Abstract

The linear economy model that is generally practised in the construction industry is one of the main reasons hindering the achievement of sustainability in construction. Alternatively, the Circular Economy (CE) model is becoming a promising approach to achieve sustainable construction, in which materials and products are circulated at their highest economic value and, thereby, contribute towards mitigating the negative economic, social, and environmental impacts of the construction industry. For a successful transition towards CE in the construction industry, it is important not only to understand CE practices that could be implemented across different stages of the life cycle of construction projects, but also to understand how a particular practice relates to another at those stages. Having limited studies identifying such relationships, this study aims to improve the successful implementation of CE practices in the construction industry by comprehending the practices, along with their relationships, throughout the project life cycle. A qualitative research method consisting of a systematic literature review was adopted using the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) framework to identify CE practices. Amongst the identified highly cited CE practices applicable to construction projects, design for disassembly, design for adaptability and flexibility, and design for manufacture and assembly ended up being the most significant ones. Consequently, a relationship matrix was developed, highlighting the relationships among the highly cited practices. The matrix emphasises that practices applied in the design stage relate frequently to ones at the following stages, necessitating projects to start with proper planning. This study ultimately assists construction industry stakeholders in successfully and rationally implementing CE practices throughout the project life cycle while enhancing the value addition on the economy, society, and environment.

1. Introduction

The construction industry is a complex and dynamic industrial sector [1] in which the majority of products are unique, produced majorly on an outside site, with the involvement of different stakeholders. Given that the construction industry is the largest contributor to the economies of many countries [2], it is not surprising that the industry consumes the majority of natural resources and raw materials for production [3,4]. As confirmed by Norouzi, Chàfer [5], the construction industry is responsible for half of all raw material consumption and 36% of total energy consumption, globally. On the other hand, Zhang, Han [6] pointed out that, while natural resources are used to construct new structures, some ageing structures are demolished, and a large amount of waste is released into the environment. According to Benachio, Freitas [7], the linear economic model practised makes the construction industry responsible for 25% of all solid waste produced in the world. Kirchherr, Reike [8] opined that the growing demand for construction products resulted in material scarcity and growing environmental concerns. Thus, it is imperative that the construction sector converts from linear models to sustainable models [9,10,11,12]. Ossio, Salinas [13] found that changes in the construction sector consistent with a circular economy (CE) model would be ideal for becoming more sustainable.

As defined by the Ellen MacArthur Foundation (EMF), CE is an industrial system which is restorative or regenerative by intention and design concerning both technical and biological cycles [14]. CE has been implemented gradually across many industrial sectors at different levels, since its inception in the late 1990s [15]. Applying CE in the construction industry is termed as ‘circular construction’. Kubbinga, Bamberger [16] describe circular construction as “the development, use and reuse of buildings and infrastructure, without avoidable depletion of natural resources, pollution of the environment or negatively impacting ecosystems”. According to Ghisellini, Ripa [17], CE focuses on the entire supply chain in the construction industry with a circular vision and, thereby, achieves sustainability in construction [10]. The EMF [18] has emphasised that the built environment can benefit from savings of natural resources and energy to a considerable amount by applying CE. Furthermore, the construction industry has great potential to create value and leverage CE implementation because of the significant environmental, social, and economic impacts created through the implementation [19]. However, the construction industry is still in the early stages of adapting to CE, despite the vast benefits it can generate through the transition [13,20].

A systematic review carried out by Osobajo, Oke [21] on CE application in the construction industry revealed that approximately 64% of the research reviewed was related to construction materials and resources, with 34% and 30% related to resource reuse and waste management, respectively. Agreeing with this, Ogunmakinde, Sher [22] mentioned that the construction industry still lacks CE initiatives related to many aspects of the construction life cycle and focuses only on major aspects like resource handling and waste management. While waste management and resource handling have gained significant attention in the literature related to CE in the construction industry [10], limited attention has been given to other areas like design, supply chain management, land use, energy efficiency, risk management, cost management, and health and safety management, which are considered to be critical areas in a construction project [21]. The design of a construction project is critical as it is the focal point that decides the future performance of the completed project [23]. Therefore, how CE can be integrated into the design process needs to be studied in depth. Nasir, Genovese [24] opined that, since the construction supply chain involves multiple entities, it is worth considering how CE can be integrated into it. Investigating how CE initiatives can assist the efficient use of energy is essential as the energy requirement of the construction industry is significantly high [7]. The effective management of cost and other uncertainties is critical for the successful completion of a construction project [21]; accordingly, it is important to focus on CE initiatives in these areas. Less focus given to the aforementioned critical areas would hinder the successful transition towards CE in the construction industry [23], as a successful transition requires a comprehensive understanding of the entire construction process and a focus on possible CE practices at each stage of the construction life cycle [11,25,26].

CE practices control resource intake, waste emission, and energy outflows through slowing, closing, and narrowing loops [27]. As opined by van Stijn and Gruis [28], the transition towards a circular construction industry necessitates alterations of current practices that are based on the linear model. In general, projects are organised into stages or processes, referred to as the project life cycle. Due to the unique and complex nature of the construction industry, it has a lengthy life cycle which involves distinct activities in each stage [29]. The life cycle perspective is paramount in CE implementation as the activities at one stage may be highly related to the decisions taken at another stage [30]. Hence, focusing on individual CE practices or a single life cycle stage without identifying the relationships among CE practices throughout the life cycle may not optimise CE implementation within the construction industry as a whole [31].

Even though several studies have identified CE practices used in the construction industry, less focus has been given to the entire life cycle of a construction project. Moreover, studies that identify the relationships of CE practices throughout the construction life cycle are not common. Furthermore, Charef, Lu [32] stress the timely need to study not only CE practices but also the relationships between those throughout the construction life cycle to provide an overall understanding of CE implementation in the construction industry. In consequence, and to fulfil the above briefed research needs, this study aims to enhance the successful implementation of CE in the construction industry through a holistic understanding of CE practices and their relationships throughout the entire life cycle of a construction project. Accordingly, highly cited CE practices were identified through a systematic literature review and a relationship matrix was developed to demonstrate the relationships among those practices. This study would be beneficial to construction project stakeholders including investors/clients, manufacturers and suppliers, contractors, and end users in successfully implementing CE practices in their projects by having a proper understanding of how those practices could relate to each other, providing value additions.

This review paper contains two analyses, a bibliographic analysis and a content analysis using the existing literature, followed by the development of a relationship matrix. Section 2 and Section 3, respectively, present the background and research methods. Thereafter, Section 4 outlines the results of both the bibliometric and content analyses, along with a discussion of the results and an explanation of the contribution of the research findings. Finally, Section 5 concludes the research with recommendations and limitations of the study, followed by further research directions identified by the authors.

2. Circular Economy (CE) Practices Used in the Built Environment (BE)

Circular economy is currently a prime focus area of many industries including construction. The implementation of CE in the construction industry is critical for achieving sustainability [21,28,33]. A report from the World Economic Forum (WEF) [34] suggests that the implementation of CE in the construction sector could result in savings of over USD 100 billion per year due to increased productivity. Similarly, Mhatre, Panchal [11] opined that the CE concept has the potential to reduce the carbon footprint of the construction industry, being a sound alternative to intake less natural resources and produce less waste [22].

CE can be implemented in four different systematic levels: nano, micro, meso and macro. In the construction context, all types of materials and components are in the first level (nano), all types of structures including buildings and infrastructure are in the second level (micro), industrial areas are in the third level (meso), and cities and countries can be considered to be the fourth level (macro) [19]. To successfully implement CE in the built environment, practising CE in parallel at all four implementation levels is essential [11,19,21].

The use of circular practices facilitates the transition of the construction industry towards CE [35]. Even though circular concepts related to the construction industry are discussed frequently in the literature, the practical application of the same remains negligible due to the lack of known standard practices [7,35,36]. Similarly, van Bueren, Leenders [37] identified the lack of existing standard practices as a barrier to adopting CE concepts in the construction industry.

In addition, Ababio and Lu [38] identified that CE-related terms have been used inconsistently in the literature, which can also be seen as a barrier to the successful implementation of CE in the construction industry. For instance, some authors name CE practices as ‘CE principles’ [39], while others refer to the same as ‘CE aspects’ [36] or ‘CE strategies’ [35]. Since the CE literature has used terms in contradictory ways, the dictionary meanings of the terms were explored to proceed with a proper term in the current study. According to the Oxford Dictionary, ‘principle’ means ‘a fundamental truth or proposition on which others depend’; ‘strategy’ means ‘a plan, scheme, or course of action designed to achieve an overall aim’, and ‘practice’ means ‘an activity or action considered as being the realisation of a theory’ [40]. The quoted definitions exhibit a clear difference between the terminology and place the term ‘principle’ at the high level in the hierarchy of CE-related terms. Thus, the term ‘principle’ is not appropriate for use in the current study, which is only associated with CE implementation in the construction industry. Strategies are more from an organisational perspective, and they refer to an overall plan to achieve CE which may contain practices as part of it. Since this study majorly looks at how CE could be implemented within a construction project domain practically, it was decided to utilise the term ‘practice’ throughout the study, aligning with Benachio, Freitas [7] and Asante, Faibil [33].

The concept of CE in the construction industry is studied along with the life cycle stages of a construction project. Guerra, Shahi [41] opined that CE practices can also be implemented in different stages of the life cycle of a construction project. Furthermore, CE practices in different life cycle stages can be related in different ways, and sometimes the absence of one will create no existence of others at a different stage [42]. Hence, classifying CE practices from the perspective of the construction life cycle and identifying relationships among practices are significant [7,43]. The life cycle of a construction project starts with the design phase; continues at the manufacturing phase, construction phase, use phase; and ends with the end-of-life phase [7,44]. This five-stage categorisation has been used in the current study for studying CE practices further.

3. Materials and Methods

This study utilises a systematic literature review (SLR) with both qualitative and quantitative analyses. It not only identifies the patterns which can be observed in literature but also discusses the findings related to CE practices in the construction industry qualitatively. SLR is seen as a suitable means of comprehensively reviewing the literature to define an area of study [45]. Furthermore, SLRs aid in carrying out transparent and reproducible studies [46]. PRISMA was used as the guideline for the study, which is largely used as a structured way of reporting the outcomes of SLRs. The use of PRISMA enables planning studies so that reviews are more transparent, accurate, qualitative, and complete [47]. The sub-sections mentioned below elaborate on how each step of the SLR was carried out in a detailed manner.

3.1. Database Selection and Searching

The SLR process commenced with the selection of databases and database searching. Accordingly, both Scopus and Web of Science databases were selected to carry out the systematic search. Scopus and Web of Science are identified as two of the most highly used databases for academic research and publication. Numerically, Scopus and Web of Science cover more than 42,000 and 32,000 peer-reviewed journals across the world, respectively. Being the most popular and comprehensive databases, those are guaranteed to obtain the highest number of scientific publications for this study. Using multiple databases in the SLR enhances the comprehensiveness of the study and ensures that it covers most of the available studies in the study area. The keywords string used to carry out the database searching in this study is (Circular Economy OR Cradle to Cradle) AND (practices OR strategies) AND (Construction Industry OR buildings OR Built Environment). The keyword searching was carried out within the ‘Title-Abstract-Keywords’ and ‘Topic’ fields, respectively, from Scopus and the Web of Science databases. The search process was conducted in November 2023.

3.2. Conducting Review

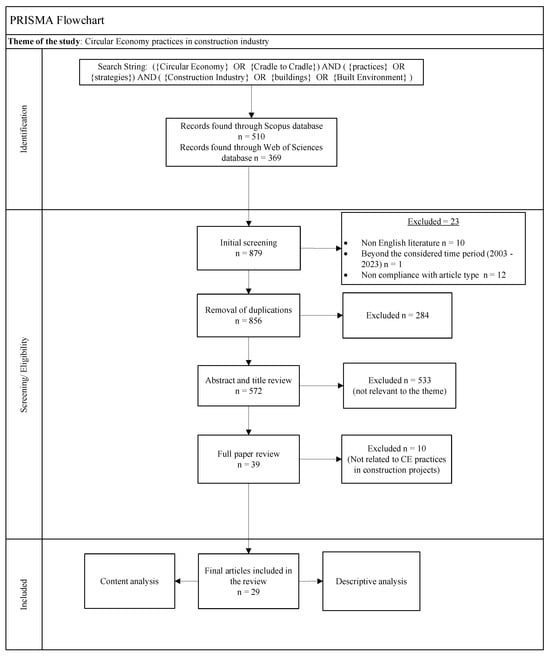

In the beginning, 879 documents were identified from the database search. The complete process and the outcome of the SLR is demonstrated in Figure 1. During the initial screening, articles were filtered considering the language, time period, and document type. Ten (10) documents were excluded as those were not written in the English language. A twenty (20)-year period was considered for the SLR from 2003 to 2023 to observe the development of CE practices with the technological advancements from the inception of CE concepts. As a result, only one article was excluded, as it was published in year 1999. To ensure that the study includes most of the studies in the area being reviewed, authors considered only journal articles, conference proceedings, books, and book chapters, and excluded other publications like editorials and conference reviews to maintain the quality of the review. Accordingly, 12 articles were excluded considering the document type. At the end of the initial screening process, 23 articles in total were excluded and the remaining 856 articles were examined for duplications. Consequently, 284 duplications were identified and excluded. Thereafter, the titles and abstracts of the articles were inspected to identify the articles, which fall under the theme of the study which was related to CE practices that can be applied in the construction industry. Correspondently, 39 documents were identified. Even though all 572 articles after duplication removal fulfilled the requirements in the keyword search, the majority of studies are not related to CE practices of construction projects. Furthermore, many articles contained practices and strategies related to various sustainability aspects within the built environment and did not fulfil the requirements of this study. For instance, those articles merely focus on specific themes such as waste management, supply chain management, and recycling materials. As the final step, the selected 39 articles underwent a subsequent full-text review, and, finally, 29 articles were selected for the analysis. After reviewing documents fully, 10 articles were excluded as a result of being noncompliant with the aim of the research which was to identify CE practices that can be utilised throughout the life cycle of a construction project.

Figure 1.

PRISMA flow diagram of the SLR.

Interpretation of the results of SLR was assisted with a proper data abstraction template created by the authors through summarising the ultimate sample of accepted articles. Data extracted from each article included the name of the author(s), year of publication, source (journal title/conference title), countries of co-authors, all keywords, and identified CE practices.

3.3. Descriptive Analysis

Descriptive analysis of the selected literature was performed using the software package “VOSviewer version 1.6.19”, which is popular among researchers and available for free download and use. Compared to other widely used bibliometric analysis methods like Bibliometrix and CiteSpace, visualisations created with VOSviewer have better clarity and user-friendliness. In addition, it is technically robust and, thus, easy to use. As such, it has been extensively tried and tested by many studies of a similar nature. The analysis of literature was conducted by considering three selected bibliometric indicators including co-occurrence of keywords, co-authorship by countries, and the leading journals in the field of CE practices in the construction industry.

3.4. Content Analysis

The selected articles were analysed using manual content analysis to identify the CE practices, which can be applied in the context of a construction project, and, thereby, develop a relationship matrix for the identified highly cited CE practices. To avoid subjectivity and biases in the analysis, it is advisable to incorporate two or more researchers in the content analysis [48]. Thus, three researchers were engaged in finalising research findings, obtained through the analysis performed by the first author of the study. A similar kind of approach was utilised by Wijewickrama, Chileshe [48] and Prajapati, Kant [45].

4. Results and Discussion

This section outlines and discusses the results of the systematic literature review. Section 4.1, Section 4.2 and Section 4.3 are related to descriptive analysis performed using VOSviewer version 1.6.19 software, while Section 4.4 and Section 4.5 relate to the results of the manual content analysis.

4.1. Leading Journals for CE Practices in BE

Out of 29 articles in total, 27 journal articles were included in the final set of accepted articles through SLR. The distribution of journal articles for each journal is shown in Table 1.

Table 1.

Contribution of the journals in the study area.

The ‘Journal of Cleaner Production’ concentrates the highest number of articles related to CE practices in construction, followed by the ‘Resources, Conservation and Recycling’ journal within the period of 2003–2023. The majority of the systematic searches carried out in the area of CE ended up with the same results [9,13]. Next in line are the ‘Buildings’, ‘Sustainability’ and ‘Sustainable Production and Consumption’ journals. Both top journals are from Elsevier and focus on main CE principles, namely, productions with minimum waste and resource circulation, respectively. It could be the reason that many CE-related articles are published more often in those journals compared to other journals in the list, which are not directly aimed at CE principles.

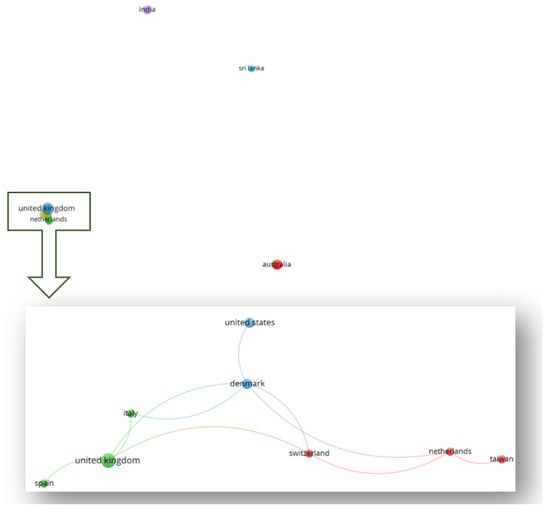

4.2. Co-Authorship Analysis by Countries

The co-authorship analysis recognised scientific collaborations in terms of the most productive and influential authors, institutions/organisations, and countries [49]. The selected 29 articles in this study underwent a co-authorship analysis to figure out the most influential countries in the research area. Figure 2 provides VOSviewer maps created for the analysis of highly contributed countries emphasising the collaboration among identified countries. The data showed that 23 countries contributed to the 29 research articles selected for the study. However, only 13 countries were found to have a minimum of two research articles per country.

Figure 2.

Most research-oriented countries and the collaborations among countries.

According to Figure 2, there are altogether six clusters in the primary diagram with 13 links, and, out of that, 10 links are among three clusters as shown in the secondary diagram. According to the diagrams, more collaboration can be seen within the European region, whereas less collaboration can be seen in other continents with a smaller number of articles in the research area. The United Kingdom has contributed more (6 articles) in researching CE practices in the built environment, followed by Australia (4 articles).

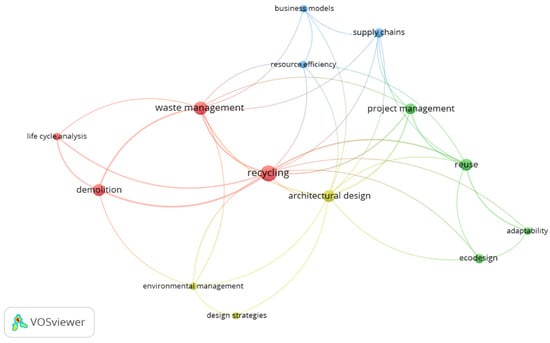

4.3. Analysis of Highly Focused Themes Related to CE Practices

Keyword analysis is the next focus under the descriptive analysis aiming at identifying the frequently discussed themes related to CE practices in the built environment. Figure 3 demonstrates the VOSviewer map for the co-occurrence of all keywords in the selected articles for SLR. The threshold was kept at two, since the authors assumed that a particular keyword occurring more than once should be considered as a common keyword because the current study contains only a small number of articles. Fifty-five (55) keywords satisfied the minimum threshold. Those keywords were refined considering their similarities and relationships with the theme of this study. Accordingly, the VOSviewer map was generated with 14 keywords under four clusters, 39 links, and a total link strength of 55. The strength of the link connecting two keywords indicates the number of articles in which the keywords appear together, showing the connection of their corresponding research focuses.

Figure 3.

Co-occurrence of keywords.

‘Recycling’ could be identified as the most frequently appearing keyword within the selected articles, followed by ‘waste management’. This result is consistent with Adams, Osmani [36], who stated that CE in construction is heavily limited to construction waste minimisation and recycling. Recycling is the most popular end-of-life route as it is a popular solution for end-of-life waste management [50]. Similarly, Ghisellini, Ripa [17] found that recycling was the most researched practice in the construction industry and many firms prefer starting CE thinking from the recycling of materials. Four main clusters could be identified as shown in Figure 3. The red colour cluster contains four keywords, which are related to recycling and managing the waste of a construction project and the majority of keywords in this cluster have highly appeared in the literature. The next highlighted cluster is represented with green colour, and it majorly contains practices related to effectively managing constructed projects, which enhance flexibility and reusability. The yellow cluster highlights design-related practices and the blue cluster indicates supply chain and resource handling.

The following sections discuss the results of the content analysis under two main headings, CE practices and relationships among CE practices.

4.4. Highly Cited CE Practices under Different Life Cycle Stages

The discussion of CE practices is presented under five life cycle stages, namely, the design stage, material manufacturing stage, construction stage, use stage, and end-of-life stage. Practices which cannot be categorised under these stages are discussed under the heading of ‘other’ practices. Details of the selected sources for the content analysis are given in Table 2. Most of these articles are review articles and a few of them are based on the primary data collected through surveys, interviews, expert forums, and case studies.

Table 2.

Sources for the systematic literature review.

As the first step of the analysis, the selected articles were reviewed, and CE practices were identified in accordance with the respective life cycle stages. The identified practices were then merged considering the similarities in their meanings. Accordingly, 148 different CE practices used in the built environment were identified from the initial analysis. The highest number of CE practices are related to the construction stage (37 practices), followed by the design stage (35 practices). Thereafter, highly cited CE practices under each stage were identified. The selection was carried out by dividing the number of articles falling under each CE practice by the number of articles falling under the highly cited CE practice in that stage. Practices resulting in more than 0.5 were recognised as highly cited practices within the respective stage. This method was considered since all 29 articles selected for the analysis were not identified with CE practices covering the entire life cycle; hence, dividing the article count of each practice by 29 would create an unreasonable value. The identified highly cited CE practices are shown in Table 3.

Table 3.

Highly cited CE practices in the literature.

According to Table 3, the most cited design-related practices are design for disassembly; design for adaptability and flexibility; design for manufacture and assembly; and design for preventing waste generation. This result is well-aligned with the study carried out by [35] in which design for disassembly and design for adaptability and flexibility are identified as strategies cited by every author. The main aim of design for disassembly is to provide the ability to carefully disassemble building components to maximise the potential reuse and recovery of building components and materials [51]. Design with high-quality, long-performing components is essential in order to increase the durability of the design and it directly impacts on the next-service life of the particular product or component [23]. Designs which reduce waste have gained much attention in the literature because construction and demolition waste is identified as a severe threat to the environment. Incorporating CE at the design stage requires design professionals who are familiarised with CE principles; thus, CE awareness programmes should be carried out.

Reusing secondary materials and components in new productions appears as the most cited CE practice during the manufacturing stage. Agreeing with that, Eberhardt, Birkved [23] and Timm, Maciel [60] identified that the most common CE strategies in the construction sector are related to reusing materials. It also reduces the energy consumption of the manufacturing processes in the construction industry and other industries [26]. Using recycled resources is a cascading approach for effective resource consumption in a construction project [56]. However, some recycling processes may consume more energy compared to the initial production, which should be considered and managed carefully during the implementation process. Many authors emphasise the need for safe and healthier buildings that can be used for a long time, and, therefore, it is necessary to choose materials suitable for long-term use [53]. Using less hazardous and less toxic contents in the production of construction materials is paramount for ensuring the overall health and safety of building occupants.

Using prefabricated components or offsite construction has been identified as the topmost cited practice in literature for the construction stage. Charef, Lu [32] have ended up with a similar result in their review. According to the authors’ view, prefabrication would make reusing components easier in the next service life. Additionally, prefabrication methods are often combined with modular construction, which improves the constructability and construction speed [32]. Waste management is another aspect that needs to be considered during construction and many studies have identified that proactive waste management is better than reactive waste management. It has been identified that innovative processes and concepts have taken the lead in reducing waste generated at construction sites [51]. However, the authors opined that these in-site waste management options may incur additional costs; thus, a better analysis of positive and negative impacts should be considered before implementing the same.

Sharing spaces, facilities, and products is the highly cited CE practice in the literature for the use stage. During the use stage, spaces and facilities of a particular building can be shared by other building users, if those buildings are in close proximity. This practice may need behavioural changes of the occupants as some may be reluctant to share spaces and facilities. In addition, Adams, Osmani [36] highlighted that preventive maintenance would be ideal for keeping the building components in good condition and for increasing their reusing capabilities [53]. Preventive maintenance has been prioritised in the literature since reactive maintenance can be more expensive and may not guarantee reinstatement to the exact original condition to achieve the desired output again. Using renewable energy throughout the use phase is paramount to achieving circular economy targets. From the viewpoint of Sáez-de-Guinoa, Zambrana-Vasquez [26], two fine examples are generating electricity through solar power and utilising more efficient technologies that consume less energy for building operations. However, some renewable energy options may have negative impacts on land usage, for instance, solar installation.

The majority of studies have highlighted that the most important practice in the end-of-life (EOL) stage is to analyse the potential of reusing and recycling building materials and components. Simultaneously, evaluating the existing buildings using a circularity tool is important, as found in the literature review. Bertino, Menconi [67] clearly indicated that the circularity assessment of existing buildings is critical in order to make decisions at the EOL stage. Based on these analyses, a proper plan can be developed and executed for deciding whether the building is to be reused, disassembled, or deconstructed and whether materials are recycled or disposed of [26]. Another highly cited CE practice in the EOL stage is the effective management of demolition waste. Even though waste generation is inevitable during all phases of a building’s life cycle, the end-of-life stage accounts for the highest portion due to demolition and disposal taking place [7]. Government involvement in mandating proper EOL waste management, along with an incentive scheme, is crucial for the implementation of this practice effectively in construction projects.

The preparation of material passports for a particular project starts at the design stage, is further developed at the manufacturing stage, and is updated throughout the rest of the life cycle of the building. Thus, this study categorised the same under the ‘other’ category of CE practices. A passport for a material is a collection of data and indicators that enhances the transparency of material or system properties and assists in measuring and optimising its effectiveness [7,60,63]. Applying take-back and trade-in systems is another well-cited CE practice in the literature, which relates to the CE business model context. As defined by Kalmykova, Sadagopan [68], a take-back system lets products be recovered from the user at the EOL and proceeded for a next use either via remanufacturing or reusing. On the other hand, this system requires manufacturers to be responsible for their products once they reach their end of life [36]. Furthermore, this emphasises that innovative management structures within organisations and new stakeholder networks along the construction value chain are essential in the journey towards CE [25].

Apart from the fact that there are different CE practices at each stage of the life cycle, there are some practices that may be related to other practices at different stages. Such relationships are discussed in detail in the following section, as the identification of such relationships will be beneficial for the proper implementation of CE practices throughout the life cycle of a construction project.

4.5. Relationships among Highly Cited CE Practices

The current study analyses the relationships among CE practices in terms of their interdependences and interconnections. Oxford Dictionary defines ‘interdependence’ as ‘the fact of depending on each other’, and ‘interconnection’ as ‘connection to or with similar things’. When it comes to the context of CE practices, interdependencies occur where one practice would not exist in the absence of another, while interconnections occur where one practice is related to another to deliver a collective advantage but is not decisive towards the existence of the other. CE practices identified in Section 4.4 relate with each other in either way and the same has been shown in the relationship matrix in Table 4. The matrix reflects relationships of CE practices identified through the systematic literature review and potential relationships identified by the authors. Two symbols have been used in the matrix, ‘x’ and ‘o’, to represent the interdependencies and interconnections among CE practices, respectively. The matrix would indicate the identified relationship type between two practices in the box where two practices have crossed each other. For instance, D1 and EL3 have an interdependency, while D1 and D3 have an interconnection. Similarly, all other cross points of the matrix can be interpreted.

Table 4.

Relationship matrix for highly cited CE practices.

Most of the EOL stage and use stage practices have interdependencies with design stage practices. Charef, Lu [32] also depicted the dominant connections between the design and the EOL stages. Table 4 shows that, if a building has not been designed for disassembly, disassembling parts at the end of life is infeasible, which was duly agreed by Charef, Lu [32]. Similarly, if the design is not considered for waste minimisation, end-of-life waste handling would be critical. Sharma, Kalbar [42] highlighted that design stage actions are highly impactful to waste prevention at both EOL and construction stages. In addition, the waste minimisation of the construction stage depends on employing modular construction, where the production takes place outside the site at mass scales. Sharing spaces and facilities in the use phase is induced by designing with adaptability and flexibility. No sharing would be possible without a design, which entails common spaces to be shared. Repairs and upgrades would be highly dependent on the consideration of the durability of the building at the design stage.

On the other hand, some CE practices have interconnections with other CE practices in the same phase and other phases. Those are not dependent on each other, and one can exist in the absence of the other, but there will be a collective impact with the presence of all. As an example, design for preventing waste generation is linked with design for modular construction and design for disassembly. Design for preventing waste generation is more meaningful when taken together with design for modular construction, where modules are planned to be manufactured on outside premises and no site construction will be present except the erection and fixing of the modules. Offsite constructions and modularity are important features to consider while designing for disassembly [55]. However, modularisation is for the easiness of handling and erection of components and is not necessarily meant for disassembly at the EOL stage [63].

Design stage practices like design for durability relate to evaluating the condition of existing buildings at EOL, as a durable design would provide optimistic results hence, ensure suitability for its second life. Similarly, a few use phase CE practices are also connected with EOL stage practices. For instance, preventive maintenance and timely repairs would connect with practices like evaluating the condition of the existing buildings using a circularity tool. Preventive maintenance delays a building from reaching demolition where it no longer meets its serviceability requirements [42]. If fewer preventive maintenance actions were carried out at the use stage, the existing condition of the building may not comply with the circular requirements at the EOL stage.

Analysing the capability of reusing and recycling building materials and components is another CE practice at the EOL stage, which has many connections with other CE practices. Manufacturing new materials from recovered or recycled materials becomes more effective if a proper analysis can be performed at the EOL stage to predict their potential to be recycled or reused. Preparing material passports as a significant, technology-aided CE practice has connections with CE practices related to material reusing and recycling. Apart from that, take-back and trade-in business models are becoming popular in the construction industry, yet another CE practice which has connections over several life cycle stages including manufacturing, construction, and EOL.

The relationship matrix in Table 4 confirms that most of the CE practices are related to each other across the construction life cycle. The developed matrix will contribute to the existing body of knowledge as a novel approach to recognise how CE practices collectively contribute to the successful implementation of CE in the construction industry. This matrix can be converted and further developed as a guideline to select CE practices for construction projects depending on the life cycle stage. Furthermore, the developed relationship matrix can serve as a basis for the circularity assessment of construction projects since the relationship among CE practices would be beneficial in assessing the collective impact.

Rational decision making during the inception and feasibility stages of a construction project is paramount for the success of any construction project. Similarly, rational decision making about different CE options that a project can implement is important for the successful implementation of CE in the construction industry. The implemented CE practices in construction projects should amplify the value addition for the project itself, the economy, society, and the environment. As the developed relationship matrix shows the practices having relationships with others, it can be used as a methodology to select the most impactful CE practices throughout the construction life cycle and, thereby, to make sound decisions at the inception stage of the project. Once a CE practice is selected for implementation in a project, the proposed matrix allows project stakeholders to review other CE practices that need to be implemented in parallel or sequentially to optimise better results. In addition, the implementation of CE practices might incur some additional initial costs, which can be managed by applying the proposed matrix as it facilitates the prioritisation and selection of CE practices to gain collective value additions. The developed relationship matrix can be used at any stage of a construction project to recognise the practices that have a high number of relationships, thereby producing a collective impact after implementation.

5. Conclusions

The study conducted a SLR of CE practices in the construction industry inclusive of a descriptive analysis and a content analysis. Through the descriptive analysis, leading journals, the most common keywords, and leading countries engaged in the study area were first identified. Highly cited CE practices and the relationships among those practices throughout the construction life cycle were next identified by performing the content analysis. Altogether, 29 articles were selected for the systematic review after a multistep filtering process.

The Journal of Cleaner Production, and Resources, Conservation and Recycling are the leading journals out of which the majority of articles were selected for this study. Thereafter, a co-authorship analysis was performed to identify the most contributing and collaborative countries in this research area. Findings depicted that many articles were co-authored in the Europe region, emphasising that Europe, particularly the UK, is at the forefront of researching CE practices in the construction sector compared to other countries. The keyword analysis revealed that recycling and waste management are the most common keywords falling under the study area. Circular design and circular business models are also considered in the literature but are not as extensive as recycling and waste management. Thus, many under-explored areas associated with CE practices pertaining to the construction industry can be observed.

The content analysis identified 148 CE practices in total under five life cycle stages and one common stage, and 25 of them were recognised as highly cited CE practices. Amongst them, design for disassembly, design for adaptability and flexibility to change, design for manufacture and assembly (modular construction), design for preventing waste generation, reusing secondary materials and components in new productions, analysing the potential of reusing and recycling of building materials and components, and the effective management of demolition waste are important, and over 14 occurrences per each were found within the selected 29 articles. The interdependencies and interconnections of CE practices were demonstrated using a matrix diagram. Many relationships were observed between design stage practices with other stages emphasising the importance of proper planning. Furthermore, it was highlighted that practices in the EOL stage are highly dependent on practices in the early stages.

Identifying the highly cited CE practices, along with their relationship matrix, is the main contribution to the knowledge of this study, which provides a holistic understanding of the implementation of CE practices across the life cycle stages of construction projects. The findings are significantly important for the stakeholders of the construction industry as they can identify the relationships between CE practices and utilise more rational decision making when selecting the most suitable CE practices to apply in their projects. Investors/clients, manufacturers and suppliers, contractors, and end users are the main stakeholder categories that would benefit from this study.

Investors/clients can use the findings of this study to figure out CE practices which would benefit them in the long run, depending on the relationships that exist with other practices. Furthermore, details in the relationship matrix can be used to assist any economic feasibility assessment of CE practices. Based on a comparison of different CE practices and their relationships shown in the developed matrix added with a feasibility assessment, investors can decide whether to proceed with a particular CE practice or not. Manufacturers and suppliers play a crucial role in a construction project and their understanding of how CE can be implemented within the manufacturing processes is significant. The findings of this research revealed key CE practices to be followed in the manufacturing stage and how those practices would impact other stages. It is recommended to use this information to enhance the circularity of manufactured products and to enhance the consumer and supplier responsibility. This study has identified a set of CE practices that can be applied in the construction stage and their relationships with other practices. Contractors can use this information to decide which CE practice is better to implement in their projects, delivering the ability to increase the buildability and durability of the project. End users of a building engage with a longer time duration than others in the construction life cycle; hence, the findings of this research are helpful for them to identify CE practices that are effective during the operational phase of the project. Using this information is recommended when maintaining and repairing buildings to expect effective outcomes during the EOL phase. Collectively, the developed relationship matrix of CE practices would guide almost every stakeholder in the construction industry to identify the contribution that each one should make to productively implement CE.

A few difficulties were encountered during the filtering process of articles which can be highlighted as limitations of the study. Initially, there were close to 800 articles which satisfied the keyword search criteria from both the Scopus and Web of Sciences databases. Removing duplications in two databases was time-consuming since the same article name was sometimes displayed differently; thus, a manual check was performed to remove duplications. Moreover, selecting the most relevant studies for the SLR was challenging as the majority of articles that satisfied the keyword search were not relevant to the aim.

The study was restricted to identifying the relationships of highly cited CE practices in the literature. However, there are many other CE practices (not highly cited) that are not discussed here, which may have interdependencies and interconnections with each other. Future studies need to be carried out to reveal those hidden relationships, thereby enhancing the rationale of implementing CE practices in construction projects. In addition, more research can be carried out to come across specific CE practices falling in line with the type of the project, as this study did not differentiate CE practices falling under infrastructure projects and building projects. Another area to be researched is to analyse the stakeholder contribution towards implementing each of these CE practices, along with the information to be shared by stakeholders.

Finally, this study would enhance the sustainability aspects of the construction industry while contributing to the United Nations’ Sustainable Development Goals 9—Industry innovation and infrastructure; 11—Sustainable cities and communities; and 12—Responsible consumption and production.

Author Contributions

Conceptualisation, I.G., S.S., S.P. and X.J; methodology, I.G. and S.S.; formal analysis, I.G.; original draft preparation, I.G.; review and editing, S.S., S.P. and X.J.; and supervision, S.S., S.P. and X.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nawi, M.N.M.; Baluch, N.H.; Bahaudin, A.Y. Impact of fragmentation issue in construction industry: An overview. In Proceedings of the MATEC Web of Conferences, Perak, Malaysia, 27 August 2014. [Google Scholar]

- Carra, G.; Magdani, N. Circular Business Models for the Built Environment; Ellen MacArthur Foundation: Isle of Wight, UK, 2017; pp. 1–44. [Google Scholar]

- Munaro, M.R.; Freitas, M.d.C.D.; Tavares, S.F.; Bragança, L. Circular Business Models: Current State and Framework to Achieve Sustainable Buildings. J. Constr. Eng. Manag. 2021, 147, 04021164. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; de Soto, B.G. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Zhang, N.; Han, Q.; de Vries, B. Building circularity assessment in the architecture, engineering, and construction industry: A new framework. Sustainability 2021, 13, 12466. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A systematic literature review on the circular economy initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- Wuni, I.Y. Burden of proof beyond the triple bottom line: Mapping the benefits of circular construction. Sustain. Prod. Consum. 2022, 34, 528–540. [Google Scholar] [CrossRef]

- Ossio, F.; Salinas, C.; Hernández, H. Circular economy in the built environment: A systematic literature review and definition of the circular construction concept. J. Clean. Prod. 2023, 414, 137738. [Google Scholar] [CrossRef]

- EMF. Towards the Circular Economy—An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- Mhatre, P.; Gedam, V.; Unnikrishnan, S.; Verma, S. Circular economy in built environment—Literature review and theory development. J. Build. Eng. 2021, 35, 101995. [Google Scholar] [CrossRef]

- Kubbinga, B.; Bamberger, M.; van Noort, E.; van den Reek, D.; Blok, M.; Roemers, G.; Hoek, J.; Faes, K. A Framework For Circular Buildings—BREEAM Report English; COLOFON: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- EMF. Towards a Circular Economy_ Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A systematic review of circular economy research in the construction industry. Smart Sustain. Built Environ. 2020, 11, 39–64. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Sher, W.; Egbelakin, T. Circular economy pillars: A semi-systematic review. Clean Technol. Environ. Policy 2021, 23, 899–914. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar] [CrossRef]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and barriers towards circular economy in the building sector: Stakeholder interviews and analysis of five european countries policies and practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- Sáez-de-Guinoa, A.; Zambrana-Vasquez, D.; Fernández, V.; Bartolomé, C. Circular Economy in the European Construction Sector: A Review of Strategies for Implementation in Building Renovation. Energies 2022, 15, 4747. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- van Stijn, A.; Gruis, V. Towards a circular built environment: An integral design tool for circular building components. Smart Sustain. Built Environ. 2020, 9, 635–653. [Google Scholar] [CrossRef]

- OECD. A circular transition for construction. In Towards a National Circular Economy Strategy for Hungary; OECD: Paris, France, 2023. [Google Scholar] [CrossRef]

- Mesa, J.M.; Fuquence-Retamoso, C.; Maury-Ramires, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Gheewala, S.H.; Silalertruksa, T. Life Cycle Thinking in a Circular Economy. In An Introduction to Circular Economy; Liu, L., Ramakrishna, S., Eds.; Springer: Singapore, 2021; pp. 35–53. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Asante, R.; Faibil, D.; Agyemang, M.; Khan, S.A. Life cycle stage practices and strategies for circular economy: Assessment in construction and demolition industry of an emerging economy. Environ. Sci. Pollut. Res. 2022, 29, 82110–82121. [Google Scholar] [CrossRef]

- WEF. Shaping the Future of Construction a Breakthrough in Mindset and Technology; World Economic Forum: Cologny, Switzerland, 2016. [Google Scholar]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Inst. Civ. Eng. -Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- van Bueren, B.J.A.; Leenders, M.A.A.M.; Nordling, T.E.M. Case Study: Taiwan’s pathway into a circular future for buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012060. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W. Barriers and enablers of circular economy in construction: A multi-system perspective towards the development of a practical framework. Constr. Manag. Econ. 2022, 41, 3–21. [Google Scholar] [CrossRef]

- Cheshire, D. Building Revolutions: Applying the Circular Economy to the Built Environment; Routledge: London, UK, 2019. [Google Scholar]

- Stevenson, A. Oxford Dictionary of English; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Sharma, N.; Kalbar, P.P.; Salman, M. Global review of circular economy and life cycle thinking in building Demolition Waste Management: A way ahead for India. Build. Environ. 2022, 222, 109413. [Google Scholar] [CrossRef]

- Lee, P.-H.; Juan, Y.-K.; Han, Q.; Vries, B.D. An investigation on construction companies’ attitudes towards importance and adoption of circular economy strategies. Ain Shams Eng. J. 2023, 14, 102219. [Google Scholar] [CrossRef]

- Smitha, J.S.; Thomas, A. A Life Cycle Analysis Based Framework to Promote Circular Economy in the Building Sector. In Proceedings of the Recent Developments in Sustainable Infrastructure (ICRDSI-2020)—Structure and Construction Management, Bhubaneswar, India, 19–20 December 2020; pp. 173–183. [Google Scholar]

- Prajapati, H.; Kant, R.; Shankar, R. Bequeath life to death: State-of-art review on reverse logistics. J. Clean. Prod. 2019, 211, 503–520. [Google Scholar] [CrossRef]

- Skaar, C.; Labonnote, N.; Gradeci, K. From Zero Emission Buildings (ZEB) to Zero Emission Neighbourhoods (ZEN): A Mapping Review of Algorithm-Based LCA. Sustainability 2018, 10, 2405. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Chileshe, N.; Rameezdeen, R.; Ochoa, J.J. Information sharing in reverse logistics supply chain of demolition waste: A systematic literature review. J. Clean. Prod. 2021, 280, 124359. [Google Scholar] [CrossRef]

- Gomis, K.; Kahandawa, R.; Jayasinghe, R.S. Scientometric Analysis of the Global Scientific Literature on Circularity Indicators in the Construction and Built Environment Sector. Sustainability 2022, 15, 728. [Google Scholar] [CrossRef]

- Medina, E.M.; Fu, F. A new circular economy framework for construction projects. Proceedings of the Institution of Civil Engineers-Engineering Sustainability 2021, 174, 304–315. [Google Scholar] [CrossRef]

- Zaman, A.; Caceres Ruiz, A.M.; Shooshtarian, S.; Ryley, T.; Caldera, S.; Maqsood, T. Development of the Circular Economy Design Guidelines for the Australian Built Environment Sector. Sustainability 2023, 15, 2500. [Google Scholar] [CrossRef]

- Appendino, F.; Roux, C.; Saadé, M.; Peuportier, B. The Circular Economy in Urban Projects: A Case Study Analysis of Current Practices and Tools. Trans. AESOP 2021, 5, 71–83. [Google Scholar] [CrossRef]

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

- Smitha, J.S.; Thomas, A. Integrated model and index for circular economy in the built environment in the indian context. Constr. Econ. Build. 2021, 21, 198–220. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Implementing circular economy strategies in buildings—From theory to practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Ghobadi, M.; Sepasgozar, S.M.E. Circular economy strategies in modern timber construction as a potential response to climate change. J. Build. Eng. 2023, 77, 107229. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Tserng, H.-P.; Chou, C.-M.; Chang, Y.-T. The key strategies to implement circular economy in building projects—A case study of Taiwan. Sustainability 2021, 13, 754. [Google Scholar] [CrossRef]

- Victar, H.C.; Waidyasekara, K.G.A.S. A Study of Circular Economy Strategies for the Life Cycle of Building Construction Projects: A Systematic Review. In Proceedings of the International Conference on Sustainable Built Environment, Kandy, Sri Lanka, 16–18 December 2022. [Google Scholar]

- Timm, J.F.G.; Maciel, V.G.; Passuello, A. Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment. Buildings 2023, 13, 2059. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; Freire, F.; Halog, A.; Piekarski, C.M.; Antonio, C. Circular economy strategies on business modelling: Identifying the greatest influences. J. Clean. Prod. 2021, 299, 126918. [Google Scholar] [CrossRef]

- Nußholz, J.; Çetin, S.; Eberhardt, L.; De Wolf, C.; Bocken, N. From circular strategies to actions: 65 European circular building cases and their decarbonisation potential. Resour. Conserv. Recycl. Adv. 2023, 17, 200130. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. The ecodesign methodologies to achieve buildings’ deconstruction: A review and framework. Sustain. Prod. Consum. 2022, 30, 566–583. [Google Scholar] [CrossRef]

- Montella, I.; Marrone, P. Material Efficiency design strategies for the circular transition. TECHNE-J. Technol. Archit. Environ. 2021, 22, 86–95. [Google Scholar] [CrossRef]

- Ishan, M.; Gamage, I.; Lingasabesan, V. Highly effective circular economic practices for the life cycle of a construction project. In Proceedings of the 11th World Construction Symposium, Colombo, Sri Lanka, 21–22 July 2023; pp. 532–544. [Google Scholar]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Bertino, G.; Menconi, F.; Zraunig, A.; Terzidis, E.; Kisser, J. Innovative circular solutions and services for new buildings and refurbishments. WIT Trans. Built Environ. 2019, 183, 83–91. [Google Scholar]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).