Investigation on the Natural Convection Inside Thermal Corridors of Industrial Buildings

Abstract

1. Introduction

2. CFD Methodology and Validation

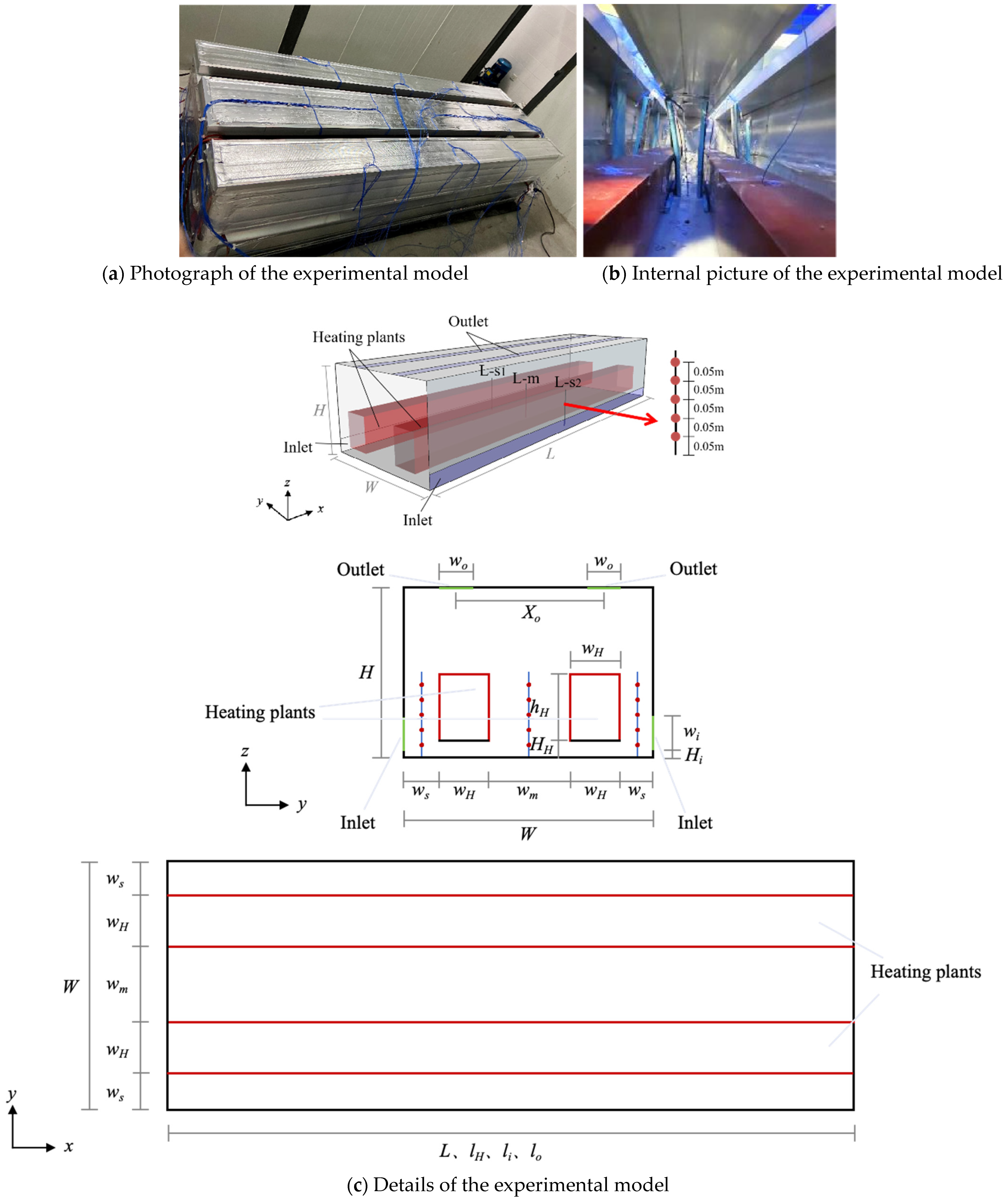

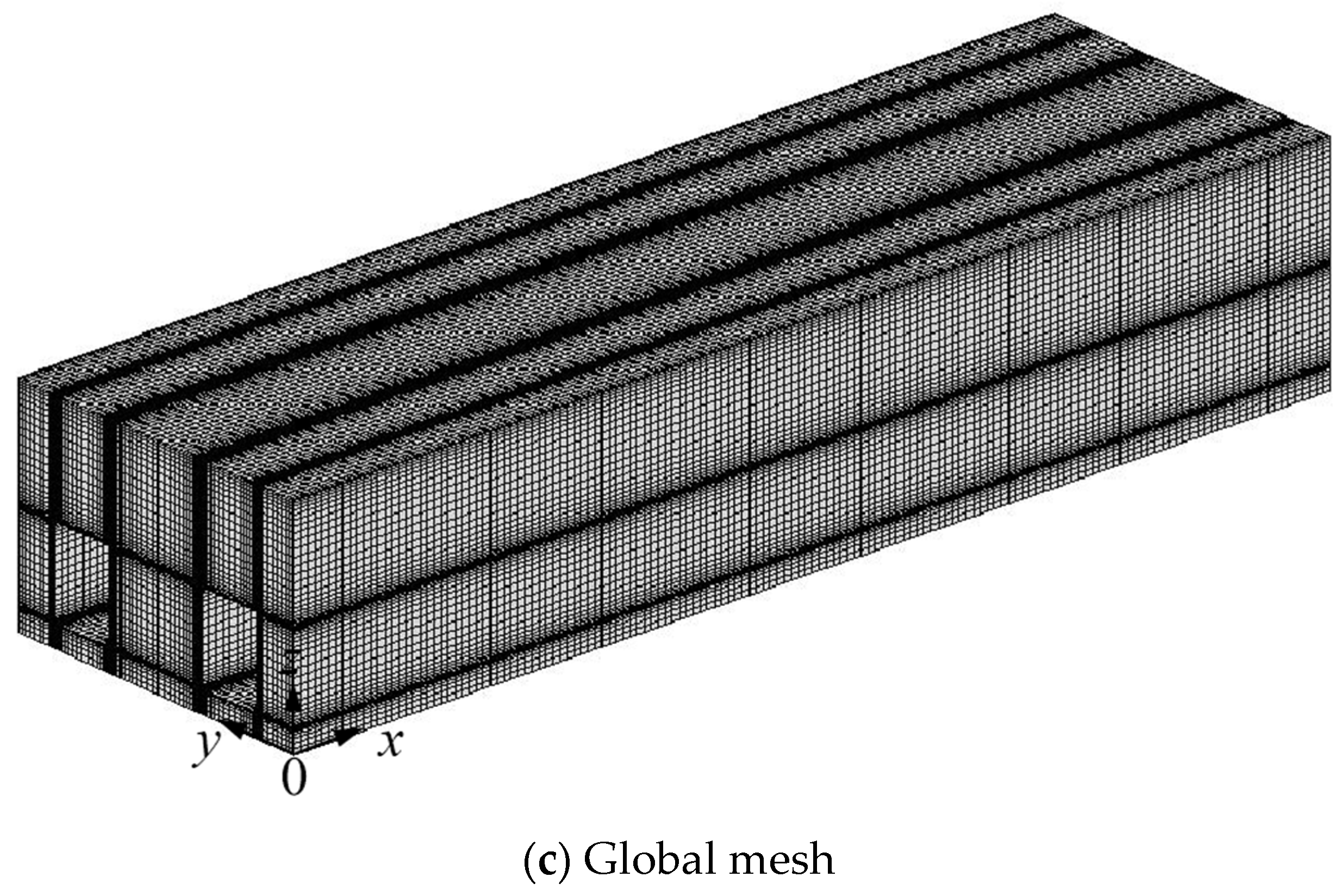

2.1. Scaled Experimental Model for Validation

2.2. Governing Equations

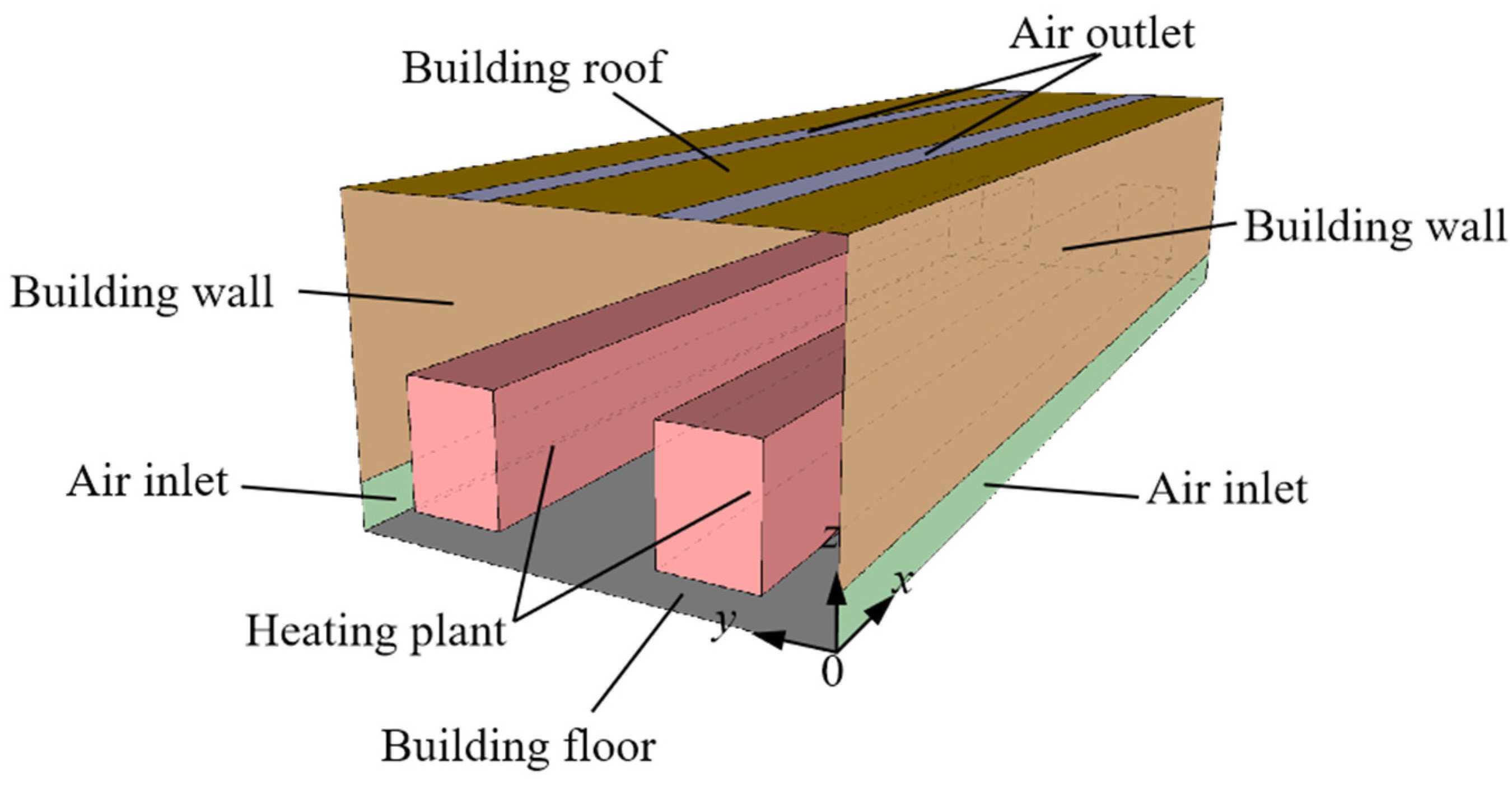

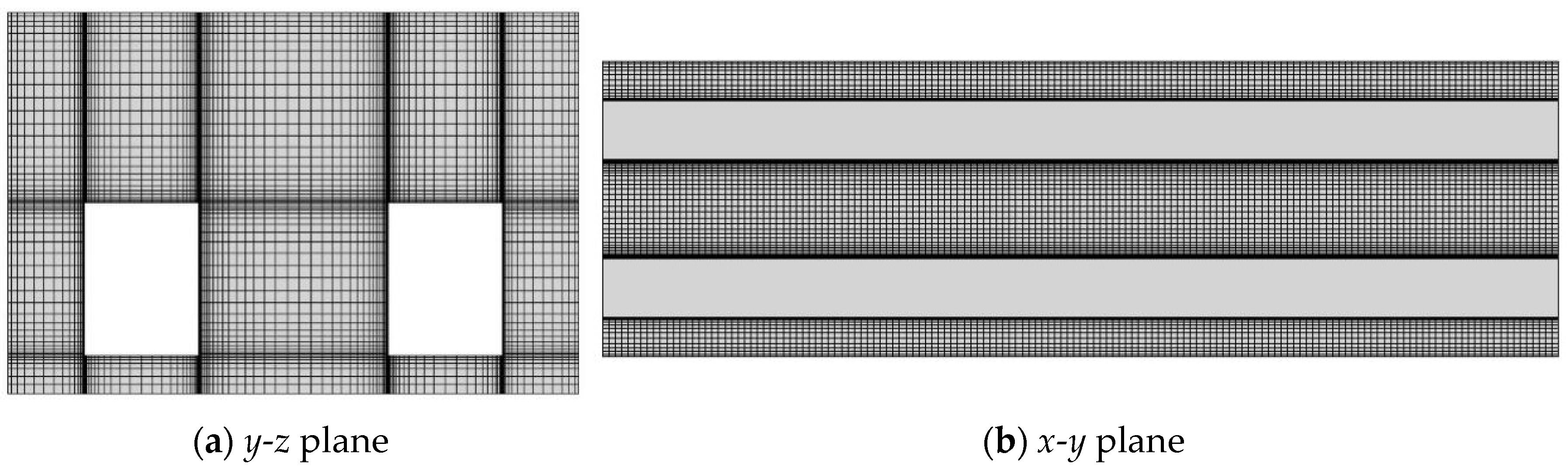

2.3. Computational Grids and Boundary Conditions

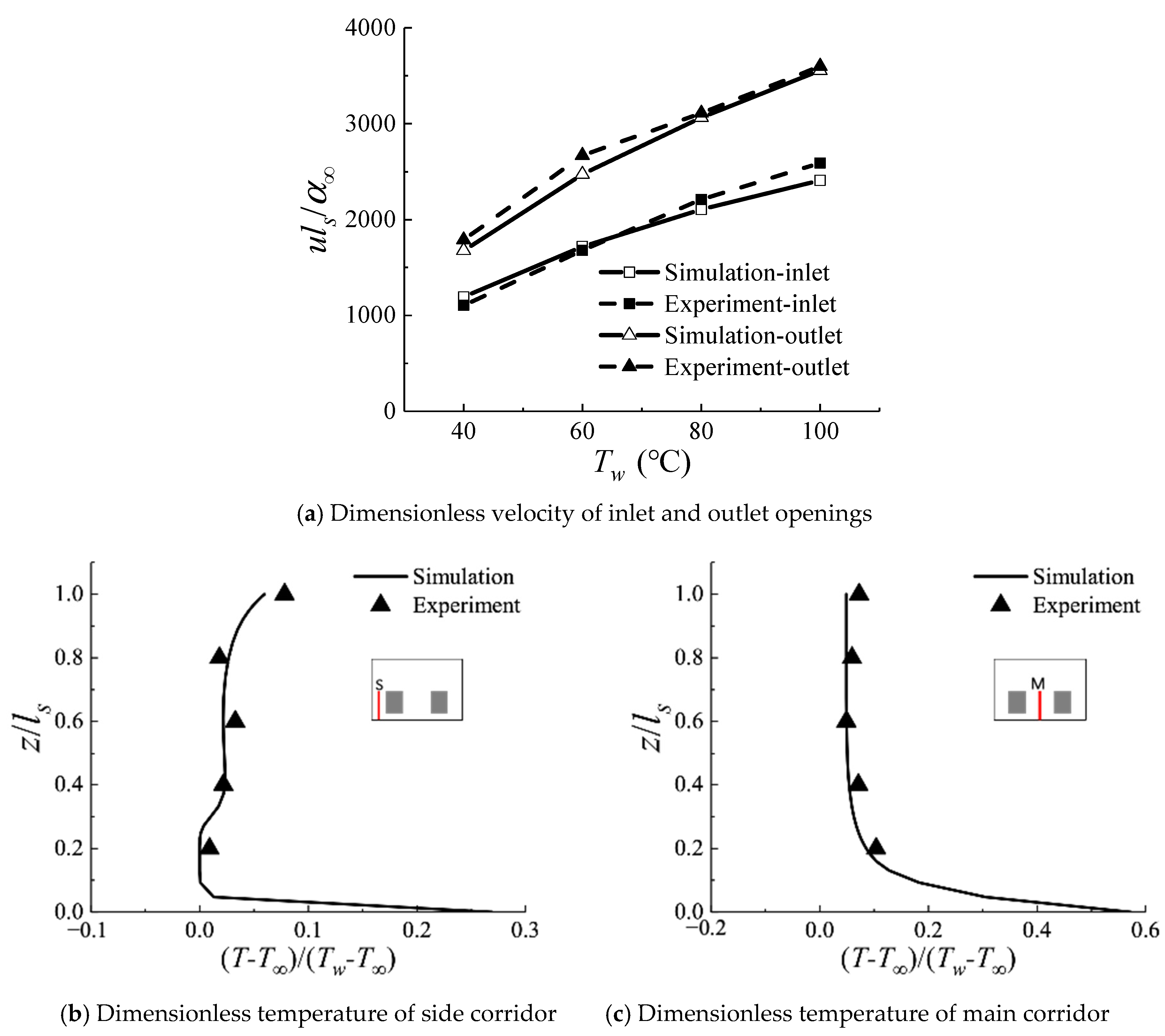

2.4. Solver Schemes and Model Validation

3. Results and Discussion

3.1. Temperature and Velocity Distribution Investigations

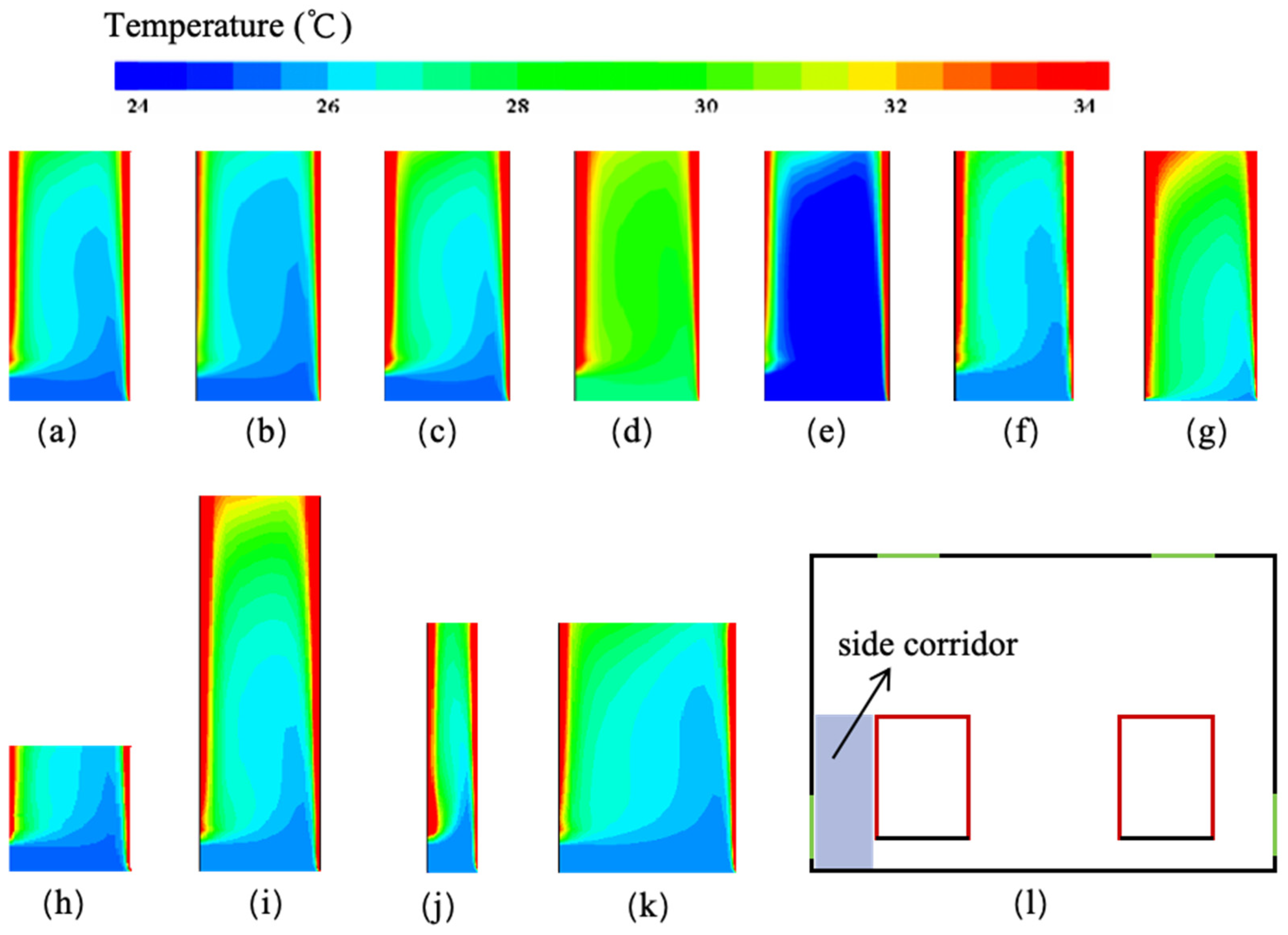

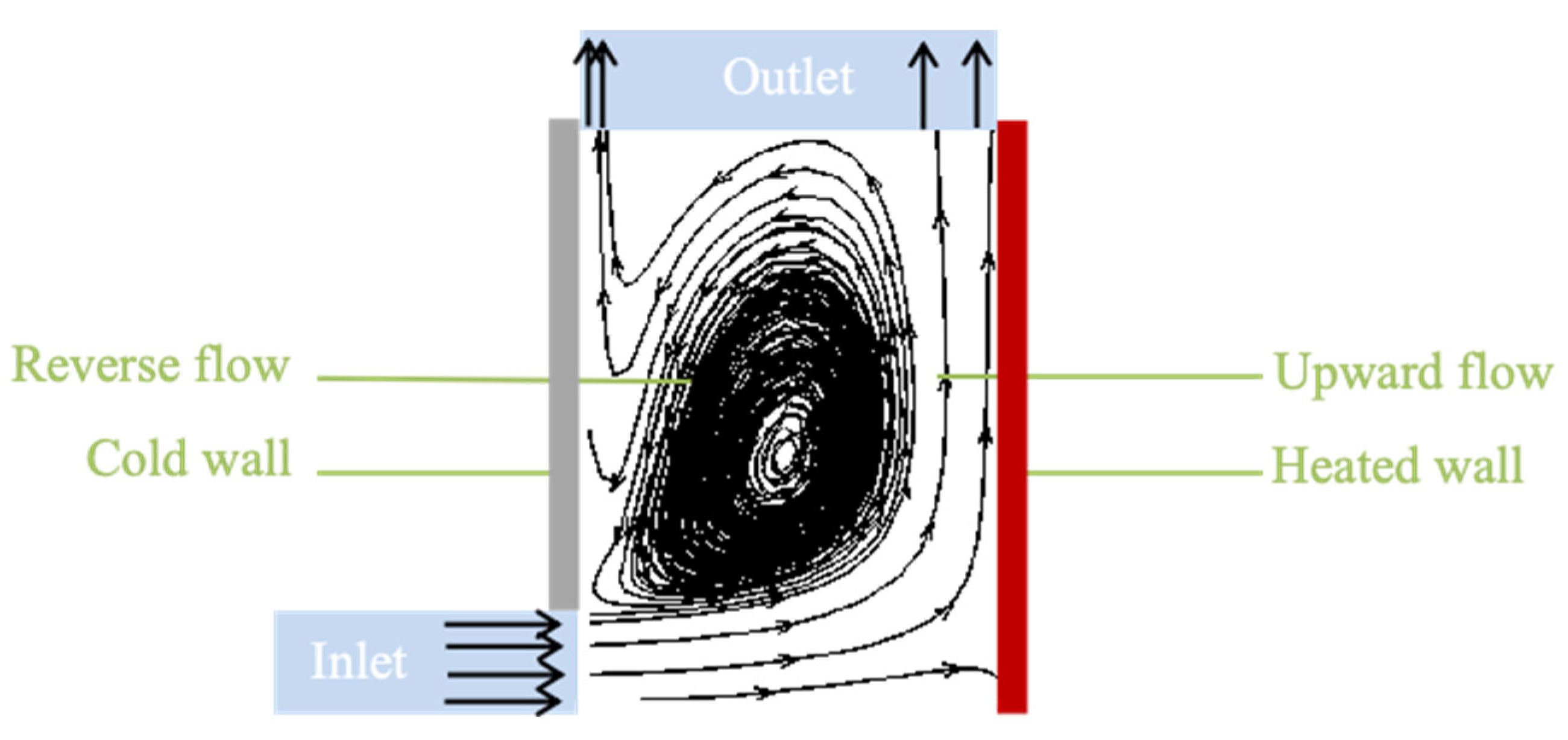

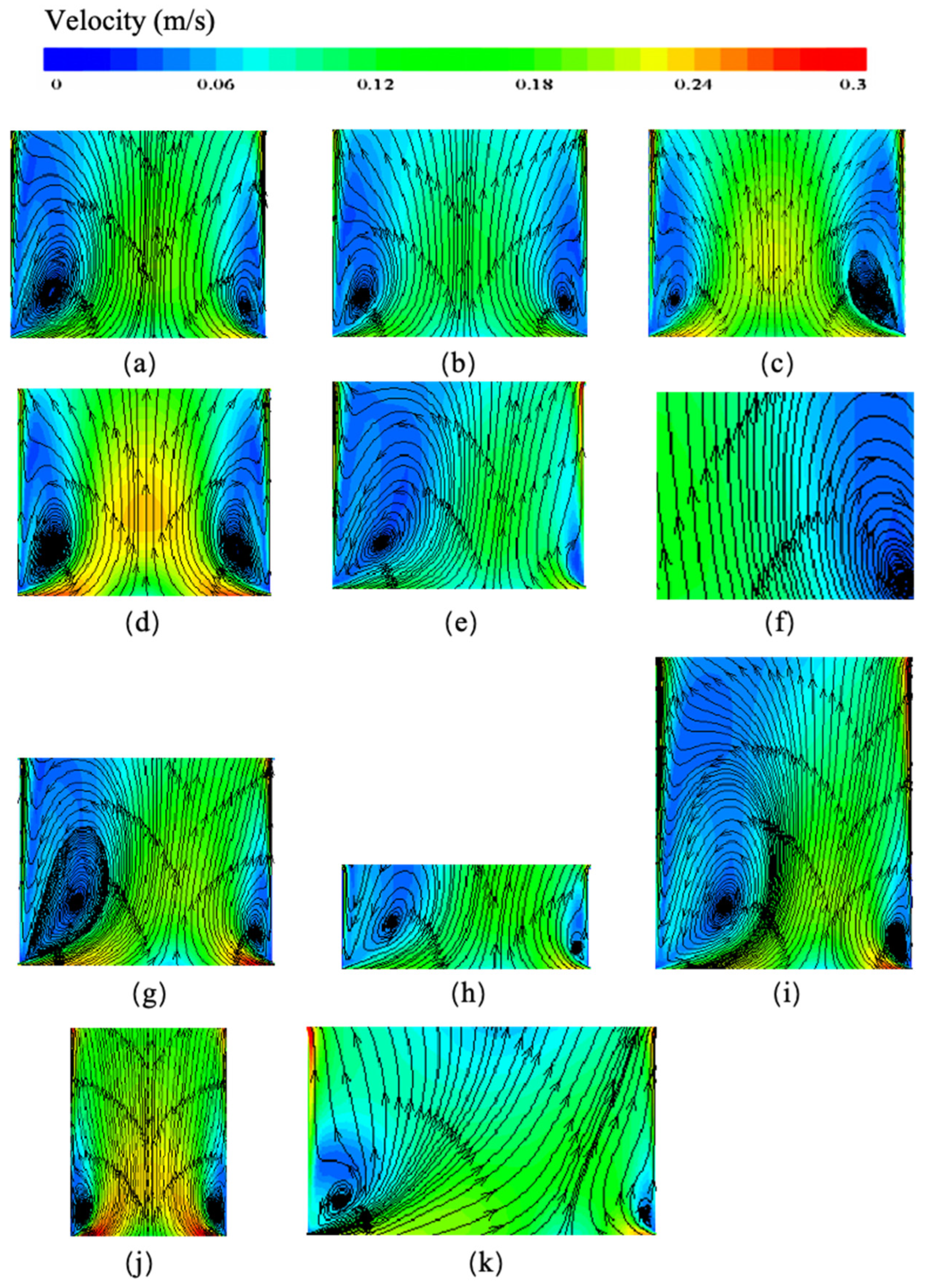

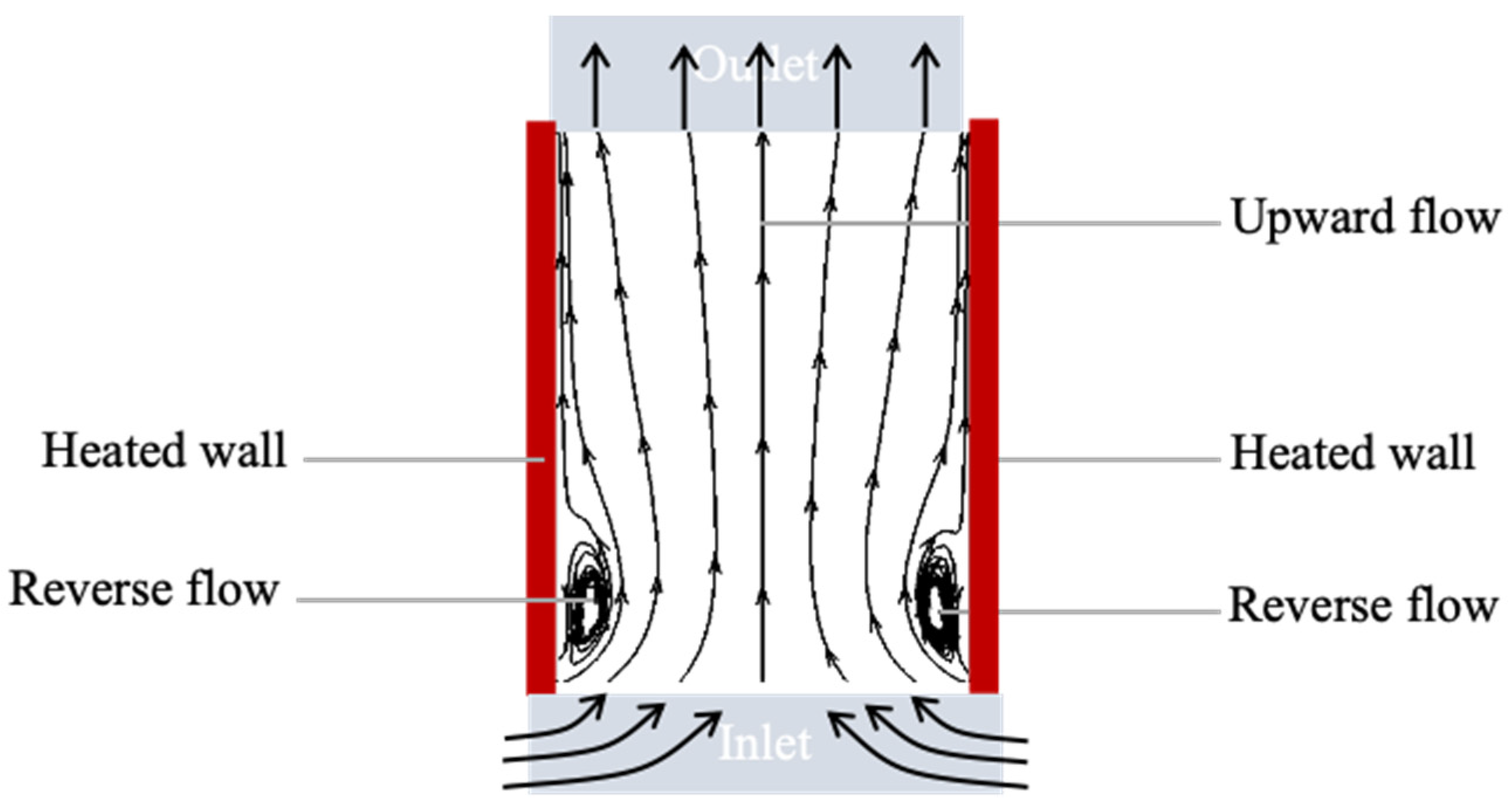

3.1.1. Side Corridor

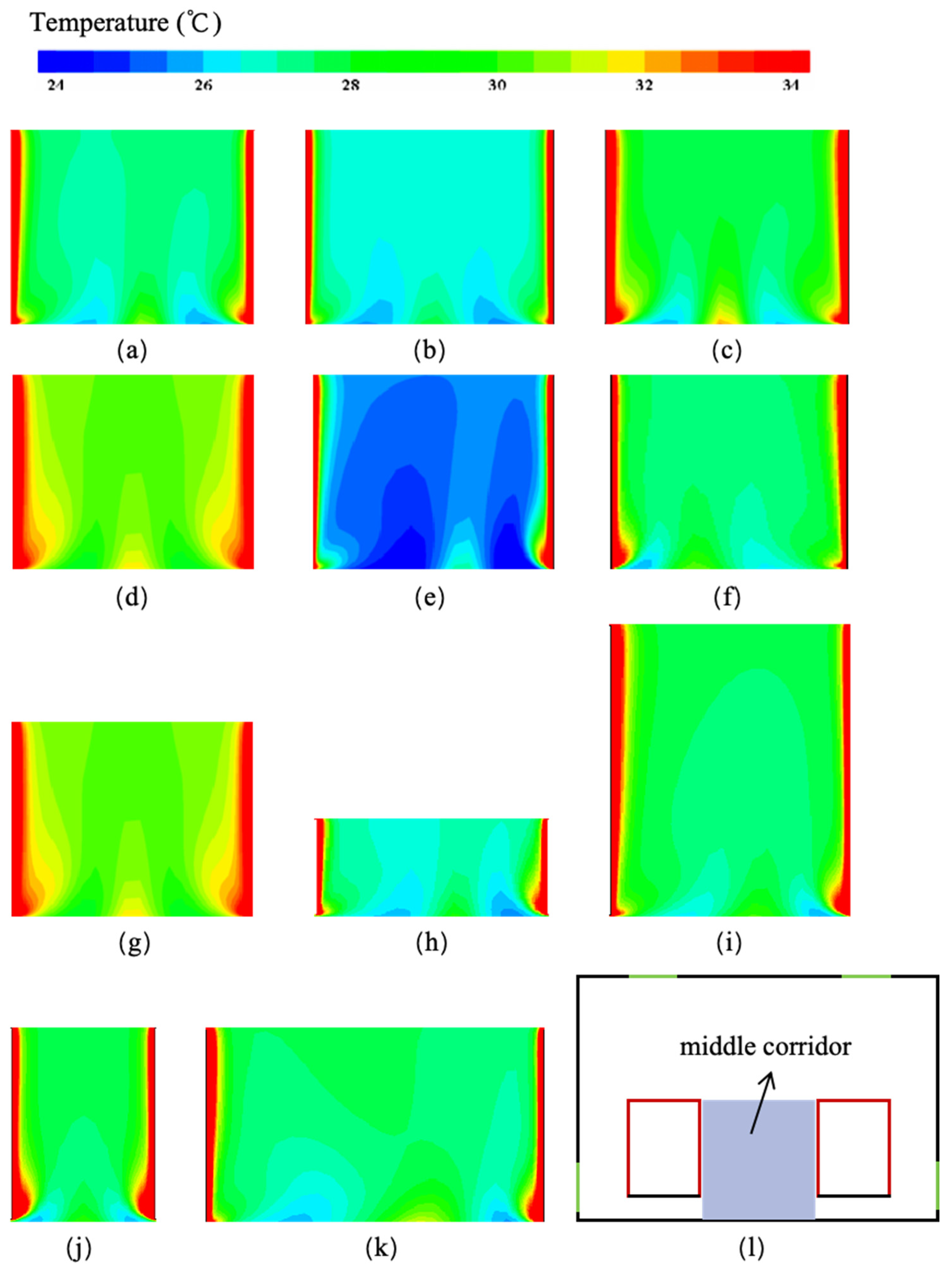

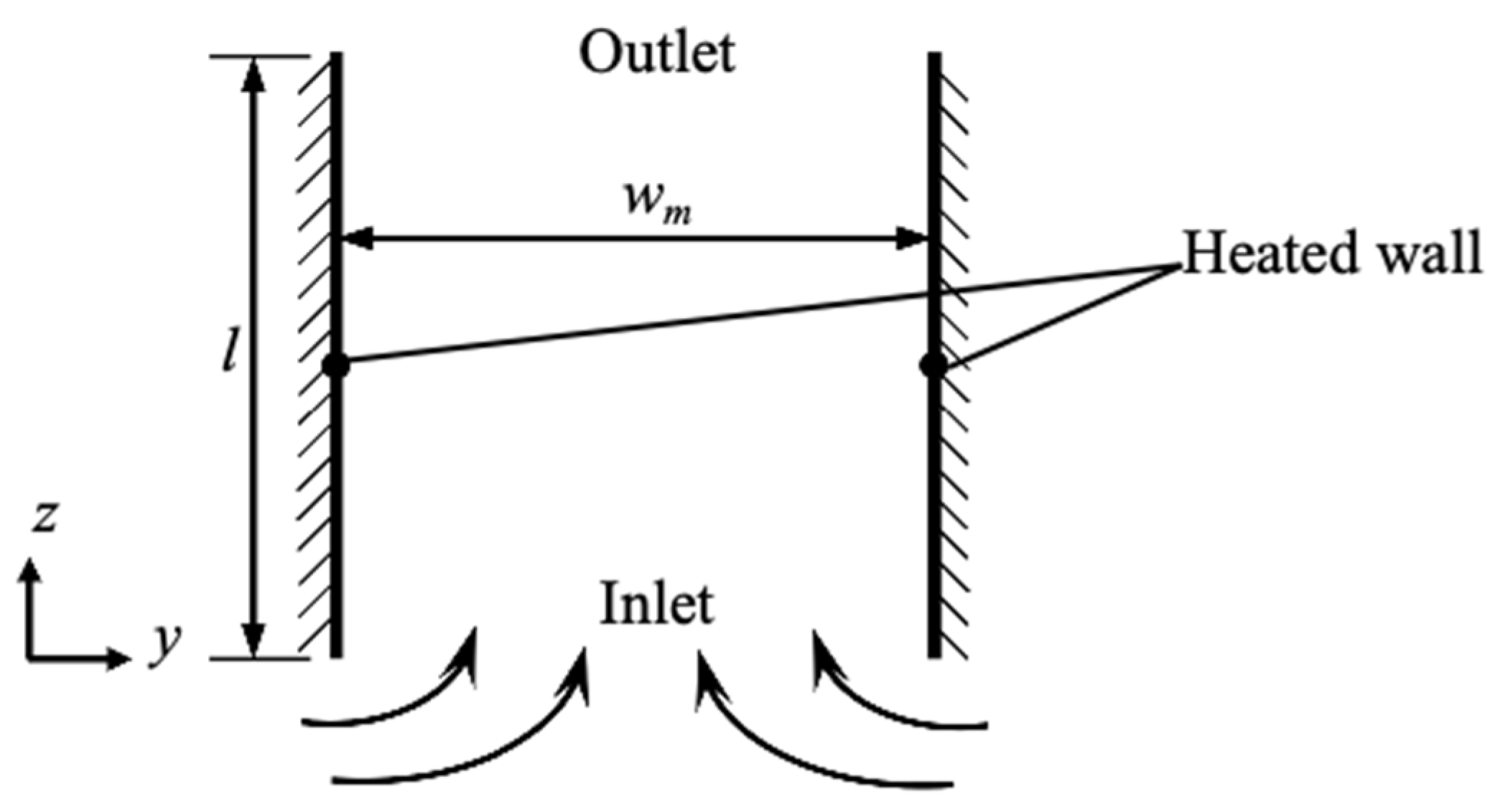

3.1.2. Middle Corridor

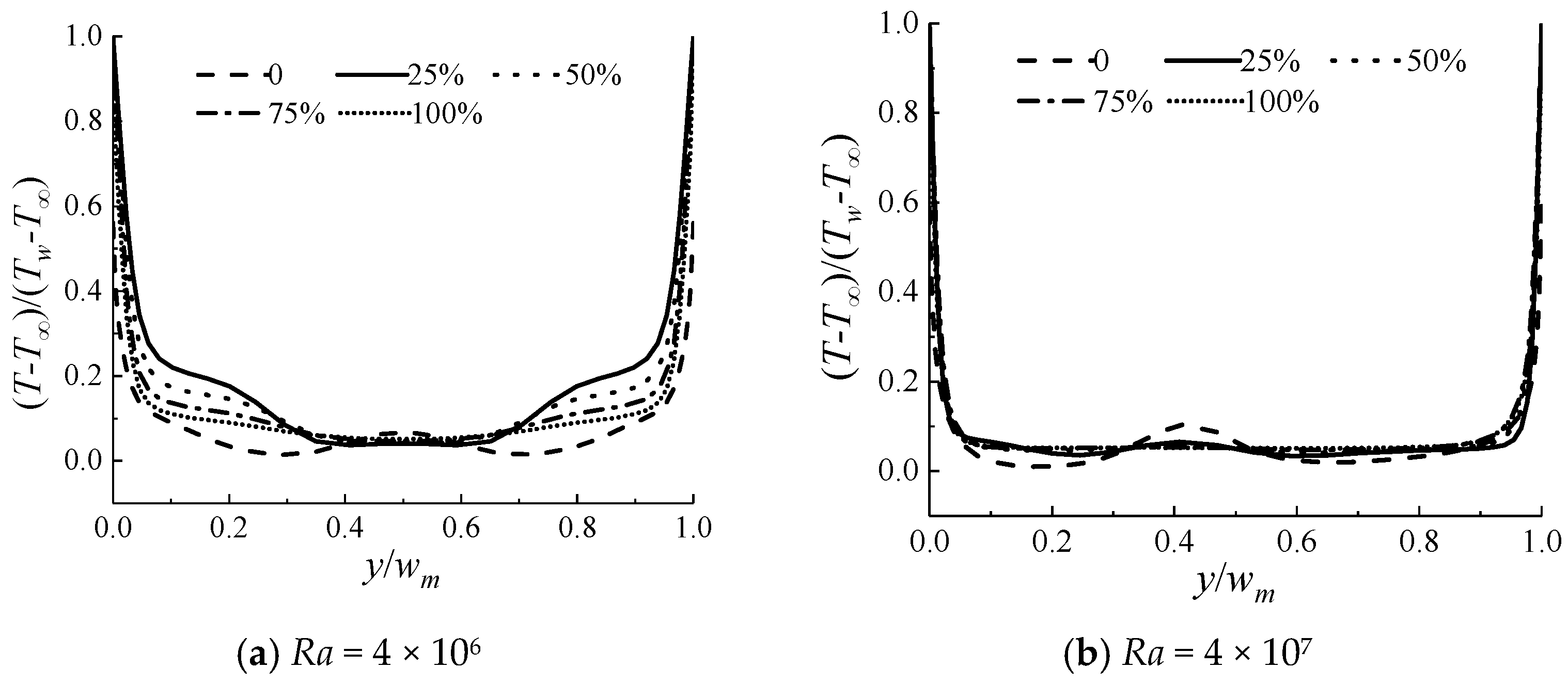

3.2. Correlations for Heat Transfer and Flow Prediction

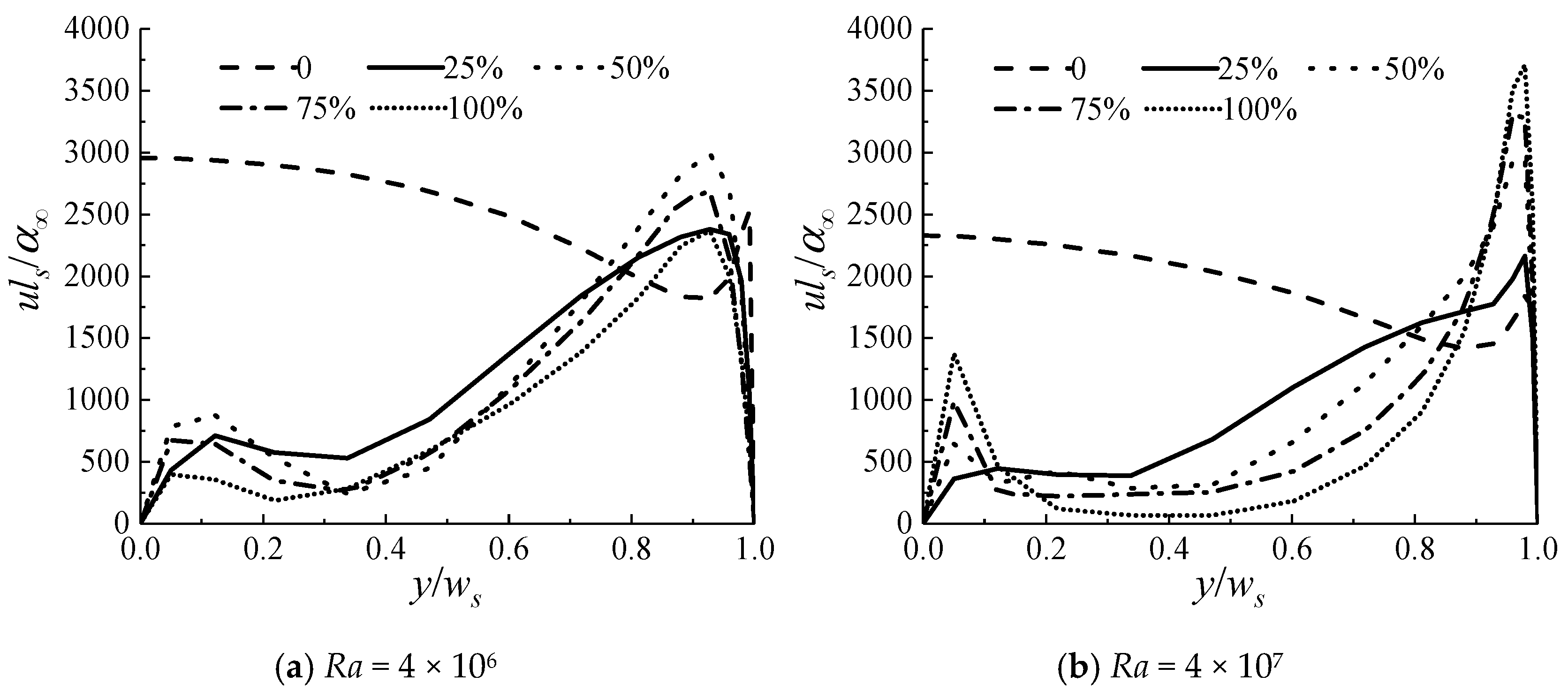

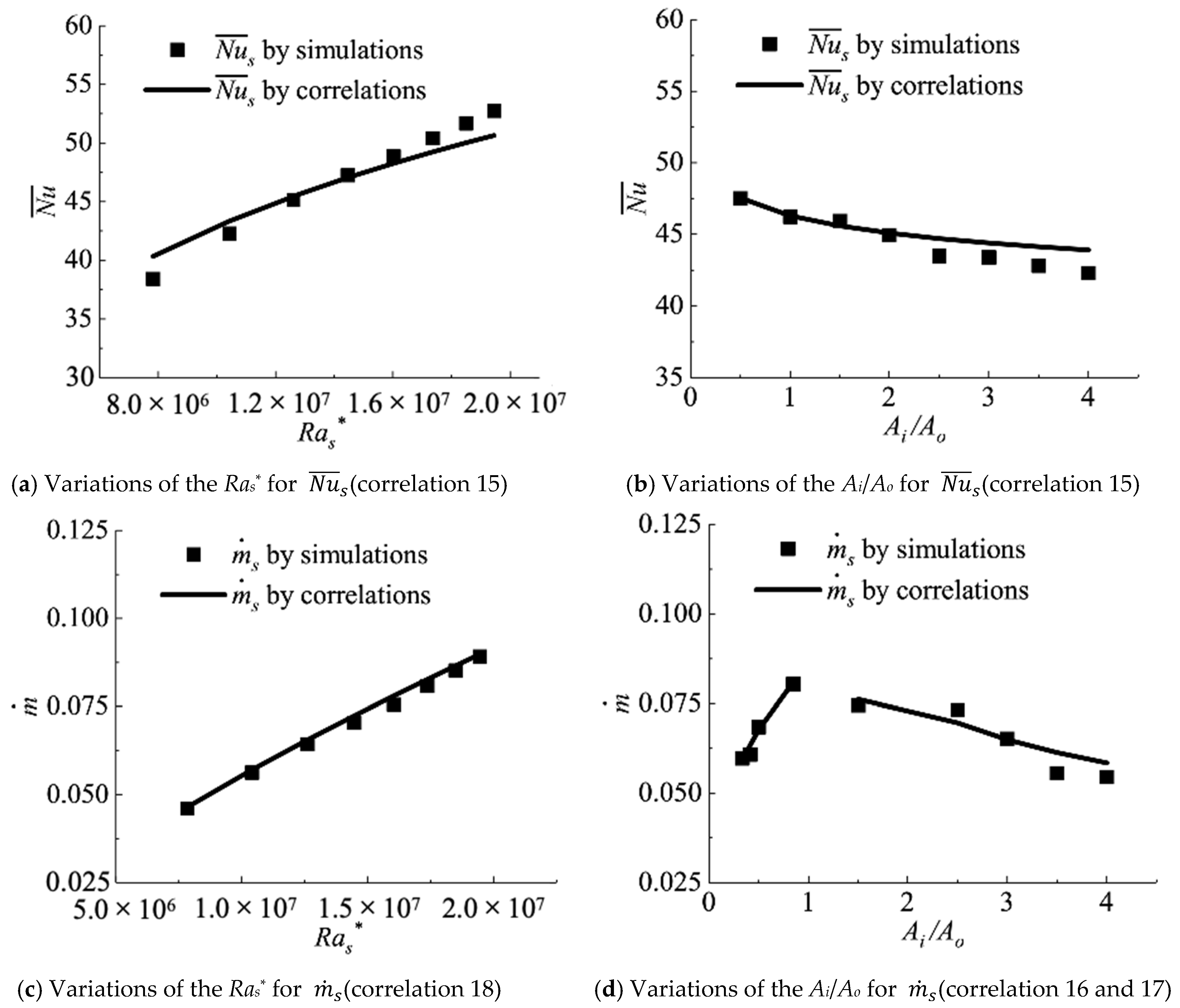

3.2.1. Side Channel

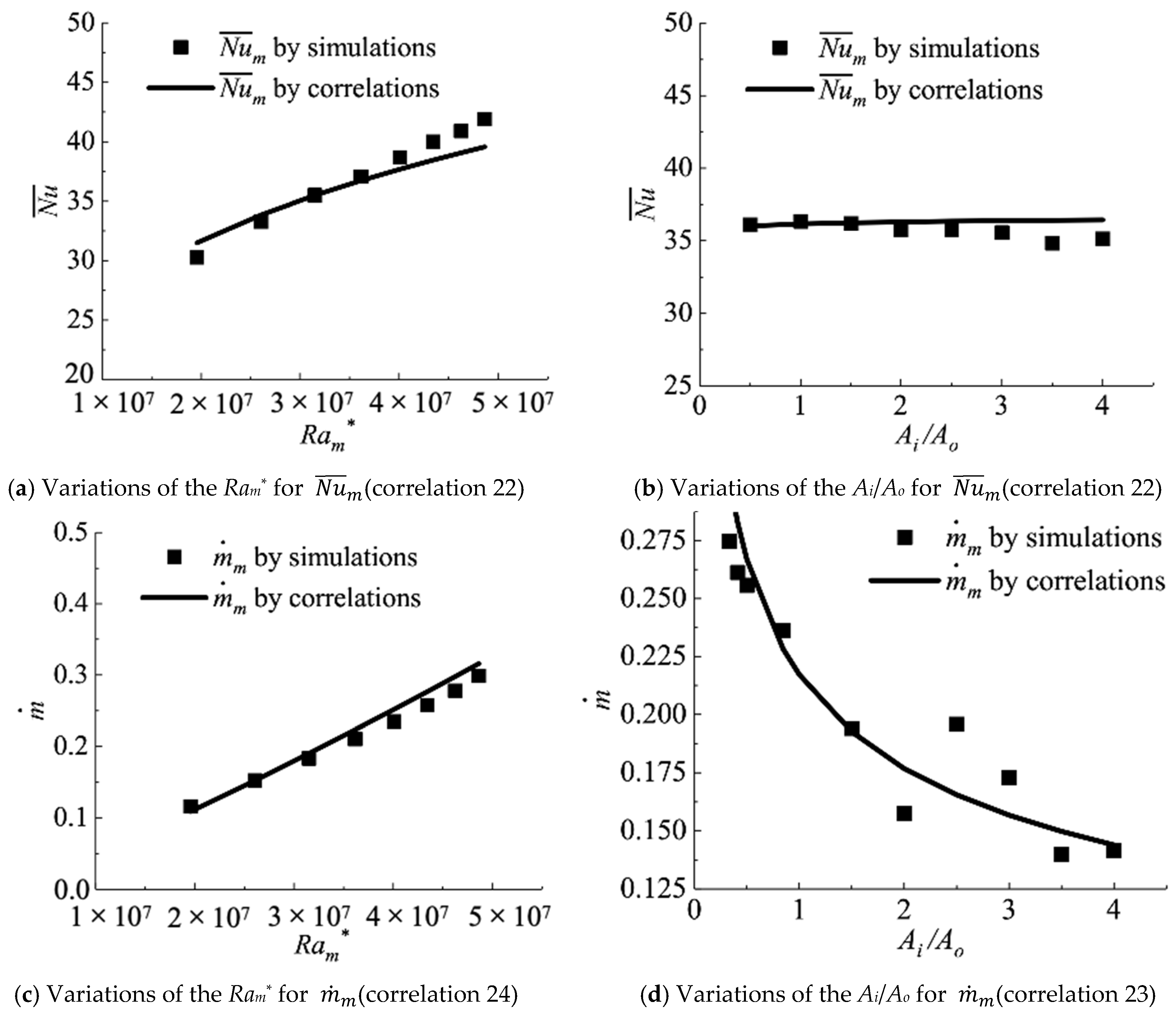

3.2.2. Middle Channel

4. Conclusions

- (1)

- In the side corridor, the prevalence of reverse flow dominates much of the channel, leading to an uncomfortable thermal environment within the working zone. The ambient air temperature significantly influences the temperature distribution throughout the entire corridor. Increasing the ambient air temperature at the inlet from 22 to 28 °C results in a substantial temperature rise in the side corridor, by approximately 6 °C.

- (2)

- In the middle corridor, the occurrence of reverse flow near the bottom corner is noted, while the air within the middle corridor exhibits a more stable yet elevated air temperature. The ambient air temperature at the inlet plays a significant role in the middle corridor’s thermal environment, while the surface temperature of the heating plants has a lesser impact. When the outlet size remains constant and the inlet size decreases by 30%, the air temperature in the middle corridor increases by 3 °C.

- (3)

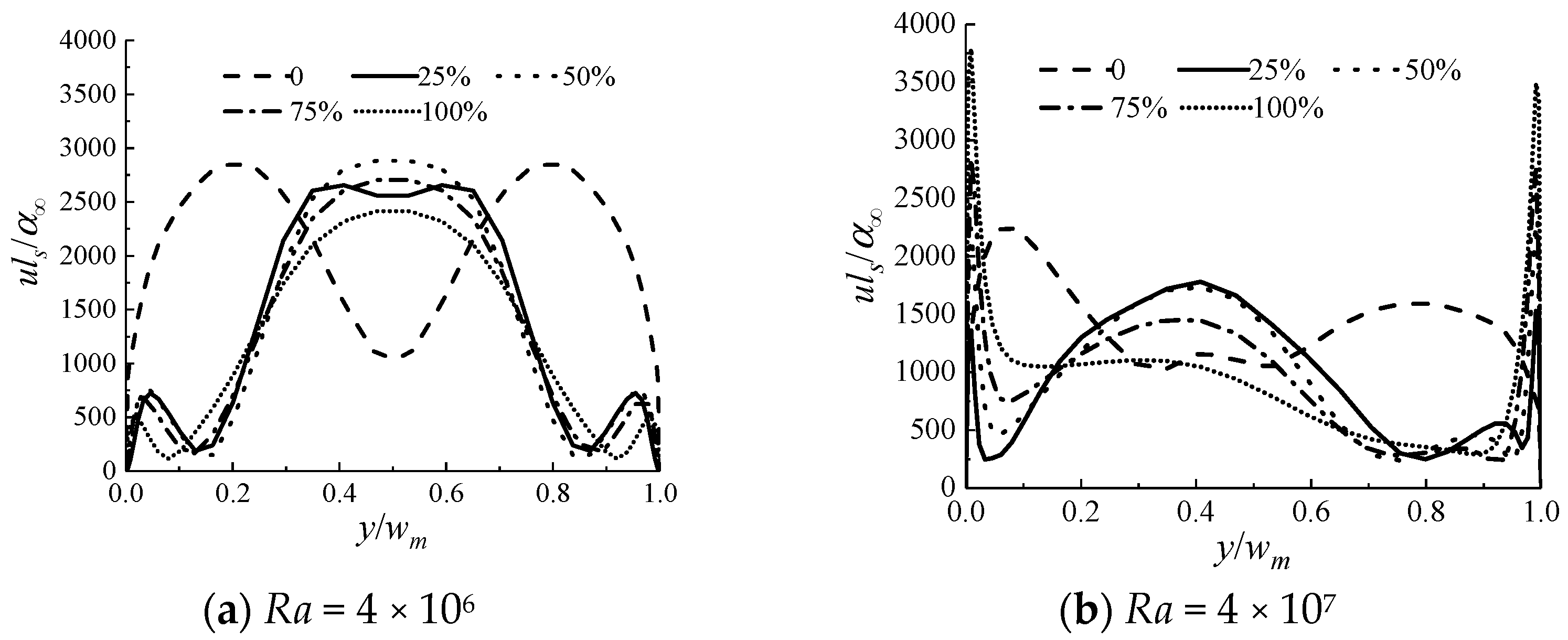

- The Rayleigh number significantly affects heat transfer and flow. For high Rayleigh numbers, the steady flows become disturbed and disorderly in the middle corridor. The peak velocity near the heated walls is substantially enhanced for a higher Rayleigh number. As the Rayleigh number increases, the peak sharpens and shifts towards the heated wall, signifying a rapid acceleration of the air in proximity to the heated wall.

- (4)

- Through theoretical analysis and the fitting of simulation results, semi-empirical correlations have been established to describe the surface-averaged of the heated wall as a function of the inlet-to-outlet area ratio and modified Rayleigh number and the induced mass flow rate, , of the channel as a function of the inlet-to-outlet area ratio, modified Rayleigh number, and Prandtl number. These correlations displayed favorable consistency with simulation results, with maximum relative errors of less than 16%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| cp | Heat capacity of the air, J·(kg·K)−1 |

| L | Workshop length, m |

| W | Workshop width, m |

| H | Workshop height, m |

| li | Inlet length, m |

| wi | Inlet height, m |

| lo | Outlet length, m |

| wo | Outlet width, m |

| lH | Heating plant length, m |

| wH | Heating plant width, mf |

| hH | Heating plant height, m |

| HH | Distance from the bottom of heating plant to the ground, m |

| Hi | Distance from the bottom of inlet to the ground, m |

| Xo | Distance between the center of two outlets, m |

| ws | Side channel width, m |

| wm | Middle channel width, m |

| l | Channel height, m |

| Ai | Inlet area, m2 |

| Ao | Outlet area, m2 |

| u | Air velocity, m·s−1 |

| T | Temperature, °C |

| ∆T | Temperature difference, °C |

| Mass flow rate, kg·(m·s)−1 | |

| h | Heat transfer coefficient, W·(m2·K)−1 |

| qcv | Heat flux of convective heat exchange, W·m−2; |

| U | Dimensionless velocity, |

| Nu | Nusselt number, |

| Pr | Prandtl number, |

| Gr | Grashof number, |

| Ra | Rayleigh number, |

| Ra* | Modified Rayleigh number, |

| x, y, z | Coordinates, m |

| X, Y, Z | Dimensionless coordinates |

| Greek symbols | |

| β | Volume expansion coefficient, 1·K−1 |

| ε | Surface emissivity |

| α | Thermal diffusivity, m2·s−1 |

| λ | Thermal conductivity, W·(m·K)−1 |

| μ | Dynamic viscosity, kg·(m·s)−1 |

| ν | Kinematic viscosity, m2·s−1 |

| ρ | Air density, kg·m−3 |

| ϴ | Dimensionless temperature, |

| Subscripts | |

| m, s | Middle/side channel |

| w | Heating plant |

| ∞ | Outdoor conditions |

References

- Wang, H.; Wang, T.; Liu, L.; Long, Z.; Zhang, P. Numerical evaluation of the performances of the ventilation system in a blast furnace casthouse. Environ. Sci. Pollut. Res. 2021, 28, 50668–50682. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Qian, H.; Ma, J.; He, P. A simple model for predicting dispersion characteristics of high-temperature airflow and particle distribution during smelting process in a thermally stratified foundry shop. Energy Build. 2023, 278, 112614. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, J.; Xing, X.; Liu, Y.; Meng, X. Measurement and evaluation of indoor thermal environment in a naturally ventilated industrial building with high temperature heat sources. Build. Environ. 2016, 96, 35–45. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A.P. Effects of heat stress on construction labor productivity in Hong Kong: A case study of rebar workers. Int. J. Environ. Res. Public Health 2017, 14, 1055. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, T.; Cao, Z.; Zhai, C.; Wu, S.; Zhang, C.; Zhang, Q.; Lv, W. The influence of indoor thermal conditions on ventilation flow and pollutant dispersion in downstream industrial workshop. Build. Environ. 2021, 187, 107400. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Kim, H.T.; Lee, H.W. Efficiency of different roof vent designs on natural ventilation of single-span plastic greenhouse. J. Bio-Environ. Control 2019, 28, 225–233. [Google Scholar] [CrossRef]

- Yang, D.; Dong, S.; Du, T.; Ji, W. Influences of vent location on the removal of gaseous contaminants and indoor thermal environment. J. Build. Eng. 2020, 32, 101679. [Google Scholar] [CrossRef]

- Aich, W.; Kolsi, L.; Borjini, M.N.; Aissia, H.B.; Öztop, H.; Abu-Hamdeh, N. Three-dimensional CFD Analysis of Buoyancy-driven Natural Ventilation and Entropy Generation in a Prismatic Greenhouse. Therm. Sci. 2016, 52, 1–12. [Google Scholar]

- Izadyar, N.; Miller, W.; Rismanchi, B.; Garcia-Hansen, V. Impacts of façade openings’ geometry on natural ventilation and occupants’ perception: A review. Build. Environ. 2020, 170, 106613. [Google Scholar] [CrossRef]

- Bovo, M.; Santolini, E.; Barbaresi, A.; Tassinari, P.; Torreggiani, D. Assessment of geometrical and seasonal effects on the natural ventilation of a pig barn using CFD simulations. Comput. Electron. Agric. 2022, 193, 106652. [Google Scholar] [CrossRef]

- Yıldız, Ç.; Yıldız, A.E.; Arıcı, M.; Azmi, N.A.; Shahsavar, A. Influence of dome shape on flow structure, natural convection and entropy generation in enclosures at different inclinations: A comparative study. Int. J. Mech. Sci. 2021, 197, 106321. [Google Scholar] [CrossRef]

- Chati, D.; Bouabdallah, S.; Ghernaout, B.; Tunçbilek, E.; Arıcı, M.; Driss, Z. Turbulent mixed convective heat transfer in a ventilated enclosure with a cylindrical/cubical heat source: A 3D analysis. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 12423–12440. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Y.; Xue, P.; Mizutani, K. Review and development of the contribution ratio of indoor climate (CRI). Energy Built Environ. 2022, 3, 412–423. [Google Scholar] [CrossRef]

- Tian, G.; Fan, Y.; Wang, H.; Peng, K.; Zhang, X.; Zheng, H. Studies on the thermal environment and natural ventilation in the industrial building spaces enclosed by fabric membranes: A case study. J. Build. Eng. 2020, 32, 101651. [Google Scholar] [CrossRef]

- Yang, C.; Gao, T.; Li, A.; Gao, X. Buoyancy-driven ventilation of an enclosure containing a convective area heat source. Int. J. Therm. Sci. 2021, 159, 106551. [Google Scholar] [CrossRef]

- Liu, Q.; Linden, P. The fluid dynamics of an underfloor air distribution system. J. Fluid Mech. 2006, 554, 323–341. [Google Scholar] [CrossRef]

- Yang, C.; Luo, W.; Li, A.; Gao, X.; Che, L.; Qiao, L.; Gao, T.; Liu, Y. Natural ventilation driven by a restricted heat source elevated to different levels. In Building Simulation; Springer: Berlin/Heidelberg, Germany, 2022; Volume 15, pp. 281–289. [Google Scholar]

- Tlili, O.; Mhiri, H.; Bournot, P. Empirical correlation derived by CFD simulation on heat source location and ventilation flow rate in a fire room. Energy Build. 2016, 122, 80–88. [Google Scholar] [CrossRef]

- Park, H.-J.; Holland, D. The effect of location of a convective heat source on displacement ventilation: CFD study. Build. Environ. 2001, 36, 883–889. [Google Scholar] [CrossRef]

- Su, Y.; Miao, C. The effect of fresh air opening locations on natural ventilation and thermal environment in industrial workshop with heat source. In Proceedings of the 8th International Symposium on Heating, Ventilation and Air Conditioning: Volume 3: Building Simulation and Information Management; Springer: Berlin/Heidelberg, Germany, 2014; pp. 93–100. [Google Scholar]

- Pu, J.; Yuan, Y.; Jiang, F.; Zheng, K.; Zhao, K. Buoyancy-driven natural ventilation characteristics of thermal corridors in industrial buildings. J. Build. Eng. 2022, 50, 104107. [Google Scholar] [CrossRef]

- Elenbaas, W. Heat dissipation of parallel plates by free convection. Physica 1942, 9, 1–28. [Google Scholar] [CrossRef]

- Kihm, K.; Kim, J.; Fletcher, L. Onset of flow reversal and penetration length of natural convective flow between isothermal vertical walls. Trans.-Am. Soc. Mech. Eng. J. Heat Transf. 1995, 117, 776. [Google Scholar] [CrossRef]

- Habib, M.; Said, S.; Ahmed, S.; Asghar, A. Velocity characteristics of turbulent natural convection in symmetrically and asymmetrically heated vertical channels. Exp. Therm. Fluid Sci. 2002, 26, 77–87. [Google Scholar] [CrossRef]

- Badr, H.; Habib, M.; Anwar, S.; Ben-Mansour, R.; Said, S. Turbulent natural convection in vertical parallel-plate channels. Heat Mass Transf. 2006, 43, 73–84. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Ryms, M.; Denda, H. Natural convection in symmetrically heated vertical channels. Int. J. Therm. Sci. 2018, 134, 530–540. [Google Scholar] [CrossRef]

- Aung, W.; Worku, G. Developing flow and flow reversal in a vertical channel with asymmetric wall temperatures. J. Heat Transfer. 1986, 108, 299–304. [Google Scholar] [CrossRef]

- Kim, K.M.; Nguyen, D.H.; Shim, G.H.; Jerng, D.-W.; Ahn, H.S. Experimental study of turbulent air natural convection in open-ended vertical parallel plates under asymmetric heating conditions. Int. J. Heat Mass Transf. 2020, 159, 120135. [Google Scholar] [CrossRef]

- Cherif, Y.; Sassine, E.; Lassue, S.; Zalewski, L. Experimental and numerical natural convection in an asymmetrically heated double vertical facade. Int. J. Therm. Sci. 2020, 152, 106288. [Google Scholar] [CrossRef]

- Fedorov, A.G.; Viskanta, R. Turbulent natural convection heat transfer in an asymmetrically heated, vertical parallel-plate channel. Int. J. Heat Mass Transf. 1997, 40, 3849–3860. [Google Scholar] [CrossRef]

- Yilmaz, T.; Fraser, S.M. Turbulent natural convection in a vertical parallel-plate channel with asymmetric heating. Int. J. Heat Mass Transf. 2007, 50, 2612–2623. [Google Scholar] [CrossRef]

- Walker, C.; Tan, G.; Glicksman, L. Reduced-scale building model and numerical investigations to buoyancy-driven natural ventilation. Energy Build. 2011, 43, 2404–2413. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Liu, L.; Geng, M.; Wang, X.; Qiu, L. Experimental and numerical research of backfill cooling based on similarity theory. J. Build. Eng. 2023, 70, 106380. [Google Scholar] [CrossRef]

- Pucciarelli, A.; Ambrosini, W. A successful general fluid-to-fluid similarity theory for heat transfer at supercritical pressure. Int. J. Heat Mass Transf. 2020, 159, 120152. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, J.; Wang, Z.; Wang, Y.; Wu, Q.; Wang, L.; Liu, J. Evaluation of stack ventilation in a large space using zonal simulation and a reduced-scale model experiment with particle image velocimetry. J. Build. Eng. 2021, 34, 101958. [Google Scholar] [CrossRef]

- Ding, W.; Hasemi, Y.; Yamada, T. Natural ventilation performance of a double-skin façade with a solar chimney. Energy Build. 2005, 37, 411–418. [Google Scholar] [CrossRef]

- Moosavi, L.; Zandi, M.; Bidi, M.; Behroozizade, E.; Kazemi, I. New design for solar chimney with integrated windcatcher for space cooling and ventilation. Build. Environ. 2020, 181, 106785. [Google Scholar] [CrossRef]

- Liu, P.-C.; Lin, H.-T.; Chou, J.-H. Evaluation of buoyancy-driven ventilation in atrium buildings using computational fluid dynamics and reduced-scale air model. Build. Environ. 2009, 44, 1970–1979. [Google Scholar] [CrossRef]

- Etheridge, D.W.; Sandberg, M. Building Ventilation: Theory and Measurement; John Wiley & Sons: Chichester, UK, 1996. [Google Scholar]

- Walker, C.E. Methodology for the Evaluation of Natural Ventilation in Buildings Using a Reducedscale Air Model. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2005. [Google Scholar]

- Shinji, S. Modeling Criteria for the Room Air Motion, Part 1-Practical Similarity Criteria for the Room Air Motion. Pap. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 1981, 17, 1–10. [Google Scholar]

- Izadyar, N.; Miller, W.; Rismanchi, B.; Garcia-Hansen, V. A numerical investigation of balcony geometry impact on single-sided natural ventilation and thermal comfort. Build. Environ. 2020, 177, 106847. [Google Scholar] [CrossRef]

- Farea, T.G.; Ossen, D.R.; Alkaff, S.; Kotani, H. CFD modeling for natural ventilation in a lightwell connected to outdoor through horizontal voids. Energy Build. 2015, 86, 502–513. [Google Scholar] [CrossRef]

- Liu, J.; Srebric, J.; Yu, N. Numerical simulation of convective heat transfer coefficients at the external surfaces of building arrays immersed in a turbulent boundary layer. Int. J. Heat Mass Transf. 2013, 61, 209–225. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, L.; Huang, Y.; Cao, Y. Lateral ventilation performance for removal of pulsating buoyant jet under the influence of high-temperature plume. Indoor Built Environ. 2020, 29, 543–557. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, M.; Wang, M.; Wang, Y. Predictive accuracy of Boussinesq approximation in opposed mixed convection with a high-temperature heat source inside a building. Build. Environ. 2018, 144, 349–356. [Google Scholar] [CrossRef]

- Menchaca-Brandan, M.A.; Espinosa, F.A.D.; Glicksman, L.R. The influence of radiation heat transfer on the prediction of air flows in rooms under natural ventilation. Energy Build. 2017, 138, 530–538. [Google Scholar] [CrossRef]

- Serageldin, A.A.; Ye, M.; Radwan, A.; Sato, H.; Nagano, K. Numerical investigation of the thermal performance of a radiant ceiling cooling panel with segmented concave surfaces. J. Build. Eng. 2021, 42, 102450. [Google Scholar] [CrossRef]

- Jiang, F.; Yuan, Y.; Li, Z.; Zhao, Q.; Zhao, K. Correlations for the forced convective heat transfer at a windward building façade with exterior louver blinds. Sol. Energy 2020, 209, 709–723. [Google Scholar] [CrossRef]

- Sevilgen, G.; Kilic, M. Numerical analysis of air flow, heat transfer, moisture transport and thermal comfort in a room heated by two-panel radiators. Energy Build. 2011, 43, 137–146. [Google Scholar] [CrossRef]

- Zhang, Y.-P.; He, Y.-L.; Liu, Y.-H.; Ma, Y.-X.; Li, Y.-R.; Dou, J.-X. Thermal Effects of Building’s External Surfaces in City—Characteristics of Heat Flux into and out of External Wall Surfaces. Chin. Geogr. Sci. 2004, 14, 343–349. [Google Scholar] [CrossRef]

- Embaye, M.; Al-Dadah, R.; Mahmoud, S. Numerical evaluation of indoor thermal comfort and energy saving by operating the heating panel radiator at different flow strategies. Energy Build. 2016, 121, 298–308. [Google Scholar] [CrossRef]

- Yigit, C.; Coskun, G.; Buyukkaya, E.; Durmaz, U.; Güven, H.R. CFD modeling of carbon combustion and electrode radiation in an electric arc furnace. Appl. Therm. Eng. 2015, 90, 831–837. [Google Scholar] [CrossRef]

- Huang, Y.; Tao, Y.; Shi, L.; Liu, Q.; Wang, Y.; Tu, J.; Gan, X. Numerical study of the performance for a curved double-skin façade in summer. Build. Environ. 2023, 233, 110103. [Google Scholar] [CrossRef]

- El Ghandouri, I.; El Maakoul, A.; Saadeddine, S.; Meziane, M. Design and numerical investigations of natural convection heat transfer of a new rippling fin shape. Appl. Therm. Eng. 2020, 178, 115670. [Google Scholar] [CrossRef]

- Liu, M.; Jimenez-Bescos, C.; Calautit, J. CFD investigation of a natural ventilation wind tower system with solid tube banks heat recovery for mild-cold climate. J. Build. Eng. 2022, 45, 103570. [Google Scholar] [CrossRef]

- Acikgoz, O. A novel evaluation regarding the influence of surface emissivity on radiative and total heat transfer coefficients in radiant heating systems by means of theoretical and numerical methods. Energy Build. 2015, 102, 105–116. [Google Scholar] [CrossRef]

- Falsetti, C.; Kapulla, R.; Paranjape, S.; Paladino, D. Thermal radiation, its effect on thermocouple measurements in the PANDA facility and how to compensate it. Nucl. Eng. Des. 2021, 375, 111077. [Google Scholar] [CrossRef]

- Zhang, X.; Ge, Y.; Lang, P. Experimental investigation and CFD modelling analysis of finned-tube PCM heat exchanger for space heating. Appl. Therm. Eng. 2024, 244, 122731. [Google Scholar] [CrossRef]

- Bakkas, M.; Amahmid, A.; Hasnaoui, M. Steady natural convection in a horizontal channel containing heated rectangular blocks periodically mounted on its lower wall. Energy Conv. Manag. 2006, 47, 509–528. [Google Scholar] [CrossRef]

- Mouhtadi, D.; Amahmid, A.; Hasnaoui, M.; Bennacer, R. Natural convection in a horizontal channel provided with heat generating blocks: Discussion of the isothermal blocks validity. Energy Conv. Manag. 2012, 53, 45–54. [Google Scholar] [CrossRef]

- Bakkas, M.; Hasnaoui, M.; Amahmid, A. Natural convective flows in a horizontal channel provided with heating isothermal blocks: Effect of the inter blocks spacing. Energy Conv. Manag. 2010, 51, 296–304. [Google Scholar] [CrossRef]

- Churchill, S.W.; Chu, H.H. Correlating equations for laminar and turbulent free convection from a vertical plate. Int. J. Heat Mass Transf. 1975, 18, 1323–1329. [Google Scholar] [CrossRef]

- Olsson, C.-O. Prediction of Nusselt number and flow rate of buoyancy driven flow between vertical parallel plates. J. Heat Transf. 2004, 126, 97–104. [Google Scholar] [CrossRef]

- Song, C.; Nie, B.; Xu, F. Scaling analysis of natural convection in a vertical channel. Int. Commun. Heat Mass Transf. 2020, 117, 104739. [Google Scholar] [CrossRef]

- Franco, A.T.; Santos, P.R.; Lugarini, A.; Loyola, L.T.; De Lai, F.C.; Junqueira, S.L.; Nardi, V.G.; Ganzarolli, M.M.; Lage, J.L. The effects of discrete conductive blocks on the natural convection in side-heated open cavities. Appl. Therm. Eng. 2023, 219, 119613. [Google Scholar] [CrossRef]

- Nghana, B.; Tariku, F.; Bitsuamlak, G. Numerical assessment of the impact of transverse roughness ribs on the turbulent natural convection in a BIPV air channel. Build. Environ. 2022, 217, 109093. [Google Scholar] [CrossRef]

| Name | Details |

|---|---|

| Dimensions of the experiment scaled-model, L × W × H | 2.5 m × 0.75 m × 0.5 m |

| Dimensions of the heating plants, lH × wH × hH | 2.5 m × 0.15 m × 0.2 m |

| Dimensions of the air openings, li × wi/lo × wo | 2.5 m × 0.075 m |

| Width of the side corridor, ws | 0.1 m |

| Width of the middle corridor, wm | 0.25 m |

| Distance from the heating plants bottom to ground, HH | 0.05 m |

| Distance from the inlet opening bottom to ground, Hi | 0 m |

| Centre spacing of the outlet openings, Xo | 0.325 m |

| Parameter | Range |

|---|---|

| Heating plants surface temperature, Tw | 40–120 °C |

| Outdoor air temperature, T∞ | 21–31 °C |

| Air inlet/outlet area, Ai, Ao | 0.125–0.2625 m2 |

| Width of the heating plant, wH | 0.1–0.3 m |

| Height of the heating plants, hH | 0.05–0.175 m |

| Rayleigh number, Ra | 4 × 106, 4 × 107 |

| Description of the Area | Type | Boundary Conditions |

|---|---|---|

| Building walls and roof | Wall | Overall heat transfer coefficient: 0.8 W/(m2·K), heat transfer coefficient in the outer surface of the walls: 20.9 W/(m2·K), temperature: 25 °C, emissivity: 0.85 |

| Building floor | Wall | Adiabatic |

| Heating plant (top and side) | Wall | Temperature: 80 °C, emissivity: 0.85 |

| Air inlet | Pressure inlet | Temperature: 25 °C, pressure: 0 Pa |

| Air outlet | Pressure outlet | Temperature: 25 °C, pressure: 0 Pa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, J.; Zhu, A.; Wu, J.; Xie, F.; Jiang, F. Investigation on the Natural Convection Inside Thermal Corridors of Industrial Buildings. Buildings 2024, 14, 1406. https://doi.org/10.3390/buildings14051406

Pu J, Zhu A, Wu J, Xie F, Jiang F. Investigation on the Natural Convection Inside Thermal Corridors of Industrial Buildings. Buildings. 2024; 14(5):1406. https://doi.org/10.3390/buildings14051406

Chicago/Turabian StylePu, Jing, Aixin Zhu, Junqiu Wu, Fuzhong Xie, and Fujian Jiang. 2024. "Investigation on the Natural Convection Inside Thermal Corridors of Industrial Buildings" Buildings 14, no. 5: 1406. https://doi.org/10.3390/buildings14051406

APA StylePu, J., Zhu, A., Wu, J., Xie, F., & Jiang, F. (2024). Investigation on the Natural Convection Inside Thermal Corridors of Industrial Buildings. Buildings, 14(5), 1406. https://doi.org/10.3390/buildings14051406