Semiautomated Primary Layout Definition with a Point Cloud for Building-Envelope Renovation

Abstract

1. Introduction

- Is accuracy guaranteed with an automated layout generation?

- Is the time spent in an accurate Point Cloud acquisition of the building and an automated layout generation faster and more accurate than a manual marking and data acquisition procedure and a manual design? Moreover, a secondary objective is to define the characteristics of the Point Cloud in terms of point density and accuracy.

- Which are the key points in a Point Cloud to automatically generate the layout?

2. State of the Art in Data Acquisition and Processing

- The automated data acquisition and recognition of construction objects is a topic that has been developed, but it lacks the required accuracy. There have been advances in the scanning hardware used for Digital Twins [58]. Continuous improvements have been made in order to gain accuracy [59]. However, accuracy of the Point Cloud is still a major issue.

- Recognition of known shapes is not applicable for acquiring and processing data with high accuracy.

- The automated design was based on previously drafted existing buildings.

- Regarding the boundary conditions, or tolerances, DIN 18202 [60] specifies the accuracy requirements of external walls. As a reference, in a facade of 15 m, 20 mm of deviation are accepted.

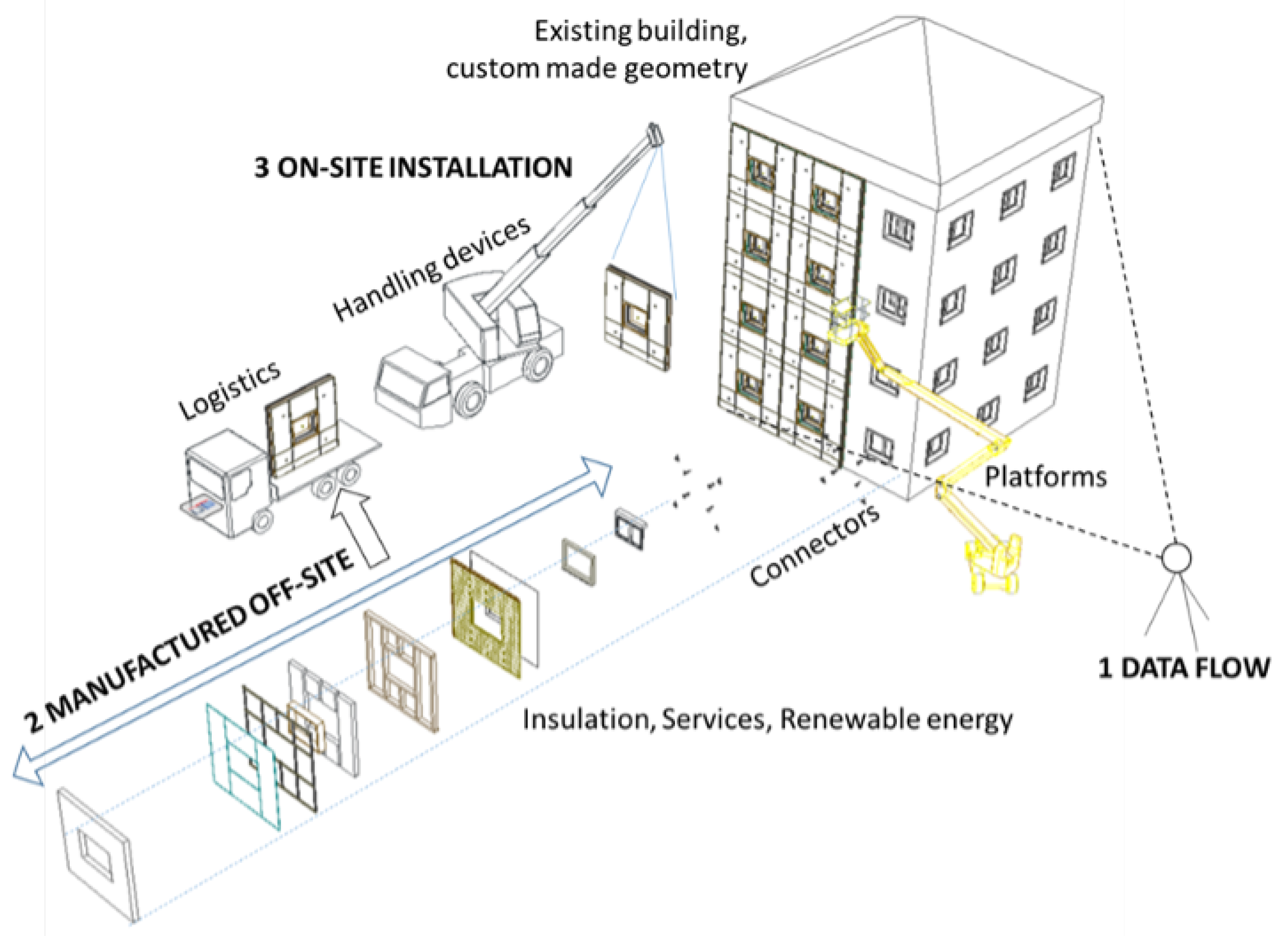

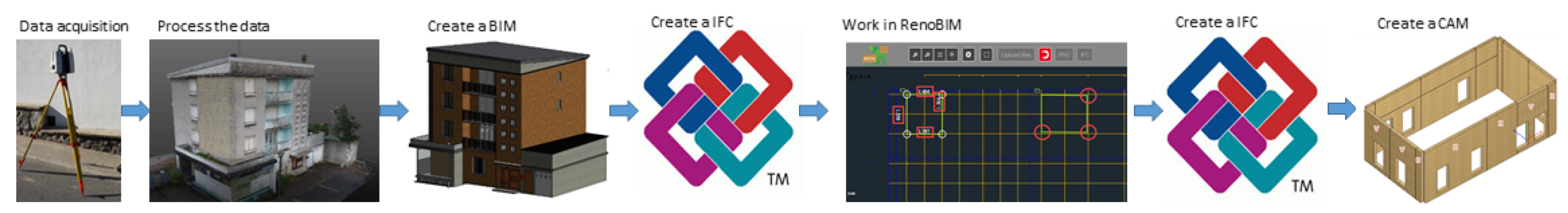

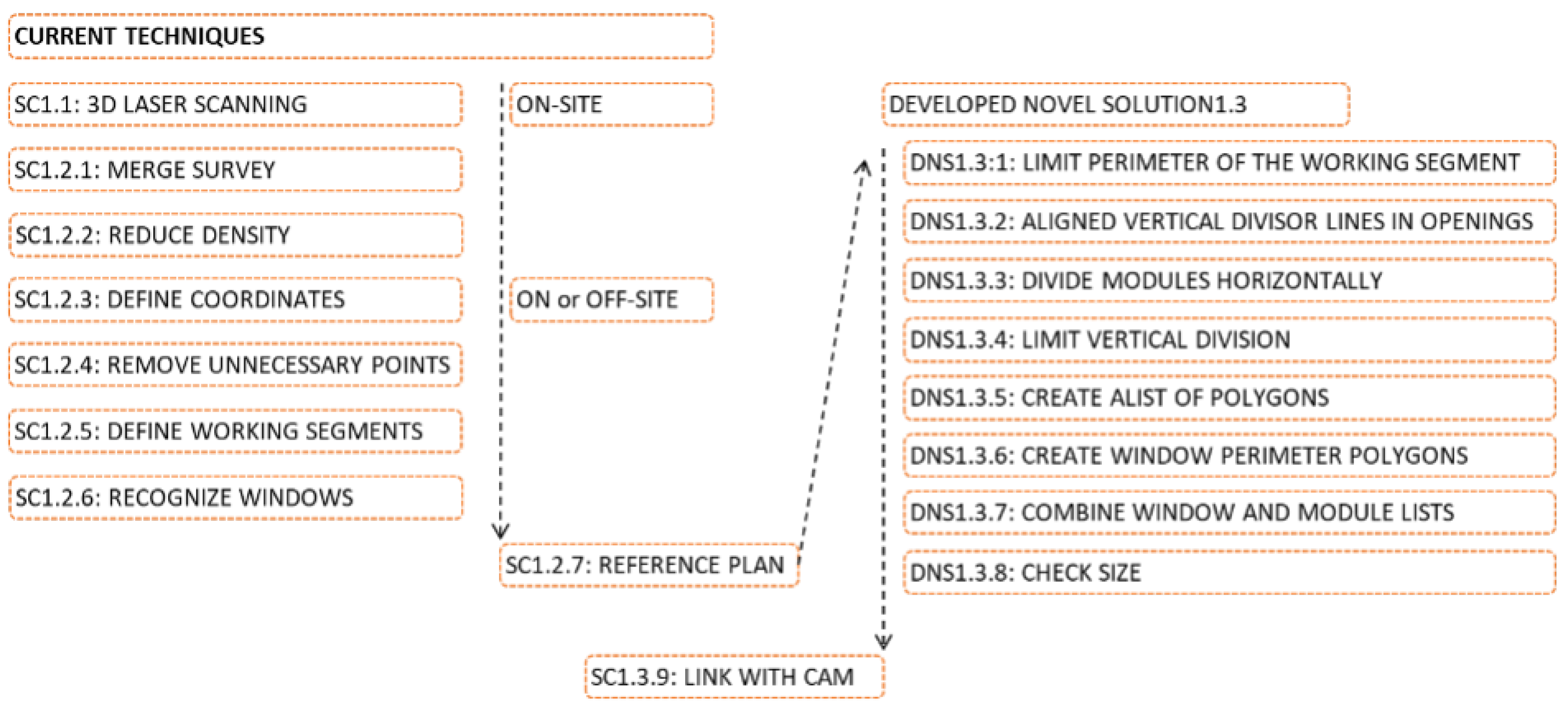

3. Development of a Novel Solution

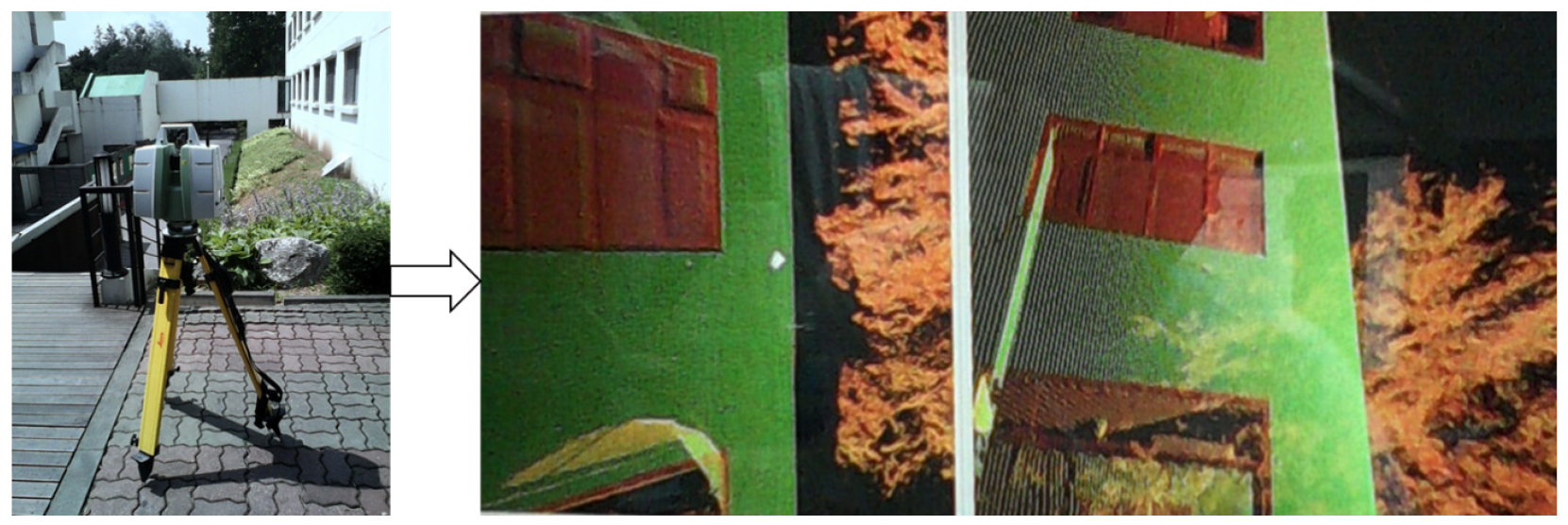

- SC1.1. With current techniques, data acquisition is achieved with a 3D laser scanner, such as the one in Figure 7. Several scanning surveys might be necessary, depending on the size of the façade.

- SC1.2.1. After data acquisition, these surveys can be merged with current software.

- SC1.2.2. For the application explained in this dissertation, it is recommended to reduce the point density of the Point Cloud to a grid that is manageable. In the case of 3D Point Clouds, the points to be processed could reach hundreds of millions. At this time, it can be said that this is too much data processing [61]; therefore, the density needs to be minimized. The density will depend on the processing capacity of the computer.

- SC1.2.3. After the density is reduced, the coordinates of the building origin must be defined to manage the Point Cloud more efficiently.

- SC1.2.4. The next step consists of removing the points that are not necessary, which means all the points that are out of range of the building façade.

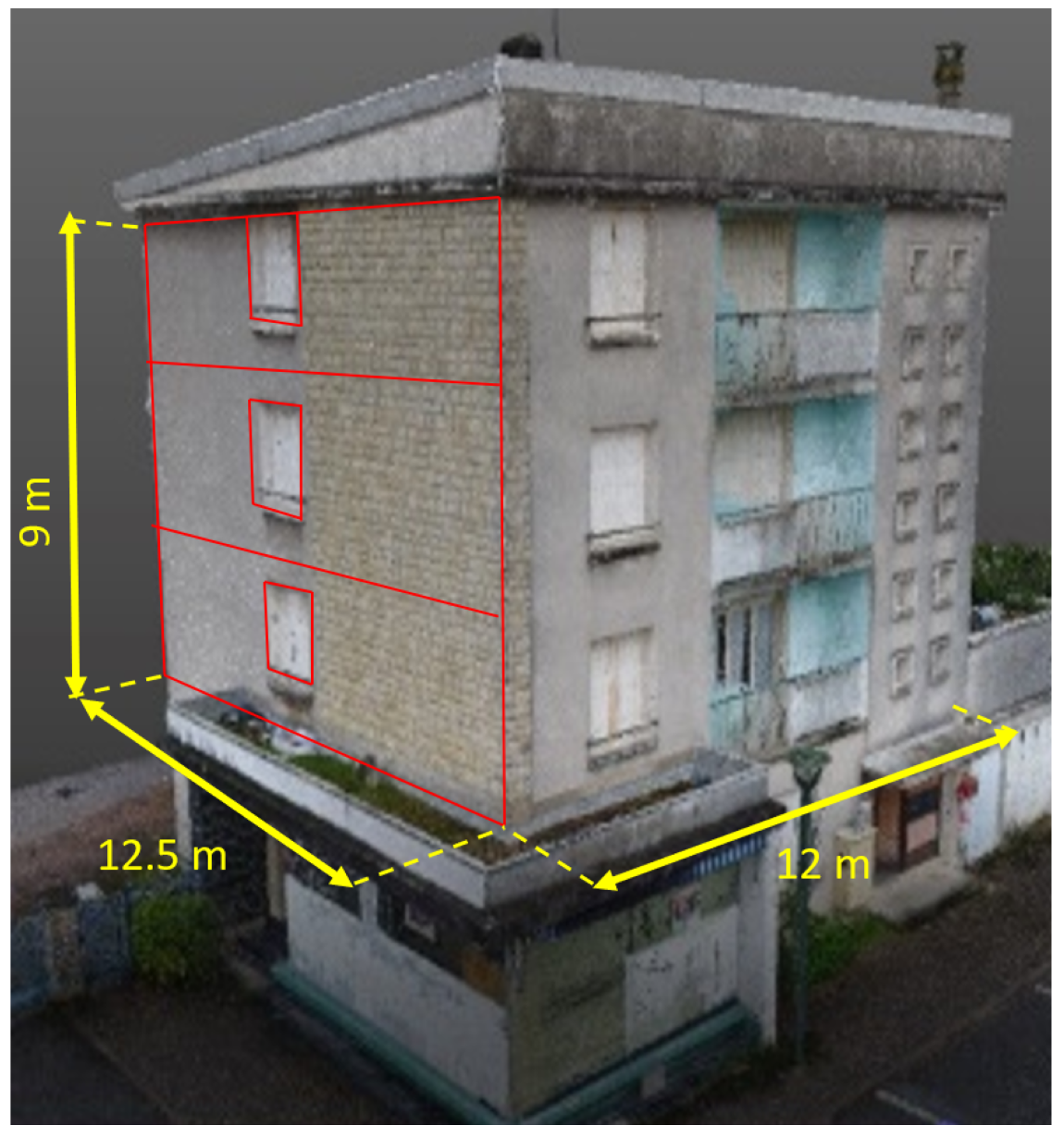

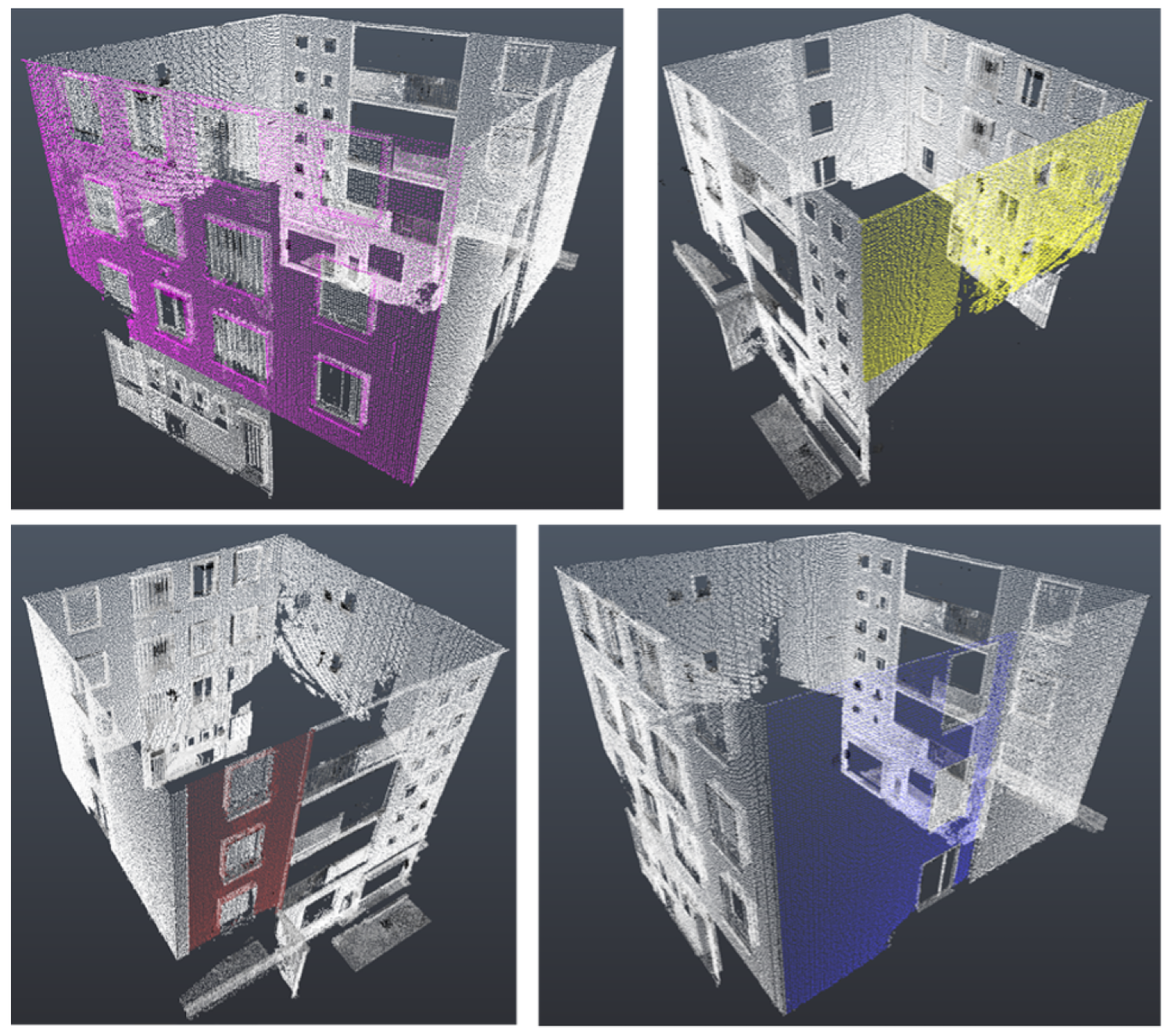

- SC1.2.5. The next step consists of defining manageable working segments of the façades. Buildings normally have heterogeneous envelopes. Therefore, in this step, the façade segments that include these characteristics need to be isolated and defined as a manageable working segment. For this purpose, the points that include these segments should be selected.

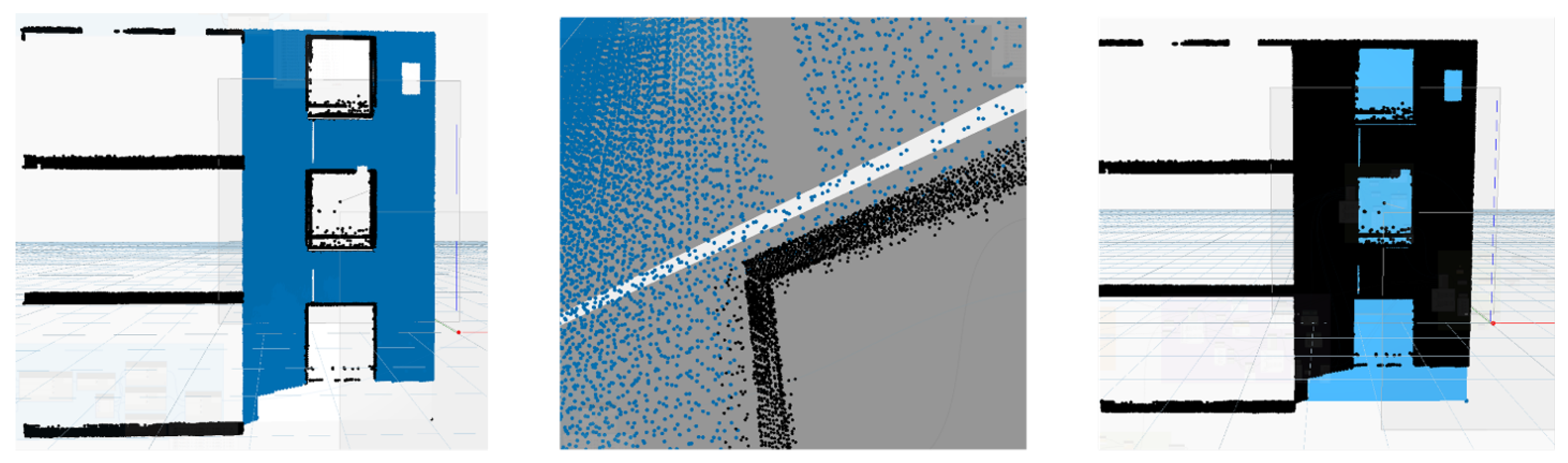

- SC1.2.6: Recognize windows (wall openings). The building elements should be recognized for determining elements such as the walls and windows of the facade. Point Cloud processing software permits, in a semi-automated way, the categorization of points within a range of distances concerning a plan. The inner window has an outdoor sill and a jamb and can be classified separately from the façade plan. The window is placed in the interior with respect to the wall plan. The difference in depth in the x-axis facilitates the categorization of the window opening. In addition to that, the slab’s z coordinate is necessary to define the separator of the horizontal module of the primary layout. The rest of the points would be part of the solid wall.

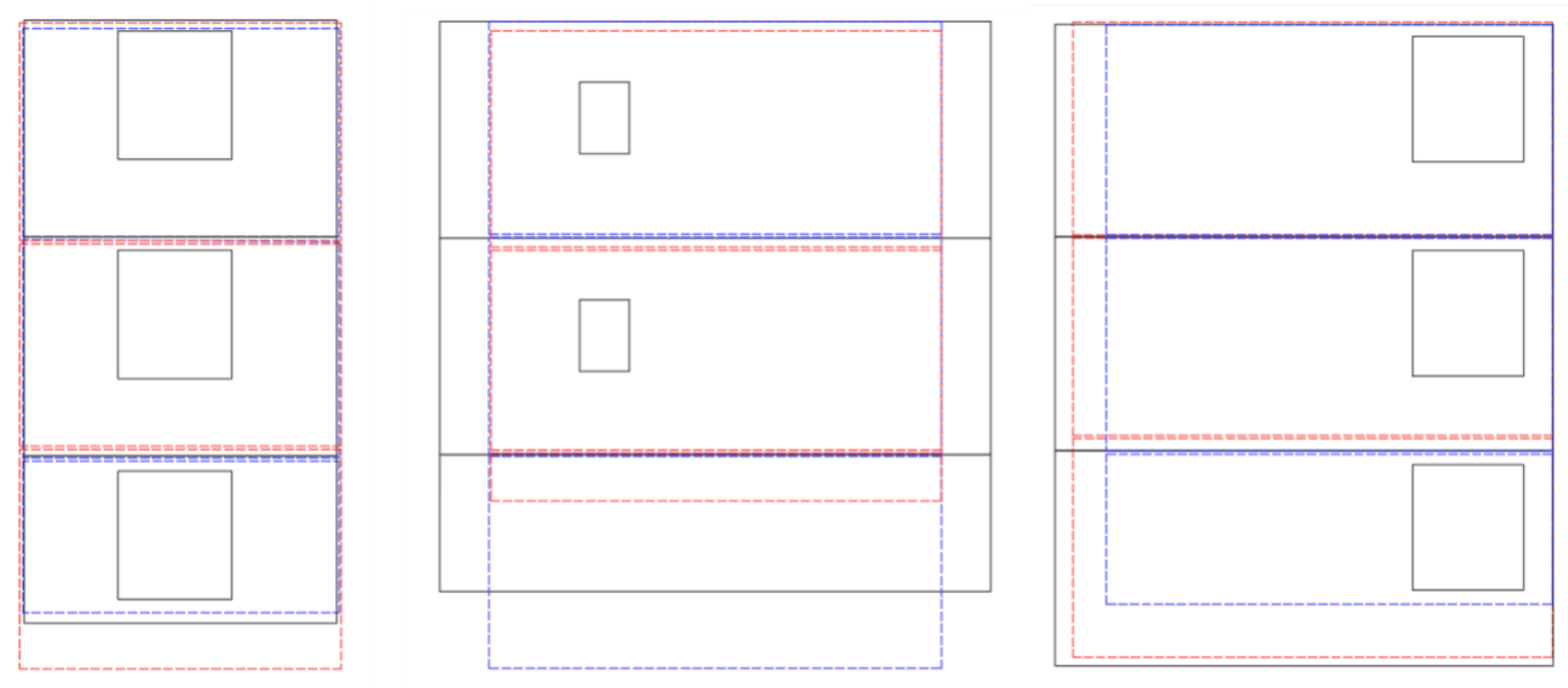

- SC1.2.7. We select the appropriate reference plan for each of the working segments. Walls and façades have irregularities, and the Point Cloud collects these irregularities. The selection of an appropriate reference is necessary. If an inappropriate coordinate system and preference plan are selected, excessive separation and non-parallel location of the modules might occur (see where the dashed coordinate systems are exaggeratedly deviated to explain the importance of the topic). As a consequence, excessive insulation might be foreseen to cover the gap between the existing wall and the module. Due to this, the internal insulation of the module may collide during insulation. Additionally, the separation between the existing wall and the modules must also be considered, which usually depends on the insulation thickness that the modules have in the inner face. Therefore, there is a need to automatically define the points of the cloud in the coordinate system accurately. For this reason, an average plan must be determined for each manageable working segment. The Working Plan is where the primary layout is arranged. It needs to be parallel to the average façade plan, which is determined by the Point Cloud of the façade. For defining such a plan, a coordinate system must be determined.

- DNS1.3.1: Limit the perimeter of the working segment. Create the geometry of the wall by finding the outer points of the wall segment and complete the geometry of a façade if necessary. Check what happens in the corner when there is a blind spot. For that purpose, partial reconstruction is needed and suppose that the geometry follows a certain pattern.

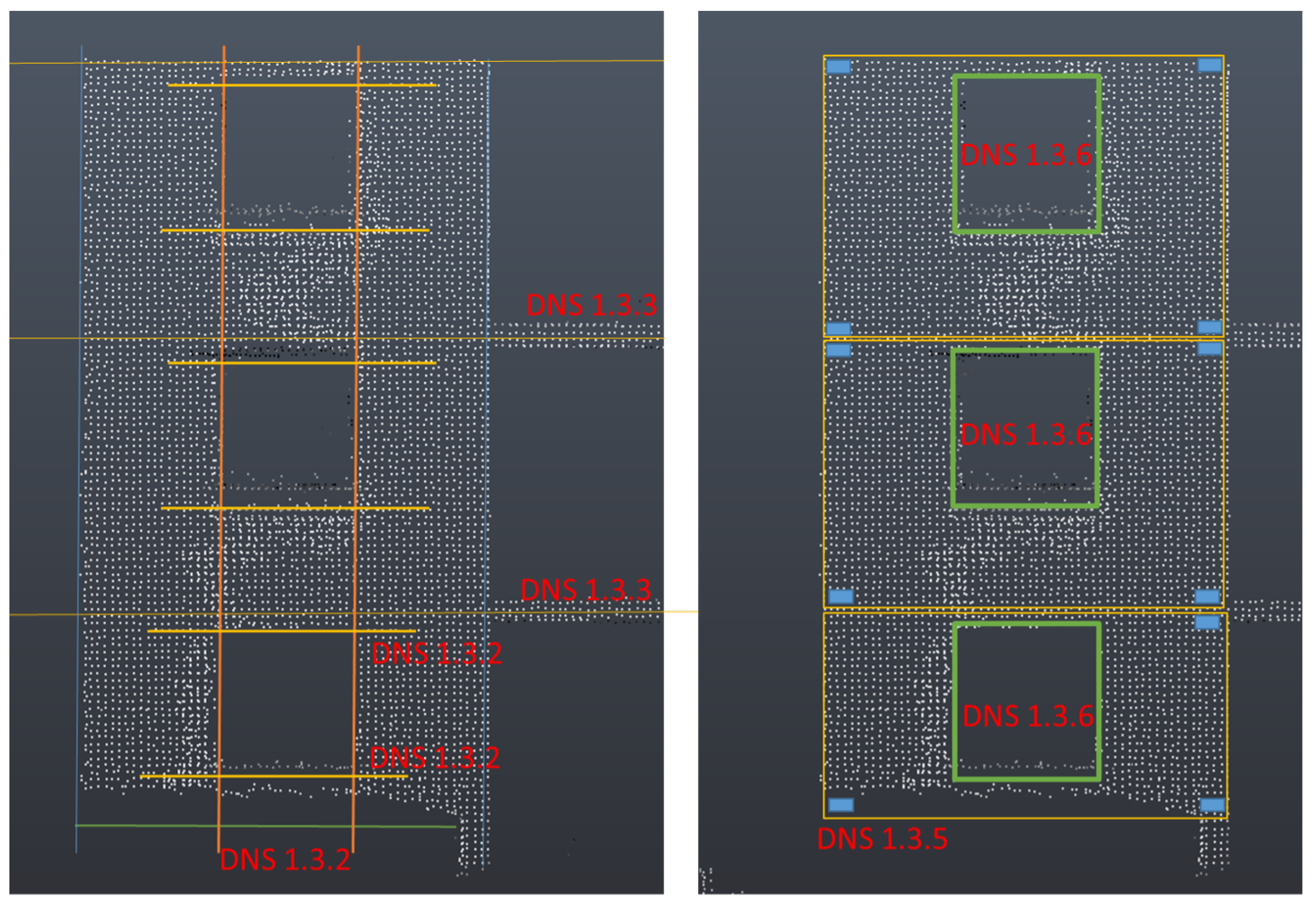

- DNS1.3.2: Modules with aligned vertical divisor lines in openings. When upgrading a building façade, it is normally desirable to plumb the lines of the modules and the lines of the window openings, not only for aesthetic aspects but also to regularize the size of the windows and the production of the modules. Selecting the axe of the window vertical limit correctly is crucial. The strategy used in this research consisted of obtaining the outer points of the window hole.

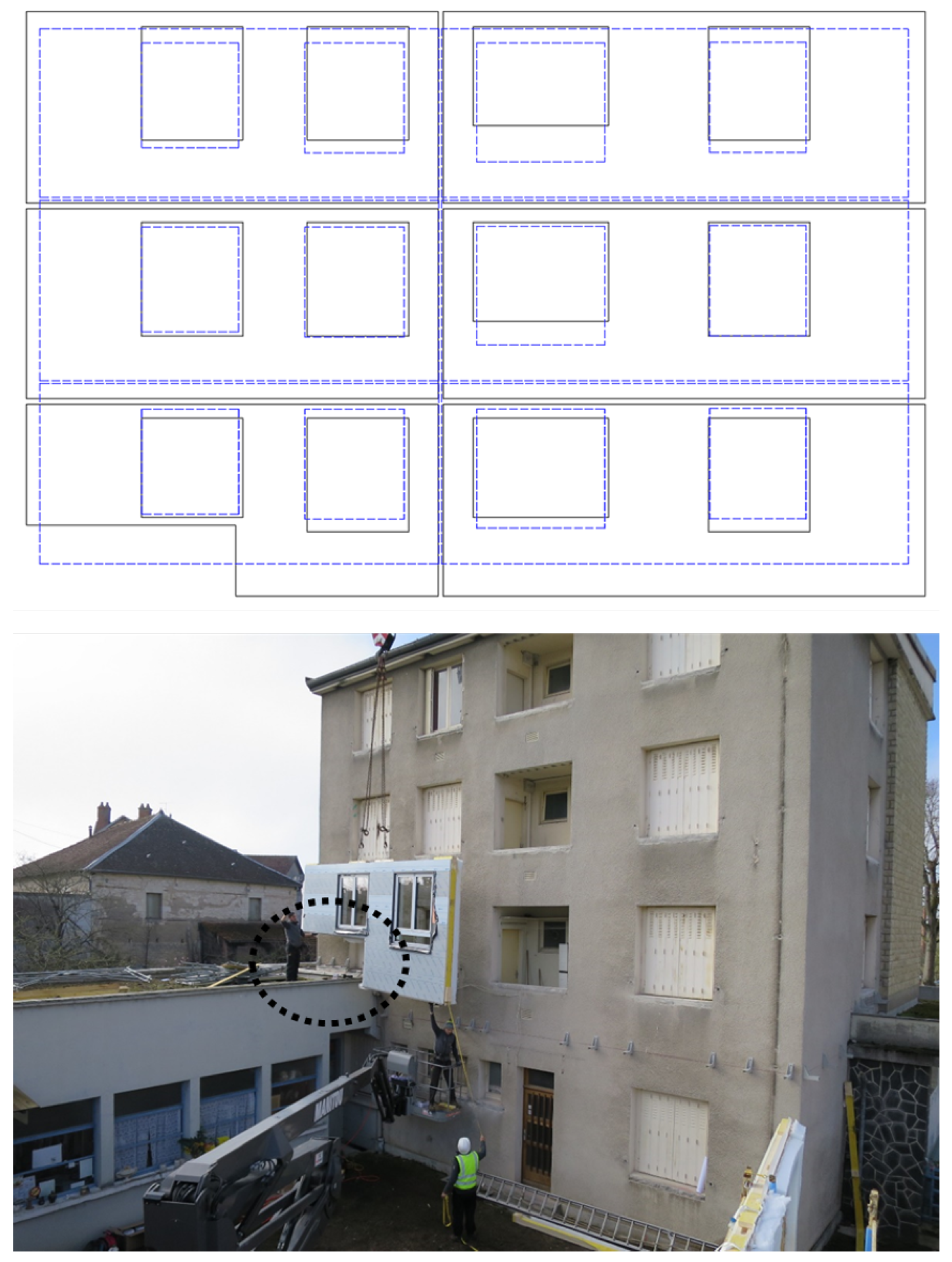

- DNS1.3.3: Divide the modules horizontally according to the middle Z-value of the floor slab, or in other words, obtain the medium Z-value of the slab to divide the modules horizontally. Also, it is required that the horizontal module division meets with the slab of the existing building. In this way, the connector can be placed on the structural support. The importance of the primary layout lies not only in the module divisor and the openings of the windows but also in the location of the connector in the corners of the modules (see the blue squares in Figure 9).

- DNS1.3.4: Limit the vertical division of the modules according to a given width. Module size according to given parameters. When defining the module layout, it is necessary to consider the maximum and minimum sizes of the manufacturers.

- DNS1.3.5. Create a list of polygons of modules.

- DNS1.3.6: Create the window perimeter geometry segment by joining the lines generated in DNS1.3. and create a list of polygons. The window lines should be aligned.

- DNS1.3.7: Combine the window list and the module list.

- DNS1.3.8: Check that the size is correct according to the parameters given (height and width).

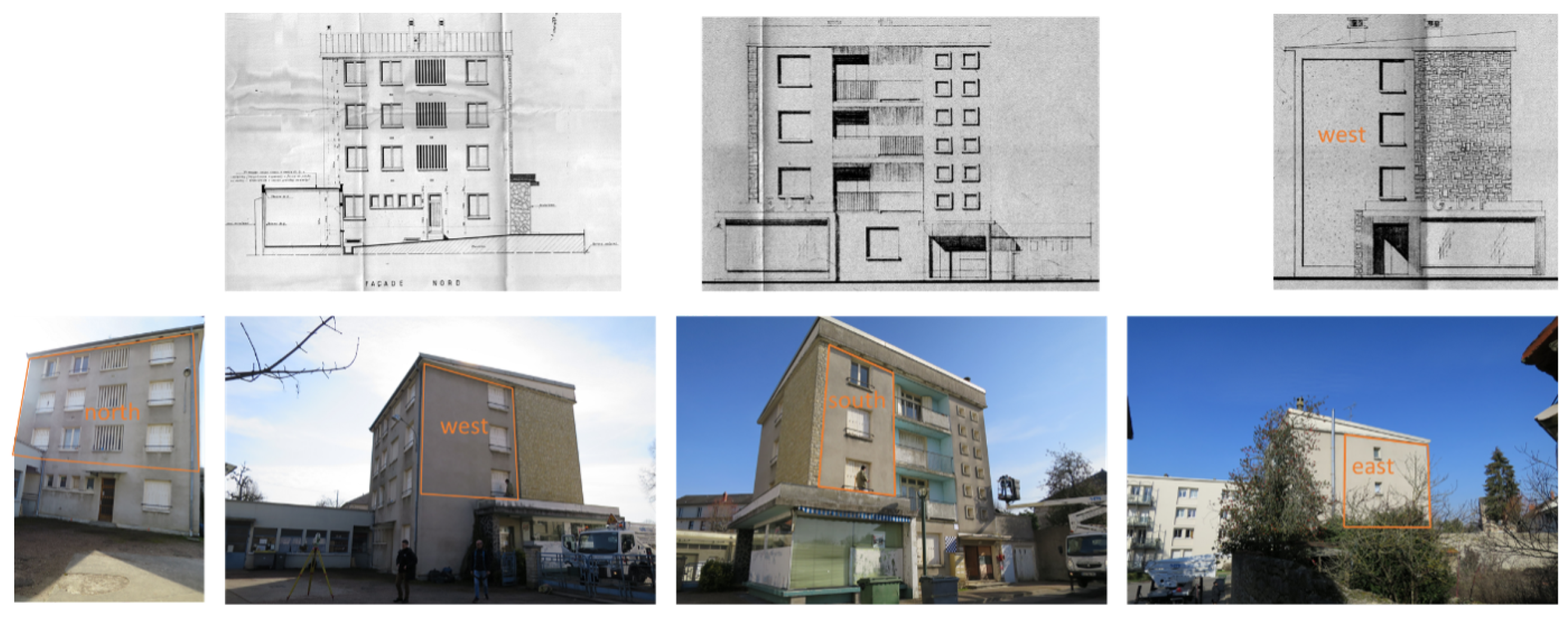

4. Tests of the Novel Process

- A low density of points with a grid of 100 mm by 100 mm.

- A higher density of points with a grid of 20 mm by 20 mm.

- Four manageable working façade segments without the interior of the window (SC1.2.6).

- The same four manageable façade working segments with the interior of the window (SC1.2.6).

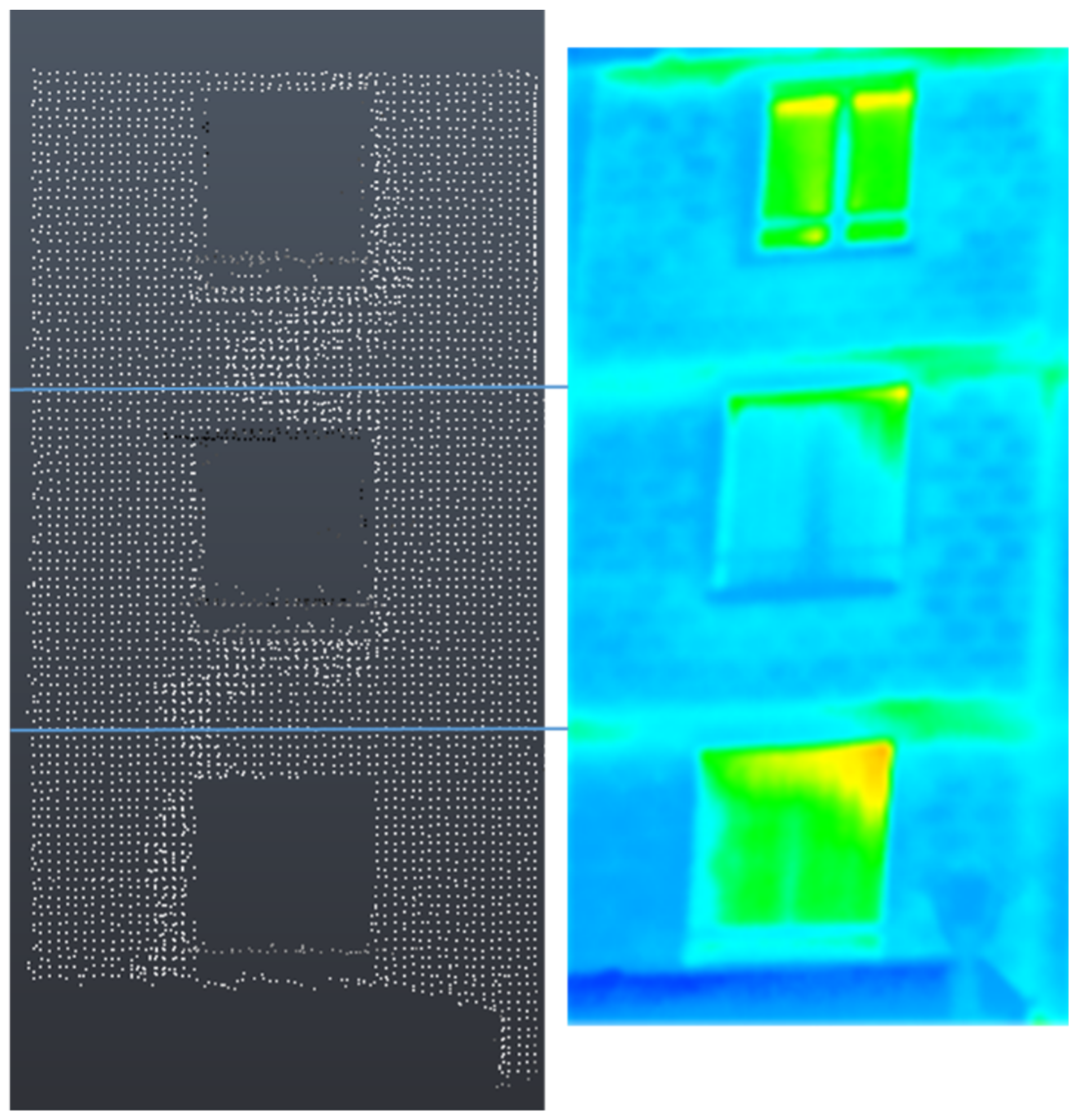

- Slabs of a balcony used as a reference for horizontally dividing the module.

5. Results and Discussion

5.1. Working Time

5.2. Output Accuracy

6. Conclusions and Future Needs

- FN1.1: Accuracy of the measuring device and acquired data. The primary layout definition is dependent on the accuracy of the Point Cloud data acquisition. The limitations of the building measurement, lack of enough information, and blind spots are a major threat to putting into practice the methods explained in this article.

- FN1.3.1: Accuracy of the selected segments. The Point Cloud does not offer a surface per se. Data processing and decision making are necessary to select surfaces. Determining the working plan and section of the primary layout properly has primordial importance.

- FN1.3.3: This study is limited by the definition of the coordinates of the building slab. Without that data, it is difficult to know where to horizontally split the building module layout and where to place the connectors. In future work, thermal camera images should be considered and matched with the Point Cloud to find the slab’s position (Figure 18). There was an interesting combination of thermal images and 3D laser scanning [62]. Unfortunately, the accuracy of the solution was not defined.

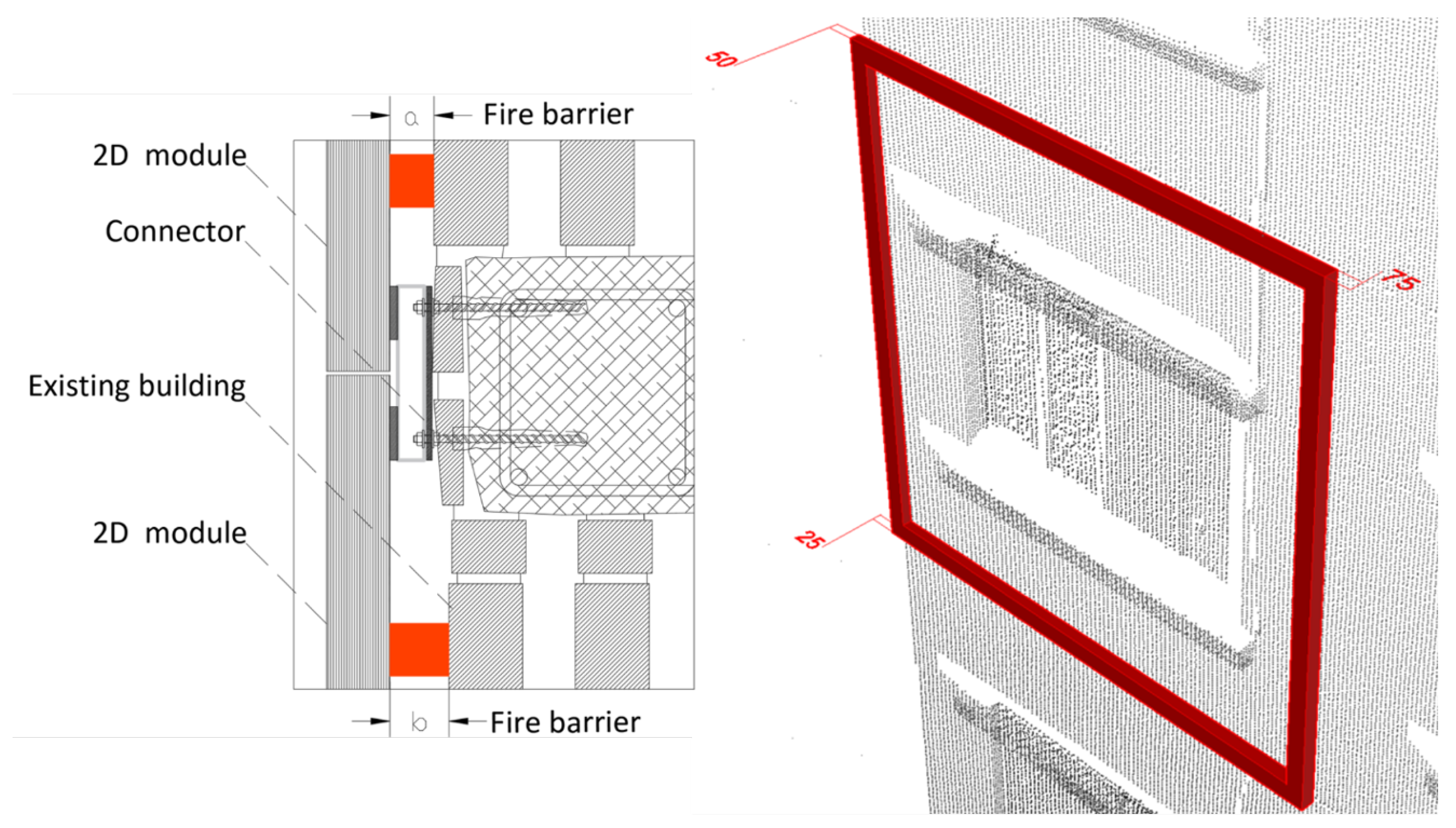

- Define the geometry for customized fire barriers. According to the latest research on the topic, each module should define a separate fire area. This means that each module should have a fire barrier in the whole perimeter. As explained above, the walls are not plumbed and are irregular, and it is necessary to remark that the panels need to be fireproof and that the areas of each module need to be protected with barriers or cavity barriers. Fire-resistant barriers can be placed on top of the modules. Each module should be independently fireproof. Therefore, it is necessary to know the approximate thickness of the barrier to avoid gaps or excessive thickness. The depth of the perimeter varies depending on the irregularities of the wall (Figure 19).

- Create a library to recognize objects in complex façade elements. A more complex façade typology beyond the scope of this research should be taken into account for a broader market approach. To do so, the development of different processing algorithms would be necessary.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NZEB | Nearly Zero-Energy Building |

| CAM | Computer-Aided Manufacturing |

| CAD | Computer-Aided Design |

| BIM | Building Information Modeling |

| UAV | Unmanned Aerial Vehicle |

| SC | Subcategory |

| DNS | Developed Novel Solution |

| RG | Research Gap |

| PCL | Point Cloud Library |

| FN | Future Need |

References

- Sesana, M.; Salvalai, G.; Brutti, D.; Mandin, C.; Wei, W. ALDREN: A Methodological Framework to Support Decision-Making and Investments in Deep Energy Renovation of Non-Residential Buildings. Buildings 2020, 11, 3. [Google Scholar] [CrossRef]

- Rodríguez-Álvarez, J. Urban Building Energy Modelling for the Renovation Wave: A Bespoke Approach Based on EPC Databases. Buildings 2023, 13, 1636. [Google Scholar] [CrossRef]

- Iturralde, K.; Linner, T.; Bock, T. Matching kit interface for building refurbishment processes with 2D modules. Autom. Constr. 2020, 110, 103003. [Google Scholar] [CrossRef]

- Iturralde, K.; Linner, T.; Bock, T. Development of a Modular and Integrated Product-Manufacturing-Installation System Kit for the Automation of the Refurbishment Process in the Research Project BERTIM. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Auburn, AL, USA, 18–21 July 2016. [Google Scholar] [CrossRef]

- Iturralde, K.; Linner, T.; Bock, T. First Monitoring and Analysis of the Manufacturing and Installation Process of Timber Based 2D Modules for Accomplishing a Future Robotic Building Envelope Upgrading. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Taipei, Taiwan, 27–30 June 2017; Tribun EU, s.r.o.: Brno, Czech Republic, 2017. [Google Scholar] [CrossRef]

- Tsai, I.C.; Kim, Y.; Seike, T. Decision-making Consideration in Energy-conservation Retrofitting strategy for the Opening of Existing Building in Taiwan. AIJ J. Technol. Des. 2017, 23, 963–968. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Site Automation; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar] [CrossRef]

- Pérez-Navarro, J.; Bueso, M.C.; Vázquez, G. Drivers of and Barriers to Energy Renovation in Residential Buildings in Spain—The Challenge of Next Generation EU Funds for Existing Buildings. Buildings 2023, 13, 1817. [Google Scholar] [CrossRef]

- Barco, A.F.; Vareilles, É.; Gaborit, P.; Aldanondo, M. Building renovation adopts mass customization. J. Intell. Inf. Syst. 2016, 49, 119–146. [Google Scholar] [CrossRef]

- Doukari, O.; Seck, B.; Greenwood, D. The Creation of Construction Schedules in 4D BIM: A Comparison of Conventional and Automated Approaches. Buildings 2022, 12, 1145. [Google Scholar] [CrossRef]

- Sandberg, K.; Orskaug, T.; Andersson, A. Prefabricated Wood Elements for Sustainable Renovation of Residential Building Façades. Energy Procedia 2016, 96, 756–767. [Google Scholar] [CrossRef]

- Haslam, R.; Hide, S.; Gibb, A.; Gyi, D.; Pavitt, T.; Atkinson, S.; Duff, A. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, M.; Ma, L. Gaps and requirements for applying automatic architectural design to building renovation. Autom. Constr. 2023, 147, 104742. [Google Scholar] [CrossRef]

- Ishikawa, T.; Seike, T.; Kim, Y.; Wakayama, A.; Hayashi, T. A Study on the Actual Situation about the Saving Energy Renovation of an Existing Apartment House by External Insulation. AIJ J. Technol. Des. 2015, 21, 35–40. [Google Scholar] [CrossRef][Green Version]

- Bosché, F. Automated recognition of 3D CAD model objects in laser scans and calculation of as-built dimensions for dimensional compliance control in construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Kim, C.; Son, H.; Kim, C. Fully automated registration of 3D data to a 3D CAD model for project progress monitoring. Autom. Constr. 2013, 35, 587–594. [Google Scholar] [CrossRef]

- Arayici, Y. An approach for real world data modelling with the 3D terrestrial laser scanner for built environment. Autom. Constr. 2007, 16, 816–829. [Google Scholar] [CrossRef]

- Becker, S.; Haala, N. Grammar supported facade reconstruction from mobile lidar mapping. In Proceedings of the CMRT09, Paris, France, 3–4 September 2009; IAPRS: Hannover, Germany, 2009; Volume XXXVIII. Part 3/W4. [Google Scholar]

- Pu, S.; Vosselman, G. Knowledge based reconstruction of building models from terrestrial laser scanning data. ISPRS J. Photogramm. Remote Sens. 2009, 64, 575–584. [Google Scholar] [CrossRef]

- Tang, P.; Akinci, B.; Huber, D. Quantification of edge loss of laser scanned data at spatial discontinuities. Autom. Constr. 2009, 18, 1070–1083. [Google Scholar] [CrossRef]

- Tang, P.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic reconstruction of as-built building information models from laser-scanned point clouds: A review of related techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Ostrowski, W.; Pilarska, M.; Charyton, J.; Bakuła, K. Analysis of 3D building models accuracy based on the airborne laser scanning point clouds. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-2, 797–804. [Google Scholar] [CrossRef]

- Awrangjeb, M. Using point cloud data to identify, trace, and regularize the outlines of buildings. Int. J. Remote Sens. 2016, 37, 551–579. [Google Scholar] [CrossRef]

- Jung, J.; Hong, S.; Jeong, S.; Kim, S.; Cho, H.; Hong, S.; Heo, J. Productive modeling for development of as-built BIM of existing indoor structures. Autom. Constr. 2014, 42, 68–77. [Google Scholar] [CrossRef]

- Macher, H.; Landes, T.; Grussenmeyer, P.; Alby, E. Semi-automatic Segmentation and Modelling from Point Clouds towards Historical Building Information Modelling. In Digital Heritage. Progress in Cultural Heritage: Documentation, Preservation, and Protection; Springer International Publishing: Berlin/Heidelberg, Germany, 2014; pp. 111–120. [Google Scholar] [CrossRef]

- Wang, C.; Cho, Y.K.; Kim, C. Automatic BIM component extraction from point clouds of existing buildings for sustainability applications. Autom. Constr. 2015, 56, 1–13. [Google Scholar] [CrossRef]

- Roca, D.; Lagüela, S.; Díaz-Vilariño, L.; Armesto, J.; Arias, P. Low-cost aerial unit for outdoor inspection of building façades. Autom. Constr. 2013, 36, 128–135. [Google Scholar] [CrossRef]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Cawood, A.J.; Bond, C.E.; Howell, J.A.; Butler, R.W.; Totake, Y. LiDAR, UAV or compass-clinometer? Accuracy, coverage and the effects on structural models. J. Struct. Geol. 2017, 98, 67–82. [Google Scholar] [CrossRef]

- Pu, S.; Vosselman, G. Extracting windows from terrestrial laser scanning. In Proceedings of the ISPRS Workshop on Laser Scanning 2007 and SilviLaser 2007, Espoo, Finland, 12–14 September 2007; ISPRS: Hannover, Germany, 2007. [Google Scholar]

- Tuttas, S.; Stilla, U. Window Detection in Sparse Point Clouds Using Indoor Points. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, XXXVIII-3/W22, 131–136. [Google Scholar] [CrossRef]

- Malihi, S.; Zoej, M.V.; Hahn, M.; Mokhtarzade, M. Window Detection from UAS-Derived Photogrammetric Point Cloud Employing Density-Based Filtering and Perceptual Organization. Remote Sens. 2018, 10, 1320. [Google Scholar] [CrossRef]

- Macher, H.; Roy, L.; Landes, T. Automation of Windows Detection from Geomatric and Radiometric Iinformation of Point Clouds in a Scan-to-BIM Process. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2021, XLIII-B2-2021, 193–200. [Google Scholar] [CrossRef]

- Quintana, B.; Prieto, S.; Adán, A.; Bosché, F. Door detection in 3D coloured point clouds of indoor environments. Autom. Constr. 2018, 85, 146–166. [Google Scholar] [CrossRef]

- Macher, H.; Landes, T.; Grussenmeyer, P. From Point Clouds to Building Information Models: 3D Semi-Automatic Reconstruction of Indoors of Existing Buildings. Appl. Sci. 2017, 7, 1030. [Google Scholar] [CrossRef]

- Kim, D.; Kwon, S.; Cho, C.S.; de Soto, B.G.; Moon, D. Automatic Space Analysis Using Laser Scanning and a 3D Grid: Applications to Industrial Plant Facilities. Sustainability 2020, 12, 9087. [Google Scholar] [CrossRef]

- Rusu, R.B.; Cousins, S. 3D is here: Point Cloud Library (PCL). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Aldoma, A.; Márton, Z.C.; Tombari, F.; Wohlkinger, W.; Potthast, C.; Zeisl, B.; Rusu, R.B.; Gedikli, S.; Vincze, M. Tutorial: Point Cloud Library: Three-Dimensional Object Recognition and 6 DOF Pose Estimation. IEEE Robot. Autom. Mag. 2012, 19, 80–91. [Google Scholar] [CrossRef]

- Point Cloud Library. PCL. Available online: https://pointclouds.org (accessed on 4 September 2023).

- Ramiya, A.M.; Nidamanuri, R.R.; Krishnan, R. Segmentation based building detection approach from LiDAR point cloud. Egypt. J. Remote Sens. Space Sci. 2017, 20, 71–77. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Gomez-Donoso, F.; Garcia-Rodriguez, J.; Orts-Escolano, S.; Cazorla, M.; Azorin-Lopez, J. PointNet: A 3D Convolutional Neural Network for real-time object class recognition. In Proceedings of the 2016 International Joint Conference on Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Nan, L.; Wonka, P. PolyFit: Polygonal Surface Reconstruction from Point Clouds. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Su, H.; Jampani, V.; Sun, D.; Maji, S.; Kalogerakis, E.; Yang, M.H.; Kautz, J. SPLATNet: Sparse Lattice Networks for Point Cloud Processing. 2018. Available online: https://pointclouds.org (accessed on 4 September 2023). [CrossRef]

- Selimovic, E.; Noichl, F.; Forth, K.; Borrmann, A. Retrofitting Potential of Building envelopes Based on Semantic Surface Models Derived From Point Clouds. J. Facade Des. Eng. 2022, 10, 127–140. [Google Scholar] [CrossRef]

- Stiny, G.; Gips, J. Shape Grammars and the Generative Specification of Painting and Sculpture. In The Best Computer Papers of 1971; Auerbach: Philadelphia, PA, USA, 1972; pp. 125–135. [Google Scholar]

- Schneider, S.; Fischer, J.R.; König, R. Rethinking Automated Layout Design: Developing a Creative Evolutionary Design Method for the Layout Problems in Architecture and Urban Design. In Design Computing and Cognition ’10; Springer: Dordrecht, The Netherlands, 2011; pp. 367–386. [Google Scholar] [CrossRef]

- Ordóñez, C.; Martínez, J.; Arias, P.; Armesto, J. Measuring building façades with a low-cost close-range photogrammetry system. Autom. Constr. 2010, 19, 742–749. [Google Scholar] [CrossRef]

- Leberl, F. Automated photogrammetry for three-dimensional models of urban spaces. Opt. Eng. 2012, 51, 021117. [Google Scholar] [CrossRef]

- Neuhausen, M.; König, M. Improved Window Detection in Facade Images. In Advances in Informatics and Computing in Civil and Construction Engineering; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Photomodeler Technologies. Photomodeler. 2020. Available online: https://www.photomodeler.com (accessed on 4 August 2023).

- Yang, J.; Shi, Z.K.; Wu, Z.Y. Towards automatic generation of as-built BIM: 3D building facade modeling and material recognition from images. Int. J. Autom. Comput. 2016, 13, 338–349. [Google Scholar] [CrossRef]

- Neuhausen, M.; Martin, A.; Mark, P.; König, M. A Cascaded Classifier Approach to Window Detection in Facade Images. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction (ISARC), Taipei, Taiwan, 27–30 June 2017; Tribun EU, s.r.o.: Brno, Czech Republic, 2017. [Google Scholar] [CrossRef]

- Neuhausen, M.; Obel, M.; Martin, A.; Mark, P.; König, M. Window detection in facade images for risk assessment in tunneling. Vis. Eng. 2018, 6, 1. [Google Scholar] [CrossRef]

- Fawzy, H.E.D. 3D laser scanning and close-range photogrammetry for buildings documentation: A hybrid technique towards a better accuracy. Alex. Eng. J. 2019, 58, 1191–1204. [Google Scholar] [CrossRef]

- Technology, D. Dietrich’s. 2020. Available online: https://www.dietrichs.com/en/ (accessed on 4 September 2023).

- Pine, B. Mass Customization: The New Frontier in Business Competition; Harvard Business School Press: Boston, MA, USA, 1993. [Google Scholar]

- CORDIS European Commission. Building Energy Renovation through Timber Prefabricated Modules. 2015. Available online: https://cordis.europa.eu/project/id/636984 (accessed on 4 August 2023). [CrossRef]

- Lu, R.; Ma, Y.; Guo, L.; Thorpe, T.; Brilakis, I. An Automated Target-Oriented Scanning System for Infrastructure Applications; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar] [CrossRef]

- Kulawiak, M.; Lubniewski, Z. Improving the Accuracy of Automatic Reconstruction of 3D Complex Buildings Models from Airborne Lidar Point Clouds. Remote Sens. 2020, 12, 1643. [Google Scholar] [CrossRef]

- DIN 18202:2019-07; Tolerances in Building Construction-Buildings. Beuth Verlag: Berlin, Germany, 2019. Available online: https://www.beuth.de/de/norm/din-18202/307314612 (accessed on 8 August 2023).

- Mashey, J.R. Big Data and the Next Wave of InfraStress Problems, Solutions, Opportunities. In Proceedings of the 1999 USENIX Annual Technical Conference (USENIX ATC 99), Monterey, CA, USA, 7–11 June 1999. [Google Scholar]

- Alba, M.I.; Barazzetti, L.; Scaioni, M.; Rosina, E.; Previtali, M. Mapping Infrared Data on Terrestrial Laser Scanning 3D Models of Buildings. Remote Sens. 2011, 3, 1847–1870. [Google Scholar] [CrossRef]

| 100 × 100 density grid | ||||

| Segment | Window | Wall | Total | |

| 1 | North | 15,997 | 19,642 | |

| 3 | East | 11,969 | 12,229 | |

| 4 | South | 5297 | 7708 | |

| 5 | West | 8212 | 8912 | |

| 6 | Slab | - | - | 1461 |

| 20 × 20 density grid | ||||

| Segment | Window | Wall | Total | |

| 1 | North | 173,260 | 483,150 | |

| 3 | East | 30,110 | 37,766 | |

| 4 | South | 72,072 | 110,683 | |

| 5 | West | 100,971 | 215,728 | |

| 6 | Slab | - | - | 44,589 |

| Time | m2 | h/m2 | |

|---|---|---|---|

| SC 1.1: data acquisition | 3 h | 234.85 | 0.0127 |

| SC 1.2: data processing | 0.5 h | 234.85 | 0.0021 |

| DNS 1.3: layout definition | 0.5 h | 234.85 | 0.0021 |

| Total | 0.0017 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iturralde, K.; Gambao, E.; Bock, T. Semiautomated Primary Layout Definition with a Point Cloud for Building-Envelope Renovation. Buildings 2024, 14, 351. https://doi.org/10.3390/buildings14020351

Iturralde K, Gambao E, Bock T. Semiautomated Primary Layout Definition with a Point Cloud for Building-Envelope Renovation. Buildings. 2024; 14(2):351. https://doi.org/10.3390/buildings14020351

Chicago/Turabian StyleIturralde, Kepa, Ernesto Gambao, and Thomas Bock. 2024. "Semiautomated Primary Layout Definition with a Point Cloud for Building-Envelope Renovation" Buildings 14, no. 2: 351. https://doi.org/10.3390/buildings14020351

APA StyleIturralde, K., Gambao, E., & Bock, T. (2024). Semiautomated Primary Layout Definition with a Point Cloud for Building-Envelope Renovation. Buildings, 14(2), 351. https://doi.org/10.3390/buildings14020351