Strength- and Moisture-Related Studies of Historical Building Materials: A Case Study from Southern Estonia

Abstract

1. Introduction

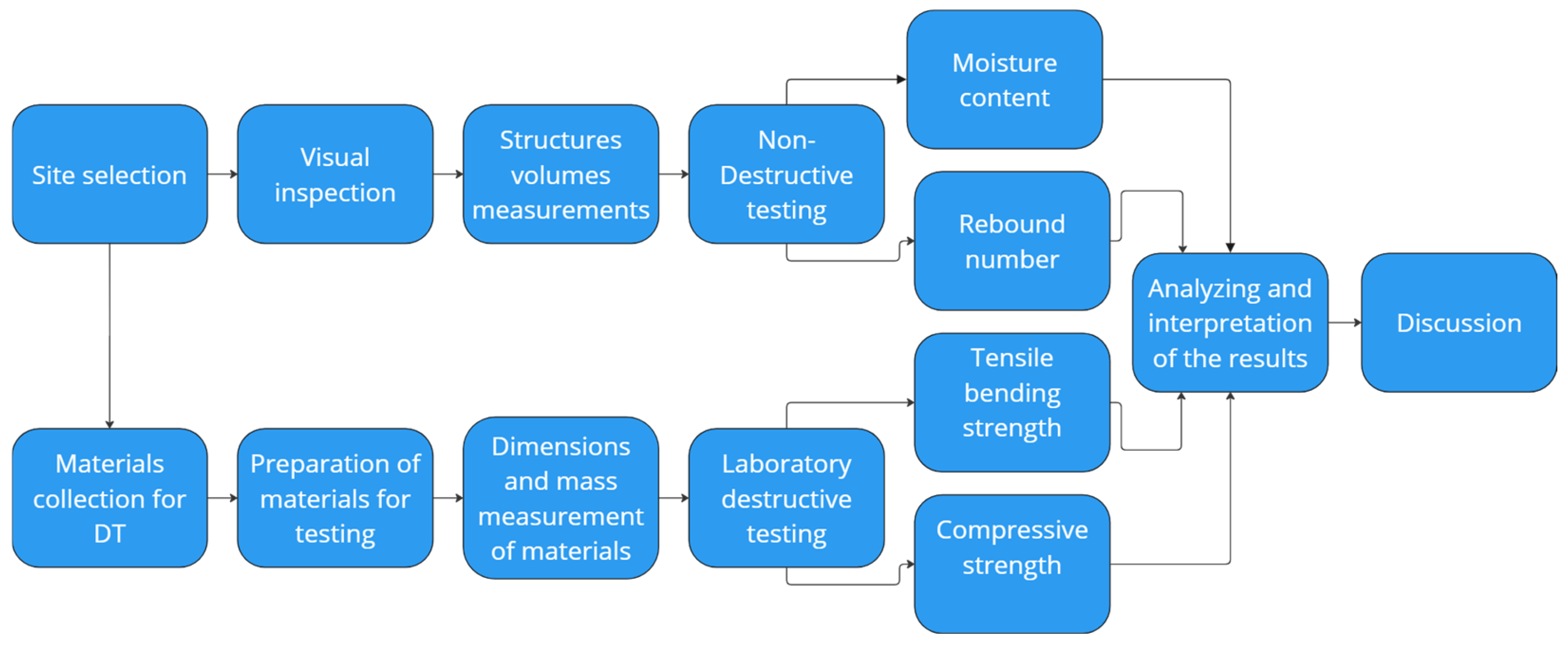

2. Materials and Methods

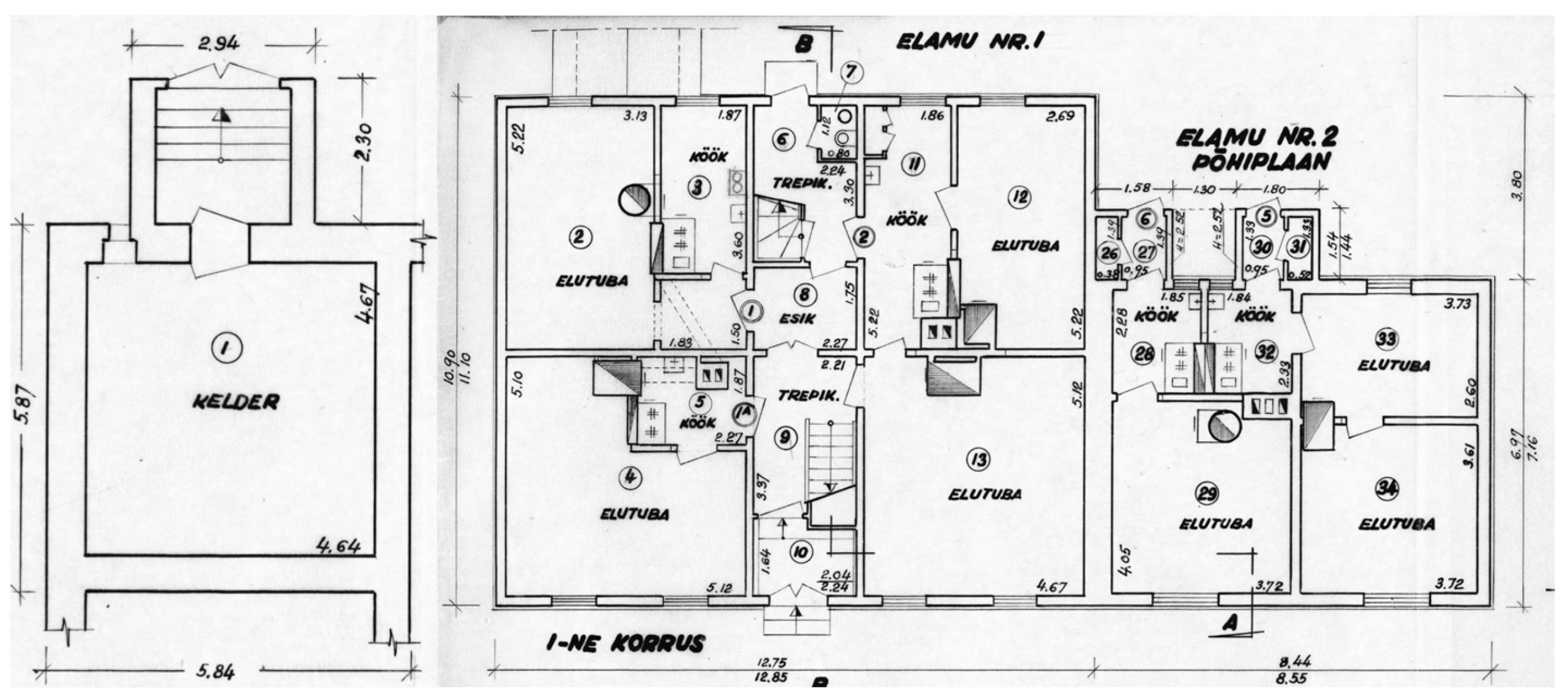

2.1. Case Study Building

2.2. In Situ Non-Destructive Testing

2.2.1. Rebound Hammer Testing of Stone and Concrete Structures

2.2.2. Moisture Content Testing of Timber Structures by Resistive Method

2.2.3. Moisture Level Testing of Timber Structures by Microwave Method

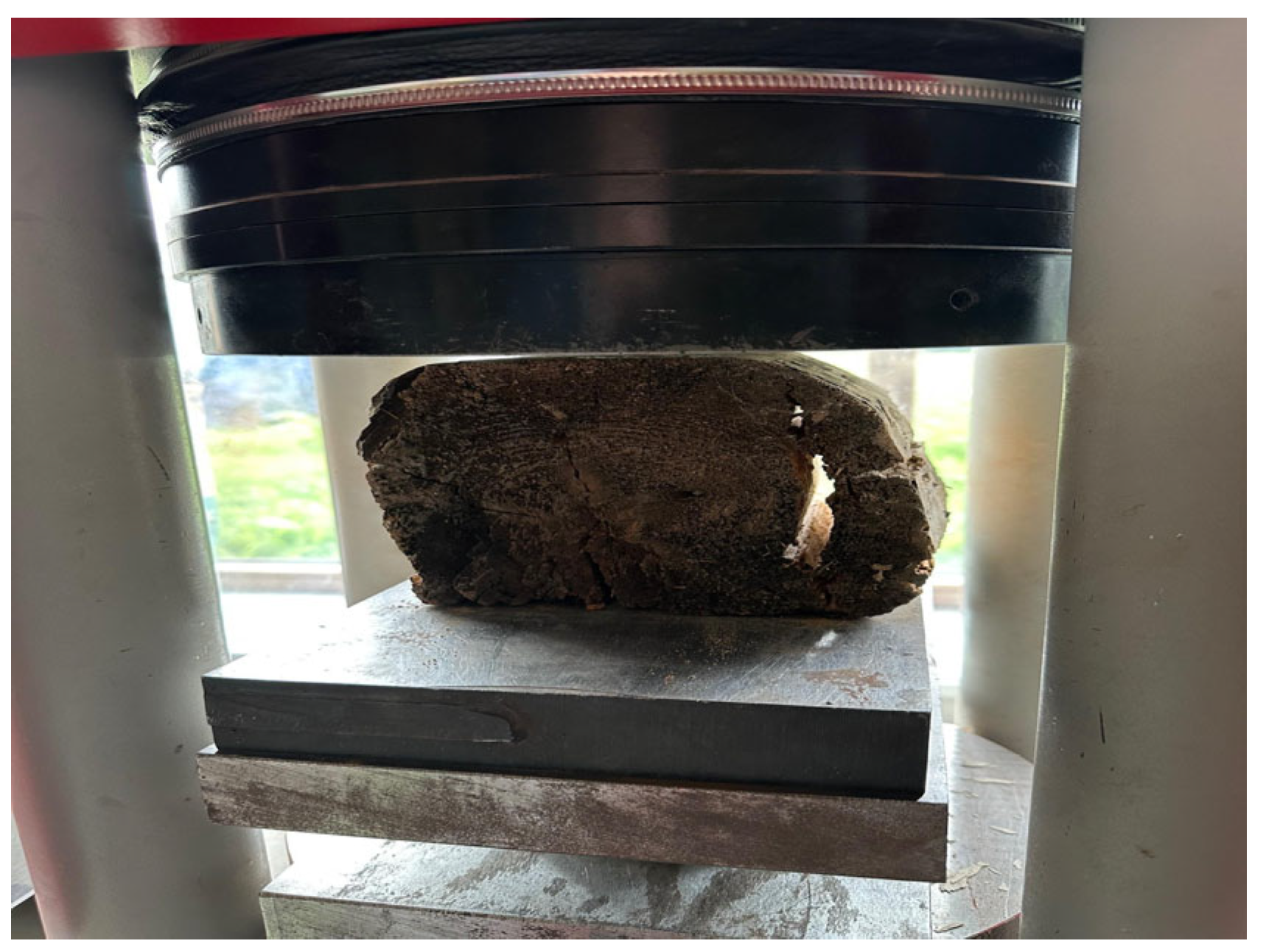

2.3. Destructive Testing (DT) in Laboratory

2.3.1. Ceramic Brick Testing

2.3.2. Timber Testing

3. Results and Discussion

3.1. Non-Destructive Rebound Hammer Testing

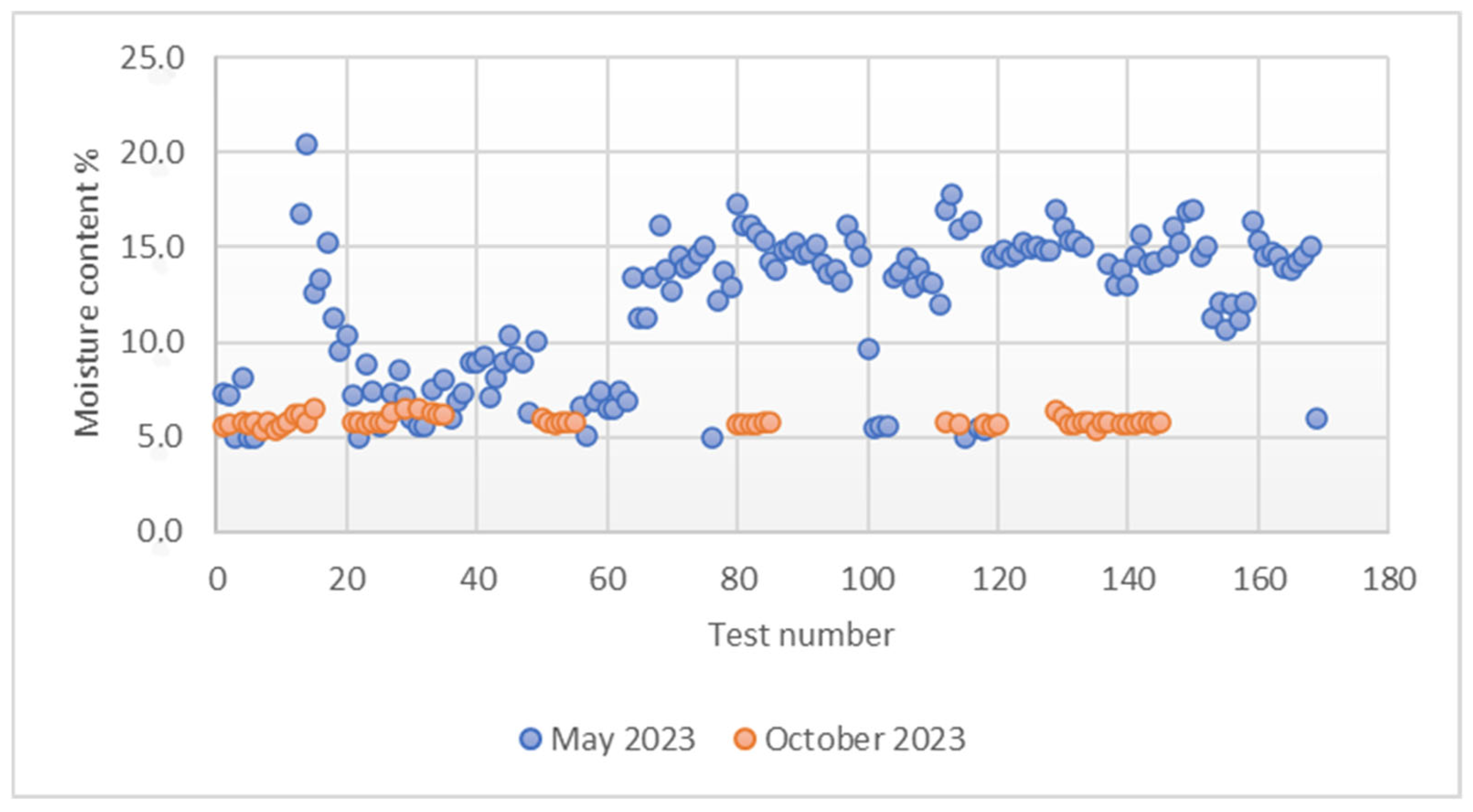

3.2. Moisture Content of Timber Structures by Resistive Method

3.3. Moisture Content Testing by Microwave Method

3.4. Density, Flexural and Compressive Strengths of Ceramic Bricks

3.5. Density, Bending and Compressive Strength of Timber

4. Discussion on Strength and Moisture Estimates of Materials

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| DT | Destructive testing |

| EVS-EN | European Standard adopted by Estonian Centre for Standardisation and Accreditation |

| FW | Foundation wall |

| MDT | Minor destructive testing |

| NDT | Non-destructive testing |

| NE | north-east orientation |

| NW | north-west orientation |

| P | Plinth (structure) |

| SE | south-east orientation |

References

- Construction Waste Market Share, Research Insights by 2025. (n.d.). Transparency Market Research. Available online: https://www.transparencymarketresearch.com/construction-waste-market.html (accessed on 15 October 2024).

- Lu, W.; Webster, C.; Peng, Y.; Chen, X.; Zhang, X. Estimating and calibrating the amount of building-related construction and demolition waste in urban China. Int. J. Constr. Manag. 2016, 17, 13–24. [Google Scholar] [CrossRef]

- Eurostat (2019) Waste Statistics—Statistics Explained. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics (accessed on 16 October 2024).

- Advancing Sustainable Materials Management: 2015 Fact Sheet. 2018. U.S. Environmental Protection Agency. Available online: https://www.epa.gov/sites/production/files/2018-07/documents/2015_smm_msw_factsheet_07242018_fnl_508_002.pdf (accessed on 15 October 2024).

- Diagnosis of Heritage Buildings by Non-Destructive Techniques. 2024. ScienceDirect. Available online: https://www.sciencedirect.com/book/9780443160011/diagnosis-of-heritage-buildings-by-non-destructive-techniques#book-description (accessed on 18 October 2024).

- Murzyn-Kupisz, M.; Dziazek, J. Cultural heritage in building and enhancing social capital. J. Cult. Herit. Manag. Sustain. Dev. 2013, 3, 35–54. [Google Scholar] [CrossRef]

- Haupt, T. A case study of industrial heritage buildings at the Rjukan and Notodden Site in Norway (1905–1929). Proc. Inst. Civ. Eng. Eng. Hist. Herit. 2024, 177, 16–30. [Google Scholar] [CrossRef]

- Amro, D.K.; Ammar, S. Rehabilitation of heritage buildings in conflict zones: A case study of Al-Khader Library in Gaza Strip and its impact on sustainable development. Buildings 2024, 14, 2759. [Google Scholar] [CrossRef]

- Imtiaz, S.; Arif, S.; Nawaz, A.; Shah, S.a.R. Conservation of Socio-Religious Historic Buildings: A Case study of Shah Yousuf Gardez Shrine. Buildings 2024, 14, 2116. [Google Scholar] [CrossRef]

- Ehitismälestised. (2024). Muinsuskaitseamet. In Estonian. Available online: https://www.muinsuskaitseamet.ee/kultuuriparand-eestis/malestised/ehitismalestised (accessed on 5 April 2024).

- Nair, G.; Verde, L.; Olofsson, T.A. Review on Technical Challenges and Possibilities on Energy Efficient Retrofit Measures in Heritage Buildings. Energies 2022, 15, 7472. [Google Scholar] [CrossRef]

- Panakaduwa, C.; Coates, P.; Munir, M. Identifying sustainable retrofit challenges of historical Buildings: A systematic review. Energy Build. 2024, 313, 114226. [Google Scholar] [CrossRef]

- Brahmi, B.F.; Sassi Boudemagh, S.; Kitouni, I.; Kamari, A. IPD and BIM-focussed methodology in renovation of heritage buildings. Constr. Manag. Econ. 2022, 40, 186–206. [Google Scholar] [CrossRef]

- Pinchin, S.E. Techniques for monitoring moisture in walls. Rev. Conserv. Int. Inst. Conserv. Hist. Artist. Work. 2008, 9, 33–45. [Google Scholar] [CrossRef]

- Hafsa, W.; Nguyen, T.A.; Angellier, N.; Ulmet, L.; Takarli, M.; Pop, O.; Dubois, F. Assessment of moisture content profile in Douglas-fir wood using electrical resistivity-based tomography. Constr. Build. Mater. 2023, 366, 130193. [Google Scholar] [CrossRef]

- Gineiko, A.; Kiviste, M. Condition of Historical Materials, Restoration Scenarios Cost Comparison and Environmental Impact: Case Study from Võru, Estonia. Archit. Civ. Eng. Environ. 2024. submitted on 5 June 2024. [Google Scholar]

- Gineiko, A.; Kiviste, M. Protocol of the Technical Condition of Case Study Building in Võru and On-Site Non-Destructive Testing (May and October 2023). 2024. Zenodo. Available online: https://doi.org/10.5281/zenodo.13358295 (accessed on 17 September 2024).

- Cabané, A.; Pelà, L.; Roca, P. Laboratory and in-situ mechanical characterisation of masonry components by comparing destructive and minor destructive testing techniques. Constr. Build. Mater. 2024, 411, 134474. [Google Scholar] [CrossRef]

- Boccacci, G.; Frasca, F.; Bertolin, C.; Siani, A.M. Diagnosis of historic reinforced concrete buildings: A Literature Review of Non-Destructive Testing (NDT) Techniques. Procedia Struct. Integr. 2024, 55, 160–167. [Google Scholar] [CrossRef]

- Ali-Benyahia, K.; Kenai, S.; Ghrici, M.; Sbartaï, Z.; Elachachi, S. Analysis of the accuracy of in-situ concrete characteristic compressive strength assessment in real structures using destructive and non-destructive testing methods. Constr. Build. Mater. 2023, 366, 130161. [Google Scholar] [CrossRef]

- Kumavat, H.R.; Chandak, N.R.; Patil, I.T. Factors influencing the performance of rebound hammer used for non-destructive testing of concrete members: A review. Case Stud. Constr. Mater. 2021, 14, e00491. [Google Scholar] [CrossRef]

- Borosnyoi-Crawley, D. Non-destructive strength estimation of vintage clay bricks based on rebound hardness in architectural heritage buildings. J. Build. Eng. 2023, 80, 108055. [Google Scholar] [CrossRef]

- Võru Technical Inventory bureau. (1966). Inventory project of Liiva 19 nr. 162, inventory folder nr. 2. In Estonian.

- Gineiko, A.; Kiviste, M. (2023) Test report. Rebound hammer tests of the materials and structures of Liiva 19, Võru city. In Estonian.

- EVS-EN 13183-2:2002; Moisture Content of a Piece of Sawn Timber—Part 2: Estimation by Electrical Resistance Method. EVS: Tallinn, Estonia, 2002. Available online: https://www.evs.ee/et/evs-en-13183-2-2002 (accessed on 5 October 2023).

- EVS-EN 12504-2:2021; Testing Concrete in Structures—Part 2: Non-Destructive Testing—Determination of Rebound Number. EVS: Tallinn, Estonia, 2021. Available online: https://www.evs.ee/en/evs-en-12504-2-2021 (accessed on 5 October 2023).

- Camuffo, D. Microclimate for Cultural Heritage. Measurement, Risk Assessment, Conservation, Restoration, and Maintenance of Indoor and Outdoor Monuments; Elsevier Science: Amsterdam, The Netherlands, 2019; Volume 19, pp. 459–482. Available online: https://www.sciencedirect.com/book/9780444641069/microclimate-for-cultural-heritage (accessed on 17 October 2024).

- Trotec. (n.d). Material moisture measuring device T660. Operating manual. Available online: https://uk.trotec.com/fileadmin/downloads/Messgeraete/Feuchte/T660/TRT-BA-T660-TC-003-EN.pdf (accessed on 7 November 2024).

- Compression and Bending Testing Machine Type MEGA 7—FORM+TEST. (n.d.). Available online: https://www.formtest.de/en/Products/Machine-Series/MEGA-7-Series.php (accessed on 5 June 2024).

- ISO 7500-1:2018; Metallic Materials—Calibration and Verification of Static Uniaxial Testing Machines. Part 1: Tension/Compression Testing Machines—Calibration and Verification of the Force-Measuring System. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/72572.html (accessed on 5 June 2024).

- EVS-EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. EVS: Tallinn, Estonia, 2019. Available online: https://www.evs.ee/en/evs-en-12390-4-2019 (accessed on 15 October 2023).

- EVS-EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. EVS: Tallinn, Estonia, 2019. Available online: https://www.evs.ee/en/evs-en-12390-5-2019 (accessed on 15 August 2023).

- EVS-EN 772-16:2011; Methods of Test for Masonry Units—Part 16: Determination of Dimensions. EVS: Tallinn, Estonia, 2011. Available online: https://www.evs.ee/en/evs-en-772-16-2011 (accessed on 15 August 2023).

- EVS-EN 771-1:2011+A1:2015; Specification for Masonry Units—Part 1: Clay Masonry Units. EVS: Tallinn, Estonia, 2015. Available online: https://www.evs.ee/en/evs-en-771-1-2011-a1-2015-consolidated (accessed on 17 October 2023).

- EVS-EN 772-6:2005; Methods of test for masonry units - Part 6: Determination of bending tensile strength of aggregate concrete masonry units. EVS: Tallinn, Estonia, 2005. Available online: https://www.evs.ee/en/evs-en-772-6-2005 (accessed on 18 October 2023).

- EVS-EN 772-1:2011+A1:2015; Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength. EVS: Tallinn, Estonia, 2015. Available online: https://www.evs.ee/en/evs-en-772-1-2011-a1-2015-consolidated (accessed on 18 October 2023).

- EVS-EN 772-13:2004; Methods of Test for Masonry Units—Part 13: Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone). EVS: Tallinn, Estonia, 2004; EVS. Available online: https://www.evs.ee/en/evs-en-772-13-2004 (accessed on 18 October 2023).

- EVS-EN 338:2016; Structural Timber—Strength Classes. EVS: Tallinn, Estonia, 2016. Available online: https://www.evs.ee/en/evs-en-338-2016 (accessed on 20 October 2023).

- DIN EN 13791/A20-2017-02-Beuth.de; Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; Amendment A20. DIN Media: Berlin, Germany, 2017. Available online: https://www.beuth.de/en/standard/din-en-13791-a20/263605032 (accessed on 15 October 2023).

- EVS-EN 13791:2020; Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components. EVS: Tallinn, Estonia, 2020. Available online: https://www.evs.ee/en/evs-en-13791-2020 (accessed on 2 May 2023).

- Roknuzzaman Hossain, B.; Mostazid, I.; Haque, R. Application of Rebound Hammer Method for Estimating Compressive Strength of Bricks. J. Civ. Eng. Res. 2017, 7, 99–104. [Google Scholar]

- Mengistu, G.M.; Gyurkó, Z.; Nemes, R. The Influence of the Rebound Hammer Test Location on the Estimation of Compressive Strength of a Historical Solid Clay Brick. Solids 2023, 4, 71–86. [Google Scholar] [CrossRef]

- Aliabdo, A.; Elmoaty, A.E.M.A. Reliability of using nondestructive tests to estimate compressive strength of building stones and bricks. Alex. Eng. J. 2012, 51, 193–203. [Google Scholar] [CrossRef]

- Buyuksagis, S.I.; Goktan, M.R. The effect of Schmidt hammer type on uniaxial compressive strength prediction of rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 299–307. [Google Scholar] [CrossRef]

- Glass, V.S.; Zelinka, L.S. Wood Moisture Relations Andneral Technical Report FPL–GTR–282; 2021 The Society of Friends of Võrumaa, NGO: Võru, Estonia, ch.4; pp. 1–22.

- The Society of Friends of Võrumaa, NGO. 10 December 2022. Brief Historical Overview of the City of Võru (In Estonian). Available online: https://www.vorumaa.eu/projektid/voru-linn/#google_vignette (accessed on 15 June 2024).

- Wienerberger. 2013. Declaration of Performance DoP:25100700-B1W2510. Red Ceramic Brick VTT65. Available online: https://dop.wienerberger.net/ceapp/pdf.do?parsleyId=5&sitelang=wb_ee_home_et&sis=prod&rollout_name=wb_at_zCeCert_de&pagename=WBTools%2FInterfaces%2FCEDoP%2FgetCEDopPDF&language=ET&cs.contenttype=application%2Fpdf&countrycode=EE&countryValue=wb_ee_home_et&certID=25100700-B1W2510&cachno=727933.5433095228https://dop.wienerberger.net/ceapp/pdf.do?parsleyId=5&sitelang=wb_ee_home_et&sis=prod&rollout_name (accessed on 17 June 2024).

- Wienerberger. 2023. Declaration of Performance DoP:25101700-B1W2510. Red ceramic Brick FTT65. Available online: https://dop.wienerberger.net/ceapp/pdf.do?parsleyId=5&sitelang=wb_ee_home_et&sis=prod&rollout_name=wb_at_zCeCert_de&pagename=WBTools%2FInterfaces%2FCEDoP%2FgetCEDopPDF&language=ET&cs.contenttype=application%2Fpdf&countrycode=EE&countryValue=wb_ee_home_et&certID=25101700-B1W2510&cachno=521355.3137260916 (accessed on 17 June 2024).

- Wienerberger. 2023. Declaration of Performance DoP:25101700-B1W2510. Red Ceramic Brick FAT65. Available online: https://dop.wienerberger.net/ceapp/pdf.do?parsleyId=5&sitelang=wb_ee_home_et&sis=prod&rollout_name=wb_at_zCeCert_de&pagename=WBTools%2FInterfaces%2FCEDoP%2FgetCEDopPDF&language=ET&cs.contenttype=application%2Fpdf&countrycode=EE&countryValue=wb_ee_home_et&certID=25102020-B1W2510&cachno=566615.3834129702 (accessed on 17 June 2024).

- El Abd, A.; Kichanov, S.E.; Taman, M.; Nazarov, K.M.; Kozlenko, D.P.; Badawy, W.M. Determination of moisture distributions in porous building bricks by neutron radiography. Appl. Radiat. Isot. 2020, 156, 108970. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0969804319307067 (accessed on 25 October 2024). [CrossRef] [PubMed]

- Gummerson, R.J.; Hall, C.; Hoff, W.D. Water movement in porous building materials—II. Hydraulic suction and sorptivity of brick and other masonry materials. Build. Environ. 1980, 15, 101–108. Available online: https://www.sciencedirect.com/science/article/abs/pii/0360132380900153 (accessed on 25 October 2024). [CrossRef]

- Kahangi Shahreza, S.; Niklewski, J.; Molnár, M. Experimental investigation of water absorption and penetration in clay brick masonry under simulated uniform water spray exposure. J. Build. Eng. 2021, 43, 102583. Available online: https://www.sciencedirect.com/science/article/pii/S2352710221004411 (accessed on 25 October 2024). [CrossRef]

| Lowest Rebound Number from All Test Locations in the Test Region | Median of the Rebound Numbers for the Test Region | Compressive Strength Class (EVS-EN 206:2014) |

|---|---|---|

| ≥26 | ≥30 | C 8/10 |

| ≥30 | ≥33 | C 12/15 |

| ≥32 | ≥35 | C 16/20 |

| ≥35 | ≥38 | C 20/25 |

| ≥37 | ≥40 | C 25/30 |

| ≥40 | ≥43 | C 30/37 |

| ≥44 | ≥47 | C 35/45 |

| ≥46 | ≥49 | C 40/50 |

| ≥48 | ≥51 | C 45/55 |

| ≥50 | ≥53 | C 50/60 |

| ≥53 | ≥57 | C 55/67 |

| Structure | Material | No of Rebound Hammer Tests | Lowest Rebound Number | Median of the Rebound Numbers | Estimated Compressive Strength of Material or Strength Class [MPa] |

|---|---|---|---|---|---|

| Basement | |||||

| Walls | Plastered ceramic brick | 48 | 35.5 | 37.0 | 11 [42] |

| Ceramic brick | 48 | 50.0 | 55.25 | 43 [43] | |

| Mortar between granite stones | 48 | 24.5 | 26.75 | 8 (German annex to EN 13791) [42] | |

| Granite stones | 36 | 50.0 | 55.0 | 78 [44] | |

| Floor | Reinforced concrete | 36 | 29.0 | 31.0 | C 8/10 (German annex to EN 13791) |

| Ceiling | Reinforced concrete | 48 | 37.0 | 40.25 | C 25/30 (German annex to EN 13791) |

| Foundation (F) | |||||

| Plinth (P), exterior, edgewise position | Ceramic brick | 36 | 49.5 | 54.0 | 45…50 (German annex to EN 13791) |

| Foundation wall (FW), exterior | Granite stones | 12 | 56.0 | 79 [44] | |

| Mortar between granite stones | 12 | 16.3 | 16.3 | 4 (German annex to EN 13791 | |

| P and FW, exterior | Mortar between plinth and foundation wall | 12 | 31.5 | 8 (German annex to EN 13791) | |

| P, interior, edgewise position | Ceramic brick | 48 | 46.5 | 47.5 | 37 [28] 35…40 (German annex to EN 13791) |

| Chimney | |||||

| 19th century chimney | Chamotte brick | 36 | 48.1 | 55.5 | 38 [30] 45…50 (German Annex to EN 13791) |

| Structure | Orientation | Moisture Content (May 2023) | Moisture Content (Oct. 2023) |

|---|---|---|---|

| Load-bearing structures | |||

| External surface of exterior log wall (LW) (without finishing) | south-east (yard) (SE) | 5…8.8% | 5.6…6.2% |

| Internal surface of LW | SE (yard) | 5.5…17.3% | 5.7…5.8% |

| External surface (shadow spot) of LW(without finishing) | SE (yard) | 9.6…20.4% | 5.8…6.5% |

| Timber board surface of LW | north-west (street) (NE) | 5.6…8.9% | 6.2…6.5% |

| Same LW from the interior | NE (street) | 15…17% | 5.7…6.4% |

| Interior LW between old and new building, conducted from both sides | perpendicular to north-west (NW) facade | 5…17% | 5.6…5.8% |

| 19th c. exterior with newer type of facade board | NW (street) | 5.1…10.4% | 5.7…6.0% |

| Roof structures | |||

| Exterior rafters (R), 19th c. | NW (street) | 11…13.4% | |

| Interior R, 19th c. | NW (street) | 12.7…16.2% | |

| Interior R, 19th c. | SE (yard) | 5…14.6% | |

| Queens posts, 20th c. | parallel to NW and SE facades | 10.7…16.4% | |

| Structure | Material | Instrument Orientation | Moisture Level |

|---|---|---|---|

| Basement walls | unplastered ceramic brick | SE | 38…39 |

| plastered ceramic brick | SE | 54…56 | |

| granite stones | SE | 58…59 | |

| lime mortar | SE | 75…76 | |

| Foundation exterior | ceramic brick plinth | SE, NE | 44…45 |

| Walls, exterior surface, 20th c. | uncovered logs | SE | 27 |

| Walls, interior surface, 20th c. | plaster on wooden mesh | SE | 25.5 |

| Walls, exterior surface, 19th c. | facade boards | perpendicular to NW facade | 25…27 |

| Sample | Average Dimensions [m] | Volume [m3] | Mass [kg] | Density [kg/m3] | Flexural Strength [MPa] | Compressive Strength [MPa] | ||

|---|---|---|---|---|---|---|---|---|

| a (Length) | b (Width) | c (Height) | ||||||

| Flatwise position in structure | ||||||||

| Brick T1 | 0.246 | 0.116 | 0.064 | 0.00183 | 3.5 | 1 906.4 | 8.1 | 19.6 20.8 |

| Brick T3 | 0.236 | 0.116 | 0.063 | 0.00172 | 3.3 | 1 924.8 | 8.1 | 31.0 21.2 |

| Brick T4 | 0.253 | 0.121 | 0.061 | 0.00186 | 3.8 | 2 031.3 | 6.8 | 29.4 36.2 |

| Brick T5 Võrukivi | 0.233 | 0.120 | 0.064 | 0.00178 | 3.3 | 1 847.0 | 0.9 | 10.1 20.1 |

| Brick T6 | 0.252 | 0.121 | 0.066 | 0.00203 | 3.8 | 1 885.4 | 6.8 | 33.1 34.4 |

| Brick T7 | 0.245 | 0.121 | 0.063 | 0.00188 | 3.0 | 1 600.0 | 2.1 | 23.3 25.6 |

| Brick T8 | 0.254 | 0.123 | 0.064 | 0.00200 | 3.8 | 1 901.4 | 1.5 | 40.5 24.5 |

| Brick T9 | 0.256 | 0.122 | 0.065 | 0.00203 | 3.8 | 1 857.4 | 7.6 | 29.4 15.5 |

| Brick T10 | 0.253 | 0.123 | 0.065 | 0.00202 | 3.7 | 1 821.3 | 5.0 | 23.1 19.2 |

| Brick T11 | 0.208 | 0.101 | 0.053 | 0.00111 | 2.2 | 1 969.1 | 7.6 | 35.7 28.3 |

| Edgewise position in structure | ||||||||

| Brick T2 | 0.266 | 0.131 | 0.068 | 0.00238 | 4.3 | 1 798.1 | 2.2 | 7.4 8.1 |

| Brick | Dimensions [m] * | Volume [m3] | Mass [kg] * | Density [kg/m3] * | Compressive Strength [MPa] * | ||

|---|---|---|---|---|---|---|---|

| a (Length) | b (Width) | c (Height) | |||||

| VTT65 solid [47] | 0.250 | 0.120 | 0.065 | 0.00195 | 4 | 2 100 | 45.0 |

| FTT65 solid [48] | 0.250 | 0.085 | 0.065 | 0.00138 | 2.8 | 2100 | 45.0 |

| perforated FAT65 [49] | 0.250 | 0.085 | 0.065 | 0.000995 | 2.08 | 1500 | 35.0 |

| Average of samples data | 0.2423 | 0.1183 | 0.0667 | 0.00191 | 3.4 | 1872 | 27.0 |

| Sample | Average Dimensions [m] | Volume [m3] | Mass [kg] | Density [kg/m3] | Bending Strength [MPa] | Compressive Strength [MPa] | ||

|---|---|---|---|---|---|---|---|---|

| a (Length) | b (Width) | c (Height) | ||||||

| Slat P1.1 | 0.613 | 0.047 | 0.047 | 0.00135 | 0.6 | 445.4 | 47.3 42.3 | 3.3 |

| Slat P1.2 | 0.680 | 0.046 | 0.043 | 0.00237 | 0.6 | 409.8 | 54.4 47.3 | |

| Slat P1.3 | 0.570 | 0.046 | 0.044 | 0.00172 | 0.5 | 424.0 | 55.7 48.2 | |

| Slat P1.4 | 0.510 | 0.046 | 0.047 | 0.00185 | 0.5 | 481.0 | 54.4 52.1 | |

| Strength Class of Structural Timber | Bending [MPa] | Compression Perpendicular [MPa] | Mean Density [kg/m3] |

|---|---|---|---|

| C45 | 45 | 2.9 | 490 |

| C40 | 40 | 2.8 | 480 |

| C35 | 35 | 2.7 | 470 |

| C30 | 30 | 2.7 | 460 |

| C27 | 27 | 2.5 | 430 |

| C24 | 24 | 2.5 | 420 |

| C22 | 22 | 2.4 | 410 |

| Sample | Average Dimensions [m] | Volume [m3] | Mass [kg] | Density [kg/m3] | Bending Strength [MPa] | Compressive Strength [MPa] | ||

|---|---|---|---|---|---|---|---|---|

| a (Length) | b (Width) | c (Height) | ||||||

| Log PA1.1 | 0.146 | 0.148 | 0.157 | 0.00340 | 1.9 | 547.4 | 4.2 | |

| Log PA1.2 | 0.136 | 0.140 | 0.140 | 0.00265 | 1.3 | 481.5 | 3.4 | |

| Log PA1.3.11 * | 0.736 | 0.084 | 0.077 | 0.00476 | 2.1 | 436.1 | 24.2 22.8 25.0 | |

| Log PA1.3.12 * | 0.925 | 0.068 | 0.075 | 0.00472 | 2.8 | 585.1 | 35.5 | |

| Log PA1.3.13 * | 0.916 | 0.069 | 0.084 | 0.00526 | 2.3 | 427.0 | 24.5 22.6 22.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gineiko, A.; Kiviste, M. Strength- and Moisture-Related Studies of Historical Building Materials: A Case Study from Southern Estonia. Buildings 2024, 14, 3565. https://doi.org/10.3390/buildings14113565

Gineiko A, Kiviste M. Strength- and Moisture-Related Studies of Historical Building Materials: A Case Study from Southern Estonia. Buildings. 2024; 14(11):3565. https://doi.org/10.3390/buildings14113565

Chicago/Turabian StyleGineiko, Aljona, and Mihkel Kiviste. 2024. "Strength- and Moisture-Related Studies of Historical Building Materials: A Case Study from Southern Estonia" Buildings 14, no. 11: 3565. https://doi.org/10.3390/buildings14113565

APA StyleGineiko, A., & Kiviste, M. (2024). Strength- and Moisture-Related Studies of Historical Building Materials: A Case Study from Southern Estonia. Buildings, 14(11), 3565. https://doi.org/10.3390/buildings14113565