3. Design and Measurement of Mock Structures

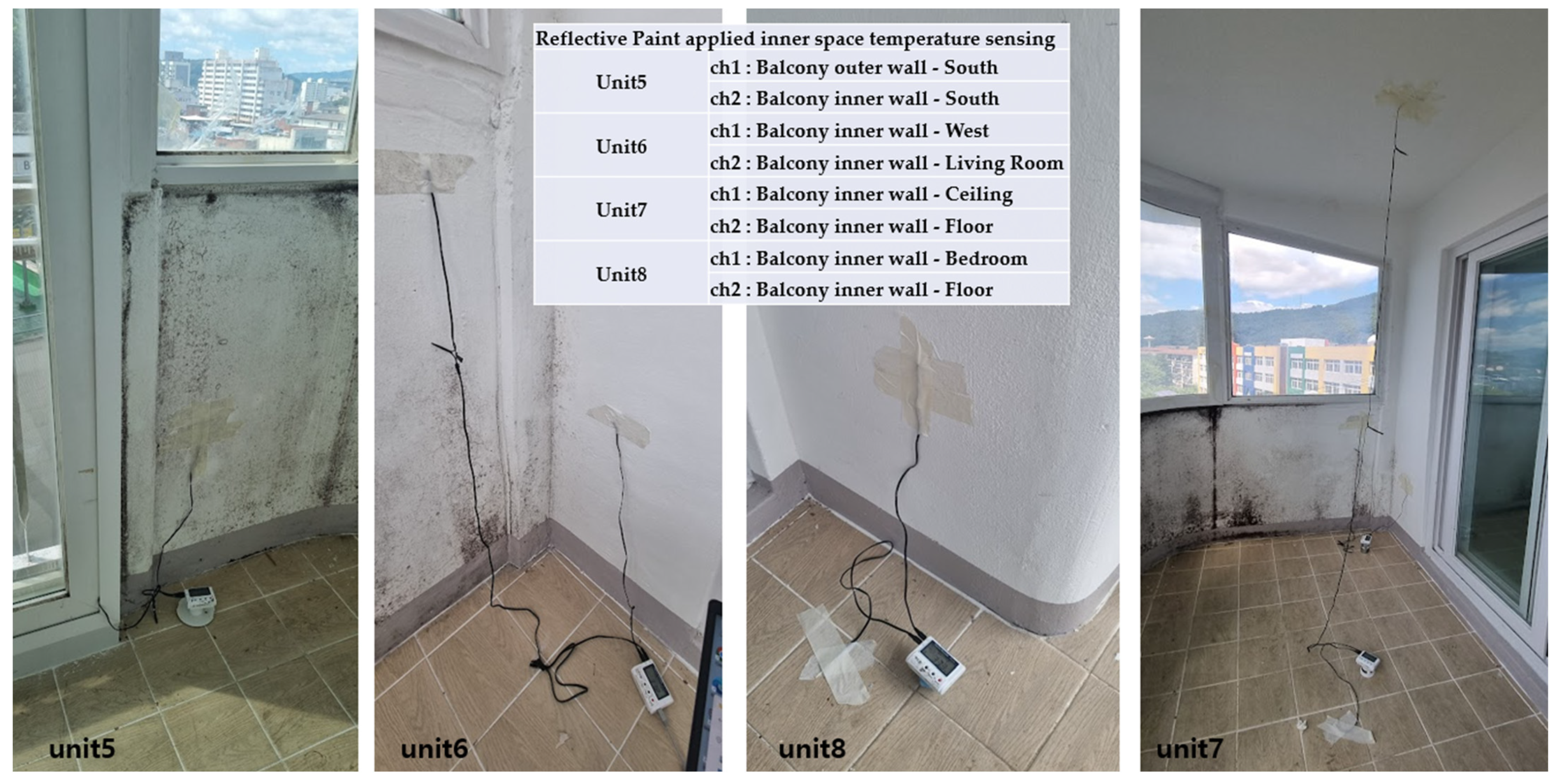

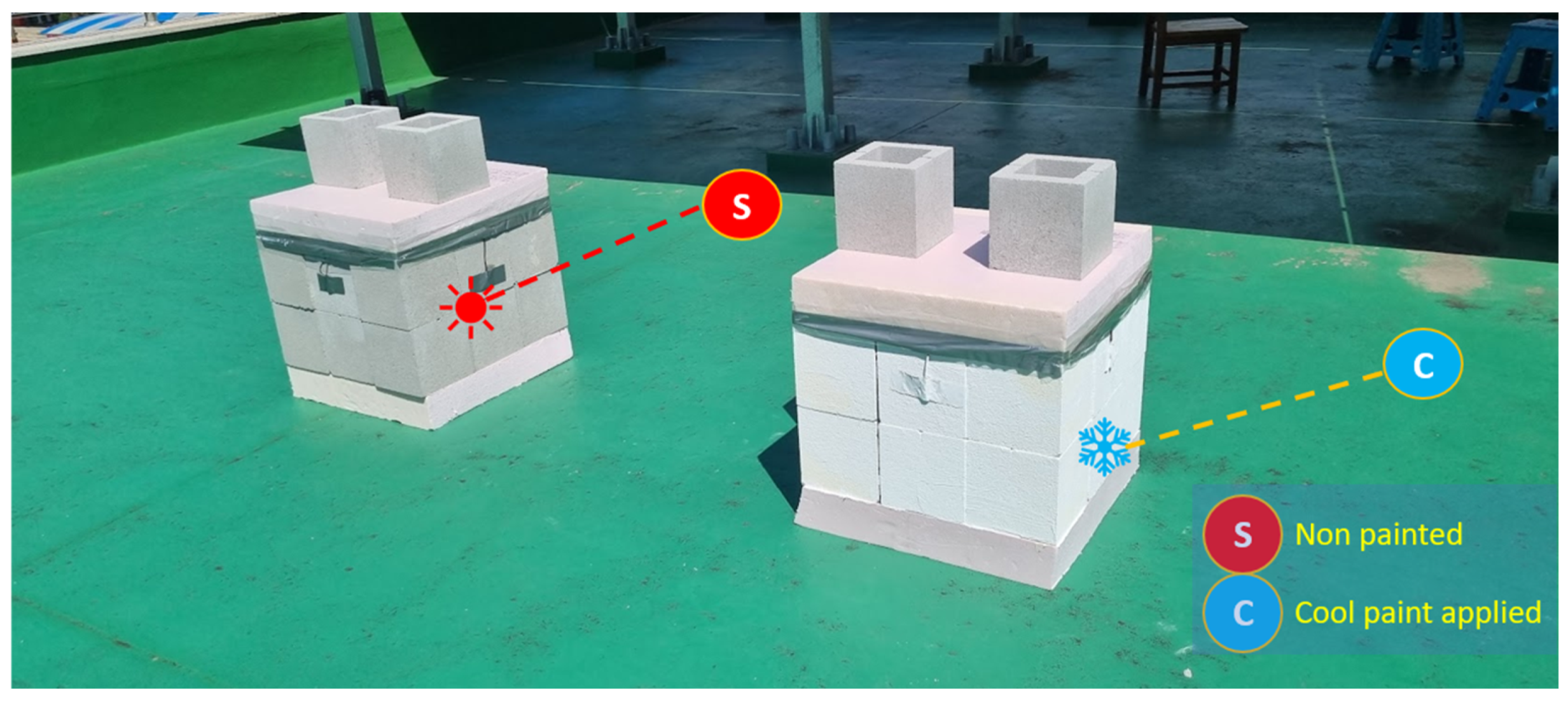

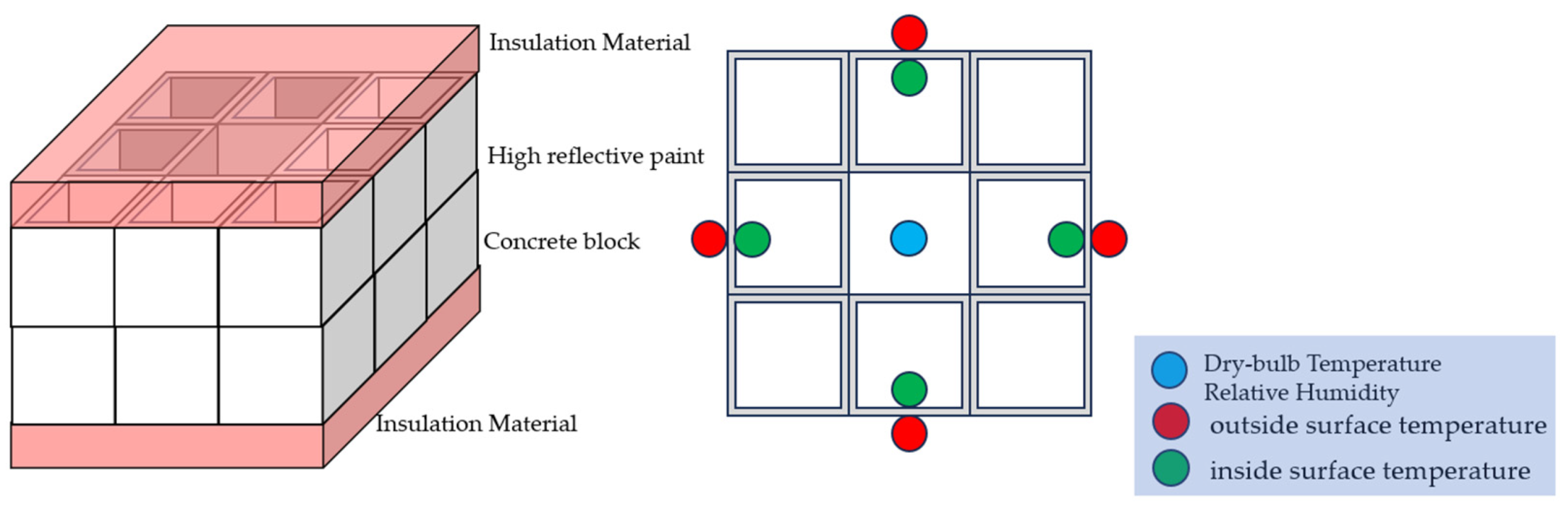

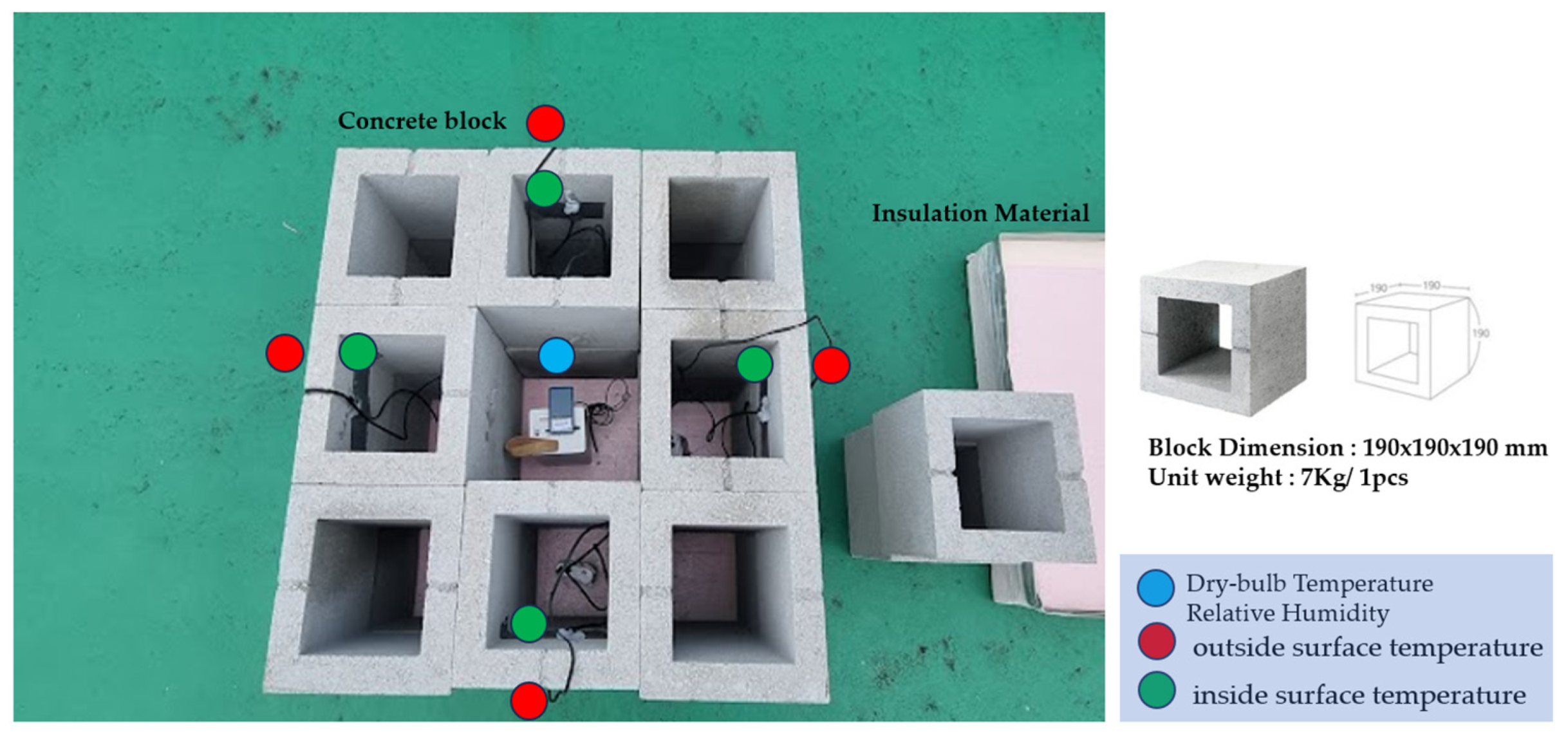

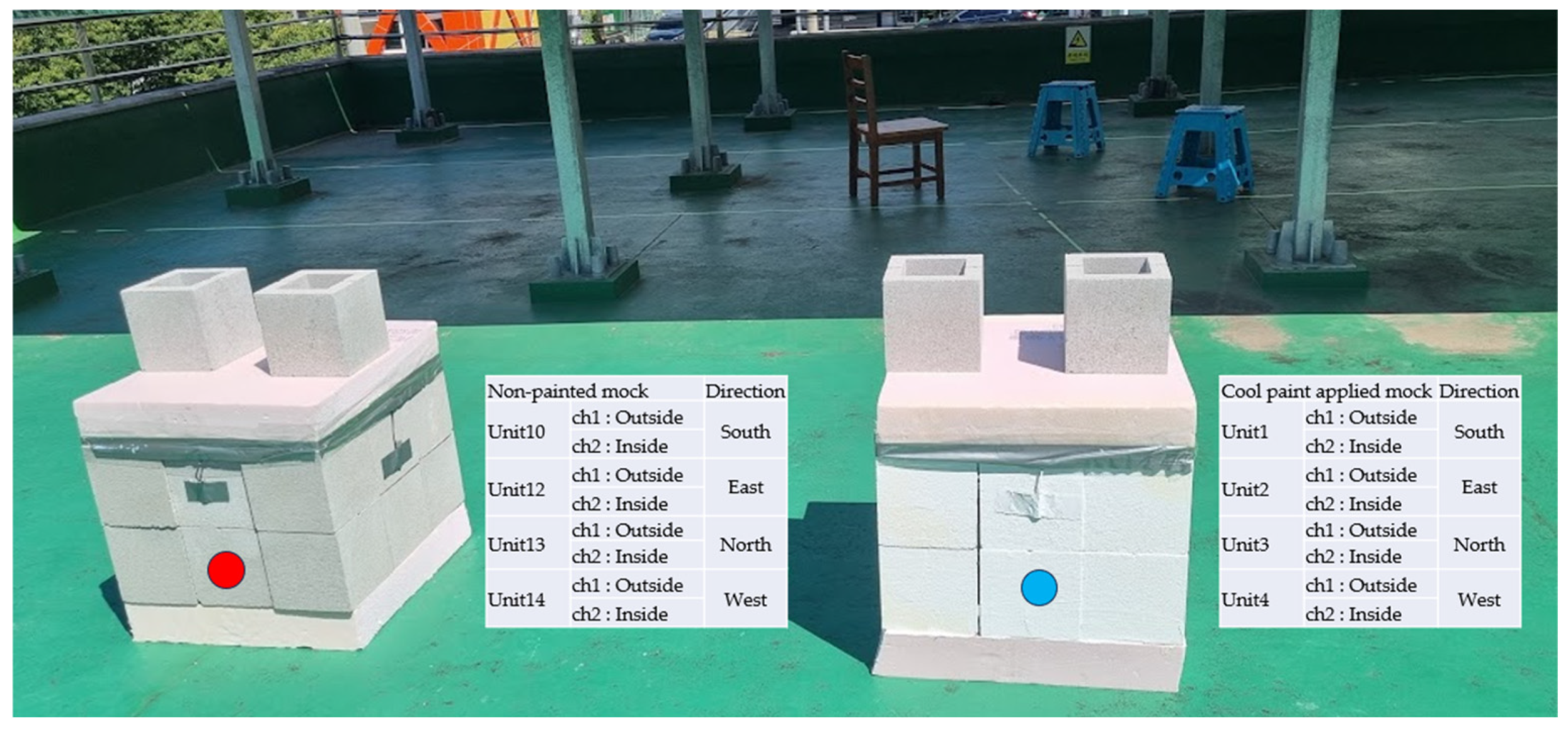

To study the thermal impacts of applying heat-reflective paint, two mock structures were designed—one with heat-reflective paint applied and one without (control). Data loggers were installed at eight different points, both inside and outside the structures, as shown in

Figure 5. In addition, real-time weather sensors were placed in the center of the mock structures to monitor indoor room and external weather conditions. These sensors allowed us to measure external surface temperature, internal surface temperature, and indoor temperature variations for the experimental and control groups.

Similar mock experiments have been used in other studies to test the effectiveness of cooling technologies. For instance, Monge-Barrio and Gutiérrez [

14] employed passive energy strategies in mock structures to analyze the impact on residential buildings. These studies serve as valuable models for examining the effect of heat-reflective technologies in controlled environments.

However, the merit and differentiation of this study lie in the specific construction of the mock structures, as well as the materials used. Unlike previous studies that focused solely on exterior reflective coatings, this experiment integrates detailed insulation mechanisms, such as 100 mm thick insulation panels placed on both the top and bottom surfaces of the mock structures. This design ensures that heat transfer is predominantly measured through the treated and untreated side walls, offering a more accurate reflection of real-world apartment settings where roofing and floor insulation are common practices. Additionally, the cubic concrete blocks (190 mm × 190 mm × 190 mm) used in this study more closely replicate the material and structure of actual apartment building walls, offering a more precise simulation of urban residential conditions. (

Figure 6)

3.1. Data Collection Methods

To accurately measure surface and ambient air temperatures, along with other climatic factors such as humidity, wind speed, and solar radiation, IoT-based sensors and dataloggers were utilized. The devices employed for this study included T&D TR-71wf Data Loggers and Ecowitt WS69 IoT Weather Station Sensors. These devices were strategically positioned both indoors and outdoors to monitor changes in thermal comfort caused by the application of cooling technologies.

The accuracy and reliability of such sensors are well-documented in previous studies. For example, Malz et al. [

20] used similar IoT-based methods to measure the energy-saving potentials of reflective wall paints and their effect on thermal comfort.

Dataloggers: The T&D TR-71wf loggers were placed at key locations to record temperature changes on surfaces treated with heat-reflective paint, as well as non-painted external and internal surfaces. These loggers captured temperature data every five minutes, providing real-time insights into temperature variations between the experimental and control groups.

Ecowitt WS69 IoT Sensors: These sensors measured environmental conditions, including wind speed, humidity, and solar radiation, which were critical for understanding the broader climatic impact of the cooling interventions. Data from the sensors were wirelessly transmitted to a cloud-based server for continuous monitoring and analysis. These sensors were specifically used to monitor indoor temperature and humidity, as well as external factors such as wind speed, humidity, and solar radiation through the external AWS sensor unit.

For indoor temperature measurements, real-time sensors were installed at the center of the mock structures. These sensors recorded data on temperature, humidity, atmospheric pressure, and solar radiation at five-minute intervals.

Table 1 provides the specific measurement items and technical details of the weather sensors used.

Data collection took place from mid-July to early August, with the most complete and continuous data recorded between 30 July and 1 August. These three days were selected for detailed analysis.

3.2. Field Measurements

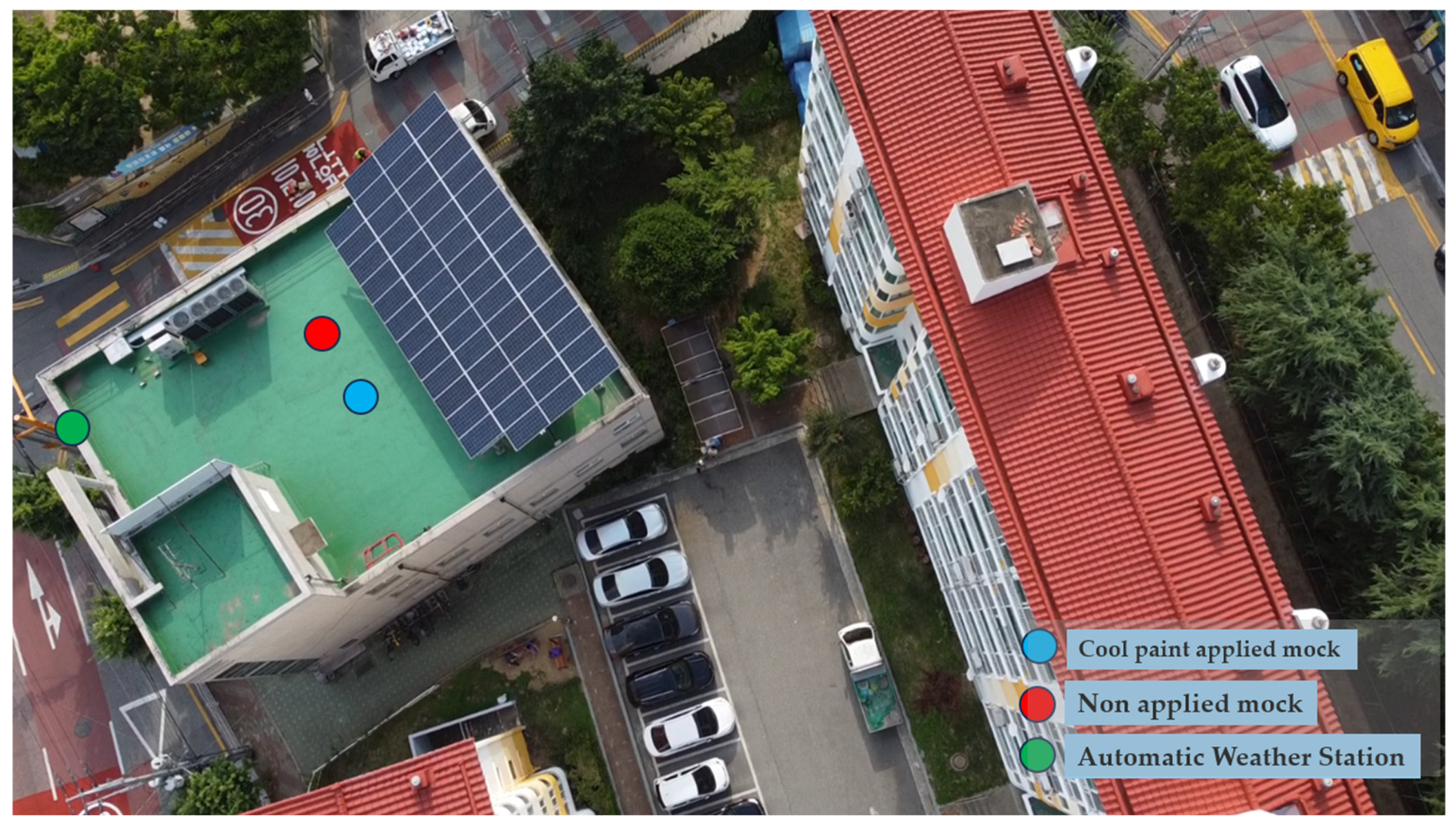

Before conducting detailed experiments, aerial photographs (

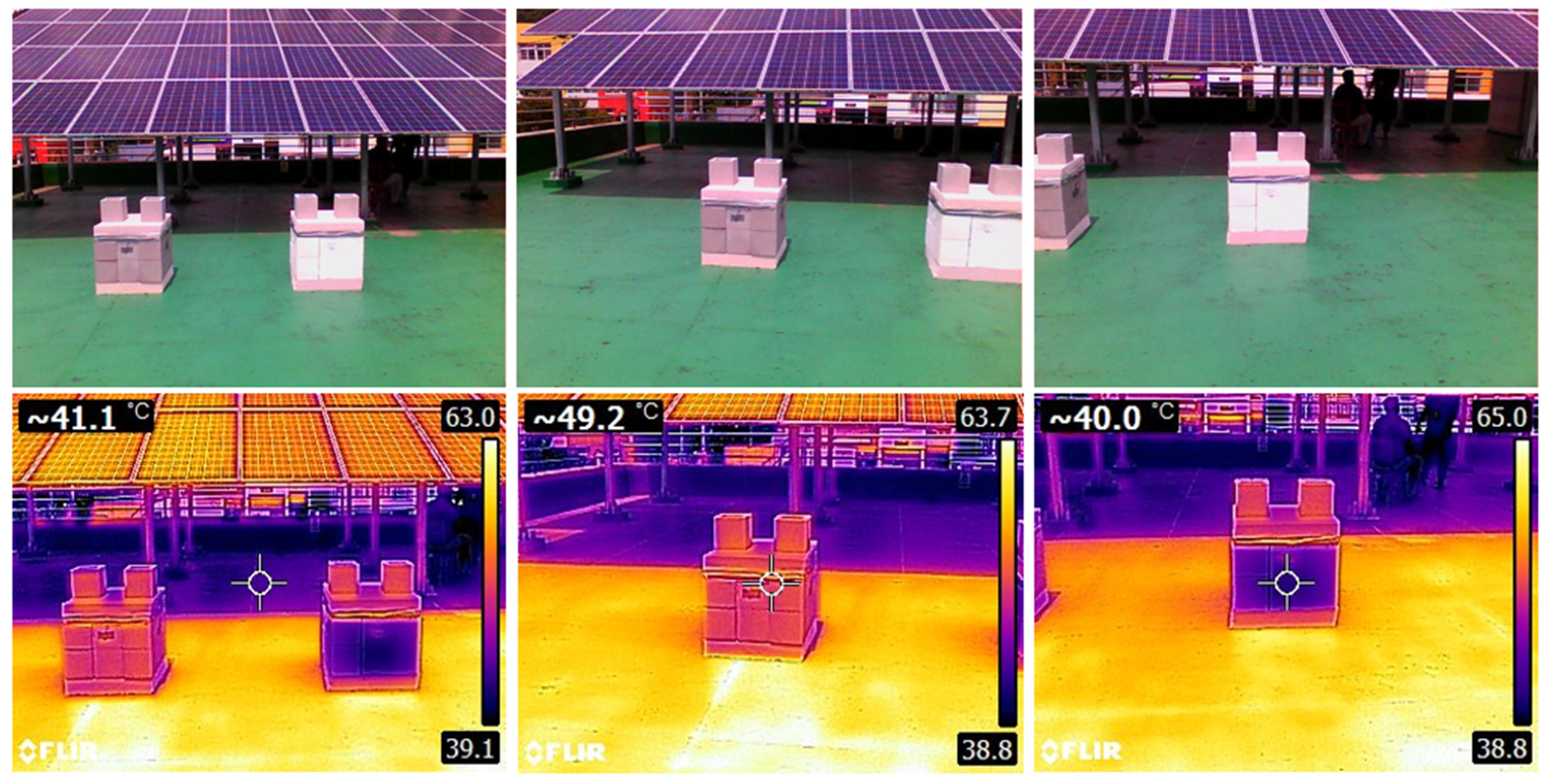

Figure 7) were taken using a drone to confirm that the conditions of the experimental site were similar to those of the project site, and to check the overall solar altitude and position. Additionally, thermal imaging cameras were used (

Figure 8) to capture surface temperature differences between the experimental and control groups during the hottest hours of the afternoon.

Thermal imaging has proven to be an effective tool in similar studies to highlight temperature differences in treated versus untreated structures. Zinzi and Fasano [

12] used thermal imaging to demonstrate how advanced reflective paints reduce surface temperatures, thereby mitigating the heat island effect.

As shown in

Figure 8, the surface temperature of the control building, which did not have heat-reflective paint, reached approximately 40.6 °C, whereas the surface temperature of the building with heat-reflective paint applied was significantly lower at 36.7 °C. This 3.9 °C difference highlights the effectiveness of the heat-reflective paint in reducing surface temperatures, thereby mitigating heat absorption and enhancing indoor thermal comfort.

4. Results

4.1. Surface Temperature Changes (Thermal Imaging Camera)

In this study, the surface temperatures of the experimental group (with heat-reflective paint) and the control group (without heat-reflective paint) were measured using a thermal imaging camera. As shown in

Figure 9, the surface temperature of the structure treated with heat-reflective paint was consistently lower than that of the untreated structure.

On 8 August at 12:20 p.m., the surface temperature of the structure with heat-reflective paint was observed to be 40.0 °C, whereas the temperature of the untreated structure reached 49.2 °C.

Figure 9 shows a significant reduction in surface temperature due to the application of the heat-reflective paint. Additionally, the shadowed area between the two mock structures recorded a temperature of 41.1 °C, further highlighting the efficiency of the heat-reflective paint in lowering surface temperatures. The lower temperature of the treated block demonstrates the paint’s effectiveness in reducing solar heat absorption and maintaining a cooler surface, which can contribute to improved thermal comfort in buildings.

This aligns with previous studies by Bretz and Akbari [

7] and Malz et al. [

20], which also highlighted the cooling effects of high-albedo coatings and reflective materials in reducing surface temperatures. These reductions in surface temperatures directly translate to improved energy efficiency and indoor comfort by minimizing heat transfer into the building’s interior.

4.2. Surface Temperature Changes (Data Logger)

The data logger results clearly highlight the effectiveness of heat-reflective paint in reducing surface temperatures across all orientations of the mock structure. Measurements taken between 30 July and 1 August indicate that, on average, external surface temperatures of the treated walls were 2.2 °C to 4.3 °C lower than untreated walls, while internal surface temperatures were 2.1 °C to 4.1 °C lower (

Table 2).

Figure 10 shows the temperature fluctuations over time, with notable differences observed particularly on the south- and west-facing walls, which receive the most solar exposure during the day. For example, the maximum temperature difference for the external surface on the west-facing wall was 15.3 °C, and the internal temperature difference reached 11.1 °C during peak sunlight exposure.

One challenge encountered during the data collection was the delayed activation of the north-facing wall’s data logger due to a power supply issue. The data from the north-facing wall were available starting 31 July, and despite receiving less direct sunlight compared to the southern and western walls, there was still a notable temperature difference of 6.3 °C externally and 4.6 °C internally.

This analysis provides clear evidence that heat-reflective paint reduces the heat absorbed by external surfaces, which subsequently lowers the internal surface temperatures and improves indoor thermal comfort. The paint’s effectiveness is especially pronounced in areas exposed to direct solar radiation, making it a valuable passive cooling solution for buildings in hot climates. This is consistent with studies conducted by Zinzi and Fasano [

12], which showed that advanced reflective paints significantly reduce cooling loads in buildings.

4.3. Indoor Temperature Changes

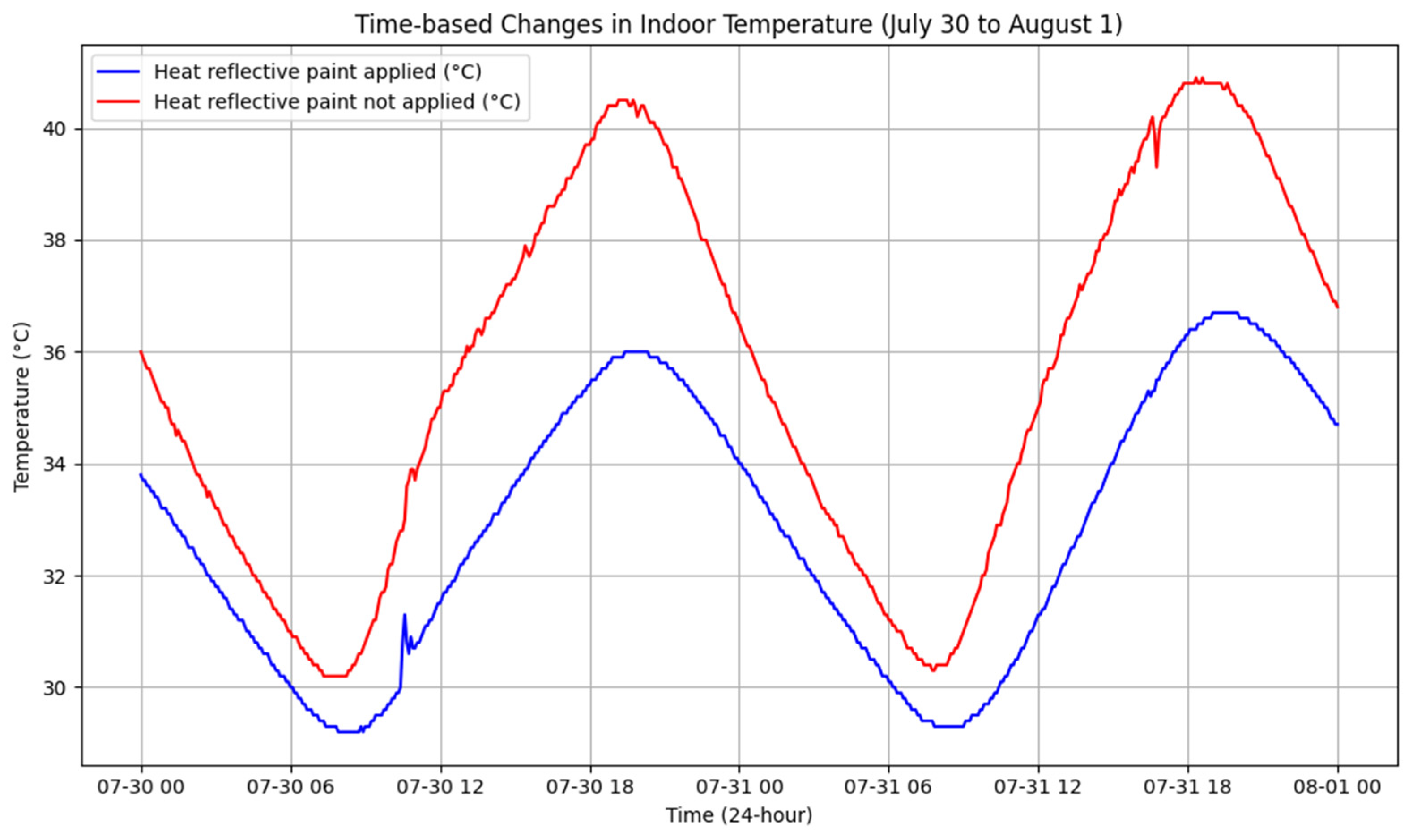

The indoor temperature measurements taken from 30 July to 1 August are summarized in

Table 3 and

Figure 11. Over the three days of measurement, the average difference in indoor temperature between the experimental group (with heat-reflective paint applied) and the control group (without heat-reflective paint) ranged from 2.5 °C to 3.8 °C. The largest temperature difference observed was between 3.8 °C and 4.5 °C, typically occurring during the hottest hours of the day.

As shown in

Figure 11, the control group consistently recorded higher indoor temperatures, peaking at around 40 °C, while the experimental group with the heat-reflective paint showed a maximum temperature closer to 36 °C. The heat-reflective paint not only reduced the peak indoor temperature but also delayed the rise and fall of temperatures throughout the day, providing a more stable indoor thermal environment.

The cooling effect of the heat-reflective paint is most noticeable during the afternoon hours (12:00 to 18:00), where the difference between the two groups is the largest. Additionally, during the early morning (00:00 to 06:00), the experimental group’s indoor temperatures remained lower than those in the control group by approximately 2 °C to 3 °C, indicating a sustained benefit of heat reduction even during non-peak sunlight hours.

This is consistent with the findings of Bretz and Akbari [

7], who also demonstrated that reflective roof coatings contribute to lower indoor temperatures by reducing solar heat gains. Moreover, Levinson and Akbari [

20] also showed that reflective materials provide consistent cooling benefits during both peak and non-peak periods by mitigating heat absorption.

The continuous fluctuations observed in the control group’s indoor temperatures suggest that the lack of reflective paint allows for greater heat absorption and re-radiation into the indoor space. On the other hand, the experimental group’s more gradual temperature increase and decrease points to the improved insulation and heat mitigation properties of the reflective paint.

Table 3 presents the measured indoor temperatures with and without the application of heat-reflective paint over three days: 30 July, 31 July, and 1 August 2024. The table includes data for average, maximum, and minimum temperatures recorded during this period for both the experimental group (with heat-reflective paint applied) and the control group (without heat-reflective paint).

Key observations from the table include:

Average Temperature: Across all three days, the experimental group consistently showed lower average indoor temperatures compared to the control group. For instance, on 30 July, the average temperature for the experimental group was 34.2 °C, while the control group recorded an average of 38 °C, indicating a temperature reduction of 3.8 °C due to the application of heat-reflective paint.

Maximum Temperature: The maximum indoor temperature in the control group reached as high as 40.5 °C on 30 July, while the experimental group with the heat-reflective paint had a lower maximum temperature of 36 °C, showing a 4.5 °C reduction. Similar reductions were observed on the other two days, with a maximum difference of 4.2 °C on 31 July and 3.8 °C on 1 August.

Minimum Temperature: Even during the cooler periods, such as in the early mornings, the experimental group maintained lower indoor temperatures. For example, the minimum temperature on 31 July was 29.3 °C for the experimental group, while the control group recorded 30.3 °C, highlighting a 1 °C reduction. A similar trend was observed on the other days.

Temperature Differences: The overall temperature differences between the experimental and control groups ranged from 2.5 °C to 4.5 °C across the three days. The largest differences were observed during the afternoon when the impact of solar radiation was highest, with a 4.5 °C difference on 30 July.

These data clearly demonstrate the effectiveness of heat-reflective paint in reducing indoor temperatures. Reducing indoor temperatures during peak heating hours is essential to minimize heat stress and improve thermal comfort for occupants, particularly during the hottest part of the day when solar radiation is most intense. This cooling effect can reduce the reliance on air conditioning, leading to energy savings and increased comfort, especially in buildings with vulnerable populations, such as the elderly, who are more susceptible to high indoor temperatures. This is true particularly during peak heating hours, resulting in improved thermal comfort for the occupants of the experimental group.

4.4. Time-Based Temperature and Humidity Changes

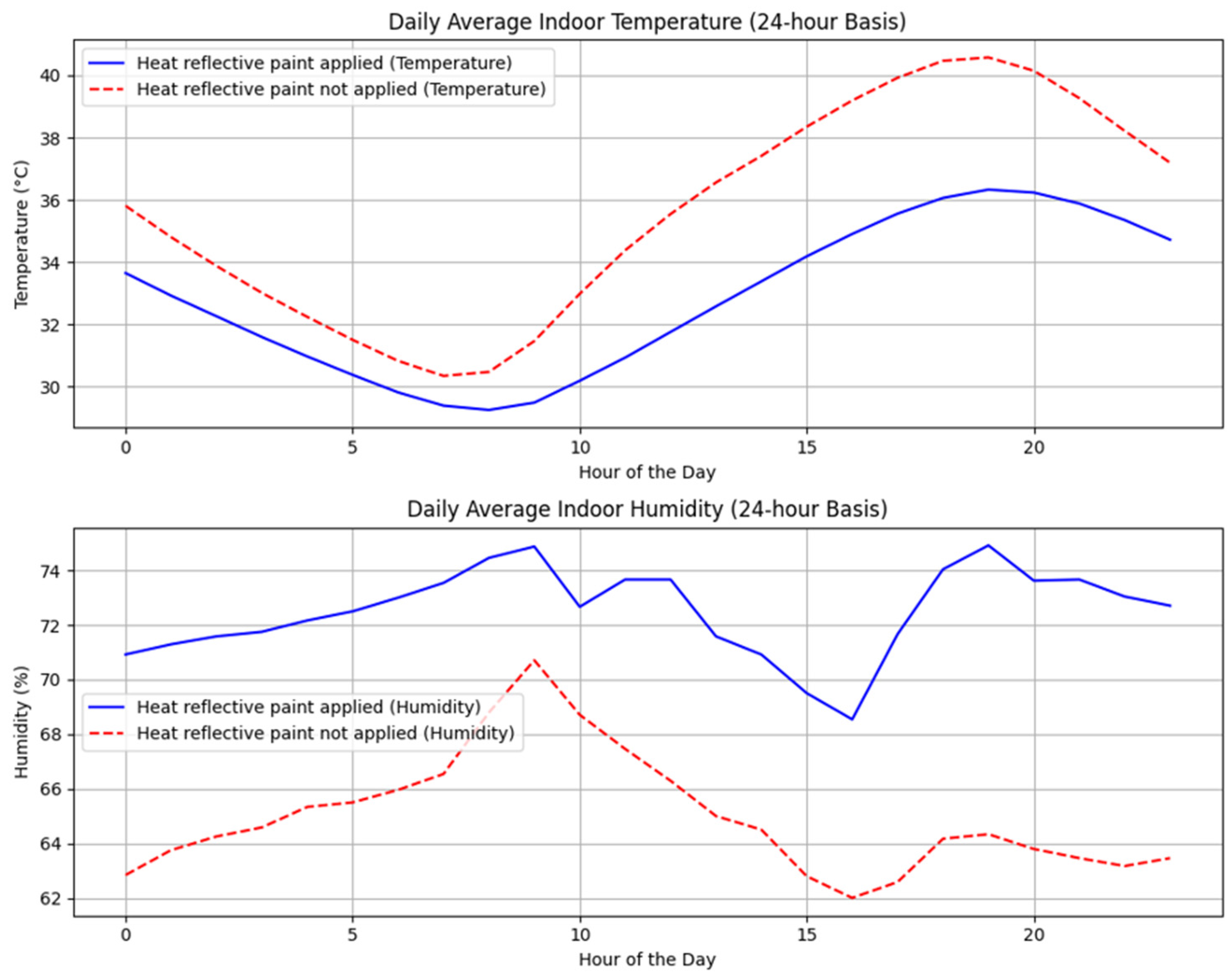

The time-based changes in temperature and humidity, measured over the course of three days (30 July–1 August), are presented in

Figure 12. As the figure shows, the difference in indoor temperature between the experimental and control groups widened as the day progressed, particularly during the late morning and early afternoon when solar radiation intensity was highest.

In the top panel of

Figure 12, the indoor temperature in the control group (without heat-reflective paint) increased rapidly after 9:00 a.m., reaching a peak of around 38 °C to 40 °C by 2:00 p.m. to 3:00 p.m. In contrast, the experimental group (with heat-reflective paint) maintained a lower and more stable temperature profile, with a peak temperature of approximately 34 °C to 36 °C during the same period.

The time-based differences in temperature demonstrate the cooling effect of the heat-reflective paint, which helps mitigate indoor heat buildup during peak solar radiation hours. Similar trends were observed in studies by Zinzi and Fasano [

12] and Malz et al. [

20], which also demonstrated the long-term cooling effects of reflective coatings.

The bottom panel of

Figure 12 shows the indoor humidity levels for both groups. The experimental group consistently exhibited higher humidity levels, which can be attributed to the reduction in indoor heat caused by the reflective paint. This stabilizing effect on temperature helped maintain indoor moisture content, while the control group experienced greater fluctuations in both temperature and humidity. Notably, the difference in humidity levels became most pronounced during the peak afternoon hours, with the experimental group showing an average humidity of 72–74%, compared to 62–66% in the control group.

4.5. Statistical Analysis of Temperature and Humidity Differences

To further verify the significance of the observed temperature and humidity differences between the experimental and control groups, an independent t-test was conducted using IBM SPSS Statistics (28.0.11). The test was based on data collected at 5 min intervals and analyzed across two key time periods: the entire day (24 h period) and the peak heat period (2:00 p.m.–5:00 p.m.).

The results of the independent

t-test, shown in

Table 4 and

Table 5, provide statistical confirmation that the differences in both temperature and humidity between the experimental and control groups were statistically significant. The application of heat-reflective paint led to lower indoor temperatures and higher humidity levels, particularly during the hottest parts of the day.

For the overall 24 h period, the average temperature in the experimental group was 2.72 °C lower than in the control group (33.01 °C vs. 35.73 °C), with a variance of 5.13 °C and 10.34 °C, respectively. During the peak heat period, the temperature difference became even more pronounced, with the experimental group maintaining a 4.14 °C lower temperature (34.27 °C vs. 38.41 °C).

Similarly, significant differences were found in humidity levels. Over the entire day, the experimental group recorded an average humidity of 73.06%, which was 7.9% higher than the control group’s 65.16%. During the peak heat period, this difference remained substantial, with the experimental group maintaining an average humidity of 70.72%, which was 7.1% higher than the control group’s 63.62%.

These results are consistent with findings from Bretz and Akbari [

7], who highlighted the long-term energy-saving benefits of reflective coatings, as well as Malz et al. (2020) [

20], who noted the thermal comfort improvements from infrared reflective wall paints.

These results indicate that the application of heat-reflective paint significantly reduced indoor temperatures while maintaining higher humidity levels. The paint’s cooling effect not only minimized heat buildup during peak solar radiation but also helped preserve indoor moisture, contributing to improved thermal comfort for the building’s occupants.

Table 4 and

Table 5 summarize the

t-test results for temperature and humidity, with the corresponding

p-values confirming the significance of the observed differences. The experimental group’s temperature and humidity levels during the entire day, as well as during the peak heat period, were consistently lower and higher, respectively, than those in the control group.

4.6. UTCI and MRT Measurement and Analysis

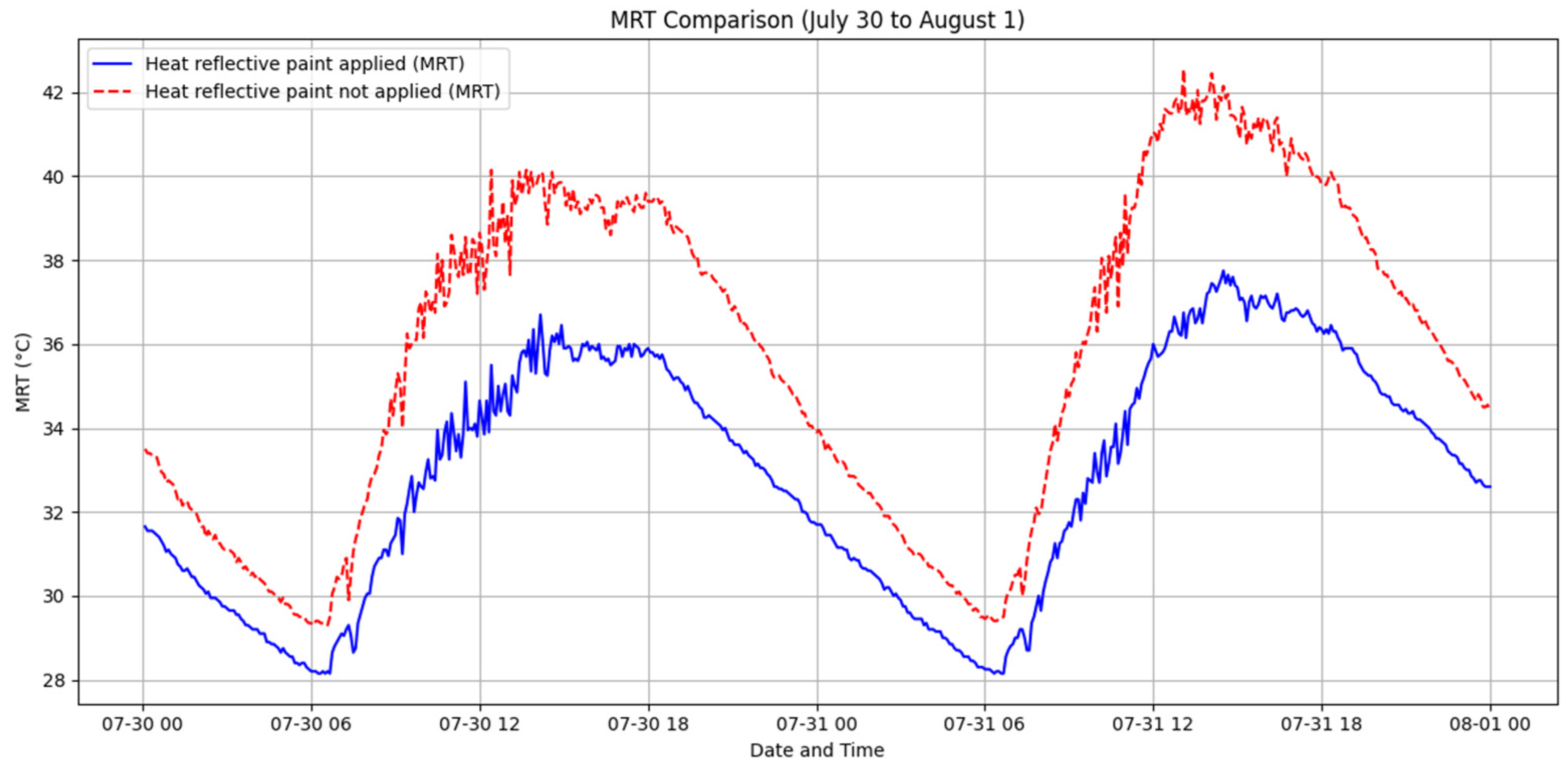

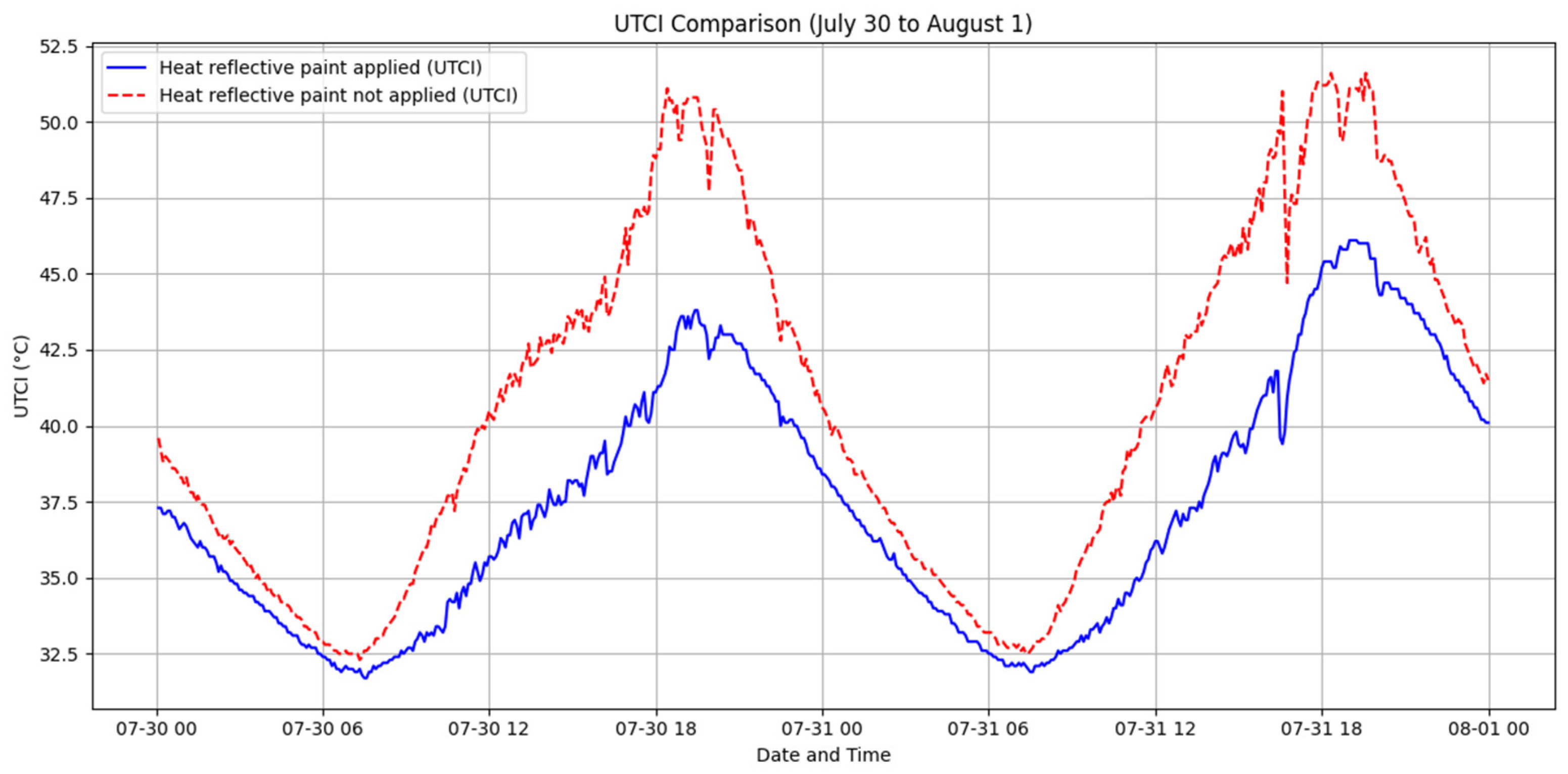

The Universal Thermal Climate Index (UTCI) and Mean Radiant Temperature (MRT) values were calculated for both the experimental and control groups, based on the surface temperature of the south-facing wall and indoor ambient temperature.

Figure 13 and

Figure 14 present the trends of the MRT and UTCI from 30 July to 1 August.

The UTCI scale categorizes thermal comfort into the following categories—<9 °C: No thermal stress (comfortable), 9–26 °C: Moderate thermal stress, 26–32 °C: Strong thermal stress, and >32 °C: Extreme thermal stress (uncomfortable).

Figure 13 shows that the buildings treated with heat-reflective paint exhibited lower MRT values compared to untreated buildings, with a significant difference during peak solar hours. The application of heat-reflective paint effectively reduced the radiant heat gain from external sources, contributing to improved indoor thermal comfort.

Similarly,

Figure 14 illustrates the UTCI trends, where the treated buildings consistently displayed lower UTCI values, indicating reduced thermal stress. During peak heat hours, the UTCI remained below 45 °C in the experimental group, compared to over 50 °C in the control group, demonstrating the heat-reflective paint’s effectiveness in mitigating heat stress.

These results align with previous studies by Zinzi and Fasano [

12], who emphasized the role of reflective paints in reducing building cooling loads, as well as the work of Levinson and Akbari [

21], who highlighted the potential energy savings from reflective roof technologies.

The key observations from

Figure 14 are as follows:

Heat-Reflective Paint Applied (Blue Line): The UTCI values are consistently lower, demonstrating that the heat-reflective paint effectively mitigates heat gain from external sources. During peak heat hours, the UTCI remains below 45 °C, indicating more comfortable indoor thermal conditions. The reflective paint helps reduce thermal stress indoors, making the environment more tolerable even during the hottest parts of the day.

Heat-Reflective Paint Not Applied (Red Dashed Line): The UTCI values rise significantly, exceeding 50 °C during midday, which indicates higher thermal stress and discomfort. The absence of heat-reflective paint allows for increased radiative heat transfer from the uncoated surfaces, leading to greater heat exposure indoors and less favorable thermal conditions.

The Mean Radiant Temperature (MRT), as shown in

Figure 13, plays a crucial role in influencing the UTCI values. The lower MRT in buildings with heat-reflective paint applied directly translates into reduced UTCI values, thereby improving indoor thermal comfort.

Analysis of Results

The application of heat-reflective paint leads to better thermal regulation, reducing both the MRT and UTCI. The following key conclusions can be drawn from the UTCI results:

Heat Stress Reduction: the heat-reflective paint reduced the UTCI by approximately 5–7 °C during the hottest parts of the day, effectively lowering thermal discomfort and stress.

Impact on Indoor Comfort: with the reflective paint applied, indoor conditions remained within a more moderate thermal stress range, significantly improving overall comfort for the building’s occupants.

Environmental Control: The reflective paint significantly reduced the amount of heat gained from solar radiation, particularly on surfaces exposed to direct sunlight. This demonstrates the paint’s ability to control indoor temperature passively, even during peak solar radiation hours.

These findings align with the objectives of this study, demonstrating that using heat-reflective paint can be an effective passive strategy for improving indoor thermal comfort in hot climates.

The results clearly highlight the effectiveness of heat-reflective paint in mitigating heat stress and enhancing indoor thermal comfort, especially during peak heating hours. The application of heat-reflective paint led to an average reduction in external surface temperatures by approximately 5% to 10%, with peak reductions reaching up to 30% on walls with high sun exposure. Indoor temperatures in the experimental mock structures were reduced by around 5% to 8%, demonstrating the paint’s potential as an effective passive cooling strategy. This cooling effect is particularly valuable in regions with high solar exposure, where extreme heat can lead to uncomfortable and potentially unsafe indoor conditions.

The primary aim of this study is to benefit disadvantaged residents by offering a cost-effective solution to reduce indoor temperatures during the hot summer months. By reducing reliance on air conditioning, heat-reflective paint can provide a sustainable means to improve the quality of life for vulnerable populations, such as elderly or economically disadvantaged residents, who may be more susceptible to heat-related health issues. These findings suggest that implementing heat-reflective paint on aging buildings in hot climates could play a crucial role in addressing thermal comfort disparities and improving urban resilience.

5. Discussion

The results of this study demonstrate the significant cooling effect of heat-reflective paint on both external and internal temperatures in simulated mock structures. The analysis showed consistent reductions in surface and indoor temperatures when compared to untreated surfaces, confirming that heat-reflective paint is an effective passive cooling strategy for mitigating heat gain in buildings.

5.1. Comparison with Previous Studies

The reductions in surface temperatures observed in this study (ranging from 2.2 °C to 4.3 °C for external surfaces and 2.1 °C to 4.1 °C for internal surfaces) align with findings from Kwon et al. [

3], who reported similar temperature reductions with cool roof and cool wall applications. Additionally, studies such as those by Bretz and Akbari [

7] and Pisello et al. [

8] have demonstrated the energy-saving effects of reflective coatings in reducing the solar heat load on building surfaces. However, the present study’s approach, using mock structures, adds a unique dimension to this body of research by simulating real-world apartment conditions with controlled variables, providing a more granular analysis of the cooling effect under similar environmental conditions to those found in occupied residential buildings.

Moreover, this study builds on findings from Malz et al. [

20], who examined the benefits of infrared reflective wall paints in improving thermal comfort. In contrast to existing studies, this study used a simulated approach that enabled continuous monitoring without disturbing actual residents, offering both practical and scientific insights.

5.2. Impact of Environmental Factors

The mock structure experiments revealed that temperature reductions were more pronounced on the south- and west-facing walls, which were exposed to more direct solar radiation. This is consistent with findings from Zinzi and Fasano [

12], who found that reflective paints are especially effective in reducing heat loads on sun-exposed surfaces. By reflecting this radiation, heat-reflective paint can mitigate the heat load on exterior surfaces, particularly in climates like that of Gumi City, which experiences high solar radiation during summer months.

Environmental factors, such as wind speed and humidity, measured by the meteorological sensors, notably influenced the overall thermal environment. Higher wind speeds likely contributed to the cooling effect by enhancing heat dissipation from surfaces, while relative humidity impacted perceived thermal comfort, as shown in the UTCI results. Additionally, these environmental factors, recorded by the Ecowitt WS69 AWS sensors, played a crucial role in influencing both thermal comfort and energy efficiency, as also highlighted by Levinson and Akbari [

21].

5.3. Limitations of This Study

While the results are promising, there are several limitations to this study that must be addressed. First, the mock structures, while simulating real-world conditions, cannot fully replicate the thermal dynamics of occupied apartment buildings. The lack of human occupants, variations in room use, and heat-generating appliances may influence the actual temperature reductions in a residential setting. Therefore, caution must be exercised when generalizing these results to fully inhabited apartment complexes.

Moreover, this study only considered the effect of heat-reflective paint in the short term, over a period of three days. Longer-term studies are needed to assess how the performance of reflective coatings holds up over time, particularly under varying weather conditions and over multiple seasons, as highlighted by Rawat and Singh [

13].

Finally, the UTCI and MRT measurements, while providing insights into thermal comfort, may not fully capture the complex interactions between radiant heat, humidity, and air movement in real indoor environments. Future studies should consider more detailed comfort analysis and possibly integrate additional factors, such as air conditioning usage patterns.

5.4. Broader Implications for Urban Heat Island Mitigation

The findings of this study have broader implications for urban heat island mitigation strategies in high-density urban environments. As cities such as Gumi continue to experience rising temperatures due to climate change, passive cooling technologies such as heat-reflective coatings could play a crucial role in reducing indoor heat stress, particularly for vulnerable populations, such as the elderly and low-income residents. These technologies not only improve indoor comfort but also have the potential to lower cooling energy demand, contributing to overall energy savings and reducing greenhouse gas emissions.

The findings of this study highlight the potential for heat-reflective paint as a practical and cost-effective cooling solution, particularly for disadvantaged communities living in apartment complexes. In South Korea, where apartment complexes are the most widely used type of residential building, this approach could be scaled to provide significant thermal comfort improvements across broad urban areas. By reducing surface and indoor temperatures, heat-reflective coatings offer a passive cooling strategy that can mitigate heat stress without the need for energy-intensive air conditioning systems, which are often unaffordable or inaccessible to low-income residents.

The implications of these findings extend beyond individual buildings; implementing heat-reflective paint on a larger scale could help cities reduce their overall energy demand and manage urban heat island effects. For vulnerable populations in high-density residential areas, this strategy provides an equitable, sustainable means to address the health risks associated with extreme heat. Thus, this study contributes to a growing body of research focused on passive cooling technologies, underscoring their role in promoting urban resilience, social equity, and sustainability.

7. Conclusions

This study was conducted in industrial Gumi City, in the southeastern part of the Korean Peninsula. The project, which is funded by the Ministry of Environment, concerns mitigation measures for extreme thermal events in highly urbanized areas. Using simulated measurement equipment, surface and indoor temperatures were monitored in both experimental (painted) and control (non-painted) mock structures to assess the cooling potential of heat-reflective coatings.

Overall, this study confirms that heat-reflective coatings can significantly reduce surface and indoor temperatures, particularly on walls exposed to direct solar radiation. This passive cooling solution holds promise for mitigating the effects of heat waves and urban heat islands, especially in aging apartment complexes with poor insulation. By improving thermal comfort and reducing energy demand, heat-reflective paint is an eco-friendly option to combat the challenges of rising global temperatures.

7.1. Key Findings

The application of heat-reflective paint resulted in an average reduction of external surface temperatures of between 2.2 °C and 4.3 °C, with peak reductions reaching as high as 15.3 °C on the west-facing walls, which corresponds to approximately a 5% to 10% decrease in heat load on treated surfaces. In peak conditions, the reduction reached up to 15.3 °C, translating to a significant 25% to 30% decrease in heat load on west-facing walls with high sun exposure.

Indoor temperatures in the experimental group were consistently lower than the control, with reductions ranging from 2.1 °C to 4.1 °C. The largest difference observed during the peak heat period was 4.14 °C, demonstrating the potential of heat-reflective paint in reducing heat stress indoors. This represents around a 5% to 8% decrease in heat load entering indoor spaces through the walls. This internal reduction is particularly beneficial during peak heat hours, when the difference in temperature is most pronounced.

Thermal imaging captured distinct differences in surface temperatures between the experimental and control groups, further highlighting the cooling effect of reflective coatings.

The use of the Universal Thermal Climate Index (UTCI) and Mean Radiant Temperature (MRT) as key metrics demonstrated that the painted surfaces provided more favorable thermal comfort levels, especially during the hottest hours of the day.

7.2. Implications

These findings provide strong evidence supporting the effectiveness of heat-reflective paint as a passive cooling strategy for urban buildings, particularly in regions experiencing extreme heat. This technology offers a cost-effective means of improving indoor comfort while also contributing to energy savings by reducing the reliance on air conditioning during hot periods. Importantly, this study aims to help vulnerable populations, such as elderly and economically disadvantaged residents, by providing a sustainable solution that reduces heat exposure and enhances their quality of life in aging urban buildings.

Although similar studies have been conducted, this paper contributes new insights by focusing on the specific environmental and socio-economic conditions of an old apartment complex. In particular, our measurements in apartment complexes, which are prevalent yet under-studied in the South Korean context, could offer meaningful implications for both policymaking and academic research. In addition, the use of mock structures provides a controlled setup that simulates real-world building conditions while overcoming the practical challenges of experimenting in occupied residential buildings. This approach enables detailed measurement of temperature variations and thermal comfort metrics under replicated environmental conditions, contributing valuable data specific to aging urban buildings with poor insulation, which house vulnerable populations.

7.3. Limitations and Suggestions for Future Research

While the mock structures allowed for precise control and measurement, this approach introduces certain limitations due to potential differences between mock structures and fully occupied residential buildings. For instance, the lack of human activity, interior heat sources, and occupant behavior in mock structures may lead to differences in thermal dynamics when compared to real buildings. Additionally, the results may vary depending on specific environmental factors, such as variations in local climate and building materials, which the mock structures may not fully replicate. The large uncertainties associated with using mock structures to simulate real conditions are acknowledged, particularly regarding their ability to fully capture the complex interactions present in actual residential settings. Moreover, there are several limitations that should be acknowledged and considered for future research.

First, the experimental setup used mock structures rather than real apartment blocks, and the study was conducted during a limited period, which may not fully represent the year-round performance of the paint. Testing on actual apartment buildings across different seasons would provide a more comprehensive understanding of the product’s overall impact on thermal comfort and energy savings.

Additionally, long-term monitoring of both treated and untreated structures, including during colder seasons, could reveal the paint’s effects on the overall energy balance. Heat-reflective paint might prove counterproductive in cooler months, as it reflects radiant energy that could otherwise contribute to passive warming indoors. This seasonal effect could influence heating costs and the thermal comfort of residents during winter.

Finally, conducting the study in fully occupied apartments, where openings such as windows play a key role in ventilation and humidity control, would offer more realistic results. There is a possibility that heat-reflective coatings could trap excess humidity in treated buildings, potentially leading to mold growth and other health-related issues.

To address these limitations, future studies should aim to implement and evaluate heat-reflective coatings in real occupied buildings, and those studies should explore these aspects by monitoring indoor humidity levels and air quality in treated apartments over an extended period.

This would provide more accurate insights into the impact of reflective coatings in daily use conditions, accounting for occupant behavior and internal heat sources. Additionally, combining heat-reflective coatings with other passive cooling technologies, such as green roofs or cool pavements, could provide a holistic approach to urban heat management and further enhance thermal comfort. By expanding the scope to include real-world applications, future research can validate and build on the findings presented in this study, contributing to a more robust scientific understanding of passive cooling strategies.

In conclusion, heat-reflective paint represents a viable, eco-friendly technology that can enhance thermal comfort, reduce energy consumption, and contribute to urban resilience in the face of increasing global temperatures.