Simulation Analysis of the Structure of an Integrated Modular House by Flat Pack Based on the Elastic–Plastic Contact Theory and Experimental Study of Its Corner Fitting Joint

Abstract

1. Introduction

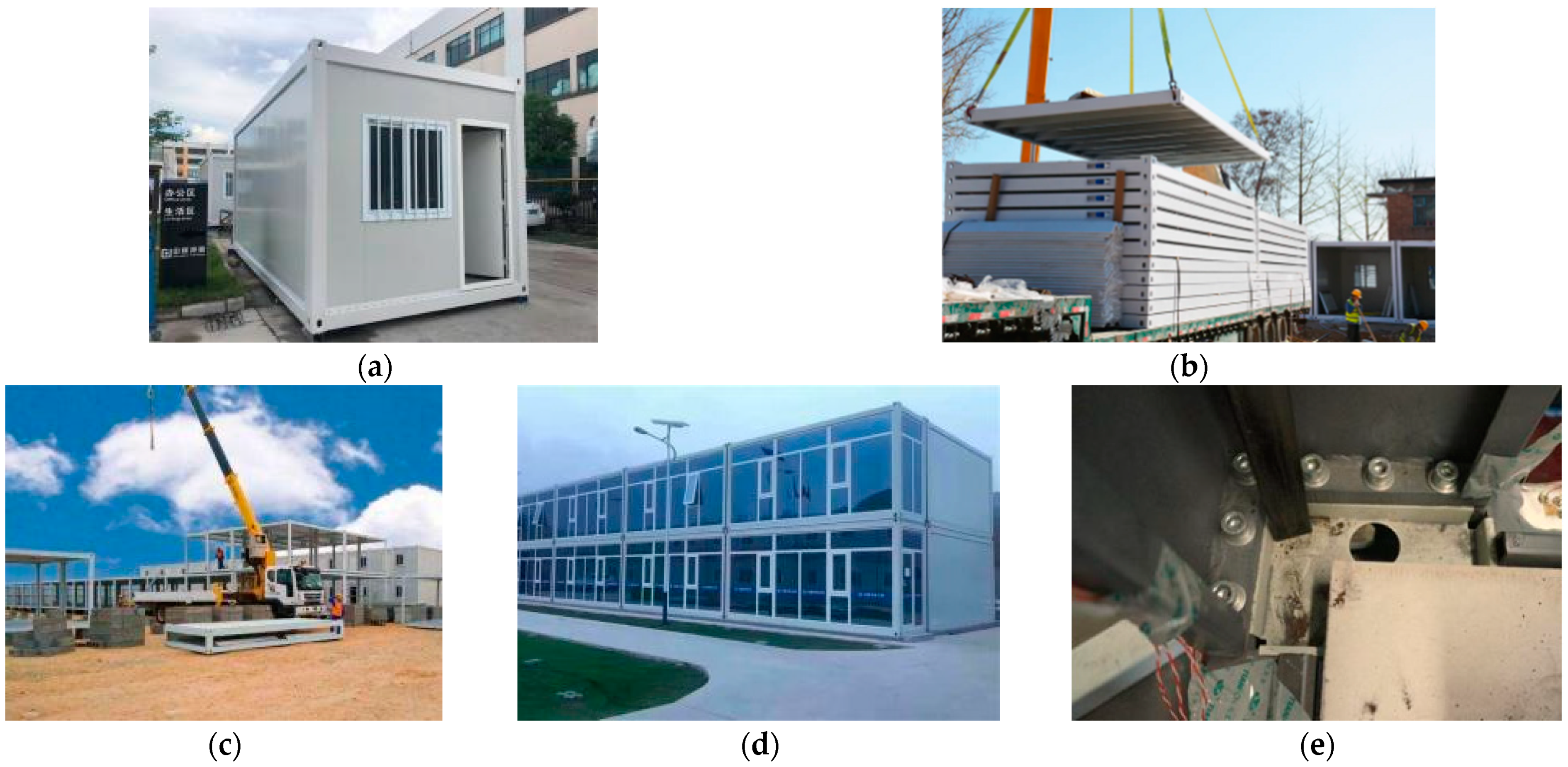

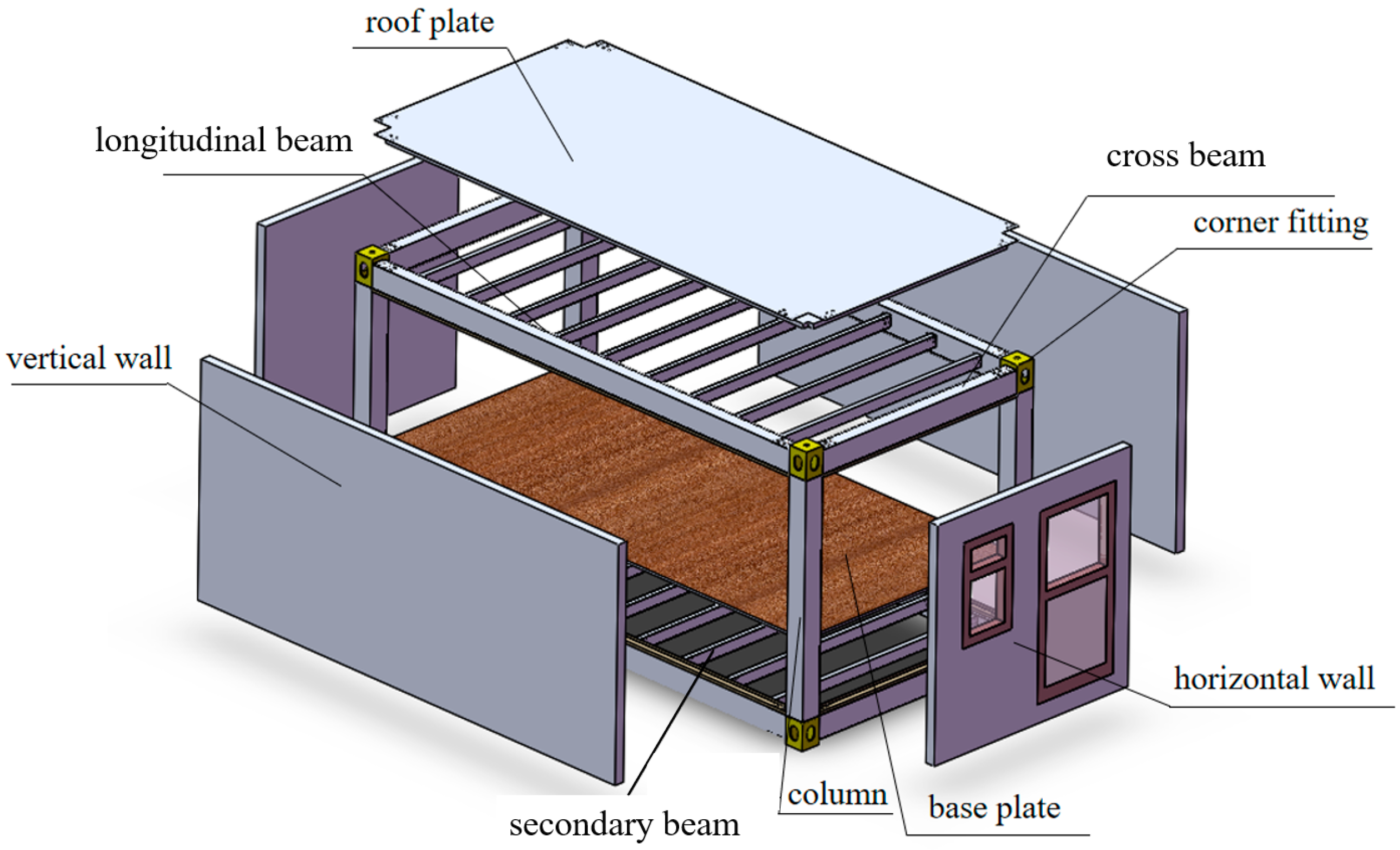

2. Elastic–Plastic Contact Theory and Penalty Function Method

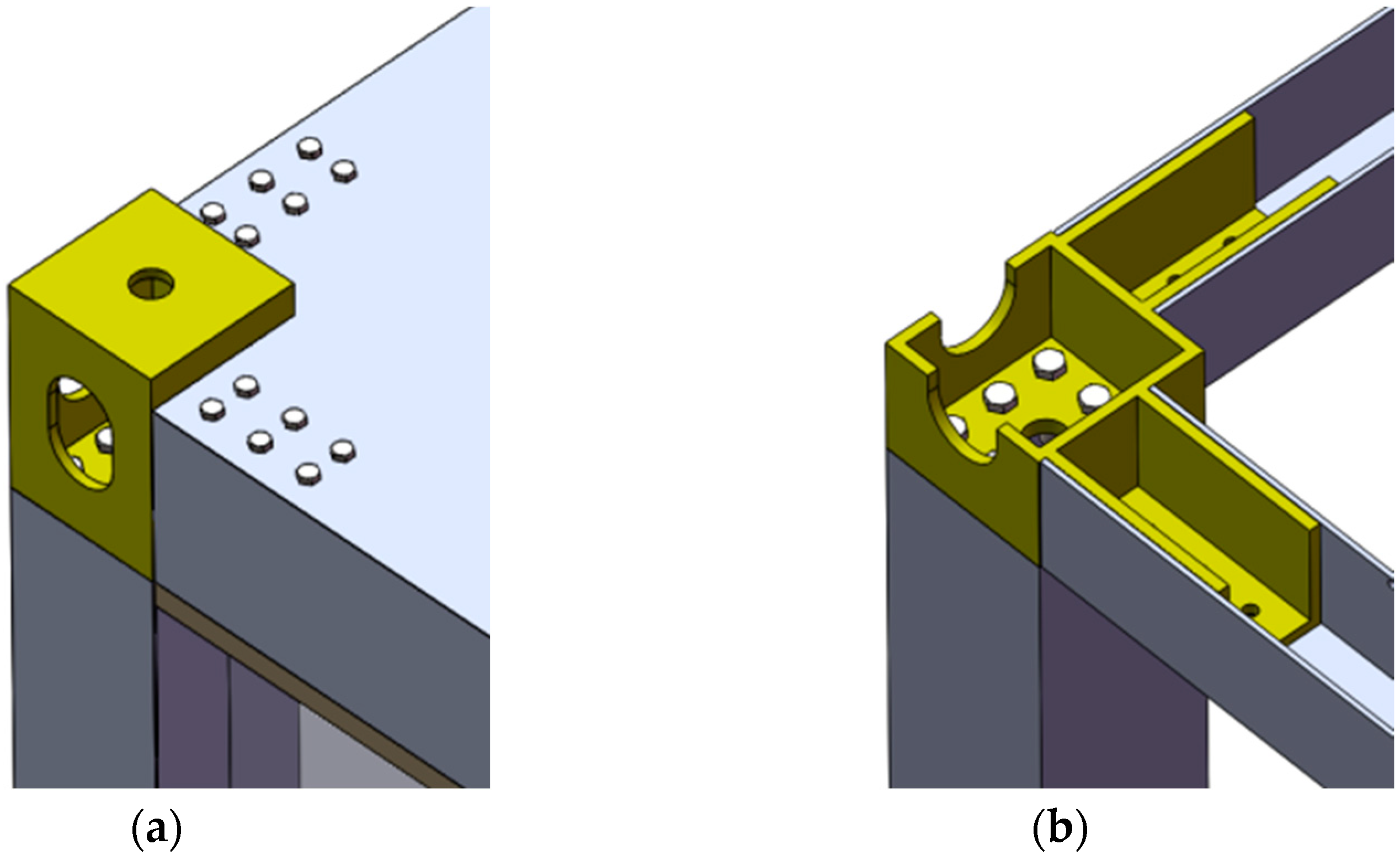

3. Structural Composition of Integrated Modular House by Flat Pack

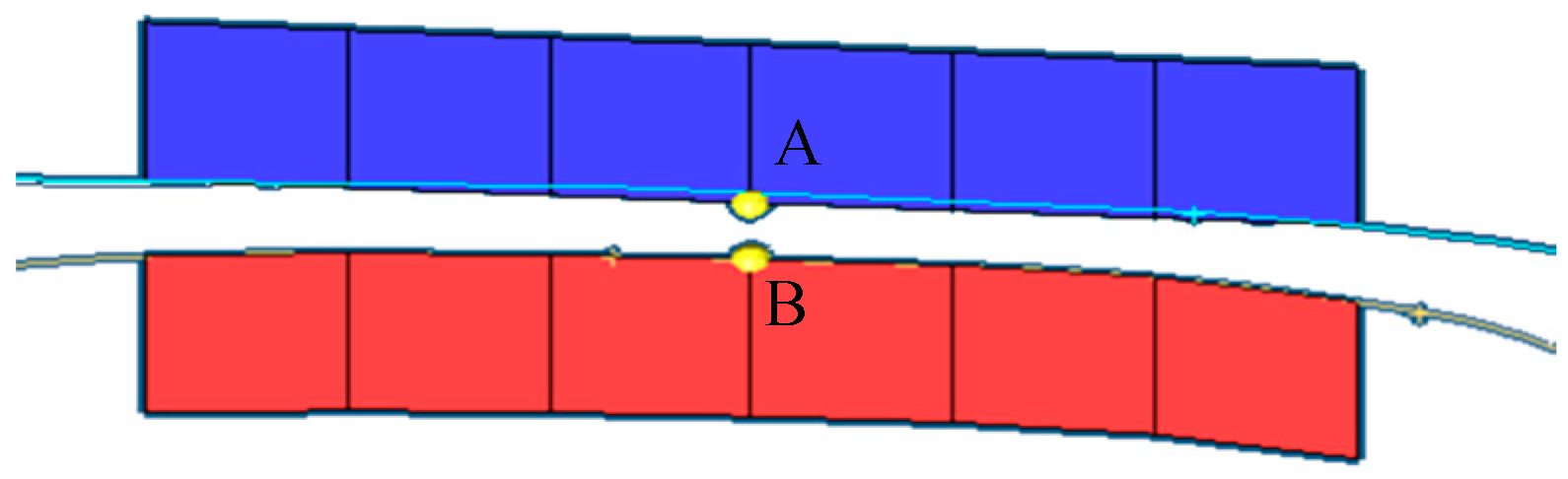

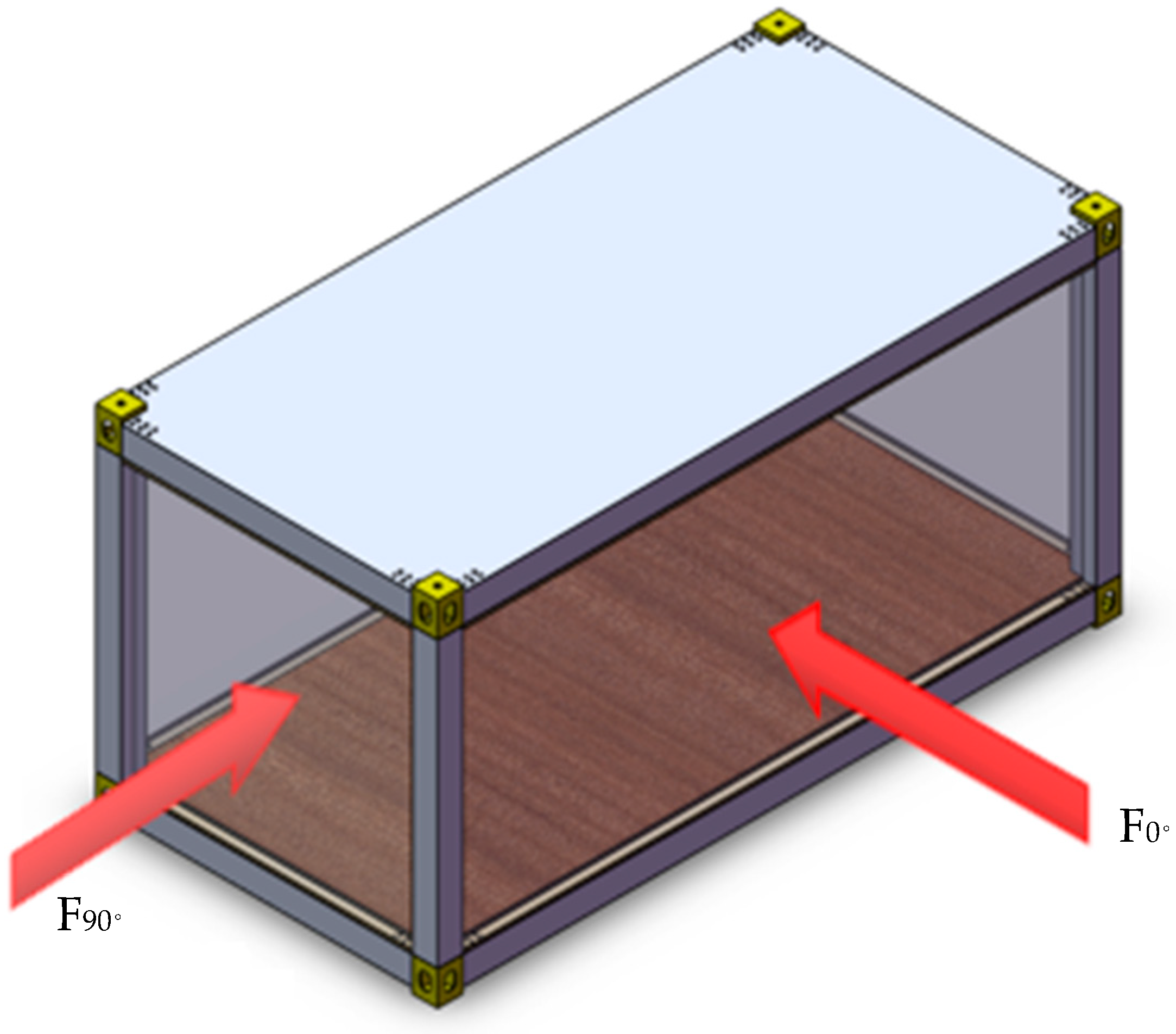

4. Simulation Analysis of Integrated Modular House by Flat Pack

4.1. Finite Element Modeling

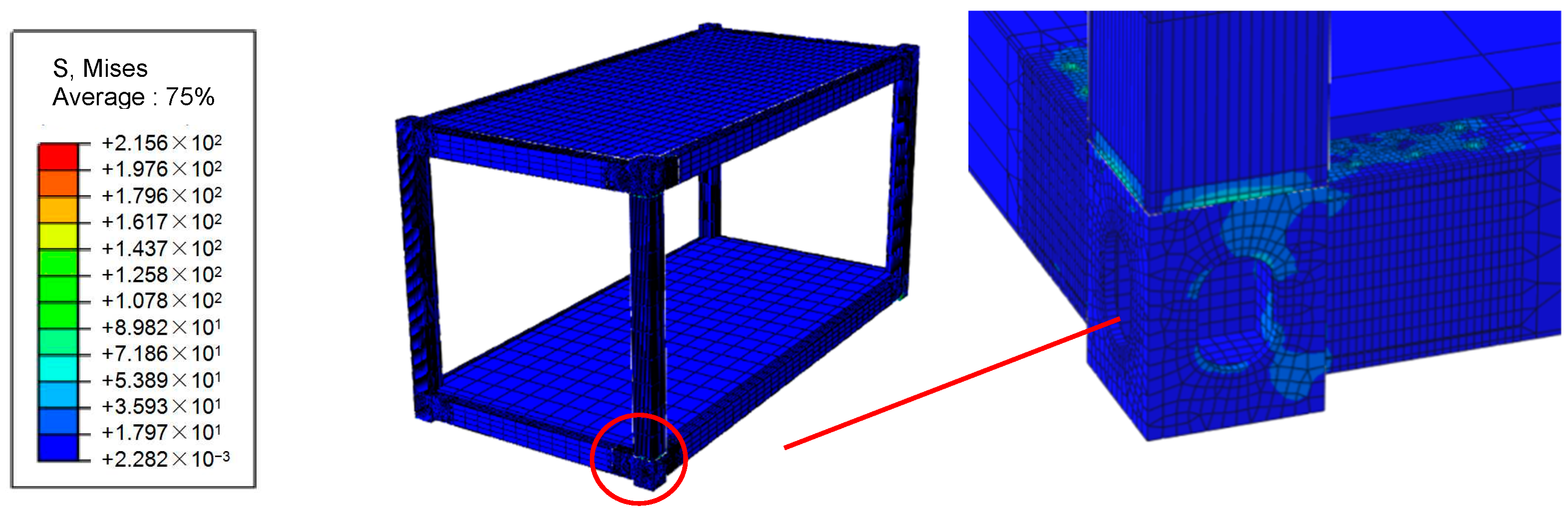

4.2. Analysis for Integral Deformation and Equivalent Stress

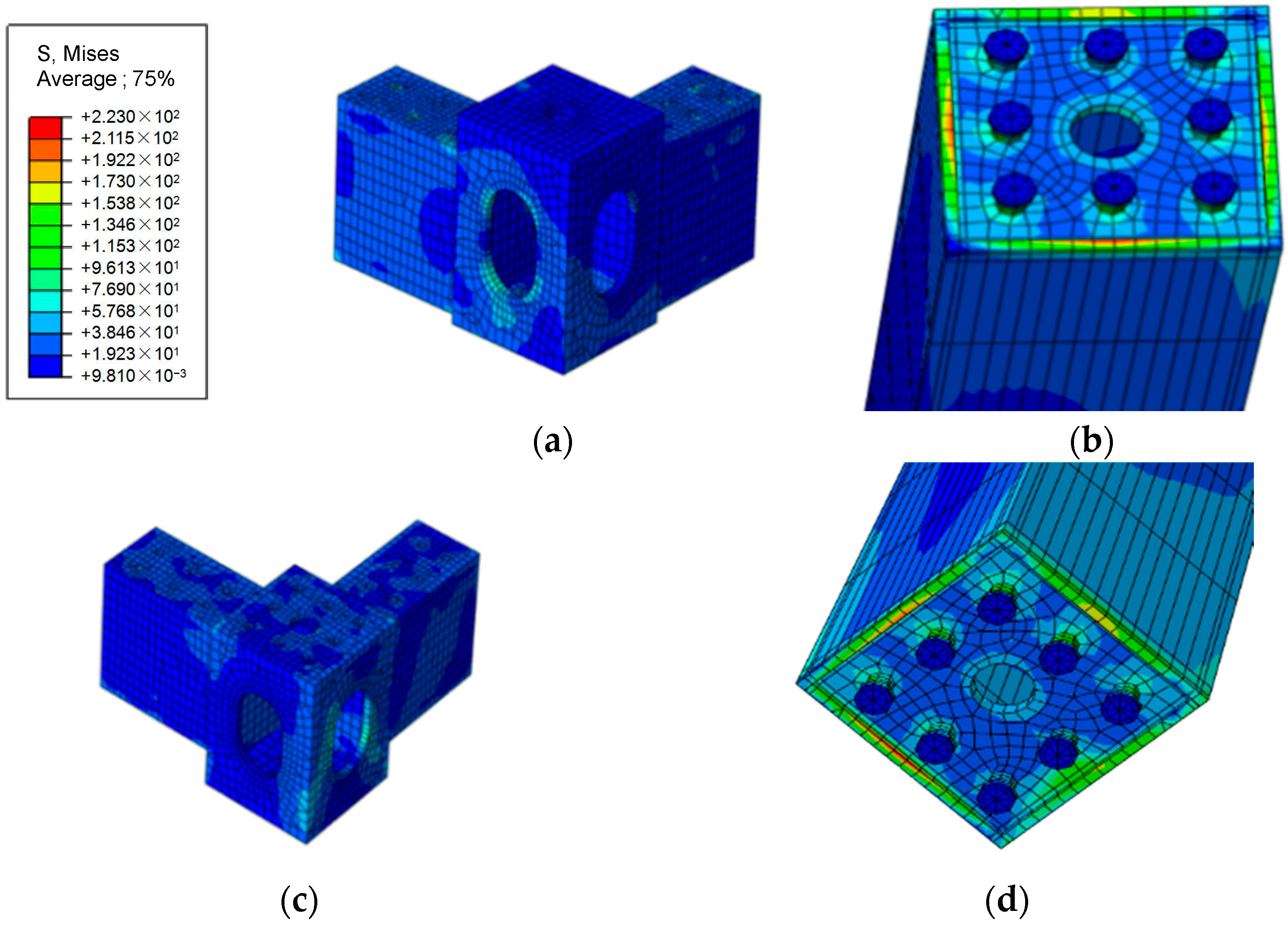

4.3. Equivalent Stress at Contact Part of Joint

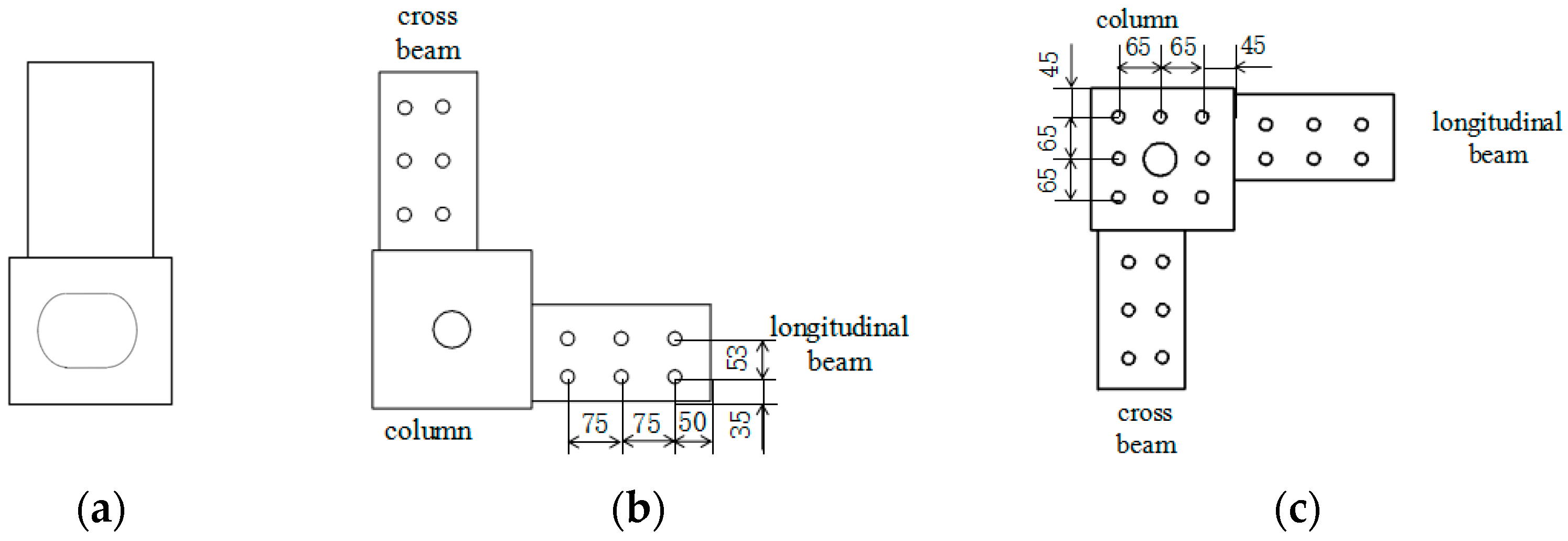

5. Experimental Study on Corner Column–Corner Fitting Joint

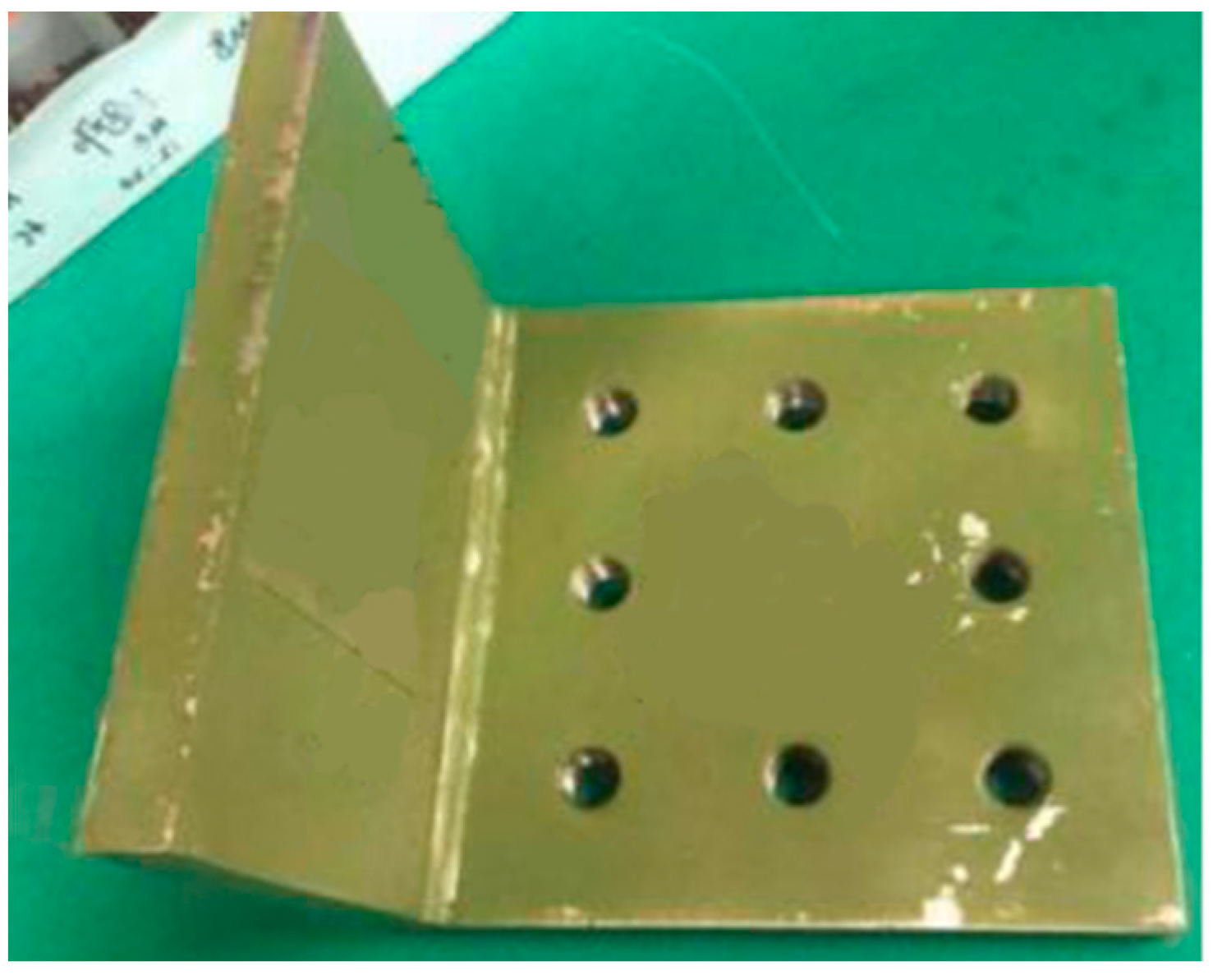

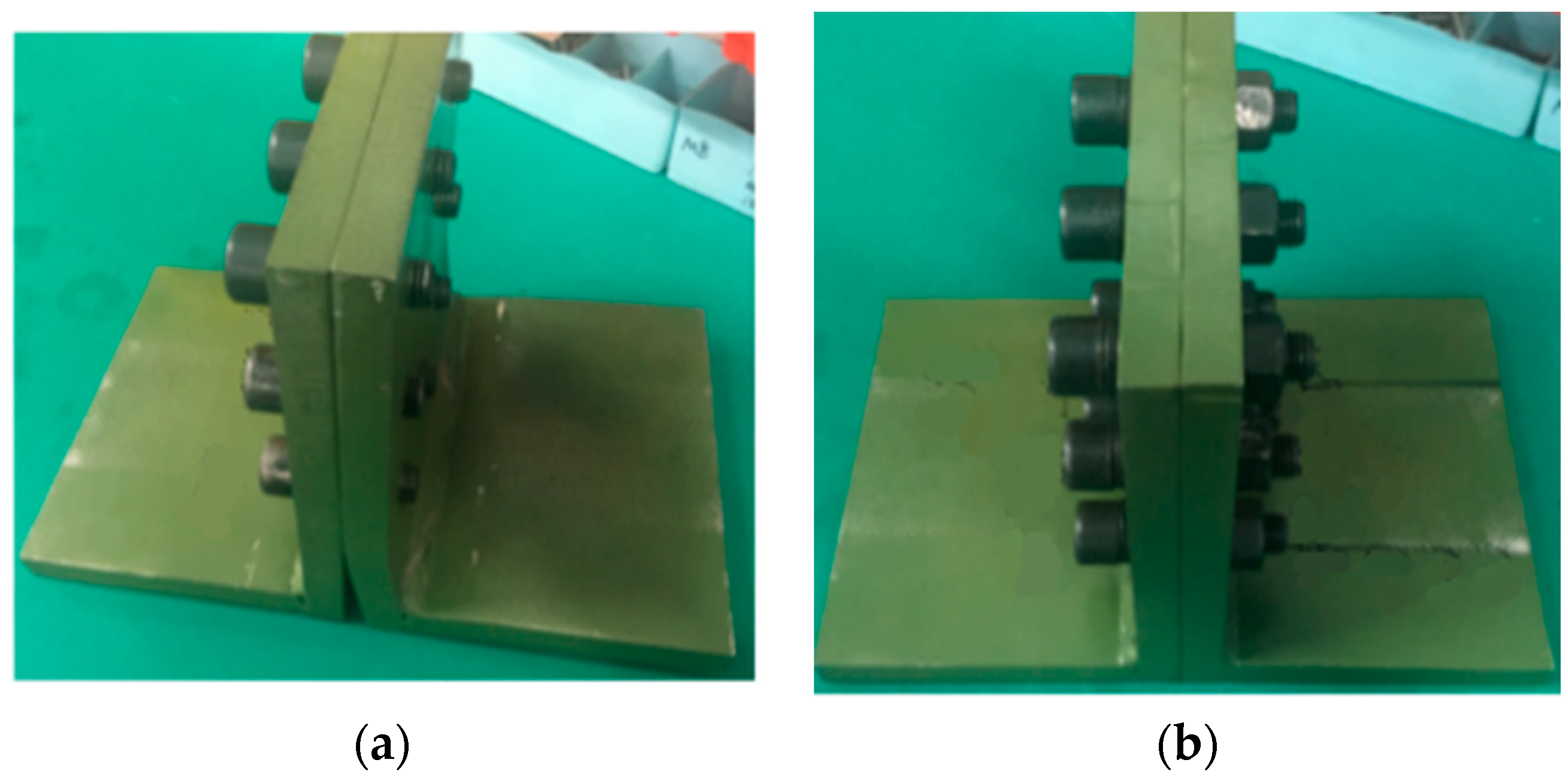

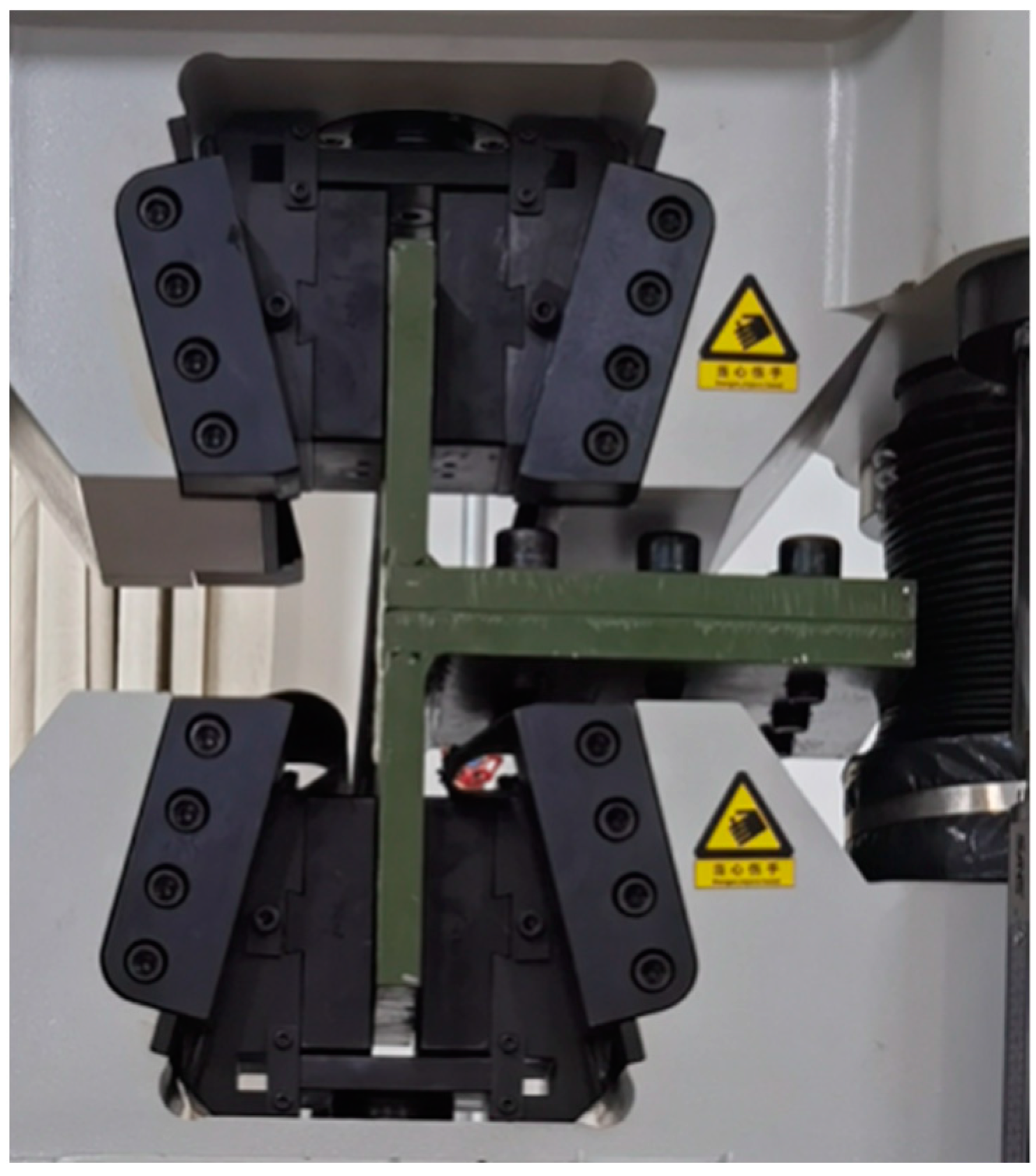

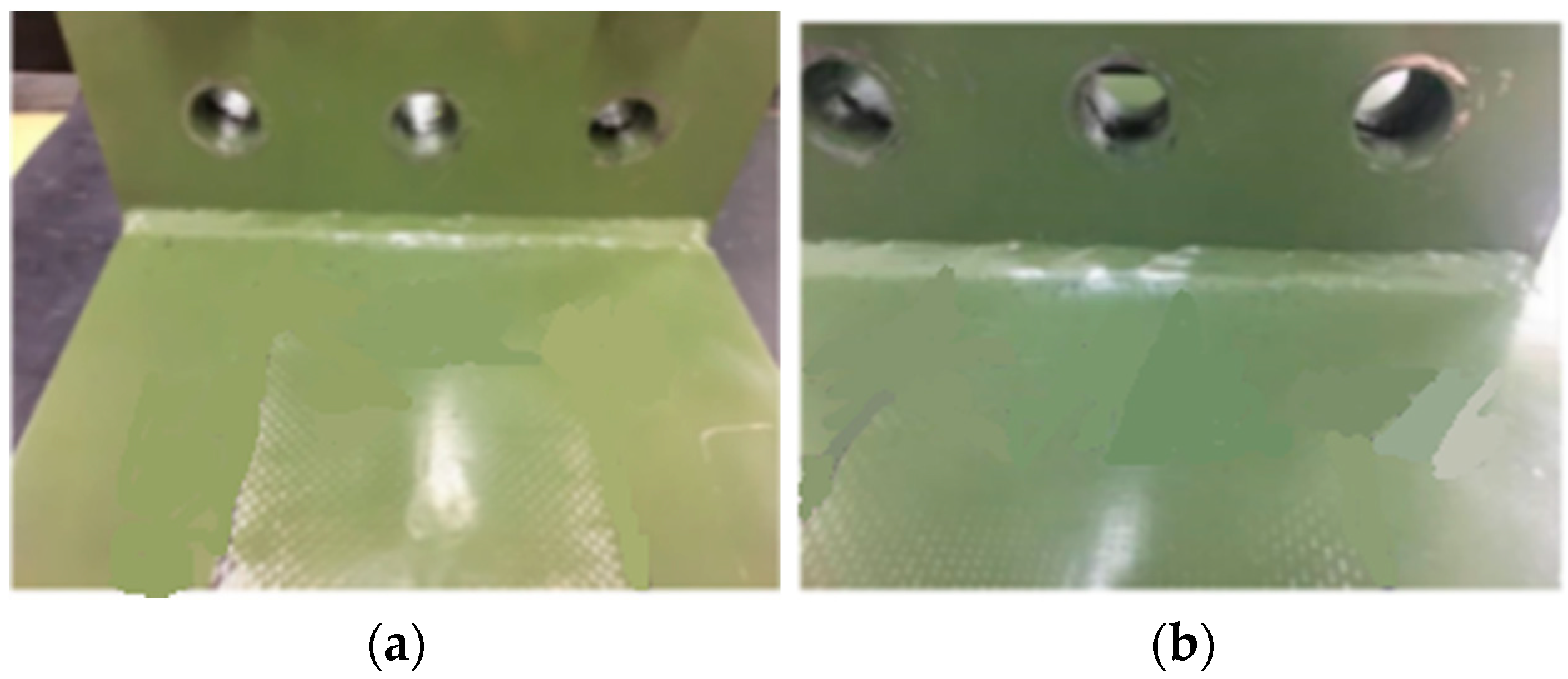

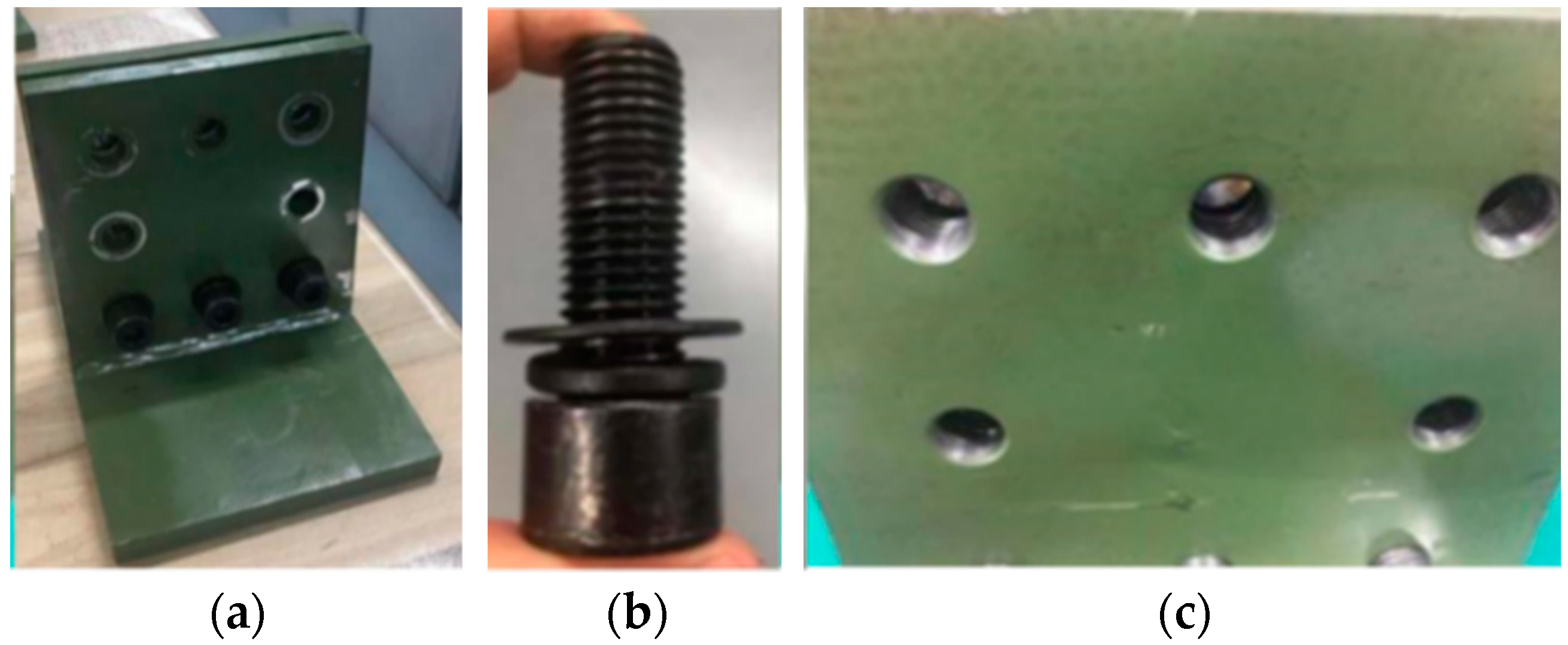

5.1. Specimen and Test Equipment

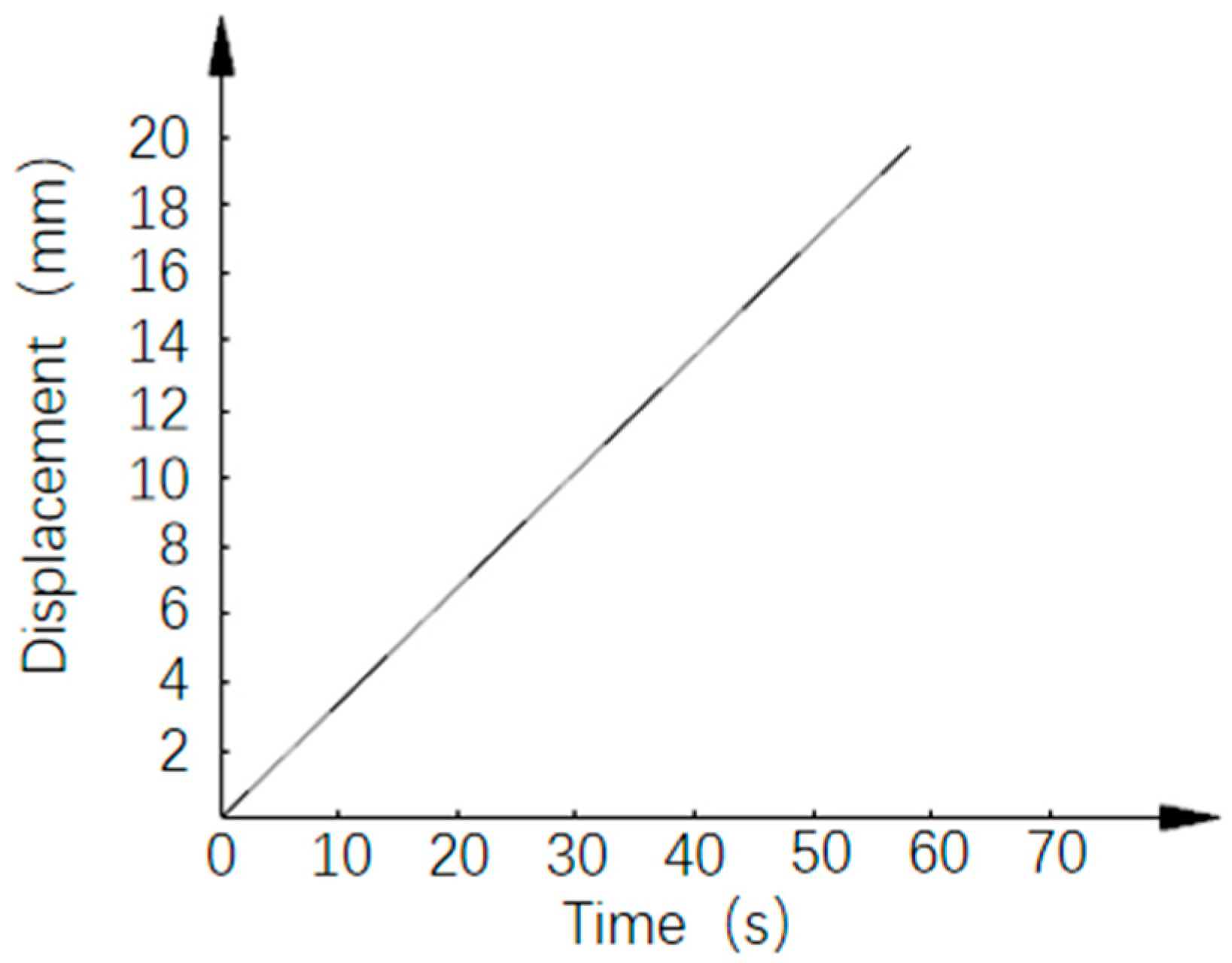

5.2. Test Methods

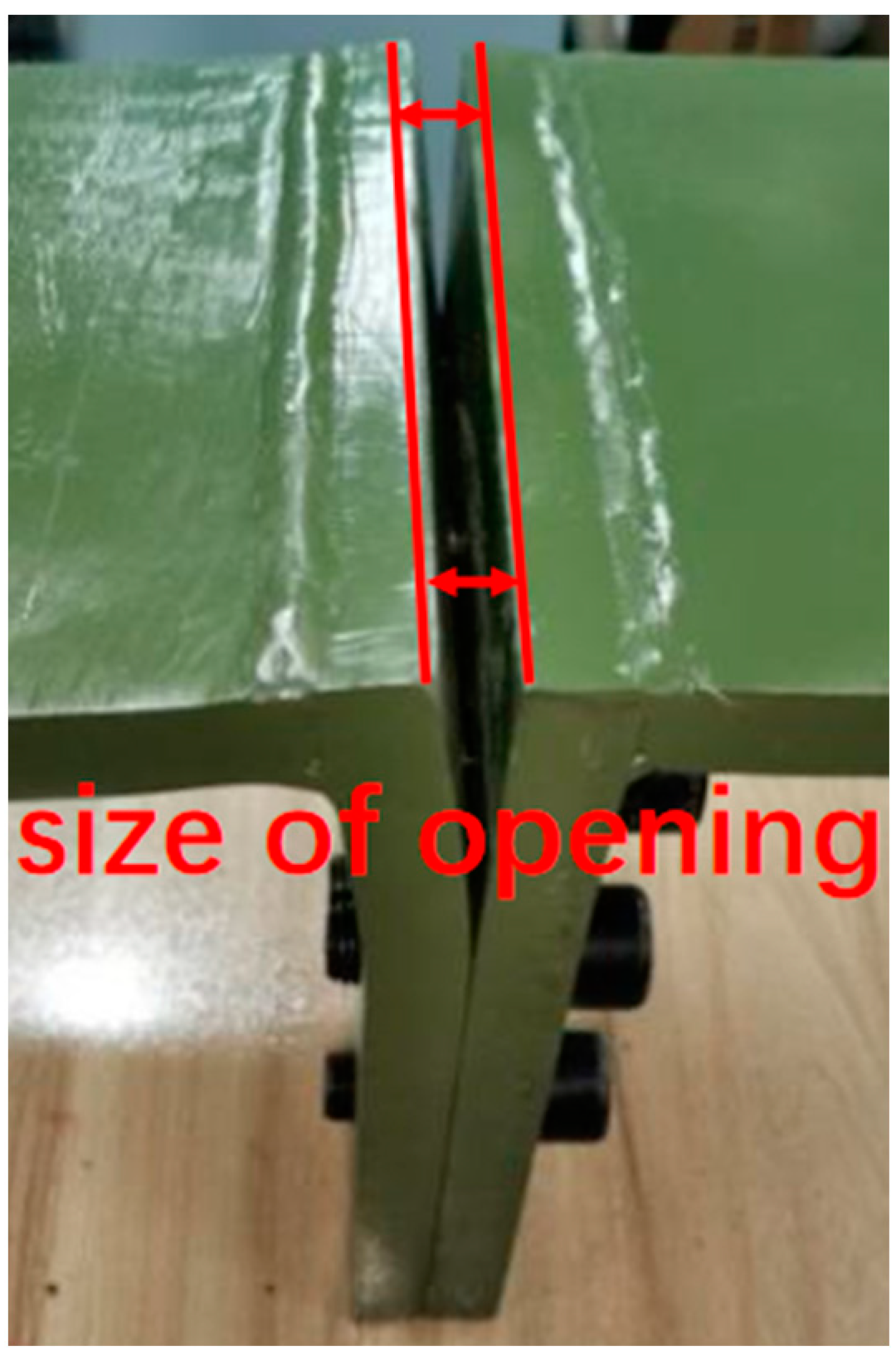

6. Result Analysis of Graded Loading Test

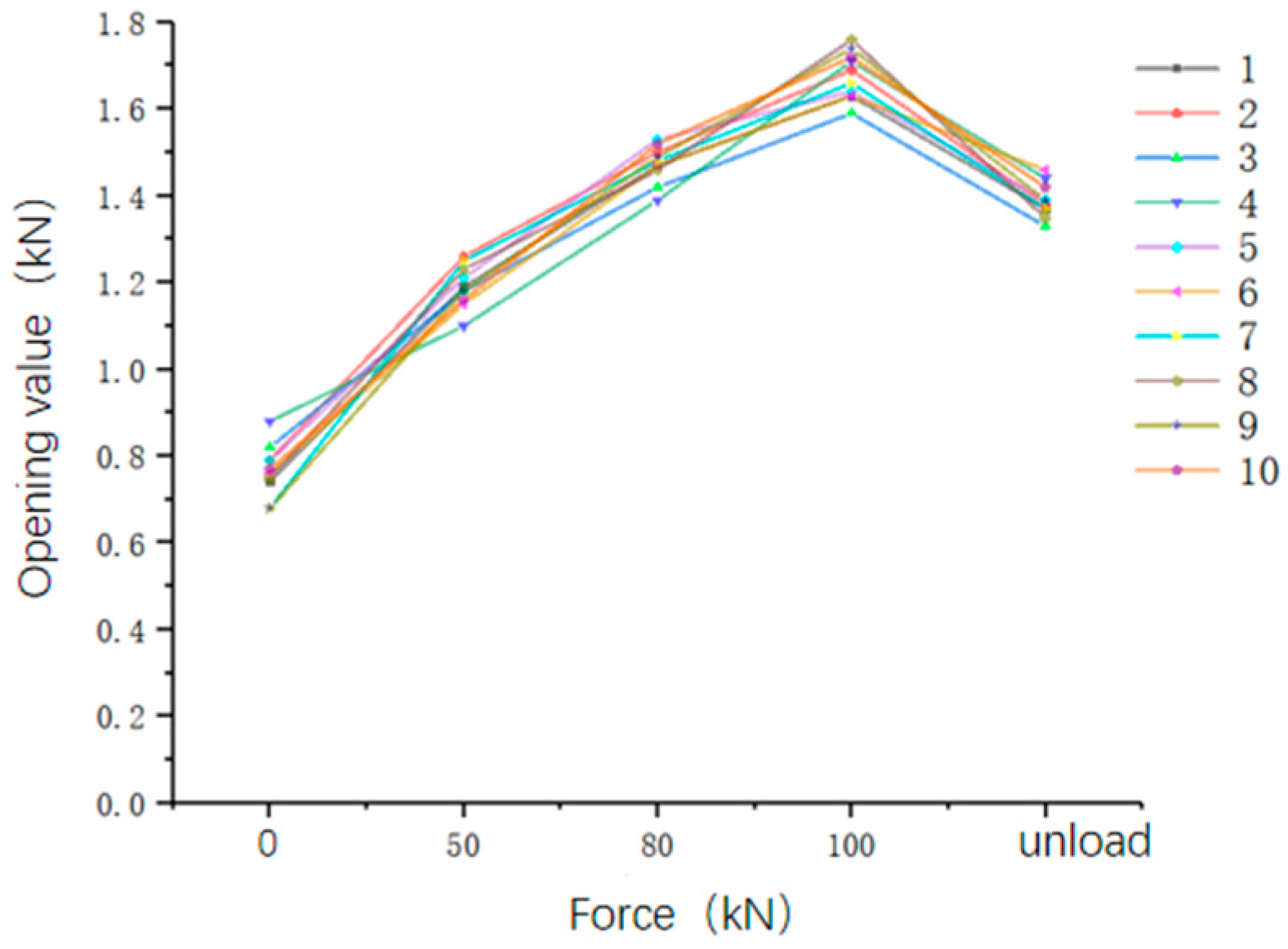

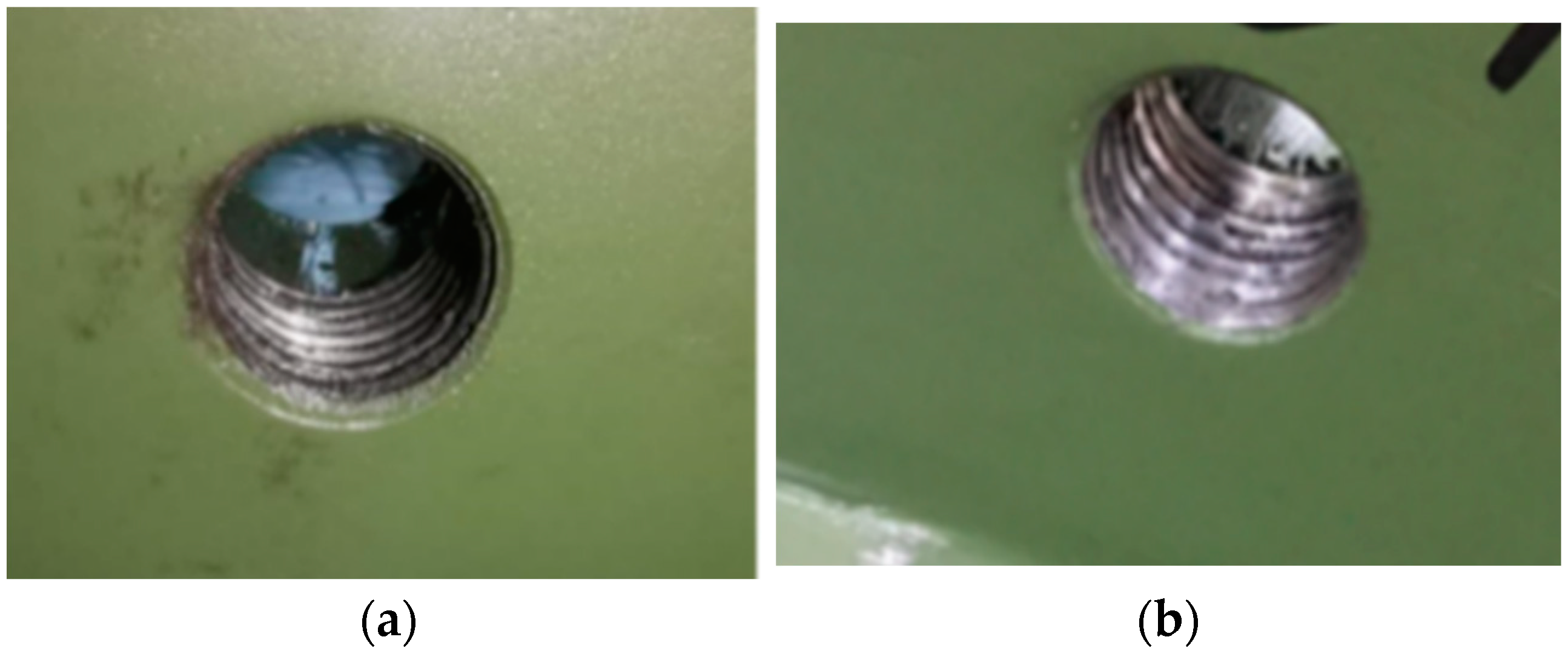

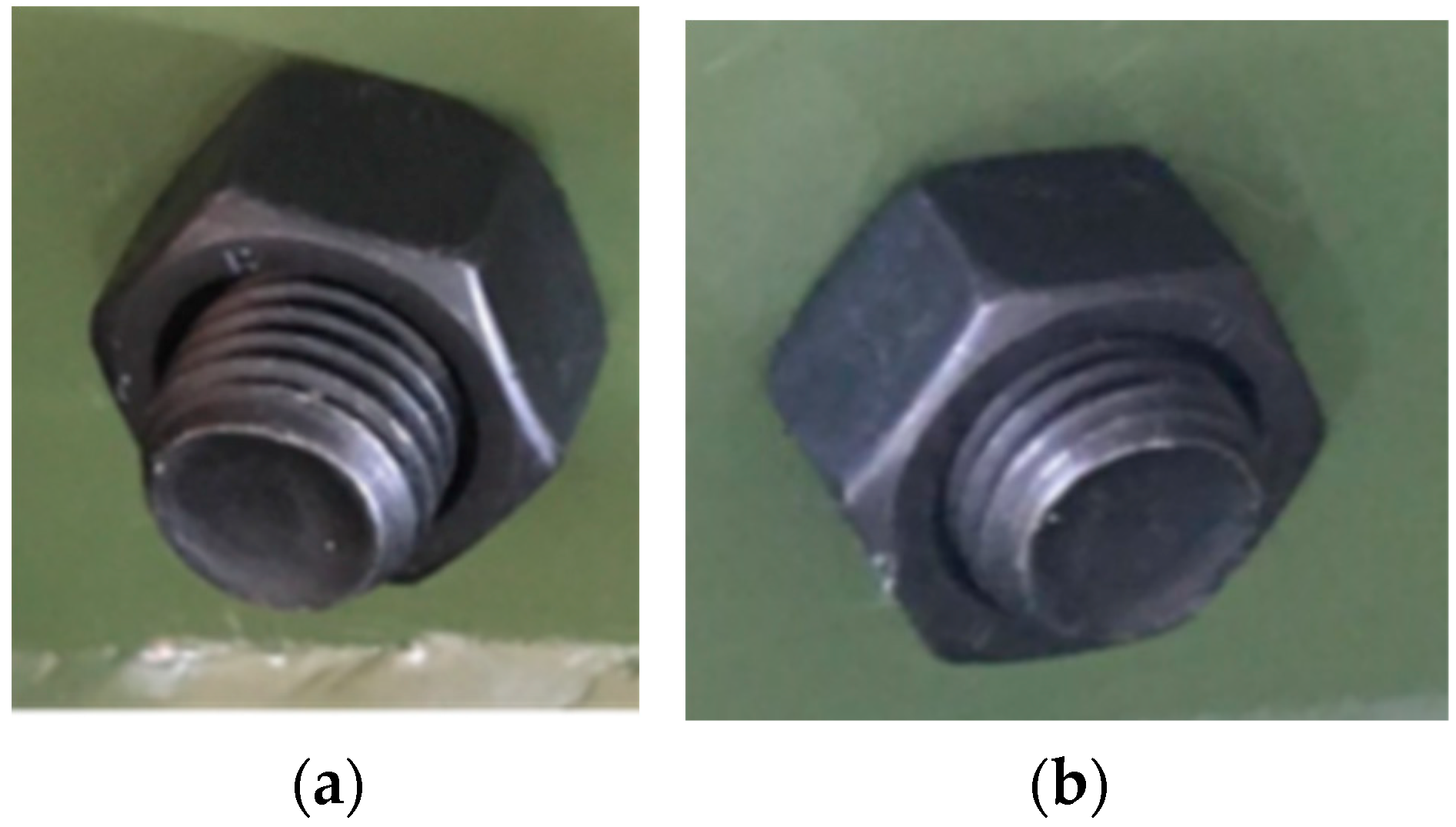

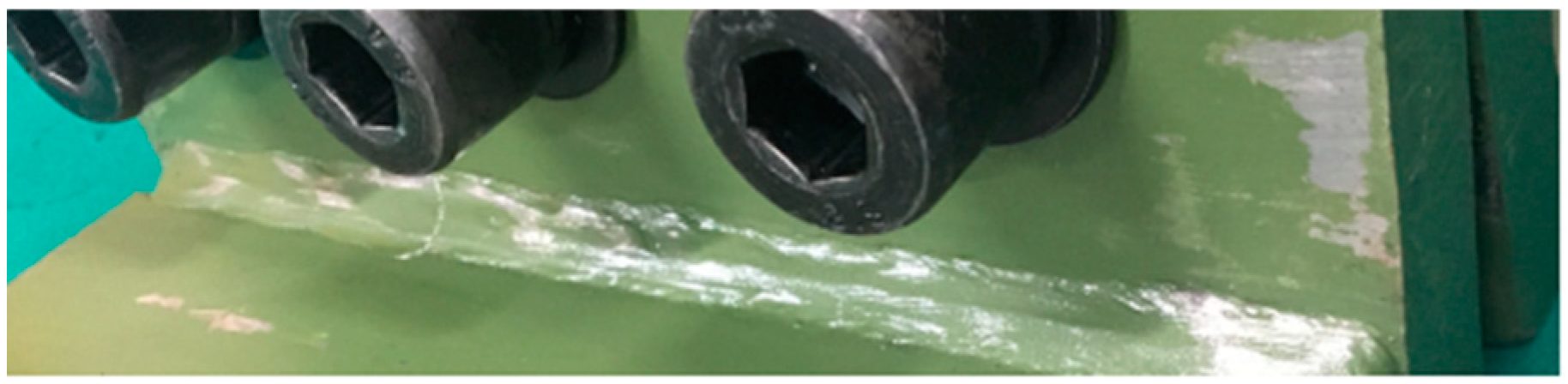

6.1. Results of Graded Loading Test of through Hole–Thread Hole Specimen

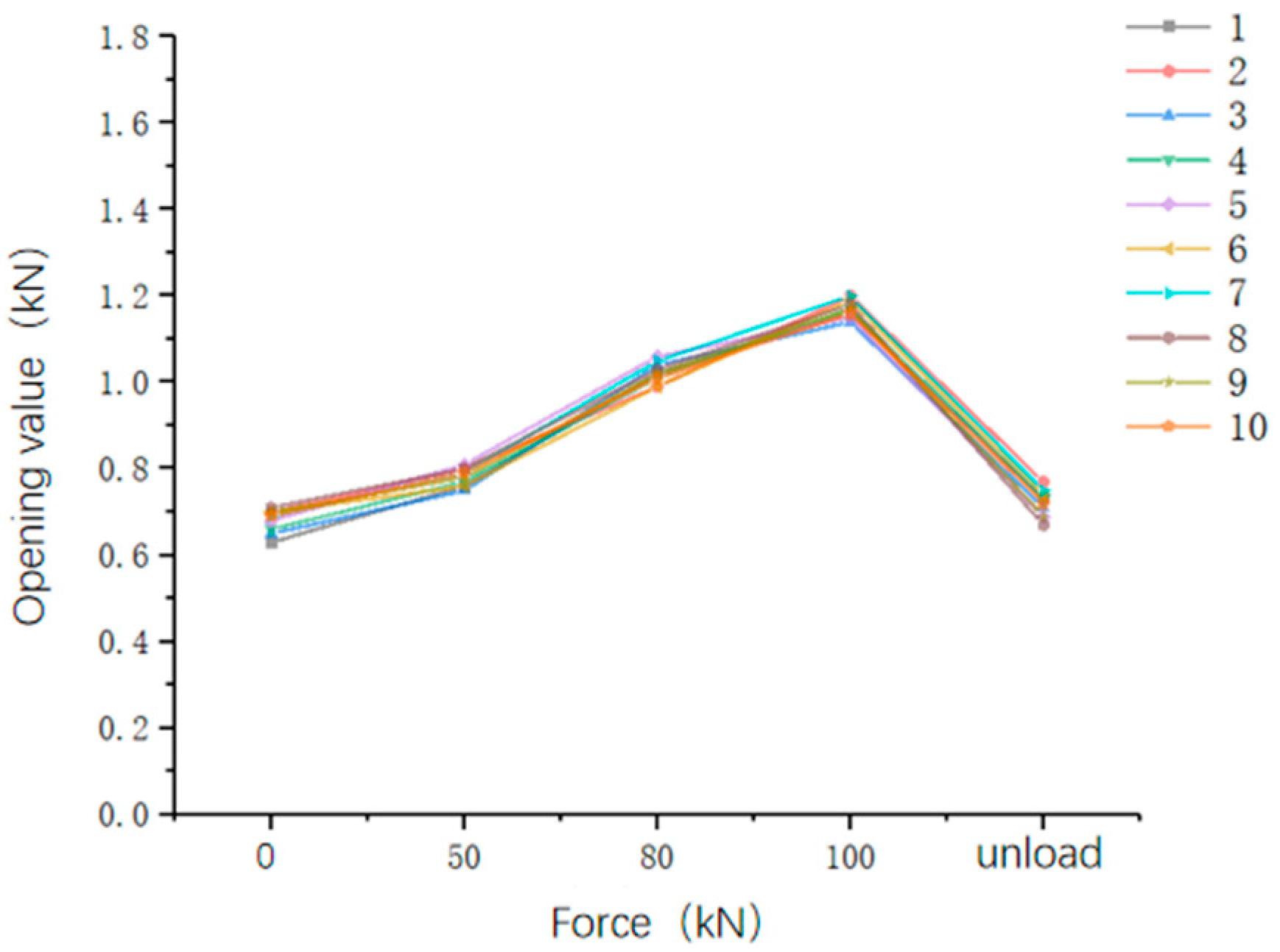

6.2. Test Results of Graded Loading of Through Hole–Through Hole Specimens

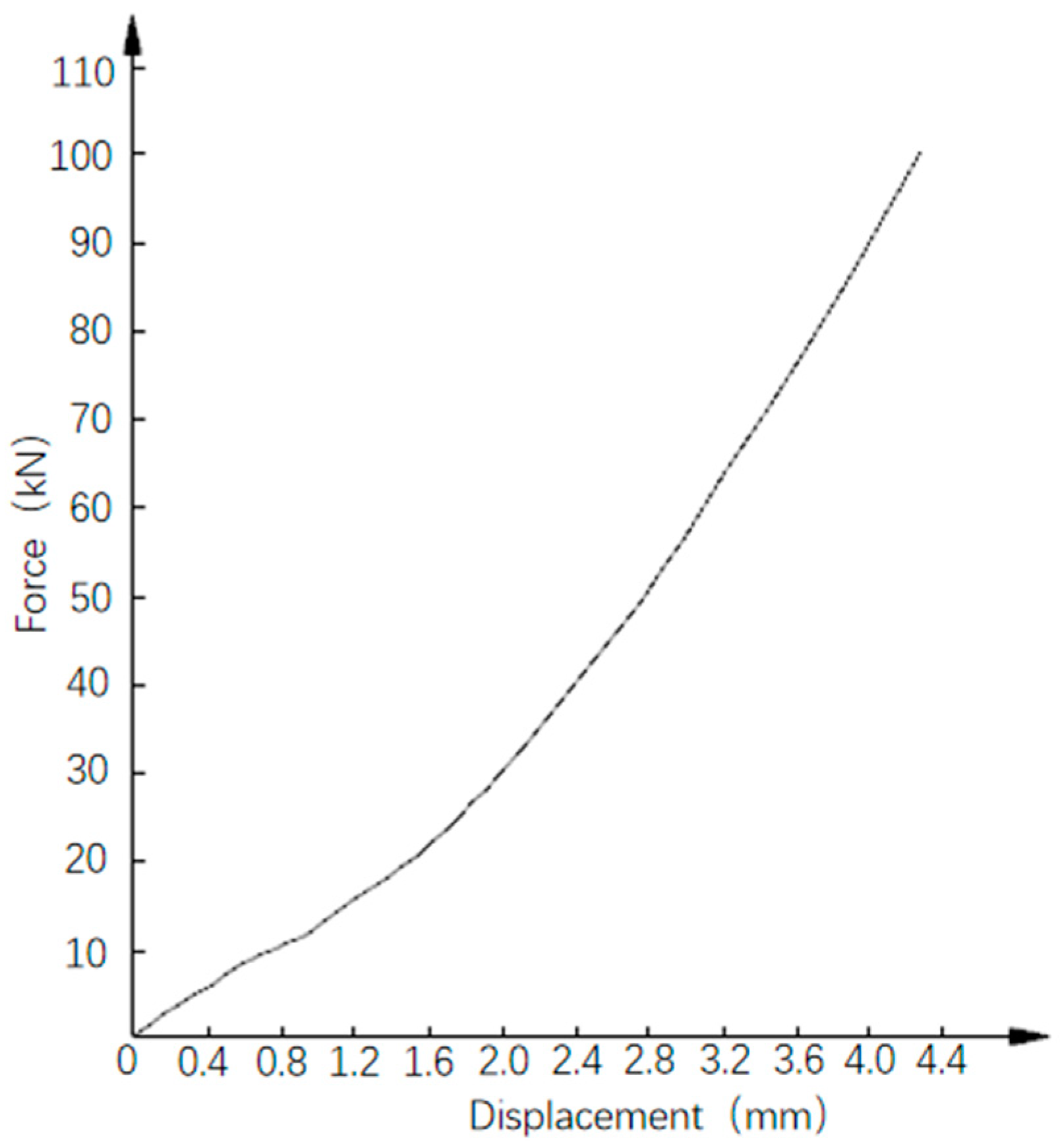

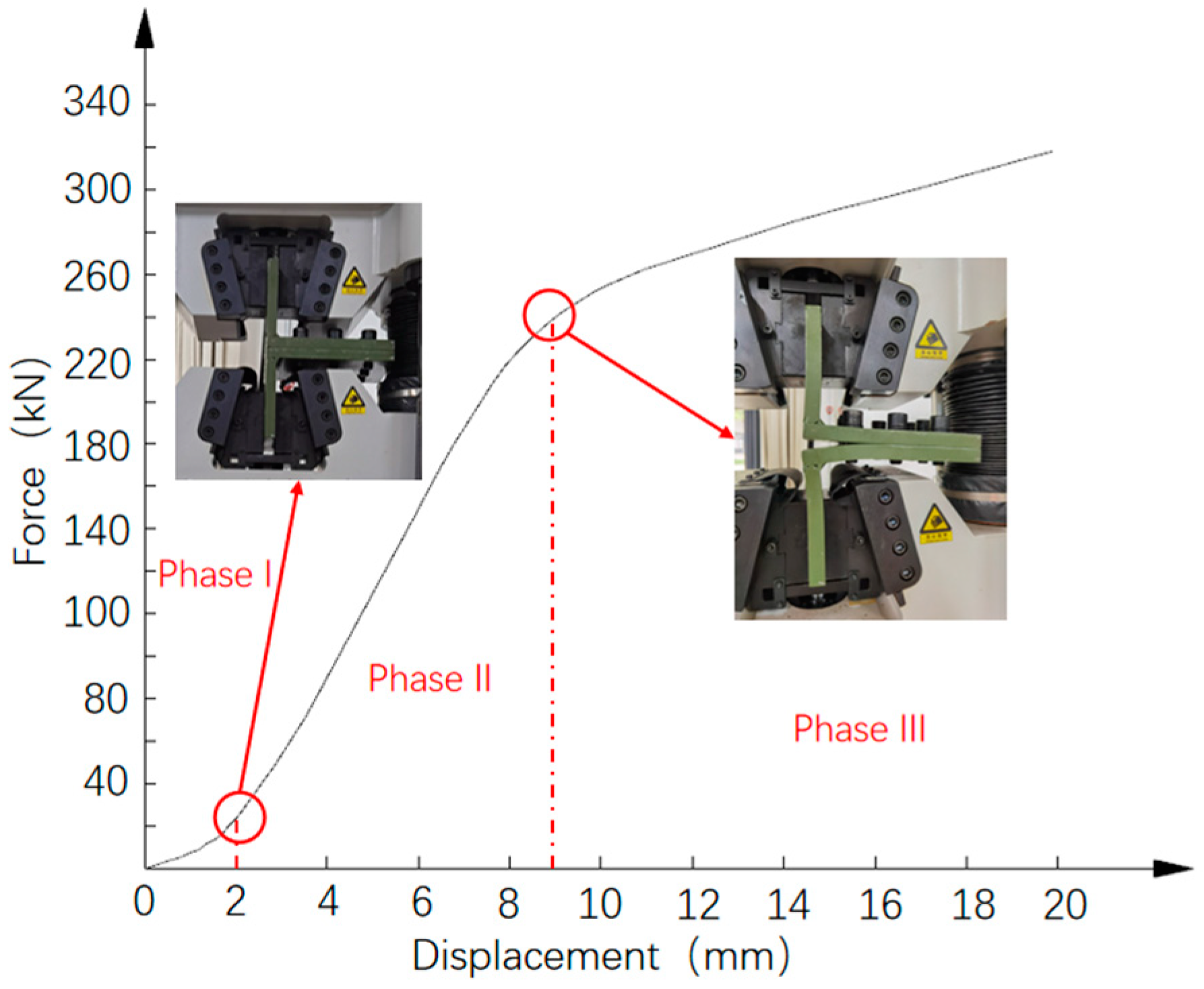

7. Results Analysis of Destructive Test

8. Conclusions

- (1)

- The finite element model of connection joints, based on elastic–plastic contact theory, addresses the problem of oversimplification in traditional rigid or semi-rigid connection methods. It clearly and intuitively shows the deformation of the contact surface between the corner and the main beam, along with the law of equivalent stress distribution. Combined with the tensile test, the stiffness and strength of the corner fitting could be evaluated comprehensively, and the analysis results are deemed reliable.

- (2)

- Under the load conditions listed in this paper, the maximum displacement of the integrated modular house by flat pack is 6.813 mm, and the maximum equivalent stress is 223.0 MPa, which is less than the allowable stress of the material. The whole structure meets the requirements of the relevant design codes.

- (3)

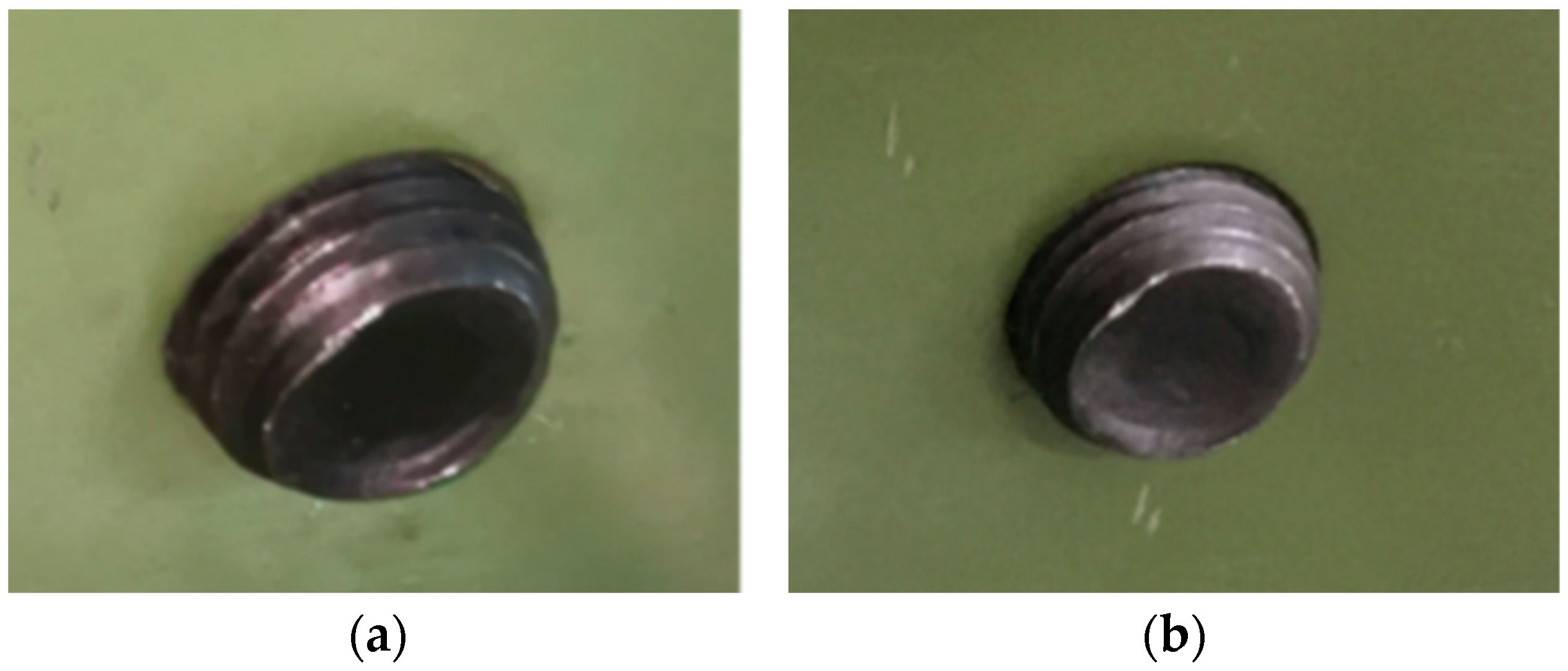

- When the end plate connection holes of the corner column seal are designed by through holes and internal screw holes, respectively, the fastening effect of bolting between the corner fitting and corner column using the internal screw hole is superior.

- (4)

- In the simulated cycle test of fastening and unloading the specimen, all bolts and threads could be used normally after ten repeated loading and unloading cycles, which demonstrates the continuous fault-free use of corner column-corner fitting joint connections. It also illustrates the reliability of the disassembly and use capability of the key connection joints of the house.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, R.B. Research on Development and Technical System of Steel Structure Assembly Building. J. Real Estate World 2021, 20, 137–139. [Google Scholar]

- Liu, H.J.; Zhu, Y.X.; Wang, Q. New Strategy under the Current Development of Prefabricated Residential Buildings. J. Sichuan Archit. 2021, 41 (Suppl. S1), 22–24. [Google Scholar]

- Mei, J.H. Developing Steel Structure Assembly Building. J. China Eng. Consult. 2018, 4, 67. [Google Scholar]

- Xu, J.C.; Cai, J.W.; Cai, J.Z. Research on a new type of temporary building-environmentally friendly folding house. J. China Stand. 2019, 540, 28–29. [Google Scholar]

- Yi, J.; Park, J.H.; Park, W.; Choo, J.F. Design and Cost-Effectiveness of 5-Tier Foldable Container. Arab. J. Sci. Eng. 2022, 47, 12839–12852. [Google Scholar] [CrossRef]

- Giriunas, K.; Sezen, H.; Dupaix, R. Evaluation, modeling, and analysis of shipping container building structures. J. Eng. Struct. 2012, 43, 48–57. [Google Scholar] [CrossRef]

- Wei, Q.C. Realization of a new type of solar foldable emergency relief house. J. Green Sci. Technol. 2018, 3, 145–147. [Google Scholar]

- Sun, Y.; Wang, J.; Wu, J.; Shi, W.; Ji, D.; Wang, X.; Zhao, X. Constraints Hindering the Development of High-Rise Modular Buildings. J. Appl. Sci. 2020, 10, 7159. [Google Scholar] [CrossRef]

- Dai, M.M. In-Situ Experimental Study on Overall Lateral Resistance of Assembled Cold-Formed Thin-Walled Light Steel Movable Plate House. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2017. [Google Scholar]

- Tominaga, Y.; Akabayashi, S.-I.; Kitahara, T.; Arinami, Y. Air flow around isolated gable-roof buildings with different roof pitches: Wind tunnel experiments and CFD simulations. J. Build. Environ. 2015, 84, 204–221. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.H.; Liu, J.D.; Zhong, X.; Liu, X.W.; Jiang, J.C. Effects of various reinforcing intra-module connection details on seismic behavior of corner-supported steel modular buildings. Structures 2022, 40, 555–570. [Google Scholar] [CrossRef]

- Ma, S.C.; Gu, Y.; Bao, P. Analysis and evaluation on seismic performance of the composite wallboard joints integrating thermal insulation and load bearing. J. Build. Eng. 2023, 76, 107259. [Google Scholar] [CrossRef]

- Ma, S.C.; Hou, D.F.; Bao, P.; Wano, D.T. Influence of alkali-resistant glass fiber on seismicperformance of precast ceramsite concrete sandwich wall panels. Structures 2022, 38, 94–107. [Google Scholar] [CrossRef]

- Ma, S.C.; Lou, Y.Y.; Bao, P. Experimental study of bending resistance of pre-fabricated truss beams under eccentric loads. J. Build. Eng. 2022, 49, 104119. [Google Scholar] [CrossRef]

- Li, S. Study on Dynamic Characteristics and Vibration Comfort Analysis of Light Steel Movable Plate House. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2021. [Google Scholar]

- Lin, H.H.; Cheng, J.H. A Study of the Simulation and Analysis of the Flow Field of Natural Convection for a Container House. J. Sustain. 2020, 12, 9845. [Google Scholar] [CrossRef]

- Fan, K.J.; Zha, X.X. Analysis of lateral stiffness of container house Ⅱ: Influence of side plate opening. J. Harbin Inst. Technol. 2017, 49, 109–116. [Google Scholar]

- Wang, Y.; Li, J.F. The analysis of internal force of semi-rigid steel frame. J. Mech. Eng. 2003, 2, 35–38. [Google Scholar]

- Wang, Y.Q.; Zhang, Y.Z.; Shi, G.; Shi, Y.J.; Shu, X.P. Elastic Time-history Analysis of Multi-story Steel Frame with Semi-rigid End-plate Conections in Earthquake Response. Earthq. Resist. Eng. Retrofit. 2007, 2, 28–32. [Google Scholar]

- Yang, S.S.; Wang, Y. Research on the moment capacity of fully assembled column-beam joint composed of outer sleeve and strengthed exthended end-plate. J. Ind. Constr. 2017, 47, 7–166. [Google Scholar]

- Yang, S.S.; Wang, Y.; Ma, Q.Q. Experimental study on seismic behavior of prefabricated outer sleeve-overhang plate joint between column and beam. J. China Civ. Eng. J. 2017, 50, 76–86. [Google Scholar]

- Zhang, J.F.; Yang, D.Y.; Hu, W.T. Research on overall flexural stiffness of assembled box house. J. Steel Constr. 2016, 31, 28–32. [Google Scholar]

- Zhao, B.D. Extended End-Plate Bolted Connections Performance Study of Steel Frame Structure; Xi’an University of Architecture and Technology: Xi’an, China, 2006. [Google Scholar]

- Yang, X.J.; Zhang, L.; Li, G.Q.; Liu, Y.S.; Lu, Y.; Sun, J.Y. Hysteretic Performance of End Plate Connections between Rectangular Hollow Section Columns and H-Shaped Beams Using Through-Bolts. J. Prog. Steel Build. Struct. 2013, 15, 16–23. [Google Scholar]

- Liu, W.; Tan, P.; Hao, L.F.; Zhou, F.L. Calculation of basic natural period of vibration of semi-rigid connection steel frame with sides way. J. Steel Constr. 2018, 33, 6–10+91. [Google Scholar]

- Su, J.L.; Li, X.M.; Qi, R. Second-Order Elastic Stability Analysis of Steel Semi-Rigid Frame. J. Build. Sci. 2011, 27, 15–19. [Google Scholar]

- Feng, J.B. Second-Order Analysis Design Method for Flush End-Plate Semi-Rigid Connection Steel Frames. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2016. [Google Scholar]

- Hu, X.B.; Shen, P.X.; Shu, X.P. Elastic time-history analysis of steel frame structures with semi-rigid connections. J. Earthq. Eng. Eng. Dyn. 2008, 28, 65–70. [Google Scholar]

- Wang, L.; Zhou, N.N.; Wang, G.B. Experimental research on seismic behavior of steel frame with top and seat angle with double web angles semi-rigid connections. J. Build. Struct. 2009, 39, 54–58. [Google Scholar]

- Wu, Y.; Peng, S.M.; Zhang, Q.L. Experimental and Numerical Studies on Seismic Behaviors of Steel Frames with Top-Seat and Double Web Angel Connections. J. Tongji Univ. 2005, 33, 1438–1442. [Google Scholar]

- Sun, L.; Li, F.X. Experimental study on seismic behavior of steel frame models with semi-rigid connections. J. World Earthq. Eng. 2005, 4, 143–147. [Google Scholar]

- Li, G.Q.; Wang, J.F.; Liu, Q.P. An experimental study of full-scale semi-rigid composite frames under vertical loading. China Civ. Eng. J. 2006, 7, 43–51+62. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2006&filename=TMGC200607007&uniplatform=OVERSEA&v=2z3_cOxsIlxMWlY7zhpt-h1sGtbNh7TJyZpbtT8UaXJJIsxYANTw2DltNQ__RXsO (accessed on 20 November 2023).

- Li, G.Q.; Liu, Q.P.; Wang, J.F. An experimental study of a full-scale semi-rigid composite frame under lateral loading. China Civ. Eng. J. 2007, 40, 8–16. Available online: https://www.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2007&filename=TMGC200712007&uniplatform=OVERSEA&v=euFq3z_dA5KdWz36mCJa2j17kUxX9of9VwqVqaie7wxw-ctPtpZSTXbVRIGWteOT (accessed on 20 November 2023).

- Zhang, J.F.; Yang, D.Y.; Guo, Q. Experimental research on the vertical bearing capacity of the removable box house. J. Ind. Constr. 2017, 47, 162–167. [Google Scholar]

- Zhang, J.F.; Yang, D.Y.; Hu, W.T. Experimental study on mechanical behavior of the bottom frame structure of removable box house. J. Build. Struct. 2017, 47, 22–27. [Google Scholar]

- Zhang, J.; Wu, C.H. Elasto-plastic analysis of wheel-rail contact problem. J. China Railw. Soc. 2000, 3, 16–21. [Google Scholar]

- Rajendr Prasad, R.; Chidambaram, K.R. Cost Analysis of Foldable Containers on Container Freight Station and Port in Chennai Region. Eng. Appl. Sci. 2017, 12, 6764–6768. [Google Scholar]

- Zhang, G.P.; Ma, C. The Key Issue Exploration in Modular Design of Prefabricated Houses. J. Jilin Jianzhu Univ. 2016, 33, 57–60. [Google Scholar]

- Yang, Y.P.; Huang, Y.S.; Zeng, F.L.; Zhang, H.S. Static Elastoplastic Analysis of Concrete-filled Steel Tube Gravity Column-concrete Core Tube Structure. South China J. Seismol. 2021, 41, 157–163. [Google Scholar]

- Refachinho, D.; Neto, A.G. Rigid body formulation in a finite element context with contact interaction. Comput. Mech. 2018, 62, 1369–1398. [Google Scholar] [CrossRef]

- GB/50009-2012; Load Code for the Design of Building Structures. China Construction Industry Press: Beijing, China, 2012.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Standard Publishing House: Beijing, China, 2021.

| Loading Conditions | Design Loads |

|---|---|

| Condition 1 | 1.3 × dead load + 1.5 × live load |

| Condition 2 | 1.3 × dead load + 1.5 × live load + 1.5 × 0.6 × wind load |

| Condition 3 | 1.0 × dead load + 1.0 × live load |

| Condition 4 | 1.0 × dead load + 1.0 × live load + 0.6 × wind load |

| Loading Conditions | x-Direction (mm) | y-Direction (mm) | z-Direction (mm) |

|---|---|---|---|

| Condition 1 | 0.1446 | −3.070 | −0.3919 |

| Condition 2 | 6.813 | −2.318 | −0.4818 |

| Condition 3 | 0.1078 | −2.159 | −0.2754 |

| Condition 4 | 3.720 | −1.663 | −0.2806 |

| Loading Conditions | Equivalent Stress (MPa) |

|---|---|

| Condition 1 | 215.6 |

| Condition 2 | 223.0 |

| Condition 3 | 204.1 |

| Condition 4 | 210.7 |

| Test Parameters | Destructive Test | Graded Loading Test |

|---|---|---|

| Test standard | GB/T 228.1-2021 | GB/T 228.1-2021 [42] |

| Specimen width (b)/mm | 20 | 20 |

| Specimen length (L)/mm | 220 | 220 |

| Cross-sectional area (So)/mm2 | 4400 | 4400 |

| Control mode | Displacement control | Force control |

| Control speed | 20 mm/min | 1000 N/s |

| Bolt preload force/N∙m | 60 | 60 |

| Load force value/kN | No upper limit | 50/80/100 |

| Force holding time/s | / | 30 |

| Tensile Value/kN | Opening Average Value/mm |

|---|---|

| Not loaded | 0.766 |

| 50 | 1.191 |

| 80 | 1.473 |

| 100 | 1.677 |

| Unload | 1.390 |

| Tensile Value/kN | Opening Mean Value/mm |

|---|---|

| Before load | 0.681 |

| 50 | 0.781 |

| 80 | 1.022 |

| 100 | 1.172 |

| Unload | 0.720 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, A.; Zheng, L.; Mei, Y.; Zhang, J.; Chen, S.; Wang, X.; Ma, H.; Yu, R. Simulation Analysis of the Structure of an Integrated Modular House by Flat Pack Based on the Elastic–Plastic Contact Theory and Experimental Study of Its Corner Fitting Joint. Buildings 2024, 14, 635. https://doi.org/10.3390/buildings14030635

Zhang A, Zheng L, Mei Y, Zhang J, Chen S, Wang X, Ma H, Yu R. Simulation Analysis of the Structure of an Integrated Modular House by Flat Pack Based on the Elastic–Plastic Contact Theory and Experimental Study of Its Corner Fitting Joint. Buildings. 2024; 14(3):635. https://doi.org/10.3390/buildings14030635

Chicago/Turabian StyleZhang, Ao, Lei Zheng, Yong Mei, Jun Zhang, Shengyun Chen, Xueming Wang, He Ma, and Ruodan Yu. 2024. "Simulation Analysis of the Structure of an Integrated Modular House by Flat Pack Based on the Elastic–Plastic Contact Theory and Experimental Study of Its Corner Fitting Joint" Buildings 14, no. 3: 635. https://doi.org/10.3390/buildings14030635

APA StyleZhang, A., Zheng, L., Mei, Y., Zhang, J., Chen, S., Wang, X., Ma, H., & Yu, R. (2024). Simulation Analysis of the Structure of an Integrated Modular House by Flat Pack Based on the Elastic–Plastic Contact Theory and Experimental Study of Its Corner Fitting Joint. Buildings, 14(3), 635. https://doi.org/10.3390/buildings14030635