Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact

Abstract

1. Introduction

2. Materials and Methods

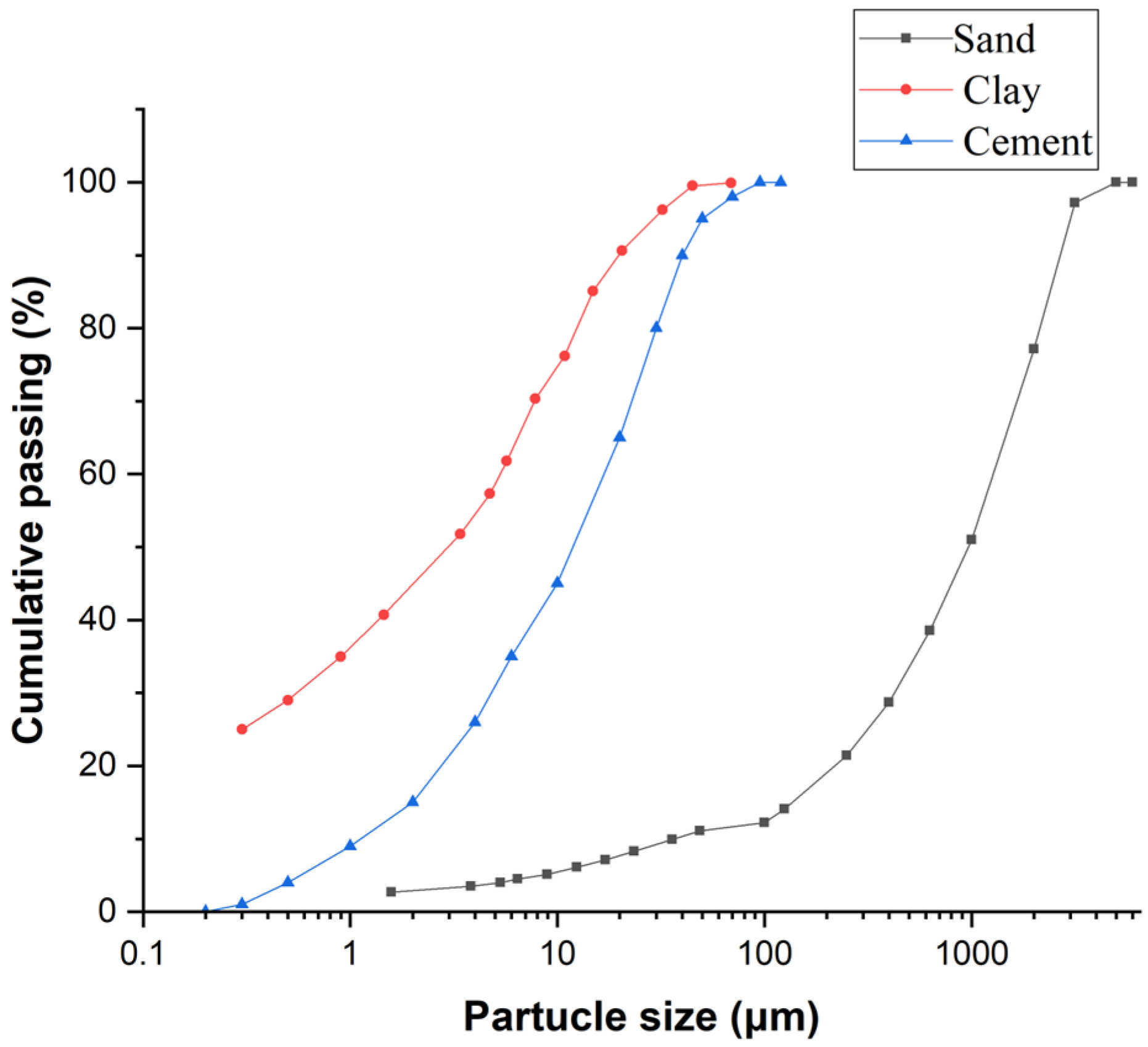

2.1. Raw Materials and Mixes Proportion

2.2. Characterization Techniques

3. Results and Discussion

3.1. Density

3.2. XRD Analysis

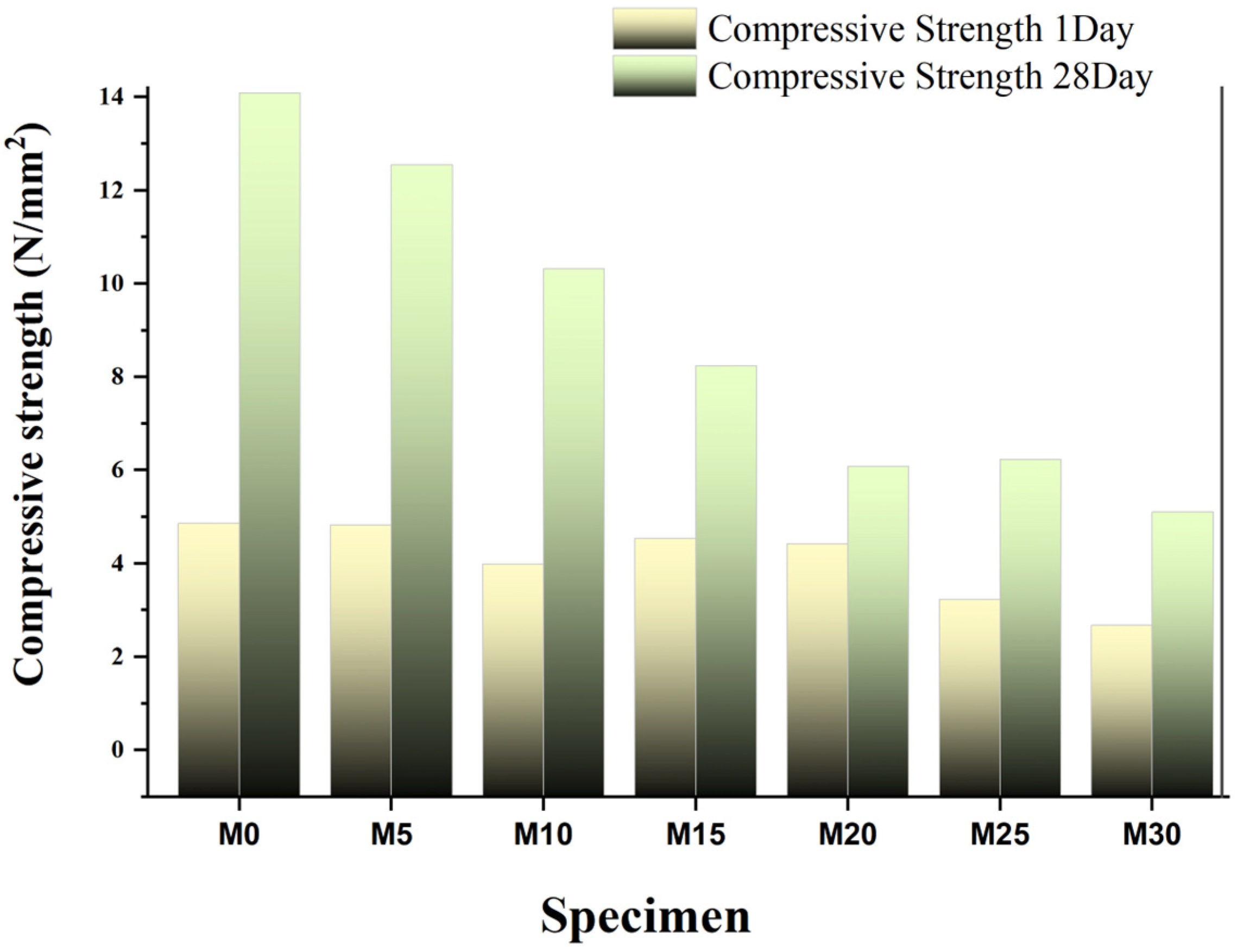

3.3. Compressive Strength

3.4. Thermal Properties

4. Carbon Emission and Cost Implication Assessment

5. Optimal Formulation and Potential Applications

6. Conclusions

- The addition of less than 5% by weight of raw clay into the mortar had minimal impact on compressive strength while reducing thermal conductivity, diffusivity, cost, and environmental impact. This suggests that such a formulation is well-suited for structural applications where maintaining high mechanical strength is essential.

- Incorporating more than 5% by weight of clay significantly reduced compressive strength but further decreased thermal conductivity and diffusivity, as well as overall costs and carbon emissions. Consequently, this formulation is more appropriate for non-structural applications or scenarios where lower mechanical strength is acceptable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rehman, S.U.; Kiani, U.A.; Yaqub, M.; Ali, T. Controlling natural resources depletion through Montmorillonite replacement for cement-low cost construction. Constr. Build. Mater. 2020, 232, 117188. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Jafer, H.; Dulaimi, A.; Hashim, K.; Atherton, W.; Sadique, M. The development of a low carbon binder produced from the ternary blending of cement, ground granulated blast furnace slag and high calcium fly ash: An experimental and statistical approach. Constr. Build. Mater. 2018, 187, 1051–1060. [Google Scholar] [CrossRef]

- Keke, L.; Yong, L.; Liuliu, X.; Junjie, Z.; Kangning, L.; Dingqiang, F.; Rui, Y. Rheological characteristics of Ultra-High performance concrete (UHPC) incorporating bentonite. Constr. Build. Mater. 2022, 349, 128793. [Google Scholar] [CrossRef]

- Jaskulski, R.; Daria, J. Calcined Clay as Supplementary Cementitious Material. Materials 2020, 13, 4734. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Kaolinitic calcined clays: Factors affecting its performance as pozzolans. Constr. Build. Mater. 2012, 28, 276–281. [Google Scholar] [CrossRef]

- Liu, M.; Hu, Y.; Lai, Z.; Yan, T.; He, X.; Wu, J.; Lu, Z.; Lv, S. Influence of various bentonites on the mechanical properties and impermeability of cement mortars. Constr. Build. Mater. 2020, 241, 118015. [Google Scholar] [CrossRef]

- Lai, H.C.; Zhang, J.F.; Li, Y.Y.; Zhou, L.P. Origin and provenance of Red Clay in north Hunan Province, China: Inferred from grain-size analysis and end-member modelling. Aeolian Res. 2021, 51, 100714. [Google Scholar] [CrossRef]

- Yu, C.; He, C.-B.; Li, Z.; Li, Y.-A.; Li, Y.; Sun, Y.-L.; Wu, Y.-Q. Disintegration characteristics and mechanism of red clay improved by steel slag powder. Constr. Build. Mater. 2024, 444, 137873. [Google Scholar] [CrossRef]

- Yang, S.; Wi, S.; Lee, J.; Lee, H.; Kim, S. Biochar-red clay composites for energy efficiency as eco-friendly building materials: Thermal and mechanical performance. J. Hazard. Mater. 2019, 373, 844–855. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Vogler, N.; Sturm, P.; Neubert, M.; Schröder, H.-J.; Kühne, H.-C.; Hünger, K.-J.; Gluth, G.J. Calcined brick clays and mixed clays as supplementary cementitious materials: Effects on the performance of blended cement mortars. Constr. Build. Mater. 2021, 266, 120990. [Google Scholar] [CrossRef]

- Janotka, I.; Puertas, F.; Palacios, M.; Kuliffayová, M.; Varga, C. Metakaolin sand-blended-cement pastes: Rheology, hydration process and mechanical properties. Constr. Build. Mater. 2010, 24, 791–802. [Google Scholar] [CrossRef]

- Mechti, W.; Mnif, T.; Chaabouni, M.; Rouis, J. Formulation of blended cement by the combination of two pozzolans: Calcined clay and finely ground sand. Constr. Build. Mater. 2014, 50, 609–616. [Google Scholar] [CrossRef]

- He, C.; Makovicky, E.; Øsbæck, B. Thermal stability and pozzolanic activity of calcined illite. Appl. Clay Sci. 1995, 9, 337–354. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Kočí, V.; Scheinherrová, L.; Maděra, J.; Keppert, M.; Suchorab, Z.; Łagód, G.; Černý, R. Experimental and computational study of thermal processes in red clays exposed to high temperatures. Energies 2020, 13, 2211. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Bhojaraju, C.; Ouellet-Plamondon, C. Clay as a Sustainable Binder for Concrete—A Review. Constr. Mater. 2021, 1, 134–168. [Google Scholar] [CrossRef]

- Kim, B.J.; Yi, C.; Kang, K.I. Microwave curing of alkali-activated binder using hwangtoh without calcination. Constr. Build. Mater. 2015, 98, 465–475. [Google Scholar] [CrossRef]

- Yang, K.H.; Hwang, H.Z.; Kim, S.Y.; Song, J.K. Development of a cementless mortar using hwangtoh binder. Build. Environ. 2007, 42, 3717–3725. [Google Scholar] [CrossRef]

- Uddin, M.N.; Saraswathy, V. A comparative study on clay and red soil based geopolymer mortar. Civ. Eng. Archit. 2018, 6, 34–39. [Google Scholar] [CrossRef]

- Nwaubani, S.O. Influence of Raw Kaolin Clay and Its Dehydroxylated Form on the Properties and Performance of Portland Cement Mortar. J. Cem. Based Compos. 2022, 4, 5747. [Google Scholar] [CrossRef]

- Ahmad, S.; Barbhuiya, S.A.; Elahi, A.; Iqbal, J. Effect of Pakistani bentonite on properties of mortar and concrete. Clay Miner. 2011, 46, 85–92. [Google Scholar] [CrossRef]

- Al-Hammood, A.A.; Frayyeh, Q.J.; Abbas, W.A. Raw bentonite as supplementary cementitious material—A review. J. Phys. Conf. Ser. 2021, 1795, 012018. [Google Scholar] [CrossRef]

- Rakhimova, N. Montmorillonite clays in Portland clinker-reduced, non-clinker cements, and cement composites: A review. Constr. Build. Mater. 2024, 411, 134678. [Google Scholar] [CrossRef]

- NM 10.1.004; Liants hydrauliques ciments et les constituants des ciments: Partie I: Composition, spécifications et critères de conformité; Partie II: Évaluation de la conformité; Partie III: Contrôle de la qualité à la livraison. Institut Marocain de Normalisation (IMANOR): Rabat, Morocco, 2003.

- NF P 94-050; Norme Française. Sol: Reconnaissance et Essai. Dé-Termination de la Teneur en Eau Pondérale des Sols. Méthode par Étuvage. AFNOR, 8. AFNOR: La Plaine Saint-Denis, France, 1995.

- El Hammouti, A.; Charai, M.; Horma, O.; Mezrhab, A.; Karkri, M. Thermal insulation of mud bricks made with walnut shells: Characterization and simulation study. Mater. Today Proc. 2022, 62, 4545–4550. [Google Scholar] [CrossRef]

- ISO 22007-2; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. International Standard: Geneva, Switzerland, 2022.

- Wang, J.; Qin, Q.; Hu, S.; Wu, K. A concrete material with waste coal gangue and fly ash used for farmland drainage in high groundwater level areas. J. Clean. Prod. 2016, 112, 631–638. [Google Scholar] [CrossRef]

- Horma, O.; Charai, M.; El Hassani, S.; El Hammouti, A.; Moussaoui, M.A.; Mezrhab, A. Thermal Performance Study of a Cement-Based Mortar Incorporating EPS Beads. Front. Built Environ. 2022, 8, 882942. [Google Scholar] [CrossRef]

- Marchetti, G.; Rahhal, V.; Pavlík, Z.; Pavlíková, M.; Irassar, E.F. Assessment of packing, flowability, hydration kinetics, and strength of blended cements with illitic calcined shale. Constr. Build. Mater. 2020, 254, 119042. [Google Scholar] [CrossRef]

- Wang, S.; Pang, D.; Chen, S.; Zhang, T.; Bi, W.; Chen, X. Study of Using Quartz Powder as a Mineral Admixture to Produce Magnesium Oxysulfate Cement. Minerals 2023, 13, 1240. [Google Scholar] [CrossRef]

- SANI, R. Etude des Transformations Microstructurales de Mélanges Argile/Combustibles Solides de Récupération (CSR) lors de la Cuisson: Relations Entre Propriétés Physico-Chimiques, Mécaniques et Thermiques. 2018. Available online: http://theses.hal.science/tel-02012314v1/document (accessed on 1 November 2024).

- Day, K.W. Properties of Concrete; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Nehdi, M.L. Clay in cement-based materials: Critical overview of state-of-the-art. Constr. Build. Mater. 2014, 51, 372–382. [Google Scholar] [CrossRef]

- He, C.; Osbaeck, B.; Makovicky, E. Pozzolanic reactions of six principal clay minerals: Activation, reactivity assessments and technological effects. Cem. Concr. Res. 1995, 25, 1691–1702. [Google Scholar] [CrossRef]

- Budelmann, H.; Hariri, K.; Krauss, H.W.; Malonn, T. Effects of a clay additive on the properties of no-slump concrete. Adv. Constr. Mater. 2007, 2007, 731–739. [Google Scholar] [CrossRef]

- Ng, S.; Petter, B.; Stæhli, T. Calcined clays as binder for thermal insulating and structural aerogel incorporated mortar. Cem. Concr. Compos. 2016, 72, 213–221. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, mechanical and durability assessment of vegetable concrete mixes made with Alfa fibers for structural and thermal insulating applications. Constr. Build. Mater. 2022, 335, 127518. [Google Scholar] [CrossRef]

- Lee, K.C.; Her, J.H.; Kwon, S.K. Red clay composites reinforced with polymeric binders. Constr. Build. Mater. 2008, 22, 2292–2298. [Google Scholar] [CrossRef]

- Charai, M.; Sghiouri, H.; Mezrhab, A.; Karkri, M. Thermal insulation potential of non-industrial hemp (Moroccan cannabis sativa L.) fibers for green plaster-based building materials. J. Clean. Prod. 2021, 292, 126064. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Asdrubali, F.; Grazieschi, G.; Roncone, M.; Thiebat, F.; Carbonaro, C. Sustainability of Building Materials: Embodied Energy and Embodied Carbon of Masonry. Energies 2023, 16, 1846. [Google Scholar] [CrossRef]

- Wang, Y.S.; Oh, S.; Ishak, S.; Wang, X.Y.; Lim, S. Recycled glass powder for enhanced sustainability of limestone calcined clay cement (LC3) mixtures: Mechanical properties, hydration, and microstructural analysis. J. Mater. Res. Technol. 2023, 27, 4012–4022. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Raj, R.S.; Lubloy, E. Techno-socio-economic aspects of Portland cement, Geopolymer, and Limestone Calcined Clay Cement (LC3) composite systems: A-State-of-Art-Review. Constr. Build. Mater. 2023, 398, 132484. [Google Scholar] [CrossRef]

- U.S. Clay Price 2010–2023|Statista. Available online: https://www.statista.com/statistics/248190/average-price-of-common-clay/ (accessed on 9 November 2024).

- Kim, K.W.; Kim, S.; Park, M.J.; Kim, H.J.; Park, J.C. Characteristics of a Reddish Residual Soil (Hwangtoh) finishing material with water-soluble adhesive for residential building. Constr. Build. Mater. 2010, 24, 1542–1546. [Google Scholar] [CrossRef]

- Zhang, G.Y.; Oh, S.; Lu, C.; Han, Y.; Lin, R.S.; Wang, X.Y. The Influence of Quartz Powder on the Mechanical–Thermal–Chemical–Durability Properties of Cement-Based Materials. Appl. Sci. 2024, 14, 3296. [Google Scholar] [CrossRef]

| Oxides | Si2O2 | Al2O3 | Fe2O3 | K2O | CaO | TiO2 | P2O5 | SrO | ZrO2 | V2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight % | 50.43 | 19.88 | 15.96 | 5.87 | 2.3 | 1.96 | 1 | 0.21 | 0.1 | 0.08 |

| Sample | Clay | Cement | Sand | Water to Cement Ratio | |||

|---|---|---|---|---|---|---|---|

| wt% | kg/m3 | wt% | kg/m3 | wt% | kg/m3 | ||

| M0 | 0 | 0 | 100 | 456.13 | 70 | 1064.31 | 0.5 |

| M5 | 5 | 22.59 | 95 | 429.34 | 70 | 1064.31 | 0.5 |

| M10 | 10 | 44.78 | 90 | 403.05 | 70 | 1064.31 | 0.5 |

| M15 | 15 | 66.57 | 85 | 377.23 | 70 | 1064.31 | 0.5 |

| M20 | 20 | 87.96 | 80 | 351.87 | 70 | 1064.31 | 0.5 |

| M25 | 25 | 108.98 | 75 | 326.96 | 70 | 1064.31 | 0.5 |

| M30 | 30 | 129.63 | 70 | 302.48 | 70 | 1064.31 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drissi, M.; Horma, O.; Mezrhab, A.; Karkri, M. Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact. Buildings 2024, 14, 3906. https://doi.org/10.3390/buildings14123906

Drissi M, Horma O, Mezrhab A, Karkri M. Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact. Buildings. 2024; 14(12):3906. https://doi.org/10.3390/buildings14123906

Chicago/Turabian StyleDrissi, Mohammed, Othmane Horma, Ahmed Mezrhab, and Mustapha Karkri. 2024. "Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact" Buildings 14, no. 12: 3906. https://doi.org/10.3390/buildings14123906

APA StyleDrissi, M., Horma, O., Mezrhab, A., & Karkri, M. (2024). Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact. Buildings, 14(12), 3906. https://doi.org/10.3390/buildings14123906