On-Site Measuring Robot Technology for Post-Construction Quality Assessment of Building Projects

Abstract

1. Introduction

2. Objectives

- (1)

- Unmanned oversight of the measurement process: the robot is capable of independently navigating and moving throughout the construction site, adapting to uneven and rugged terrain while executing its tasks.

- (2)

- Automated measurement task planning: the robot can autonomously plan measurement tasks for site, including determining the measurement path, identifying measurement points and the corresponding parameters to be measured along the path.

- (3)

- Non-contact acquisition of highly accurate measurement data: the robot should have the capability to obtain highly accurate measurement data using non-contact measurement methods.

3. Methodology

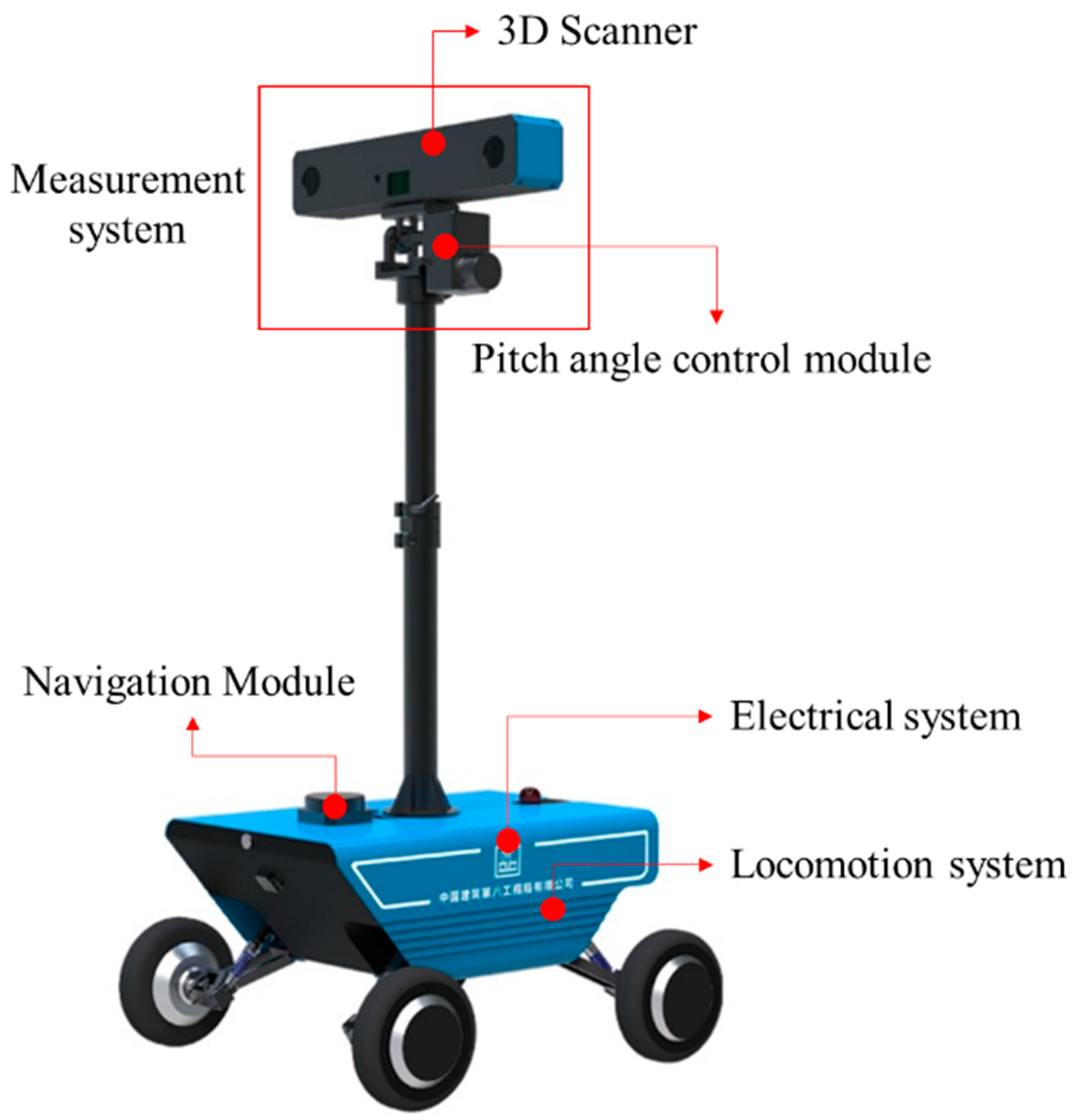

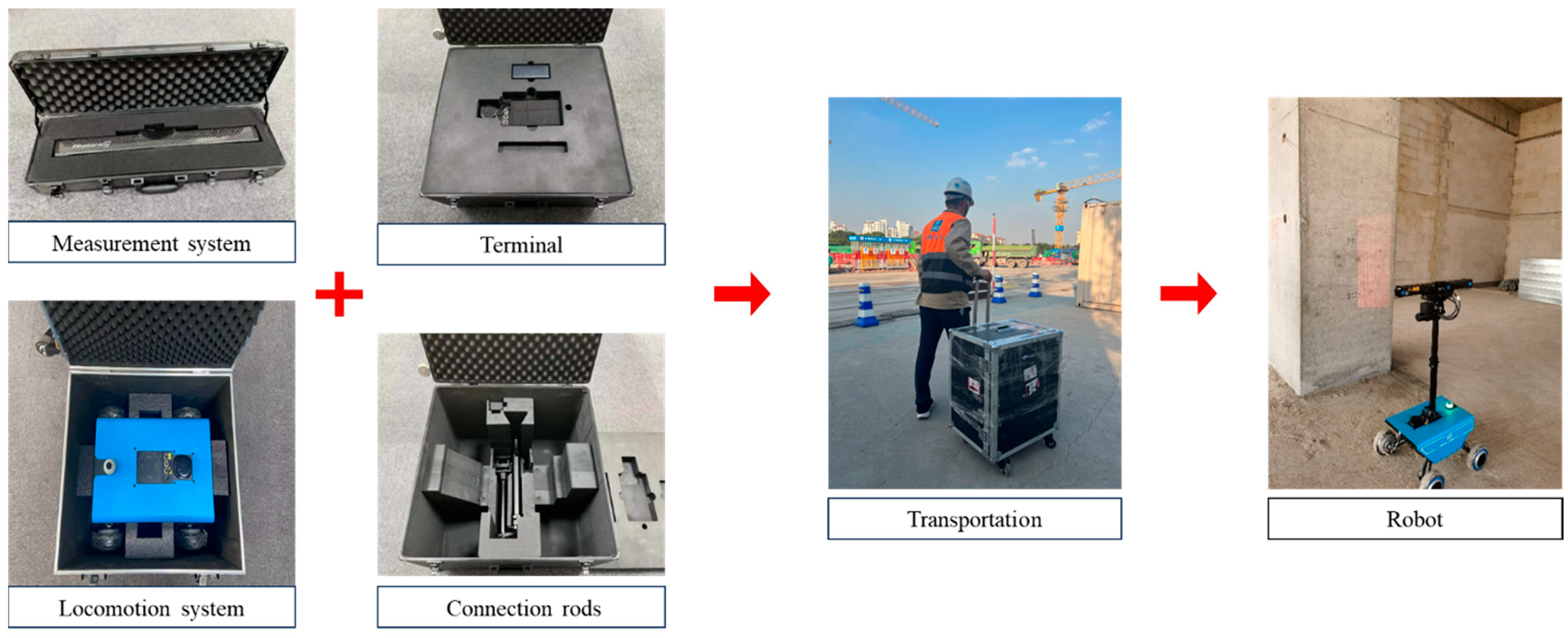

3.1. Design and Configuration of Hardware Systems

3.1.1. Overall Mechanical Design

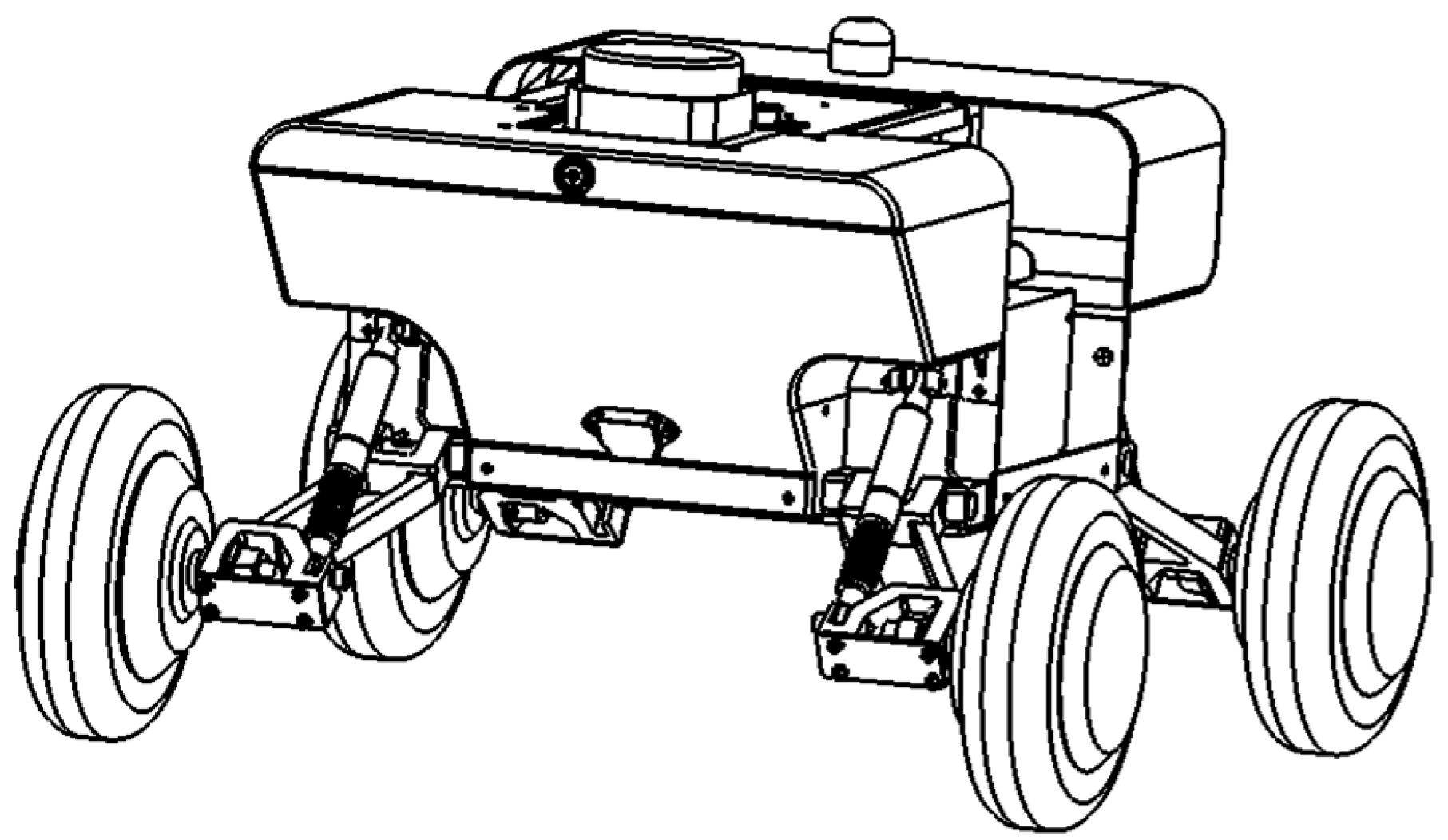

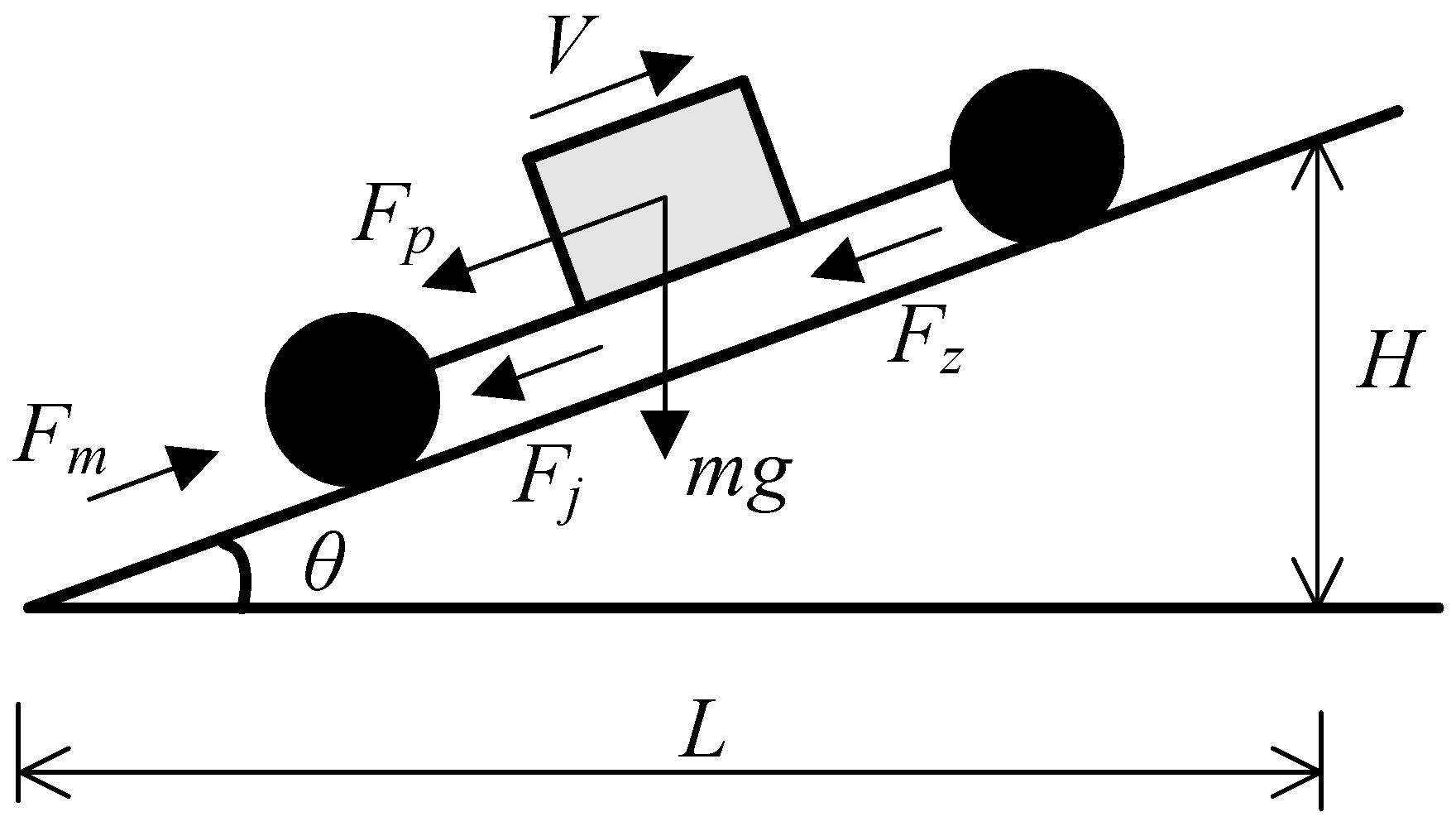

3.1.2. Locomotion System

3.1.3. Electrical System

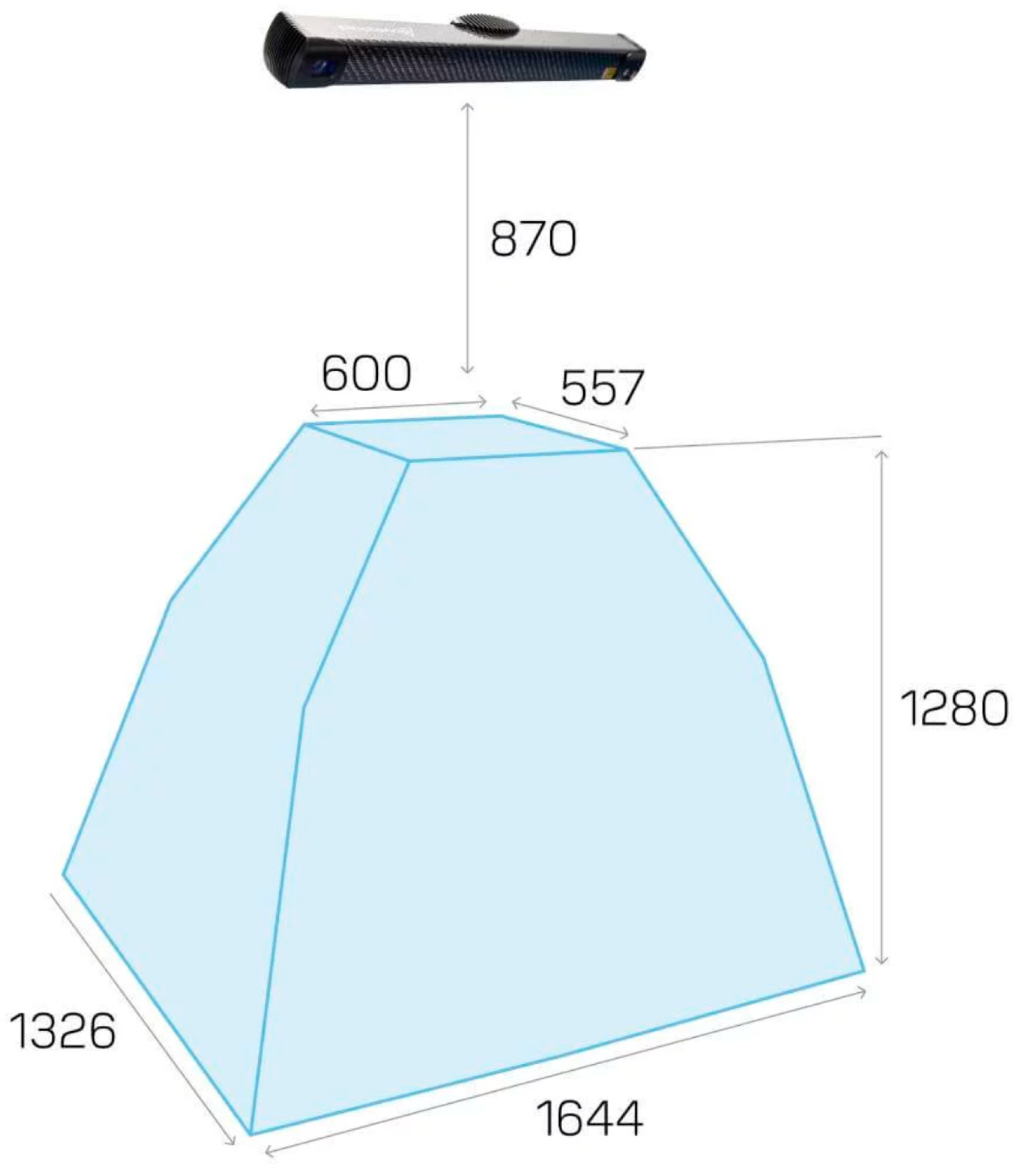

3.1.4. Measurement System

3.1.5. Navigation System

3.2. Development of Key Algorithms

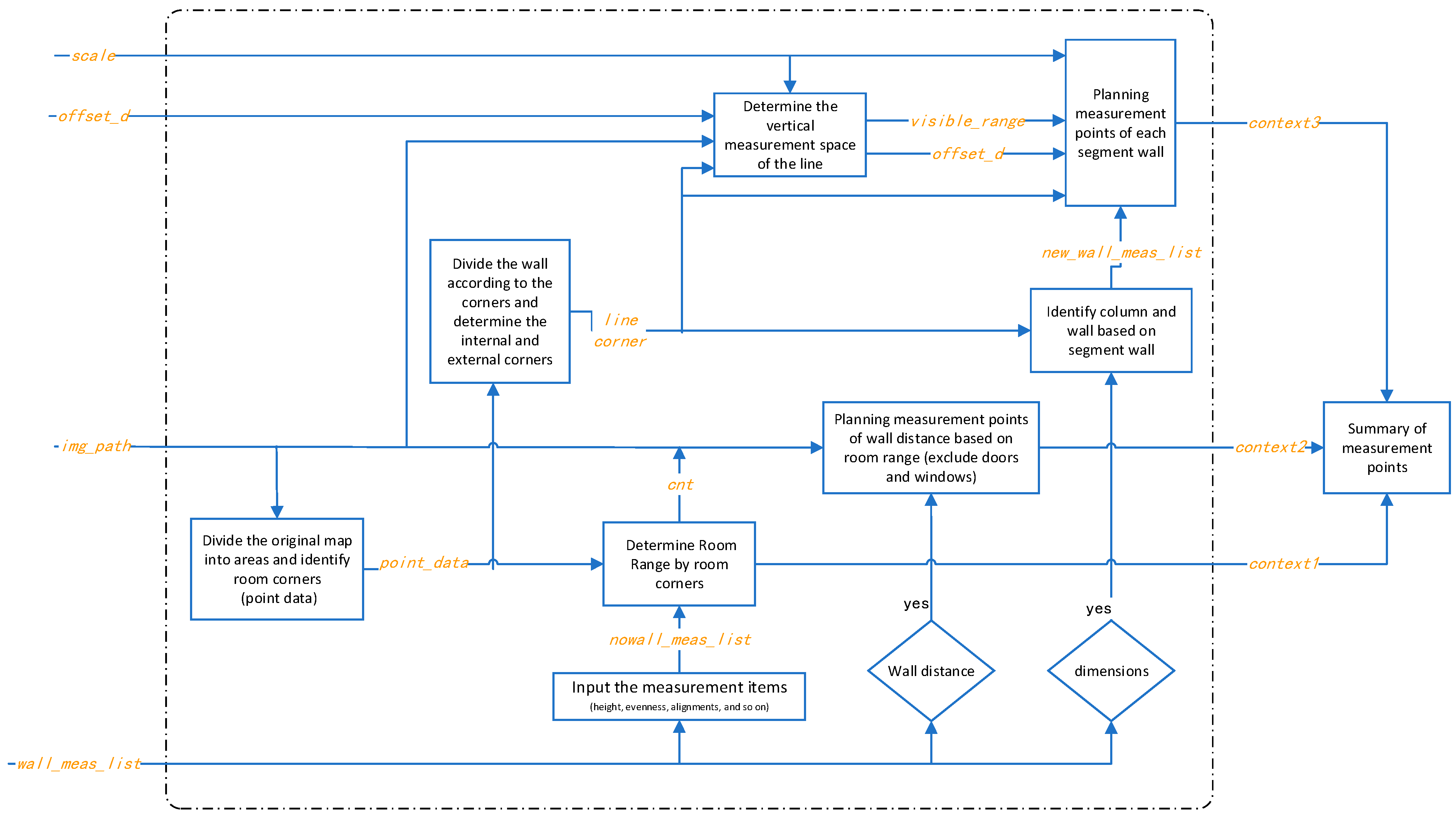

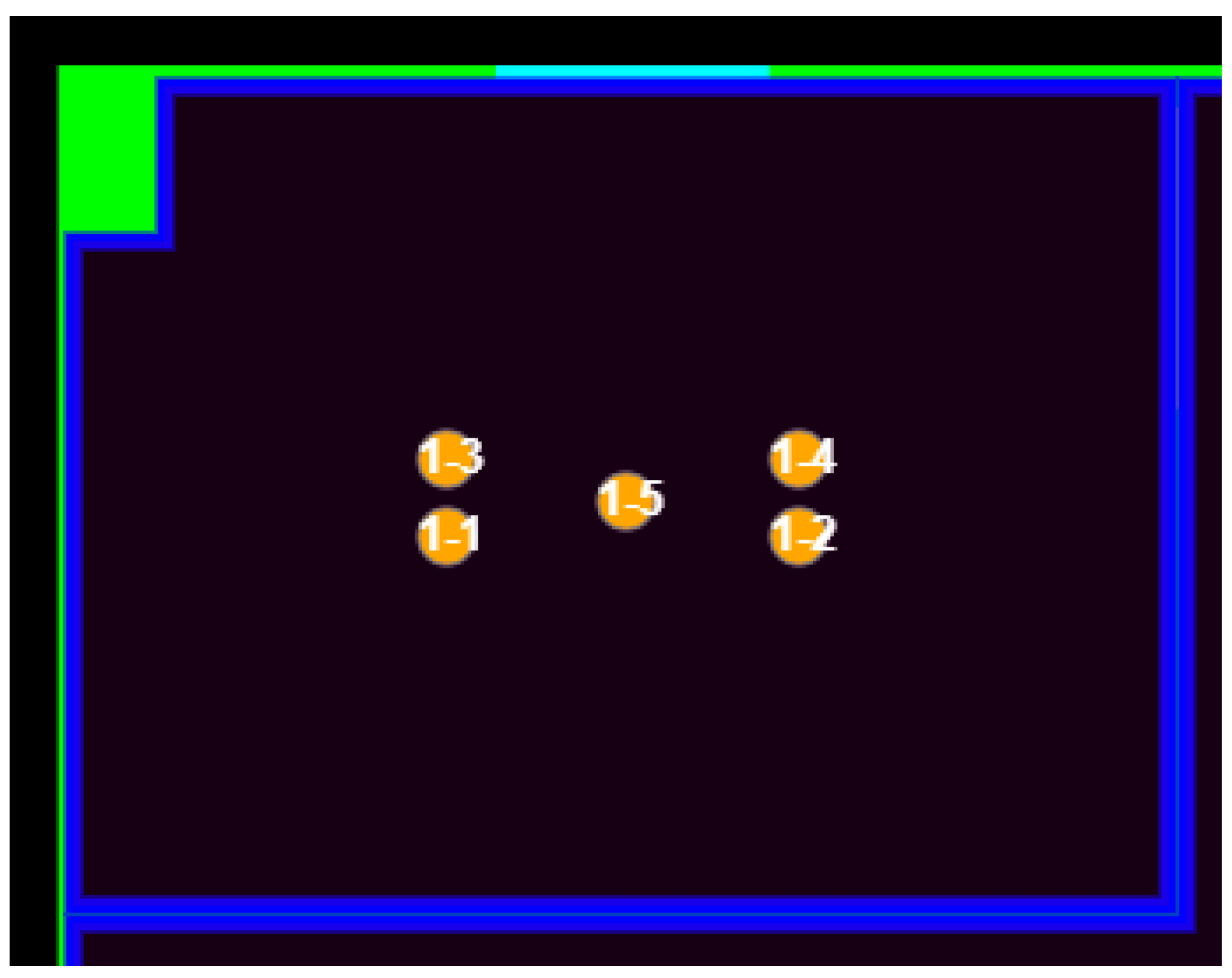

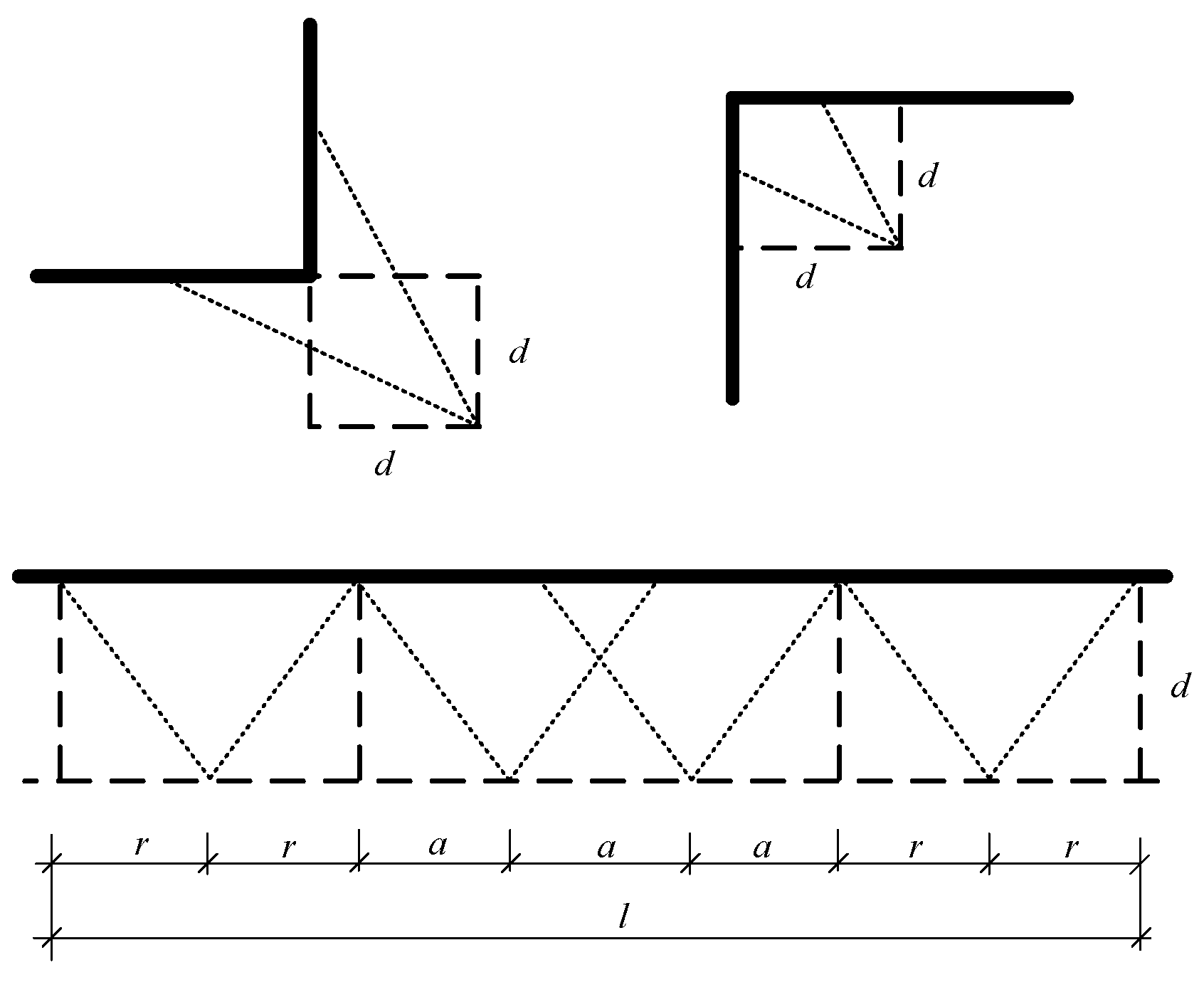

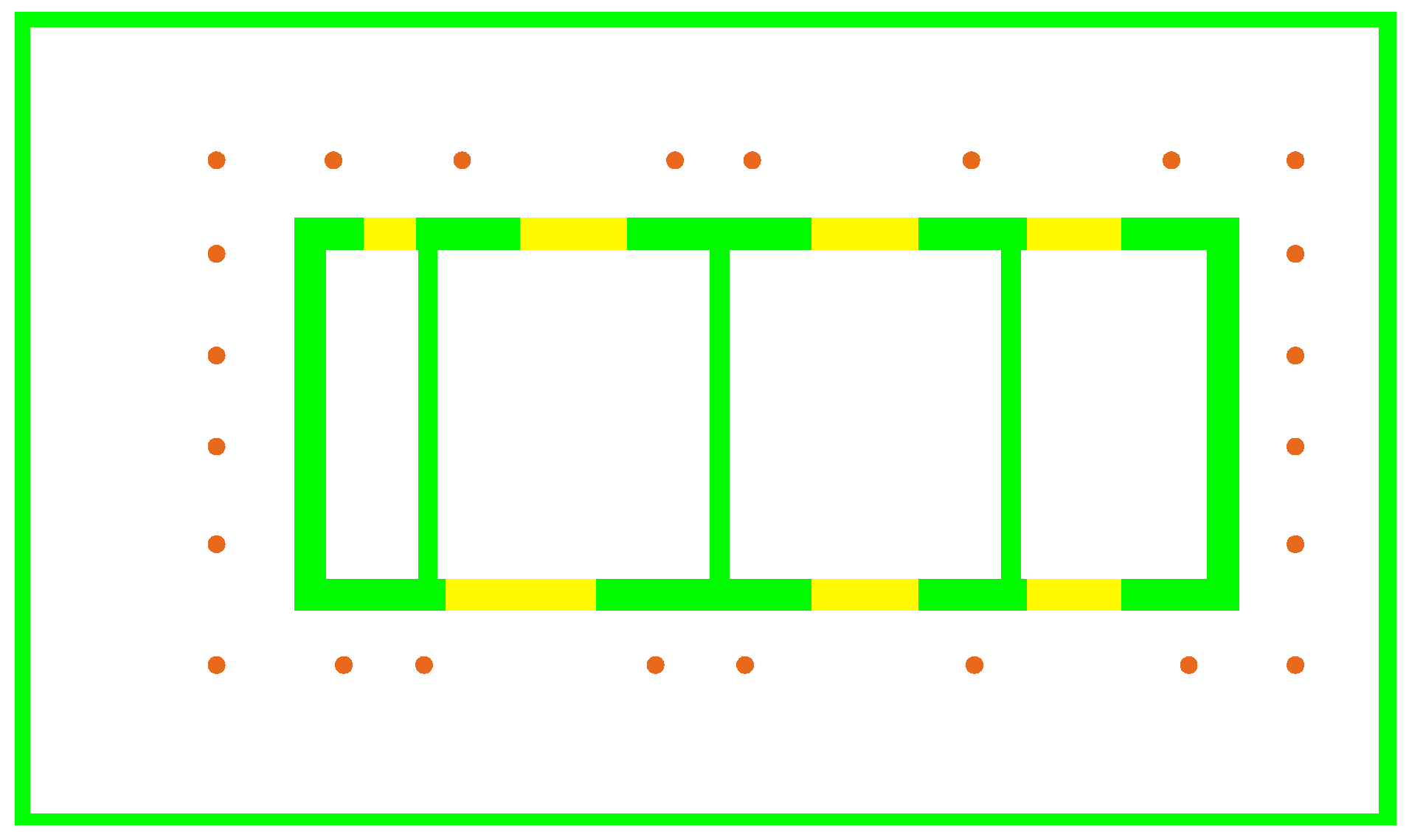

3.2.1. Method for Automated Measurement Task Planning

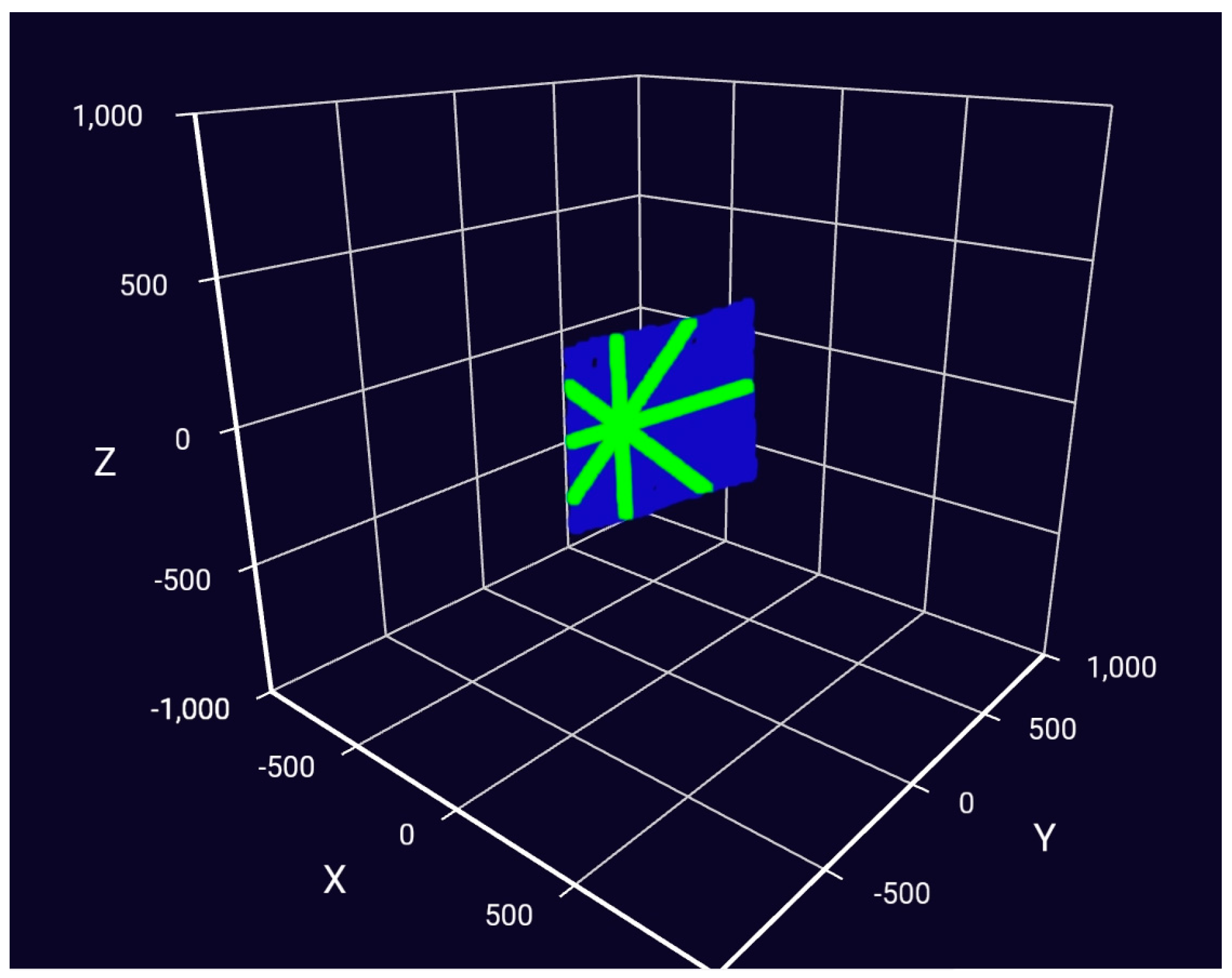

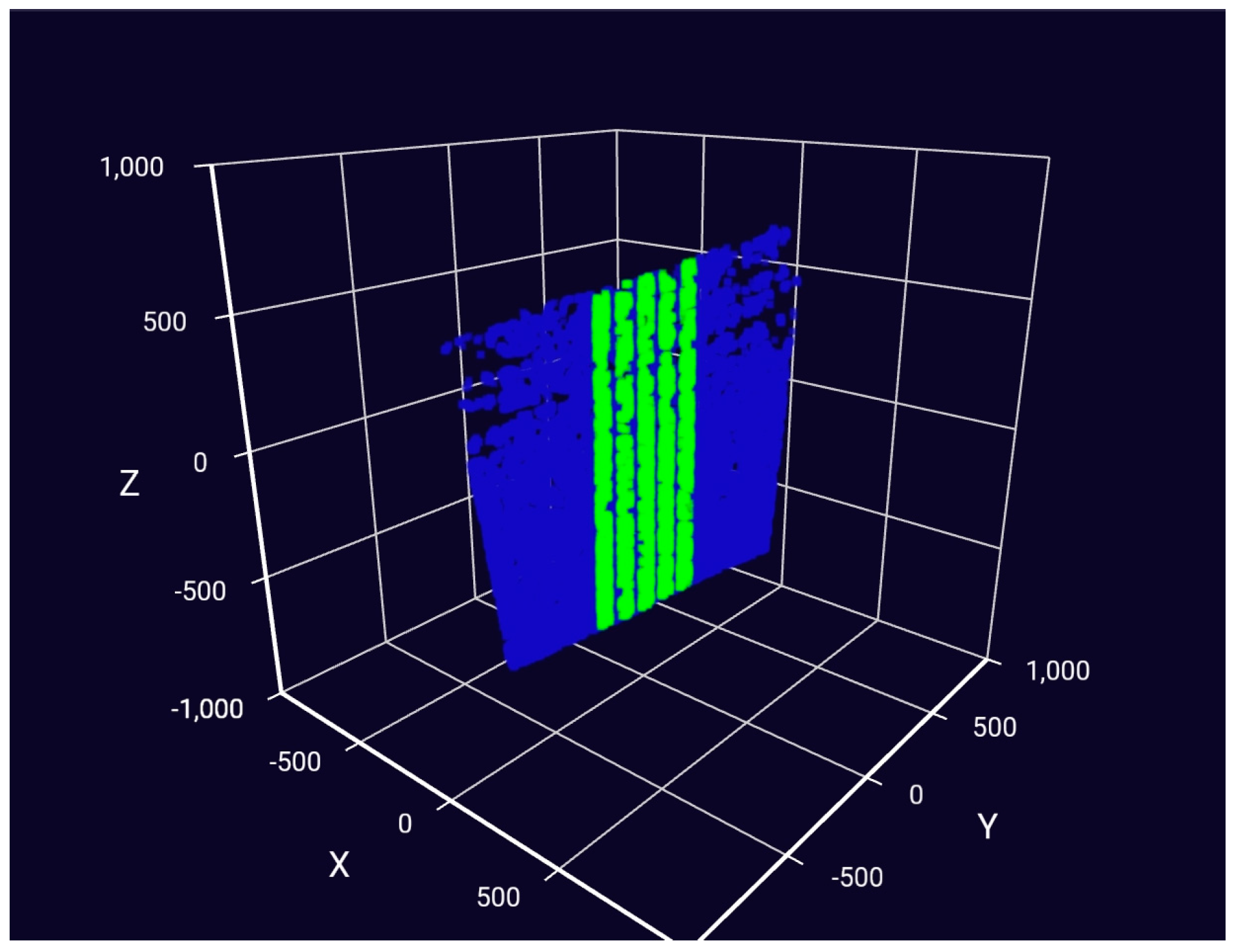

3.2.2. Algorithms for Processing Measurement Data

3.3. Measuring Accuracy Evaluation

4. Measuring Process

- (1)

- Upload the architectural drawings to the web platform.

- (2)

- Generate the measurement points on the web platform based on the architectural drawings.

- (3)

- Create a measurement task that includes all planned measurement points.

- (4)

- Upload the measurement task to the server.

- (5)

- Download the measurement task onto the control terminal and send it to the robot.

- (6)

- Specify the starting point of the robot’s measurement task through the control terminal and issue the “Start Measurement Task” command.

- (7)

- Robot executes the measurement task automatically.

- (8)

- The control terminal receives the measurement data and uploads the data to the server once connected to the network.

- (9)

- The web platform receives the data and automatically generates a measurement report with data evaluation.

- (10)

- Print the report to complete the measurement process.

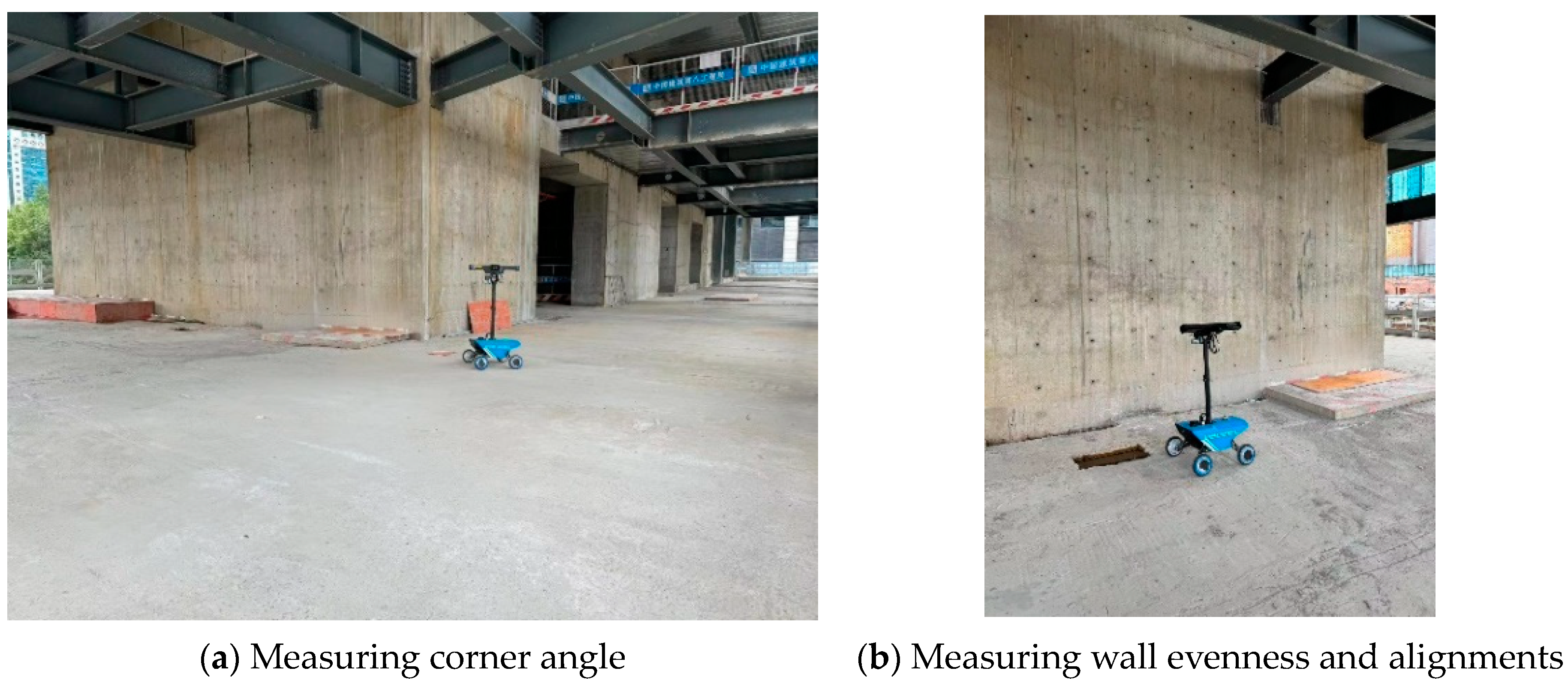

5. Application

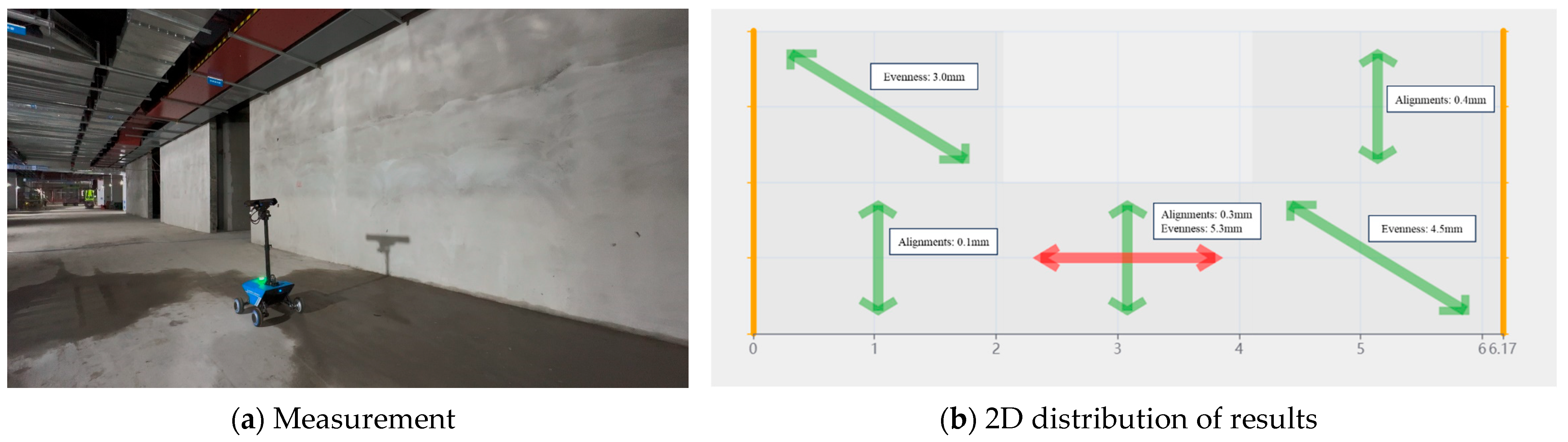

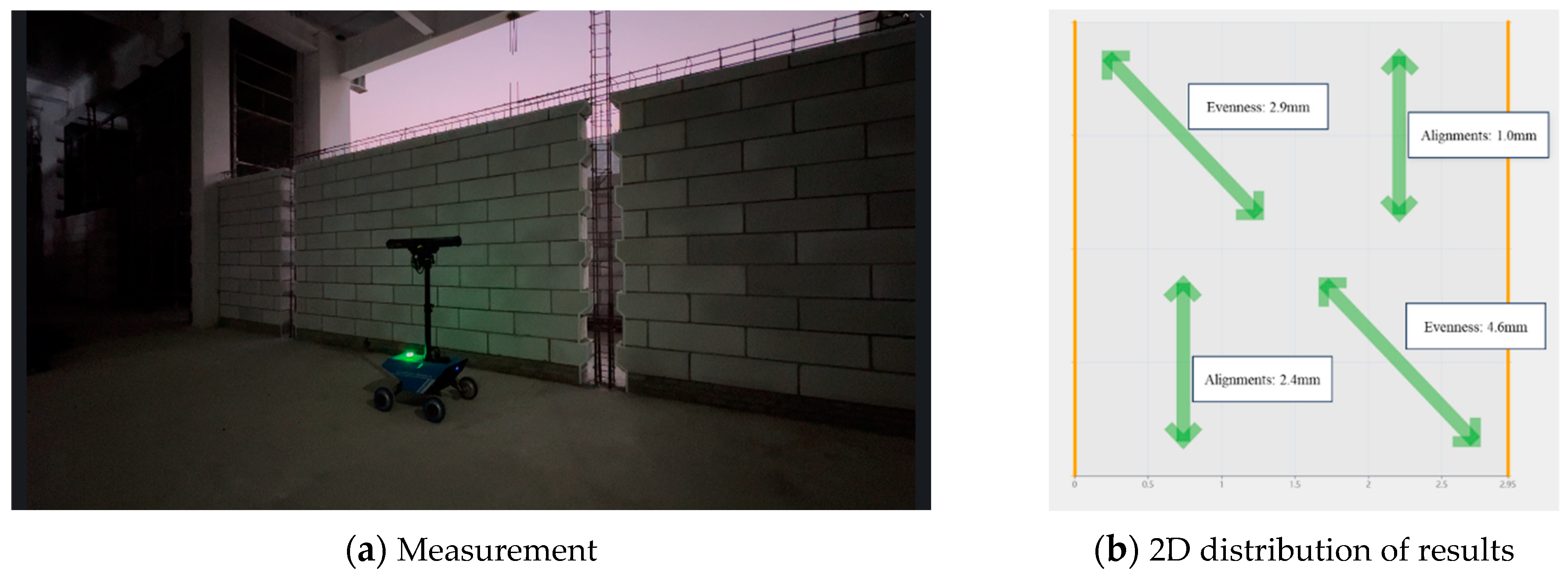

5.1. Shangxianfang Protective Renovation Project

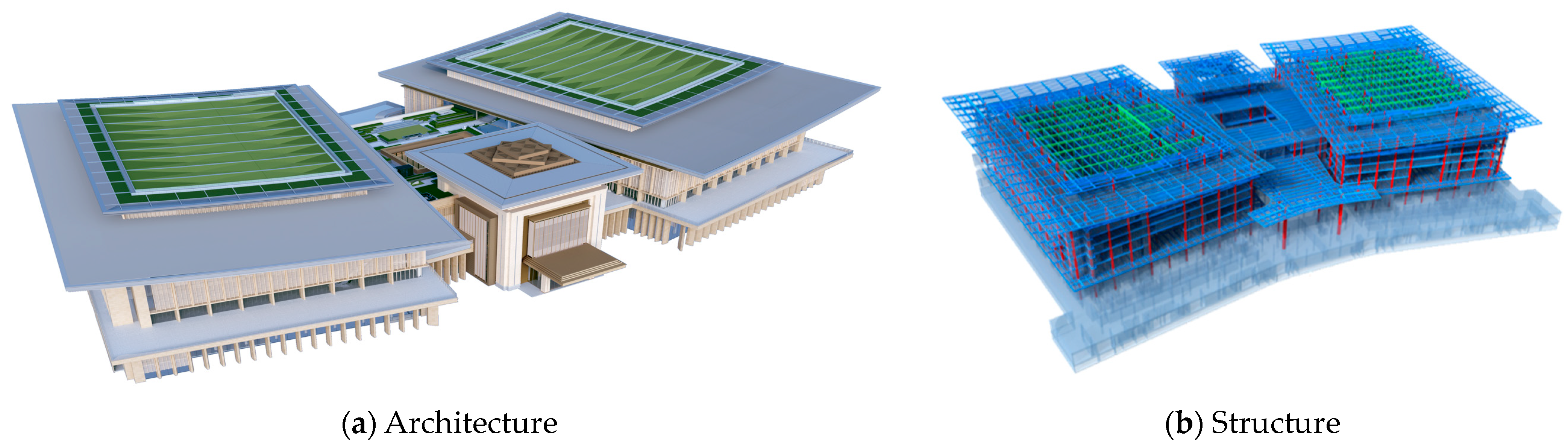

5.2. Shenzhen International Convention Center

6. Limitations

7. Conclusions

- (1)

- The robot is equipped with a comprehensive hardware setup, including a locomotion system, electrical system, 3D scanner, pitch angle control module, and navigation system. This configuration enables unmanned, mobile, and continuous measurement operations. It also developed an automated method for planning measurement tasks and processing data using algorithms based on the Point Cloud Library (PCL). It is estimated that that the system provides approximately a 30% reduction in total investment compared to commercial 3D laser scanners.

- (2)

- The robot can measure various parameters, including dimensions (e.g., column sizes and window and door dimensions), wall evenness, alignments, floor height, and internal and external corner angles. The proposed measurement algorithms focus on retaining only effective point cloud data, leading to a reduction of about 90% in data storage requirements. The accuracy and reliability of these measurements have been validated through experiments.

- (3)

- In practical applications, the robot demonstrated a 40% improvement in efficiency over manual measurements for similar tasks and achieved a minimum of 50% reduction in labor costs, highlighting the robot’s effectiveness in enhancing measurement productivity and reducing operational costs. It also shows that the developed on-site measuring robot offers a practical and automated solution for post-construction quality assessment in building projects.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Chen, I.M.; Kayacan, E.; Tiong, L.K.; Maruvanchery, V. Automated construction quality assessment: A review. In Proceedings of the 2015 10th International Symposium on Mechatronics and its Applications (ISMA), Sharjah, United Arab Emirates, 8–10 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–6. [Google Scholar]

- Lee, A.Y.; Seo, H.C.; Park, E.S. Development of a Manually Operated Mobile Robot That Prints Construction Site Layouts. Machines 2022, 10, 1192. [Google Scholar] [CrossRef]

- Desa, U.N. World population prospects 2019: Highlights. N. Y. (US) United Nations Dep. Econ. Soc. Aff. 2019, 11, 125. [Google Scholar]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Gharbia, M.; Chang-Richards, A.; Lu, Y.; Zhong, R.Y.; Li, H. Robotic technologies for on-site building construction: A systematic review. J. Build. Eng. 2020, 32, 101584. [Google Scholar] [CrossRef]

- You, S.; Kim, J.H.; Lee, S.H.; Kamat, V.; Robert, L.P., Jr. Enhancing perceived safety in human–robot collaborative construction using immersive virtual environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Chang, S.; Siu, M.F.F.; Li, H.; Luo, X. Evolution pathways of robotic technologies and applications in construction. Adv. Eng. Inform. 2022, 51, 101529. [Google Scholar] [CrossRef]

- De Santos, P.G.; Estremera, J.; Garcia, E.; Armada, M. A service robot for construction industry. In Proceedings of the Proceedings World Automation Congress, Seville, Spain, 28 June–1 July 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 15, pp. 441–446. [Google Scholar]

- King, N.; Bechthold, M.; Kane, A.; Michalatos, P. Robotic tile placement: Tools, techniques and feasibility. Autom. Constr. 2014, 39, 161–166. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current progress of 3D concrete printing technologies. In Proceedings of the ISARC, International Symposium on Automation and Robotics in Construction, Lille, France, 3–7 June 2024; IAARC Publications: Lyon, France, 2017; p. 34. [Google Scholar]

- Koch, C.; Paal, S.G.; Rashidi, A.; Zhu, Z.; König, M.; Brilakis, I. Achievements and challenges in machine vision-based inspection of large concrete structures. Adv. Struct. Eng. 2014, 17, 303–318. [Google Scholar] [CrossRef]

- Poorghasem, S.; Bao, Y. Review of robot-based automated measurement of vibration for civil engineering structures. Measurement 2023, 207, 112382. [Google Scholar] [CrossRef]

- Construction Index. Fetch, Spot! Robot Dog Gathers Construction Data; Construction Index: March, UK, 22 October 2021; Available online: www.theconstructionindex.co.uk/news/view/fetch-spot-robot-dog-gathers-construction-data (accessed on 20 October 2021).

- Frangoul, A. Boston Dynamics’ Four-Legged Robot Has Been Gathering Data at a Major Construction Site in London; CNBC: Fort Lee, NJ, USA, 12 November 2020; Available online: www.cnbc.com/2020/11/12/boston-dynamics-robot-gathering-data-at-construction-site-in-london.html (accessed on 20 October 2021).

- Şahan, N.H. Get to Know the Leica BLK2FLY and Leica BLK ARC; Surveying Group: Osborne Park, WA, USA, 4 August 2022; Available online: https://shop.leica-geosystems.com/leica-blk/blk2fly/blog/get-know-leica-blk2fly-and-leica-blk-arc (accessed on 20 March 2022).

- Yan, R.J.; Kayacan, E.; Chen, I.M.; Tiong, L.K. A novel building post-construction quality assessment robot: Design and prototyping. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 6020–6023. [Google Scholar]

- Yan, R.J.; Kayacan, E.; Chen, I.M.; Tiong, L.K.; Wu, J. QuicaBot: Quality inspection and assessment robot. IEEE Trans. Autom. Sci. Eng. 2018, 16, 506–517. [Google Scholar] [CrossRef]

- Authority, E.M. Building and Construction Authority. In Handbook for Solar Photovoltaic (PV) Systems; Building and Construction Authority: Singapore, 2017. [Google Scholar]

- Nadeem, Z.; Nadeem, H.; Khan, J.A.; Ullah, A. Wall-Distance Measurement for Indoor Mobile Robots. In Intelligent Sustainable Systems: Selected Papers of WorldS4 2021, Volume 2; Springer Nature: Singapore, 2021; pp. 1–9. [Google Scholar]

- Wang, K.; Li, D.; Li, L.; Chi, S. The Research on the Mobile Measuring Robot Technology. J. Phys. Conf. Ser. 2022, 2402, 012037. [Google Scholar] [CrossRef]

- Zahari, M.; Mutalib, N.A.; Affendi, N.N.; Hashim, N.; Hadi, D.A.; Johari, S.H.; Ab Wahab, N.; Ahmad, S. Development of mobile robot for measuring distance using optical quadrature encoder. Indones. J. Electr. Eng. Comput. Sci. 2020, 18, 745–749. [Google Scholar] [CrossRef]

- Wang, J.; Tao, B.; Gong, Z.; Yu, S.; Yin, Z. A mobile robotic measurement system for large-scale complex components based on optical scanning and visual tracking. Robot. Comput.-Integr. Manuf. 2021, 67, 102010. [Google Scholar] [CrossRef]

| No. | Parameters | Value |

|---|---|---|

| 1 | Resolution (3D points) | Up to 3.2 M |

| 2 | Scanning range | 870~2150 mm |

| 3 | Optimal scanning distance | 1239 mm |

| 4 | Scanning area at sweet spot | 1080 × 772 mm |

| 5 | Point to point distance | 0.524 mm |

| 6 | Calibration accuracy | 0.2 mm |

| 8 | Scanning time | 250~2750 ms |

| 9 | Dimensions | 77 × 68 × 616 mm |

| 10 | Baseline | 550 mm |

| 11 | 3D points throughput | 16 million points per second |

| Items | Fundamental Principles of Algorithms |

|---|---|

| Evenness | Based on the point cloud data, a plane is determined using the least squares method. The distances from all points in the calculation area to the plane are examined, and the extreme value is identified as the measurement output. |

| Alignment | Based on the point cloud data, a plane is fitted using the least squares method, and inclination sensor data is used to adjust the plane to align with the world coordinate system. The measurement output is calculated based on the normal vector of this plane. |

| Corner angles | Based on the point cloud data, two intersecting planes are determined using the least squares method. Following this, the angle between the normal vectors of these two planes is calculated and returned as the measurement output value. |

| Dimensions | Based on the point cloud data, a plane is determined using the least squares method. Subsequently, the boundary of the plane is traversed, and the dimensions of the boundary are returned as the measurement output value. |

| Height | Combining the height of the robot (1.2 m) and the point cloud depth. |

| Items | 1st Time | 2nd Time | 3rd Time | 4th Time | 5th Time | Average |

|---|---|---|---|---|---|---|

| Alignments | 0.62 | 0.48 | 0.63 | 0.68 | 0.37 | 0.556 |

| Evenness | 0.65 | 0.87 | 0.56 | 0.82 | 0.77 | 0.734 |

| External corner angle | 0.71 | 0.83 | 0.79 | 0.7 | 0.69 | 0.744 |

| Items | Objects | Conventional Measuring Tools | Average Deviation | Maximum Deviation |

|---|---|---|---|---|

| Evenness | Wall | Straight edge rule | 0.44 | 1.05 |

| Alignments | Wall | Straight edge rule | 0.99 | 1.95 |

| Internal corner angle | Wall | Inside and outside right-angle measuring ruler | 1.028 | 1.48 |

| External corner angle | Wall | Inside and outside right-angle measuring ruler | 1.12 | 1.46 |

| Dimensions | Window | Measuring tape | 1.99 | 2.47 |

| Height | / | Total station | 3.5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Ma, M.; Yang, Y.; Han, L.; Wu, S. On-Site Measuring Robot Technology for Post-Construction Quality Assessment of Building Projects. Buildings 2024, 14, 3085. https://doi.org/10.3390/buildings14103085

Wu H, Ma M, Yang Y, Han L, Wu S. On-Site Measuring Robot Technology for Post-Construction Quality Assessment of Building Projects. Buildings. 2024; 14(10):3085. https://doi.org/10.3390/buildings14103085

Chicago/Turabian StyleWu, Hangzi, Minglei Ma, Yan Yang, Lifang Han, and Siyuan Wu. 2024. "On-Site Measuring Robot Technology for Post-Construction Quality Assessment of Building Projects" Buildings 14, no. 10: 3085. https://doi.org/10.3390/buildings14103085

APA StyleWu, H., Ma, M., Yang, Y., Han, L., & Wu, S. (2024). On-Site Measuring Robot Technology for Post-Construction Quality Assessment of Building Projects. Buildings, 14(10), 3085. https://doi.org/10.3390/buildings14103085