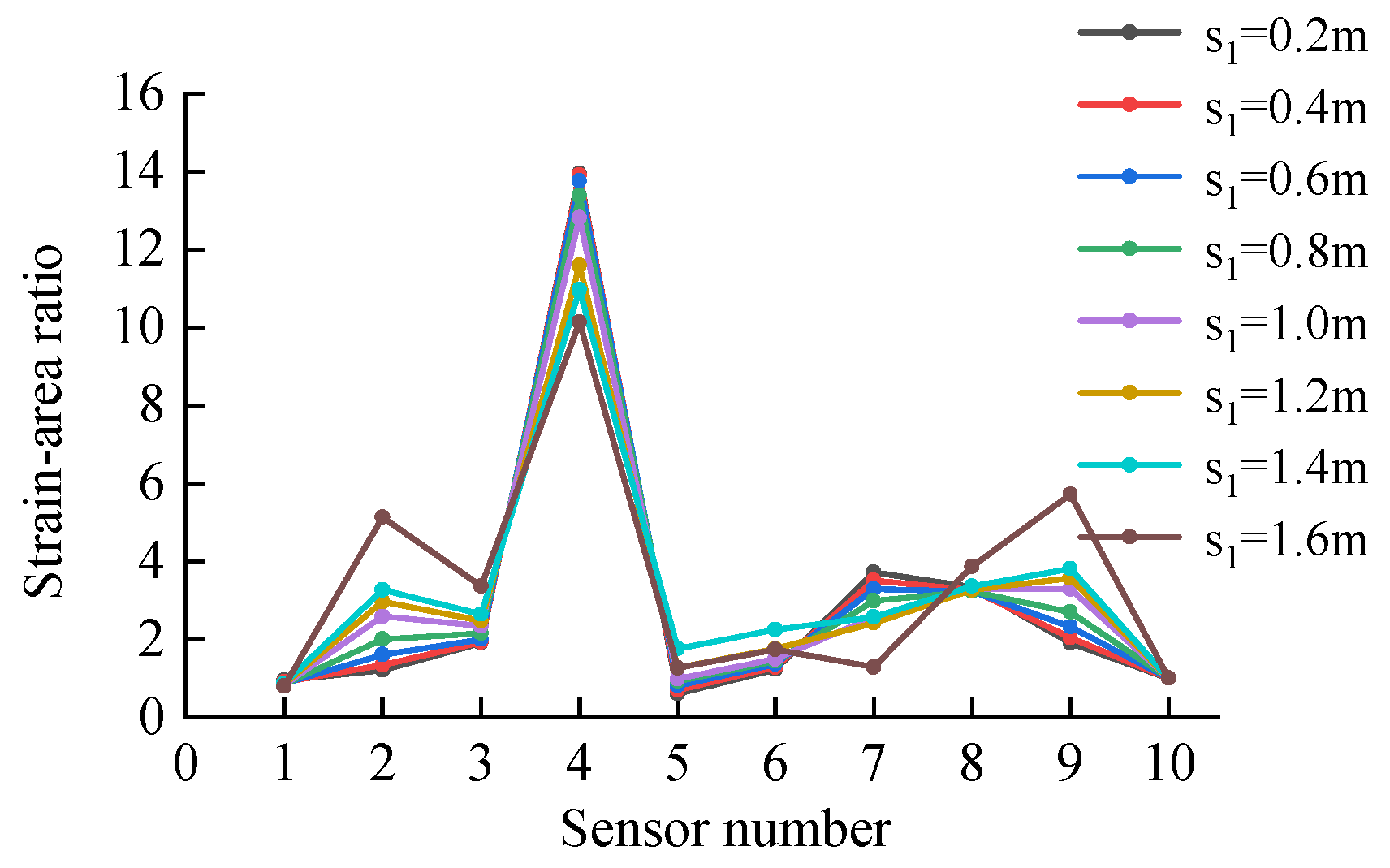

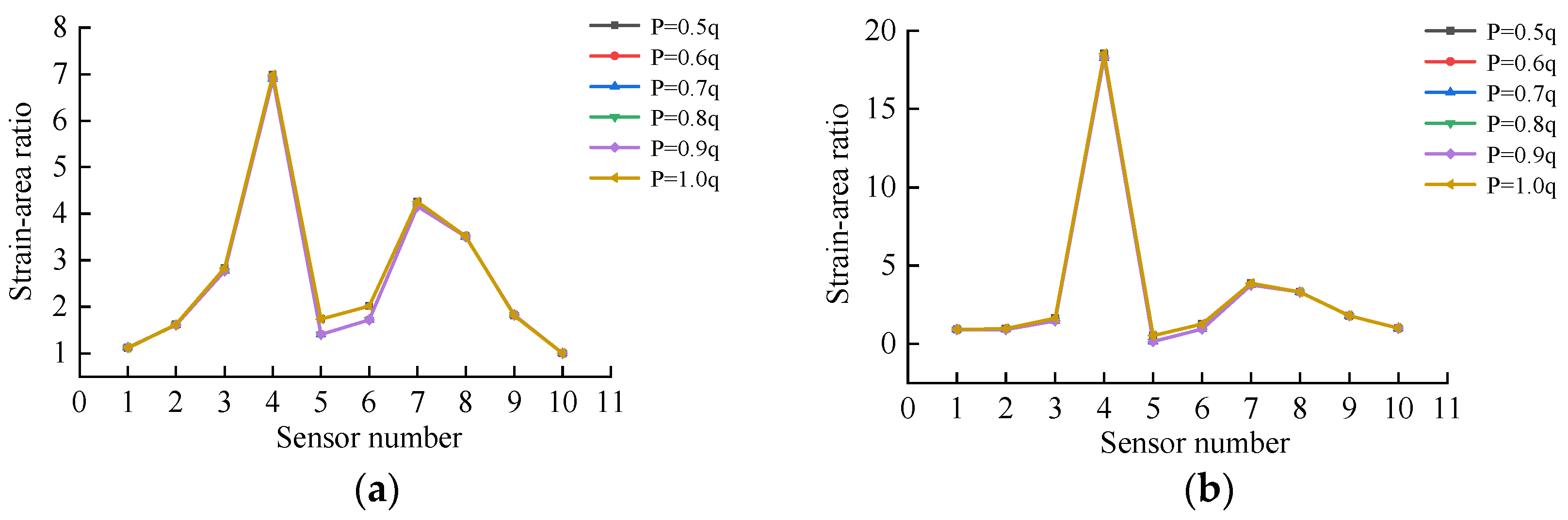

3.3.1. Aircraft Taxiing Position

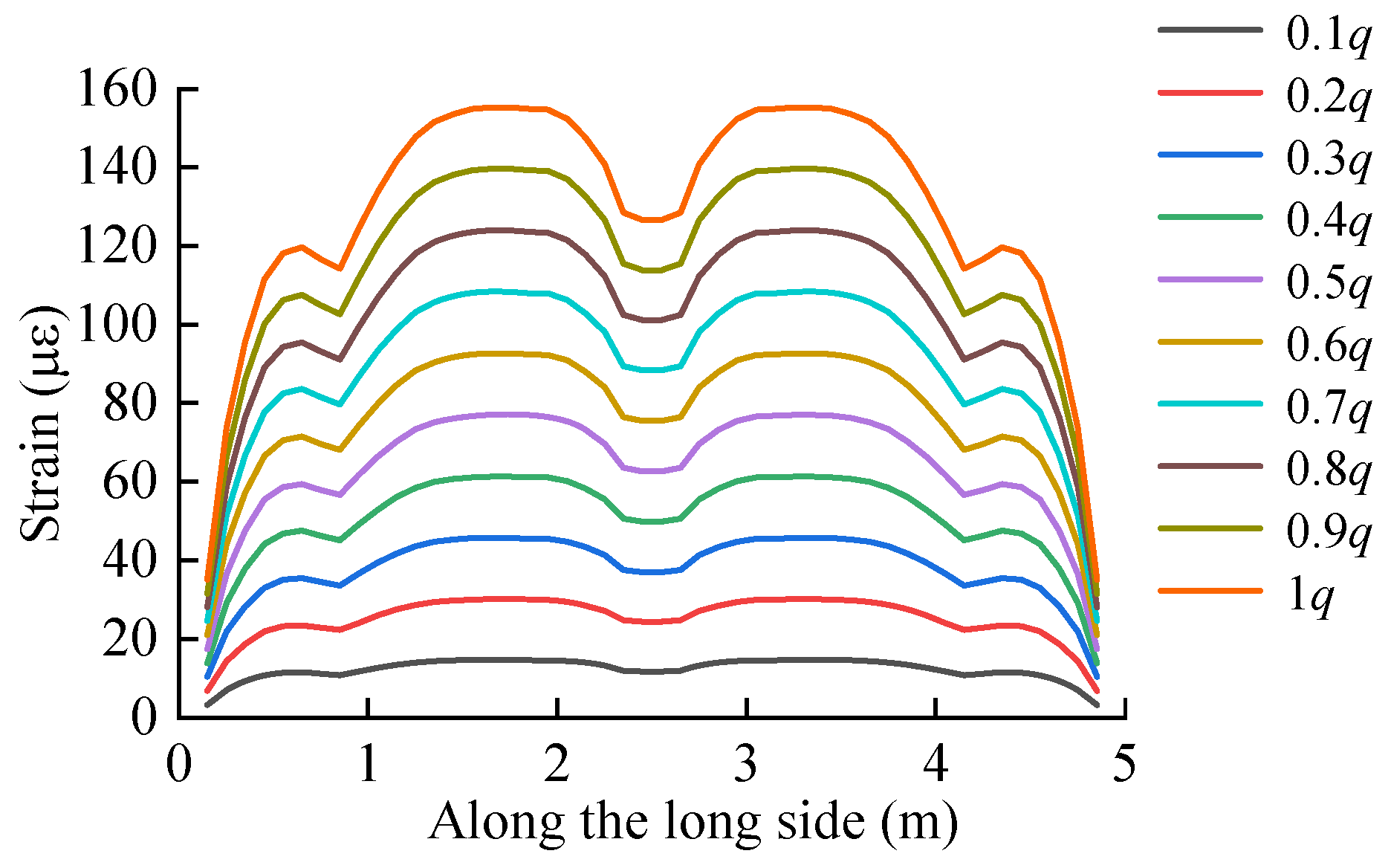

3.3.2. Aircraft Load Value

3.3.3. Aircraft Type

4. Loading Test with Small-Scale Model of Prefabricated Concrete Pavement

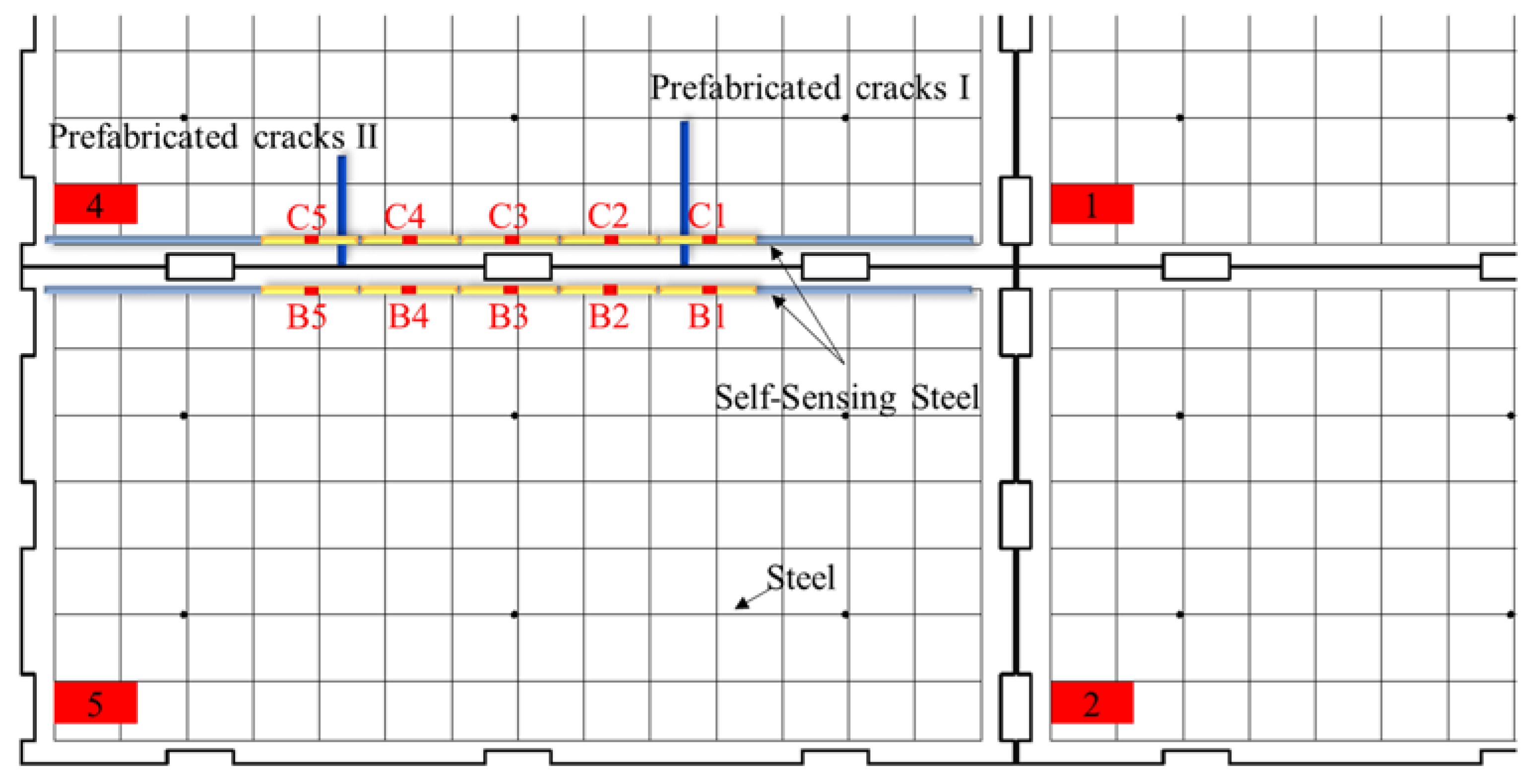

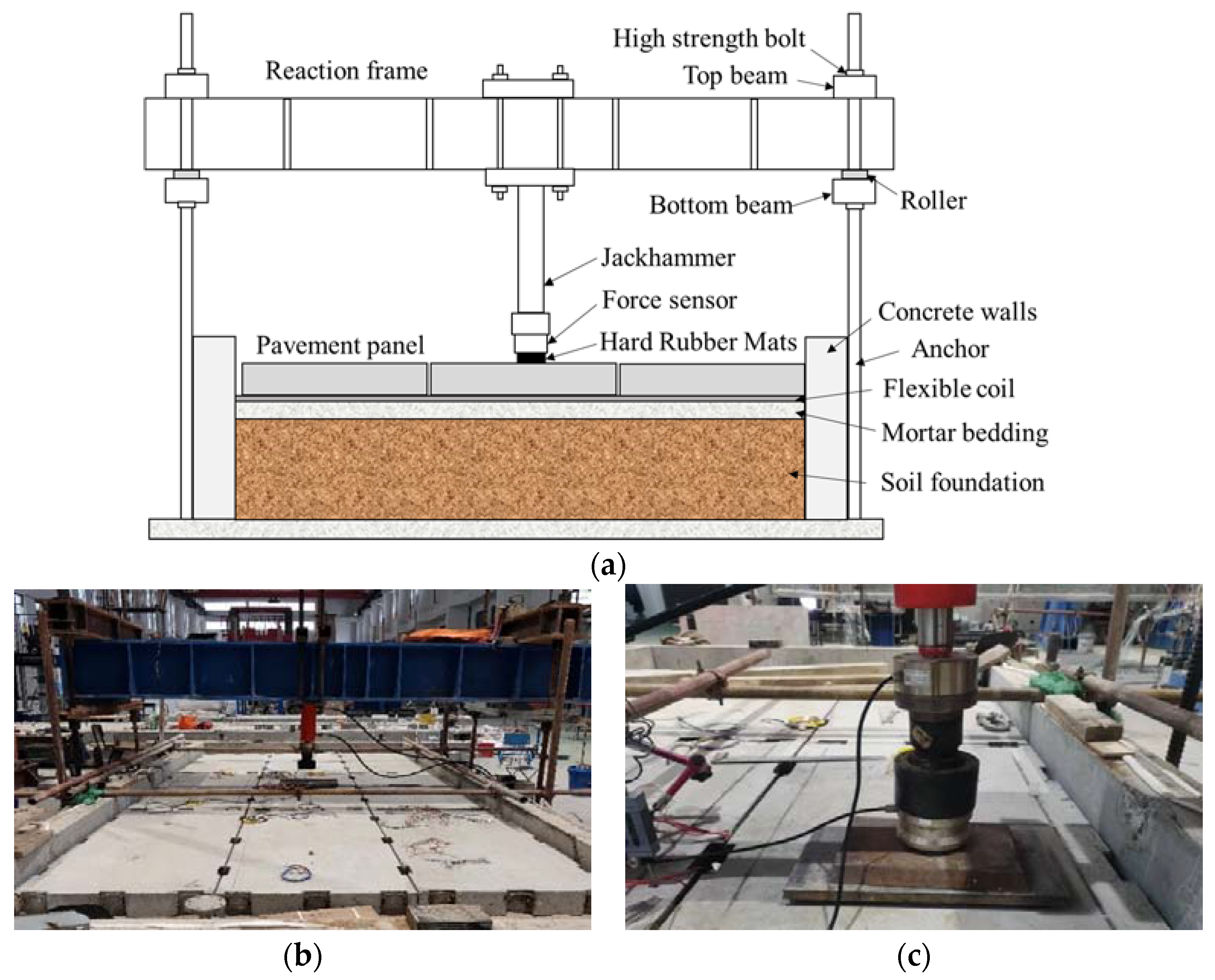

4.1. Experimental Setup

4.1.1. Test Scaling and Model Parameters

4.1.2. Monitoring System Design

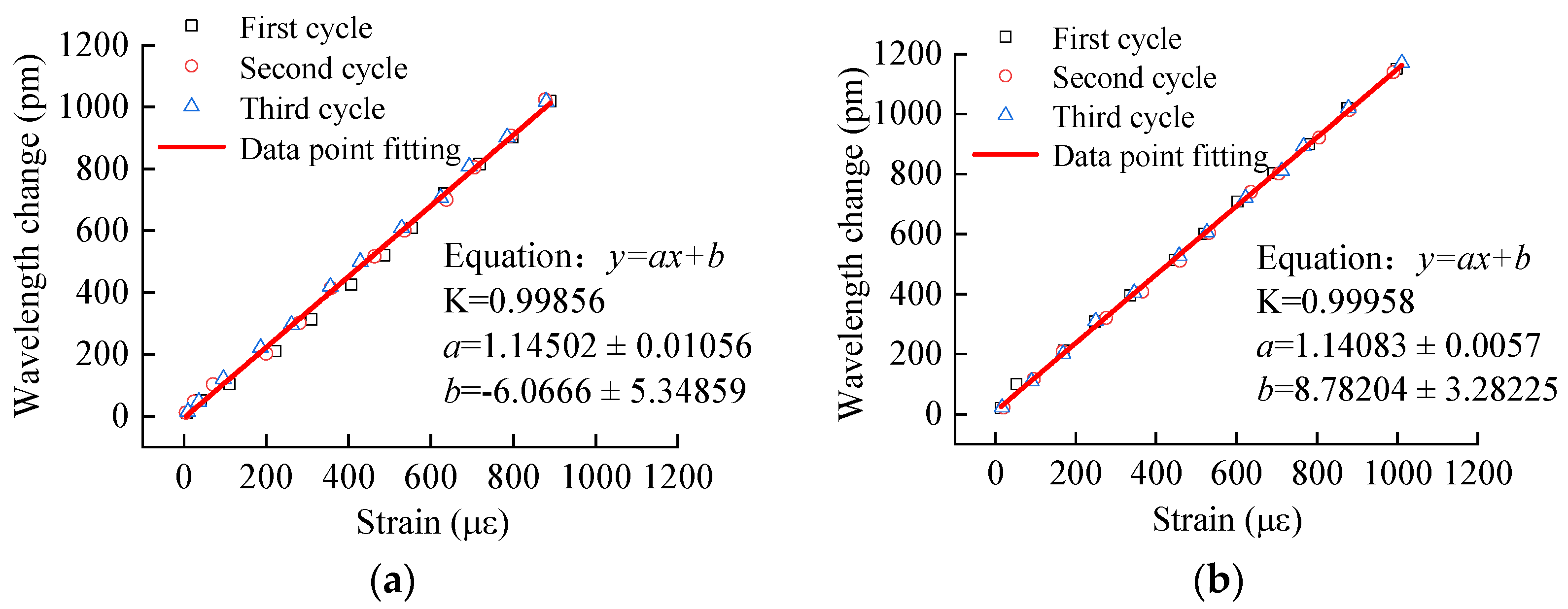

4.1.3. Performance Analysis of Self-Sensing Reinforcement and Strain Sensing

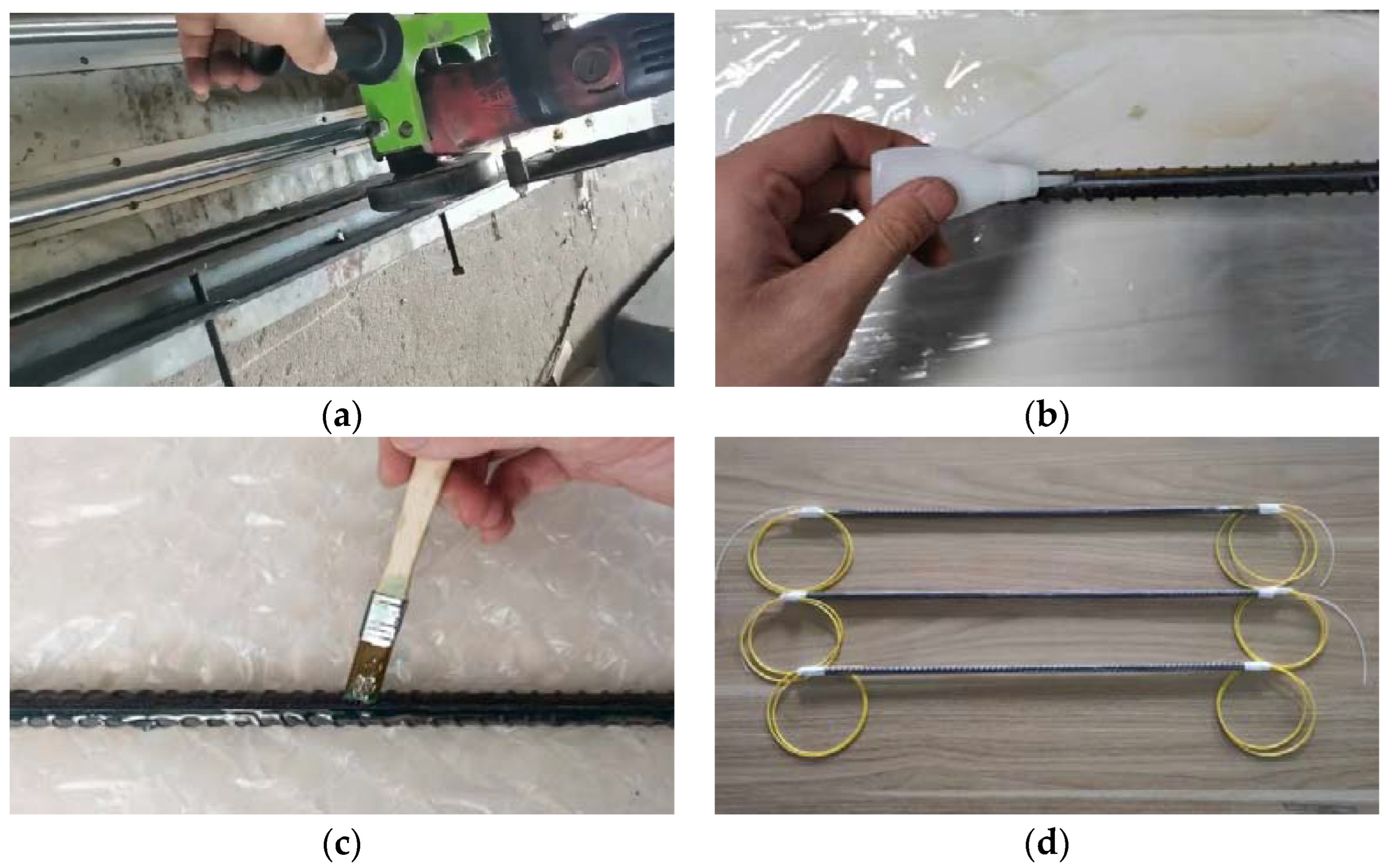

- (1)

- Self-sensing steel fabrication

- (2)

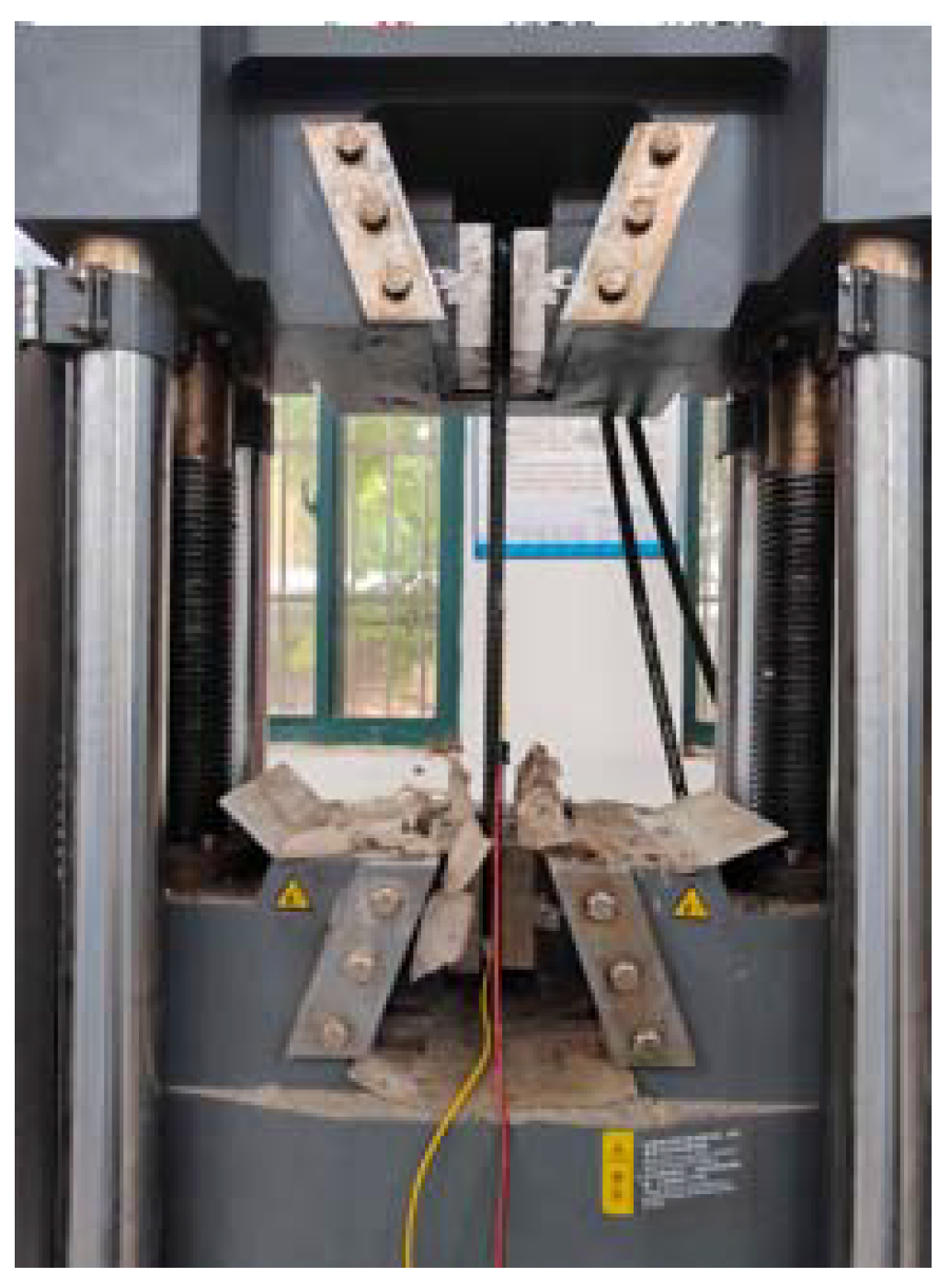

- Strain sensing performance test

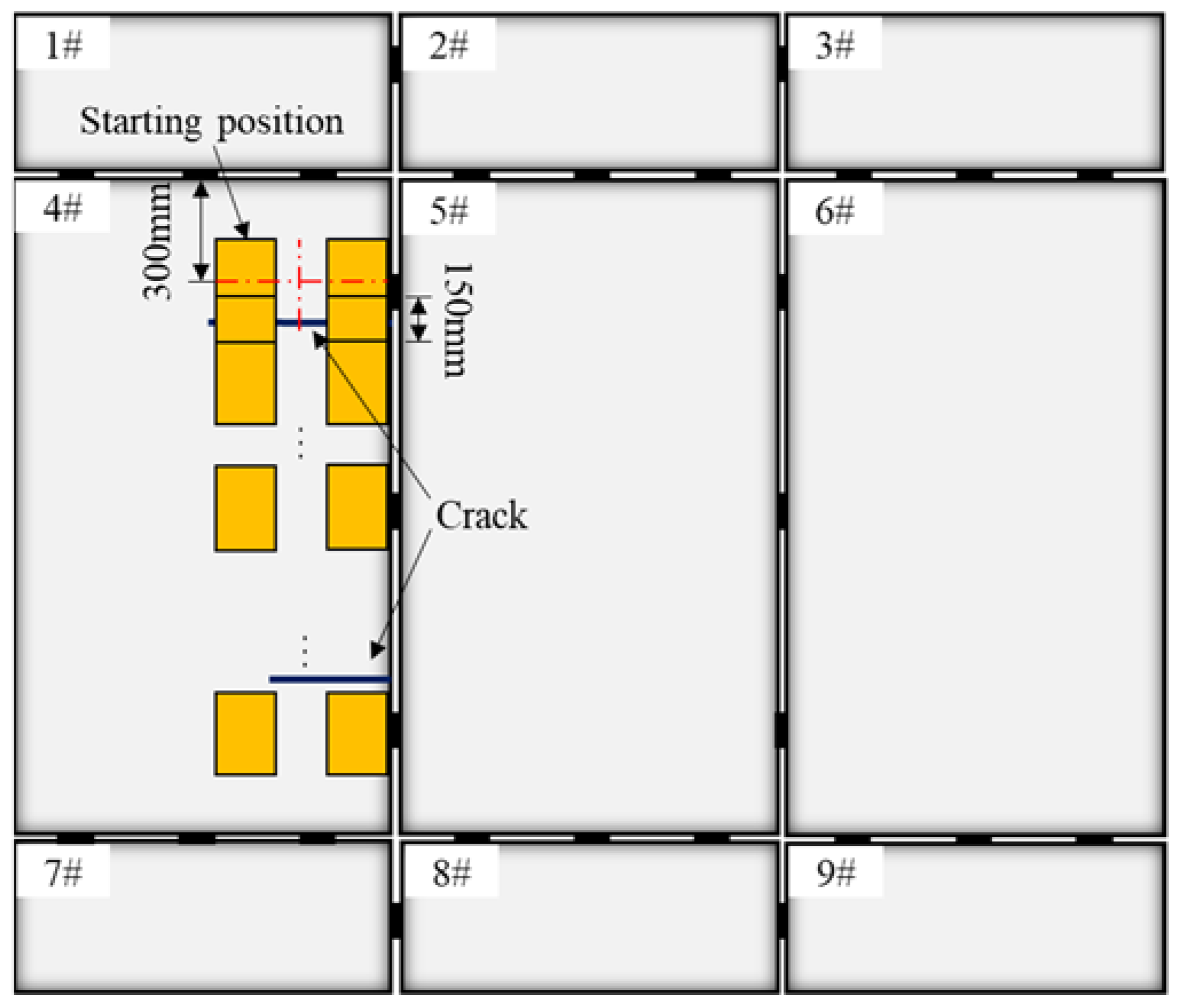

4.2. Pilot Program Implementation

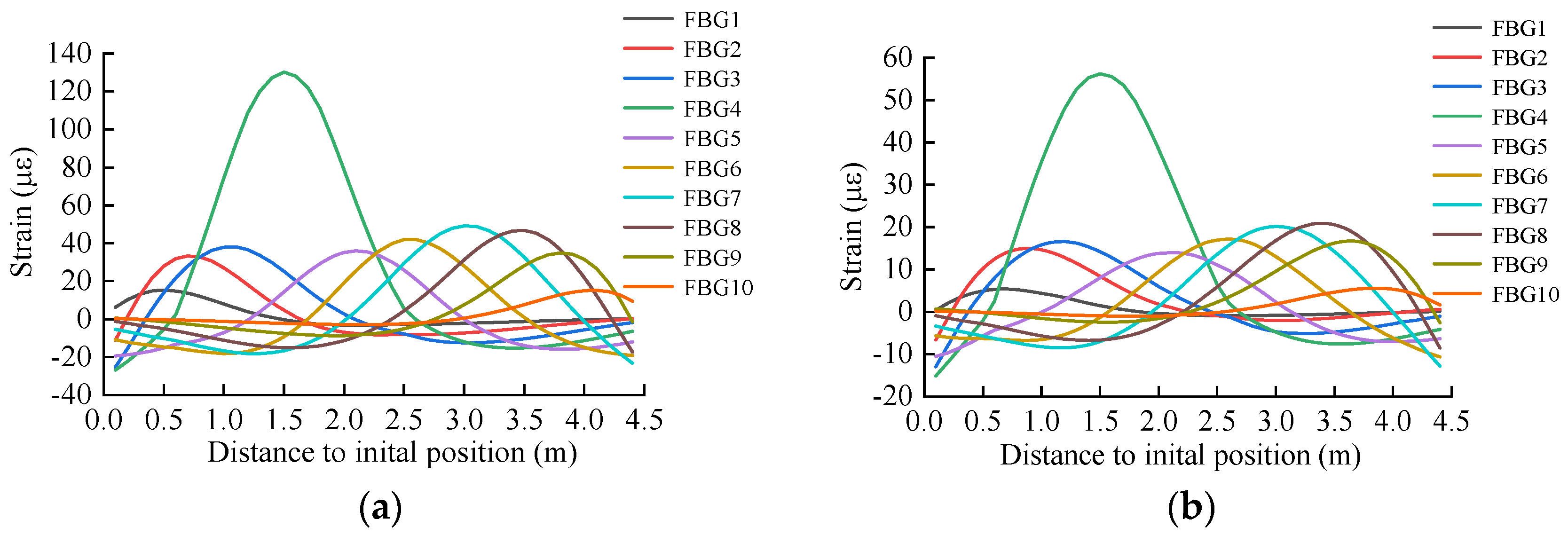

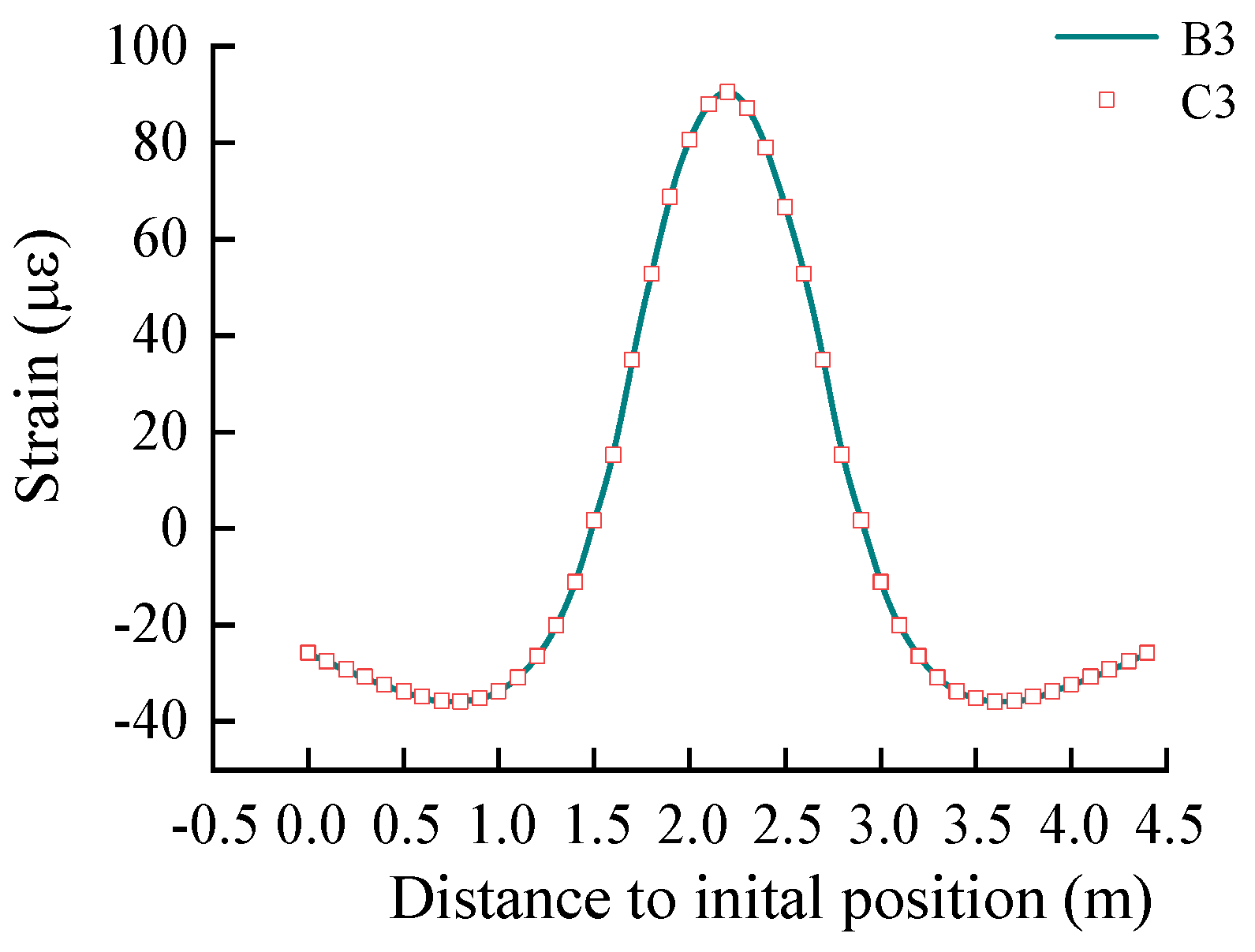

4.3. Crack Identification Analysis

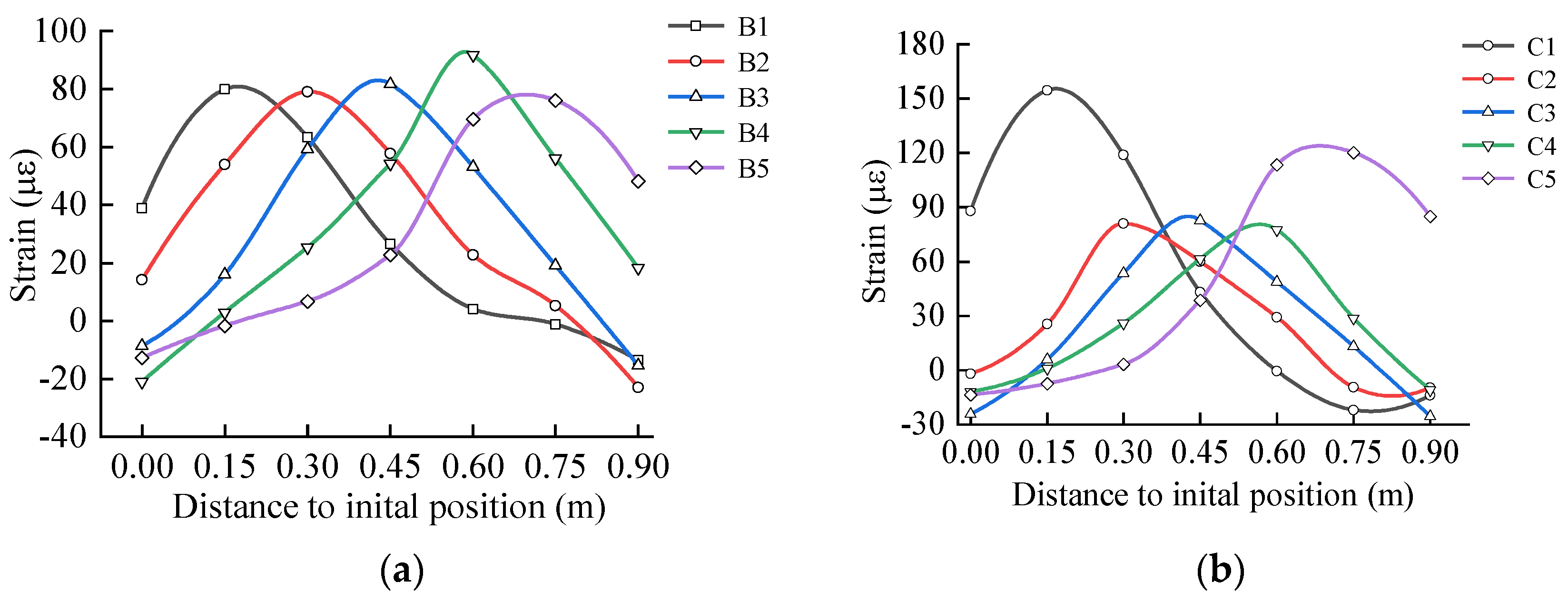

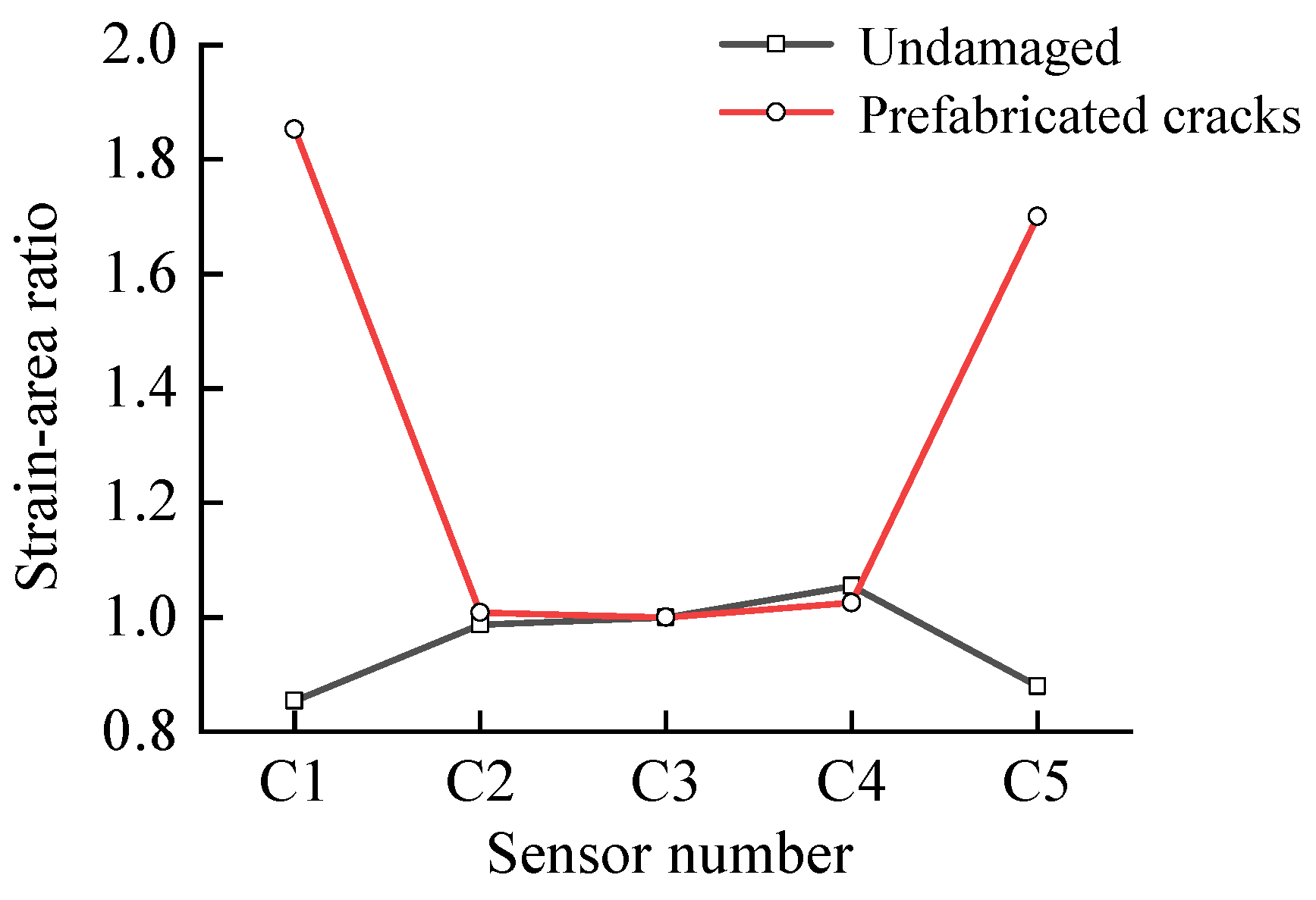

4.3.1. Test Loading Condition

4.3.2. Analysis of Test Results

5. Conclusions and Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, I.; Rahman, M.H.; Seraj, S.M.; Hoque, A.M. Performance of plain concrete runway pavement. J. Perform. Constr. Facil. 1998, 12, 145–152. [Google Scholar] [CrossRef]

- MH/T 5024-2019; Technical Specification for the Management of Civil Airport Pavement Evaluation. Civil Aviation Press of China: Beijing, China, 2019.

- Li, H.F.; Nie, J.J.; Wu, Z.L.; Peng, B.; Gui, Z.C. An airport pavement crack detection algorithm based on multi-sensor information fusion. Mod. Electron. Technol. 2020, 43, 17–21, 25. [Google Scholar]

- Yang, S.S.; Hao, L.; LI, Y.; Fu, S.J.; He, C.H. Concrete crack identification method and program development. J. Chongqing Jiaotong Univ. 2022, 41, 105–111. [Google Scholar]

- Liu, N.; Song, W.D.; Zhao, Q.H. Morphology and maximum entropy image segmentation for urban pavement crack detection. J. Liaoning Univ. Eng. Technol. 2015, 34, 57–61. [Google Scholar]

- Qu, Z.; Lin, L.D.; Guo, Y. An improved algorithm for image crack detection based on percolation model. IEEJ Trans. Electr. Electron. Eng. 2015, 10, 214–221. [Google Scholar] [CrossRef]

- Wei, J.; Cao, L.F.; Zeng, Y.X.; Dong, R.Z.; Chen, S.L. Study on feature extraction of concrete structure cracks. J. Wuhan Univ. Technol. 2011, 33, 72–75. [Google Scholar]

- Song, H.; Wang, W.; Wang, F.; Wu, L. Pavement crack detection by ridge detection on fractional calculus and dual thresholds. Int. J. Multimed. Ubiquitous Eng. 2015, 10, 19–30. [Google Scholar] [CrossRef]

- Oliveira, H.J.M.; Correia, P.L.S.L. CrackIT—An image processing toolbox for crack detection and characterization. In IEEE International Conference on Image Processing; IEEE: Paris, France, 2014; pp. 102–106. [Google Scholar]

- Shi, Y.; Cui, L.M.; Qi, Z.Q.; Meng, F.; Chen, Z.S. Automatic Road crack detection using random structured forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Park, H.; Choi, M.; Park, J.; Kim, W. A study on detection of microcracks in the dissimilar metal weld through ultrasound infrared thermography. Infrared Phys. Technol. 2014, 62, 124–131. [Google Scholar] [CrossRef]

- Li, Z.W.; Liu, X.Z.; Lu, H.Y.; He, Y.L.; Zhou, Y.L. Surface crack detection in precasted slab track in high-speed rail via infrared thermography. Materials 2020, 13, 4837. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, W.Z. Research on Ground-Penetrating Radar Forward Simulation of Highway Pavement Layer Crack Disease; Wuhan University of Technology: Wuhan, China, 2016. [Google Scholar]

- Xiao, X.; Tian, G.; Liu, D.; Robinson, M.; Gallagher, A. Developments in GPR Based NDT for ballastless track of high-speed railways. In Proceedings of the 24th International Workshop on Electromagnetic Nondestructive Evaluation, Chengdu, China, 11–14 September 2019; IOS Press: Amsterdam, The Netherlands, 2020; pp. 277–285. [Google Scholar]

- Xie, X.Y.; Tang, G.J.; Hong, G.; Wang, C. Deformation sensing method and application of intelligent duck bank structure. Chin. J. Undergr. Space Eng. 2017, 13, 1056–1065. [Google Scholar]

- Ye, Y.X.; Zhao, X.M.; Wu, G.; Xie, X.F.; Yao, J. Application of distribute dropsical fiber in the monitoring of cracks in concrete structures. J. Civ. Environ. Eng. 2018, 40, 24–29. [Google Scholar]

- He, Y.; Jiang, S.; Mao, J.H.; Xia, J.; Jin, W.L. Distributed fiber optic monitoring method and experimental study of structural cracks. Civ. Constr. Environ. Eng. 2012, 34, 1–6. [Google Scholar]

- Mao, J.H.; Cui, L.; Jin, W.L.; Xu, C.; He, Y.; Ren, X.C.; Yang, F. Experimental research on concrete crack identification and monitoring based on distributed fiber optic sensing. J. Sens. Technol. 2014, 27, 1298–1304. [Google Scholar]

- Lu, F.; Feng, M.Q.; Gu, X.; Yang, S. Field Experiment on Monitoring of Cracks in Highway Asphalt Overlay. In Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security; SPIE: Bellingham, WA, USA, 2009; Volume 7294, pp. 187–193. [Google Scholar]

- Qian, Z.D.; Han, G.Y.; Huang, W.; Yi, Z.C. Fatigue extension of steel bridge deck cracks based on BOTDA. J. Civ. Eng. 2009, 42, 132–136. [Google Scholar]

- Lu, Y.; Shi, B.; Xi, J.; Su, J.W.; Jiang, Y.H.; Li, Y.F. Field study of BOTDR-based distributed monitoring technology for ground fissures. J. Eng. Geol. 2014, 22, 8–13. [Google Scholar]

- Pang, X.R. Research on Monitoring of Concrete Girder Bridge Based on Macro Strain Distribution Technology of FBG Sensor; Suzhou University of Science and Technology: Suzhou, China, 2018. [Google Scholar]

- Wu, G.; Wu, Z.S.; Jian, Z.; Wan, H.; Tang, Y.S.; Yang, C.Q. Structural health monitoring of a steel stringer bridge with area sensing. Struct. Infrastruct. Eng. 2014, 10, 1049–1058. [Google Scholar]

- Li, H.N.; Ren, L. Fiber Optic Grating Sensing Technology for Structural Health Monitoring; China Construction Industry Press: Beijing, China, 2008. [Google Scholar]

- Zhang, Y. Rapid Inversion Study of Airport Pavement Bending and Settlement Curves Based on Winkler Foundation; Civil Aviation University of China: Tianjin, China, 2020. [Google Scholar]

- Liu, D. Research on Joints and Structural Optimization of Cement Concrete Pavement; Wuhan University of Technology: Wuhan, China, 2003. [Google Scholar]

- Guo, C.C.; Zhang, S.J.; Zhou, H.C.; Diao, Y.L.; Yan, W.H. Mechanical response analysis of airport composite pavement under moving load. J. Zhengzhou Univ. 2023, 44, 113–119. [Google Scholar]

- Zhang, W.H. XFEM Cracking Analysis of Cement Concrete Pavement Based on Double-K Fracture Model; Chang’an University: Xi’an, China, 2022. [Google Scholar]

- Peng, Y.F.; Lu, J.; Qin, J.H. Extended finite element analysis of cracking process in pressurized tunnel lining. Hydropower Gener. 2017, 43, 40–43, 122. [Google Scholar]

- MH/T5004-2010; Specification for the Design of Cement Concrete Pavement at Civilian Airports. Civil Aviation Press of China: Beijing, China, 2010.

- GB/T 228.1-2021; Tensile Test for Metallic Materials Part 1: Room Temperature Test Method. Civil Aviation Press of China: Beijing, China, 2021.

| Maximum Take-Off Weight (kN) | Tire Pressure (MPa) | Main Landing Gear Configuration | Single Wheel Load (kN) | Area of a Single Wheel (m2) | Wheel Print Length (m) | Wheel Printing Width (m) |

|---|---|---|---|---|---|---|

| 792.04 | 1.47 | Two axles and two wheels | 376.22 | 0.25593 | 0.610 | 0.420 |

| Crack length (mm) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 |

| Crack height (mm) | 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 |

| D | 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| Aircraft Type | Tire Pressure (MPa) | Main Landing Gear Configuration | Single Wheel Load (kN) | Wheel Length (m) | Wheel Width (m) |

|---|---|---|---|---|---|

| Su-30 | 1.53 | Single axle, single wheel | 157.22 | 0.432 | 0.298 |

| A320 | 1.14 | two axles and two wheels | 183.83 | 0.484 | 0.333 |

| A330-300 | 1.42 | two axles and two wheels | 560.19 | 0.756 | 0.522 |

| B777-300ER | 1.50 | tricycle with two wheels | 532.12 | 0.717 | 0.495 |

| Structural Configuration | Parameters | Value (mm) | |

|---|---|---|---|

| Prototype | Model | ||

| Pavement panel | Plane size | 5000 × 2500 | 1500 × 750 |

| High degree | 400 | 120 | |

| Steel | Caliber | 14 | 8 |

| Connection | Caliber | 20 | 8 |

| Value | Aircraft Type | Tire Pressure (MPa) | Quality (t) | Loading (kN) | Tire Spacing (mm) | Tire Ground Size/mm | |

|---|---|---|---|---|---|---|---|

| Length | Height | ||||||

| Archetype | B-737-800 | 1.47 | 75.24 | 752.44 | 860 | 610 | 420 |

| Pattern | B-737-800 | 1.47 | 3.89 | 38.90 | 258 | 183 | 126 |

| Gauge (mm) | 1# | 2# | 3# | Average Value | Standard Deviation | Coefficient of Variation (%) |

|---|---|---|---|---|---|---|

| 150 | 1.1450 | 1.1408 | 1.1417 | 1.1425 | 0.0018 | 0.1580 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Zheng, B.; Yu, T. Crack Identification Method for Prefabricated Concrete Pavement Based on Distributed Strain Monitoring. Buildings 2024, 14, 2520. https://doi.org/10.3390/buildings14082520

Tang Y, Zheng B, Yu T. Crack Identification Method for Prefabricated Concrete Pavement Based on Distributed Strain Monitoring. Buildings. 2024; 14(8):2520. https://doi.org/10.3390/buildings14082520

Chicago/Turabian StyleTang, Yongsheng, Bohan Zheng, and Tao Yu. 2024. "Crack Identification Method for Prefabricated Concrete Pavement Based on Distributed Strain Monitoring" Buildings 14, no. 8: 2520. https://doi.org/10.3390/buildings14082520

APA StyleTang, Y., Zheng, B., & Yu, T. (2024). Crack Identification Method for Prefabricated Concrete Pavement Based on Distributed Strain Monitoring. Buildings, 14(8), 2520. https://doi.org/10.3390/buildings14082520