Eco-Friendly Improvement of Comprehensive Engineering Properties of Collapsible Loess Using Guar Gum Biopolymer

Abstract

1. Introduction

2. Materials and Test Methods

2.1. Materials

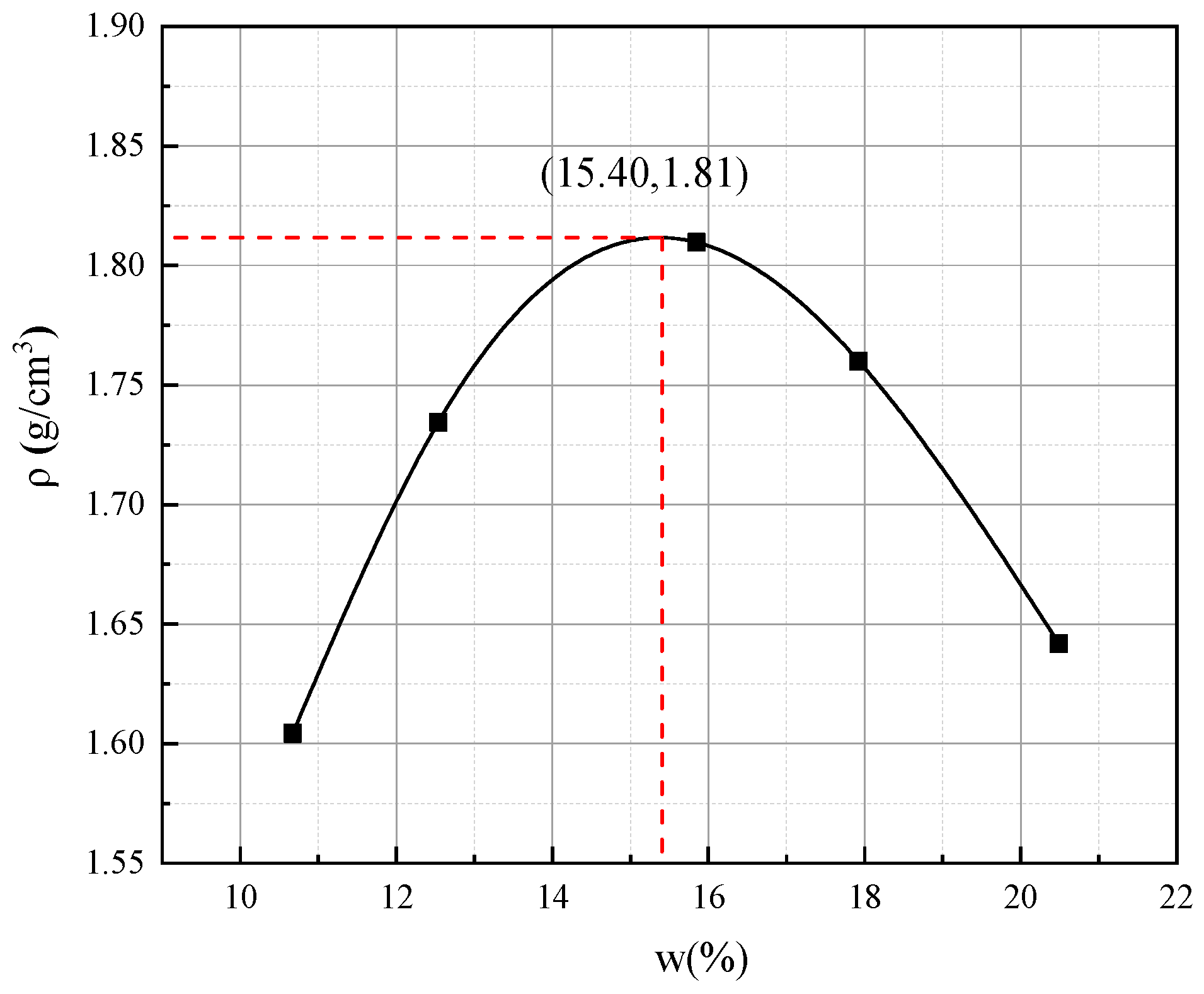

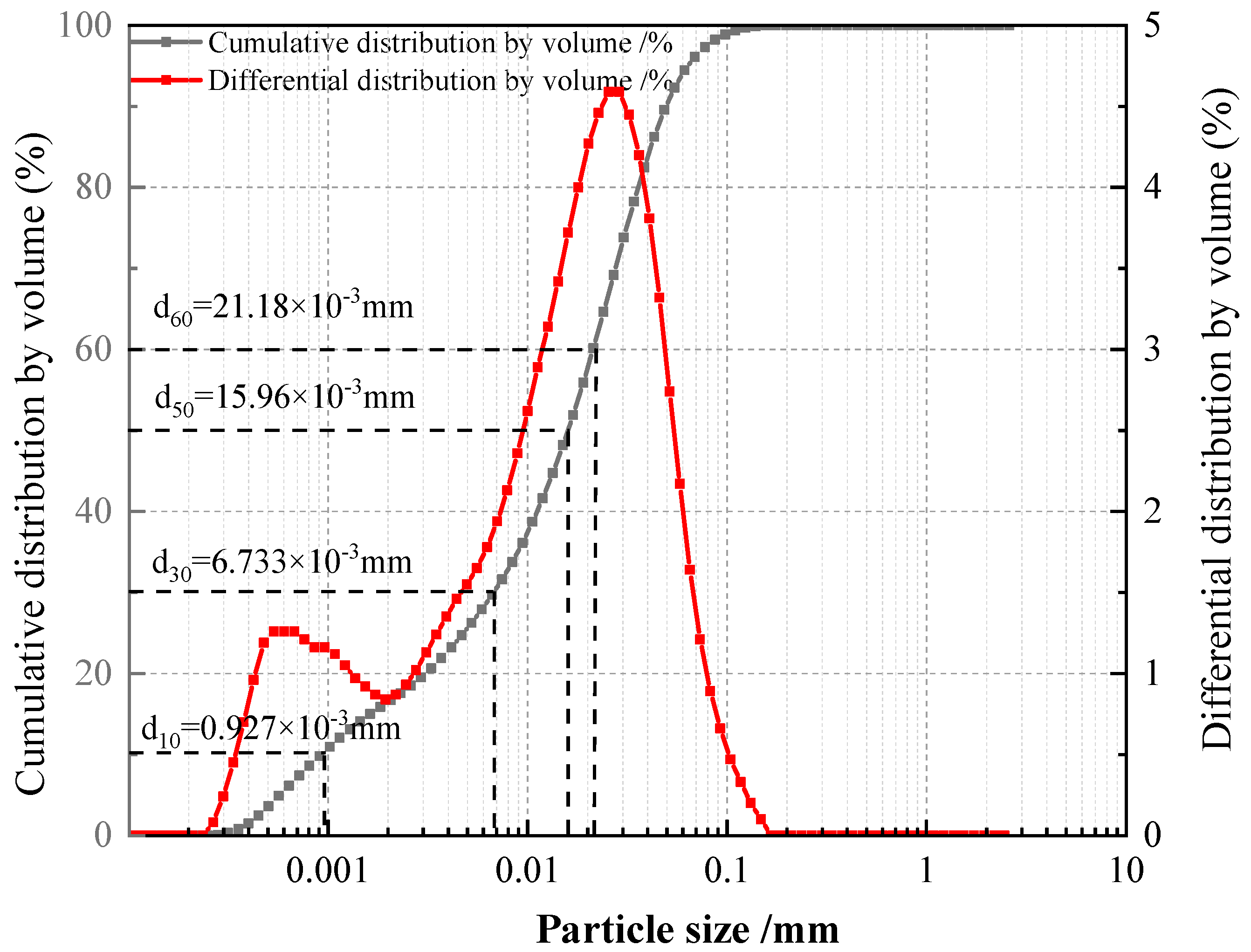

2.1.1. Soil Samples

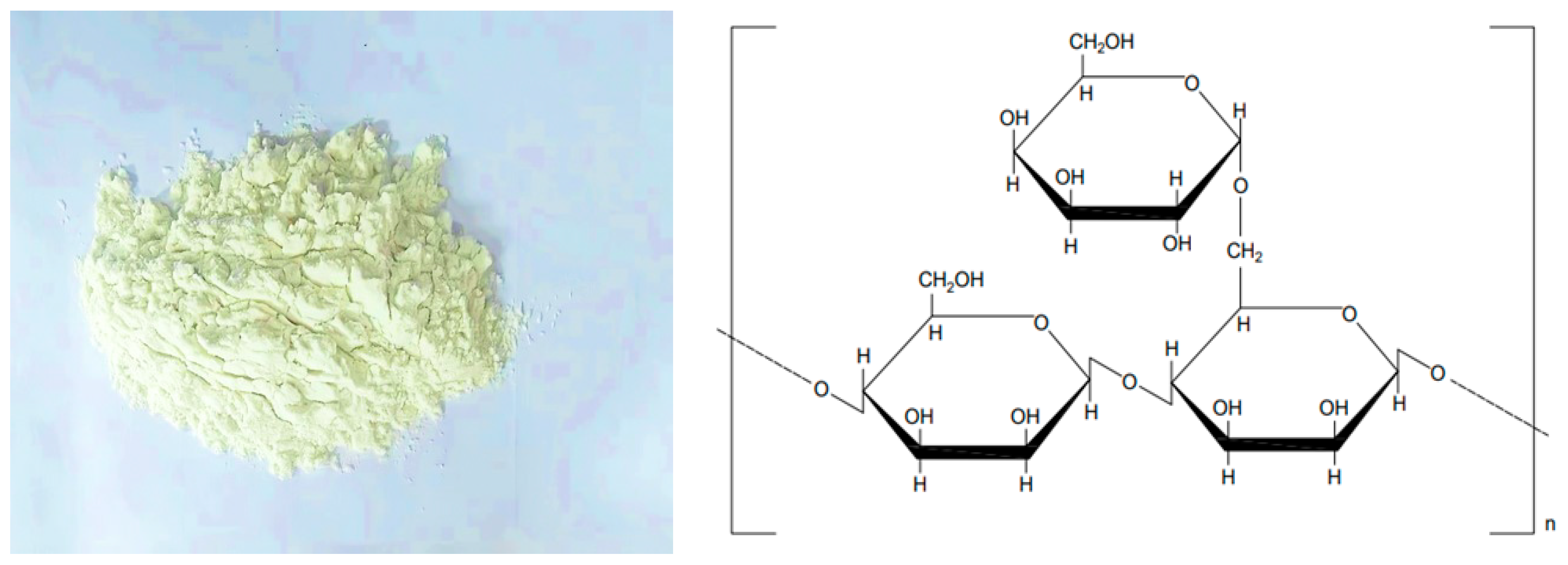

2.1.2. Guar Gum

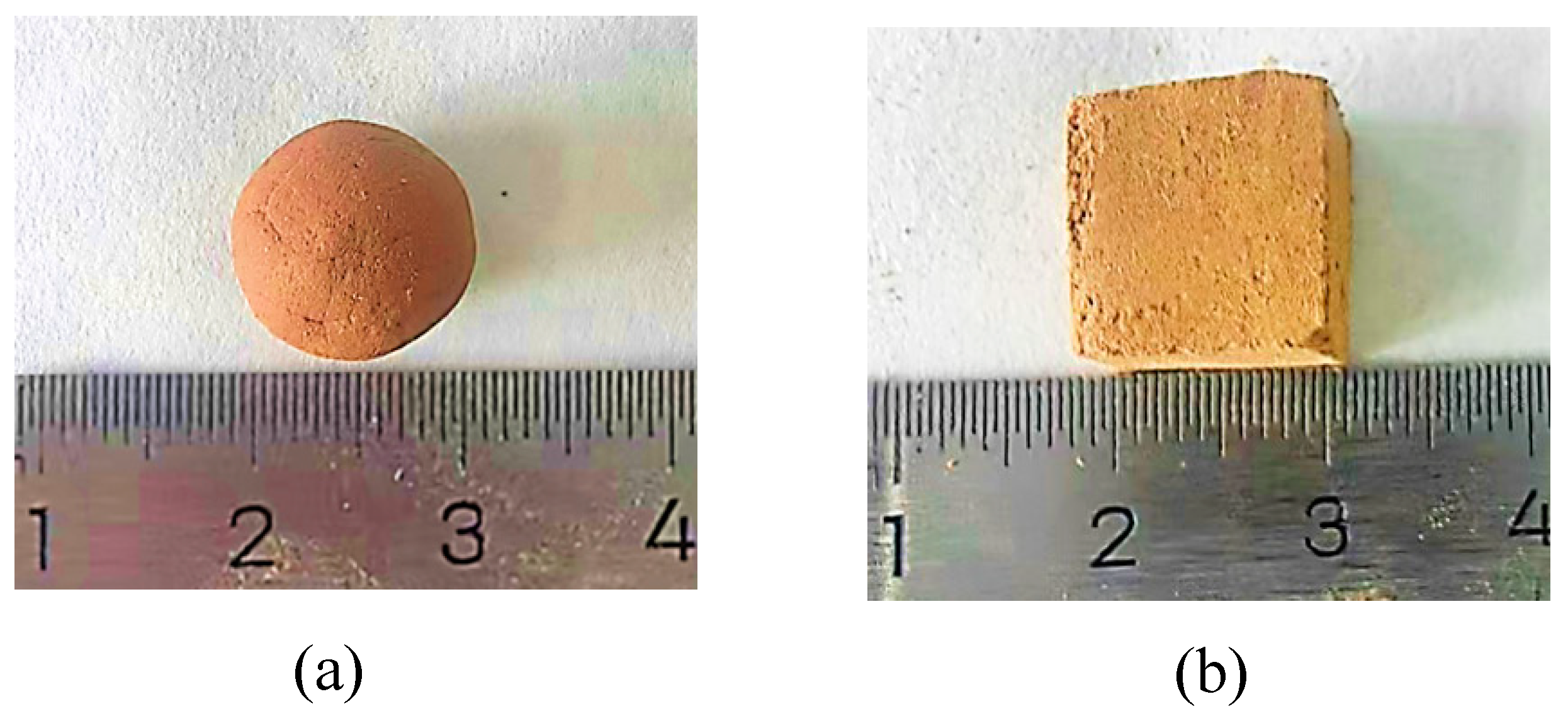

2.1.3. Sample Preparation

2.2. Test Methods

2.2.1. Mechanical Tests

2.2.2. Water Stability Tests

2.2.3. Collapsibility and Consolidation Tests

2.2.4. pH Test

2.2.5. Microstructure and Mineral Analysis

3. Results

3.1. Mechanical Properties

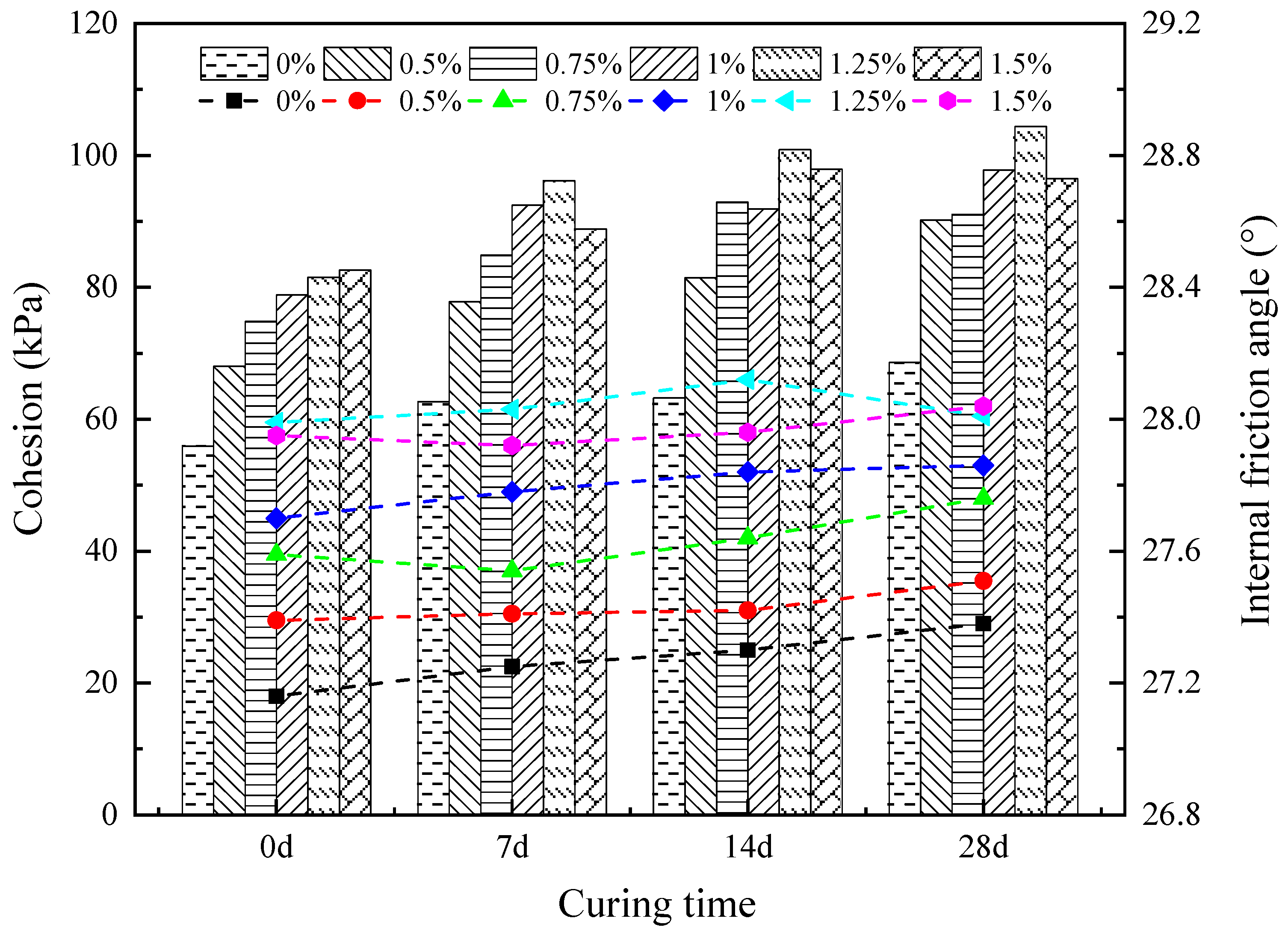

3.1.1. Shear Strength

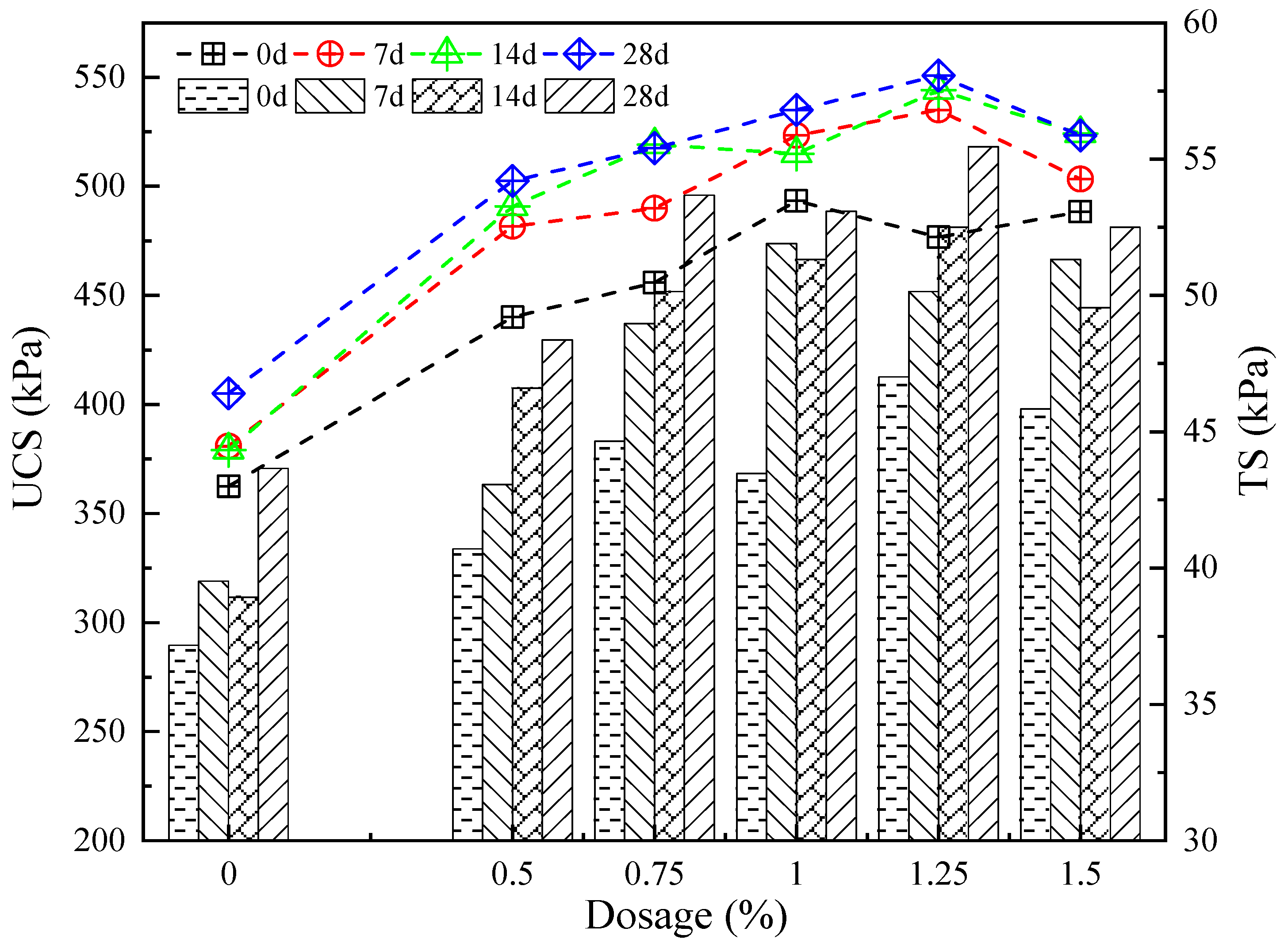

3.1.2. Compressive and Tensile Strengths

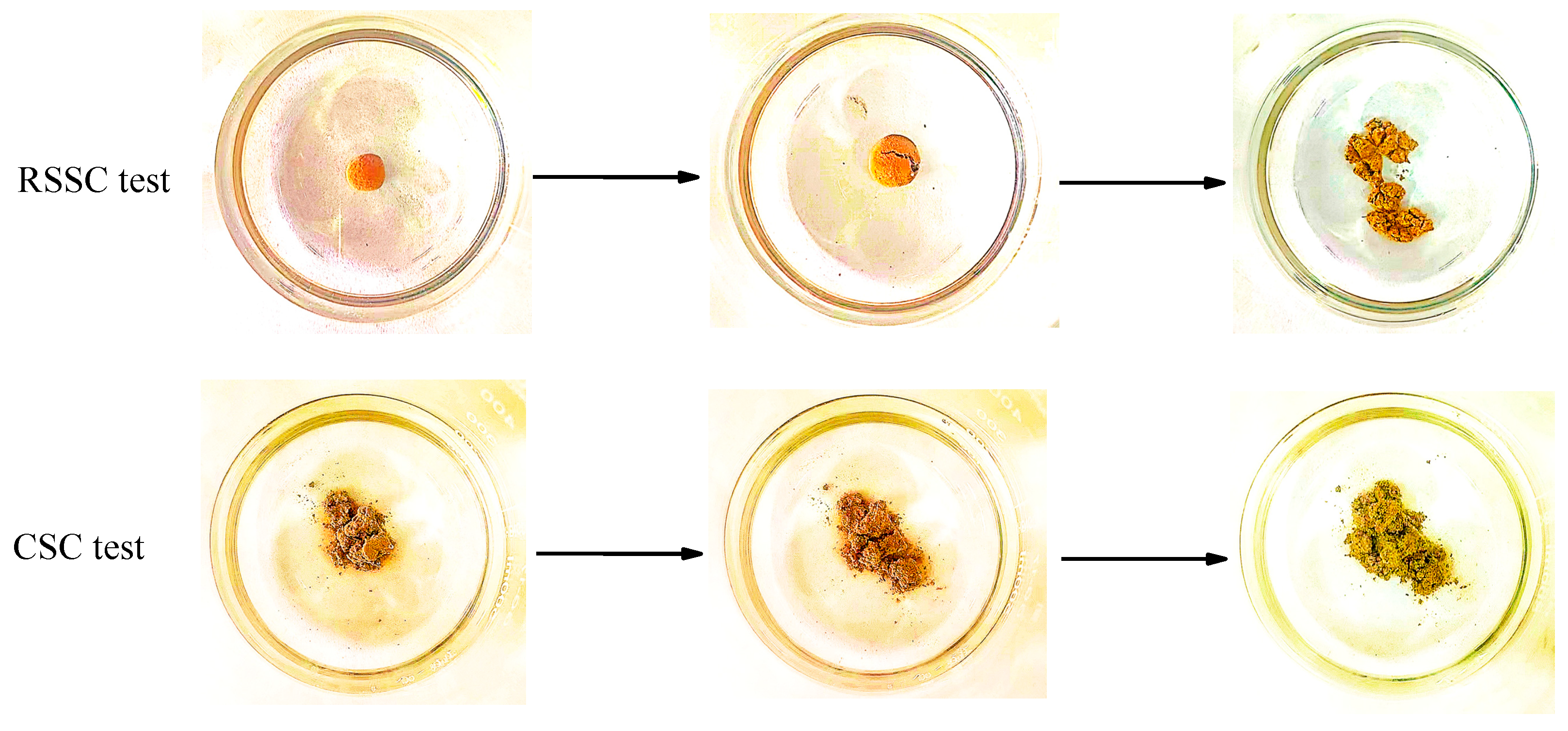

3.2. Water Stability

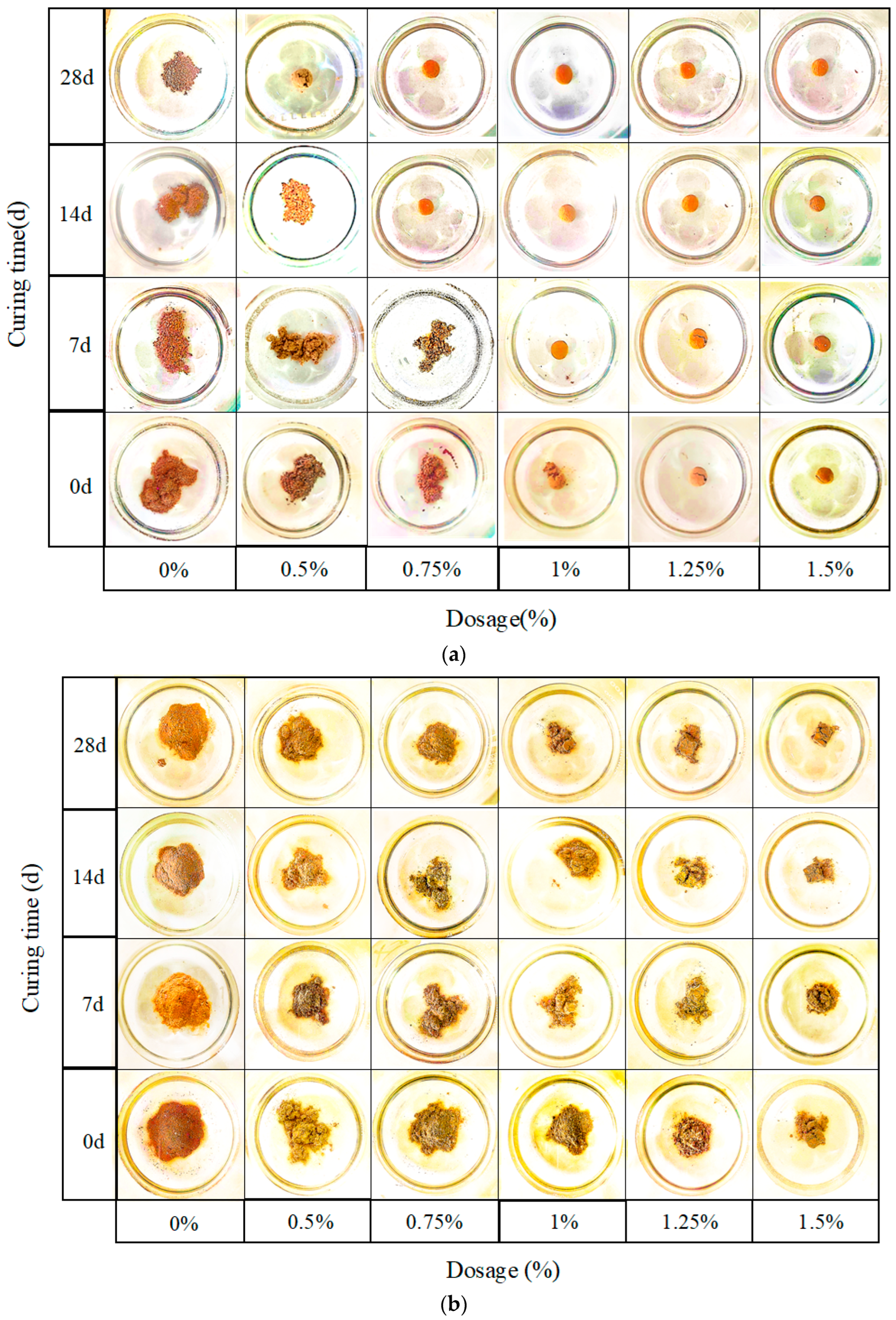

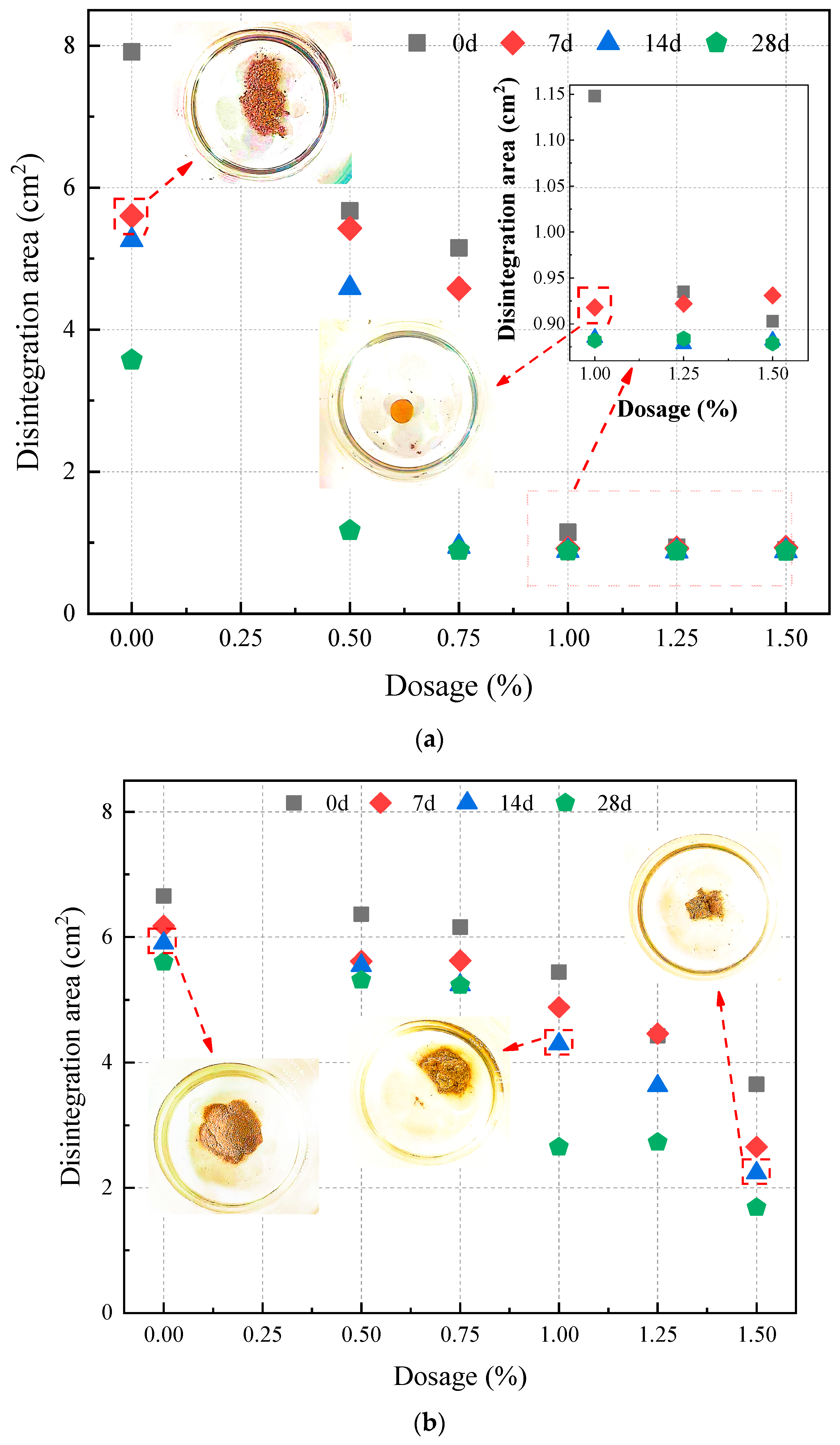

3.2.1. Disintegration Area

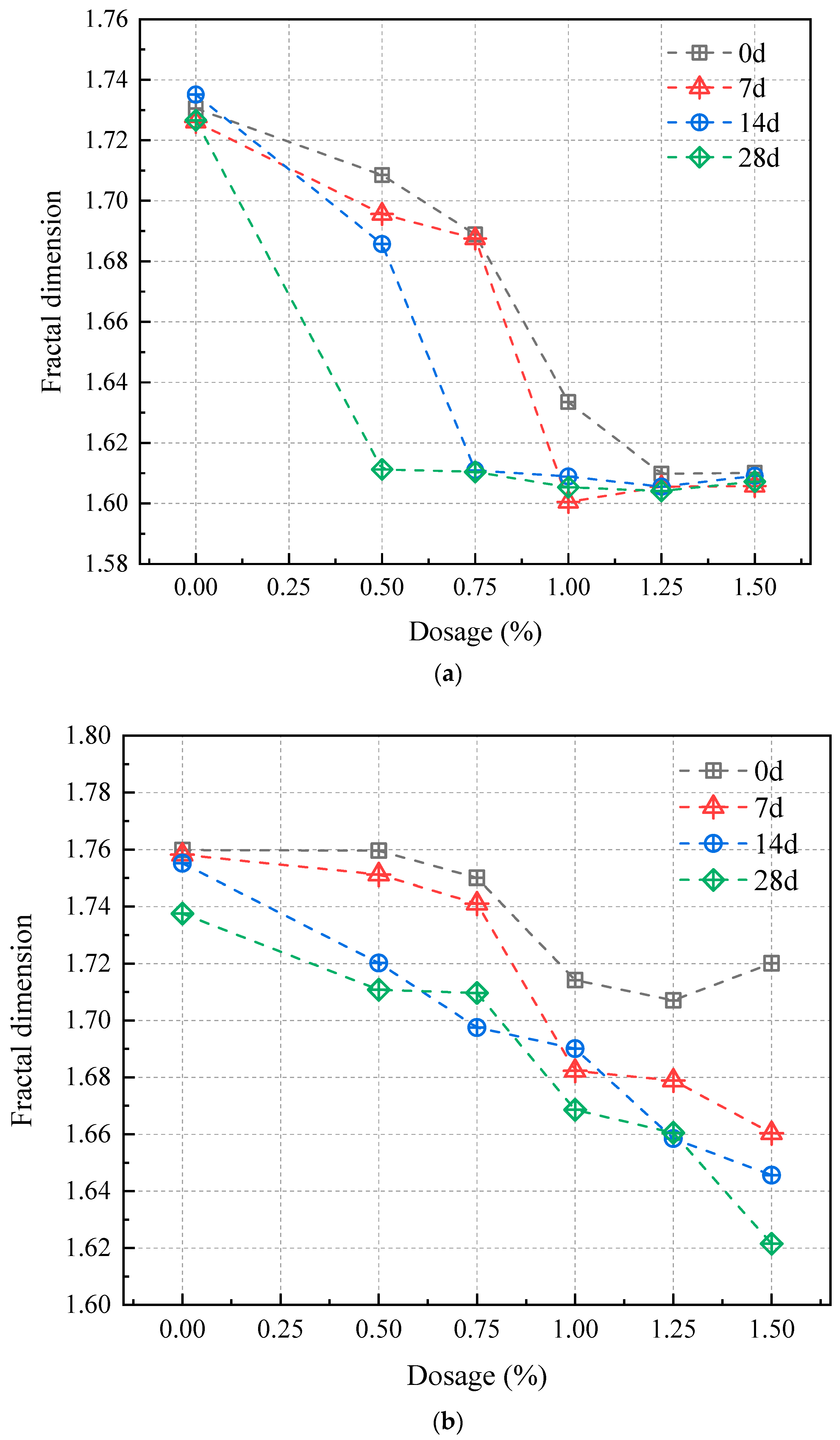

3.2.2. Fractal Dimension

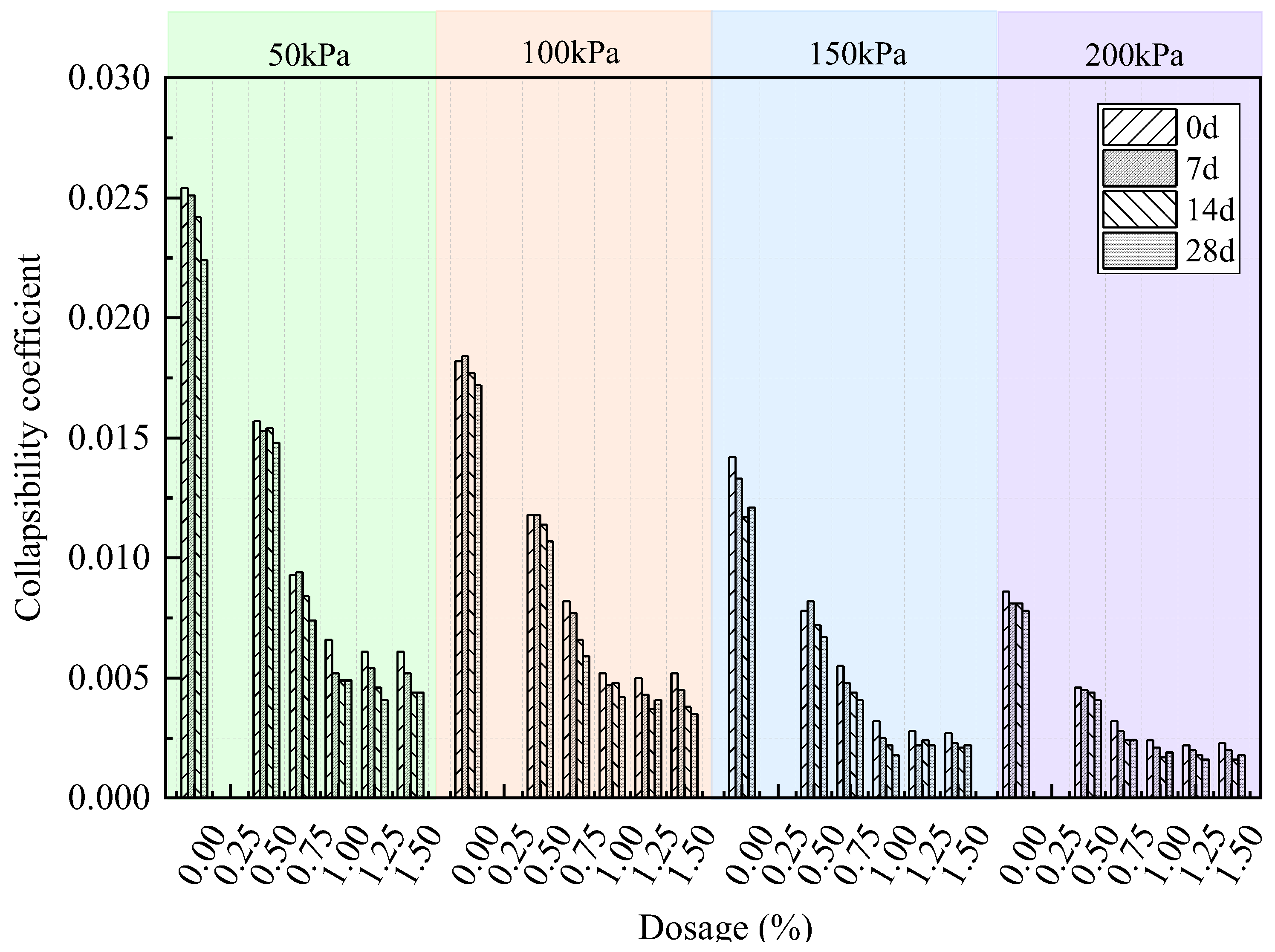

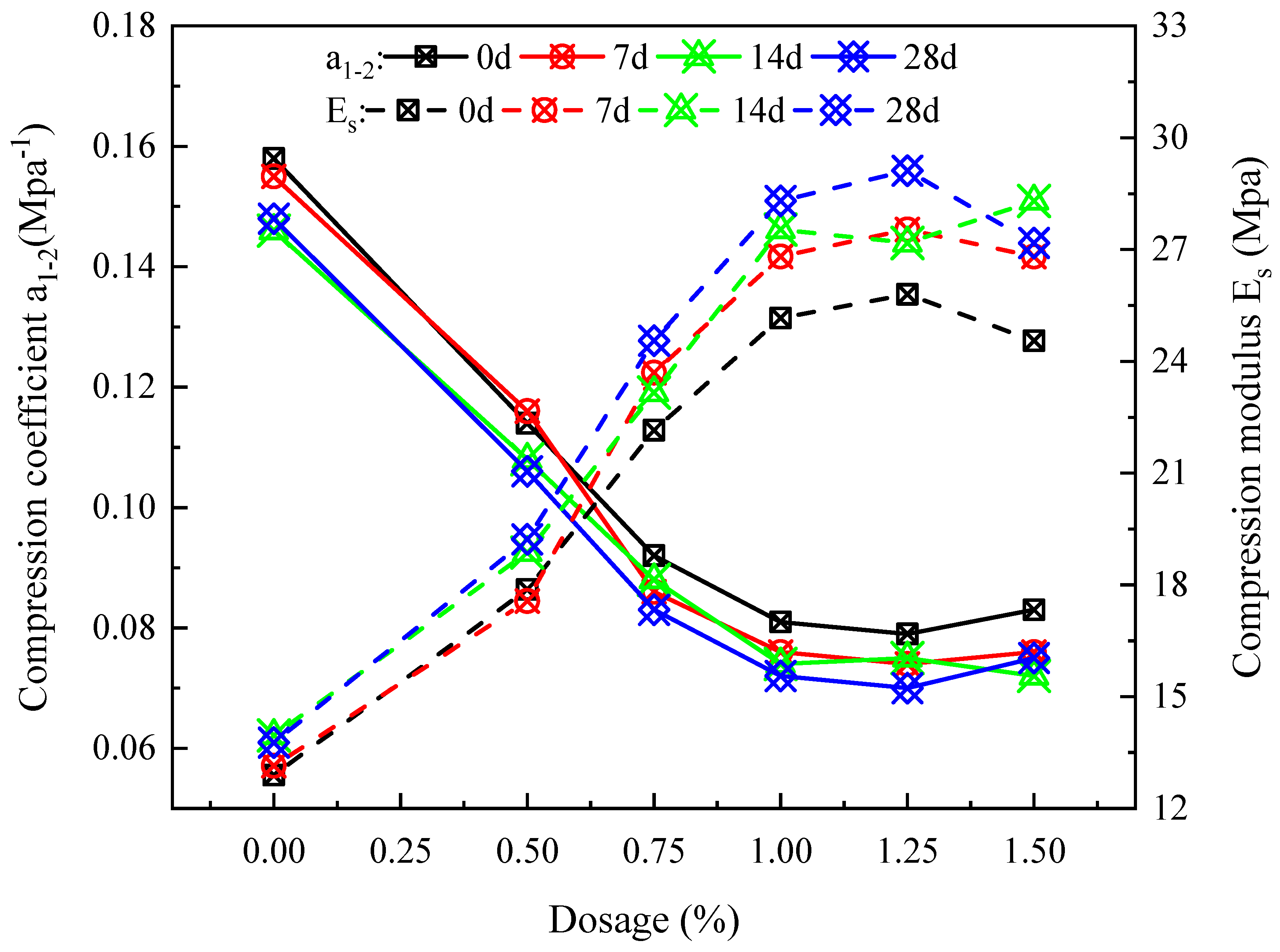

3.3. Collapsibility and Consolidation Properties

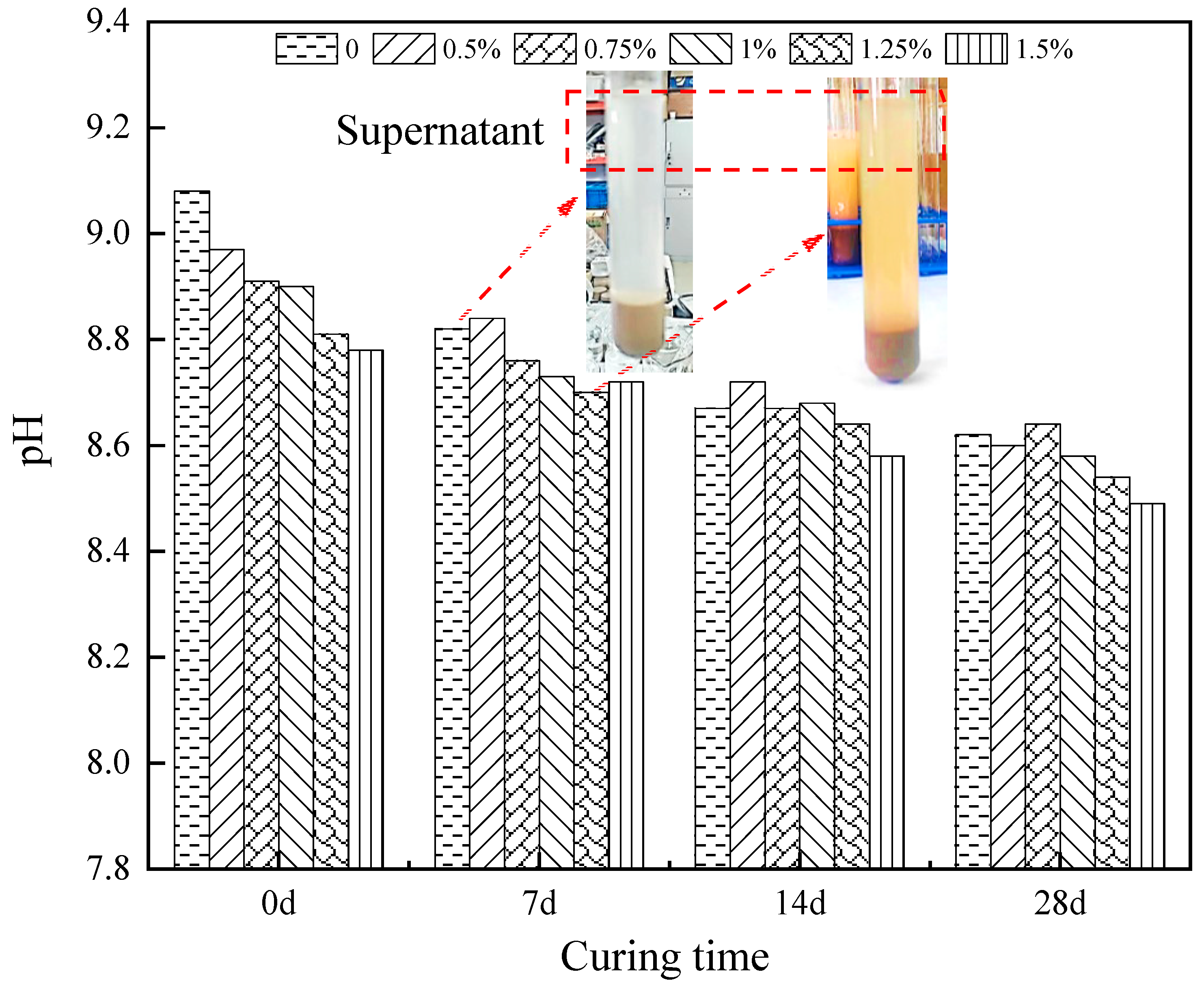

3.4. pH

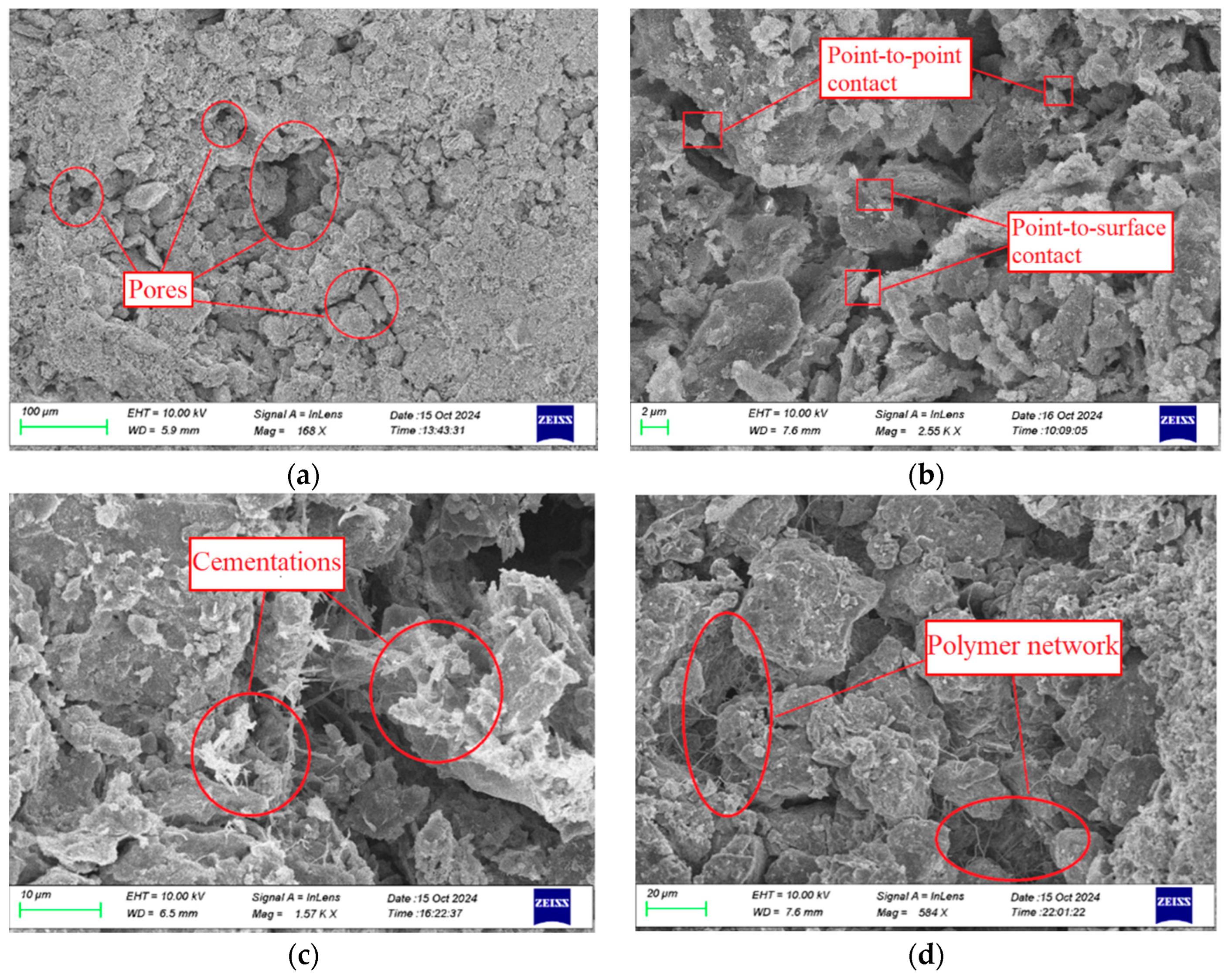

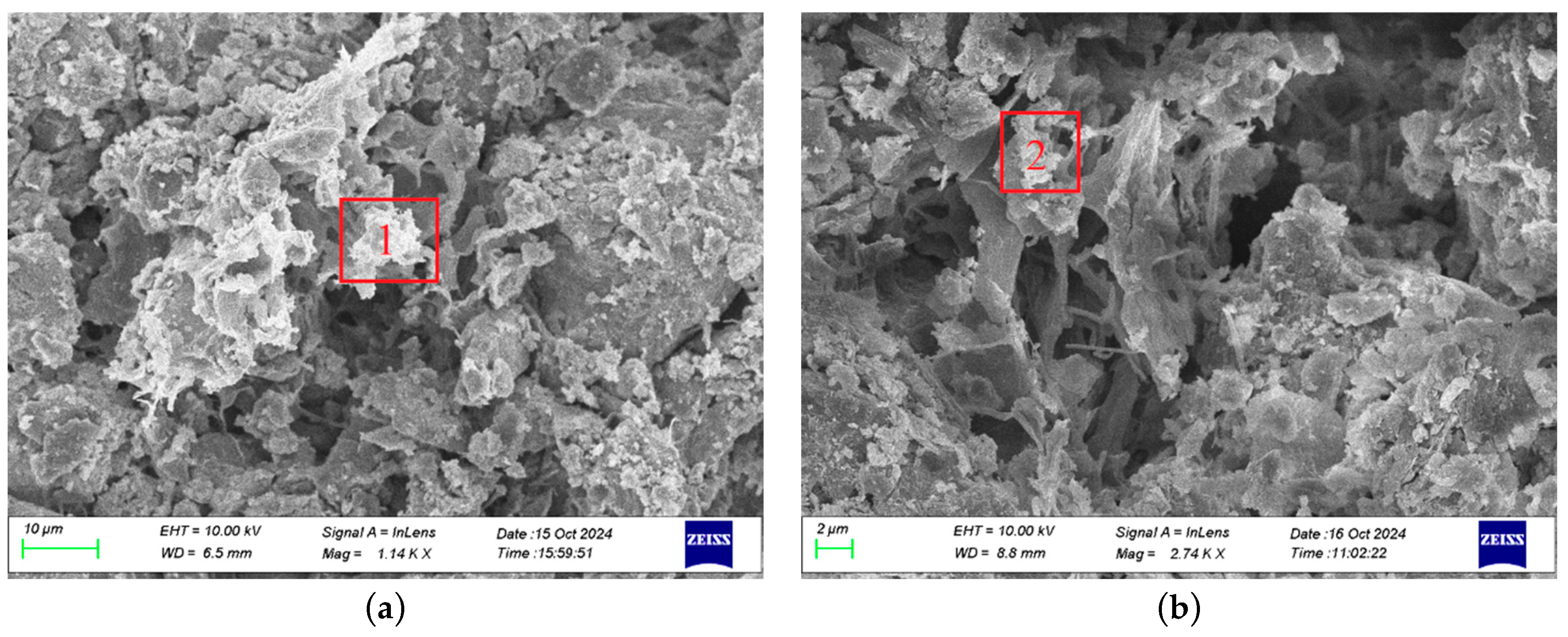

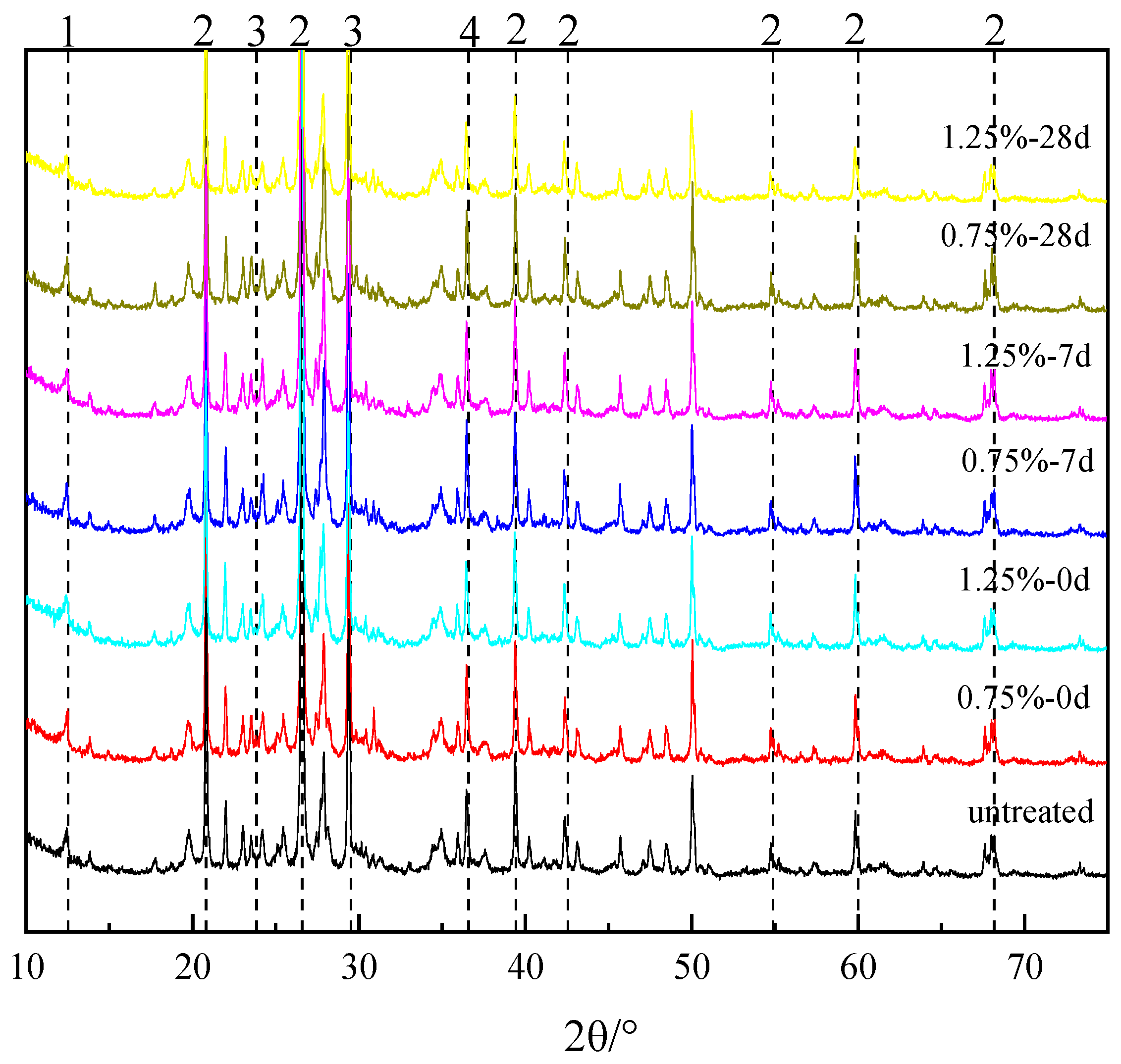

3.5. Microstructure and Mineral Analysis

4. Discussion

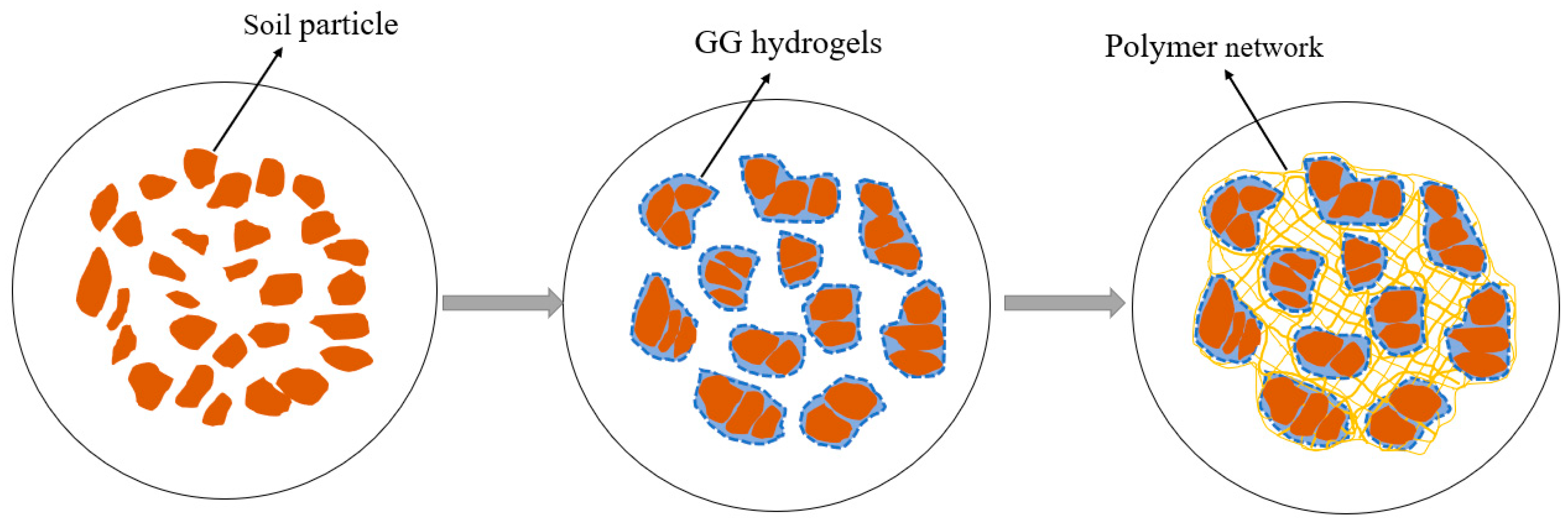

4.1. Improvement Mechanism of Mechanical Properties

4.2. Improvement Mechanism of Hydrophysical Properties

4.3. Practicality and Feasibility of GG-Modified Loess

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Xie, W.; Pak, R.Y.S.; Vanapalli, S.K. Microstructural evolution of loess soils from the Loess Plateau of China. CATENA 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Gu, L.; Lv, Q.; Wang, S.; Shu, H.; Xiang, J.; Guo, L.; Jiang, J. Effect of sodium silicate on the properties of loess stabilized with alkali-activated fly ash-based. Constr. Build. Mater. 2021, 280, 122515. [Google Scholar] [CrossRef]

- Li, N.; Sun, J.; Wang, Q.; Zhong, X.; Feng, M.; Guo, P. Progress review and perspective problems on loess foundation reinforcement by means of modification treatment. AES 2017, 32, 209–219. [Google Scholar]

- Hou, Y.; Li, P.; Wang, J. Review of chemical stabilizing agents for improving the physical and mechanical properties of loess. Bull. Eng. Geol. Environ. 2021, 80, 9201–9215. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium-and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Sun, H.; Xie, M.; Cui, W.; Xie, X.; Zong, S. Research progress of loess reinforcement technology: A bibliometric network analysis. Constr. Build. Mater. 2024, 436, 136942. [Google Scholar] [CrossRef]

- Latifi, N.; Meehan, C.L.; Abd Majid, M.Z.; Horpibulsuk, S. Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: A micro-level study. Appl. Clay Sci. 2016, 132, 182–193. [Google Scholar] [CrossRef]

- Mariri, M.; Ziaie Moayed, R.; Kordnaeij, A. Stress–strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Awraheem, M.H.; Khalaf, M.M. Geotechnical properties of a low-plasticity clay with biopolymer. J. Mater. Civil. Eng. 2018, 30, 04018170. [Google Scholar] [CrossRef]

- Biswas, M.C.; Jony, B.; Nandy, P.K.; Chowdhury, R.A.; Halder, S.; Kumar, D.; Ramakrishna, S.; Hassan, M.; Ahsan, M.A.; Hoque, M.E.; et al. Recent advancement of biopolymers and their potential biomedical applications. J. Polym. Environ. 2021, 30, 51–74. [Google Scholar] [CrossRef]

- Abinash, D.; Togam, R.; Sampad, G.; Nabakumar, P. A comprehensive review on recent advances in preparation, physicochemical characterization, and bioengineering applications of biopolymers. Polym. Bull. 2023, 80, 7247–7312. [Google Scholar]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civil. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Reddy, N.G.; Rao, B.H.; Reddy, K.R. Biopolymer amendment for mitigating dispersive characteristics of red mud waste. Géotech. Lett. 2018, 8, 201–207. [Google Scholar] [CrossRef]

- Bao, H.; Liu, C.; Lan, H.; Yan, C.; Li, L.; Zheng, H.; Dong, Z. Time-dependency deterioration of polypropylene fiber reinforced soil and guar gum mixed soil in loess cut-slope protecting. Eng. Geol. 2022, 311, 106895. [Google Scholar] [CrossRef]

- Reddy, J.J.; Varaprasad, B.J.S. Long-term and durability properties of xanthan gum treated dispersive soils–An eco-friendly material. Mater. Today Proc. 2021, 44, 309–314. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhuang, J.; Wang, Y.; Jia, Y.; Niu, P.; Jia, K. Improvement of loess characteristics using sodium alginate. Bull. Eng. Geol. Environ. 2020, 79, 1879–1891. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.C. Geotechnical behavior of a beta-1, 3/1, 6-glucan biopolymer-treated residual soil. Geomech. Eng. 2014, 7, 633–647. [Google Scholar] [CrossRef]

- Ayeldeen, M.K.; Negm, A.M.; El Sawwaf, M.A. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 1–13. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M.; Structural Engineering Department, TU; Faculty of Engineering, ZU; Civil, Environmental Engineering Department, TIoT. Enhancing mechanical behaviors of collapsible soil using two biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Construction Ministry of PRC: Beijing, China, 2019.

- Highway Research Institute of the Ministry of Communications. Test Methods of Soils for Highway Engineering; People’s Communications Publishing House: Beijing, China, 2020; 428p. [Google Scholar]

- Jang, J. A review of the application of biopolymers on geotechnical engineering and the strengthening mechanisms between typical biopolymers and soils. Adv. Mater. Sci. Eng. 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Baig, M.A.A.; Venkata, V.K. State-of-the-art review on efficacy of xanthan gum and guar gum inclusion on the engineering behavior of soils. Innov. Infrastruct. Solut. 2021, 6, 1–14. [Google Scholar]

- D2487-17e1; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshohocken, PA, USA, 2017.

- D6572-21; Standard Test Methods for Determining Dispersive Characteristics of Clayey Soils by the Crumb Test. ASTM: West Conshohocken, PA, USA, 2021.

- Li, T.; Zhu, Z.; Wu, T.; Ren, G.; Zhao, G. A potential way for improving the dispersivity and mechanical properties of dispersive soil using calcined coal gangue. J. Mater. Res. Technol. 2024, 29, 3049–3062. [Google Scholar] [CrossRef]

- Yang, Y.; Han, S.; Liu, H.; Chen, H.; Jiang, S. Influence of particle size distribution on biocarbonation method produced microbial restoration mortar for conservation of sandstone cultural relics. Biogeotechnics 2023, 1, 100051. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotech. lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Wang, S.; Tang, H.; Guo, J.; Wang, K. Effect of pH on the rheological properties of borate crosslinked hydroxypropyl guar gum hydrogel and hydroxypropyl guar gum. Carbohydr. Polym. 2016, 147, 455–463. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Yan, D.; Ren, G.; Zhu, Z.; Wu, T.; Ding, S.; Shi, M.; Fan, H. Influence of ground granulated blast furnace slag on the dispersivity and mechanical property of dispersive soil. Constr. Build. Mater. 2023, 409, 134036. [Google Scholar] [CrossRef]

- Ai, T.; Zhang, R.; Zhou, H.; Pei, J. Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl. Surf. Sci. 2014, 314, 610–621. [Google Scholar] [CrossRef]

- Mohammad, S.; Akhlaq, H.; Jaideep, R.; Mohammad, T.A.; Sulaiman, A.A.Y.; Ahmed, A. Box dimension of the border of Kingdom of Saudi Arabia. Heliyon 2023, 9, e14846. [Google Scholar]

- Liu, Y.; Tang, C.; Fan, H.; Zhu, Z.; Jiang, S.; Zhang, B. Study on the disintegration characteristics and mechanism of modified dispersive soil based on the CSH synthesis principle. Sustainability 2022, 14, 14370. [Google Scholar] [CrossRef]

| ρ/(g/cm3) | w/% | wL/% | wP/% | IP/% | e0 | GS |

|---|---|---|---|---|---|---|

| 1.46 | 10.06 | 23.71 | 14.08 | 9.63 | 1.04 | 2.70 |

| Type of Element | C | O | Na | Mg | Al | Si | S | K | Ca | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass ratio (%) | 9.27 | 40.41 | 0.34 | 1.75 | 6.22 | 22.96 | 3.07 | 1.49 | 12.32 | 2.17 |

| Atomic ratio (%) | 15.71 | 51.41 | 0.30 | 1.46 | 4.69 | 16.64 | 1.95 | 0.78 | 6.26 | 0.79 |

| Type of Element | C | O | Na | Mg | Al | Si | S | K | Ca | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass ratio (%) | 12.28 | 39.57 | 0.29 | 1.63 | 6.46 | 22.77 | 1.57 | 2.34 | 9.99 | 3.08 |

| Atomic ratio (%) | 20.29 | 49.08 | 0.25 | 1.33 | 4.75 | 16.09 | 0.97 | 1.19 | 4.95 | 1.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Li, T.; Qi, D.; Xi, X.; Peng, F.; Ding, S.; Nie, Z.; Hu, X.; Zhao, G.; Xiao, B.; et al. Eco-Friendly Improvement of Comprehensive Engineering Properties of Collapsible Loess Using Guar Gum Biopolymer. Buildings 2024, 14, 3804. https://doi.org/10.3390/buildings14123804

Zheng Y, Li T, Qi D, Xi X, Peng F, Ding S, Nie Z, Hu X, Zhao G, Xiao B, et al. Eco-Friendly Improvement of Comprehensive Engineering Properties of Collapsible Loess Using Guar Gum Biopolymer. Buildings. 2024; 14(12):3804. https://doi.org/10.3390/buildings14123804

Chicago/Turabian StyleZheng, Yuesong, Tianhao Li, Daokun Qi, Xiaojuan Xi, Fengzu Peng, Shijun Ding, Zhibao Nie, Xin Hu, Gaowen Zhao, Bo Xiao, and et al. 2024. "Eco-Friendly Improvement of Comprehensive Engineering Properties of Collapsible Loess Using Guar Gum Biopolymer" Buildings 14, no. 12: 3804. https://doi.org/10.3390/buildings14123804

APA StyleZheng, Y., Li, T., Qi, D., Xi, X., Peng, F., Ding, S., Nie, Z., Hu, X., Zhao, G., Xiao, B., Tang, Y., & Wang, W. (2024). Eco-Friendly Improvement of Comprehensive Engineering Properties of Collapsible Loess Using Guar Gum Biopolymer. Buildings, 14(12), 3804. https://doi.org/10.3390/buildings14123804