1. Introduction

Construction, following the transportation sector, is one of the economic sectors with the greatest influence on climate change [

1]. The strategy and policy of the European Commission, through a set of climate laws known as the European Green Deal, is to reduce greenhouse gas emissions by at least 55% by 2030. The main aims of the European Green Deal are to enhance the quality of life for people living in and using buildings, reduce Europe’s greenhouse gas emissions, foster digitalization, and improve the reuse and recycling of materials [

2,

3,

4]. Conventional materials commonly used in construction (concrete, steel, ceramics, etc.) meet the requirements set by European construction sector standards, either on their own or with the assistance of other materials, often synthetic (polymeric or mineral). However, these materials have a high carbon footprint or may contain undesirable substances [

5,

6].

The underlying idea of this study is to minimize the effects and offer new solutions to emerging problems in the quest for materials that can be termed as natural [

7,

8], such as gypsum (calcium sulphate dihydrate) and rice straw (

Oryza sativa). The acquisition of these materials involves a lower carbon footprint compared to the aforementioned conventional materials [

9].

For this reason, the use of gypsum and straw is a topic of growing interest in construction due to its sustainability, cost-effectiveness, and insulating properties. In recent years, it has gained relevance because of its ease of installation, which allows for a significant degree of self-building, reducing labor costs as well as construction times. It is being used in modular constructions and environmentally friendly housing. Gypsum with straw is gaining worldwide recognition and has begun to be evaluated under ecological building standards, such as LEED (Leadership in Energy and Environmental Design), as well as the development of specific legal frameworks regulating its use in some countries. In Spain, although its use as a building material is permitted, there is no specific regulation; however, it must comply with energy efficiency, structural stability, fire safety, and moisture protection criteria outlined in the Technical Building Code (CTE).

This material is particularly attractive for sustainable and low-cost housing projects, as well as for eco-communities seeking to minimize their environmental impact. European countries like Germany and France are at the forefront of implementing these construction solutions.

The use of gypsum is supported by centuries of experience [

2,

5,

10]; undoubtedly, common gypsum is one of the construction materials requiring minimal resources for its production while maintaining a high energy–performance ratio [

11]. In the case of rice straw [

12], its use as a construction material would signify the valorization of an agricultural waste [

13,

14,

15,

16], the management of which currently poses an unresolved environmental problem in its cultivation areas [

17]. This issue is evident in both the combustion alternative (CO

2 emissions) and the incorporation into the soil, leading to the proliferation of diseases, phytosanitary problems, an increased need for pesticides, and the generation of methane during the decomposition of the residue.

In this regard, there are references to other developed materials that can be considered as alternatives to conventional ones in terms of their mechanical properties, primarily compression and bending. Interesting results in bending have been achieved for structural elements that combine gypsum (dihydrate calcium sulfate) with macrofibers from common reed (

Arundo donax L.) [

2,

5]. The improvements are based on the increased adhesion of the contact surfaces of both materials, resulting in enhanced bending strength.

Similarly, in addition to mechanical properties, studies have also been conducted on thermal conductivity. It has been found that the addition of fibers increases porosity in the matrix, reducing thermal conductivity, which shows promising results as insulating materials [

18,

19].

It is important to highlight that, besides mechanical properties, there are other aspects in the construction and civil engineering sectors that can also be improved, such as fire resistance or behavior, thermal conductivity (essential for determining the energy consumption of a building throughout its lifespan), and acoustic performance.

In this context, and with the mentioned objective, the possibility of using this natural fiber as an additive in construction binders is proposed, specifically with gypsum (dihydrate calcium sulfate), a material with a low carbon footprint, which has already been tested for use with other fibers, such as reeds (

Arundo donax L.) mentioned earlier; esparto (

Stipa tenacissima) [

5]; or synthetic fibers like carbon, polypropylene, and glass.

Although there are certain possibilities for the valorization of the straw generated in rice production, challenges such as difficulty accessing flooded fields, the potential development of anoxia situations when straw is not adequately managed, low preference of animals for feeding on this type of straw, and issues caused by smoke in communities affected by traditional burning (in addition to those related to the greenhouse effect) point to the necessity of exploring valorization methods.

The high availability and widespread global distribution of both materials also work in their favor, regarding the environmental benefit of local trade [

20], and the resulting material from this addition could be used for manufacturing substitutes for widely used elements, such as masonry tiles or concrete blocks. Unfortunately, the production of the former involves the firing of clay, while concrete blocks rely on cement, both manufactured at very high temperatures with considerable energy consumption.

In the proposed hypothesis of creating elements primarily composed of gypsum and rice straw, the straw, considered an agricultural production residue, would replace a portion of the gypsum used in gypsum-only pieces. This substitution aims to reduce the consumption of the gypsum mineral (alabaster) and, consequently, the carbon footprint associated with gypsum manufacturing, even though it is much lower than that of other materials like cement [

2,

21].

However, it should be emphasized that, in addition to friendly environmental properties, the physical and mechanical properties in the construction and civil engineering sector are very important and have to be guaranteed [

22].

In this study, for the proposed biobased material, specific tests, such as thermal conductivity, flexural and compressive strength, and fire resistance, were carried out to evaluate the principal physical and mechanical characteristics for different compositions of water, gypsum, and straw fibers of the samples.

2. Materials and Methods

Calcium sulphate hemihydrate (powdered gypsum) has been utilized as a binding agent or matrix for the mixing process. This gypsum is categorized as construction gypsum or brown gypsum, according to Standard UNE EN 13279-1) [

18], classification B1, according to the specifications in

Table 1.

The gypsum used in the tests is of the “B1 construction gypsum” type, sourced from the manufacturer Yesos Rubio, located at Av. Juan de la Cierva s/n, CP 30620, Fortuna, Murcia, Spain.

The required water was sourced from the supply network, with the corresponding analysis of its contents available in

Table 2.

The mixture maintains water-to-gypsum ratios (W/G) of 0.5, 0.6, and 0.7, including in the mentioned W/G ratio the water absorbed by the rice straw.

For the handling of the gypsum–water–straw mixture, a retardant additive was employed: gypsum additive patented with registration number P201700812 [

19]. The additive is a super plasticizing and retarding fluidizer composed of colloidal silica dioxide plus citric acid (or polycarboxylic acid), with proportions of 1–3% colloidal silica dioxide and 99–97% ground and sieved citric acid; this combination is used to enhance and prolong the workability of gypsum. The mixtures were manually kneaded, except for drier mixes (with lower water content), where an electric mixer was also used.

On the other hand, rice straw (

Oryza sativa) was used as an addition to the gypsum-additive conglomerate. To create the various samples, two types of fibers were chosen with the premise of keeping the manufacturing process as unaltered as possible (with minimal labor input). For this purpose, “raw straw” fibers were used, without cutting or classification, obtained in the packaged form but naturally dried (outdoors, but covered), and the more processed fiber, “cut straw”, was created using a manual forage cutter. Although it requires prior handling to be introduced into the cutter, its performance is acceptable, and it is easily mechanizable (

Figure 1).

The gypsum that was used does not require any prior conditioning, as it is a commercially available product ready for use (construction gypsum B1/8/2). Apart from the need to prevent the natural hydration of the product, rice straw (

Oryza sativa) delivered in bales has a high moisture content. It requires prior decompaction or opening of the bales and spreading in a covered area until achieving a consistent moisture level (

Figure 1 and

Figure 2).

The remaining materials and equipment that were used are described in each of the tests in which they were employed.

Firstly, the powdered gypsum was kneaded into the water (with the retardant added beforehand to the water), making it rotate while adding the gypsum powder. Once the gypsum was fully incorporated, the mixture continued to rotate until the gypsum lumps disappeared, and subsequently, the predetermined amount of rice straw fibers of the corresponding type were gradually added, while the mixture was continuously rotated, until no dry fibers were visible.

The molds were manually filled with the mixture by pouring without compaction, using fingers to fill all gaps.

The dimensions of the test specimens for each series were selected based on their suitability for various tests to which they were subjected (

Table 3 and

Table 4).

The amount of gypsum, in grams, used in each kneading corresponded to the volume in mm3 of the molds to be filled, plus a 10% excess based on previous experience to ensure there was enough material for filling the molds without wasting the used material. The remaining components of each kneading were calculated as percentages of the amount of gypsum in that kneading.

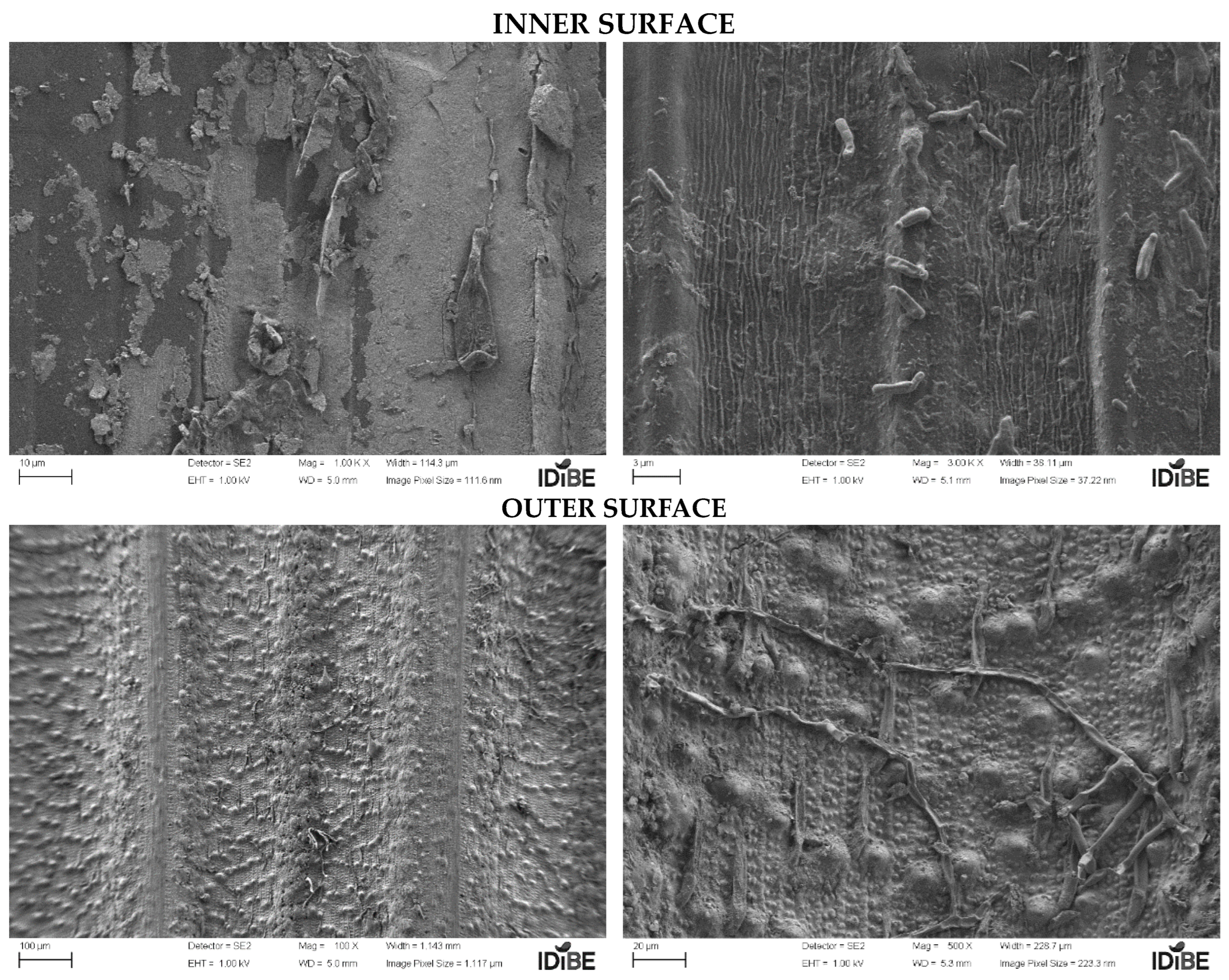

However, rice straw, due to the environmental conditions as a water-excessive crop, not only arrived damp but also presented other issues, such as the occurrence of fungi, as observed in the conducted microscopies (

Figure 2). This implies that drying is necessary. For the construction of raw straw bales—as used in some construction systems currently—this would not be convenient and would require prior fungicidal treatments. However, with the proposed system of using gypsum in the matrix, which acts precisely as a fungicide, this treatment can be avoided. Therefore, the use of calcium sulfate can be an innovative element for combining it with rice straw [

23]. The specimens were demolded 30 min after being filled. Subsequently, they were weighed and left to dry in a laboratory atmosphere, on racks with separation between them to facilitate natural convection drying. The specimens were weighed every 24 h until a constant weight was achieved; this drying process took a few weeks, depending on the water proportions in the mixture and the thickness of the different types of specimens. The various tests were conducted, starting from 60 days after demolding.

The repeatability of the experiment, as far as the manufacture of the test pieces is concerned, regardless of the type of fiber and the water/gypsum ratio used, was based on the proportions of fiber used (with respect to gypsum, which was 8.6%). This parameter is in turn based on the manual mixing time, which was 30 s, after which the setting of the gypsum greatly hindered the homogeneity of the gypsum–straw mixture, and the straw fibers were not well impregnated in the mixture.

After these previous descriptions, an analysis was conducted on certain characteristics of both the straw and the manufactured specimens, including the moisture content of the straw, its size characterization, and the density of the specimens.

2.1. Determination of the Moisture Content

It is crucial to determine the moisture content of the straw to ascertain when its use is feasible and to assess the necessary drying time. This moisture factor influences all aspects of the material as water acts as a conductor and, conversely, as a medium for the propagation of bacteria and fungi. However, in the gypsum matrix, this water can either contribute to its hydration or remain fixed in the matrix for subsequent evaporation.

This test to determine the water content consisting of drying the specimens was conducted through successive weighing of a specific quantity of straw, introduced into an oven at 100 °C, until a constant weight was achieved (

Figure 3). The determination was carried out for the straw both as it was supplied in commercial bales and after opening them and drying them through natural ventilation under cover. By difference, through this test, we obtained the moisture content of the ventilated rice straw (without compaction), which was used in the different mixtures. The straw heated to 100 °C was solely employed for this moisture test.

The moisture content of the straw used to add to the gypsum is crucial when estimating the likelihood of this straw being attacked by fungi or other microorganisms, which could accelerate its decomposition.

2.2. Characterization by Fiber Size

A characterization of raw rice straw (as it was when it arrived packaged and was subsequently dried) was conducted based on fiber sizes. Three samples of 100 g each were taken, with each sample being a random composition of straw collected from 10 different points in the drying area.

The characterization relies on the longitudinal dimension of the straw fibers, as these were horizontally deposited on the various sieves with the help of the eccentric shaker. After 5 min, no variations in the weights collected by each sieve were observed in any case.

Therefore, the straw was passed through stainless steel sieves with the following mesh sizes (in mm): 63/31.5/16/8/4/2/1/rest. The sieves were shaken for 5 min using an eccentric shaker (

Figure 3b), resulting in 8 fractions, and each fraction was weighed using a precision weighing scale (

Figure 3c).

The characterization described refers at all times to the raw straw. Another characterization of sizes for the cut straw would be interesting, especially to dispel doubts about the smaller fractions (<1 mm), which might be considered for removal due to their detrimental effect on mechanical tests.

Density of gypsum and rice straw (Oryza sativa) specimens.

It was necessary to establish the different variables considered when manufacturing the specimens: type of fiber (raw or cut), and the water-to-gypsum ratio in the mixture (W/G ratio: 0.5; 0.6; and 0.7). With the W/G ratio of 0.5, both raw and cut straw were tested, while with the cut straw, W/G ratios of 0.6 and 0.7 were also tested. The resulting series of specimens are shown in

Table 5, along with the numbering of the specimens manufactured for each series.

Raw straw was not tested with different W/G ratios, as the effect of reduced mechanical properties of gypsum is known to increase with the percentage of water in the mix. In this case, the tests from series 2, 3, and 4 (with cut straw) serve to contrast these results.

To measure the density of the specimens from different series (specimens of type A were used), the real dimensions of the specimens needed to be considered. While the length and width were deemed valid as they corresponded to the dimensions of the completely filled molds, the same did not apply to the thickness of the specimens. The upper surface of the specimen had not been manually planed and highlighted some irregularities; therefore, the thickness was considered as the average of the measurements taken at the four corners of the specimens using a manual or digital caliper. This resulted in different theoretical (mold) and actual volumes (measurement), and hence, different densities (

Figure 4 and

Figure 5).

2.3. Determination of the Saturation Amount of Straw in the Mixing Process

Another necessary determination for the entire test was the amount of straw to be used in the mixtures, expressed as a percentage of the gypsum mass.

This determination is crucial since, a priori, it is desirable for this quantity to be as high as possible. A higher amount of straw is a priori related to more voids, resulting in lower material weight and increased thermal resistance.

The procedure involves manual mixing, gradually adding straw until a point called “saturation” is reached, at which the added straw is not sufficiently impregnated with the gypsum and water mixture (lack of bleaching of the straw); additionally, an excess of straw hinders the manual filling of the molds, and these two indicators define the aforementioned point of “saturation” of straw in the mixture.

The obtained result, as an average of several tests performed under the same conditions, was 86/1000 (kg straw/kg gypsum) (8.6%). This percentage was also maintained for the tests conducted with cut straw; therefore, the mixtures for the specimens in all series were prepared with this proportion of straw.

As observed, the discovery of this saturation amount of straw was directly related to the mixing technique, so that improving this technique could likely achieve higher saturation doses. However, the ultimate purpose of the test was to find a dose of straw fiber in the kneading that is as high as possible and consistent across all series of specimens.

In addition to the previous determinations, the tested properties included flexural strength, compressive strength, the thermal conductivity test, and the fire resistance test.

2.4. Flexural Strength Test

For the mechanical tests, the methods described in the CEN-EN 13279-2 [

24] were utilized, and the calculation of flexural strength was conducted using a Universal Testing Machine (Controls brand, Italy) (

Figure 6) with a maximum load of 145 tons, equipped with data acquisition hardware using ARDUINO, as well as a real-time display of specimen break curves (N-mm) through MATLAB software (R2006b). The specimens had dimensions of 160 × 40 × 40 mm (specimen type A), conforming to the mentioned standard for testing methods for construction gypsum.

In addition to these specimens, those of type H were also tested, which more closely resemble conventional ceramic bricks, the elements they would ultimately be intended to replace.

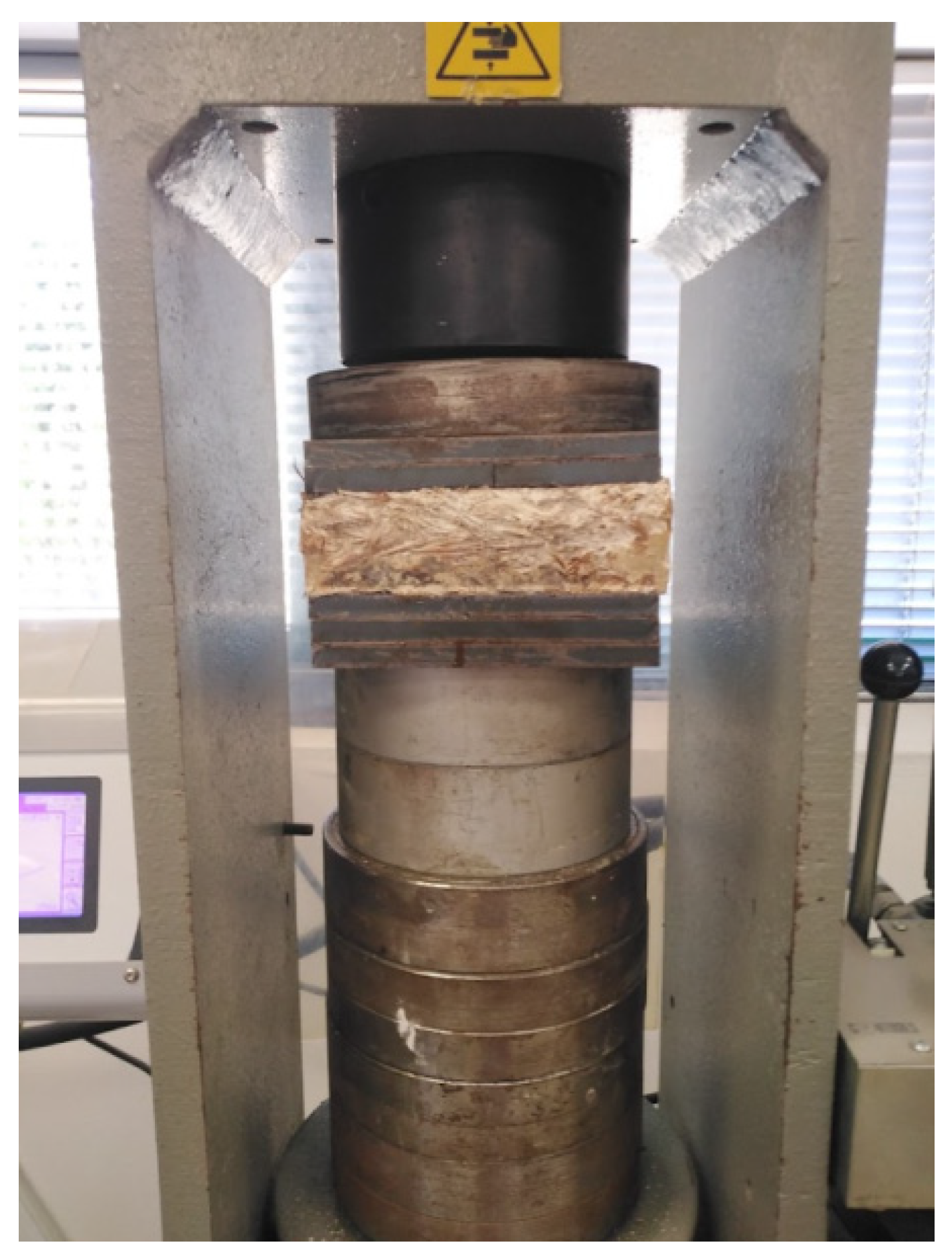

2.5. Compressive Strength Test

For gypsum-based binding materials, the minimum compressive strength the material must withstand is ≥2.00 N/mm2, according to the UNE-EN 13279-1 Standard Definitions and Specifications (CEN-EN 13279-1, 2008).

The compressive strength mechanical test was conducted on the same Universal Testing Machine used for flexural testing. The specimens had dimensions of 40 × 40 × 40 mm (standardized), obtained from the remaining ends of the previous flexural test; additionally, specimens of type E were tested due to their size and similar shape to real elements (solid ceramic bricks) (

Figure 7).

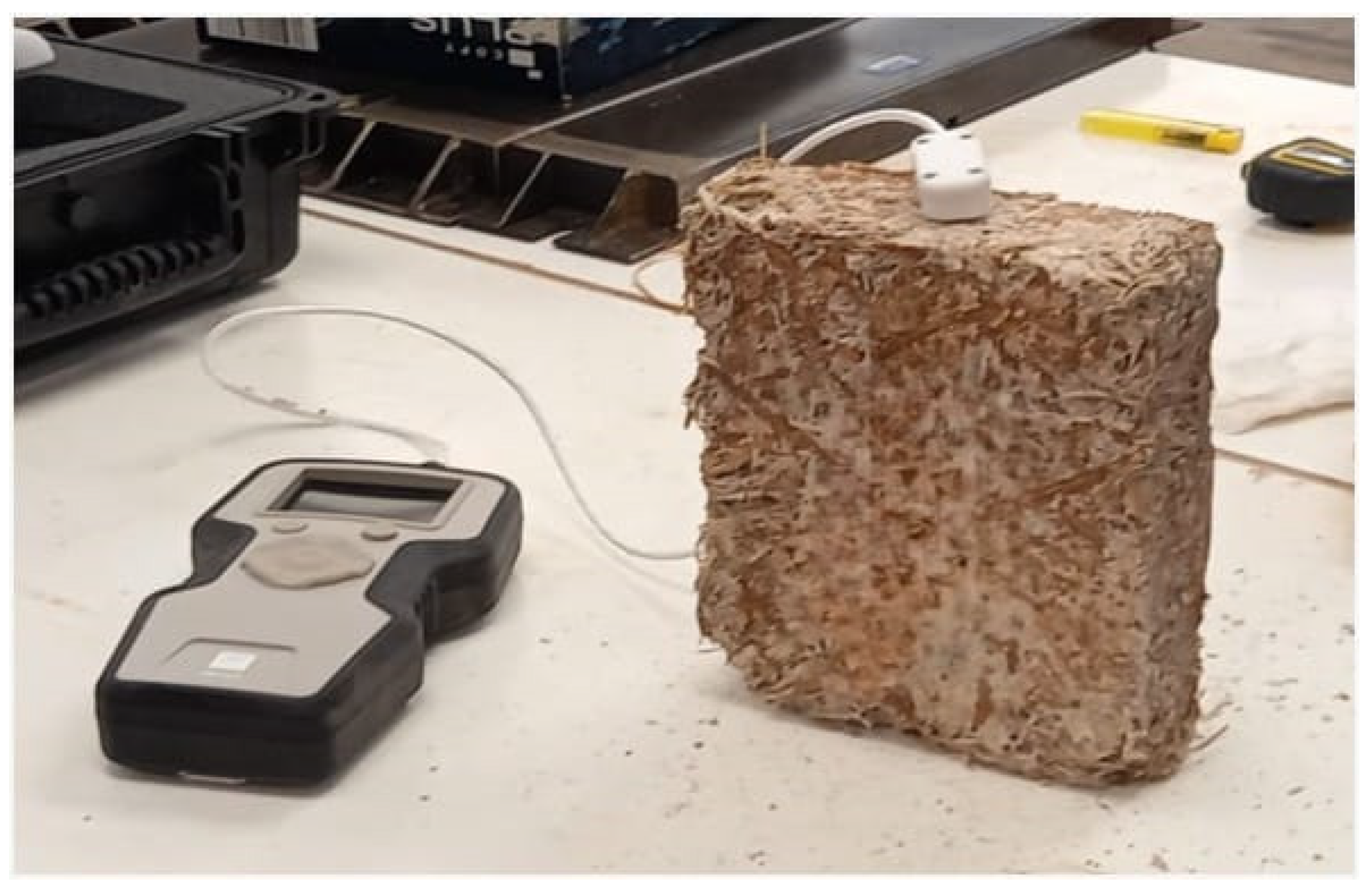

2.6. Thermal Conductivity Test

The thermal conductivity was tested on specimens of type E using the Tempos Meter needle equipment, as well as on other specimens, type I specifically, with the Lambda Conductometer. The thermal conductivity test with the Tempos Meter equipment (

Figure 8) is based on the variation in the transmission of an electric signal due to the temperature difference between two points in a material. This is facilitated by a 100 mm metal probe inserted into the material through a previously made perforation. Several specimens from each series were tested to calculate the average results of the obtained conductivity (W/mK), and the data were collected from all four sides of the edge of each specimen.

On the other hand, the thermal conductivity test with the Lambda equipment was based on the heat transmission from a known source through the specimen of the material being analyzed [

25]. These specimens were manufactured with the material corresponding to the different series from the rest of the tests (type of straw and W/G ratios), but the dimensions, in this case, were specific to the test with this equipment (300 × 300 mm and between 10 and 20 mm thick). In the case of the test with the Lambda equipment, due to the difficulty of achieving a perfectly flat manual finish on the upper faces of the specimens (without formwork), it was necessary to polish them to achieve a constant thickness throughout the piece. The polishing was performed with the help of a rotating cardboard sanding belt machine.

2.7. Fire Resistance Test

To assess the material’s durability under direct exposure to fire, testing was conducted on specimens of type C and D, using a propane-fueled torch (

Figure 9).

The temperature reached at the torch’s tip is 1000 °C, and the exposure was conducted at that temperature. For the test, 5 probes (thermocouples) were placed on the backside (non-exposed), along with an additional control probe on the exposed face to measure the test temperature.

The probes were inserted 5 mm into the interior of the material, while the torch was positioned 100 mm from the exposed wall, varying in each test based on the thickness of the specimens (30/50 mm).

The test must conform to a standardized fire curve according to the CEN EN 1363-1:2000 standard [

26]—this standard indicates that the test concludes when the increase in the average temperature of the probes on the non-exposed face, over the initial average temperature, exceeds 140 °C, or when the temperature increase at any point on this non-exposed face does not exceed the initial average temperature by more than 180 °C. The results were recorded in a data logger that registers temperature measurements from all probes at 10 s intervals.

3. Results and Discussion

Results of the determinations and tests conducted are presented below:

3.1. Moisture Content of Rice Straw (Oryza sativa)

The determination of moisture content through successive weightings in a 100 °C oven yielded the following values:

- -

Moisture content of rice straw from the interior of the commercial bale, measured upon bale opening: 17.58% (mass percent) of the total wet straw.

- -

Moisture content of rice straw from opened bales previously dried by natural ventilation until reaching constant weight: 7.08% of the total wet straw.

This determination highlights the hygroscopic nature of the analyzed material, capable of retaining more than double the moisture when compacted (baled). This characteristic can impact the material by promoting fungal growth and accelerating decay.

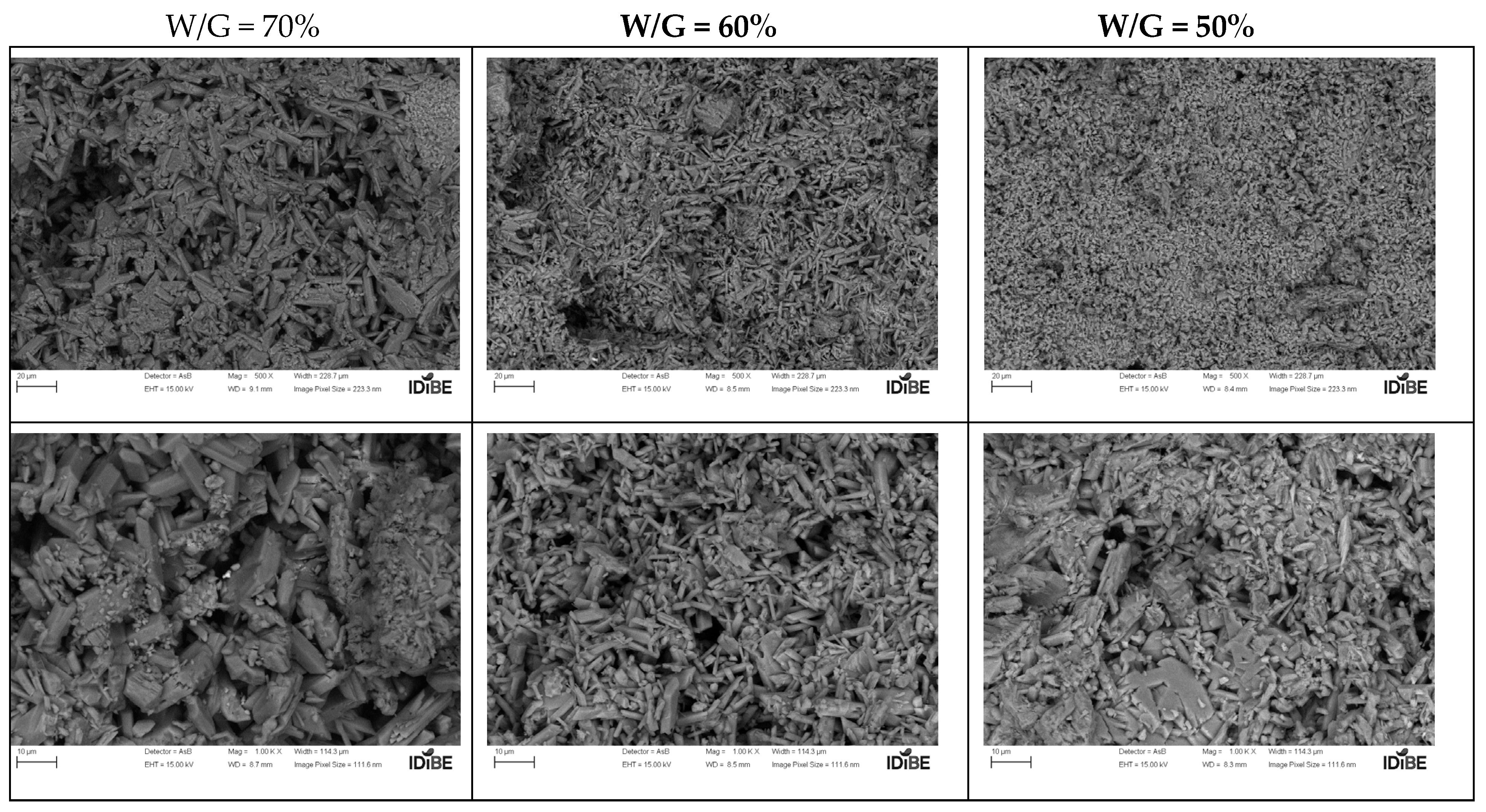

The inner and outer surfaces of the blade, as well as the calcium sulphate matrix with the addition of different water contents (

Figure 10), were observed using a scanning electron microscope (

Figure 11).

The grain size varies depending on the setting time, and this is influenced by the amount of water added to the matrix. For a specific mechanical strength, the ratio that performs best is the one with the least amount of water. However, the straw–gypsum conglomerate is complicated by the lack of fluidity in the mixture.

On the other hand, it is also important to consider this characteristic when producing mixtures with different binders for use in construction. In each case, the water content provided by the straw itself should be taken into account. It was observed that the mixing water amounts, W/G, as indicated by 0.5, 0.6, and 0.7, included the proportion of mixing water added to what the straw absorbs when dry. This could potentially reduce the ratio in cases where the straw contains more moisture.

Through the conducted tests, it was verified that specimens manufactured with naturally dried straw (with a moisture content of 7.08%) and kept in a laboratory atmosphere showed no signs of fungal attack on the straw. In contrast, the same gypsum and straw specimens submerged in water until all occluded air was expelled (completion of bubble emission), and subsequently dried in a laboratory atmosphere, exhibited clear signs of decay after 72 h (

Figure 12a–c).

These verifications validate the indoor use of gypsum specimens with rice straw, as no biological degradation was observed, provided that, at the very least, they were previously dried indoors with natural ventilation.

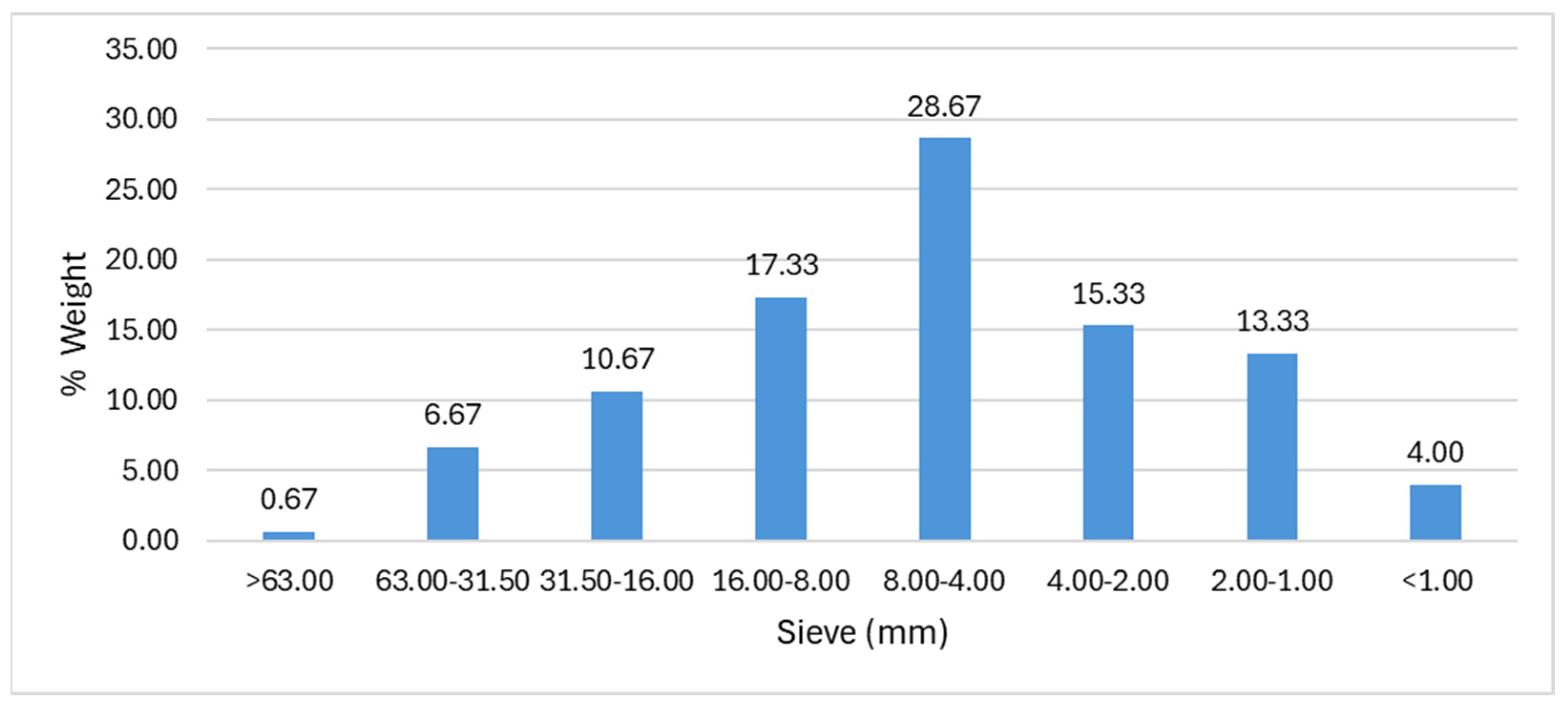

3.2. Characterization of Rice Straw (Oryza sativa) by Sizes

Figure 13 presents the quantities recorded for each of the eight size fractions of the considered fibers, along with the percentages of each fraction relative to the total analyzed sample. A total of 88.66% of the fibers was found in the central five fractions, ranging from 1 mm to 31.5 mm. The remaining fibers below 1 mm (4%) could be disregarded, as they are practically a powder that lacks the binding effect on the binder and rather adversely affect its mechanical properties [

27]. In the conducted tests, given the small percentage of fibers < 1 mm, this fraction was not removed, although this effect should be the subject of a specific analysis. On the other hand, the fractions above 31.5 mm, representing 7.34% of the sample, although complicating the mixing process, could be interesting to include due to their greater binding effect on the gypsum matrix.

3.3. Density of Gypsum and Rice Straw (Oryza sativa) Specimens

For each of the four main series of manufactured specimens of type A, their average real densities are shown in the following

Table 6.

In the previous

Table 4, it was observed how, for the same W/G ratio of 0.5, there was a reduction in density when adding rice straw compared to specimens with only gypsum (11.5% with raw straw and 7.2% with cut straw). This result is very interesting as it signifies a reduction in self-weight for structural calculations.

On the other hand, it was observed that for the same ratio (W/G = 0.5), the specimens with “raw straw” had a lower average density than those manufactured with “cut straw” (4.9% lower). This result is associated with a higher proportion of voids in the filling of the specimens with larger fibers (“raw” fiber) compared to those with smaller fibers (“cut” fiber), although this outcome is not statistically significant given the high variability in the individual results obtained.

Furthermore, for the series with “cut” fiber type, the average real density of the specimens decreased as the mixing water ratio (W/G) increased, confirming the behavior observed in previous studies [

28] conducted with gypsum only (without straw).

All density results with any type of straw fibers in gypsum, compared to results with gypsum only, led to a decrease in the density of the specimens, regardless of water ratios, fiber type, specimen type, or the addition of additives to prolong setting time.

In

Figure 14, an image of a specimen surface can be observed, showing the voids created by the incorporation of straw fibers, causing a decrease in density in the specimens, as well as their anchoring in the gypsum matrix. The mentioned voids also contribute to the reduction of thermal conductivity by increasing the amount of air in the material.

3.4. Amount of Rice Straw (Oryza sativa) at Saturation in Mixing

The result obtained, as an average of several tests conducted under the same conditions, was 86/1000 (kg straw/kg gypsum) (8.6%). This percentage remained consistent for tests conducted with both “raw” and “cut” straw. Consequently, with this straw proportion, the mixtures for all series of specimens were prepared.

3.5. Flexural Strength of Gypsum and Rice Straw (Oryza sativa) Specimens

Table 7 presents the results of the flexural test (average breaking load in N) for specimens of type A for each of the four tested series. The flexural results for gypsum-only specimens are also included.

In view of these results, a clear improvement in the performance of raw fibers compared to cut fibers was observed for the same W/G ratio: 0.5 (series 1 and 2) up to 248%. This improved performance is attributed to a greater anchoring effect of the fibers in the gypsum matrix as they were longer (

Table 7).

As expected from previous studies [

29], the gypsum-only control specimen yielded better results in flexural strength (and also in compression) compared to the rest of the series. However, it has the significant drawback of a very fragile failure mechanism, which largely nullifies its use as a load-bearing element without adding some type of fiber.

On the other hand, the superior performance of specimens made with “raw straw” compared to those made with “cut straw” was also repeated for the specimens of type H, as can be seen in

Table 8, with the difference being even greater in this case (321% higher).

However, the results obtained when varying the water ratio in the gypsum conglomerate were contradictory in the case of specimens of type A compared to those of type H. While, for the former, the maximum breaking load progressively decreased with the water ratio in the mix (as expected due to a greater presence of pores in the conglomerate), in the case of the latter, the flexural strength increased as the water ratio increased.

This contradictory result could be due to the greater ease in the manufacturing of large specimens (specimens of type H) as the W/G ratio increases. By increasing the fluidity of the mix with more water, filling the molds is facilitated, and they have fewer voids, a condition much more difficult to achieve for small specimens (specimens of type A).

In either case, a substantial improvement in the flexural failure mechanism [

30] was observed for all specimens containing any type of straw, shifting from “brittle” failure for “gypsum-only” specimens to a progressive “quasi-ductile” failure for those with straw. The straw absorbs the tensions in the fracture section from the moment the first crack occurs, even being able to maintain loads with slight increases in deformation. In

Figure 5, the anchoring of straw fibers in the gypsum matrix, responsible for the overall better performance of the specimens in mechanical tests, can be appreciated.

3.6. Compression Strength of Gypsum and Rice Straw (Oryza sativa) Specimens

In

Table 9, the average compressive strength data (N/mm

2) are reported for the four tested series for the specimen type specified in the previous standard (specimens of type A).

With these results, no significant difference was observed between the use of “raw” straw and “cut” straw. However, for the case of “cut” straw, a reduction in compression strength was noticeable as the water proportion in the mixture with gypsum increased (W/G).

On the other hand, as with the flexural test, there was a modification in the fracture process or mechanism of the specimens with straw compared to those with only gypsum. They transitioned from a “brittle” fracture (with little deformation or crushing) to a “plastic” fracture (with greater deformation or “crushing”), due to the effect of “consolidation” or “binding” of the conglomerate material by the addition of straw.

In any case, the obtained strengths were well above the requirements specified by the aforementioned standard.

3.7. Thermal Conductivity with a Tempos Meter

This test was conducted on specimens of type E, with the insertion of a 100 mm probe. Multiple specimens from each series were tested to calculate the mean of the found conductivity results (in W/mK). Additionally, data from all four sides of the edge were collected for each specimen. The average of the obtained results is presented in

Table 10.

The results indicate a better performance of the raw fiber compared to the cut fiber regarding thermal conductivity. This is interpreted as a higher presence of voids when using “raw straw” compared to “cut straw”, and therefore, a lower density (as mentioned in section above).

On the other hand, for the type of cut fiber, the effect of the increased water-to-gypsum ratio (W/G) seemed to be rather masked by the use of the fiber. One might expect a progressive and clear reduction in thermal conductivity as the W/G ratio increases, but this is not reflected in the obtained results.

3.8. Thermal Conductivity with Lambda Equipment

For this test, specimens of type I adapted to the Lambda equipment (300 × 300 × 15 mm) were manufactured, similar to gypsum laminated products. Additionally, for both fiber types (raw and cut), the three W/G ratios were tested. The obtained results are presented in

Table 11.

Compared to the commercial 15 mm gypsum laminated product (0.250 W/mK), a significant reduction in conductivity was observed with the addition of “raw” or “cut” straw.

For the “raw” straw type, conductivity decreased as the water proportion in the mixture (W/G) increased, as expected. However, the same trend was not observed for the “cut” straw series. There was also no discernible stable trend for this fiber type. It is noteworthy that there was a range of lower thermal conductivity results for “raw” fiber compared to “cut” fiber, with average values of 0.101 W/mK for “raw” fiber and 0.136 W/mK for “cut” fiber. This indicates a better insulating performance of pieces manufactured with “raw” fiber compared to those made with “cut” fiber.

This enhanced thermal performance of “raw” straw over “cut” straw aligns with the findings from the Tempos Meter equipment and suggests a higher presence of voids when working with “raw” straw.

The use of bio-based insulation material in the building sector not only improves the buildings health indoor quality for the occupants but also improves the building’s energy efficiency and reduces the greenhouse gas emission [

31].

3.9. Fire Resistance Test

The obtained exposure time results for different thicknesses, fiber types, and W/G ratios are presented in

Table 12.

Firstly, we highlight a positive aspect: calcium sulphate delays the deterioration and ignition of straw when exposed to fire, preventing rapid fire propagation within the gypsum matrix.

In the flame application zone, surface deterioration of the specimen was observed, which increased as the W/G ratio rose due to a more porous matrix (lower density). This translates into shorter exposure times to reach 180 °C on the unexposed face, and simultaneously, the reduction in exposure times with an increase in the W/G ratio was more noticeable for thicker specimens (50 mm) than for thinner ones (30 mm). This corresponds to the typical heat transmission curve in fire resistance tests.

Furthermore, comparing both fiber types at a W/G ratio of 0.5, better performance was observed for “cut” fiber over “raw” fiber for both tested thicknesses (30 mm and 50 mm). This is interpreted as greater difficulty for fire penetration into the specimen when the fibers are shorter.

It is important to highlight that the fire exposure time could be raised with the techniques of partially carbonizing the biomass [

32,

33]. In fact, the carbonization process can increase the ignition temperature of the straw fibers, and the distribution of carbonized wheat straw in composite insulation materials is more uniform and therefore smoke is less because of the decrease in particle size and volatile content and protocols associated with the publication available to readers.

4. Conclusions

Initially, the outstanding thermal conductivity of gypsum (around 0.250 W/m·K, depending on the type of gypsum and water proportions in mixing) can be enhanced in a mixture with rice straw fibers when voids or spaces that can contain entrapped air are generated. The incorporation of fibers into a gypsum matrix serves as reinforcement, potentially providing increased flexural strength and ductility, as well as improved modulus of elasticity. Nevertheless, the material must maintain acceptable mechanical properties, demonstrating a minimum compressive strength of around 4 N/mm2, as indicated by the obtained results, which depend on the water proportion in the mixing. As mentioned, the use of low-hydration gypsum additives enhances the overall performance of both materials, making them suitable for specific applications in the construction sector, being even more environmentally friendly.

This study began with the observation that calcium sulfate, using a low amount of hydration water, achieved compressive strengths of up to 22.3 N/mm2 at maximum values and averages of 15.2 N/mm2. In this case, the binding material is a crucial factor in obtaining the appropriate conglomerate for use in construction. However, as is discussed in the Materials and Methods section, the amount of water used cannot be minimized to the level required for the hydration chemical reaction, as this minimum amount would impede the mixing of straw with gypsum

Following the conducted experiments, the following conclusions have been drawn:

In the manufacturing processes of construction elements incorporating rice straw, it is imperative to consider the initial moisture content of the straw. This factor can exceed twice the moisture content of the dried straw, significantly impacting the proliferation of fungi that expedite straw decay, as substantiated by observations in test specimens exposed to drying for 72 h subsequent to immersion in water.

It is advisable to conduct a preliminary selection of straw based on fiber sizes, discarding excessively small fibers lacking anchorage capacity within the matrix (which adversely affect the mechanical properties of the matrix). Similarly, excessively large fibers pose challenges during compounding, while ensuring a minimal deduction in the total material employed (11.34% of the total).

The utilization of “raw” or “cut” fibers did not exert a significant impact on the density of the manufactured specimens, under the premise of maintaining all other conditions constant. However, a noticeable decrease was observed in both cases when compared to specimens composed of gypsum only, approximating around 10% depending on the type of fiber employed. Additionally, the well-established effect of increased water-to-gypsum ratio (W/G) on the density persisted with the incorporation of rice straw.

The maximum amount of rice straw that the gypsum mixing process can accommodate, irrespective of the straw type (“raw” or “cut”), is around 8.6% relative to the mass of gypsum used. Mixing becomes considerably challenging beyond this proportion.

No effect was observed on the tested properties when the length/diameter ratio was modified, as the kneading process caused the straw fibers to flatten, nullifying their “diameter” effect.

The flexural behavior of specimens fabricated with “raw” straw surpassed that of specimens produced with “cut” straw. This improvement is attributed to the increased anchoring length of fibers in the gypsum matrix, positively influencing the tensile zone of the cross-section. Within the same fiber type, the flexural behavior exhibited contradictory trends as the water-to-gypsum ratio (W/G) increased, contingent upon the type of specimen under examination. This phenomenon is correlated with variations in the ease, skill, or diligence applied during the mold-filling process. In any case, a significant enhancement in the fracture mechanism of specimens is evident when supplemented with any type of straw, as opposed to those composed with gypsum only, transforming the “brittle” fracture of gypsum into a “quasi-ductile” fracture one in the presence of straw.

The compressive strength, in comparison to gypsum alone, experienced a reduction of over 50% with the inclusion of rice straw in the analyzed doses. Nevertheless, the values obtained from the tests continued to render the compressive use of straw-incorporated pieces viable. Additionally, the compressive strength was not significantly affected by the type of straw; however, in the case of tested cut straw, it was influenced by the water-to-gypsum ratio in the mixture. This strength decreased as the W/G ratio increased, analogous to the behavior observed with gypsum alone.

The thermal conductivity was lower with “raw straw” compared to “cut straw”, as evidenced by the Tempos Meter conductivity test. However, the impact of increased water-to-gypsum ratio (W/G) on thermal conductivity remained unclear when utilizing “cut straw”, with conflicting results observed.

In the Lambda equipment conductivity test with laminated products, a noteworthy reduction in thermal conductivity was achieved by incorporating rice straw (approximately 50% compared to products composed gypsum only). Furthermore, superior insulation was observed with “raw straw” compared to “cut straw”, aligning with the findings from the Tempos Meter equipment. However, the typical positive effect on insulation as the W/G ratio increased was disrupted with “cut straw” fiber in this case.

Fire reaction was better for “cut” fibers, although “raw” fibers still yielded very high exposure times, with gypsum preventing the ignition spread in either fiber type.

The results highlighted the good performance of the proposed material in order to spread its use in the green building industry. Nowadays, many gypsum components are used in construction, such as wall panels, brick blocks, false ceilings, and divisor elements. The addition of straw fibers improves, in different ways, some important physical characteristics of these components, so as to diminish environmental pollution and to obtain better material performance [

34,

35]. In particular, the straw fibers improve the compression strength and the thermal resistance of the gypsum more than other vegetal fibers [

36,

37,

38]. The tests have highlighted the different behaviors of the proposed material with respect to the different cuts of the straw and as well as the water/gypsum rate; this is not very well understood and probably depends on the micro structure of the straw fibers. Future researchers should address the mechanisms that are at the base of these particular behaviors.