Abstract

The investigation of soil is a particularly important stage of structural design. Cone penetration tests (CPTs) are the most common soil investigation techniques. The results of these tests provide information about the values of cone resistance (qc) and sleeve friction (fs), which correspond to depth. Previous studies have shown that the ratio of sleeve friction to cone resistance depends on the particle size distribution in soil and its use for soil classification. Unfortunately, as an analysis of the literature shows, there is no such classification for coarse-grained soils. This paper presents statistically significant differences in the ratio of fs to qc in coarse-grained soils. Based on the research performed, the proposed coefficients depend on the classification of coarse-grained soils with respect to the size of the soil particles. The data investigated were obtained from study reports on 35 sites (5934 tests) at which the main type of soil was coarse-grained and contained different sizes of particles. Following a statistical analysis, five groups of tested coarse-grained soils, silty fine sand, clayey fine sand, fine sand, medium sand and gravelly coarse sand together with gravel, are derived. The analysed data show statistically significant differences in the ratio of fs to qc considering this particular type of soil. A ratio of fs to qc with a probability of 95% is proposed for sandy soils. The values for silty fine sand, clayey fine sand, fine sand, medium sand and gravelly coarse sand mixed with gravel are 0.009459, 0.010982, 0.009268, 0.008001 and 0.006741, respectively. A linear relationship between the fs and qc indexes is also suggested.

1. Introduction

The modern construction industry is focused on the rational design of sustainable buildings. The effectiveness of a structural solution depends on the design procedure and the reliability of the initial data. Foundation structures are crucial structural elements. Research data on soil and the interpretation of the information obtained directly affect the accuracy of solutions for foundation structures. Therefore, soil investigation is an especially important stage and must be conducted with high precision.

The cone penetration test (CPT) is one of the most popular in situ testing methods used in modern geotechnics. The technique is fast (20 mm/s), has an excellent price/performance ratio and provides reliable derived soil indicators [,,]. Over the course of this test, direct measurements are obtained to develop the main indicators—cone resistance (qc) and local sleeve friction (fs). The CPT is applied to all types of soil. Although it is hardly possible to accurately determine the granulometric composition of soil using this particular testing method, fairly clear differences in soil behaviour can be found. Cone resistance (qc) is higher in sand than in clay of the same strength, and the ratio of fs to qc is lower in sand than in clay [].

The very first tests conducted for soil classification, in agreement with the CPT, included a mechanical cone. Begemann (1965) noticed a linear relationship between qc and fs []. Based on CPT studies of Dutch soils, Begemann proposed and graphically presented a relationship between sleeve friction, cone resistance and soil type.

Charts presented later used the qc and friction ratio (Rf = (fs/qc) × 100%) (Douglas and Olsen, 1981) []. The ratio was widely employed by Robertson to classify soils in line with their different behaviours [,,,,]. The resulting diagrams show that the friction ratio Rf of the tested types of soil varies within wide limits.

The CPT is important for classifying soils and designing foundation structures; it is also widely used for calculating the bearing capacity of pile foundations. There are two approaches to such calculations. The load-bearing capacity of friction is calculated directly using fs (sleeve friction) values, or the cone resistance (qc) values determined via the CPT are multiplied by an empirical coefficient αs, which indicates the ratio between fs and qc (Vukicevic et al., 2017) []. In the second case, a problem originates because the empirical coefficient barely reflects real ratios and does not adequately assess the soil’s behaviour based on its granulometry.

Both soil classification and the calculation of the bearing capacity of pile foundations clearly show that the friction ratio of cone resistance reflects the type of soil behaviour, considering the evaluation of its type in consonance with its granulometric composition [,].

This study aimed to analyse data obtained using the CPT on coarse soils and to examine the possibility of dividing similar soils into smaller groups (for example, fine sand, medium sand and gravel), considering their friction to cone resistance ratios. The introduced classification of soil is important from a practical point of view for solving design tasks [,,]. Regulatory documents do not provide the above classification, although it significantly affects the results of design tasks. A more precise classification of soils leads to more reliable and thus more accurate solutions.

2. Theoretical Basis for the Analysis of Soil Behaviour in Line with Data from the CPT

The use of qc and fs values obtained from the CPT is integral to various pile design methods, including empirical, limit state design, load and resistance factor design and advanced numerical analyses. These methods leverage the information provided by the CPT to accurately assess pile bearing capacity and ensure the safety and efficiency of foundation structures. As already mentioned in Section 1, there two methods used to determine load shaft resistance []. The first method directly uses fs (sleeve friction) values from the CPT. In the second method, empirical coefficients are used to evaluate the behaviour of different soils with different soil granulometric compositions. This method is used because experience has shown that the CPT sleeve friction (fs) value is less repeatable (±0.5% of the full-scale output) than the cone resistance (qc) value due to differences in cone design and tolerances.

The second method is widely used in Lithuania when calculating the bearing capacity of piles.

The characteristic pile ultimate compressive resistance, determined from ground test results according to the widely used method in Lithuania proposed by Furmonavičius [,], is as follows:

where Rs is the ultimate shaft resistance of a pile, calculated using ground parameters from test results; Rb is the compressive resistance of the ground against a pile in the ultimate limit state, calculated using ground parameters from test results; and ξ represents correlation factors used to derive characteristic values from ground test results, depending on the number of profiles of tests (Table 1 []).

Table 1.

Correlation factors used to derive characteristic values from ground test results, depending on the number of profiles of tests according to EU 7 [].

The ultimate shaft resistance of a pile may be obtained by calculating

where As;i is the pile shaft surface area in layer I; γR;s is the modelling coefficient, which evaluates the type of pile, as shown in Table 2; and qs;i is the unit shaft resistance in layer I, according to Furmonavičius [,]:

where qc;i is the cone resistance in layer i from the cone penetration test; and αs;i is the correlation coefficient between the pile shaft resistance and the cone resistance in layer i [,], which depends on the soil type (see Table 3).

Table 2.

Modelling coefficient values according to Furmonavičius [,].

Table 3.

αs and αb, according to Furmonavičius [,].

The compressive resistance of the ground against a pile, in the ultimate limit state, is

where Ab is the area of the pile base, qb is the average base resistance obtained from the cone resistance qc from the cone penetration test and γR;b is the coefficient of modelling, which evaluates the type of pile (see Table 2).

The average base resistance qb is calculated as the average value of the base resistance in the interval between one width of pile up to the pile base and from four widths of pile to below the pile base:

where αb;j is the correlation coefficient between the base resistance qb;j and the cone resistance qc;j in layer j [,], which depends on the type of soil (see Table 3), and hj is the thickness of soil layer j in the analysed interval.

From the long-term experience of the authors, it was noticed that in coarse and mixed soils (from gravel to clayey fine sand), the unit shaft resistance qs is often lower than the sleeve friction resistance fs measured via the CPT. Particularly large differences are observed in coarse soils.

According to the calculation method presented above, the shaft resistance qs from the cone penetration test is calculated according to the cone resistance qc. Table 3 presents the obtained values of shaft resistance qs and their corresponding αs depending on qc.

Statistical research methods were used to investigate differences in the fs/qc ratio depending on soil coarseness. Subsequent to the formation of samples with respect to granulometry, descriptive statistics were used to describe statistical samples. Thus, statistical values, including the mean, mode, median, standard deviation, standard error, sample variance, kurtosis, skewness, range, minimum and maximum values observed in the sample, coefficients of determination and correlation, count or sample size and a confidence level of 95%, were determined.

The determination coefficient R2 (R-Squared) is a statistical measure in a regression model determining the proportion of variance in a dependent variable explained by an independent variable. R-Squared is an indicator of how properly the collected data fit the regression model, and it is equal to the square of the correlation coefficient R:

where x and y are two variables determining the linear correlation.

The formula for calculating R-Squared indicates that in the case of a correlation between two variables, a change in the independent variable will likely result in a change in the dependent variable. Interpretations of the correlation coefficient R are shown in Table 4.

Table 4.

Interpretations of the correlation coefficient [].

3. Analysis and Evaluation of Statistical Data

To conduct this study, data from reports on engineering geological surveys carried out in the territory of the Republic of Lithuania were obtained. The figures of 35 different objects containing static probes and boreholes were analysed. Regarding the boreholes, soil layers were identified; thus, only cases of sandy soils were selected. The choice of sandy soils was due to the fact that pore pressure was not measured. Therefore, an uncorrected cone resistance was used for the analysis. CPTs recorded qc and fs every 0.2 m. In order for the recorded values of qc and fs to be assigned to an appropriate layer of soil, the values at the top and bottom of the layer were excluded, i.e., the upper and lower 0.2 m of the layer were not accepted. The completed data formed a sample of 5934 positions (qc and a corresponding fs).

A tensometric CPT was used for the tests, with cone compression force measurement limits from 0 to 100 kN and an area of 10 cm2. Therefore, 100 kN corresponds to 100 MPa. The cone resistance accuracy is ±0.1% of the cone capacity (full-scale output). The sleeve friction measurement force ranged from 0 to 15 kN, and the area was 150 cm2. A 15 kN force corresponds to 1 MPa. The sleeve friction accuracy is ± 0.5% of the full-scale output.

For each measured pair of qc and fs, an empirical coefficient αsd equal to the qc/fs ratio was calculated:

where fs is the local sleeve friction, kPa, and qc is the cone resistance, kPa.

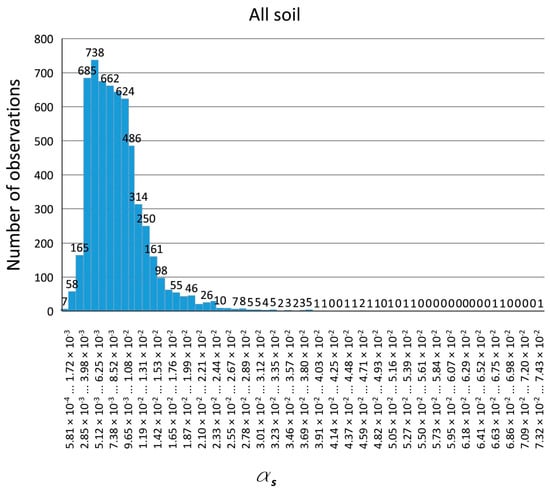

Figure 1 shows the distribution of the values of the empirical coefficient αs.

Figure 1.

The distribution of all values of αsd = fs/qc.

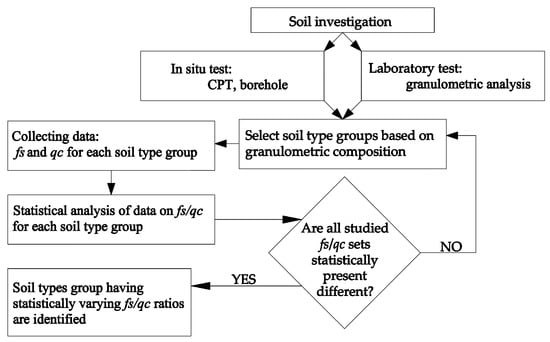

This stage of the research is schematically described by the algorithm presented in Figure 2.

Figure 2.

The algorithm of the conducted research.

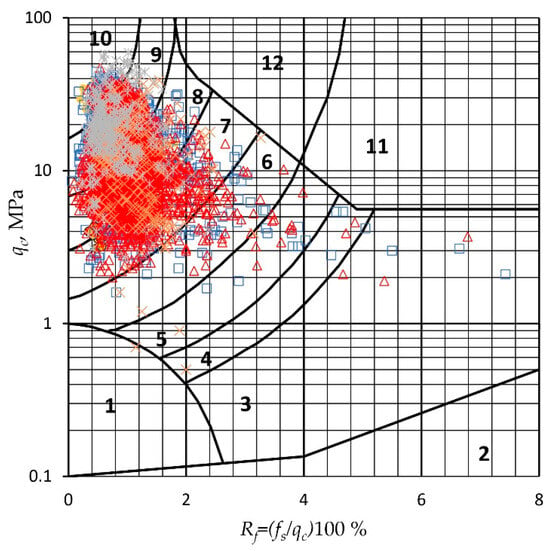

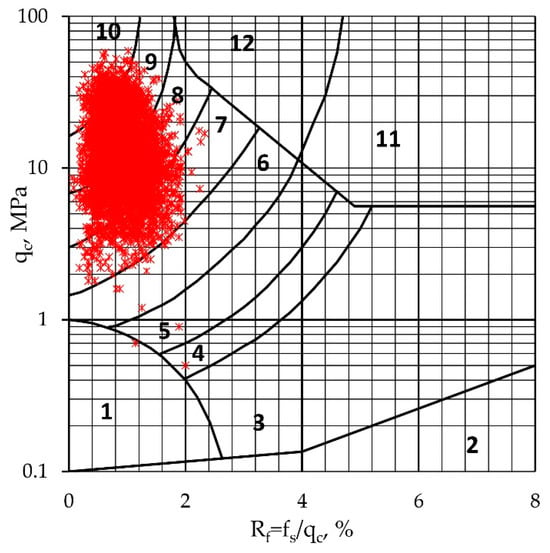

Next, as stated in the diagram of soil behaviour proposed by Roberson, Figure 3 presents the distribution of the friction ratio Rf (Rf = (fs/qc)100%) values of all the conducted tests depending on the cone resistance qc.

Figure 3.

The dependence of Rf distribution on qc (Robertson, 2010) []. The numbered zones correspond to the following: 1—sensitive fine-grained; 2—organic material; 3—clay; 4—silty clay to clay; 5—clayey silt to silty clay; 6—sandy silt to clayey silt; 7—silty sand to sandy silt; 8—sand to silty sand; 9—sand; 10—gravelly sand to sand; 11—very stiff fine-grained (overconsolidated or cemented); 12—sand to clayey sand (overconsolidated or cemented).

The majority of the surveyed points fall into zones 6–10, which correspond to the soil names determined during the survey. Also, some points strongly deviate from the majority of observations. Due to the testing specificity, the findings of the soil tests vary widely. Thus, not all the results reflect the characteristics of the studied set. Excessively deviant values must be eliminated from further evaluations.

Therefore, having found the mean values of fs/qc and their standard deviations, excessively deviant values were eliminated from the sample in line with the rule of three standard deviations.

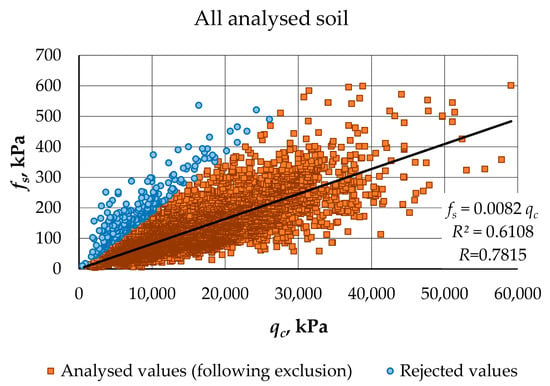

Having excluded the values deviating from the average value of αs by three standard deviations, corresponding to a confidence level of P = 99.7% in the studied case, for sandy soils, a strong linear relationship between cone resistance and the corresponding local sleeve friction was observed.

Table 5 presents the statistical characteristics of the soil tests conducted on the entire set (prior to exclusion). Table 5 also shows the statistical characteristics of the set when, in agreement with the assumption of three standard deviations, excessively deviant values (following exclusion) were eliminated.

Table 5.

Statistical indicators for the sets of soil prior to and following exclusion.

Figure 4 reflects the results in Table 5 and shows the part of the results falling within the area of three standard deviations (results that were not excluded) and the part that was rejected from the area of three standard deviations and was therefore excluded (blue dots).

Figure 4.

The relationship between cone resistance and sleeve friction in sandy soils.

Having eliminated the values that were three standard deviations from the mean, the equation of the line passing through the origin of the coordinates was derived by applying the least squares method:

where αsd = 0.0082 and the strength of the relationship between the variables in the linear model is R = 0.7815.

The value of R shows a strong correlation. Having processed the statistical data, a linear relationship between cone resistance qc and local sleeve friction fs in sandy soils was obtained.

Having calculated the friction ratio Rf of the remaining pairs, the latter corresponds to the distribution of sandy soils, as proposed by Roberson in the diagram of soil behaviour (Figure 5). The figure provides data on the exclusion of excessively deviant values (see Table 5).

Figure 5.

The relationship between Rf and qc. (1) Sensitive fine-grained; (2) clay–organic soil; (3) clays—clay to silty clay; (4) silt mixtures—clayey silt and silty clay; (5) sand mixtures—silty sand to sandy silt; (6) sands—clean sands to silty sands; (7) dense sand to gravelly sand; (8) stiff sand to clayey sand (overconsolidated or cemented); (9) stiff fine-grained (overconsolidated or cemented); (10) gravelly sand to sand; (11) very stiff fine-grained (overconsolidated or cemented soil); (12) sand to clayey sand (overconsolidated or cemented soil).

Figure 5 shows that having excluded excessively deviant values, most of the observed values fall within zones 7 to 10, which confirms that sandy soil is under consideration.

In line with the granulometric composition (conforming to the data on the boreholes made next to the probes), the total sample suggests six types of soil:

- Clayey fine sand (c f S);

- Silty fine sand (sl f S);

- Fine sand (f S);

- Medium sand (m S);

- Gravelly coarse sand (g c S);

- Gravel (G).

Having found the average values and standard deviations of the obtained samples, excessively deviant values were eliminated from the samples in accordance with the rule of three standard deviations. The resulting samples had the statistical characteristics presented in Table 6.

Table 6.

Statistical indicators for the sets of soils grouped according to granulometric composition.

Next, using Student’s t-test, the samples of the groups identified in accordance with the granulometric composition were checked in order to determine whether the samples were statistically different. The calculation results are presented in Table 7. Each cell of the table contains a correlation coefficient indicating the relationship significance between the individual samples. An intercomparison of the samples (Table 7) indicates that certain samples are interdependent.

Table 7.

The values of correlation coefficients (Pearson’s correlation) among 6 identified samples.

Above, 1.00 × 100 indicates no statistical difference between the corresponding samples, 1.06 × 10−3 shows a statistically very low similarity between the samples and 1.10 × 10−1 demonstrates statistically similar samples. For this reason, the last two samples, including gravelly coarse sand (c g S) and gravel (G), are combined into a single sample.

The procedure for statistical processing was repeated after finding the average value (c g S + G) of the new sample and the standard deviation. Excessively deviant values were eliminated from the sample in line with the rule of three standard deviations. The statistical characteristics of the samples were obtained (Table 8).

Table 8.

Statistical indicators for soils in line with granulometric composition after combining g c S and G sets.

Next, the samples of the groups newly identified with respect to granulometric composition were checked to determine whether the samples were statistically different by applying Student’s t-test. The calculation results are presented in Table 9.

Table 9.

The values of correlation coefficients (Pearson’s correlation) among 5 identified samples.

The remaining five samples correspond to soils categorised as clayey fine sand, silty fine sand, fine sand, medium sand and gravelly coarse sand mixed with gravel and are described as statistically different.

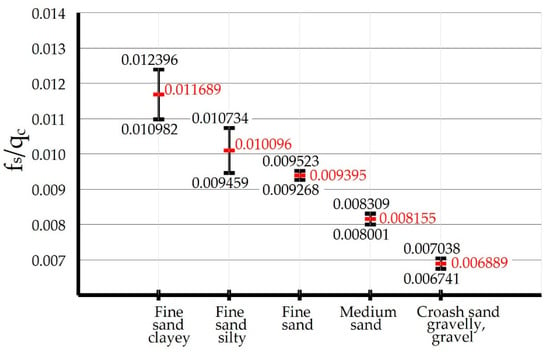

Figure 6 presents the mean values of all the statistically different samples Rf/100% and intervals with a confidence level of 95%. The figure also shows the relationship between the granulometric composition of the soil; the finer a soil is or the more it is composed of finer particles, the higher its Rf/100%. Additionally, a greater dispersion of the values of fine soil is observed.

Figure 6.

fs/qc with respect to the granulometric composition of soil, with a confidence level of 95%.

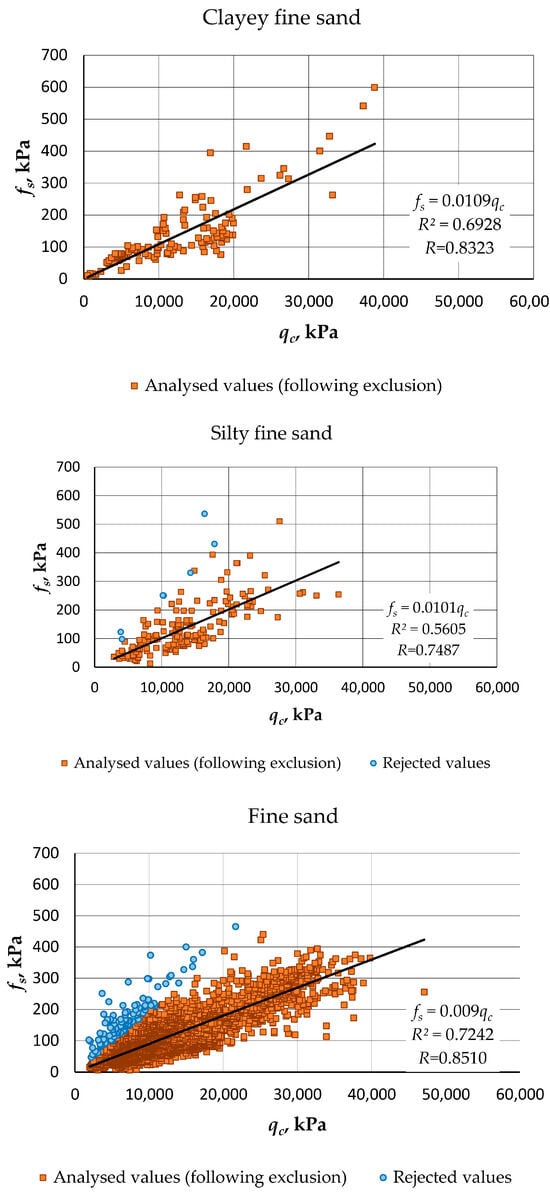

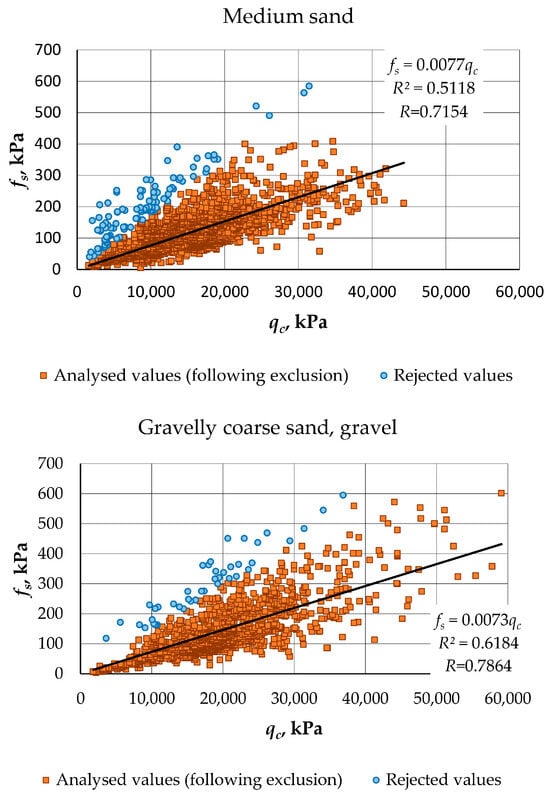

In consonance with Rf/100%, for five identified statistically different samples, the linear relationships of the lines passing through the origin of the coordinates were recorded by employing the least squares method:

The strength of the relationship between the linear model and R2 (Figure 7) was determined.

Figure 7.

Linear relationship of the identified statistically different samples.

Figure 7 shows blue points, the values of which deviate within a margin of three standard deviations (3σ). In the search for a linear relationship, these values were rejected.

αsd and R2 are given in Table 10 together with the mean values of the samples Rf/100% and the confidence intervals of those values.

Table 10.

Statistical parameters of different samples.

The strength of the relationship between the variables in the linear model, R, shows a strong correlation between fs and qc in all samples without separating the soils into the groups determined according to granulometry; regarding αsd and Rf/100% (or fs/qc), the values for the medium sand and gravelly coarse sand + gravel groups are too high and for the remaining groups, they are too low.

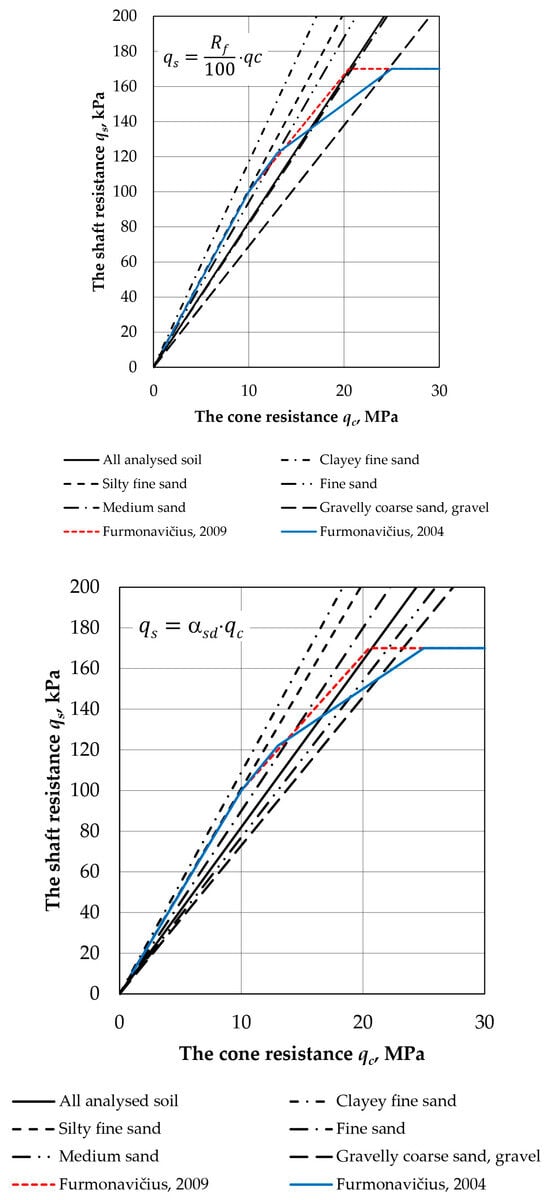

Comparing the unit shaft resistance qs used in the pile calculations with the results of this study, it can be seen that only the calculated value of the unit shaft resistance qs for clayey fine sand and silty fine sand is higher than that currently used for pile design. Meanwhile, for the rest of the soils with low qc values, the calculated values of shaft resistance qs are lower than those currently used for pile design (Figure 8).

Figure 8.

The relationship between qs and qc for the analysed groups of soils and croase soils according Furmonavičius [,].

Thus, a finer division provides more accurate results. Following more detailed research, the αsd value obtained could be applied for calculating the bearing capacity of a pile foundation.

4. Conclusions and Suggestions

- A statistical analysis of the tested soil showed that the correlational relationship of the tested coarse-grained soil between the sleeve friction and cone resistance in the studied sample (5634 observations) is strong and reaches R = 0.7815. The obtained relationship of the sample is fs = 0.0082qc.

- Regarding the boreholes, six samples of different soils were identified: silty fine sand, clayey fine sand, fine sand, medium sand, gravelly coarse sand and gravel. The difference between the samples of gravelly coarse sand and gravel was found to be statistically insignificant (0.11049). The other samples showed statistically significant differences.

- Statistically different samples like silty fine sand, clayey fine sand, fine sand, medium sand and gravelly coarse sand mixed with gravel were identified. The soils of these isolated groups have a strong correlation between the local sleeve friction and cone resistance (R = 0.7154…0.8510).

- The statistical analysis of the tested soil showed a confidence level of 95% and determined that the fs/qc ratio is not lower than the ratio calculated for silty fine sand, reaching 0.009459; for clayey fine sand, this ratio is equal to 0.010982, for fine sand, it reaches 0.009268, for medium sand, it is 0.008001 and for gravelly coarse sand and gravel, it is 0.006741. An increase in the particle size of sandy soil leads to a decrease in the ratio between the local sleeve friction and cone resistance.

- The determined fs/qc values are applicable only to the tested types of soil. In order to apply fs/qc ratios to the classification of coarse-grained soils, performing a statistical analysis of CPT data in a specific area is required. The studied relationships between fs and qc in five identified statistically different groups of soil demonstrated a strong relationship between the above-mentioned indicators, thus providing linear equations for the established relationships. The relationships found are valid only for the tested soils. For a broader application, additional research is needed.

- The study showed that the shaft resistance qs values currently used in pile load-bearing capacity calculations can be more accurately estimated using αsd or Rf/100% for finer coarse-grained soil types, depending on the granulometric composition. However, to determine exact values, more extensive studies are needed, including larger soil samples and evaluating additional properties of the gravel (origin, moisture, etc.).

Author Contributions

Conceptualisation, D.S., R.Š. and K.U.; methodology, D.S. and R.Š.; validation, D.S. and K.U.; formal analysis, R.Š.; investigation, R.Š. and K.U.; resources, D.S., R.Š. and K.U.; data curation, D.S., R.Š. and K.U.; writing—original draft preparation, D.S., R.Š. and K.U.; writing—review and editing, D.S., R.Š. and K.U.; visualisation, D.S. and K.U.; supervision, D.S.; project administration, K.U. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All datasets are present in this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yu, X.; Liu, S.; Pei, H. Design of Cone Penetration Test Data Relay Transmission by Magnetic Communication. Sensors 2022, 22, 4777. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.N.; Gnanendran, C.T.; Sivakumar, S.T. Interpretation of Cone Penetration Test Data of an Embankment for Coupled Numerical Modeling. Appl. Mech. 2022, 3, 14–45. [Google Scholar] [CrossRef]

- Guo, Y.; Li, J.; Yu, X. Experimental Study on Load-Carrying Behavior of Large Open-Ended Pipe Pile in Cohesionless Soils. Sustainability 2022, 14, 12223. [Google Scholar] [CrossRef]

- Zwara, Ł.; Bałachowski, L. Prediction of Pile Shaft Capacity in Tension Based on Some Direct CPT Methods—Vistula Marshland Test Site. Materials 2022, 15, 2426. [Google Scholar] [CrossRef] [PubMed]

- Begemann, H.K.S. The friction jacket cone as an aid in determining the soil profile. In Proceedings of the 6th ICSMFE, Montreal, QC, Canada, 8–15 September 1965; Volume 2, pp. 17–20. [Google Scholar]

- Douglas, B.J.; Olsen, R.S. Soil classification using electric cone penetrometer. In Proceedings of the Symposium on Cone Penetration Testing and Experience, Geotechnical Engineering Division, ASCE, St. Louis, MI, USA, October 1981; American Society of Civil Engineers: New York, NY, USA, 1981; pp. 209–227. [Google Scholar]

- Robertson, P.K. In sifu testing and its application to foundation engineering. Can. Geotech. J. 1986, 23, 573–594. [Google Scholar] [CrossRef]

- Robertson, P.K.; Campanella, R.G.; Gillespie, D.; Greig, J. Use of piezometer cone data. In Proceedings of the In-Situ’86 Use of In-Situ Testing in Geotechnical Engineering, ASCE Specialty Conference, Blacksburg, VA, USA, 23–25 June 1986; pp. 1263–1280. [Google Scholar]

- Robertson, P.K. Soil classification using the cone penetration test. Can. Geotech. J. 1990, 27, 151–158. [Google Scholar] [CrossRef]

- Robertson, P.K. Interpretation of cone penetration tests—A unified approach. Can. Geotech. J. 2009, 46, 1337–1355. [Google Scholar] [CrossRef]

- Robertson, P.K. Cone Penetration Test (CPT)-Based Soil Behaviour Type (SBT) Classification System—An Update. Can. Geotech. J. 2016, 53, 1910–1927. [Google Scholar] [CrossRef]

- Vukicevic, M.; Marjanović, M.; Pujevic, V.; Obradović, N. Evaluation of methods for predicting axial capacity of jacked-in and driven piles in cohesive soils. Gradevinar 2018, 70, 685–693. [Google Scholar] [CrossRef]

- Robertson, P.K. Soil behaviour type from the CPT: An update. In Proceedings of the 2nd International Symposium on Cone Penetration Testing, CPT’10, Huntington Beach, CA, USA, 9–11 May 2010. [Google Scholar]

- Cho, S.; Kim, H.-S.; Kim, H. Locally Specified CPT Soil Classification Based on Machine Learning Techniques. Sustainability 2023, 15, 2914. [Google Scholar] [CrossRef]

- New Arc. Handbook for the Building Designer and Builder; New Arc: Kaunas, Lithuania, 2009; 1520p. (In Lithuanian) [Google Scholar]

- Technika. Civil Engineer Handbook; Technika: Vilnius, Lithuania, 2004; 1096p. (In Lithuanian) [Google Scholar]

- EN 1997–1: 2004; Eurocode 7–Geotechnical Design, Part 1: General Rules. The European Union: Maastricht, The Netherlands, 2004.

- Pabedinskaitė, A.; Činčikaitė, R. Quantitative Modeling Methods; Vilnius Gediminas Technical University Publishing House: Vilnius, Lithuania, 2016; (In Lithuanian). [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).