Abstract

Historical buildings are constructed using a variety of materials, including stone, wood, and combinations thereof. These structures serve as tangible links to the past and are of great importance to cultural heritage, thus necessitating their protection. Throughout history, these buildings and materials have been exposed to various environmental conditions, including climate, wind, humidity, and seismic activity. This study focused on the Florya Atatürk Marine Mansion, Istanbul, a coastal structure situated at the shoreline and subject to the effects of wind, moisture, and sea salt. The mansion is primarily constructed from pinewood, and due to the complexity of the material salt can cause deterioration that poses a threat to the building’s cultural and historical value. With a focus on seasonal variations, this study explored the relationship between the mechanical properties and monetary values of the pinewood materials used in the waterfront mansion. To achieve this, samples were naturally aged in a saline environment by the sea and subjected to tensile and bending tests at the end of each season. The resulting mechanical properties were compared to computer simulations using finite element methods. By subtracting the specific depreciation rate of the material at the end of each season, a relationship between mechanical properties and monetary value was calculated and presented in graphical form. It was found that the material’s mechanical properties varied throughout the year, affecting its monetary value in different ways. Therefore, optimal maintenance should be provided before January to preserve the economic value of the material, considering temperature change, exposure to direct sunlight, and humidity, which have direct effects on the front and back parts of the building.

1. Introduction

When constructing coastal structures, it is important to consider a variety of issues, such as climate, environment, and geology. Coastal structures are susceptible to different factors, including weak ground, strong winds, and the impact of sea salt on materials [1,2]. Particularly, sea salt can have damaging effects on porous structures, as it causes crystallization–dissolution, hydration–dehydration cycles, and changes in humidity and temperature [3,4,5,6,7,8,9,10,11,12,13]. To minimize the negative impact of salinity, it is important to examine the complex interaction between structural elements and environmental effects. This is particularly important for structures that are directly exposed to the sea. In addition to chemical and biological deterioration, physical and environmental factors have also resulted in wood deterioration. In a study conducted by Hızal [14], the tree species present in a traditional Turkish house located in the Konuralp district, Türkiye, was identified, and the weather conditions and biological degradation of the historical wood were evaluated. Another experimental study by Kherais et al. [15] investigated the impact of moisture content on the mechanical properties of wood structures. Mackiewicz et al. [16] emphasized the importance of maintenance and repair for the long life of wooden structures, and how deformation of wooden roof structures can occur due to biological corrosion, time, looseness in the joints, and decreased strength parameters caused by assembly errors. Water-related degradation of structures is widely accepted to be linked to fluctuations in temperature and humidity [17,18], which are caused by wind and rain [19,20], water leakage [17], and increased humidity [21,22,23]. The growth of microbes and formation of biofilms on cultural heritage structures and wood decay can be promoted by high humidity and water seepage [24,25,26,27,28]. Fluctuations in temperature and humidity can cause stress on wood panels and paint layers, accelerating cracking [29,30]. The severity of salt crystallization is affected by the degree of temperature and humidity fluctuations, while the height and duration of elevated humidity determine the location of salt decomposition [31,32,33]. As revealed by these studies, there are many factors that contribute to the deterioration of structures.

Among these factors, salt is one of the major problems in historical and cultural structures. As a biomaterial, it has a complex anatomical structure [34]. Characteristics of salt can cause deterioration of building elements and threaten the sustainable preservation of historical buildings, which are precious cultural heritage. Salt accumulation in the pores of wooden historical structures can lead to significant damage over time, resulting in color changes, flaking, material loss, and ultimately, structural instability [35,36]. These damages mostly occur in structural sections and gradually move inward from the surface, causing a decrease in the load and deformation capacity of the overall structure and affecting stability [34].

Although wood is a porous material, its properties differ from those of other porous materials such as stone or concrete. The magnitude and type of damage caused by salt on materials depends on various factors, such as the type and amount of salt present, the source of the salt, the properties of the wood, and environmental conditions [37]. These effects are particularly concerning given the cultural and historical value of these structures. However, the specific factors that contribute to salt-related damage in wooden structures are not yet fully understood. Therefore, effective maintenance and protection strategies for these structures require careful consideration. In marine environments containing saltwater, wooden building materials experience time-dependent changes in their mechanical properties, particularly in tensile strength, bending strength, and ductility. It is essential to monitor these changes over time to ensure the maintenance and replacement of various parts of waterfront wood buildings to guard against physical deterioration. Due to Türkiye’s extensive coastline and its population’s preference for coastal living, settlements are mostly located near the sea. This increased the number of historical buildings located in these regions. Istanbul’s historical buildings, situated along the coast, are not only exposed to climate effects but also saltwater effects, primarily surface abrasion due to salting. Wooden structures have been an integral part of Turkish architecture from the past to the present [38]. As such, it is crucial to determine the extent of external factors’ impact, such as climate, saltwater, and other environmental factors, on these buildings and waterside mansions located in coastal areas. Chestnut, larch, oak, beech, and other tree species are commonly used in wooden structure construction in Türkiye [39]. In humid environments, resin-rich and toxin-rich pines are used to reduce the material’s water absorption and protect against insects and fungi [40,41]. This study focuses on examining the impact of moist and salty environments on wooden materials, using pine trees as an example.

From the engineering perspective, it is also crucial to prioritize not only the safety of structures but also their cost-effectiveness. To achieve this, engineers must carefully consider the expenses associated with various methods, materials, products, and structural elements to make decisions that meet safety requirements while also minimizing costs.

Techno-economic evaluation or techno-economic analysis is a method for analyzing the economic performance of an industrial process, product, or service. It often uses software modeling to estimate the cost of capital, operating cost, and revenue based on technical and financial input parameters [42]. In the literature, there are many different areas in which techno-economic analysis was conducted, such as typical dryers with different energy sources [43], various hydrogen production methods [44], biodiesel production [45] asteroid mining [46], hybrid energy systems [47], innovative steel production technologies [48], thermal energy storage [49], green ammonia production processes [50], alternative fuels [51], phytoremediation [52], water desalination [53,54], an isolated hybrid energy system [55], hybrid biomass renewable energy systems [56], hydrogen production [57], renewable fuel alternatives in the maritime sector [58], production [59], electric vehicle charging stations [60], and hydrogen refueling stations [61]. However, no study has been found on the techno-economic analysis of the physical material properties of wooden structures built by the sea under the influence of moisture and salt according to seasonal changes.

Techno-economic evaluation is particularly important in the context of Value Engineering (VE). A limited budget can sometimes result in lower-quality products or solutions that fail to meet customer demands. However, Value Engineering is a valuable tool that allows engineers to analyze building features, systems, functions, equipment, and material selections to reduce costs while maintaining or improving performance and quality requirements. Determining the impact of external factors on wooden structures, as well as the potential loss of value, is crucial for taking necessary precautions and selecting the ideal type of wood as a building element from various alternatives. Value Engineering is an effective method used to identify the most advantageous product, in terms of initial investment and usage cost, that meets specified criteria. To make such a value-based selection, it is necessary to evaluate the benefits that each alternative can provide over its lifespan or within a given timeframe, including changes in performance and value depreciation. This allows for a comparison of products and the selection of the most valuable option for application. By taking into account costs, performance, quality, reliability, and life cycle costs, engineers can identify the most ideal and efficient solutions to problems that offer the best overall value. It is a focused, organized effort [62]. Therefore, it does not only take into account the benefit or the economy but also the “value” calculated by taking advantage of both benefit and cost [63]. The solution with the highest value is the solution that can be implemented.

While numerous studies have examined the decay and degradation of concrete and stone materials in salty marine environments [64,65,66,67,68,69], limited research has been conducted on the detrimental effects of salty air environments on wood [70,71,72,73,74]. In addition, there is still room for exploring the optimal prevention methods for historical heritage buildings by understanding the mechanical properties while considering economic aspects. The conservation of these structures, which requires a thorough understanding of the mechanical properties of the wooden components that make them up, is not just valuable from a historical and artistic perspective but also serves a structural function that must be preserved for safety and usability [75]. In this study, we aim to investigate the relationship between the mechanical properties and monetary values of pinewood materials used in waterfront buildings, with a particular focus on seasonal variations.

2. Materials and Methods

2.1. The Study Area

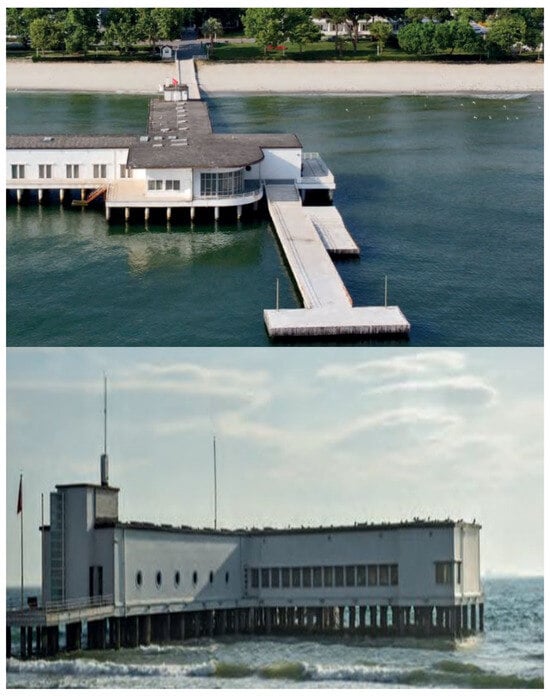

The Bosphorus, a sea that runs through Istanbul, is home to wooden structures and waterside residences built hundreds of years ago and is an integral part of Turkish architecture [38,76]. The Florya Atatürk Marine Mansion, Istanbul, Türkiye, was selected as the study area. It is a historical building located on the coast of Istanbul overlooking the Marmara Sea. Constructed in 1935 by architect Seyfi Arkan under the direction of the Istanbul Municipality, the Atatürk Marine Mansion, which was connected to the shore by a bridge spanning 70 m and built on concrete piles anchored into the seabed (see Figure 1), was created as a summer residence for Atatürk, the founder of the Republic of Türkiye [77].

Figure 1.

Different views of the studied building and placement of specimens [78].

Today, the mansion, which serves as a museum with its single-story L-shaped wooden structure made of specially designed materials and fittings, consisting of a large living room, library, relaxation area, bedrooms, and a bathroom, has undergone significant renovations, replacing part of the structure with reinforced concrete and, despite being a wooden structure, it is built on reinforced concrete legs supported by the sea [77]. However, the mansion has suffered damage from various factors such as seawater, marine environment, climatic conditions, and other events. To protect the mansion, precautions have been taken to maintain its structural integrity. Different views of the studied building and the placement of specimens are shown in Figure 1.

2.2. Sample Preparation

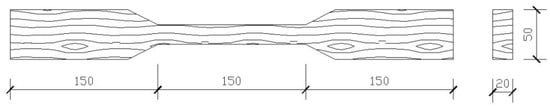

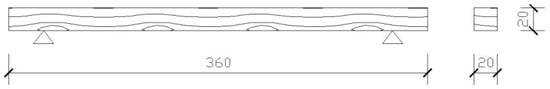

Within the scope of this study, pinewood specimens (Pinus sylvestris) were prepared in the dimensions of 20 × 50 × 400 mm according to the TS 2475 [79] standard for the tensile test and in the dimensions of 20 × 20 × 360 mm according to the TS 2474 [80] standard for the bending test (see Figure 2 and Figure 3).

Figure 2.

Tensile test specimen front and section view.

Figure 3.

Bending test specimen front and section view.

A total of 30 specimens (six for each period) were prepared for each experiment in total. We placed the specimens in the vicinity of a building to expose them to natural conditions and monitored them regularly. Table 1 provides details about the properties of these specimens, including the specific time periods (in months) during which they were placed. The “Season” column lists these periods, while the “Beginning” column refers to the original specimen used as a reference in laboratory testing only. Two types of tests were conducted—tensile and bending—with the number of samples per testing period noted in the “Pcs.” column. The “3 × 2” designation means that three samples were taken for each period, with two of these samples representing the front and back facades. The dimensions of each sample are provided in the “Dimensions” column, while the “Standard” column outlines the applicable testing standards.

Table 1.

Properties and testing specifications of specimens.

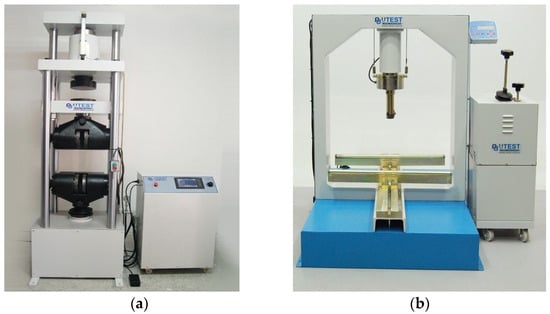

2.3. Equipment and Testing

In this research, both prepared and naturally aged samples underwent a tensile test with the hydraulic universal testing machine marked as UTM-4000 and a bending test with the electromechanical universal test device labeled as UTM-8050, as illustrated in Figure 4. The tensile test involved pulling the samples at a steady speed of 2 m/s while monitoring their strength and elongation up until the point of fracture. Similarly, the specimens were subjected to a 3-point bending test at a constant speed of 2 m/s, and the strength and deflection at the center of the samples were recorded. These tests were conducted at the university’s laboratories.

Figure 4.

The applied laboratory test for the specimens: (a) universal tensile test machine; (b) bending test machine.

2.4. Methods

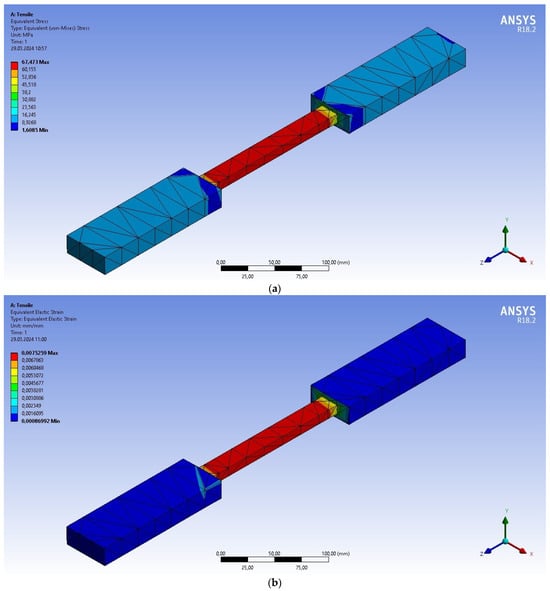

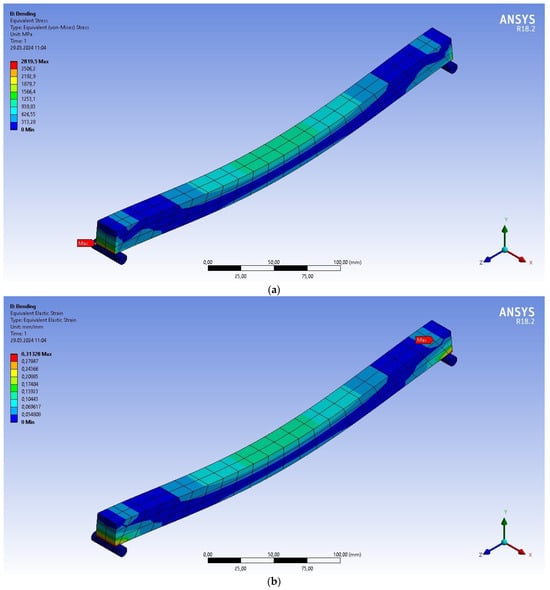

The samples were carefully prepared and left to age naturally in a predetermined seashore area. During the first phase of each period, the original three samples underwent both tensile and bending tests in the lab. At the end of the period, new samples were taken from the same location and every third sample was subjected to the same tests. This process was repeated over the course of several seasons, with each period lasting three months to reflect the changing seasons in Türkiye. The maximum tensile and bending strength values were recorded from the tests. Due to cultural heritage restrictions, the test specimens were monitored for three years and underwent the same procedure annually. The maximum tensile strength (MTS) and maximum bending strength (MBS) results were obtained for each sample, and the average results for all three years were presented in Section 3 for evaluation purposes. These experimental values were then used as input for numerical analysis in ANSYS Workbench v.18.2 software. Figure 5 and Figure 6 illustrate the simulation results for the April–May–June period, and similar results were computed for each period and provided between Table 2, Table 3, Table 4 and Table 5. The simulations yielded equivalent (von Misses) tensile stress (Figure 5a), equivalent (von Misses) bending stress (Figure 6a), equivalent tensile strain (Figure 5b), and bending deformation (Figure 6b) values.

Figure 5.

Stress and strain analysis of specimens for the tensile test: (a) tensile stress; (b) tensile strain modeling.

Figure 6.

Stress and deformation analysis of specimens for the bending test: (a) bending stress; (b) bending deformation.

Table 2.

Average temperature and humidity ratios for each season and pursued years determined from a meteorological station nearby.

The mean percentage of moisture content (%MC) of the specimens ready for mechanical testing was measured as 28.16%. It is important to note that the specimens were exposed to natural conditions, resulting in a change in physical values over time compared to their initial condition. As a result, the economic value of pinewood decreased over time. To calculate the economic value of the material for each period, the experiments were taken into consideration. The initial monetary value of the material was set at 30 €/m2 based on the unit price provided by the Ministry of Environment and Urban Planning in Turkiye [81]. At the end of each period, a certain depreciation rate was applied, which was determined to be 1.25% by the Revenue Administration in Turkiye [82]. The Maximum Equivalent Tensile Stress (METS) per unit value and Maximum Equivalent Bending Stress (MEBS) per unit value were then obtained by dividing each material’s physical properties by the monetary value of the material at the end of each period. Additionally, the change percent for METS and MEBS was calculated for each period and tested in comparison to their initial values by the formula given as follows:

where

- : Change in METS (or MEBS) in n th period.

- : METS (or MEBS) in n th period.

- METS (or MEBS) in the beginning period.

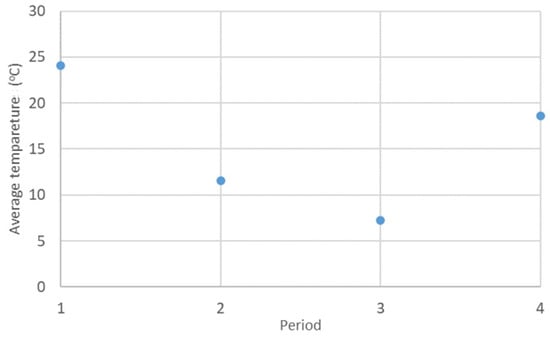

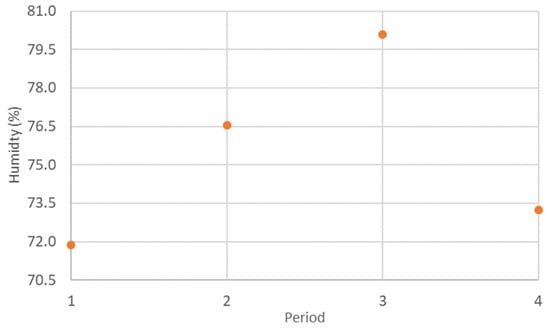

To assess the impact of seasonal and environmental factors on our study, we also gathered data on temperature and humidity from a nearby meteorological station, located 500 m away from the Atatürk Marine Mansion where our research was conducted. Table 2 displays the average values for each season, and we note a decline in temperatures from the first to the third season, followed by a rise in the fourth season. Conversely, humidity levels increase from the first to the third season and continue to rise in the fourth season. In the next section, we compare and evaluate the tensile stress values of our specimens for each season, analyzing their strength and deformation. To provide a visual representation of our findings, we have included Figure 7, which illustrates the relationship between temperature and humidity across the seasons. There is a negative correlation between temperature and humidity, resulting in a decrease in humidity as temperatures rise. Additionally, the warmest temperatures tend to occur in the 1st and 4th periods due to seasonal conditions.

Figure 7.

The variation in average temperature and humidity depending on the pursuing periods.

3. Results and Discussion

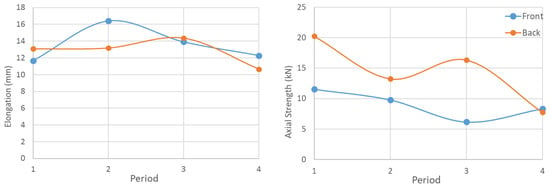

This section investigates the seasonal effects on the tensile behavior of pinewood material. Heat and humidity can have adverse effects on wooden materials, potentially increasing the severity of salt accumulation and causing detrimental effects on the physical properties, strength, and deformation capacity of the material, and can affect the stability of the material [34]. To address this issue, the strength and elongation capacity of pinewood material under tensional effects were deduced, considering the heat and humidity conditions over time, based on experimental results. The average values of strength and elongation measurements were plotted over a period and compared with temperature and humidity variations in Figure 8. These values were obtained by evaluating materials placed in different parts of the building, such as the front and back, to assess the change in mechanical properties and their dependence on seasonal effects.

Figure 8.

The variation in axial strength (left) and elongation (right) of specimens versus pursuing periods determined from tensile test.

Based on Figure 8, it appears that the temperature distribution over time aligns with the axial strength variation in pinewood material, particularly for samples taken from the front-facing side of the building. This suggests that direct sunlight and a more saline environment can affect the strength of pinewood material in building materials. On the other hand, back-facing samples are more susceptible to dry air conditions compared to front-facing ones, and this discrepancy has a nearly twofold impact on the material’s axial strength [83]. When investigating the axial deformation of materials, it seems that humidity also has a greater influence on the elongation, or axial strain, of the material compared to temperature [84]. To address this, in addition to scheduling maintenance during optimal times, thermal modification can be a viable solution for improving the mechanical properties of wooden structures, including strength, dimensional stability, and durability while reducing heterogeneity [85,86]. A study by Zhang et al. [87] on bamboo samples revealed that vacuum thermal modification enhanced dimensional and moisture stability, axial compressive strength, and hardness. In general, elongation, or ductility, of the material increased, but air conditions affected front- and back-facing specimens differently. While both sides experienced an increase in elongation with humidity, front-facing specimens in the second period showed a greater increase compared to back-facing ones. However, front-facing samples responded differently to sunlight and a saline environment, and when humidity levels peaked in the third period, the elongation of back-facing specimens continued to rise while that of front-facing ones plateaued.

In the second phase, we obtained both axial and bending results from experimental studies and these findings are presented in Table 3. The values listed in Table 3 represent the maximum applied forces that resulted in significant decay (i.e., ultimate state) during the experiment. These values were then used as input for the finite element analysis for tensile and bending forces. It is important to note that the models we created were subjected to linear analysis, and for the sake of simplicity, program-controlled automatic meshing was used. As such, we did not provide details on the numerical meshes or their influence on the solution algorithm. However, it is essential to investigate these parameters to fully understand the building’s behavior [88].

Table 3.

Results obtained from bending and tensile experiments.

Table 3.

Results obtained from bending and tensile experiments.

| Period | Season | Max. Applied Tensile Strength (kN) | Max. Applied Strength (kN) |

|---|---|---|---|

| 0 | Beginning | 12.67 | 53.06 |

| 1 | July–August–September | 15.89 | 61.81 |

| 2 | October–November–December | 11.52 | 56.32 |

| 3 | January–February–March | 11.25 | 41.50 |

| 4 | April–May–June | 8.05 | 56.51 |

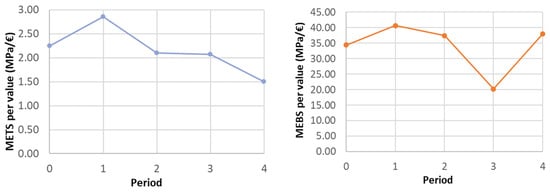

After conducting FEM analysis using the input values from Table 3, we were able to obtain the Maximum Equivalent Tensile Stress (METS) and Maximum Equivalent Bending Stress (MEBS) values. These values were then presented in Table 4 and Table 5, respectively, allowing for an economic analysis of both bending and axial stress values of pinewood material. Utilizing the FEM analysis results and calculation outlined in the previous section (i.e., Equation (1)), we drew a comparative graph in Figure 3 to illustrate the economic change in pinewood material. According to the tensile test results, the Maximum Equivalent Tensile Stress values increased from the initial value of 67.47 MPa to 84.62 MPa in the first period, before decreasing to 42.86 MPa in the following periods. Additionally, the METS per unit value of the material increased by 27% in the first period and decreased by around 33% at the end of the year. As a result, the monetary value of the material at the end of the first, second, third, and fourth periods was calculated as 29.62 €/m2, 29.25 €/m2, 28.87 €/m2, and 28.50 €/m2, respectively. These values were calculated based on the initial value per unit volume, in this way loss of monetary values was compared to initial conditions. Except for the first period per unit, losses are deepened in the last seasons of the year. It seems that the third period is critical especially if the tensile stress and strength values are considered.

Table 4.

The change in per unit value according to Maximum Equivalent Tensile Stress (METS).

Table 4.

The change in per unit value according to Maximum Equivalent Tensile Stress (METS).

| Period | Season | Max. Equivalent Tensile Stress (METS) (FEM Analysis) (MPa) | Value (€/m2) | METS per Unit Value (MPa/€) | % Change |

|---|---|---|---|---|---|

| 0 | Beginning | 67.47 | 30.00 | 2.25 | 0.0 |

| 1 | July–August–September | 84.62 | 29.62 | 2.86 | 27.0 |

| 2 | October–November–December | 61.34 | 29.25 | 2.10 | −6.8 |

| 3 | January–February–March | 59.91 | 28.87 | 2.08 | −7.7 |

| 4 | April–May–June | 42.86 | 28.50 | 1.50 | −33.1 |

Table 5.

The change in per unit value according to Maximum Equivalent Bending Stress (MEBS).

Table 5.

The change in per unit value according to Maximum Equivalent Bending Stress (MEBS).

| Period | Season | Max. Equivalent Bending Stress (MEBS) (FEM Analysis) (MPa) | Value (€/m2) | MEBS per Unit Value (MPa/€) | % Change |

|---|---|---|---|---|---|

| 0 | Beginning | 1032.1 | 30 | 34.4033 | 0 |

| 1 | July–August–September | 1205.0 | 29.62 | 40.6820 | 18.3 |

| 2 | October–November–December | 1095.2 | 29.25 | 37.4427 | 8.8 |

| 3 | January–February–March | 584.4 | 28.87 | 20.2445 | −41.2 |

| 4 | April–May–June | 1082.5 | 28.5 | 37.9825 | 10.4 |

As depicted in Table 5, the maximum bending forces determined from experiments were 53.06, 61.81, 56.32, 41.50, and 56.51 MPa for the first to fourth periods, respectively. When these bending forces were applied in the FEM model, MEBS values were calculated as shown in the table. Based on the bending test results, the MEBS values increased from the initial value of 1032.1 MPa to 1205 MPa in the first period and then decreased to 1082.5 MPa in the following periods. Additionally, the MEBS per unit value of the material increased by 18.3% in the first period, and then dramatically reduced to around 41% in the third period. Although a small increment was observed in the fourth period compared to the initial conditions, it is not of primary importance as the dramatic decrease observed in the third period. This increment may be partly due to increases in temperatures in the region.

The economic changes in per unit values, as calculated in Table 4 and Table 5, are visually represented in Figure 9. It is clear that the curves in both figures increase at first and then dramatically decrease in the third period of the year. The results show that the Maximum Equivalent Tensile Strength (METS) per unit value reaches its lowest point in the fourth period, but the decrement is relatively smaller than in the third period. Additionally, the Maximum Equivalent Bending Stress (MEBS) per unit value reaches its minimum value in the third period, resulting in a very low economic value. However, it does receive a relatively lower increment in the fourth period compared to the previous one. Therefore, it can be concluded that the loss of economic value due to changes in the physical properties of the wooden material mainly occurs in the third and fourth periods, which are exposed to marine weather conditions. Due to concerns surrounding the sustainable sourcing of wood as a raw material and procurement issues [89], the monetary values of timber structures are increasingly crucial compared to other construction methods.

Figure 9.

The change in per unit values of material over the pursuing periods determined from the tensile test (left) and bending test (right).

To preserve the economic value and originality of the material, we recommend performing annual maintenance before the start of the third period (i.e., before January). This will ensure optimal maintenance of the building. Currently, the maintenance of entire buildings occurs yearly at varying times without regard for the facade. Moreover, simple water paintwork is applied without considering environmental conditions. This study monitors the effect of environmental conditions on different facades and highlights the rationale behind selecting a maintenance period that prioritizes both sustainability and optimal economic conditions. The experimental results also indicate that protection against saline environments is necessary. As a result of this study, the third period is deemed the best option for maintenance, and various solutions can be adapted for different facades, such as waterproof or nanomaterials, to improve and protect wooden materials [90,91]. A preventative method that can also be employed is safeguarding. Mi et al. [92] conducted a study on the Yingxian Wooden Pagoda to establish an effective repair and restoration method for safeguarding the wooden components of historical buildings. They analyzed a few aged samples using various chemical techniques to determine the effects of sunlight and oxidation on the structure and to develop strategies to prevent surface deterioration.

This study explored an experimental approach, but there are other methods that can be employed to better understand the key factors contributing to the deterioration of wooden structures. For example, Deng et al. [93] utilized a variety of techniques, such as bright-field microscopy, polarized light, fluorescence, and Fourier-transform infrared (FTIR) spectroscopy, to identify wood species and assess the extent of material degradation in the walkway of the first courtyard of the Ancient Yangjia Courtyard. Similarly, Chen et al. [94] developed logistic regression models to evaluate the degradation levels of historically and culturally significant structures. Their model revealed that factors such as age, type, style, and value are important predictors of the extent of deterioration in historical buildings. In the case of historical wooden structures, there are numerous factors.

The conclusions drawn from this study have significant practical implications. Knowing the ideal time for the upkeep of wooden historical structures in coastal areas and identifying methods to improve mechanical properties while minimizing costs are crucial in the preservation of such structures. This research will also aid policymakers and local authorities in prolonging the lifespan of historical buildings, implementing new techniques for better management, and increasing the value of cultural heritage.

4. Conclusions

Wooden structures may have a shorter lifespan and be vulnerable to external factors if not properly protected. The location and exposure of wooden elements in architecture play a crucial role in their deterioration. Different factors affect the mechanical characteristics of the timber structures. Additionally, wooden elements in damp and wet environments are susceptible to brown rot fungi, while those near the ground may be attacked by insects like worms, leading to a decline in mechanical properties [95].

Wooden structures, particularly those situated near the sea, are susceptible to deterioration caused by salt. This poses a significant challenge to the preservation of historical and cultural landmarks that rely on these structures for their tourism value. Therefore, it is crucial to find sustainable ways to protect these structures from the harmful effects of salt. Research shows that salt accumulation in building materials exposed to the natural environment can lead to various forms of damage such as color changes, flaking, material loss, and even decomposition, ultimately compromising the stability, load, and deformation capacity of the structure.

Türkiye is a country that boasts a coastline surrounded by the sea on three sides. Along this beautiful coastline lies Istanbul, the most populous and developed city in Türkiye with a history dating back thousands of years. These historical wooden structures, not only in Istanbul but in other coastal cities, need protection from external factors to be preserved for future generations. Due to their proximity to the sea, these structures are particularly susceptible to the damaging effects of sea salt and other environmental factors that affect their physical and economic lifespan. Regular maintenance with appropriate materials and methods will ensure their longevity, and prevent the loss of cultural heritage. Through experimental and computer models, this study was conducted to investigate the changes in technical and economic values of the pinewood material used in waterfront buildings using Florya Atatürk Marine Mansion in different seasons. According to the obtained results, the following issues are highlighted below:

- The temperature change observed between the periods aligns with the tensile strength distribution of pinewood material, particularly for specimens taken from the front side of the building that are exposed to more severe environmental conditions. Similar results that emphasize this phenomenon have been shown in the literature [96,97,98].

- Exposure to direct sunlight and a more saline environment affects the strength of specimens.

- The axial deformation of specimens shows that humidity has a greater impact on the deformation capacity of pinewood material compared to temperature effects. This outcome has also been outlined by many researchers [99,100,101,102].

- It is worth noting that the axial and bending behavior of pinewood material may slightly differ, depending on how much exposure it has to severe conditions. This was observed for materials placed in distinct parts of the building, such as the front and back.

- This study revealed that the material’s economic worth primarily diminishes due to exposure to marine weather conditions during the third and fourth periods. The material’s monetary value was calculated to be 29.62 €/m2, 29.25 €/m2, 28.87 €/m2, and 28.50 €/m2 at the end of the first, second, third, and fourth periods, respectively. The MEBS per unit value of the material plummeted to roughly 41% in the third period. The METS per unit value of the material decreased by around 33% by year-end. Therefore, optimal maintenance to preserve the economic value of the material can be provided before January.

These results highlight the importance of annual maintenance for pinewood used in waterfront structures. Future studies can apply the same methodology to different types of wood used in waterfront structures.

Author Contributions

Conceptualization, I.C.Y., H.T., M.P. and Ş.A.; methodology, I.C.Y., H.T. and M.P.; software, I.C.Y.; validation, I.C.Y., H.T. and M.P.; formal analysis, I.C.Y. and M.P.; investigation, H.T. and Ş.A.; resources, I.C.Y. and H.T.; data curation, I.C.Y.; writing—original draft preparation, I.C.Y., H.T., M.P. and Ş.A.; writing—review and editing, I.C.Y., H.T., M.P. and Ş.A.; visualization, I.C.Y. and H.T.; supervision, M.P and Ş.A.; project administration, H.T., M.P. and Ş.A.; funding acquisition, I.C.Y., H.T., M.P. and Ş.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to it contains commercial information.

Acknowledgments

We would like to thank the Republic of Türkiye, National Places, Assembly of Türkiye and National Palaces for their support to our work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, T.; Yuan, S.; Yuan, K.; and Luo, K. Study on key points and countermeasures of a coastal construction project. In Today’s Modern Coastal Society: Technical and Sociological Aspects of Coastal Research; Liu, X., Zhao, L., Eds.; Journal of Coastal Research, Special Issue No. 111; Coastal Education & Research Foundation: Coconut Creek, FL, USA, 2020; pp. 113–117. ISSN 0749-0208. [Google Scholar]

- Price, C.; Doehne, A.; Stone, E. Conservation: An Overview of Current Research, 2nd ed.; J Paul Getty Museum Publications: Los Ángeles, CA, USA, 2010. [Google Scholar]

- Delgado, J.M.P.Q.; Guimarães, A.S.; Freitas, V.P.; Antepara, I.; Kočí, V.; Černý, R. Salt damage and rising damp treatment in building structures. Adv. Mater. Sci. Eng. 2016, 2016, 1280894. [Google Scholar] [CrossRef]

- Charola, A.E. Salts in the Deterioration of porous materials: An overview. J. Am. Inst. Con-Servation 2000, 39, 327–343. [Google Scholar] [CrossRef]

- Kalbarczyk, R.; Ziemianska, M. The effect of air temperature, precipitation and humidity on ring widths in the Black locust (Robinia pseudoacacia L.) growing in urban conditions. Wood Res. 2016, 61, 351–362. [Google Scholar]

- Lubelli, B.; Cnudde, V.; Diaz-Goncalves, T.; Franzoni, E.; van Hees, R.P.J.; Ioannou, I.; Menendez, B.; Nunes, C.; Siedel, H.; Stefanidou, M.; et al. Towards a more effective and reliable salt crystallization test for porous building materials: State of the art. Mater. Struct. 2018, 51, 55. [Google Scholar] [CrossRef]

- Guimarães, A.S.; Gonçalves, T.D.; Azevedo, J. Soluble salts amplify the effect of small heterogeneities in the structure of porous building materials during drying. Int. J. Arch. Herit. 2016, 10, 766–776. [Google Scholar] [CrossRef]

- Saidov, T.A.; Pel, L.; Kopinga, K. Sodium sulfate salt weathering of porous building materials studied by NMR. Mater. Struct. 2017, 50, 145. [Google Scholar] [CrossRef]

- Espinosa, R.M.; Franke, L.; Deckelmann, G. Phase changes of salts in porous materials: Crystallization, hydration and deliquesce. Constr. Build. Mater. 2018, 22, 1758–1773. [Google Scholar] [CrossRef]

- Castellazzi, G.; de Miranda, S.; Grementieri, L.; Molari, L.; Ubertini, F. Multiphase model for hygrothermal analysis of porous media with salt crystallization and hydration. Mater. Struct. 2016, 49, 1039–1063. [Google Scholar] [CrossRef]

- Varas, M.J.; Buergo, M.A.; Fort, R. The influence of past protective treatments on the deterioration of historic stone façades. A Case Study. Stud. Conserv. 2017, 52, 110–124. [Google Scholar] [CrossRef]

- Grossi, C.M.; Esbert, R.M.; Rio, L.M.; Montoto, M.; Tabasso, M.L. Acoustic emission monitoring to study sodium sulphate crystallization in monumental porous carbonate stones. Stud. Conserv. 1997, 42, 115–125. [Google Scholar] [CrossRef]

- Koniorczyk, M. Salt transport and crystallization in non-isothermal, partially saturated porous materials considering ions interaction model. Int. J. Heat. Mass. Transf. 2012, 55, 665–679. [Google Scholar] [CrossRef]

- Hızal, K.T. Species and deterioration of woods used in a traditional Turkish house. BioResources 2024, 19, 872. [Google Scholar] [CrossRef]

- Kherais, M.; Csébfalvi, A.; Len, A.; Fülöp, A.; Pál-Schreiner, J. The effect of moisture content on the mechanical properties of wood structure. Pollack Period. 2024, 19, 41–46. [Google Scholar] [CrossRef]

- Mackiewicz, M.; Zimiński, K.; Pawłowicz, J.; Knyziak, P. Evaluation of the historic wooden structure condition based on the results of non-destructive tests. Eng. Fail. Anal. 2024, 159, 108116. [Google Scholar] [CrossRef]

- Yao, S.; Yan, Z.; Ma, Q.; Xu, B.; Zhang, Z.; Bi, W.; Zhang, J. Analysis of the annual hygrothermal environment in the Maijishan Grottoes by field measurements and numerical simulations. J. Affect. Disord. 2022, 221, 109229. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y. Maintenance schedule optimization based on distribution characteristics of the extreme temperature and relative humidity of Cave 87 in the Mogao Grottoes. Herit. Sci. 2023, 11, 158. [Google Scholar] [CrossRef]

- Luo, Y.; Yin, B.; Peng, X.; Xu, Y.; Zhang, L. Wind-rain erosion of Fujian Tulou Hakka Earth Buildings. Sustain. Cities Soc. 2019, 50, 101666. [Google Scholar] [CrossRef]

- Martínez-Martínez, J.; Abellán, A.; Berrezueta, E. Erosion directionality and seasonality study using the anisotropy matrix. Application in a semiarid Mediterranean climate (SE Spain). Sci. Total Environ. 2022, 804, 150165. [Google Scholar] [CrossRef] [PubMed]

- Franzoni, E.; Berk, B.; Bassi, M.; Marrone, C. An integrated approach to the monitoring of rising damp in historic brick masonry. Constr. Build. Mater. 2023, 370, 130631. [Google Scholar] [CrossRef]

- Li, Y.; Ma, Y.; Xie, H.; Li, J.; Li, X. Cross validation of hygrothermal properties of historical Chinese blue bricks with isothermal sorption experiments. Front. Arch. Res. 2021, 10, 164–175. [Google Scholar] [CrossRef]

- Li, Y.-H.; Kong, Z.-Y.; Xie, H.-R.; Ma, Y.; Mu, B.-G.; Hokoi, S. Construction type influences features of rising damp of blue-brick masonry walls. Constr. Build. Mater. 2021, 284, 122791. [Google Scholar] [CrossRef]

- Bartoli, F.; Municchia, A.C.; Futagami, Y.; Kashiwadani, H.; Moon, K.H.; Caneva, G. Biological colonization patterns on the ruins of Angkor temples (Cambodia) in the biodeterioration vs bioprotection debate. Int. Biodeter. Biodegr. 2014, 96, 157–165. [Google Scholar] [CrossRef]

- Liu, X.; Koestler, R.J.; Warscheid, T.; Katayama, Y.; Gu, J.-D. Microbial deterioration and sustainable conservation of stone monuments and buildings. Nat. Sustain. 2020, 3, 991–1004. [Google Scholar] [CrossRef]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and Inside Building Components. Ph.D. Thesis, Fraunhofer Institute for Building Physics, Stuttgart, Germany, 2001; pp. 75–141. [Google Scholar]

- Sterflinger, K.; Little, B.; Pinar, G.; Pinzari, F.; Rios, A.D.L.; Gu, J.-D. Future directions and challenges in biodeterioration research on historic materials and cultural properties. Int. Biodeterior. Biodegrad. 2018, 129, 10–12. [Google Scholar] [CrossRef]

- Vasanthakumar, A.; DeAraujo, A.; Mazurek, J.; Schilling, M.; Mitchell, R. Microbiological survey for analysis of the brown spots on the walls of the tomb of King Tutankhamun. Int. Biodeterior. Biodegrad. 2013, 79, 56–63. [Google Scholar] [CrossRef]

- McAllister, D.; Warke, P.; McCabe, S. Stone temperature and moisture variability under temperate environmental con-ditions: Implications for sandstone weathering. Geomorphology 2017, 280, 137–152. [Google Scholar] [CrossRef]

- Wu, R.; Ma, Y.; Xie, H.; Wang, X.; Hokoi, S.; Yue, Y.; Hu, J.; Mu, B.; Li, Y. Influence of solar radiation on the surface loss of the painted statues in Grotto No. 3 of Maijishan Grottoes, China. J. Affect. Disord. 2023, 240, 110416. [Google Scholar] [CrossRef]

- Barone, G.; Mazzoleni, P.; Pappalardo, G.; Raneri, S. Microtextural and microstructural influence on the changes of physical and mechanical proprieties related to salts crystallization weathering in natural building stones. Ex. Sabucina Stone (Sicily). Constr. Build. Mater. 2015, 95, 355–365. [Google Scholar] [CrossRef]

- Derluyn, H.; Moonen, P.; Carmeliet, J. Deformation and damage due to drying-induced salt crystallization in porous limestone. J. Mech. Phys. Solids 2014, 63, 242–255. [Google Scholar] [CrossRef]

- Xia, C.; Liu, D.; Kong, Z.; Xie, H.; Mu, B.; Hokoi, S.; Li, Y. Spatial and temporal changes in microclimate affect disease distribution in two ancient tombs of Southern Tang Dynasty. Heliyon 2023, 9, e18054. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Li, T.; Wang, J.; Hu, Y. Evaluation of Salt-Induced Damage to Aged Wood of Historical Wooden Buildings. Int. J. Anal. Chem. 2020, 2020, 8873713. [Google Scholar] [CrossRef] [PubMed]

- Korkanç, M. Deterioration of different stones used in historical buildings within Nigde province, Cappadocia. Constr. Build. Mater. 2013, 48, 789–803. [Google Scholar] [CrossRef]

- Ruffolo, S.A.; Russa, M.F.; Aloise, P.; Belfiore, C.M.; Macchia, A.; Pezzino, A.; Crisci, G.M. Efficacy of nanolime in restoration procedures of salt weathered limestone rock. Appl. Phys. A 2013, 114, 753–758. [Google Scholar] [CrossRef]

- Lubelli, B.; van Hees, R.P.; Groot, C.J. The role of sea salts in the occurrence of different damage mechanisms and decay patterns on brick masonry. Constr. Build. Mater. 2004, 18, 119–124. [Google Scholar] [CrossRef]

- Kuban, D. Turkish Wooden House Architecture 17–19th Centuries; Işbank Culture Publications: Istanbul, Türkiye, 2020. [Google Scholar]

- Yaman, F.Z. Long Term Performance of Elements in Traditional Wooden Buildings—A Case Study in Zeytinlik District in Giresun. Ph.D. Thesis, Istanbul Technical University, Institute of Science and Technology, Istanbul, Türkiye, 2007. [Google Scholar]

- Perker, Z.S.; Akıncıtürk, N. Deteriorations of Wooden Building Components in Cumalıkızık. Uludağ Univ. J. Fac. Eng. 2006, 11, 43–51. [Google Scholar]

- Sahin, N. Traditional Wooden Frame Construction Technique for Ankara House, Wooden Magazine; The Union of Chambers of Turkish Engineers and Architects (TMMOB): Istanbul, Türkiye, 1995. [Google Scholar]

- Burk, C. Techno-economic modeling for new technology development. Chem. Eng. Prog. 2018, 114, 43–52. [Google Scholar]

- Sodha, M.; Chandra, R.; Pathak, K.; Singh, N.; Bansal, N. Techno-economic analysis of typical dryers. Energy Convers. Manag. 1991, 31, 509–513. [Google Scholar] [CrossRef]

- Kannah, R.Y.; Kavitha, S.; Preethi; Karthikeyan, O.P.; Kumar, G.; Dai-Viet, N.V.; Banu, J.R. Techno-economic assessment of various hydrogen production methods—A review. Bioresour. Technol. 2021, 319, 124175. [Google Scholar] [CrossRef]

- Marchetti, J.; Miguel, V.; Errazu, A. Techno-economic study of different alternatives for biodiesel production. Fuel Process. Technol. 2008, 89, 740–748. [Google Scholar] [CrossRef]

- Hein, A.M.; Matheson, R.; Fries, D. A techno-economic analysis of asteroid mining. Acta Astronaut. 2020, 168, 104–115. [Google Scholar] [CrossRef]

- Ali, F.; Ahmar, M.; Jiang, Y.; AlAhmad, M. A techno-economic assessment of hybrid energy systems in rural Pakistan. Energy 2021, 215, 119103. [Google Scholar] [CrossRef]

- Fischedick, M.; Marzinkowski, J.; Winzer, P.; Weigel, M. Techno-economic evaluation of innovative steel production technologies. J. Clean. Prod. 2014, 84, 563–580. [Google Scholar] [CrossRef]

- Yang, T.; Liu, W.; Kramer, G.J.; Sun, Q. Seasonal thermal energy storage: A techno-economic literature review. Renew. Sustain. Energy Rev. 2021, 139, 110732. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Van Herle, J.; Maréchal, F.; Desideri, U. Techno-economic comparison of green ammonia production processes. Appl. Energy 2019, 259, 114135. [Google Scholar] [CrossRef]

- Albrecht, F.G.; König, D.H.; Baucks, N.; Dietrich, R.-U. A standardized methodology for the techno-economic evaluation of alternative fuels—A case study. Fuel 2017, 194, 511–526. [Google Scholar] [CrossRef]

- Wang, J.; Delavar, M.A. Techno-economic analysis of phytoremediation: A strategic rethinking. Sci. Total Environ. 2023, 902, 165949. [Google Scholar] [CrossRef] [PubMed]

- Shokri, A.; Fard, M.S. Techno-economic assessment of water desalination: Future outlooks and challenges. Process. Saf. Environ. Prot. 2023, 169, 564–578. [Google Scholar] [CrossRef]

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Khatri, K.A.; Shah, K.B.; Logeshwaran, J.; Shrestha, A. Genetic algorithm based techno-economic optimization of an isolated hybrid energy system. CRF 2023, 8, 1447–1450. [Google Scholar]

- Tehrani, M.M.; Akhtari, M.; Kasaeian, A.; Rad, M.A.V.; Toopshekan, A.; Motlagh, M.S. Techno-economic investigation of a hybrid biomass renewable energy system to achieve the goals of SDG-17 in deprived areas of Iran. Energy Convers. Manag. 2023, 291, 117319. [Google Scholar] [CrossRef]

- de Abreu, V.H.S.; Pereira, V.G.F.; Proença, L.F.C.; Toniolo, F.S.; Santos, A.S. A Systematic Study on Techno-Economic Evaluation of Hydrogen Production. Energies 2023, 16, 6542. [Google Scholar] [CrossRef]

- Mukherjee, A.; Bruijnincx, P.; Junginger, M. Techno-economic competitiveness of renewable fuel alternatives in the marine sector. Renew. Sustain. Energy Rev. 2023, 174, 113127. [Google Scholar] [CrossRef]

- Abbas, M.K.; Hassan, Q.; Tabar, V.S.; Tohidi, S.; Jaszczur, M.; Abdulrahman, I.S.; Salman, H.M. Techno-economic analysis for clean hydrogen production using solar energy under varied climate conditions. Int. J. Hydrogen Energy 2023, 48, 2929–2948. [Google Scholar] [CrossRef]

- Hasan, S.; Zeyad, M.; Ahmed, S.M.; Mahmud, D.M.; Anubhove, S.T.; Hossain, E. Techno-economic feasibility analysis of an electric vehicle charging station for an International Airport in Chattogram, Bangladesh. Energy Convers. Manag. 2023, 293. [Google Scholar] [CrossRef]

- Oyewole, O.L.; Nwulu, N.I.; Okampo, E.J. Techno-economic investigation of hybrid peaker plant and hydrogen refu-elling station. Int. J. Hydrogrn Energy 2024, 49, 509–529. [Google Scholar] [CrossRef]

- Atabay, S.; Dikmeoglu, N.E. Selection of materials by value engineering method in construction sector. J. Tech. Sci. 2018, 8, 15–22. [Google Scholar]

- Dell’Isola, A. Value Engineering: Practical Applications… for Design, Construction, Maintenance and Operations; John Wiley & Sons: Hoboken, NJ, USA, 1997; Volume 35. [Google Scholar]

- Morcillo, M.; Chico, B.; Mariaca, L.; Otero, E. Salinity in marine atmospheric corrosion: Its dependence on the wind regime existing in the site. Corros. Sci. 2000, 42, 91–104. [Google Scholar] [CrossRef]

- Erkal, A.; D’ayala, D.; Sequeira, L. Assessment of wind-driven rain impact, related surface erosion and surface strength reduction of historic building materials. J. Affect. Disord. 2012, 57, 336–348. [Google Scholar] [CrossRef]

- Meira, M.C.; Andrade, I.J.; Padaratz, M.C.; Alonso, J.C.; Borba, J.R. Measurements and modelling of marine salt trans-portation and deposition in a tropical region in Brazil. Atmos. Environ. 2006, 40, 5596–5607. [Google Scholar] [CrossRef]

- Chabas, A.; Jeannette, D.; Lefèvre, R. Crystallization and dissolution of airborne sea-salts on weathered marble in a coastal environment at Delos (Cyclades–Greece). Atmos. Environ. 2000, 34, 219–224. [Google Scholar] [CrossRef]

- Alao, O.; Alexander, M.; Beushausen, H. Understanding the influence of marine microclimates on the durability per-formance of RC structures. In Construction Materials and Structures; Ekolu, S., Dundu, M., Gao, X., Eds.; IOS Press: Amsterdam, The Netherlands, 2014; pp. 1060–1067. [Google Scholar]

- Cardell, C.; Delalieux, F.; Roumpopoulos, K.; Moropoulou, A.; Auger, F.; Van Grieken, R. Salt-induced decay in calcareous stone monuments and buildings in a marine environment in SW France. Constr. Build. Mater. 2003, 17, 165–179. [Google Scholar] [CrossRef]

- Kirker, G.T.; Brischke, C.; Passarini, L.; Zelinka, S.L. Salt damage in wood: Controlled laboratory exposures and mechanical property measurements. Wood Fiber Sci. 2020, 52, 44–52. [Google Scholar] [CrossRef]

- Gomez, R.; Asencio, A.D.; Picon, J.M.; Campo, R.; Arce, M.I.; Montoya, M.S.; Suarez, M.L.; Abarca, M.R. The effect of water salinity on wood breakdown in semiarid Mediterranean stream. Sci. Total Environ. 2016, 541, 491–501. [Google Scholar] [CrossRef] [PubMed]

- Borges, L.M.S. Biodegradation of wood exposed in the marine environment: Evaluation of the hazard posed by marine wood-borers in fifteen European sites. Int. Biodeterior. Biodegrad. 2014, 96, 97–104. [Google Scholar] [CrossRef]

- Treu, A.; Zimmer, K.; Brischke, C.; Larney, E.; Goballen, L.; Aloui, F.; Cragg, S.; Flaete, P.O.; Humar, M.; Westin, M.; et al. Durability and protection of timber structures in marine environments in Europe. Overv. BioResour. 2019, 14, 10161–10184. [Google Scholar] [CrossRef]

- Azmi, M.S.; Wai, L.C.; Abdulaziz, H.; Yhaya, M.F.; Ismail, N.; Tajarudin, H.A.; Abdulaziz, H.; Ng, K.K. Preservation of rubber wood against bio-logical decay by salts derived from leachate. Wood Res. 2017, 62, 863–872. [Google Scholar]

- Nocetti, M.; Aminti, G.; Vicario, M.; Brunetti, M. Mechanical properties of ancient wood structural elements assessed by visual and machine strength grading. Constr. Build. Mater. 2024, 411, 134418. [Google Scholar] [CrossRef]

- Kahya, E. Waterside Houses in the Cultural Geography of the Bosphorus. In Geographical Research; Balcıoğulları, A., Ed.; Academician Kitabevi Inc.: Ankara, Türkiye, 2020. [Google Scholar]

- Kulturportali. 2024. Available online: https://www.kulturportali.gov.tr/turkiye/istanbul/gezilecekyer/florya-ataturk-denz-kosku (accessed on 20 February 2024).

- TBMM. 2021. Available online: https://www5.tbmm.gov.tr/yayinlar/2022/Florya_Ataturk_Deniz_Kosku_Kitabi.pdf (accessed on 20 February 2024).

- TS 2475; Determination of Ultimate Tensile Stress Parallel to Grain of Wood. Institute of Turkish Standards: Ankara, Turkey, 1976.

- TS 2474; Determination of Static Bending Properties of Wood. Institute of Turkish Standards: Ankara, Turkey, 1976.

- Presidency of the Supreme Scientific Council. Construction and Installation Unit Prices; Ministry of Environment and Urbanization: Ankara, Turkiye, 2018; ISBN 9781111168339. [Google Scholar]

- Revenue administration General Statement in Rate of Depreciation. Available online: https://www.gib.gov.tr/sites/default/files/fileadmin/user_upload/Yararli_Bilgiler/amortisman_oranlari.pdf (accessed on 20 February 2024).

- Meier, P.; Stöör, E.; Kaps, T.; Kallavus, U. Mechanical properties of pinewood (Pinus Sylvestris) swollen in organic liquids. Proc. Est. Acad. Sci. Eng. 2006, 12, 125. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.E. Fracture properties of wood and wood composites. Advanced Engineering Materials 2009, 11, 600–606. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—A review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Bonfatti, E.A.; Nisgoski, S.; de Muñiz, G.I.B.; Klock, U. Properties of thermally modified teakwood. Maderas-Cienc. Tecnol. 2021, 23, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, Y.; Wang, J.; Yi, J.; Wang, G. Effect of Thermal Modification on Axial Compression Properties and Hardness of Laminated Bamboo. Constr. Build. Mater. 2024, 411, 134747. [Google Scholar] [CrossRef]

- Figiel, Ł.; Kamiński, M. Numerical probabilistic approach to sensitivity analysis in a fatigue delamination problem of a two layer composite. Appl. Math. Comput. 2009, 209, 75–90. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Aus-tria-Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative wood surface treatments based on nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef]

- Marzi, T. Nanostructured materials for protection and reinforcement of timber structures: A review and future chal-lenges. Constr. Build. Mater. 2015, 97, 119–130. [Google Scholar] [CrossRef]

- Mi, X.; Li, Y.; Qin, X.; Li, J. Effects of natural weathering on aged wood from historic wooden building: Diagnosis of the oxidative degradation. Herit. Sci. 2023, 11, 109. [Google Scholar] [CrossRef]

- Deng, Y.; Li, Y.; Li, A. Seismic Safety Assessments of Historical Timber Buildings Using Updated Finite Element Models: Case Study of Yingxian Wooden Pagoda, China. J. Build. Eng. 2023, 63, 105454. [Google Scholar] [CrossRef]

- Chen, S.; Chen, J.; Yu, J.; Wang, T.; Xu, J. Prediction of Deterioration Level of Heritage Buildings Using a Logistic Re-gression Model. Buildings 2023, 13, 1006. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, B.; Qi, J.; Yuan, H.; Zhou, Y.; Luo, B.; Deng, S.; Xia, Y. The deterioration state and degradation mechanism of historical timber structures from the Yunnan Military Academy. Wood Mater. Sci. Eng. 2023, 18, 1878–1887. [Google Scholar] [CrossRef]

- Marais, B.N.; Brischke, C.; Militz, H. Wood durability in terrestrial and aquatic environments—A review of biotic and abiotic influence factors. Wood Mater. Sci. Eng. 2022, 17, 82–105. [Google Scholar] [CrossRef]

- Hernández, R.E.; Passarini, L.; Koubaa, A. Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci. Technol. 2014, 48, 1281–1301. [Google Scholar] [CrossRef]

- Roman, K.; Grzegorzewska, E.; Leszczyński, M.; Pycka, S.; Barwicki, J.; Golisz, E.; Zatoń, P. Effect of Seawater with Average Salinity on the Moisture Content, Ash Content and Tensile Strength of Some Coniferous Wood. Materials 2023, 16, 2984. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Akitsu, H.; Miyamoto, K.; Tohmura, S.-I.; Inoue, A. Effects of time, temperature, and humidity on acetaldehyde emission from wood-based materials. J. Wood Sci. 2014, 60, 207–214. [Google Scholar] [CrossRef]

- Sinha, A.; Nairn, J.A.; Gupta, R. The effect of elevated temperature exposure on the fracture toughness of solid wood and structural wood composites. Wood Sci. Technol. 2012, 46, 1127–1149. [Google Scholar] [CrossRef]

- Yeh, B.; Schniewind, A.P. Elasto-plastic fracture mechanics of wood using J integral method. Wood Fiber Sci. 1992, 24, 364–376. [Google Scholar]

- Lopez, J.L.; Sain, M.; Cooper, P. Performance of natural-fiber–plastic composites under stress for outdoor applica-tions: Effect of moisture, temperature, and ultraviolet light exposure. J. Appl. Polym. Sci. 2006, 99, 2570–2577. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).