Examining the Challenges for Circular Economy Implementation in Construction and Demolition Waste Management: A Comprehensive Review Using Systematic Methods

Abstract

1. Introduction

2. Methodology

3. Findings

3.1. PESTLE Analysis Classification

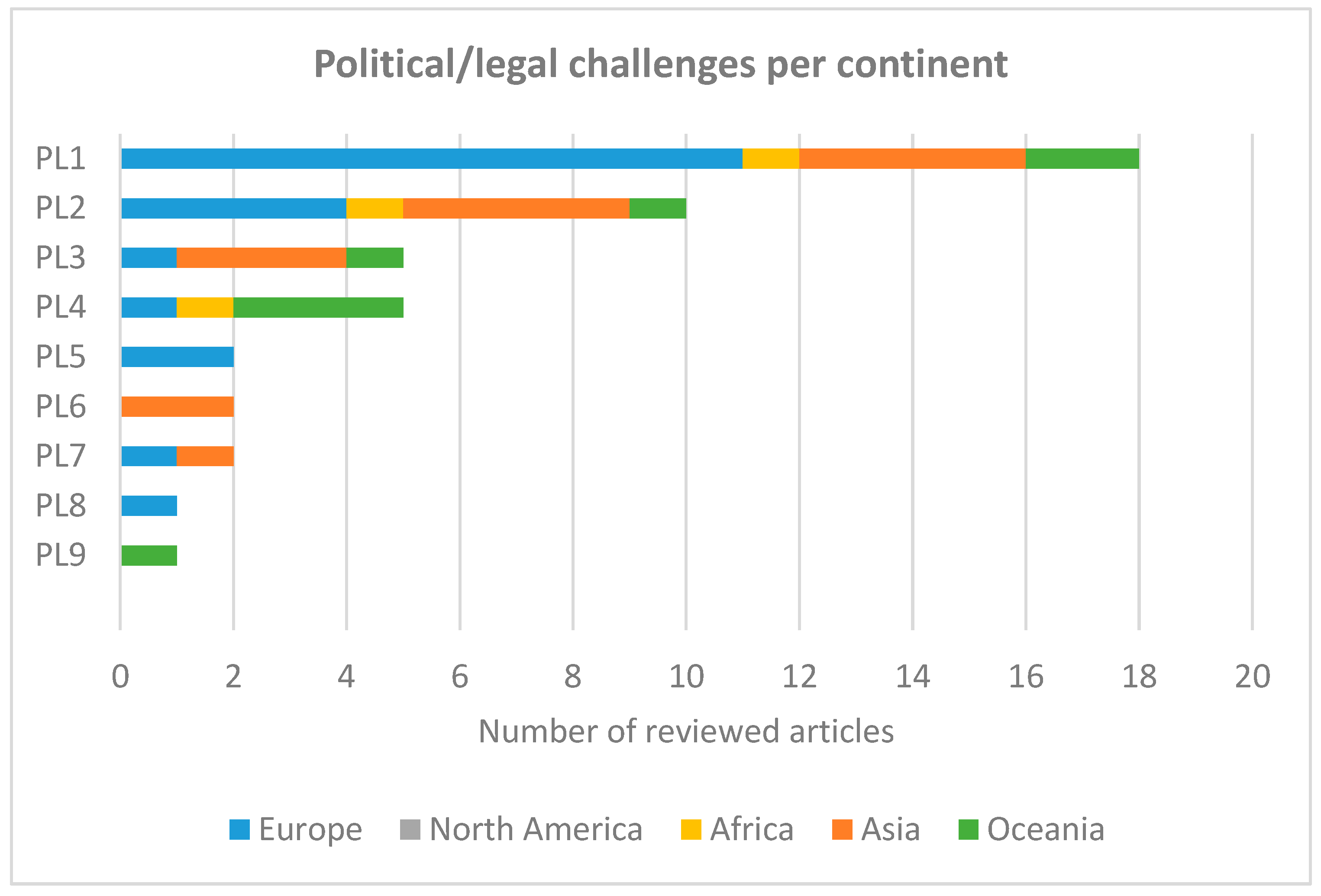

3.1.1. Political and Legal Challenges

3.1.2. Economic Challenges

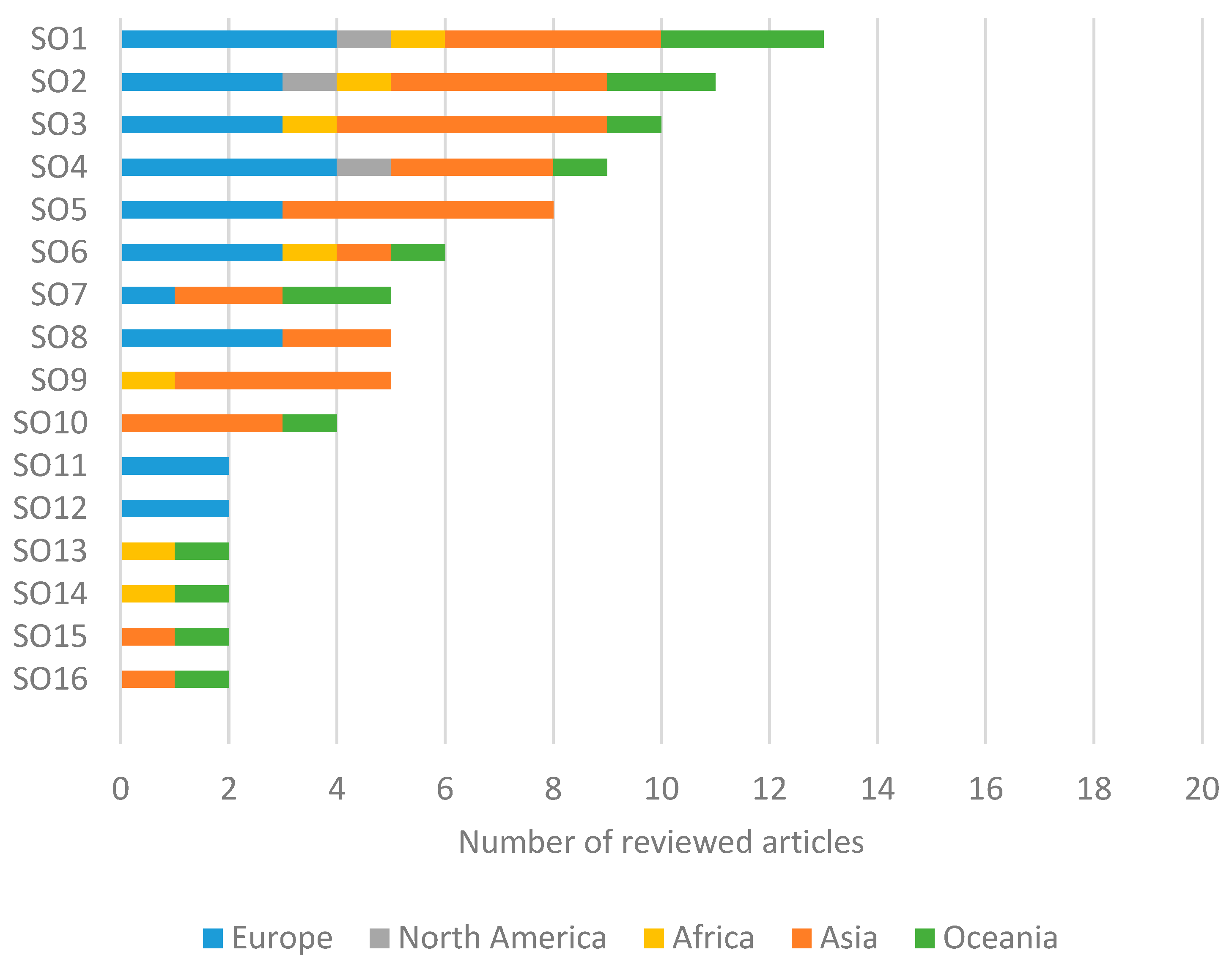

3.1.3. Social Challenges

3.1.4. Technological Challenges

3.1.5. Environmental Challenges

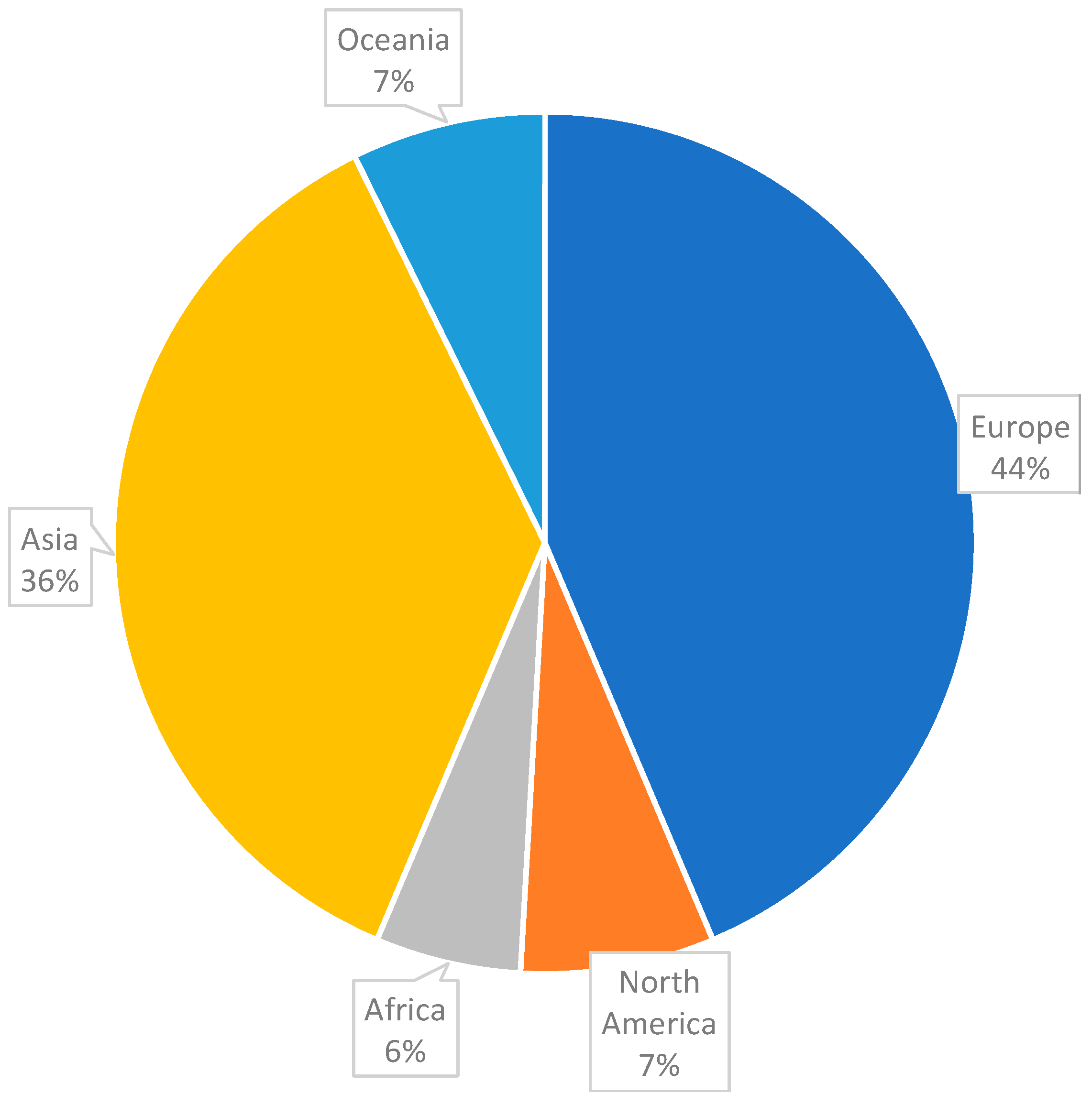

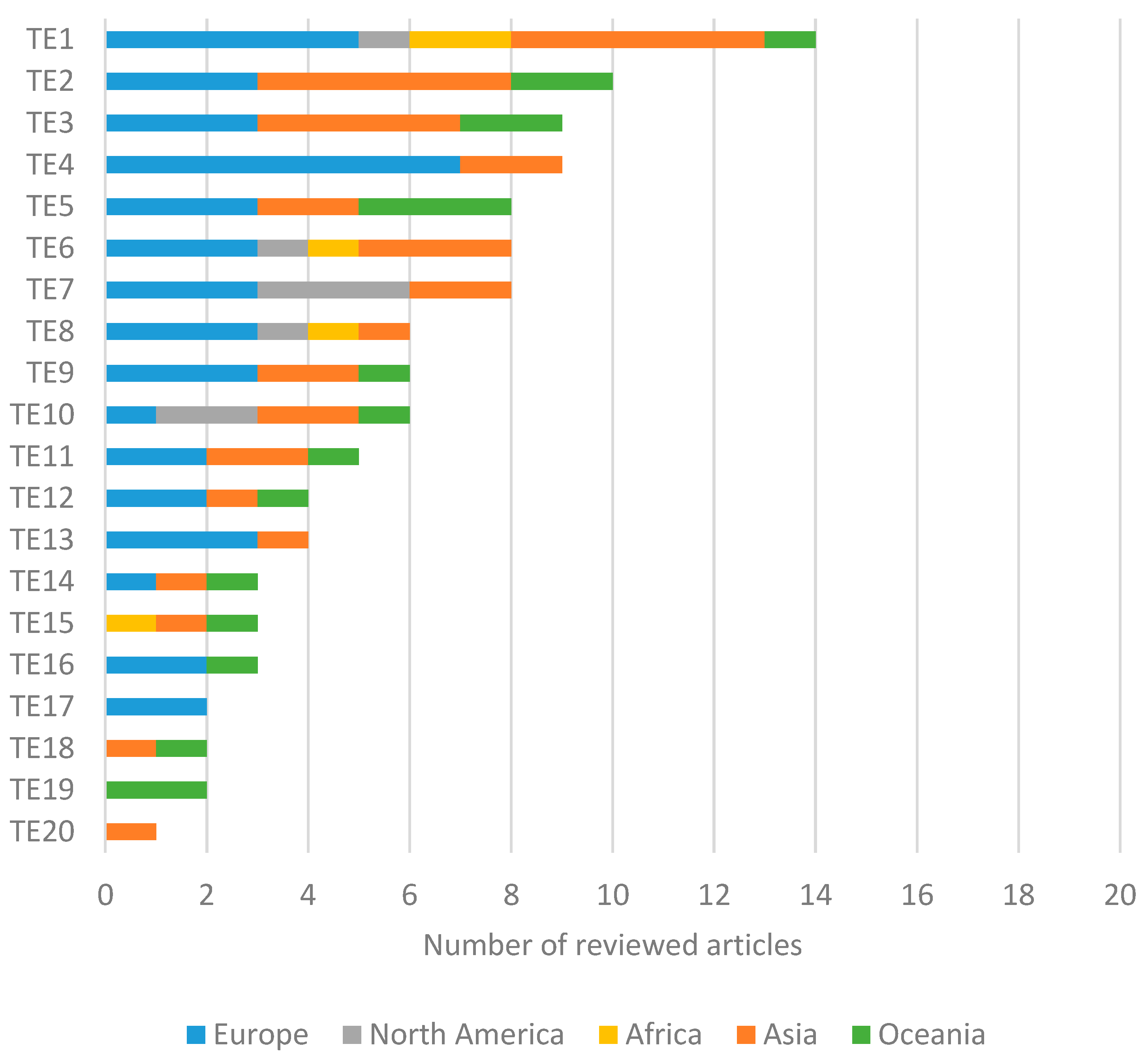

3.2. Analysis of Challenges per Continent and Specific Countries

4. Conclusions

- 1.

- Regulation is non-existent/insufficient/inadequate/ambiguous (in 18 papers)

- 2.

- Extra/high costs of waste management (in 16 papers)

- 3.

- Lack of strong CDWM practice (in 14 papers)

- 4.

- Difficulties to make a business case with waste (in 13 papers)

- 4.

- Constraints, extra time and delays due to CDW management (in 13 papers)

- 4.

- Limited/lack of awareness and education within industry (in 13 papers)

- Waste segregation. This is a basic step towards waste recovery. The purity of the different fractions sorted will determine the quality of the material and, therefore, its final recovery at a higher or lower value use. Construction methods and waste handling will determine solutions to implement.

- Improved CDW management practices. This comprises waste generation and management at the construction site, but also waste traceability and value chain until the final destiny. This includes the implementation of site waste management plans, including transport, handling, and treatment off-site. At this point, CDW management on site is substantially improved, as well as waste transfer facilities, treatment infrastructures, and the development of the waste-processing industry.

- Design out waste. At this level, the design stage is integrated, having a substantial impact on waste minimization. Standardization and modular construction are essential parts at this level.

- Whole life-cycle and value-chain strategies. Finally, the integration of all life-cycle stages in the project brings the optimization of resources and solutions for a complete circular economy in the construction industry. Data management (big data) and automated solutions bring the possibility of optimizing cost and resources, making more efficient processes and facilitating stakeholder collaboration. This involves the use of digital technologies such as IoT, visual recognition, machine learning, blockchain, etc., as well as the introduction of robotics at different levels.

- -

- Asian countries are more focused on the lack of regulations and strategies, whereas European countries target further developments around existing regulations and policies to achieve improved closed loops in construction.

- -

- There is a predominant representation of European countries in identifying economic challenges. Challenges identified mainly refer to the difficulties of making a business case, limited investment, high risk and uncertain profit margins, and the reused/recycled products market.

- -

- The representation of both European and Asian countries in the number of papers reviewed is substantial. Comparing them, it can be highlighted that the focus of the challenges identified is different. While Asian countries seek further awareness, education, and skills development, European countries demand further stakeholder collaboration and avoid change resistance.

- -

- In this regard, Asian papers make more references to challenges in waste management and processing (sorting, transport, treatment, and recovery), whereas European countries identify other challenges more related to CDW data management and the use of digital technologies, waste traceability, design standardization, and quality assurance processes for reused/recycled products.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qualisflow. The UK Construction Industry Waste Report 2023; Qflow: Saint Louis, MI, USA, 2023. [Google Scholar]

- European Commission. Construction and Demolition Waste. 2020. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 8 April 2024).

- Fang, Y. Effects of Recycled Powder on Carbonation Resistance of Concrete. Fujian Archit. Constr. 2021, 281, 161–165. [Google Scholar]

- EPA. Construction and Demolition Debris: Material-Specific Data; US EPA: Research Triangle Park, NC, USA, 2018.

- Lawson, N.; Douglas, I.; Garvin, S.; McGrath, C.; Manning, D.; Vetterlein, J. Recycling construction and demolition wastes—A UK perspective. Environ. Manag. Health 2001, 12, 146–157. [Google Scholar] [CrossRef]

- World Economic Forum. What Is the Circular Economy and Why Does It Matter That It Is Shrinking? 14 June 2022. Available online: https://www.weforum.org/agenda/2022/06/what-is-the-circular-economy/ (accessed on 7 July 2023).

- Huang, B.W.X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Ng, L.S.; Tan, L.W.; Seow, T.W. Constraints to 3R construction waste reduction among contractors in Penang. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012103. [Google Scholar] [CrossRef]

- Velenturg, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. Application of low waste technologies for design and construction: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2012, 16, 2973–2979. [Google Scholar] [CrossRef]

- Levy, Y.; Ellis, T.J. A systems approach to conduct an effective literature review in support of information systems research. Informing Sci. J. 2006, 9, 181–212. [Google Scholar] [CrossRef]

- Page, M.J.; E McKenzie, J.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- UN Climate Change. The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 7 July 2023).

- European Parliament. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste; European Parliament: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Government of the Netherlands. Circular Dutch Economy by 2050. Available online: https://www.government.nl/topics/circular-economy/circular-dutch-economy-by-2050 (accessed on 7 July 2023).

- Adams, K. Zero Avoidable Waste in Construction: What Do We Mean by It and How Best to Interpret It; Green Construction Board: London, UK, 2020. [Google Scholar]

- The People’s Republic of China. The 14th Five-Year Plan (2021–2025) for National Economic and Social Development and Vision 2035 of the People’s Republic of China; Xinhua News Agency: Beijing, China, 2021.

- EPA. Sustainable Management of Construction and Demolition Materials; US EPA: Washington, DC, USA, 2023. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 7 July 2023).

- SAjayi, O.; Oyedele, L.O. Policy imperatives for diverting construction waste from landfill: Experts’ recommendations for UK policy expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar]

- Blaisi, N.I. Construction and demolition waste management in Saudi Arabia: Current practices and roadmap for sustainable management. J. Clean. Prod. 2019, 221, 167–175. [Google Scholar] [CrossRef]

- Tafesse, S.; Girma, Y.E.; Dessalegn, E. Analysis of the socio-economic and environmental impacts of construction waste and management practices. Heliyon 2022, 26, e09169. [Google Scholar] [CrossRef] [PubMed]

- Sáez, P.V.; de Guzmán Báez, A.; Navarro, J.G.; del Río Merino, M. Redefining construction and demolition waste management systems: Best practices on civil engineering works. Balt. J. Road Bridge Eng. 2014, 9, 171–179. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Kien, T.T.; Dang, H.; Nga, T.; Nguyen, G.H.; Nguyen, D.T.; Isobe, Y.; Ishigaki, T.K.K. Current status of construction and demolition waste management in Vietnam: Challenges and opportunities. Int. J. GEOMATE 2018, 15, 23–29. [Google Scholar]

- Nasir, S.R.M.; Othman, N.; Isa, C.M.M.; Ibrahim, C.K.I.C. The challenges of construction waste management in Kuala Lumpur. J. Teknol. 2016, 78, 115–119. [Google Scholar]

- Shooshtarian, S.; Hosseini, M.; Kocaturk, T.; Arnel, T.; Garofano, N.T. Circular economy in the Australian AEC industry: Investigation of barriers and enablers. Build. Res. Inf. 2022, 51, 56–68. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Ma, M.; Tam, V.W.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef]

- Oke, A.; Aigbavboa, C.; Aghimien, D.; Currie, N. Construction professionals perception of solid waste management in the South African construction industry. In Advances in Human Factors, Sustainable Urban Plannign and Infrastructure; Springer International: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Castell-Rüdenhausen, M.Z.; Wahlström, M.; Astrup, T.F.; Jensen, C.; Oberender, A.; Johanson, P.; Waerner, E.R. Policies as drivers for circular economy in the construction sector in the Nordics. Sustainability 2021, 13, 9350. [Google Scholar] [CrossRef]

- Oluleye, B.L.; Chan, D.W.; Saka, A.B.; Olawumi, T.O. Circular economy research on building construction and demolition waste: A review of current trends and future research directions. J. Clean. Prod. 2021, 294, 131927. [Google Scholar] [CrossRef]

- Adams, K.; Osmani, M.; Thorpe, A.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and barriers towards circular economy in the building sector: Stakeholder interviews and analysis of five European countries policies and practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Jiang, Y.; Wang, X. Explore potential barriers of applying circular economy in construction and demolition waste recycling. J. Clean. Prod. 2021, 326, 129400. [Google Scholar] [CrossRef]

- Yuan, H. Barriers and countermeasures for managing construction and demolition waste: A case of Shenshen in China. J. Clean. Prod. 2017, 157, 84–93. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimisation in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Tirado, R.; Aublet, A.; Laurenceau, S.; Habert, G. Challenges and opportunities for circular economy promotion in the building sector. Sustainability 2022, 14, 1569. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing efficient circularity for construction and demolition waste management in fast emerging economies: Lessons learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef] [PubMed]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2019, 244, 118710. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practices in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T.; Khalfan, M. An investigation into challenges and opportunities in the Australian construction and demolition waste management system. Eng. Constr. Archit. Manag. 2022, 29, 4313–4330. [Google Scholar] [CrossRef]

- Ding, Z.; Yi, G.; Tam, V.W.Y.; Huang, T. A system dynamics-based environmental performance simulation of construction waste reduction management in China. Waste Manag. 2022, 51, 130–141. [Google Scholar] [CrossRef]

- Crawford, R.H.; Mathur, D.; Gerritsen, R. Barriers to improvind the environmetnal performance of construction waste management in remote communities. Procedia Eng. 2017, 196, 830–837. [Google Scholar] [CrossRef]

- Negash, Y.T.; Hassan, A.M.; Tseng, M.-L.; Wu, K.-J.; Ali, M.H. Sustainable Construction and Demolition Waste Maangement in Somaliland: Regulatory barriers lead to technical and environmental barriers. J. Clean. Prod. 2021, 297, 126717. [Google Scholar] [CrossRef]

- Condotta, M.; Zatta, E. Reuse of building elements in the architectural practice and the European regulatory context: Inconsistencies and possible improvements. J. Clean. Prod. 2021, 318, 128413. [Google Scholar] [CrossRef]

- Sáez, P.V.; del Río Merino, M.; González, A.S.-A.; Porras-Amores, C. Best practice measures assessment for construction and demolition waste management in buildng constructions. Resour. Conserv. Recycl. 2013, 75, 52–62. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Analysis of the implementation of effective waste management practices in construction projects and sites. Resour. Conserv. Recycl. 2014, 93, 99–111. [Google Scholar] [CrossRef]

- Ramos, M.; Martinho, G. Influence of construction company size on the determining factors for construction and demolition waste management. Waste Manag. 2021, 136, 295–302. [Google Scholar] [CrossRef] [PubMed]

- Luscurere, L. Materials passports: Optimising value recovery from materials. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 25–28. [Google Scholar]

- Wang, G.; Krywda, D.; Kondrashev, S.; Vorona-Slivinskaya, L. Recycling and upcycling in the practice of waste management of construction giants. Sustainability 2021, 13, 640. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Mustafa, M.K.F. Circular Economy: Challenges and opportunities in the construction sector of Kazakhstan. Buildings 2021, 11, 501. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A.; Kadiri, K.O. Waste effectiveness of the construction industry: Understanding the impediments and requisites for improvements. Resour. Conserv. Recycl. 2015, 102, 101–112. [Google Scholar] [CrossRef]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.H.C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Lee, A. A behavioural framework for construction waste minimization: The case of Jordan. Int. J. Environ. Sustain. 2021, 17, 9–32. [Google Scholar] [CrossRef]

- Umar, U.A.; Shafiq, N.; Ahmad, F.A. A case study on the effective implementation of the reuse and recycling of construction and demolition waste management practices in Malaysia. Ain Shams Eng. J. 2020, 12, 283–291. [Google Scholar] [CrossRef]

- Low, J.K.; Wallis, S.L.; Hernández, G.; Cerqueira, I.S.; Steinhorn, G.; Berry, T.-A. Encouraging circular waste economies for the New Zealand construction industry: Opportunities and barriers. Front. Sustain. Cities 2020, 2, 35. [Google Scholar] [CrossRef]

- Cristiano, S.; Ghisellini, P.; D’Ambrosio, G.; Xue, J.; Nestico, A.; Gonella, F.; Ulgiati, S. Construction and demolition waste in the metropolitan city of Naples, Italy: State of the art, circular design, and sustainable planning opportunities. J. Clean. Prod. 2021, 293, 125856. [Google Scholar] [CrossRef]

- Christensen, T.B.; Johansen, M.R.; Buchard, M.V.; Glarborg, C.N. Closing the material loops for construction and demolition waste: The circular economy on the island Bornholm, Denmark. Resour. Conserv. Recycl. Adv. 2022, 15, 200104. [Google Scholar] [CrossRef]

- Hasan, M.R.; Sagar, M.S.I.; Ray, B.C. Barriers to improving construction and demolition waste management in Bangladesh. Int. J. Constr. Manag. 2022, 23, 2333–2347. [Google Scholar] [CrossRef]

- Pellegrini, L.; Campi, S.; Locatelli, M.; Pattini, G.; Di Guida, G.M.; Tagliabue, L.C. Digital transition and waste management in Architecture, Enginnering, Construction and Operations Industry. Front. Energy Res. 2020, 8, 576462. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Li, J.; Tam, V.W.Y.; Zuo, J.; Zhu, J. Designers’ attitude and behaviour towards construction waste minimisation by design: A sutdy in Shenzhen, China. Resour. Conserv. Recycl. 2015, 105, 29–35. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C.; Lee, G. Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Rahmat, A.S.; Noor, H.R.N.R.M.; Endut, I.R.; Ridzuan, R.A.M. The practice of construction waste management in Pulau Pinang. AIP Conf. Proc. 2016, 1774, 030018. [Google Scholar]

- Shojaei, A.; Ketabl, R.; Razkenari, M.; Hakim, H.; Wang, J. Enabling a circular economy in the built environment sector through blockchain technology. J. Clean. Prod. 2021, 312, 126352. [Google Scholar] [CrossRef]

- Bernardo, M.; Gomes, M.C.; de Brito, J. Demolition waste generation for development of a regional management chain model. Waste Manag. 2015, 49, 156–169. [Google Scholar] [CrossRef] [PubMed]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Ma, L.Y.H. A BIM-based system for demolition and renovation waste estimation and planning. Waste Manag. 2013, 33, 1539–1551. [Google Scholar] [CrossRef] [PubMed]

- Guerra, B.C.; Backchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 15, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Raja Mohd Noor, R.N.H.; Ridzuan, A.R.M.; Endut, I.R.; Noordin, B.; Shehu, Z.; Ghani, A.H.A. The quantification of local construction waste for the current construction waste management practices: A case study in Klang Valley. In Proceedings of the IEEE Business Engineering and Industrial Appplications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 183–188. [Google Scholar]

- Lu, W.; Wenster, C.J.; Peng, Y.; Chen, X.; Chen, K. Big data in construction waste management: Prospects and challenges. Detritus 2018, 4, 129–139. [Google Scholar] [CrossRef]

- Palumbo, E.; Soust-Verdaguer, B.; Llatas, C.; Traverso, M. How to obtain accurate environmental impacts at early design stages in BIM when using environmental product declaration. A method to support decision-making. Sustainability 2020, 12, 6927. [Google Scholar] [CrossRef]

| Political/Legal | |||||

| Code | Challenge | Articles | Frequency | Category Ranking | Overall Ranking |

| PL1 | Regulation is non-existent/insufficient/inadequate/ambiguous | [7,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36] | 18 | 1 | 1 |

| PL2 | Inappropriate planning/strategies for CE | [7,21,25,29,30,33,34,37,38,39] | 10 | 2 | 9 |

| PL3 | Lack of institutional support, coordination, and collaboration | [21,28,35,40,41] | 5 | 3 | 26 |

| PL4 | Reused materials need to meet performance requirements | [41,42,43,44,45] | 5 | 3 | 26 |

| PL5 | Administrative procedures are long and slow | [46,47] | 2 | 5 | 41 |

| PL6 | Landfills are unregulated/not sustainably managed | [21,28] | 2 | 5 | 42 |

| PL7 | Complicated contracting system and responsibilities | [25,48] | 2 | 5 | 42 |

| PL8 | Longevity of property service life and multiple ownership | [49] | 1 | 8 | 54 |

| PL9 | Illegal activities and lack of enforcement | [41] | 1 | 8 | 54 |

| Total | 47 | ||||

| Economic | |||||

| Code | Challenge | Articles | Frequency | Category Ranking | Overall Ranking |

| EC1 | Extra/high costs of waste management | [22,23,25,26,27,28,29,30,38,41,45,46,47,50,51,52] | 16 | 1 | 2 |

| EC2 | Difficulties to make a business case with waste | [20,27,31,32,33,35,37,43,48,50,51,53,54] | 13 | 2 | 4 |

| EC3 | Time constraints, extra time, and delays due to CDWM | [22,26,27,29,30,41,43,44,45,51,52,54,55] | 13 | 2 | 4 |

| EC4 | Inadequate/lack of incentives | [21,26,28,29,31,32,34,42,54,56,57] | 11 | 4 | 7 |

| EC5 | Lack of markets for reused/recycled products | [7,25,32,33,41,43,50,57,58] | 10 | 5 | 9 |

| EC6 | Low cost of landfilling/low penalties | [7,23,29,30,41,42,47,54,57] | 9 | 5 | 13 |

| EC7 | Very low/lack of investment for recycling | [25,29,31,35,50] | 6 | 7 | 21 |

| EC8 | Low cost of raw materials/high cost of recycled materials | [20,23,30,31,41] | 5 | 8 | 26 |

| EC9 | Budget constraints | [29,47,50,54] | 5 | 8 | 26 |

| EC10 | Low value of reused/recycled materials | [32,41] | 2 | 10 | 42 |

| EC11 | Building lifespan not the same as the developer’s business plan | [27] | 1 | 11 | 54 |

| Total | 88 | ||||

| Social | |||||

| Code | Challenge | Articles | Frequency | Category Ranking | Overall Ranking |

| SO1 | Limited/lack of awareness and education within industry | [21,23,25,26,27,29,32,42,46,47,54,56,59] | 13 | 1 | 4 |

| SO2 | Limited/lack of training and knowledge | [7,25,26,27,29,32,47,48,54,56,59] | 11 | 2 | 7 |

| SO3 | Limited public awareness and attitudes | [24,25,29,32,34,41,54,57,60,61] | 10 | 3 | 9 |

| SO4 | Conservatism/change resistance from traditional practice | [25,27,29,37,40,48,54,60,61] | 9 | 4 | 13 |

| SO5 | Lack of interest from clients | [23,32,47,50,51,54,62] | 8 | 5 | 17 |

| SO6 | Non-collaboration between stakeholders | [21,26,39,60,61,63] | 6 | 6 | 21 |

| SO7 | Low acceptability of secondary materials | [20,38,41,42,51] | 5 | 7 | 26 |

| SO8 | Insufficient attention to CDWM/other priorities | [35,47,49,52,59] | 5 | 7 | 26 |

| SO9 | Poor/lack of supervision/management of waste | [22,47,54,59,64] | 5 | 7 | 26 |

| SO10 | Lack of consideration during design | [25,26,28,62] | 4 | 10 | 34 |

| SO11 | Blame culture. Shifting waste prevention responsibilities | [60,61] | 2 | 11 | 42 |

| SO12 | Temporary relationship among parties | [60,61] | 2 | 11 | 42 |

| SO13 | Personnel recruitment and retention | [22,43] | 2 | 11 | 42 |

| SO14 | Excess of material wastage | [22,59] | 2 | 11 | 42 |

| SO15 | Health and safety issues | [54,56] | 2 | 11 | 42 |

| SO16 | Theft and damage | [43,59] | 2 | 11 | 42 |

| Total | 87 | ||||

| Technological | |||||

| Code | Challenge | Articles | Frequency | Category Ranking | Overall Ranking |

| TE1 | Lack of strong CDWM practice | [7,20,22,23,25,36,43,44,47,51,59,64,65] | 14 | 1 | 3 |

| TE2 | Difficulties with waste segregation on site | [25,39,41,42,43,47,52,55,58,59] | 10 | 2 | 9 |

| TE3 | Limited/no access to waste recovery facilities | [7,21,25,31,39,41,43,51,59] | 9 | 3 | 13 |

| TE4 | Lack of uniformity/ inconsistent quality of CDW | [28,30,31,37,51,52,57,58,66] | 9 | 3 | 13 |

| TE5 | Complexity of building design | [26,32,37,42,43,51,52,54,59] | 8 | 3 | 17 |

| TE6 | Current waste prediction and analysis models are limited | [22,28,52,66,67,68,69,70] | 8 | 5 | 17 |

| TE7 | CDW data management not properly developed | [35,36,44,51,52,65,69,71] | 8 | 7 | 17 |

| TE8 | Material and waste traceability is not correctly performed | [21,28,37,47,57,65] | 6 | 8 | 21 |

| TE9 | Design errors and changes | [25,43,59,60,61,63] | 6 | 8 | 21 |

| TE10 | Limited/lack of investigation and demonstration cases | [24,26,27,42,53,66] | 6 | 8 | 21 |

| TE11 | Limited site space | [25,46,52,56,59] | 5 | 11 | 26 |

| TE12 | Incomplete designs | [43,54,60,61] | 4 | 12 | 34 |

| TE13 | BIM/digital technologies do not currently support CDWM | [33,52,67,72] | 4 | 12 | 34 |

| TE14 | Inappropriate specification and standardization | [43,49,59] | 3 | 14 | 37 |

| TE15 | Technical challenges with waste transport, treatment, and recovery | [22,43,55] | 3 | 14 | 37 |

| TE16 | Uncertain material availability and security of supply | [30,37,41] | 3 | 14 | 37 |

| TE17 | Fragmented supply chains | [32,49] | 2 | 17 | 42 |

| TE18 | Packaging waste increase | [43,59] | 2 | 17 | 42 |

| TE19 | Lack of space for recyclables storage/recycling operations | [41,43] | 2 | 17 | 42 |

| TE20 | Lack of technical support from suppliers | [54] | 1 | 20 | 54 |

| Total | 112 | ||||

| Environmental | |||||

| Code | Challenge | Articles | Frequency | Category Ranking | Overall Ranking |

| EN1 | Contamination issues and safety | [40,41,43] | 3 | 1 | 37 |

| EN2 | Energy consumption for recycling treatments | [52] | 1 | 2 | 54 |

| EN3 | End-of-pipe treatment rather than waste preventive measures | [52] | 1 | 2 | 54 |

| Total | 5 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferriz-Papi, J.A.; Lee, A.; Alhawamdeh, M. Examining the Challenges for Circular Economy Implementation in Construction and Demolition Waste Management: A Comprehensive Review Using Systematic Methods. Buildings 2024, 14, 1237. https://doi.org/10.3390/buildings14051237

Ferriz-Papi JA, Lee A, Alhawamdeh M. Examining the Challenges for Circular Economy Implementation in Construction and Demolition Waste Management: A Comprehensive Review Using Systematic Methods. Buildings. 2024; 14(5):1237. https://doi.org/10.3390/buildings14051237

Chicago/Turabian StyleFerriz-Papi, Juan Antonio, Angela Lee, and Mahmoud Alhawamdeh. 2024. "Examining the Challenges for Circular Economy Implementation in Construction and Demolition Waste Management: A Comprehensive Review Using Systematic Methods" Buildings 14, no. 5: 1237. https://doi.org/10.3390/buildings14051237

APA StyleFerriz-Papi, J. A., Lee, A., & Alhawamdeh, M. (2024). Examining the Challenges for Circular Economy Implementation in Construction and Demolition Waste Management: A Comprehensive Review Using Systematic Methods. Buildings, 14(5), 1237. https://doi.org/10.3390/buildings14051237