Design Analysis of Mass Timber and Volumetric Modular Strategies as Counterproposals for an Existing Reinforced Concrete Hotel

Abstract

1. Introduction

1.1. Prefabrication Definition

1.2. Prefabrication Advantages

1.3. Prefabrication Difficulties

1.4. Challenges

1.5. How to Increase Prefabrication

1.6. Aim of this Article

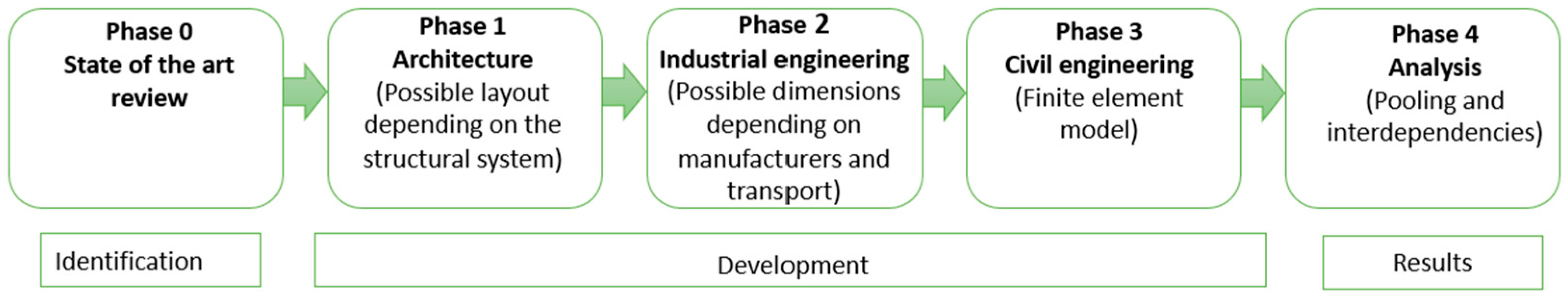

2. Materials and Methods

2.1. Phase 0: State-of-the-Art Review and Building Features

- Keeping the first two floors facing the water only since the other side faces the rockface;

- Designing alternatives according to the same building code (2010);

- Avoiding foundation design for the new timber building;

- Conserving similar building organization, dimensions, and the number of storeys.

- Conserving an equal or slightly higher number of G0 rooms;

- Conserving a similar column layout;

- Conserving a similar number of rooms of each type.

2.2. Phase 1: Architecture

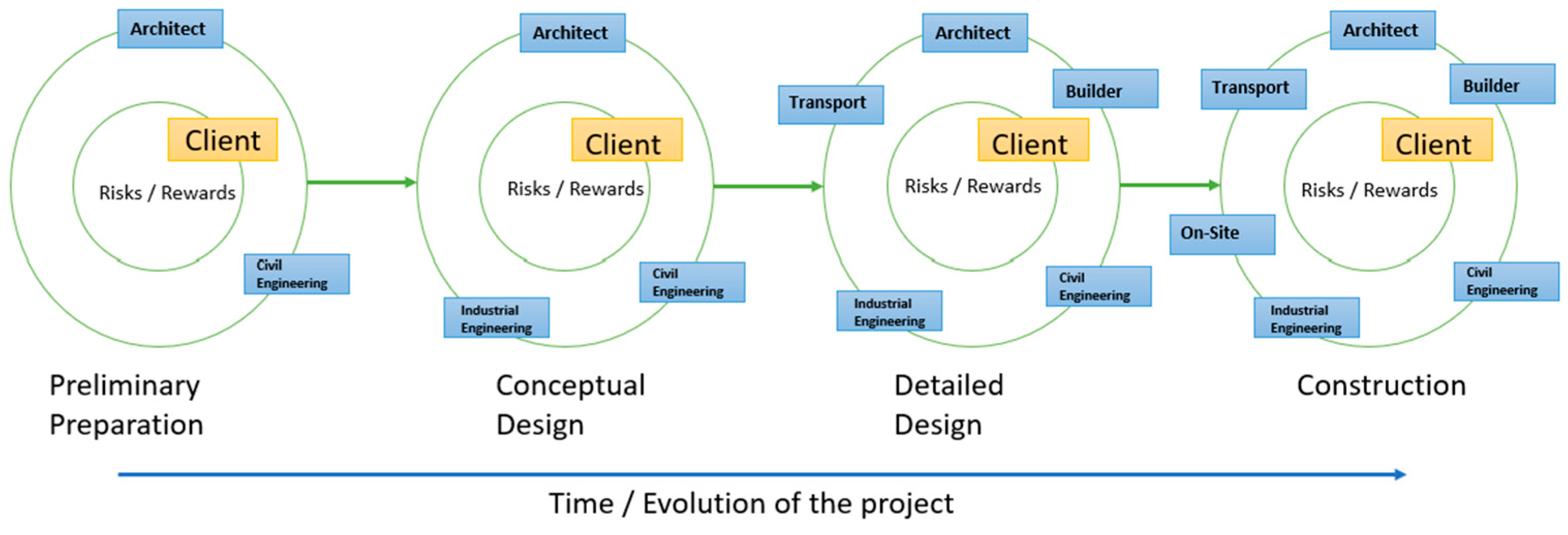

2.3. Phase 2: Industrial Engineering

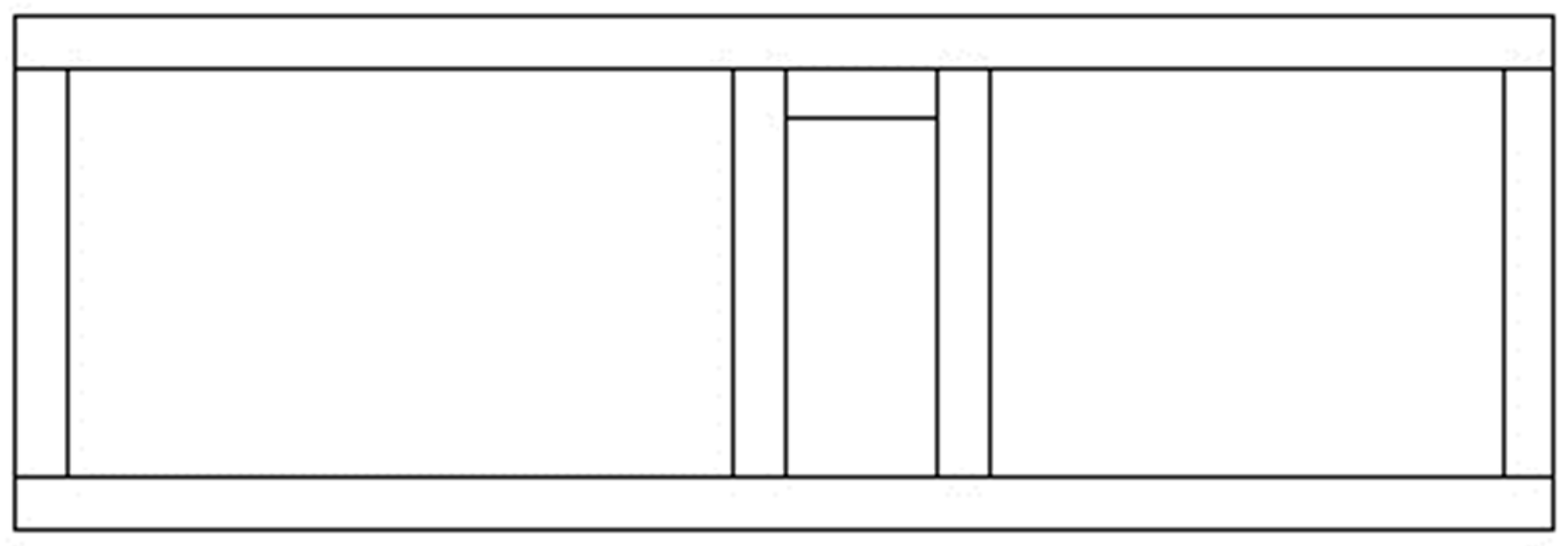

2.4. Phase 3: Civil Engineering

2.5. Phase 4: Analysis

3. Results and Discussion

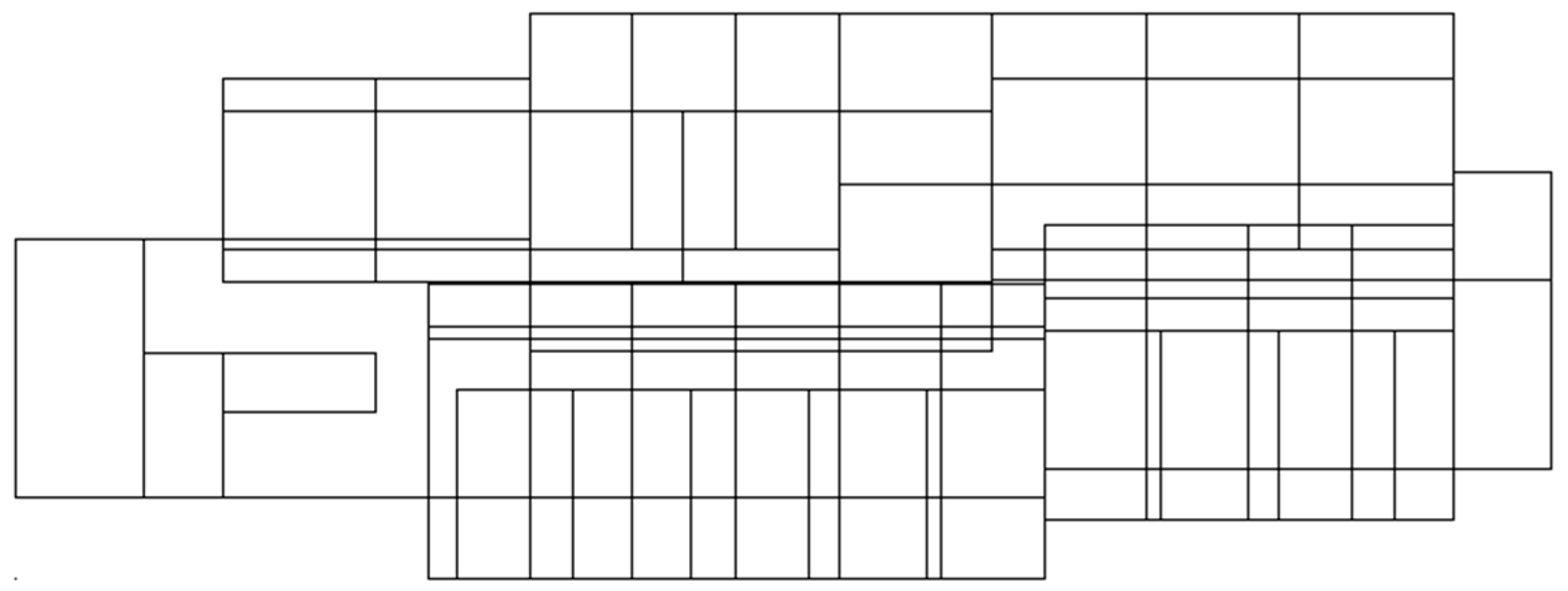

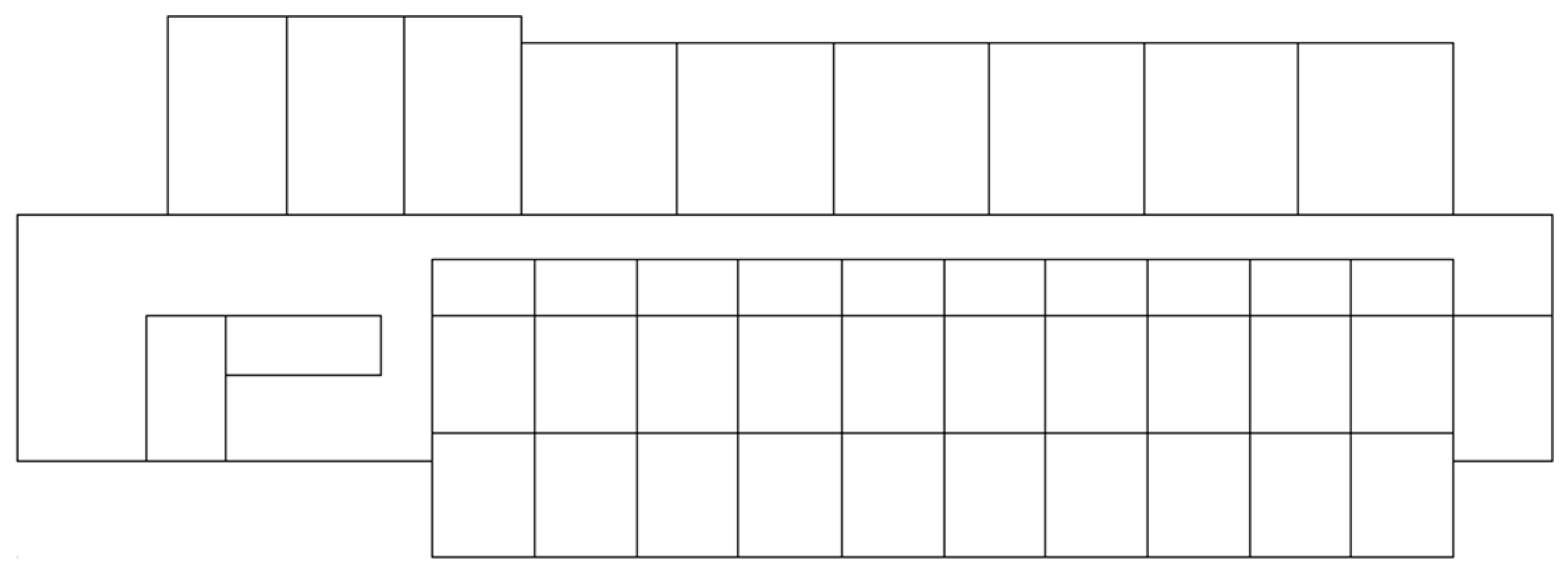

3.1. Reconceptualization of Developments and Planning: Architectural Analysis

3.2. Understanding How the Choice of an Industrialized Construction System Impacts Both the Architectural and Structural Systems: Industrial Engineering Analysis

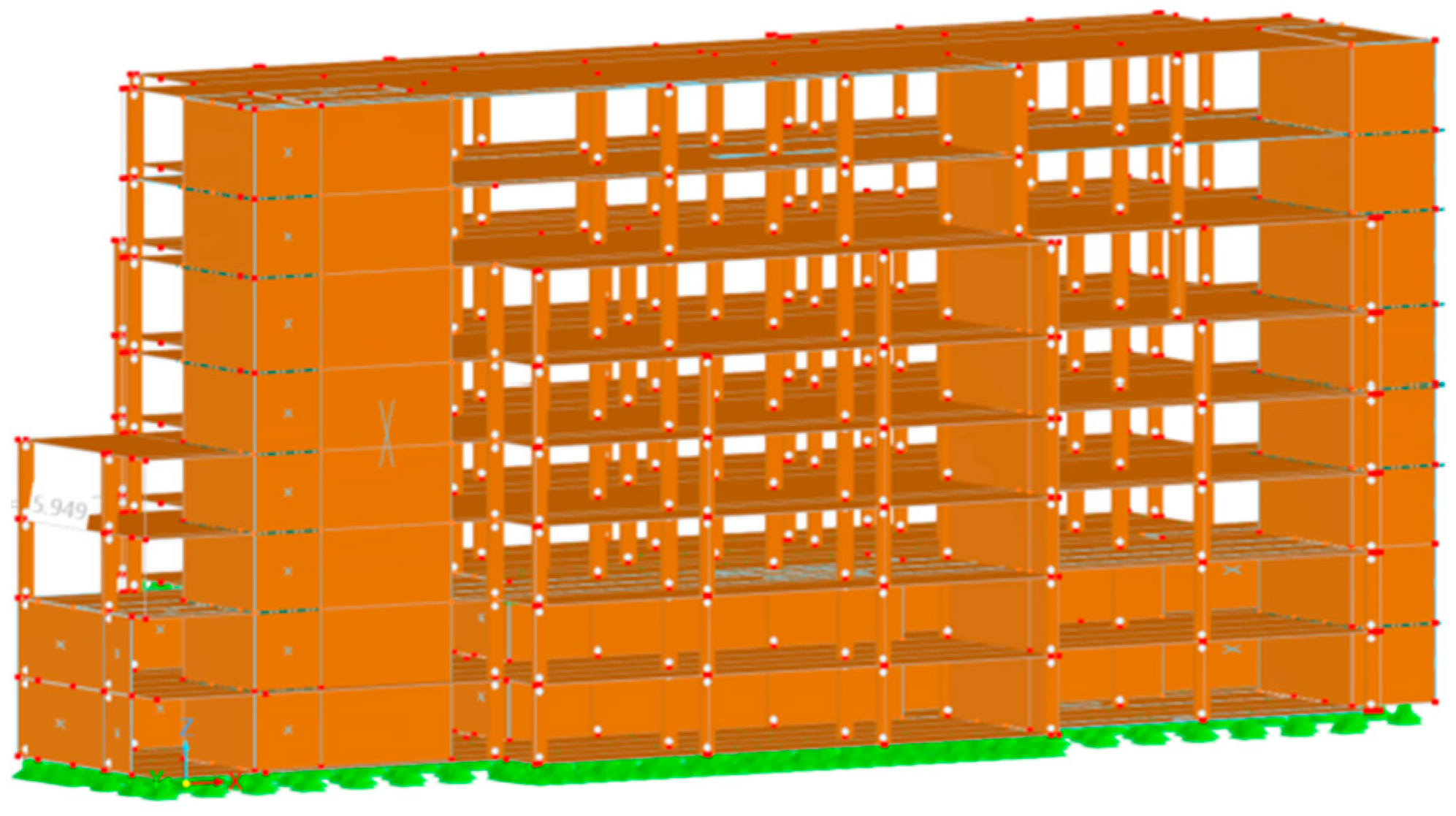

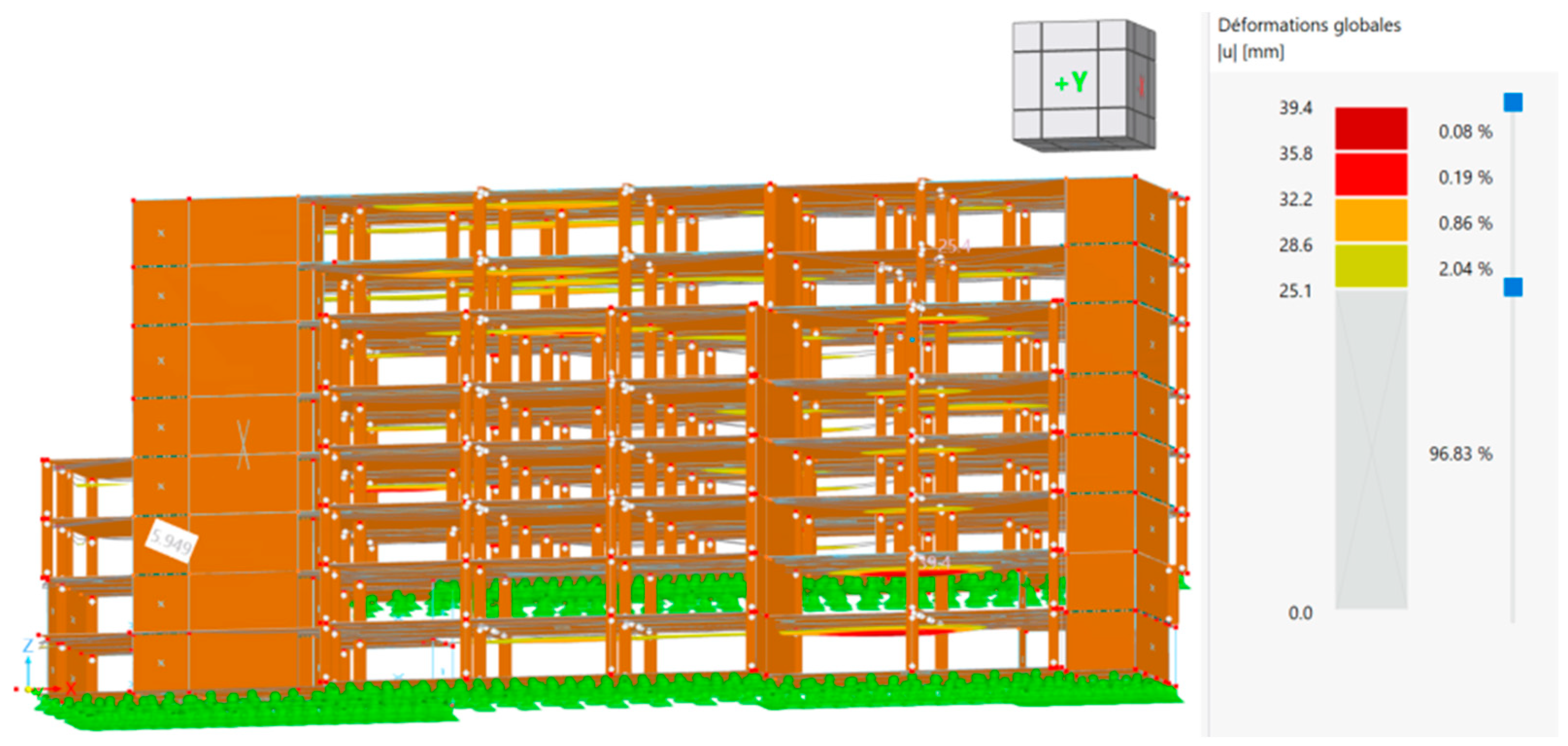

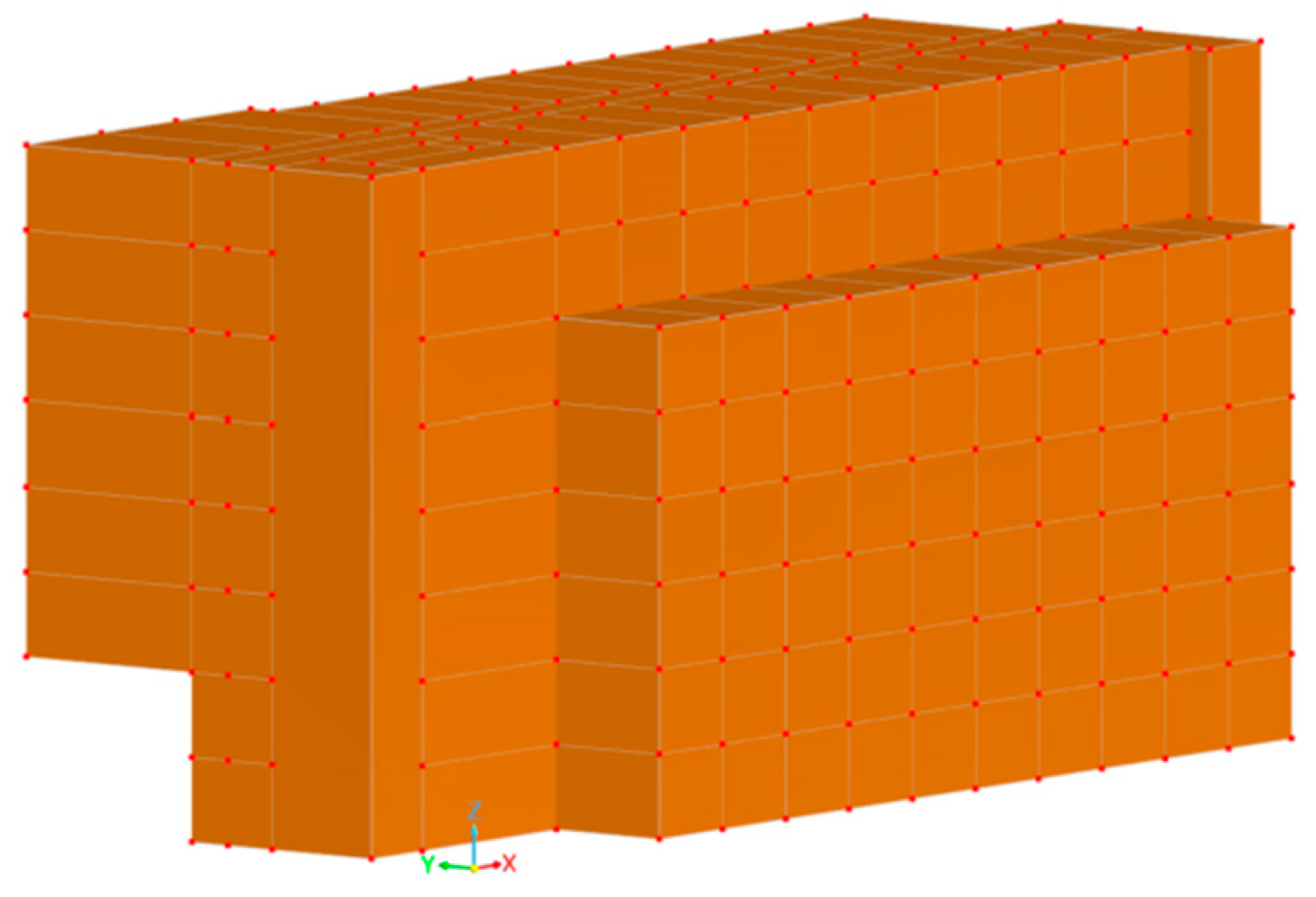

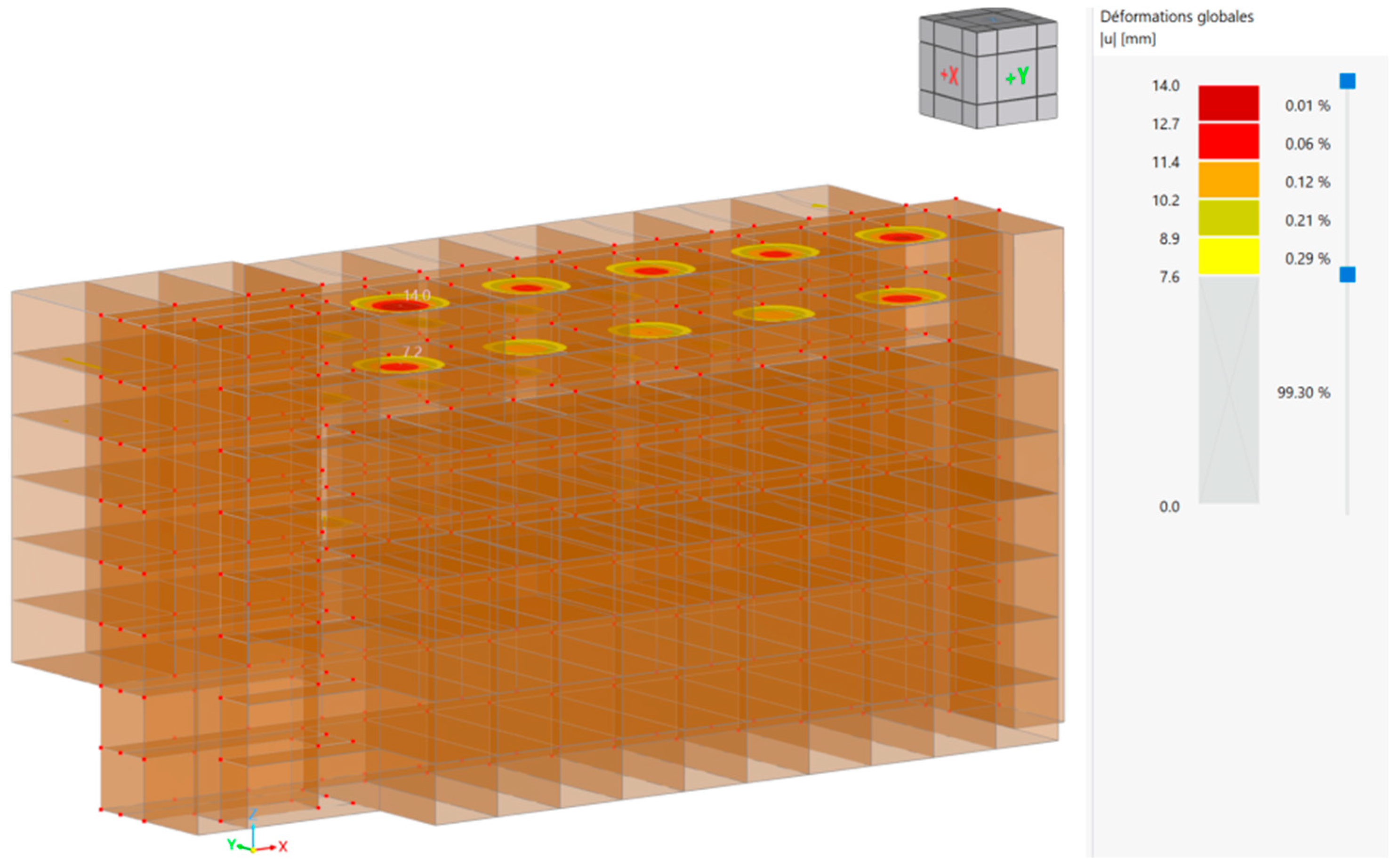

3.3. Modelling of the New Wooden Structure: Civil Engineering Analysis

3.4. Integration of the Three Disciplines (Architecture, Industrial Engineering, and Civil Engineering)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sutrisna, M.; Cooper-Cooke, B.; Goulding, J.; Ezcan, V. Investigating the cost of offsite construction housing in western Australia. Int. J. Hous. Mark. Anal. 2019, 12, 5–24. [Google Scholar] [CrossRef]

- Pan, W.; Hon, C.K. Briefing: Modular integrated construction for high-rise buildings. Proc. Inst. Civ. Eng. Munic. Eng. 2020, 173, 64–68. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Svatoš-Ražnjević, H.; Orozco, L.; Menges, A. Advanced timber construction industry: A review of 350 multi-storey timber projects from 2000–2021. Buildings 2022, 12, 404. [Google Scholar] [CrossRef]

- Assaf, M.; Hussein, M.; Abdelkhalek, S.; Zayed, T. A multi-criteria decision-making model for selecting the best project delivery systems for offsite construction projects. Buildings 2023, 13, 571. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M. Identification of structural issues in design and construction of multi-story modular buildings. In Proceedings of the 1st Residential Building Design and Construction Conference, Bethlehem, PA, USA, 20–21 February 2013; pp. 294–303. [Google Scholar]

- Sotorrío Ortega, G.; Cobo Escamilla, A.; Tenorio Ríos, J.A. Industrialized construction and sustainability: A comprehensive literature review. Buildings 2023, 13, 2861. [Google Scholar] [CrossRef]

- Wilson, J. Design for Modular Construction: An Introduction for Architects; American Institute of Architects: Washington, DC, USA, 2019. [Google Scholar]

- Pan, W.; Dainty AR, J.; Gibb AG, F. Establishing and weighting decision criteria for building system selection in housing construction. J. Constr. Eng. Manag. 2012, 138, 1239–1250. [Google Scholar] [CrossRef]

- Choi, J.O.; Chen, X.B.; Kim, T.W. Opportunities and challenges of modular methods in dense urban environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- ARUP. Rethinking Timber Buildings: Seven Perspectives on the Use of Timber in Building Design and Construction; ARUP: London, UK, 2019. [Google Scholar]

- Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings 2018, 8, 98. [Google Scholar] [CrossRef]

- Hough, M.J.; Lawson, R.M. Design and construction of high-rise modular buildings based on recent projects. Proc. Inst. Civ. Eng.-Civ. Eng. 2019, 172, 37–44. [Google Scholar] [CrossRef]

- Wozniak-Szpakiewicz, E.; Zhao, S. Modular construction industry growth and its impact on the built environment. Tech. Trans. 2020, 115, 43–52. [Google Scholar] [CrossRef]

- Boafo, F.; Kim, J.-H.; Kim, J.-T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Noordzy, G.; Whitfield, R. The new hotel development project life cycle: Doing the right new hotel project holistically, and doing it the right way. J. Mod. Proj. Manag. 2021, 8, 89–99. [Google Scholar] [CrossRef]

- Kosbar, M.M.; Elbeltagi, E.; Mahdi, I.; Kassem, M.; Ehab, A. Off-Site Manufacturing: Determining Decision-Making Factors. Buildings 2023, 13, 2856. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction–critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X. Sustainability perceptions of off-site manufacturing stakeholders in Australia. J. Clean. Prod. 2019, 227, 346–354. [Google Scholar] [CrossRef]

- Žegarac Leskovar, V.; Premrov, M. A Review of Architectural and Structural Design Typologies of Multi-Storey Timber Buildings in Europe. Forests 2021, 12, 757. [Google Scholar] [CrossRef]

- Khalfan, M.M.A.; Maqsood, T. Current state of off-site manufacturing in Australian and Chinese residential construction. J. Constr. Eng. 2014, 2014, 164863. [Google Scholar] [CrossRef]

- Salama, T.; Figgess, G.; Elsharawy, M.; El-Sokkary, H. Financial modeling for modular and offsite construction. Int. J. Eng. Adv. Technol. 2020, 10, 207–213. [Google Scholar] [CrossRef]

- Stein, A. Disruptive Development: Modular Manufacturing in Multifamily Housing. Master’s Thesis, University of California, Berkeley, CA, USA, 2016. [Google Scholar]

- Xu, J.; Ye, M.; Lu, W.; Bao, Z.; Webster, C. A four-quadrant conceptual framework for analyzing extended producer responsibility in offshore prefabrication construction. J. Clean. Prod. 2021, 282, 124540. [Google Scholar] [CrossRef] [PubMed]

- Smith, R. Solid Timber Construction, Process Practice Performance; Report Sponsored by American Institute of Architects; USDA Forest Products Laboratory and FPI Innovations: Madison, WI, USA, 2015.

- Lopez, R.; Chong, H.-Y.; Pereira, C. Obstacles preventing the off-site prefabrication of timber and mep services: Qualitative analyses from builders and suppliers in Australia. Buildings 2022, 12, 1044. [Google Scholar] [CrossRef]

- Bildsten, L. Buyer-supplier relationships in industrialized building. Constr. Manag. Econ. 2014, 32, 146–159. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Wu, J.; Shi, W.; Ji, D.; Wang, X.; Zhao, X. Constraints Hindering the Development of High-Rise Modular Buildings. Appl. Sci. 2020, 10, 7159. [Google Scholar] [CrossRef]

- Barati, R.; Charehzehi, A.; Preece, C.N. Enhancing planning and scheduling program by using benefits of BIM-based applications. Civ. Environ. Res. 2013, 3, 41–48. [Google Scholar]

- Wang, Y.; Bian, S.; Dong, L.; Li, H. Multiresolution modeling of a modular building design process based on design structure matrix. Buildings 2023, 13, 2330. [Google Scholar] [CrossRef]

- Adel, M.; Cheng, Z.; Lei, Z. Integration of building information modeling (bim) and virtual design and construction (VDC) with stick-built construction to implement digital construction: A Canadian general contractor’s perspective. Buildings 2022, 12, 1337. [Google Scholar] [CrossRef]

- Agapiou, A. Factors influencing the selection of a procurement route for UK off-site housebuilding. Proc. Inst. Civ. Eng.-Manag. Procure. Law 2022, 175, 3–15. [Google Scholar] [CrossRef]

- Programme D’Appui AU Développement de L’Industrie Québécoise de L’Habitation. Neuf Cas D’Intégration de Systèmes de Construction Préfabriqués. Available online: http://www.habitation.gouv.qc.ca/fileadmin/internet/publications/Neuf-cas-integration-Rapport-final.pdf (accessed on 3 April 2023).

- Charlson, J.; Dimka, N. Design, manufacture and construct procurement model for volumetric offsite manufacturing in the UK housing sector. Constr. Innov. 2021, 21, 800–817. [Google Scholar] [CrossRef]

- Canadian Wood Council. Green–the Canadian Wood Council–CWC. The Canadian Wood Council–CWC. 22 September 2021. Available online: https://cwc.ca/en/why-build-with-wood/sustainable/green/ (accessed on 14 September 2022).

- National Research Council of Canada. Canadian Commission on Building and Fire Codes. In National Building Code of Canada 2015; National Research Council of Canada: Ottawa, ON, Canada, 2015. [Google Scholar]

- RFEM, Version 6.03. Structural Engineering Software for Analysis and Design. Dlubal Software GmbH: Tiefenbach, Germany, 2021.

- CSA O86-19; Engineering Design in Wood. CSA Group: Toronto, ON, Canada, 2019.

- Nordic Structures|Nordic.ca|Engineered Wood|Documentation|Technical Documents. (s. d.). Available online: https://www.nordic.ca/en/documentation/technical-documents#nordicxlam (accessed on 3 April 2023).

- Gestimat, V2.0. Cecobois. 2024. Available online: https://gestimat.ca (accessed on 15 March 2024).

- Cardinal, T.; Alexandre, C.; Elliot, T.; Kouchaki-Penchah, H.; Levasseur, A. Climate change substitution factors for Canadian forest-based products and bioenergy. Ecol. Indic. 2024, 160, 111940. [Google Scholar] [CrossRef]

- Lecours, S.; Nguyen, T.-T.; Sorelli, L.; Blanchet, P.; Durand, K. Optimizing composite floors for sustainability and efficiency: Cross laminated timber, concrete types, and ductile notch connectors with enhanced shape. Clean. Eng. Technol. 2023, 14, 100635. [Google Scholar] [CrossRef]

- Halfen. Deha Spherical Head Lifting Anchor System; Halfen: Langenfeld, Germany, 2015. [Google Scholar]

- Getzner. Solid Timber Apartment Building by Meickl; Case study report; Getzner Engineering a Quiet Future: Bürs, Austria, 2015. [Google Scholar]

- Publications Québec. C-24.2, r. 31–Règlement Sur Les Normes de Charges ET de Dimensions Applicables Aux véhicules Routiers ET Aux Ensembles de Véhicules Routiers. Available online: http://legisquebec.gouv.qc.ca/fr/showdoc/cr/C-24.2,r.31 (accessed on 19 October 2022).

- Gijzen, R.P.T. Modular Cross Laminated Timber Buildings. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

| Type of Room | Number of Rooms | Width (m) | Area (m2) |

|---|---|---|---|

| G0 | 14 | 4.34 | 31.68 |

| C3 | 32 | 3.80 | 33.74 |

| C4 | 40 | 5.70 | 36.23 |

| A3 | 20 | 3.80 | 41.45 |

| A4 | 10 | 7.60 | 48.09 |

| Concrete Columns | Timber Columns |

|---|---|

| 275 × 400 mm | 265 × 418 mm |

| 275 × 500 mm | 265 × 532 mm |

| 275 × 600 mm | 265 × 608 mm |

| 350 × 500 mm | 365 × 494 mm |

| 600 × 275 mm | 315 × 608 mm |

| 600 × 600 mm | 365 × 988 mm |

| Iterations | Compliance with Number of Rooms | Compliance with Room Type | Compliance with Corridor Dimension | Hotel Profitability | Compliance with Club Med Criteria | Minimization of Materials | Minimizing Modifications | Total |

|---|---|---|---|---|---|---|---|---|

| Weight | 5 | 4 | 5 | 2 | 5 | 3 | 1 | 25 |

| Close to concrete | 4 | 2 | 1 | 1 | 5 | 1 | 0 | 14 |

| Standardization | 4 | 2 | 1 | 2 | 2 | 2 | 0 | 13 |

| Profitability | 3 | 2 | 3 | 2 | 2 | 2 | 0 | 14 |

| Large rooms facing water | 3 | 3 | 1 | 1 | 5 | 2 | 0 | 15 |

| Pyramid | 3 | 2 | 5 | 1 | 5 | 3 | 0 | 19 |

| Additions | 4 | 2 | 5 | 2 | 5 | 2 | 0 | 20 |

| Item | Value | Units | Comments | Source |

|---|---|---|---|---|

| Location category | C | Structure Plan | ||

| Risk category | 1 | Normal | Structure Plan | |

| Dead Load | ||||

| Self-weight | N.A. | Managed by RFEM | ||

| Mechanic + architecture | 1.5 | kPa | Structure Plan | |

| Live Load | ||||

| Roof | 1 | kPa | Table 4.1.5.3 | |

| Corridors | 4.8 | kPa | Table 4.1.5.3 | |

| Floors | 1.9 | kPa | Table 4.1.5.3 | |

| Stairs | 4.8 | kPa | Table 4.1.5.3 | |

| Snow Load | ||||

| Importance factor | 1 | ULS | Table 4.1.6.2A | |

| 0.9 | SLS | Table 4.1.6.2A | ||

| Sr (1/50) | 0.6 | kPa | Baie-St-Paul | Table C-2 |

| Ss (1/50) | 3.4 | kPa | Baie-St-Paul | Table C-2 |

| Snow load of the roof | 3.32 | kPa | ULS | 4.1.6.2 |

| 2.99 | kPa | SLS | 4.1.6.2 | |

| Cases | D | L | S |

|---|---|---|---|

| ULS 1 | 1.4 | ||

| ULS 2 | 1.25 | 1.5 | |

| ULS 3 | 1.25 | 1.5 | 1 |

| ULS 4 | 1.25 | 1 | 1.5 |

| ULS 5 | 1.25 | 1.5 | |

| SLS 1 | 1 | ||

| SLS 2 | 1 | 1 | |

| SLS 3 | 1 | 1 | 0.31 |

| SLS 4 | 1 | 0.3 | 0.9 |

| SLS 5 | 1 | 0.9 |

| As-Built | Volumetric Modular | |

|---|---|---|

| Area of Storey 1–2 (m2) | 542.84 | 587.04 |

| Area of Storey 3–6 (m2) | 949.17 | 932.20 |

| Area of Storey 7–8 (m2) | 717.49 | 766.18 |

| Total area (m2) | 6317.34 | 6435.23 |

| Type | Number of Rooms | Difference from the Original Concrete Plan |

|---|---|---|

| G0 | 18 | +4 |

| C3 | 36 | +4 |

| C4 | 36 | −4 |

| A3 | 20 | 0 |

| A4 | 10 | 0 |

| Total | 120 | +4 |

| Type | Actual Dimensions (m) | New Modular Dimensions (m) | New Modular Dimensions (Imperial) | Transport Consideration |

|---|---|---|---|---|

| G0 | 4.34 × 7.30 | 4.32 × 7.32 | 14′-2″ × 24′ | 1 escort |

| A3 | 3.80 × 10.91 | 3.65 × 10.90 | 12′ × 35′10″ | Sign “D” + flash |

| C3 | 3.80 × 8.80 | 3.65 × 8.80 | 12′ × 28′10″ | Sign “D” + flash |

| A4 | 7.60 × 6.33 | 2 * (3.65 × 6.35) | 2 * (12′ × 20′10″) | Sign “D” + flash |

| C4 | 5.70 × 6.36 | (2.5 × 6.36) + (3.2 × 6.36) | (8′2″ × 20′10″) + (10′6″ × 20′10″) | Sign “D” + flash |

| Concrete (Reference) | Column–Slab | Volumetric Modular | |

|---|---|---|---|

| Column (m3) | 140 | 160 | 0 |

| Slab (m2) | 6317 | 6317 | 6435 |

| Interior walls (m2) | 7044 | 7044 | 7009 |

| Exterior walls (m2) | 3332 | 3332 | 3270 |

| Concrete (Reference) | Column–Slab | Volumetric Modular | |

|---|---|---|---|

| Steel (Kg CO2 equivalent) | 227,263 | 89,298 | 15,842 |

| Concrete (Kg CO2 equivalent) | 578,023 | 0 | 0 |

| Wood (Kg CO2 equivalent) | 0 | 157,742 | 258,312 |

| Others (Kg CO2 equivalent) | 7375 | 7375 | 0 |

| Total (Kg CO2 equivalent) | 812,661 | 254,415 | 274,154 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filion, M.-L.; Ménard, S.; Carbone, C.; Bader Eddin, M. Design Analysis of Mass Timber and Volumetric Modular Strategies as Counterproposals for an Existing Reinforced Concrete Hotel. Buildings 2024, 14, 1151. https://doi.org/10.3390/buildings14041151

Filion M-L, Ménard S, Carbone C, Bader Eddin M. Design Analysis of Mass Timber and Volumetric Modular Strategies as Counterproposals for an Existing Reinforced Concrete Hotel. Buildings. 2024; 14(4):1151. https://doi.org/10.3390/buildings14041151

Chicago/Turabian StyleFilion, Marie-Laure, Sylvain Ménard, Carlo Carbone, and Mohamad Bader Eddin. 2024. "Design Analysis of Mass Timber and Volumetric Modular Strategies as Counterproposals for an Existing Reinforced Concrete Hotel" Buildings 14, no. 4: 1151. https://doi.org/10.3390/buildings14041151

APA StyleFilion, M.-L., Ménard, S., Carbone, C., & Bader Eddin, M. (2024). Design Analysis of Mass Timber and Volumetric Modular Strategies as Counterproposals for an Existing Reinforced Concrete Hotel. Buildings, 14(4), 1151. https://doi.org/10.3390/buildings14041151