Study on Structural Parameter Sensitivity and the Force Transmission Mechanism of Steel–Concrete Joints in Hybrid Beam Bridges

Abstract

1. Introduction

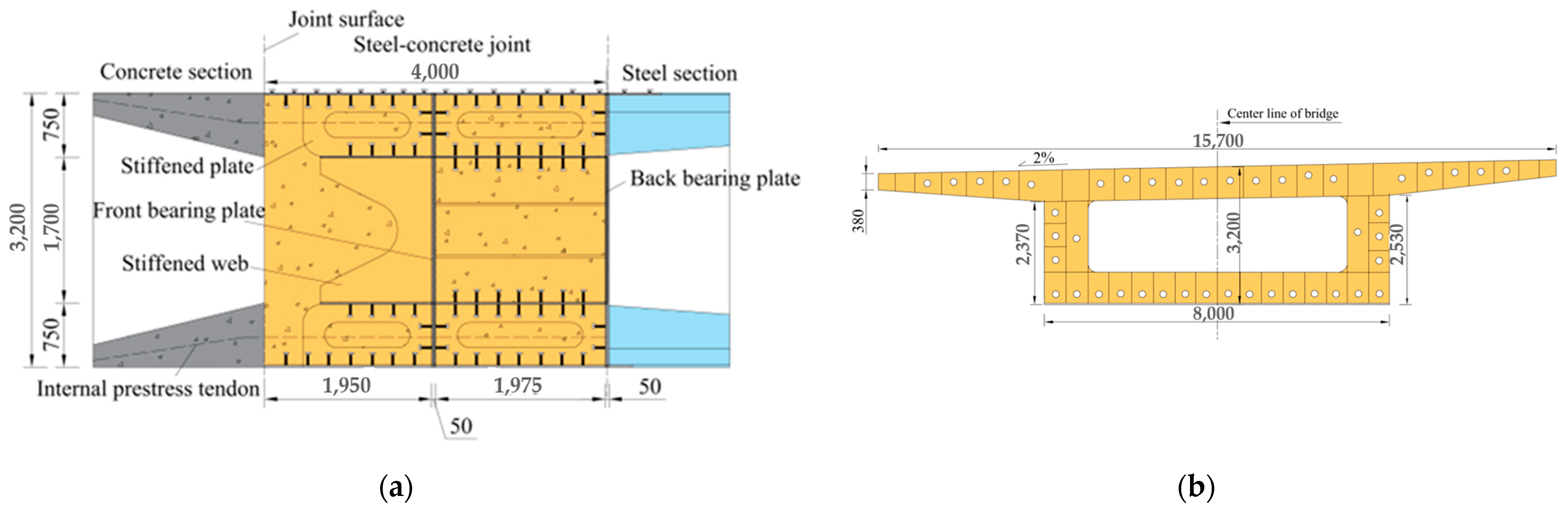

2. Engineering Background

3. Finite Element Model

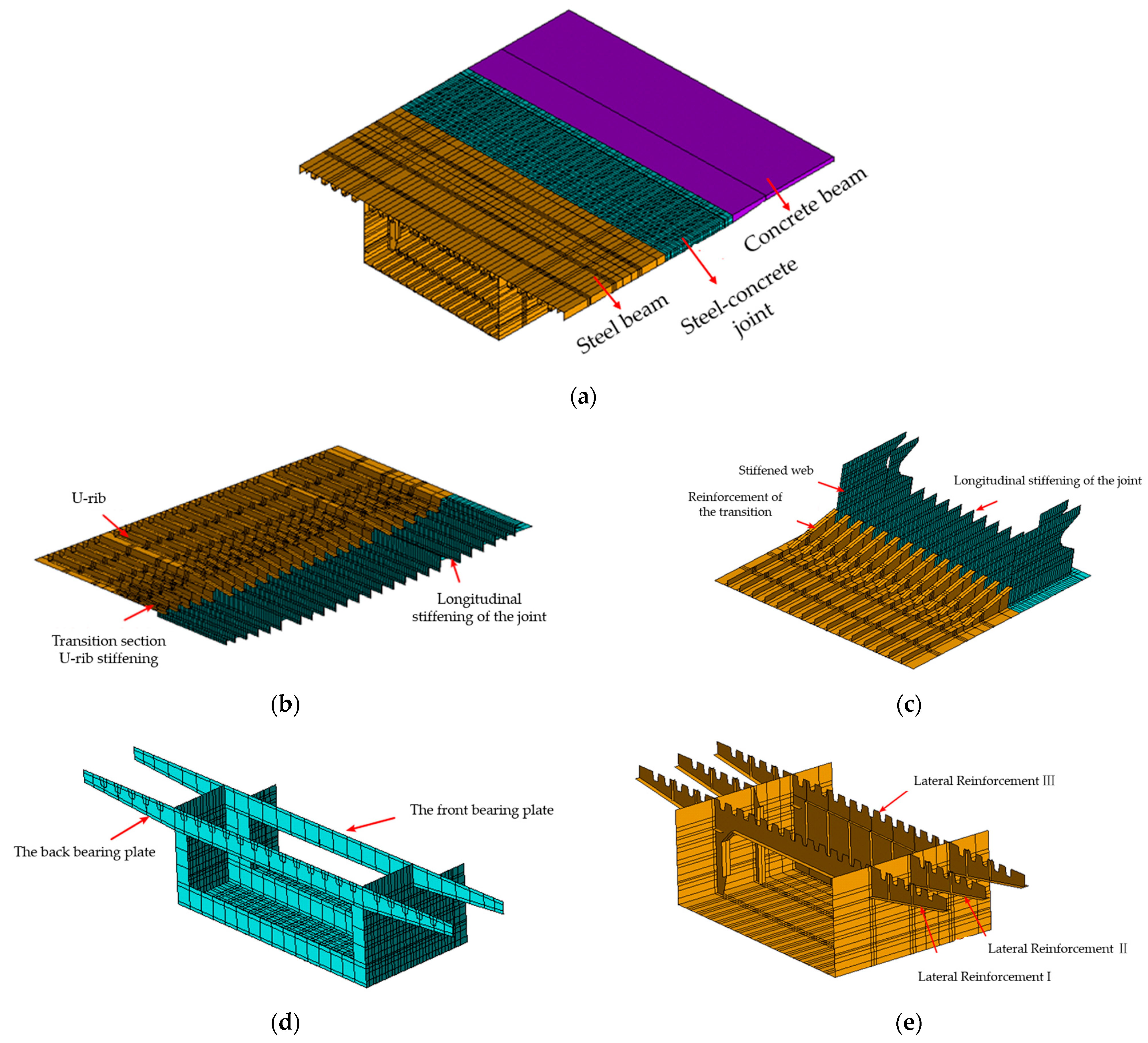

3.1. Establishment of Finite Element Model

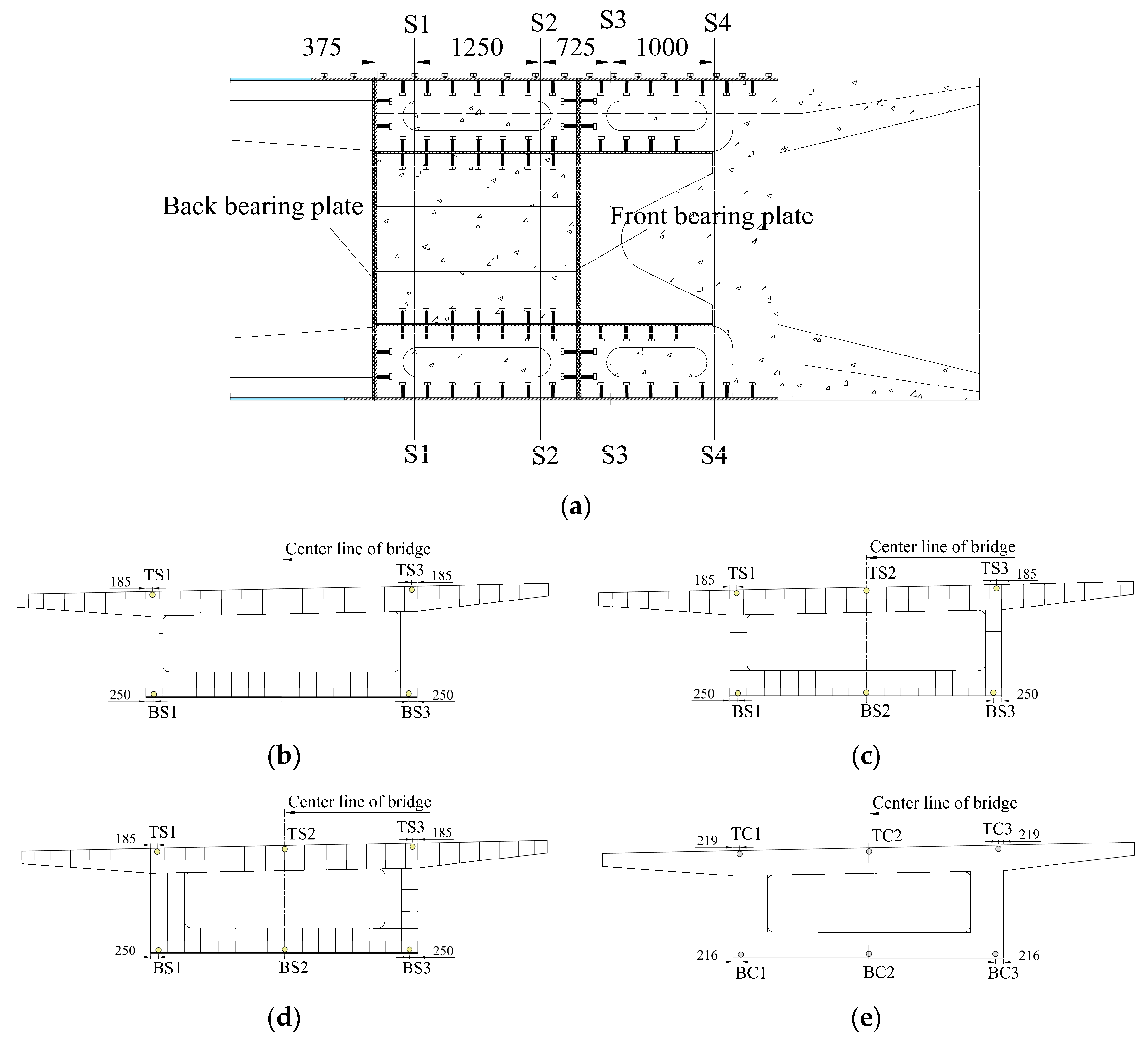

3.2. Verification of Finite Element Model

4. Structural Parameter Sensitivity

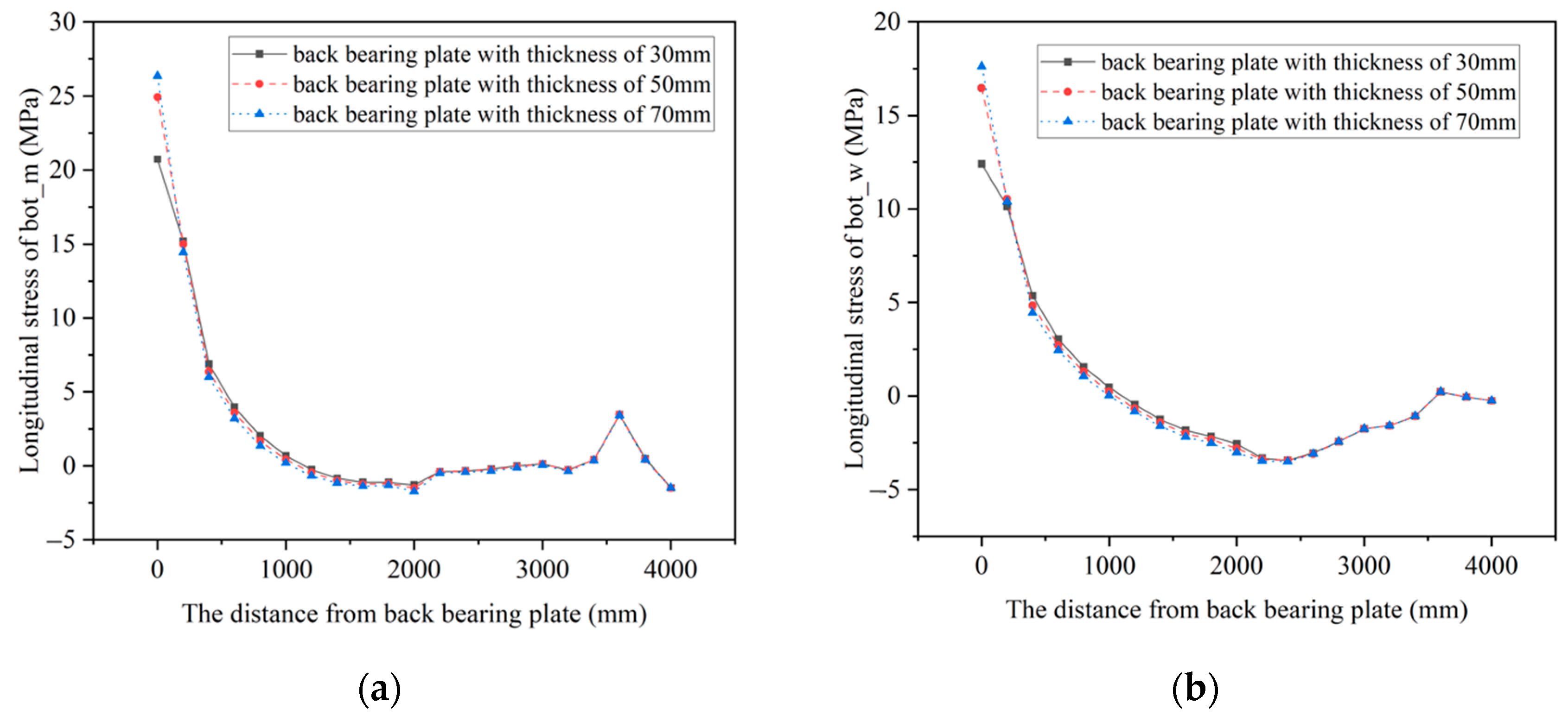

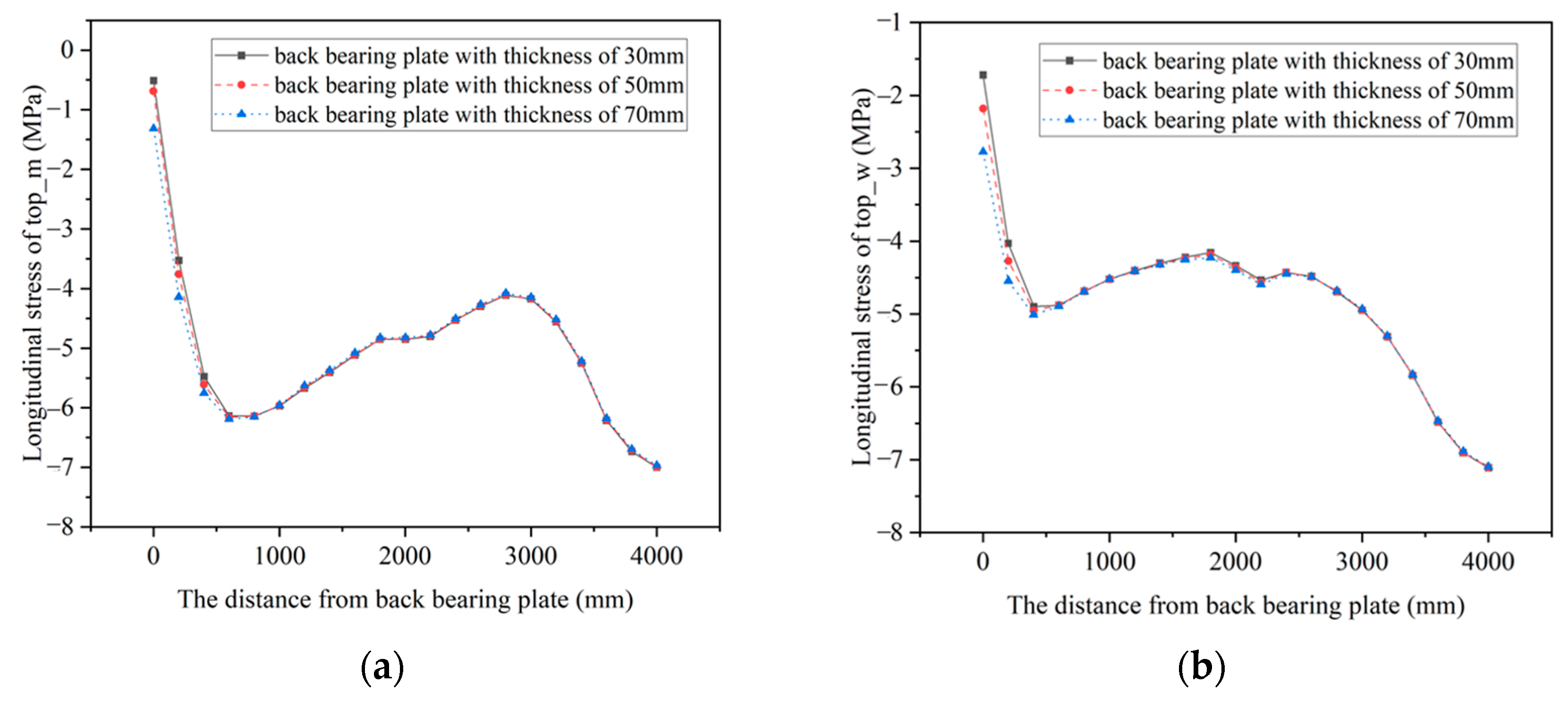

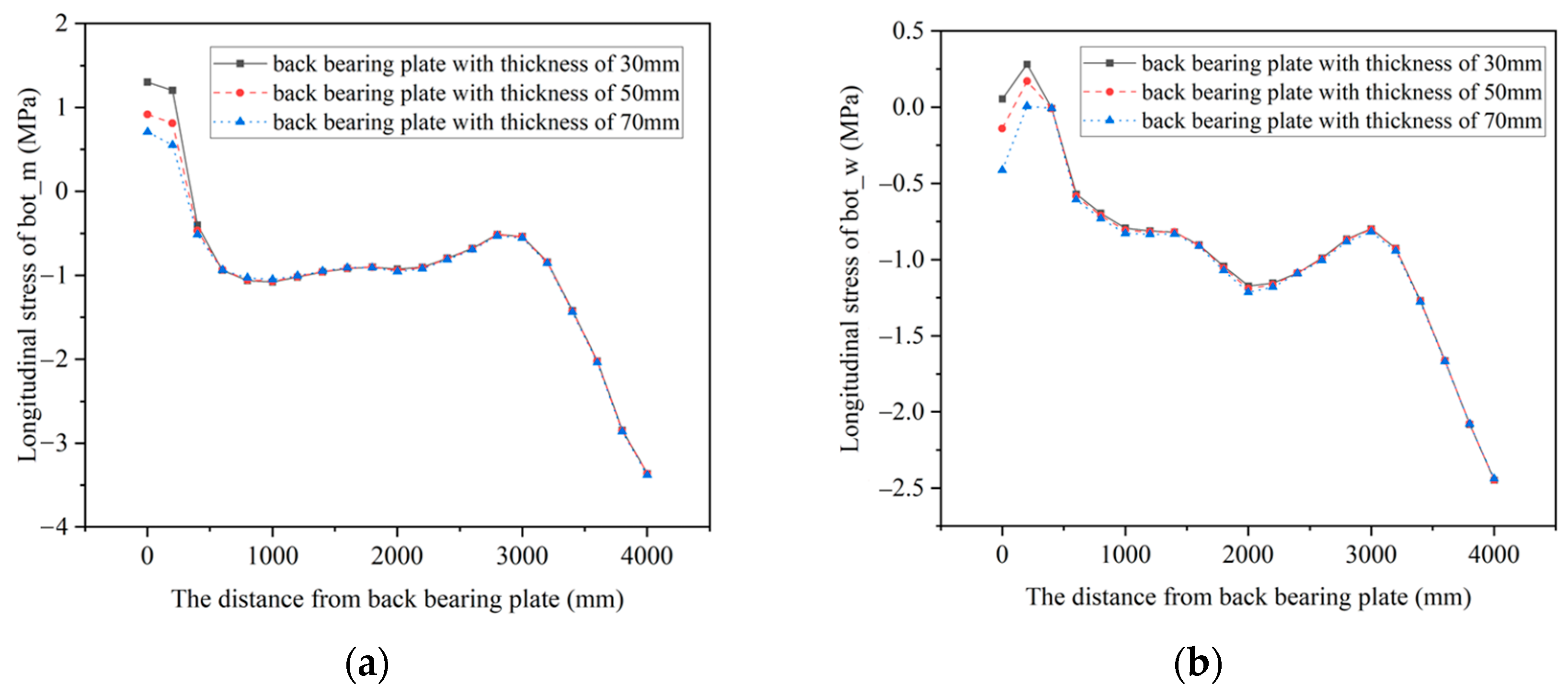

4.1. Thickness of the Back Bearing Plate

4.2. Stiffness of the Welding Studs

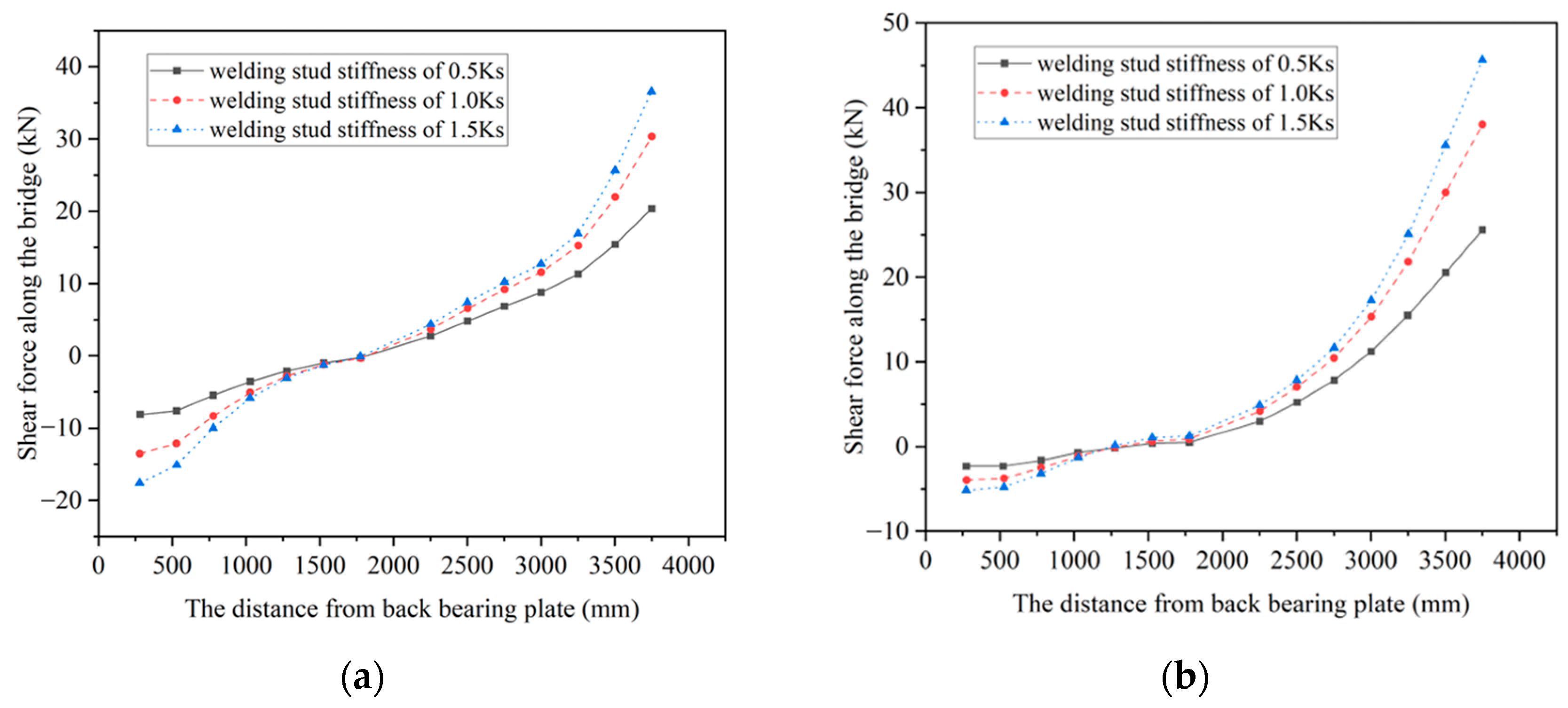

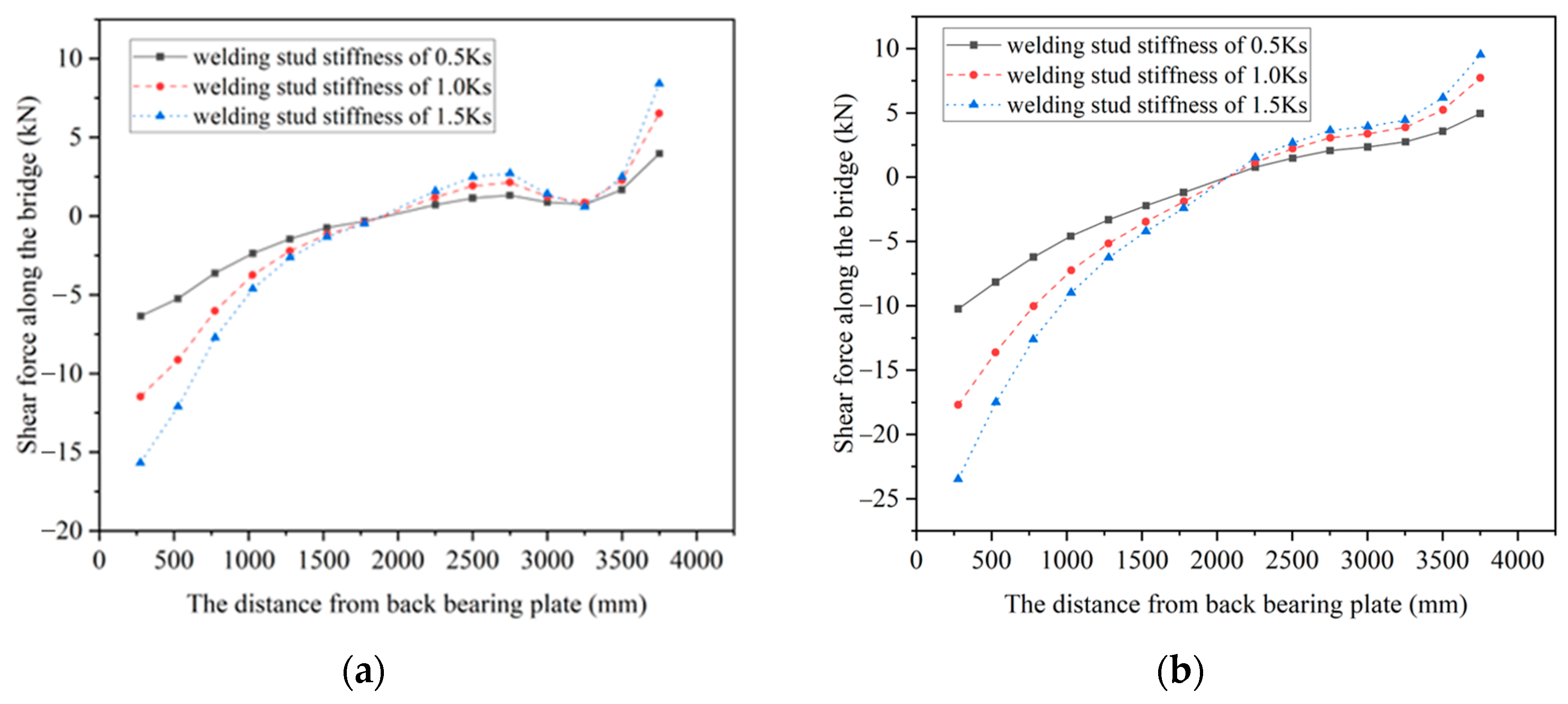

5. Force Transmission Mechanism

6. Conclusions

- The stress values calculated at the joint are in good agreement with the measured stress values, in which the maximum error between the calculated and measured values of the steel structure does not exceed 20%; the maximum error between the calculated and measured values of the concrete structure does not exceed 15%. Neglecting the frictional force transmission between the steel structure and the concrete at the joint results in a certain safety reserve for the calculation results;

- The use of a thicker back bearing plate can alleviate the stress concentration phenomenon at the welding positions between the back bearing plate and the stiffeners, as well as at the anchoring positions of the prestressed tendons, making the Mises stress distribution more uniform and the overall stress level decrease. The change in the bearing plate thickness has a large impact on the stresses within the steel structure and the concrete in the proximity of the bearing plate. For the steel structure near the back bearing plate, the compressive stress of the steel top plate decreases with an increase in the back bearing plate’s thickness, while the tensile stress in the steel bottom plate escalates correspondingly, and the opposite is true for the concrete structures. The influence range of the back bearing plate thickness on concrete stress is mainly between 0 mm and 400 mm. It is recommended to maintain a back bearing plate thickness within the range of 50 mm~70 mm;

- Reducing the stiffness of the welding studs by 0.5 times, keeping it the same, or increasing it by 0.5 times shows that an increase in the welding studs’ stiffness makes the range of the shear force along the bridge direction of the top and bottom welding studs larger, and the longitudinal distribution of the welding studs’ shear force is more uneven. To avoid the damage caused by the excessive forces of the welding studs, the stiffness of the welding studs should not be too large on the basis of ensuring the safety of the joint connection;

- The internal force bearing ratio of the concrete structure is higher than that of the steel structure in the joint. The transmission of normal stress at the junction occurs from the steel beam section to the concrete beam section through two ways: bearing and shearing. Notably, the primary mode of force transmission for normal stress involves contact bearing through the back bearing plate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yepes, V.; Dasí-Gil, M.; Martínez-Muñoz, D.; López-Desfilis, V.J.; Martí, J.V. Heuristic Techniques for the Design of Steel-Concrete Composite Pedestrian Bridges. Appl. Sci. 2019, 9, 3253. [Google Scholar] [CrossRef]

- Gara, F.; Carbonari, S.; Leoni, G.; Dezi, L. Finite Elements for Higher Order Steel–Concrete Composite Beams. Appl. Sci. 2021, 11, 568. [Google Scholar] [CrossRef]

- Lei, Q.; Wang, P.; Nan, H. Study on Mechanical Properties of Simply-Supported Composite Beams Considering Creep and Slip. Appl. Sci. 2022, 13, 193. [Google Scholar] [CrossRef]

- Brunesi, E.; Peloso, S.; Pinho, R.; Nascimbene, R. Cyclic testing and analysis of a full-scale cast-in-place reinforced concrete wall-slab-wall structure. Bull. Earthq. Eng. 2018, 16, 5309–5339. [Google Scholar] [CrossRef]

- Tang, L.; Wu, W.; Liu, G.; Xu, G. Structural performance of rear bearing-plate connection with cells in steel-concrete hybrid girder. Eng. Mech. 2010, 27, 234–243. [Google Scholar]

- Zhang, D.L.; Bao, Y.W.; Gao, J.H.; Xiao, L.; Li, X.Z. Research on load transfer mechanism of steel-concrete joint section of hybrid beam cable-stayed bridge. Adv. Mater. Res. 2013, 639–640, 216–219. [Google Scholar] [CrossRef]

- Xing, B.; Li, X.Z. The numerical simulation analysis method of steel-concrete joint section in hybrid girder of cable-stayed bridge. Adv. Mater. Res. 2014, 1049–1050, 226–233. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, C.; Liu, Y. Load transfer mechanism between cells and bearing-plate in hybrid girder joint. J. Tongji Univ. Nat. Sci. 2017, 45, 658–663. [Google Scholar]

- He, S.; Mosallam, A.S.; Fang, Z.; Liu, L. Structural evaluation of steel–concrete joint with uhpc grout in single cable–plane hybrid cable-stayed bridges. J. Bridge Eng. 2019, 24, 04019022. [Google Scholar] [CrossRef]

- Yang, S.; Pu, Q.; Shi, Z.; Hong, Y. Mechanical behavior of steel–concrete composite joints in railway hybrid cable-stayed bridges. J. Constr. Steel Res. 2020, 173, 106242. [Google Scholar] [CrossRef]

- Pu, Q.; Yang, S.; Shi, Z.; Hong, Y.; Zhou, Y. Fatigue performance of an innovative steel–concrete joint in long-span railway hybrid box girder cable-stayed bridges. J. Bridge Eng. 2021, 26, 04020129. [Google Scholar] [CrossRef]

- Gu, Y.-W.; Nie, X.; Liu, Y.-F.; Duan, S.-K.; Fan, J.-S. Experimental and numerical study of steel-to-concrete joint section in hybrid cable-stayed bridges. J. Constr. Steel Res. 2021, 187, 106982. [Google Scholar] [CrossRef]

- Yao, Y.; Yan, M.; Shi, Z.; Wang, Y.; Bao, Y. Mechanical behavior of an innovative steel–concrete joint for long-span railway hybrid box girder cable-stayed bridges. Eng. Struct. 2021, 239, 112358. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, L.; Su, Q.; Abbas, S. Mechanical behavior of a novel steel–concrete joint in concrete-composited hybrid continuous bridges. Structures 2022, 36, 291–302. [Google Scholar] [CrossRef]

- Zhou, Y.; Pu, Q.; Shi, Z.; Gou, H.; Chen, X. Experimental and numerical parametric study of the mechanical properties in a steel–concrete joint section. Int. J. Civ. Eng. 2022, 20, 1431–1446. [Google Scholar] [CrossRef]

- Liang, H.; Tan, K.; Deng, K.; Zhang, Y.; Zhao, C.; Yang, T. Crack resistance of steel–concrete hybrid joint between concrete girder and steel–concrete composite girder in long-span cable-stayed bridge under hogging moment. J. Bridge Eng. 2023, 28, 05022013. [Google Scholar] [CrossRef]

- He, J.; Liu, Y.; Pei, B. Experimental study of the steel-concrete connection in hybrid cable-stayed bridges. J. Perform. Constr. Facil. 2014, 28, 559–570. [Google Scholar] [CrossRef]

- He, S.; Fang, Z.; Fang, Y.; Liu, M.; Liu, L.; Mosallam, A.S. Experimental study on perfobond strip connector in steel–concrete joints of hybrid bridges. J. Constr. Steel Res. 2016, 118, 169–179. [Google Scholar] [CrossRef]

- Di, J.; Zou, Y.; Zhou, X.; Qin, F.; Peng, X. Push-out test of large perfobond connectors in steel–concrete joints of hybrid bridges. J. Constr. Steel Res. 2018, 150, 415–429. [Google Scholar] [CrossRef]

- Zou, Y.; Di, J.; Zhou, J.; Zhang, Z.; Li, X.; Zhang, H.; Qin, F. Shear behavior of perfobond connectors in the steel-concrete joints of hybrid bridges. J. Constr. Steel Res. 2020, 172, 106217. [Google Scholar] [CrossRef]

- Zou, Y.; Zheng, K.; Zhou, J.; Zhang, Z.; Li, X. Mechanical behavior of perfobond connector group in steel–concrete joint of hybrid bridge. Structures 2021, 30, 925–936. [Google Scholar] [CrossRef]

- Zhou, Y.; Pu, Q.-H.; Shi, Z.; Gou, H.-Y.; Yang, S.-L. Experimental study on fatigue performance of steel-concrete joint section of hybrid girder cable-stayed bridge. Adv. Steel Constr. 2022, 18, 536–543. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, C.; Yang, X. Stability analysis of edong yangtze river bridge during construction. J. Southwest Jiaotong Univ. 2012, 47, 741–747. [Google Scholar]

- He, Z.-Q.; Chen, J.; Liu, Z.; Ma, Z.J. An explicit approach for determining the rational length of steel portion in steel–concrete hybrid girder bridges. J. Bridge Eng. 2023, 28, 05022011. [Google Scholar] [CrossRef]

- Liu, M. Practices and prospects of steel-concrete composite technology in bridge engineering. Bridge Constr. 2022, 52, 18–25. [Google Scholar]

| Material/Component | Elastic Modulus (104 MPa) | Poisson’s Ratio | Volume Weight (kN/m3) |

|---|---|---|---|

| concrete | 3.55 | 0.2 | 26 |

| steel | 20.6 | 0.3 | 78.5 |

| vertical prestressed tendon | 20.0 | / | 78.5 |

| longitudinal prestressed steel strand | 19.5 | / | 78.5 |

| Loading Case | Bending Moment (kN·m) | Axial Force (kN) | Shearing Force (kN) |

|---|---|---|---|

| working condition 1 | 75,162.6 | −8930.8 | −2890.1 |

| working condition 2 | 72,647.8 | −8921.5 | −2763.2 |

| Section | Point | Measured Value | Calculated Value |

|---|---|---|---|

| S1–S1 | TS1 | −7.65 | −8.60 |

| TS3 | −7.81 | −8.03 | |

| BS1 | −5.13 | −4.22 | |

| BS3 | −4.82 | −4.16 | |

| S2–S2 | TS1 | −14.01 | −13.12 |

| TS2 | −17.24 | −18.09 | |

| TS3 | −11.31 | −12.79 | |

| BS1 | −12.98 | −13.74 | |

| BS2 | −17.35 | −17.83 | |

| BS3 | −13.89 | −13.50 | |

| S3–S3 | TS1 | −10.21 | −9.61 |

| TS2 | −12.54 | −11.78 | |

| TS3 | −8.54 | −9.37 | |

| BS1 | −12.32 | −11.41 | |

| BS2 | −11.85 | −12.16 | |

| BS3 | −11.84 | −11.15 | |

| S4–S4 | TS1 | −4.54 | −5.01 |

| TS2 | −4.24 | −4.80 | |

| TS3 | −5.33 | −4.96 | |

| BS1 | −5.88 | −5.48 | |

| BS2 | −5.23 | −5.54 | |

| BS3 | −5.56 | −5.38 |

| Section | Point | Measured Value | Calculated Value |

|---|---|---|---|

| S3–S3 | TC1 | −2.18 | −2.42 |

| TC2 | −2.68 | −2.94 | |

| TC3 | −2.54 | −2.38 | |

| BC1 | −3.25 | −3.39 | |

| BC2 | −2.98 | −2.86 | |

| BC3 | −3.41 | −3.32 | |

| S4–S4 | TC1 | −2.87 | −3.13 |

| TC2 | −3.35 | −3.13 | |

| TC3 | −2.84 | −3.03 | |

| BC1 | −3.84 | −3.98 | |

| BC2 | −3.75 | −3.65 | |

| BC3 | −3.79 | −3.92 |

| Welding Stud Number | Shear Stiffness (kN/mm) | Tensile Stiffness (kN/mm) |

|---|---|---|

| 0.5 Ks | 180 | 122.5 |

| 1.0 Ks | 360 | 245 |

| 1.5 Ks | 540 | 367.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, L.; Yuan, S.; Li, J.; Wu, T.; Zhan, G.; Pei, H. Study on Structural Parameter Sensitivity and the Force Transmission Mechanism of Steel–Concrete Joints in Hybrid Beam Bridges. Buildings 2024, 14, 708. https://doi.org/10.3390/buildings14030708

Jia L, Yuan S, Li J, Wu T, Zhan G, Pei H. Study on Structural Parameter Sensitivity and the Force Transmission Mechanism of Steel–Concrete Joints in Hybrid Beam Bridges. Buildings. 2024; 14(3):708. https://doi.org/10.3390/buildings14030708

Chicago/Turabian StyleJia, Lijun, Shanshan Yuan, Jiawei Li, Tingying Wu, Gangyi Zhan, and Huiteng Pei. 2024. "Study on Structural Parameter Sensitivity and the Force Transmission Mechanism of Steel–Concrete Joints in Hybrid Beam Bridges" Buildings 14, no. 3: 708. https://doi.org/10.3390/buildings14030708

APA StyleJia, L., Yuan, S., Li, J., Wu, T., Zhan, G., & Pei, H. (2024). Study on Structural Parameter Sensitivity and the Force Transmission Mechanism of Steel–Concrete Joints in Hybrid Beam Bridges. Buildings, 14(3), 708. https://doi.org/10.3390/buildings14030708